Modified high-strength geopolymer cementing material and preparation method thereof

A technology of cementitious materials and geopolymers, which is applied in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problem of low activity of waste concrete powder, can not fully stimulate potential activity, and does not meet practical engineering applications. and other problems, to achieve the effect of reducing the accumulation cost and the impact on the environment, breaking through the technical bottleneck, and reducing the breakthrough intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a modified high-strength geopolymer gelling material, comprising the following steps:

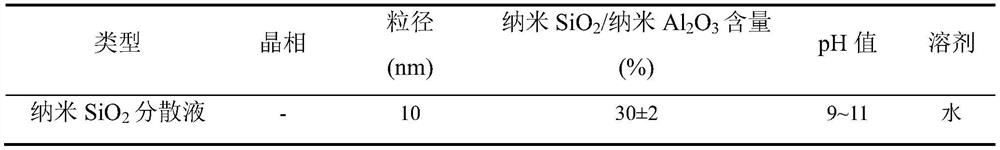

[0041] Step S1: Prepare an alkali activator solution, weigh sodium silicate solution, sodium hydroxide solid and water, of which 220.31 g of sodium hydroxide solid analytical grade, 840 g of sodium silicate solution, and 192.69 g of water are fully mixed to form solution A; Add 210g nano-SiO to solution A 2 Dispersion liquid (the mass fraction of the nano-dispersion liquid is 0.06 of the precursor), stir evenly to form a solution B, seal the solution B through a polyethylene film, and let it stand for cooling; it should be noted that the above actual water consumption removes the nano-dispersion water in liquid;

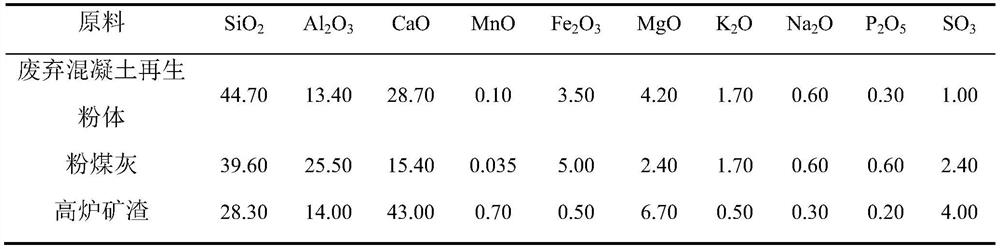

[0042] Step S2: Configure the precursor, weigh 50 parts of waste concrete regenerated powder and 50 parts of blast furnace slag respectively, put the two in a mixer and mix evenly, set the speed of the mixer to 150r / min, and the mixing time to 120s;...

Embodiment 2

[0048] A preparation method of a modified high-strength geopolymer gelling material, comprising the following steps:

[0049] Step S1: Prepare an alkali activator solution, weigh sodium silicate solution, sodium hydroxide solid and water, of which 220.31 g of sodium hydroxide solid analytical grade, 840 g of sodium silicate solution, and 290.69 g of water are fully mixed to form solution A. Add 70g nano-SiO to solution A 2 The dispersion liquid (the quality of the nano-dispersion liquid is 0.02 of the precursor), stirred evenly to form a solution B, and the solution B was sealed through a polyethylene film, and left to cool;

[0050] Step S2: Configure the precursor, weigh 50 parts of waste concrete recycled powder, 40 parts of blast furnace slag and 10 parts of fly ash, put the three in a mixer and mix evenly, set the speed of the mixer to 150r / min, and the mixing time 120s;

[0051] Step S3: Prepare the geopolymer slurry, pour the prepared alkali activator solution contain...

Embodiment 3

[0056] A preparation method of a modified high-strength geopolymer gelling material, comprising the following steps:

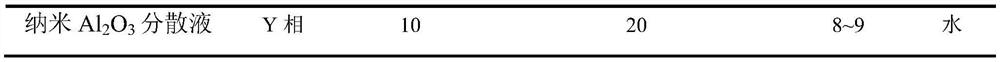

[0057] Step S1: Prepare an alkali activator solution, weigh sodium silicate solution, sodium hydroxide solid and water, of which 220.31g of sodium hydroxide solid analytical grade, 840g of sodium silicate solution, and 171.69g of water are fully mixed to form solution A. Add 210g nanometer Al into solution A 2 o 3 Dispersion liquid (the quality of nano dispersion liquid is 0.06 of precursor), stir evenly, form solution B, solution B is sealed by polyethylene film, stand and cool;

[0058] Step S2: Configure the precursor, weigh 50 parts of waste concrete recycled powder and 50 parts of blast furnace slag, put the two in a mixer and stir evenly, set the speed of the mixer to 150r / min, and the mixing time to 120s;

[0059] Step S3: Prepare the geopolymer slurry, pour the prepared alkali activator solution containing nanomaterials (ie solution B) into the unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com