Mud-water separator for wet concrete recycling system and mud-water separating method of mud-water separator

A mud-water separation and recovery system technology, applied in separation methods, sedimentation separation, chemical instruments and methods, etc., can solve the problems of power consumption, increased probability of precipitation hardening, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

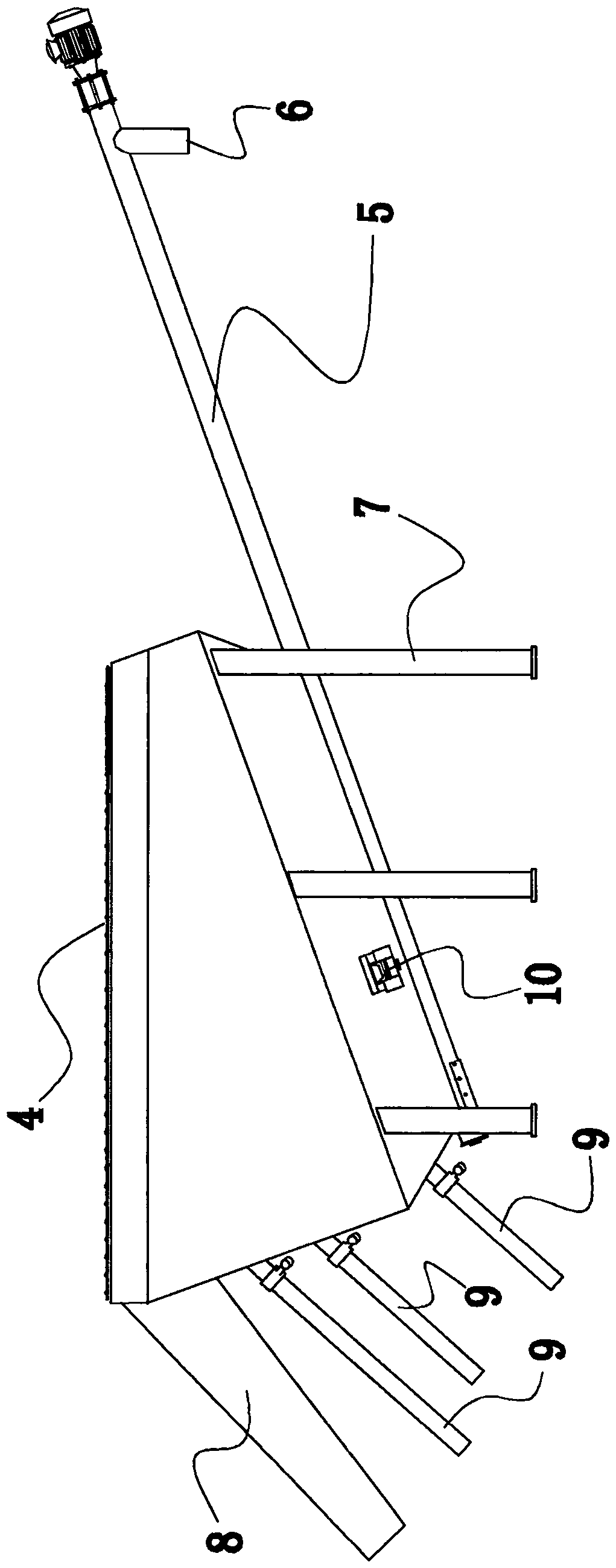

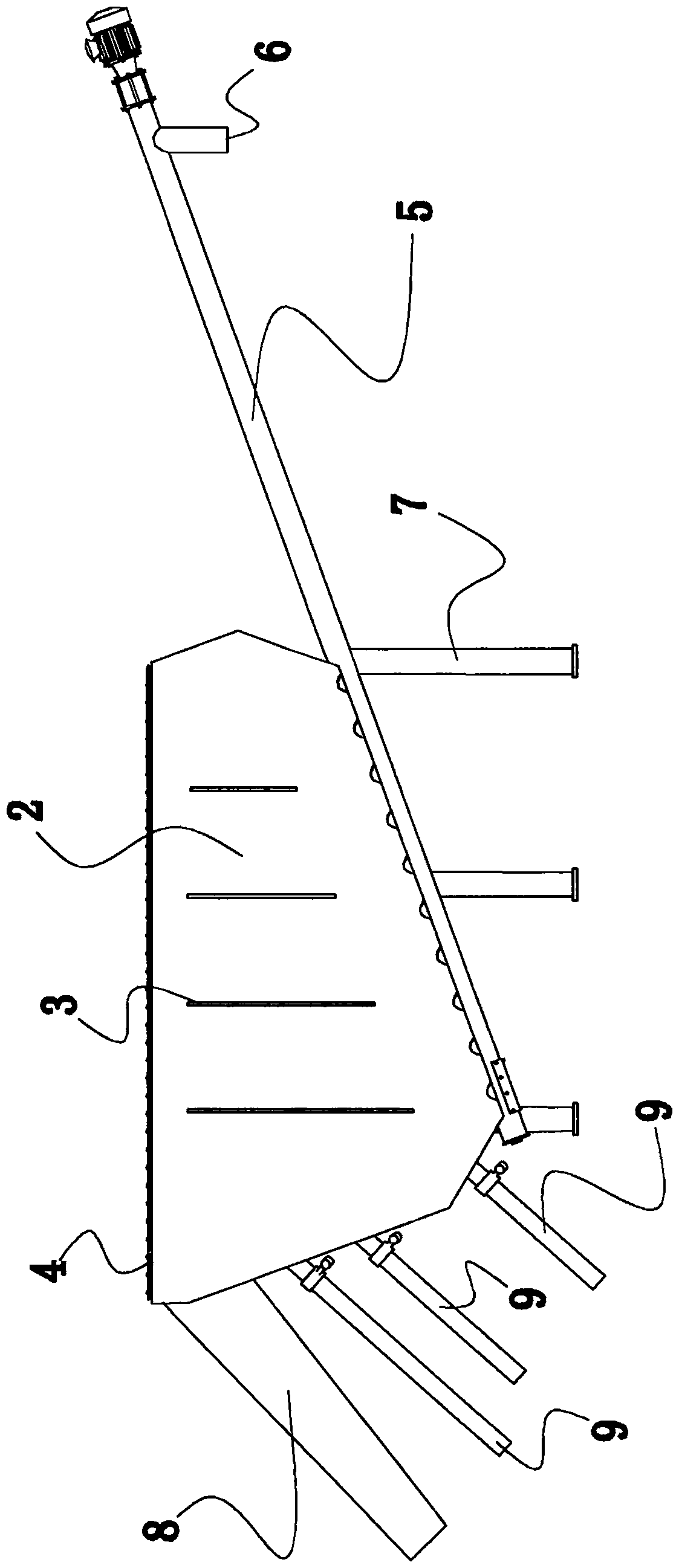

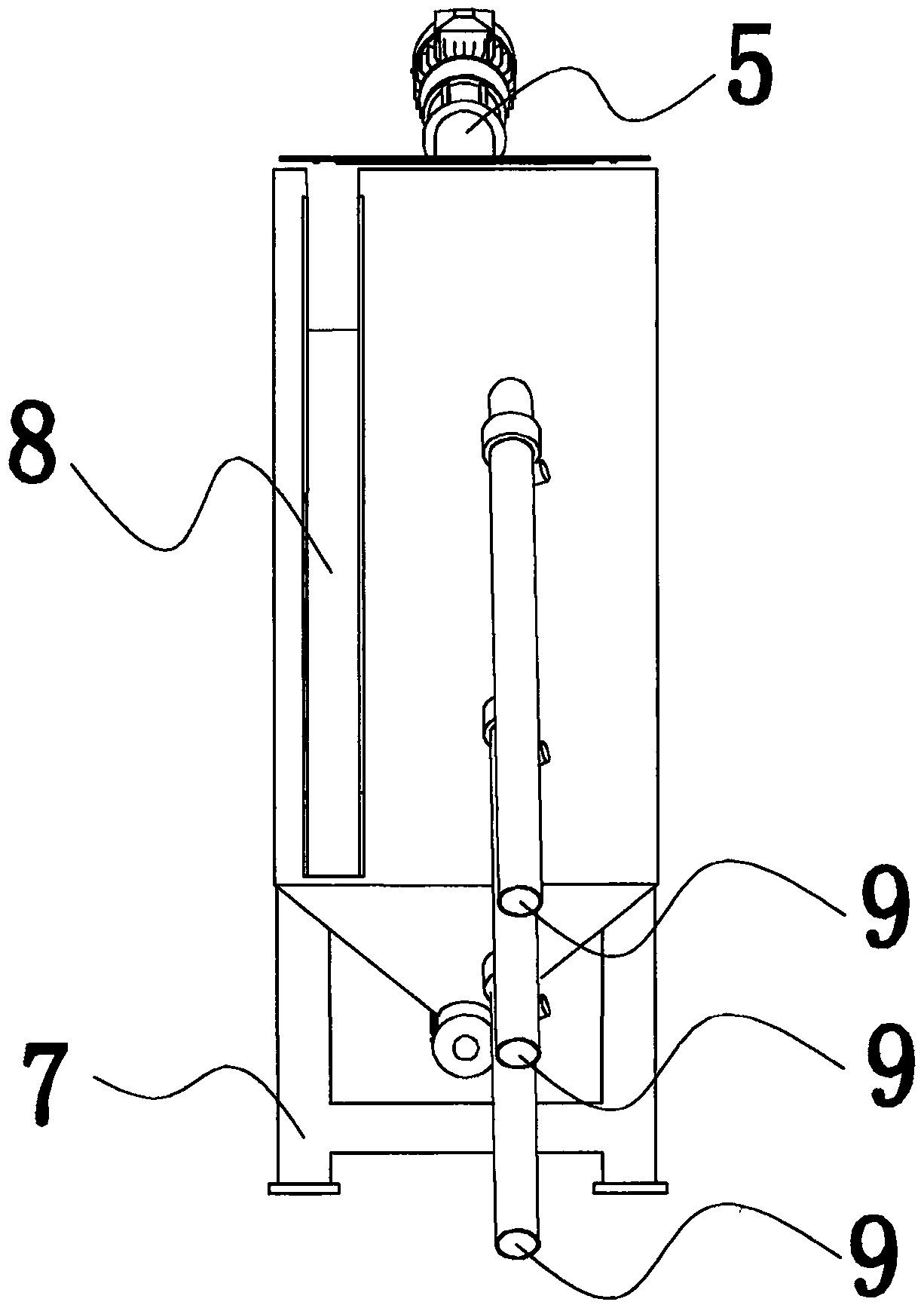

[0032] A mud-water separator of a wet concrete recovery system and a mud-water separation method thereof, such as Figure 1-Figure 8 As shown, it includes sewage water inlet 1, sedimentation bin 2, buffer wall 3, tread net 4, screw conveyor 5, sludge discharge port 6, outrigger 7, sewage overflow bucket 8, sewage pipe 9, vibrator 10, buffer overflow port 11. It is characterized in that: the sedimentation bin 2 is divided into upper and lower parts, the upper part of the sedimentation bin 2 is a box body, and the lower part is a vertebral body, and multiple buffer walls 3 are installed inside the box body of the sedimentation bin 2, and each buffer wall 3 is A buffer overflow port 11 is provided, a tread net 4 is installed on the top of the sedimentation bin 2, a screw conveyor 5 is installed at the bottom of the lower vertebral body of the sedimentation bin 2, and a sludge discharge port is set above the screw conveyor 5 6. The outriggers 7 are installed on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com