Electromagnetic damping effect classifier of non-magnetic material

A non-magnetic material and electromagnetic damping technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as inability to isolate, inefficiency, and inability to completely eliminate mixing, so as to reduce labor costs, improve work efficiency, The effect of reducing manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

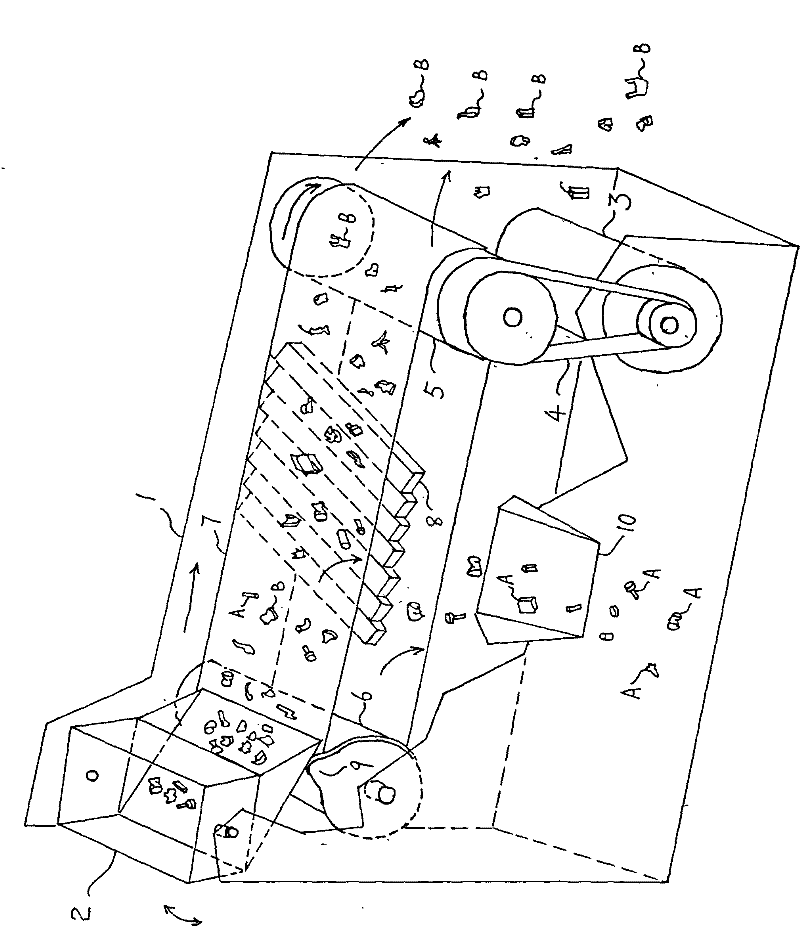

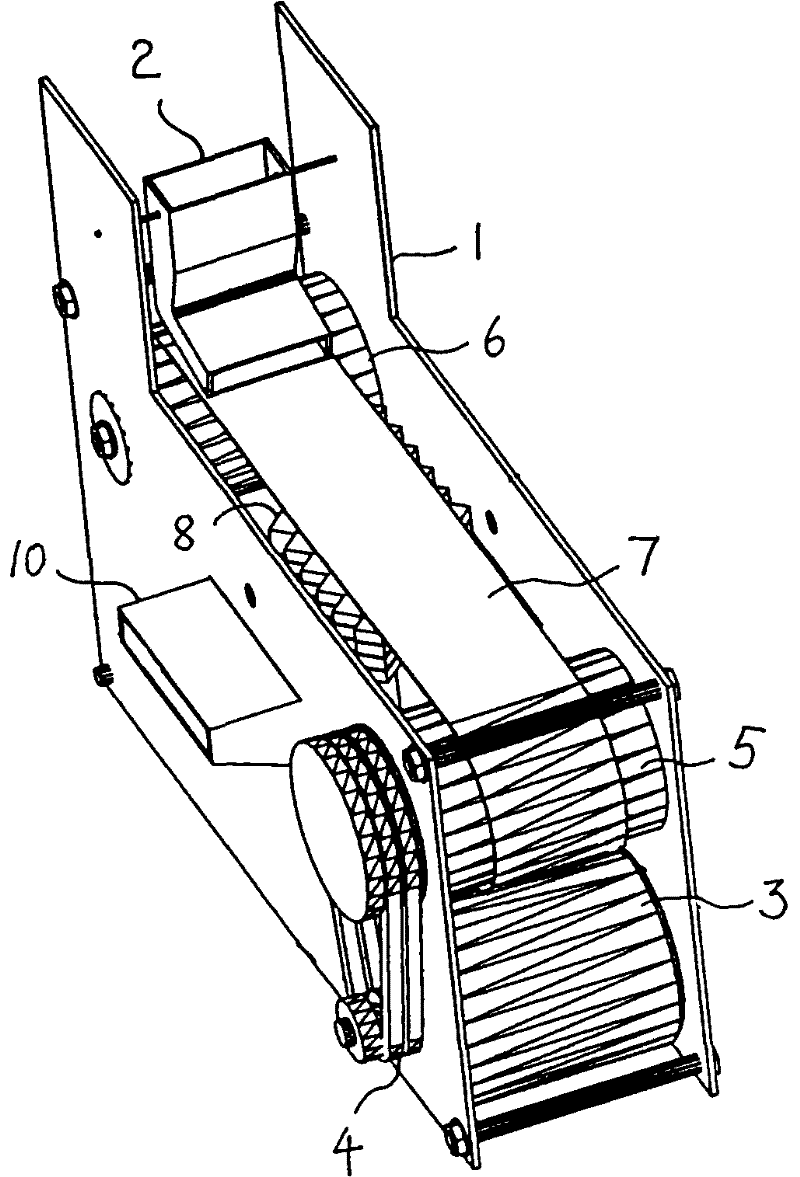

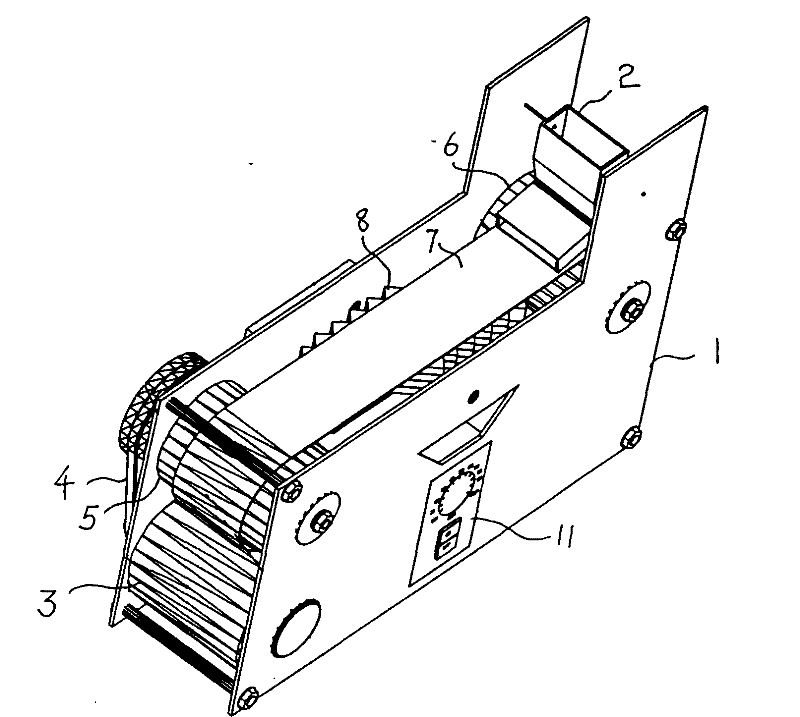

[0024] An electromagnetic damping effect classifier for non-magnetic materials, comprising a box body 1, a hopper 2 arranged above one side of the box body 1, a driving motor 3, a driving roller 5, a driven roller 6, and connecting the driving motor 3 and the driving roller 5 The driving belt 4 is a conveyor belt 7 that connects the driving roller 5 and the driven roller 6 and forms a loop. The discharge port of the hopper 2 is located above the driven roller 6. It is characterized in that the gap between the driving roller 5 and the driven roller 6 is And the position between the inner surfaces of conveyor belt 7 is provided with magnet block 8, and magnet block 8 is made up of several magnets, and the N pole of each magnet is connected with the S pole of its adjacent magnet, and the magnetic field line of magnet is connected with conveyor belt. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com