Multi-stage environmentally friendly crushing device for concrete waste

A technology of concrete waste and crushing device, which is applied in the direction of grain processing, etc., and can solve the problems of difficult processing, separation of steel bars and concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

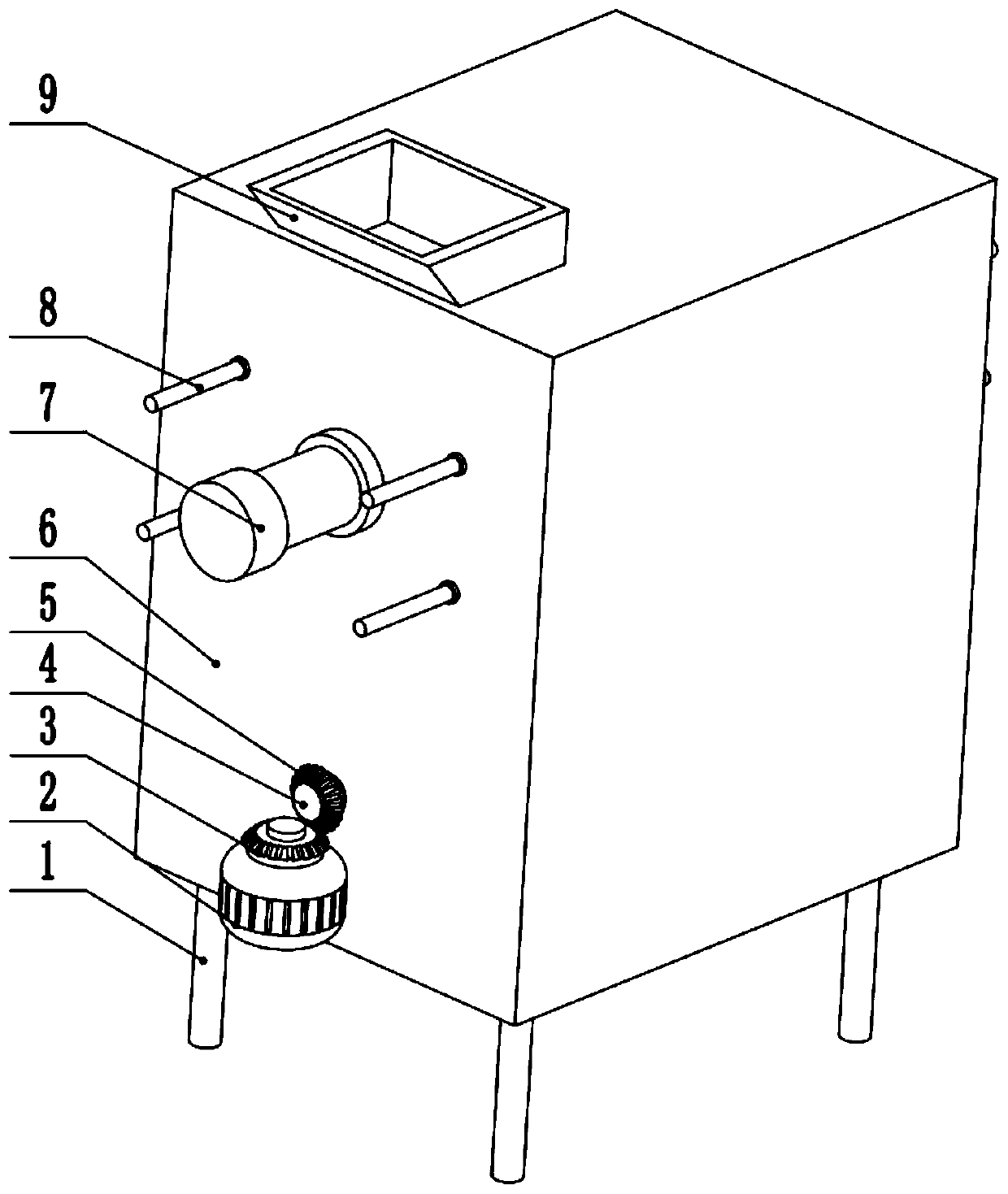

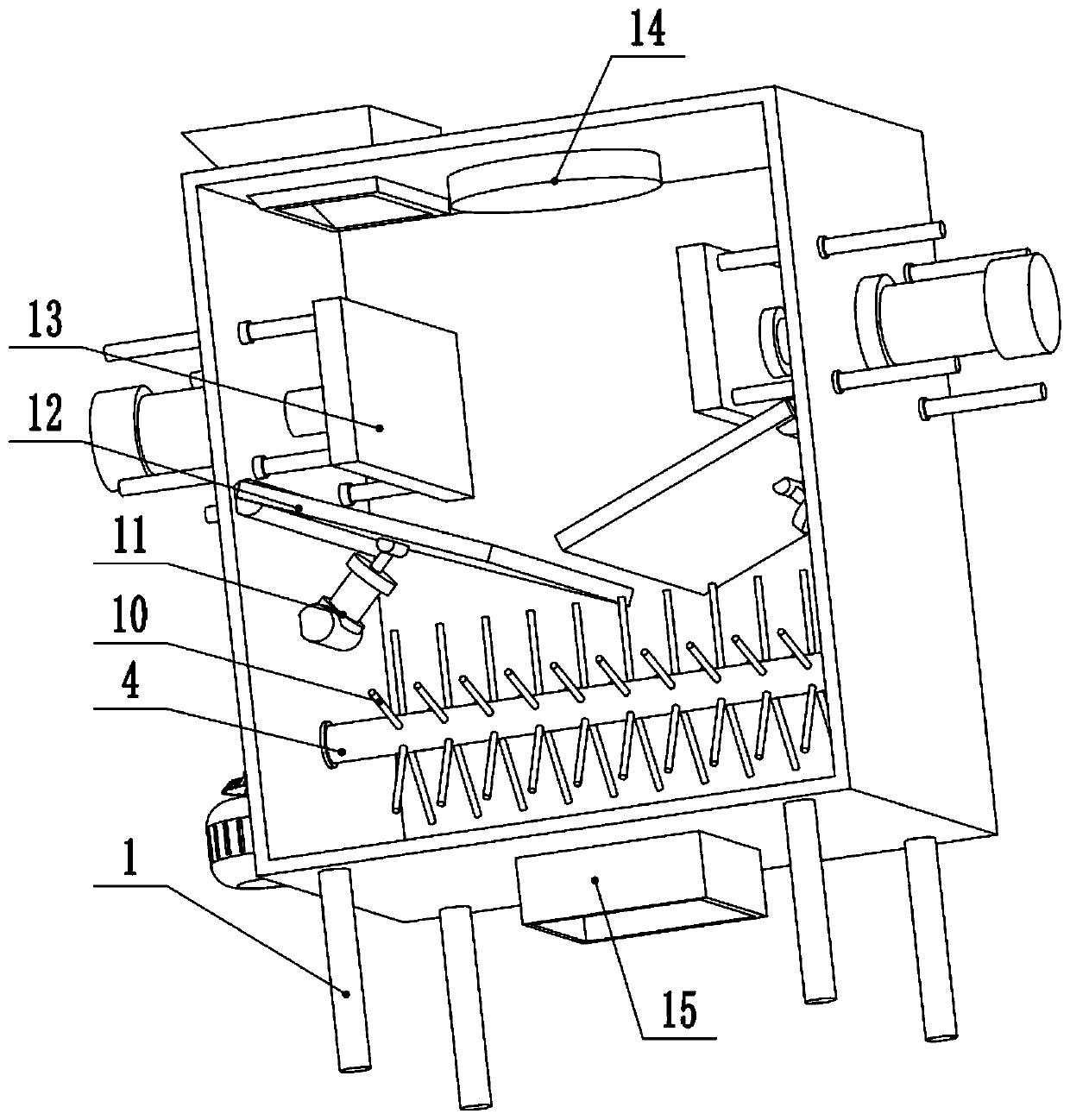

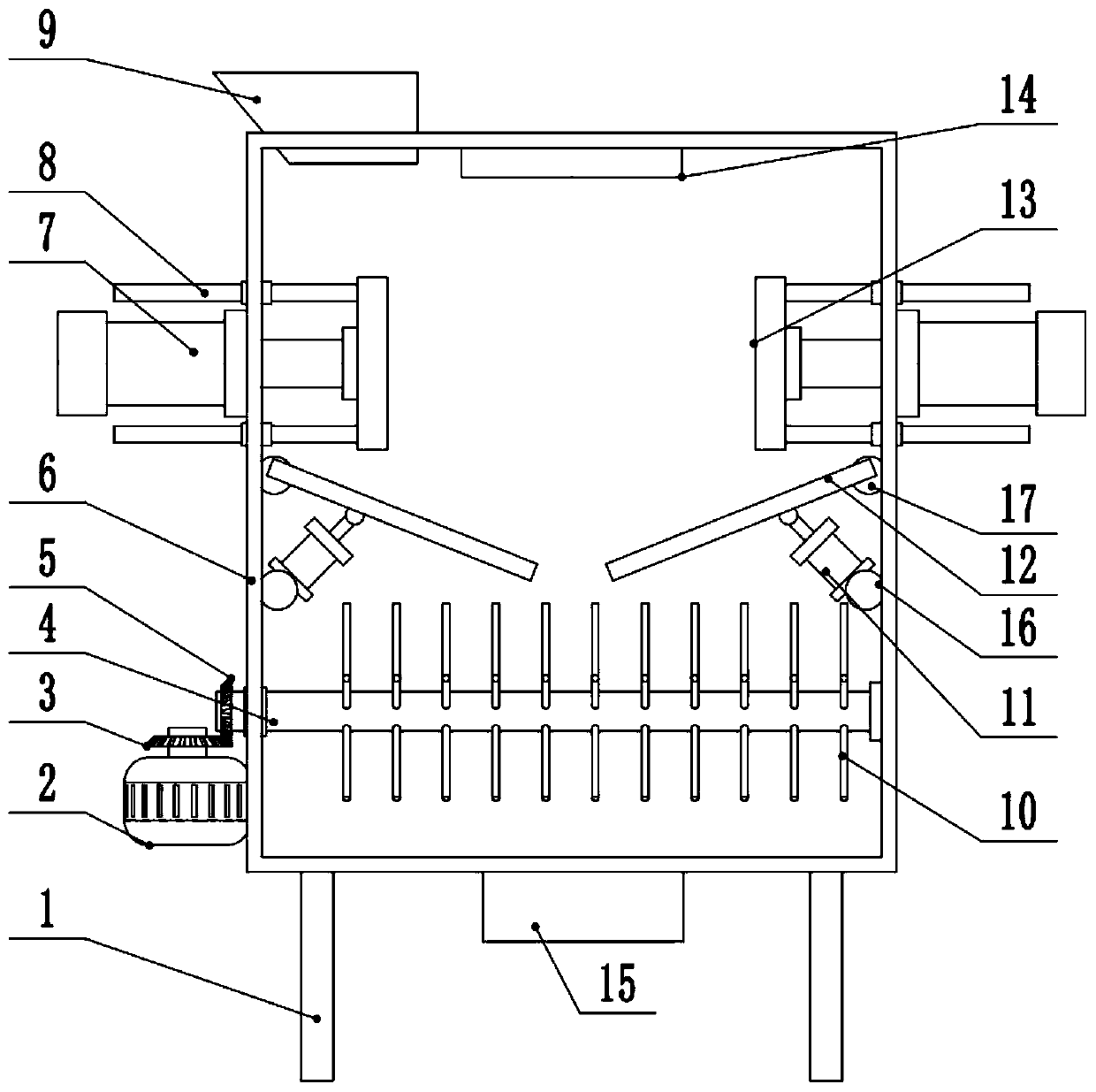

[0026] see Figure 1-4 , a multi-stage environment-friendly crushing device for concrete waste, comprising a crushing box 6, the left and right sides of the lower surface of the crushing box 6 are provided with support legs 1, the left side of the upper surface of the crushing box 6 is provided with a feed port 9, the crushing box 6 The middle part of the lower surface is provided with a discharge port 15, and the bottom of the discharge port 15 is provided with a switch device, which can control the opening and closing of the discharge port 15. The top of the crushing box 6 is provided with an electromagnet 14, and the crushing box The upper part of the left and right side walls of 6 is provided with a hydraulic cylinder 7, the piston rod of the hydraulic cylinder 7 is fixedly connected to the extrusion plate 13, the upper and lower sides of the extrusion plate 13 are provided with guide rods 8, and the middle part of the guide rod 8 is slidingly connected to the bottom of the...

Embodiment 2

[0028] see Figure 4 , The other content of this embodiment is the same as that of Embodiment 1, except that: the opposite side of the pressing plate 13 is provided with a crushing protrusion 18 . In order to improve the crushing effect of the extruding plate 13, crushing protrusions 18 are provided on the extruding plate 13, so that through the interlocking of the crushing protrusions 18, the concrete is broken and the steel bars inside the concrete can be sheared.

[0029] In the implementation process of the present invention, the cylinder 11 is started, and the piston rod of the cylinder 11 stretches out, thereby pushing the support plate 12 to rotate upwards. When the piston rod of the cylinder 11 is fully stretched out, the support plate 12 is in a horizontal position. The plate 12 blocks the middle part of the crushing box 6. At this time, the hydraulic cylinder 7 is started, and the piston rod of the hydraulic cylinder 7 shrinks, so that the two extrusion plates 13 mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com