Patents

Literature

37results about How to "Obvious environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

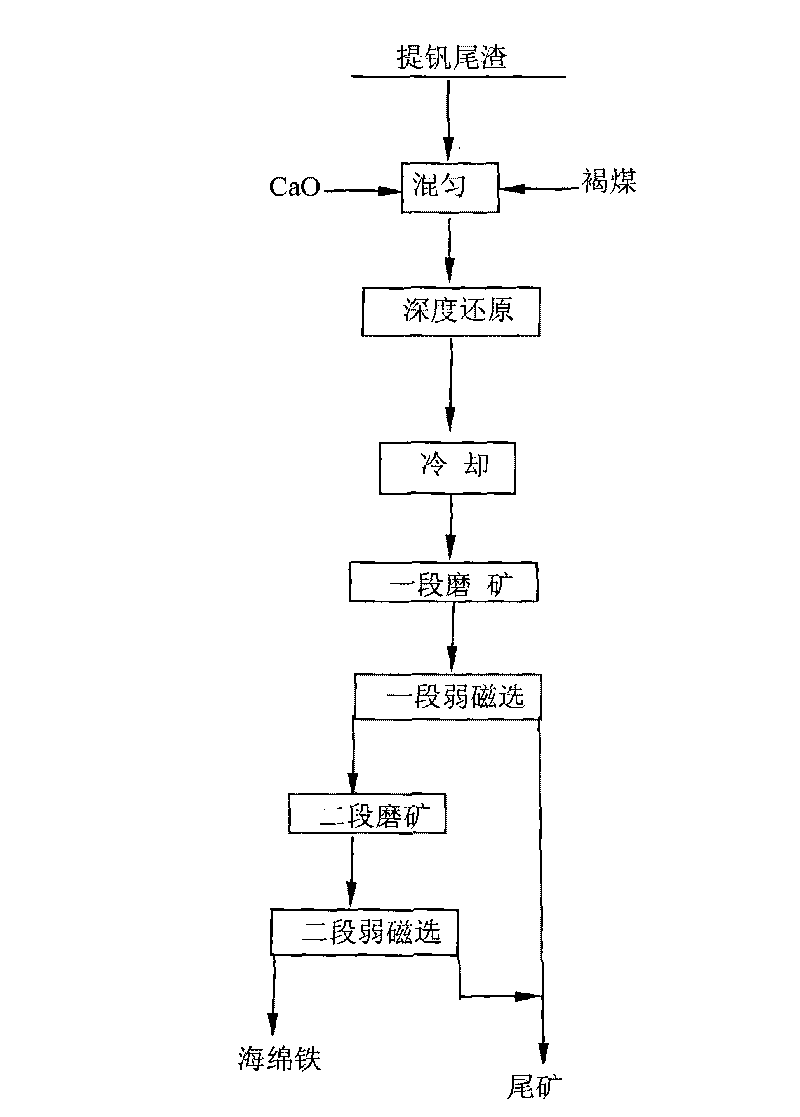

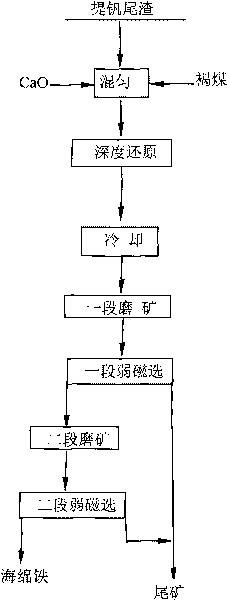

Technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings

The invention relates to a technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings, belonging to the field of iron making. The method adopts brown coal as the reducing agent, and simultaneously CaO is added as slag former and used for increasing alkalinity to synergize with Na2O and K2O in the tailings to react with SiO2 and Al2O3 to generate zeolite-like stable mineral so as to boost extraction and separation of sponge iron in products of deep reduction. The products of deep reduction are subject to two-section ore grinding-two-section low intensity magnetic separation technique to obtain sponge iron with iron grade larger than 90% and TiO2 smaller than 0.20%. The invention is simple in technique and easy to control, and has large reserves of raw materials and low price; the product can be used as raw material for steel making; other impurities meet steel making requirements, the technique flow of processing iron ore into rolled steel is shortened, the environment pollution caused by sintering, pelletizing and blast furnace iron making of iron ore concentrate obtained by other methods can be avoided, and the invention has obvious environment benefit and energy conservation and consumption reduction effects.

Owner:UNIV OF SCI & TECH BEIJING

Water-soluble colorful insulation coating and preparation method thereof

InactiveCN101712832AImprove insulation effectObvious environmental benefitsReflecting/signal paintsMicrosphereThermal insulation

The invention relates to a water-soluble colorful insulation coating and a preparation method thereof. The coating adopts the following components as raw materials by weight percent: 25-45% of acrylic acid emulsion, 5-15% of colorful hollow ceramic microspheres, 5-20% of light calcium carbonate, 10-25% of titanium dioxide powder, 0.5-1.5% of dispersant, 0.5-1.2% of thickener, 0.5-0.8% of deforming agent and 20-40% of water. The preparation method comprises the following steps: mixing acrylic acid emulsion, water, titanium dioxide powder and light calcium carbonate, stirring and dispersing, grinding with a grinder to mix evenly, wetting colorful hollow ceramic microspheres with dispersant, gradually adding colorful hollow ceramic microspheres in emulsion, then adding deforming agent and thickener to mix evenly and obtain the finished product. The color of the paint of the invention is from the colorful hollow ceramic microspheres, the paint does not contain volatile organic solvent such as benzene and formaldehyde, has thermal insulation and insulating performance, energy-saving performance and decorative performance, is beneficial for environmental protection, has outstanding thermal insulation performance and color retention performance, and has obvious environmental and social benefits.

Owner:DALIAN MARITIME UNIVERSITY

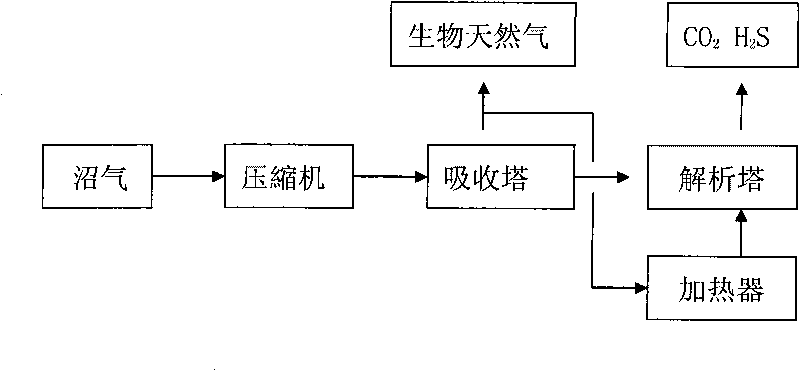

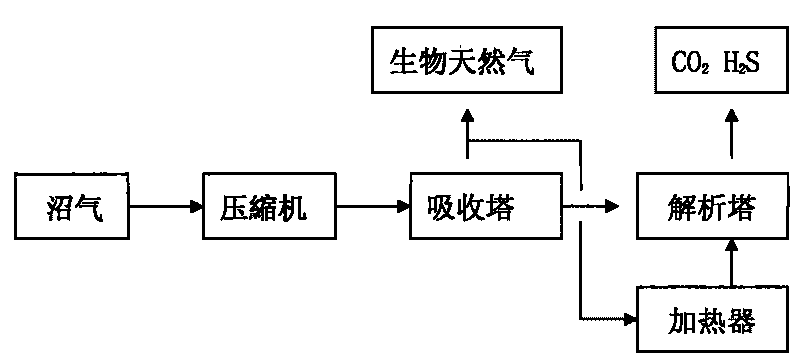

Method for preparing biological natural gas from marsh gas

The invention relates to a method for preparing biological natural gas from marsh gas. The method is characterized in that marsh gas is compressed to 0.35-0.7MPa and then enters an absorption tower; in the absorption tower, the marsh gas from bottom to top has a countercurrent contact with a monoethanolamine solution used as an absorbent from top to bottom to absorb CO2 and H2S; gas coming out of the top of the absorption tower is purified biological natural gas; and rich liquor coming out of the absorption tower is heated to 11-125 DEG C through a heater and then decomposed in a decomposing tower to release the CO2 and the H2S, wherein the pressure of the absorption tower is 0.35-0.7MPa, the temperature is normal temperature, and the temperature of the decomposing tower is 105-110 DEG C. The method utilizes the excellent absorbent (monoethanolamine) with a large solubility to absorb the carbon dioxide and the sulfide in the marsh gas so as to remove the carbon dioxide and impurities in the marsh gas, ensures that the content of methane is improved to be higher than 95 percent, and meets the requirement on components of the natural gas, thus the obtained natural gas prepared by the method is called biological natural gas. The method enlarges the application of the marsh gas, improves the use value of the marsh gas, and has obvious economic, social and environmental benefits.

Owner:KUNMING UNIV OF SCI & TECH

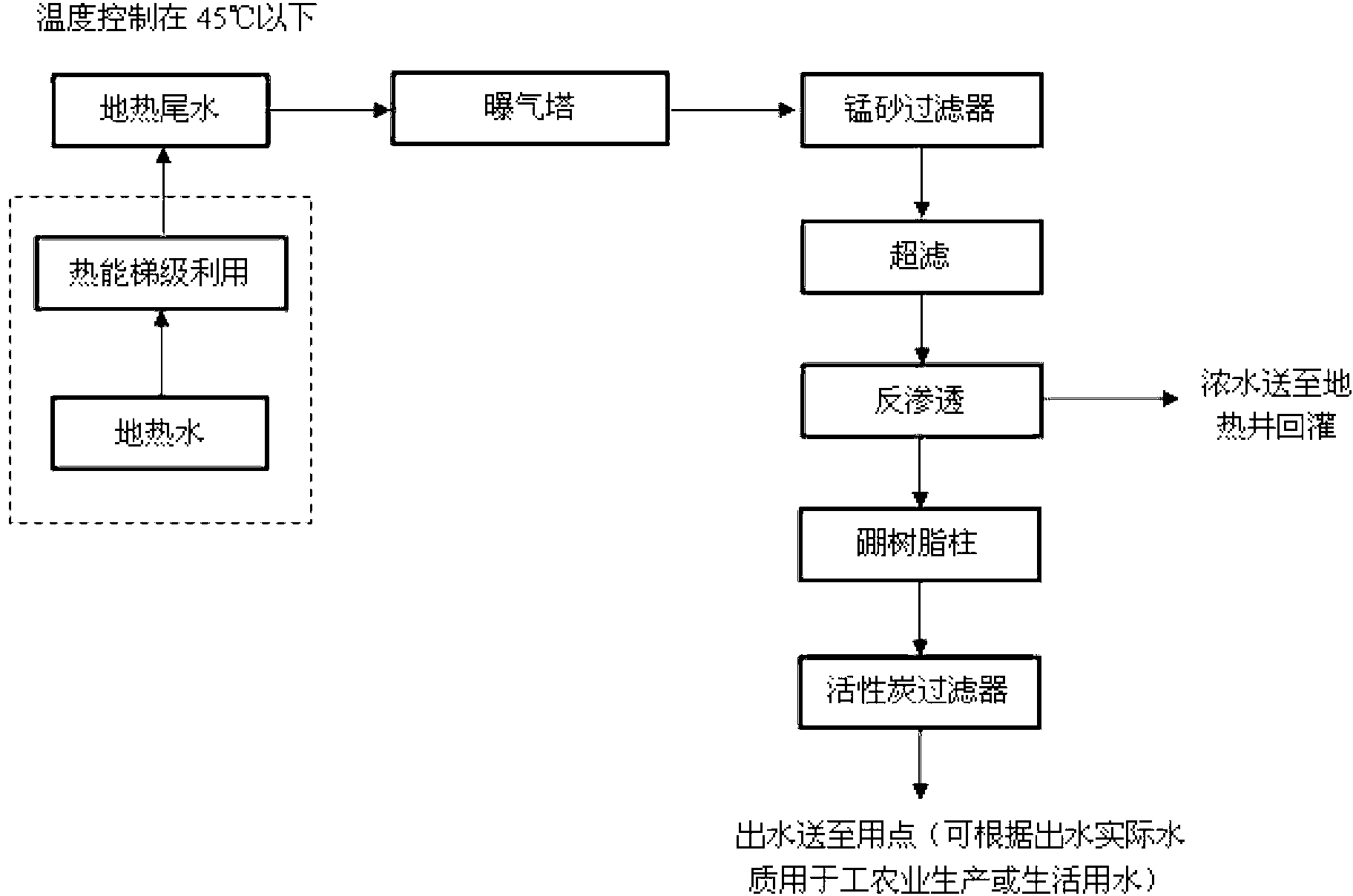

Terrestrial heat tail water treating process

InactiveCN103011454AWide range of water qualityAchieve integrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

The invention provides a terrestrial heat tail water treating process which comprises the following steps: (1) controlling the tail water temperature after the terrestrial heat water is subjected to heat energy gradient utilization to be less than 45 DEG C; (2) aerating the terrestrial heat tail water by using an aeration tower; (3) flowing the aerated terrestrial heat tail water through a manganese sand filter to be filtered; (4) carrying out membrane integrated treatment on the filtered terrestrial heat tail water by using a double-membrane method process; (5) carrying out boron selective resin absorption treatment on the reverse osmosis water; and (6) filtering the effluent subjected to boron removal by using an active carbon filter and conveying to a use point. Aiming at the harmful ingredients and pollutant types in terrestrial heat tail water, the invention integrates a plurality of water treatment unit techniques, realizes integration and optimization of process systems, is wide in water quality application range of the terrestrial heat tail water, advanced in process and reliable in technique, and has practical popularization and application values in development and utilization in terrestrial heat tail water, and as a result, significant social, economic and environmental benefits are achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

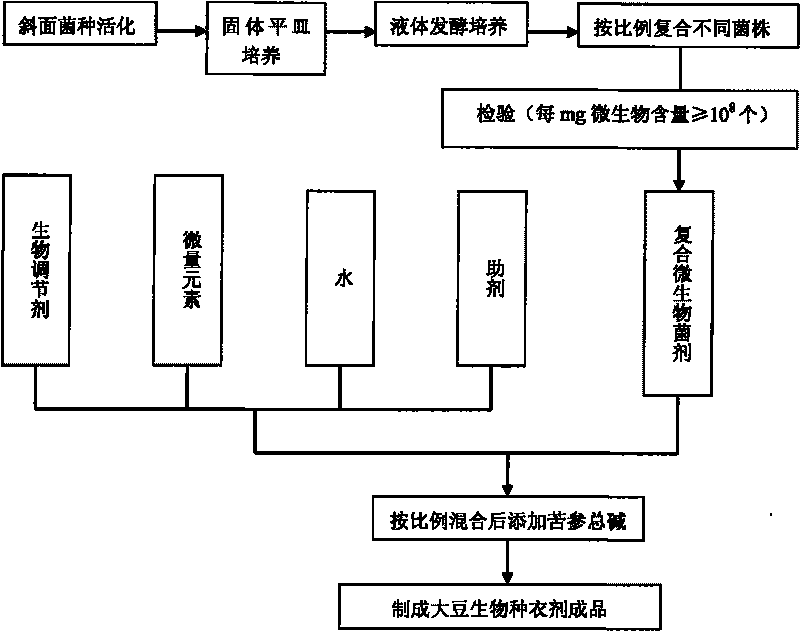

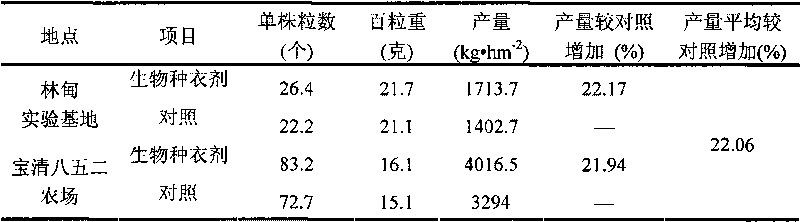

Soybean biological seed coating agent

InactiveCN101723763ALow toxicityOvercome the disadvantage of high residueBiocidePlant growth regulatorsMicroorganismMatrine

The invention discloses a soybean biological seed coating agent which is prepared from the following components in percentage by weight: 20 percent of complex microbial community, 5 percent of bio-regulator SODM, 10 percent of trace element, 10 percent of auxiliary agent, 0.4 percent of total matrines, and the balance of water. The invention has the advantages of environmental protection, enhancement of crop stress tolerance, strengthening of seedling, and improvement of yield and quality.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY +1

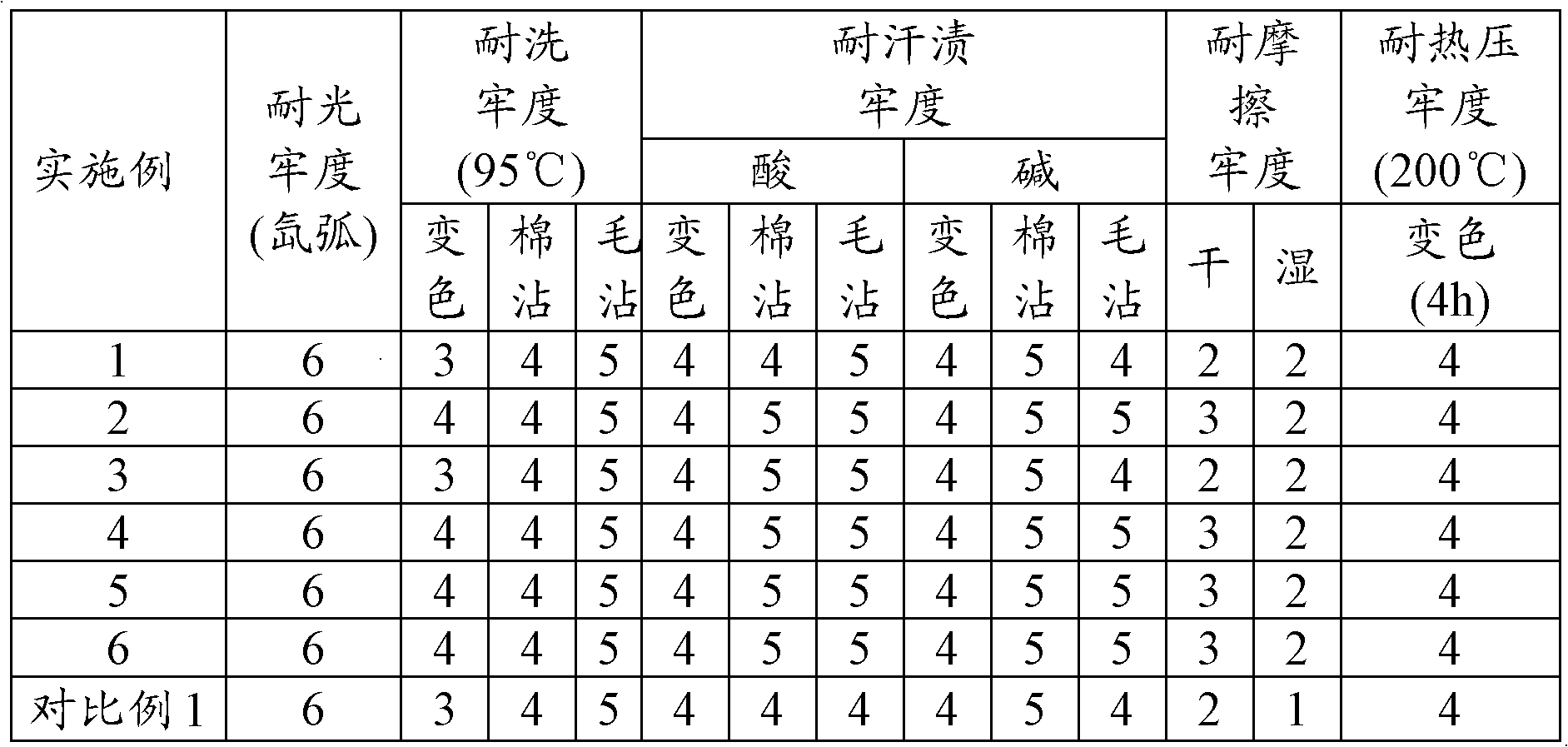

Preparation method and product of sulphur black dye

InactiveCN102174272AHigh coloring rateReduce dosageOrganic dyesDyeing processDyeing wastewaterFilter cake

The invention discloses a preparation method of a sulphur black dye. The method comprises the following steps: adding a sulphur black intermediate filter cake in water, heating to 90-100 DEG C while stirring, and adding the mixture in a sodium sulfide or sodium sulfide solution; then pulping for 30-60 minutes, adding a dispersant, and stirring for 5-30 minutes; and finally drying to obtain the sulphur black dye. The invention also discloses the sulphur black dye prepared by the method. By adding the dispersant in the dye, the strike rate of sulphur black on the cotton fabric and the cotton blended fabric can be increased, on the one hand, the dosage of the sulphur black can be reduced in the dyeing process, on the other hand, the amount of pollutants in printing and dyeing wastewater can be reduced, the treatment difficulty and environmental pollution of the printing and dyeing wastewater can be lowered, and the economic and environmental benefits are quite obvious.

Owner:浙江长征化工有限公司

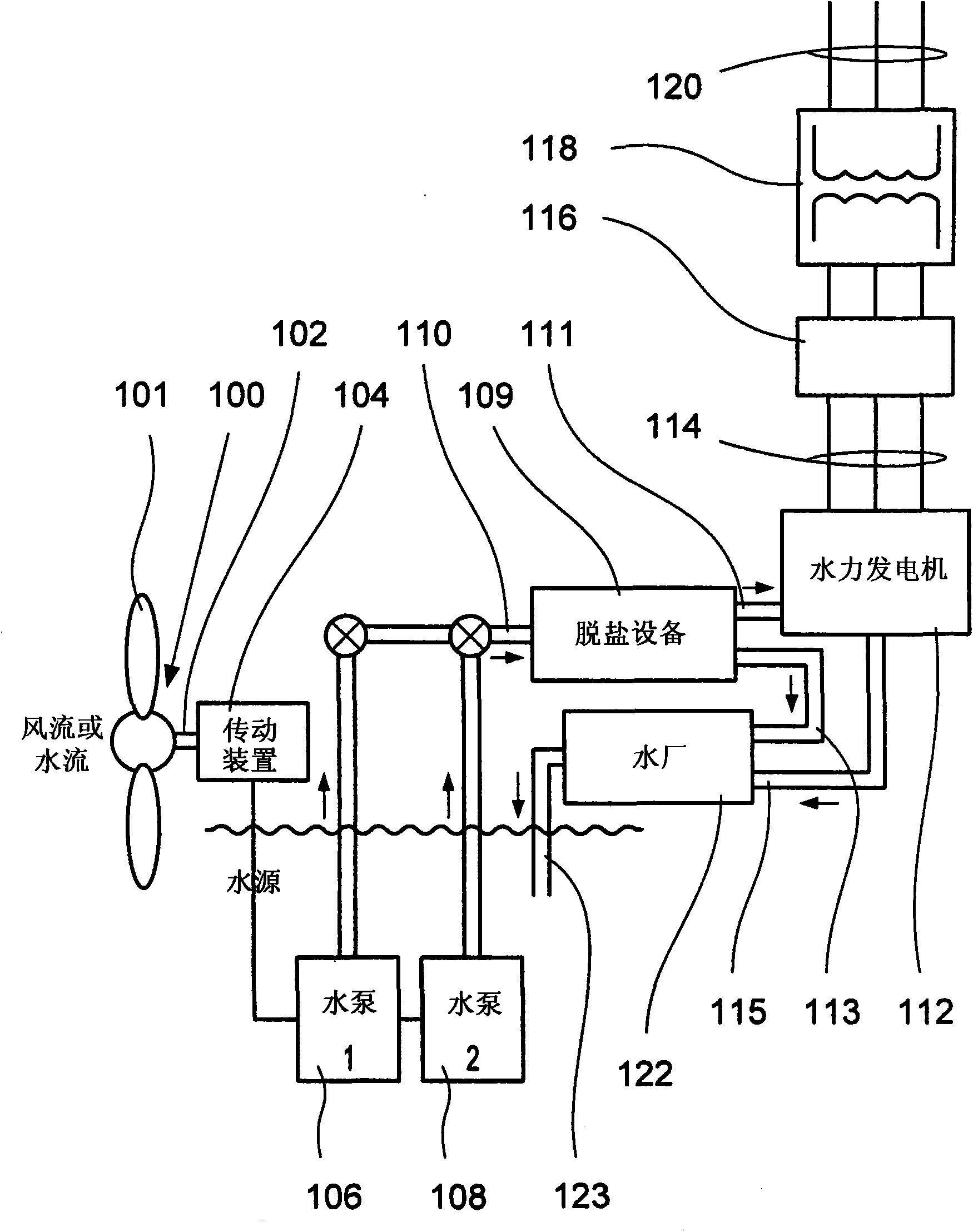

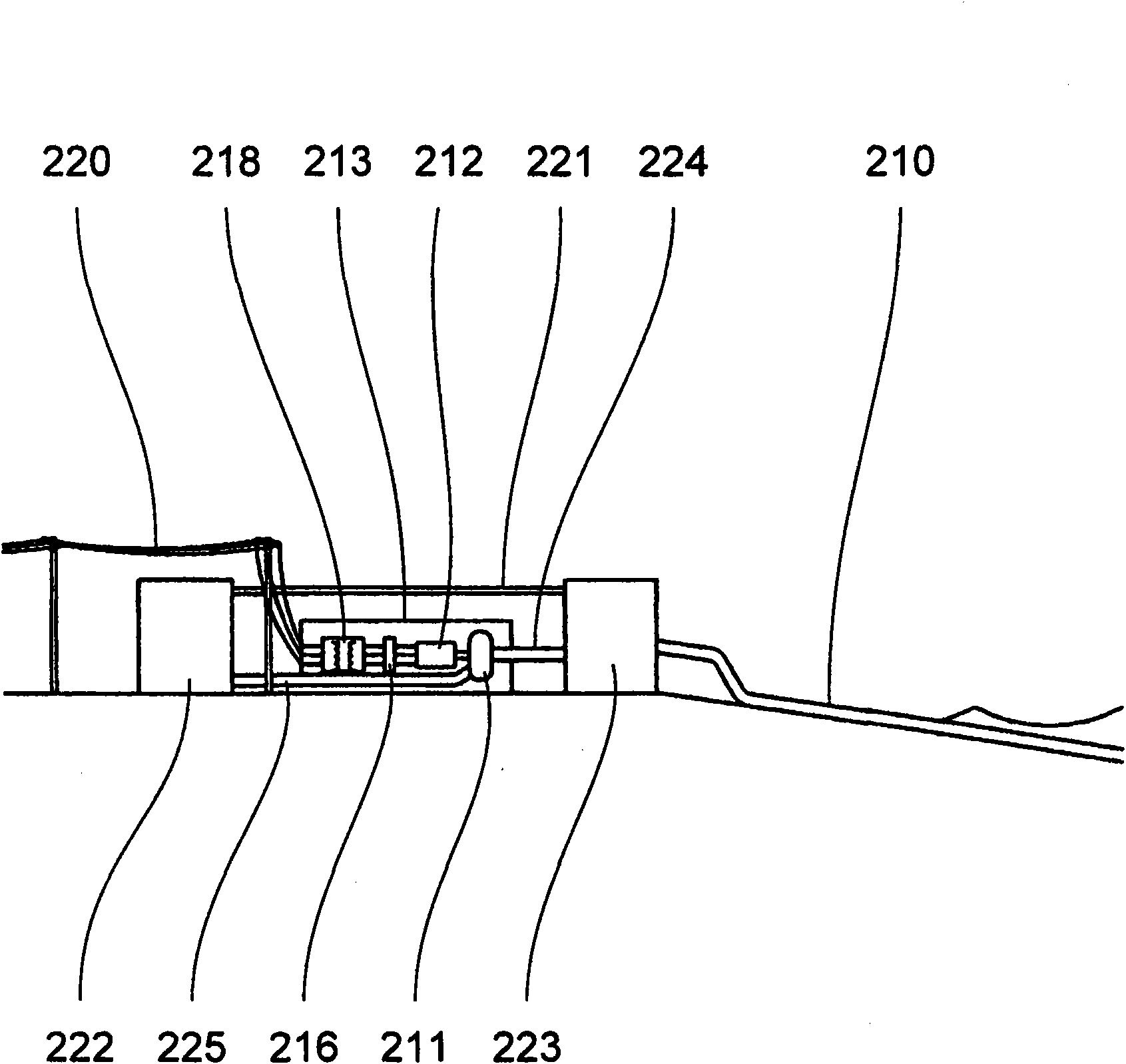

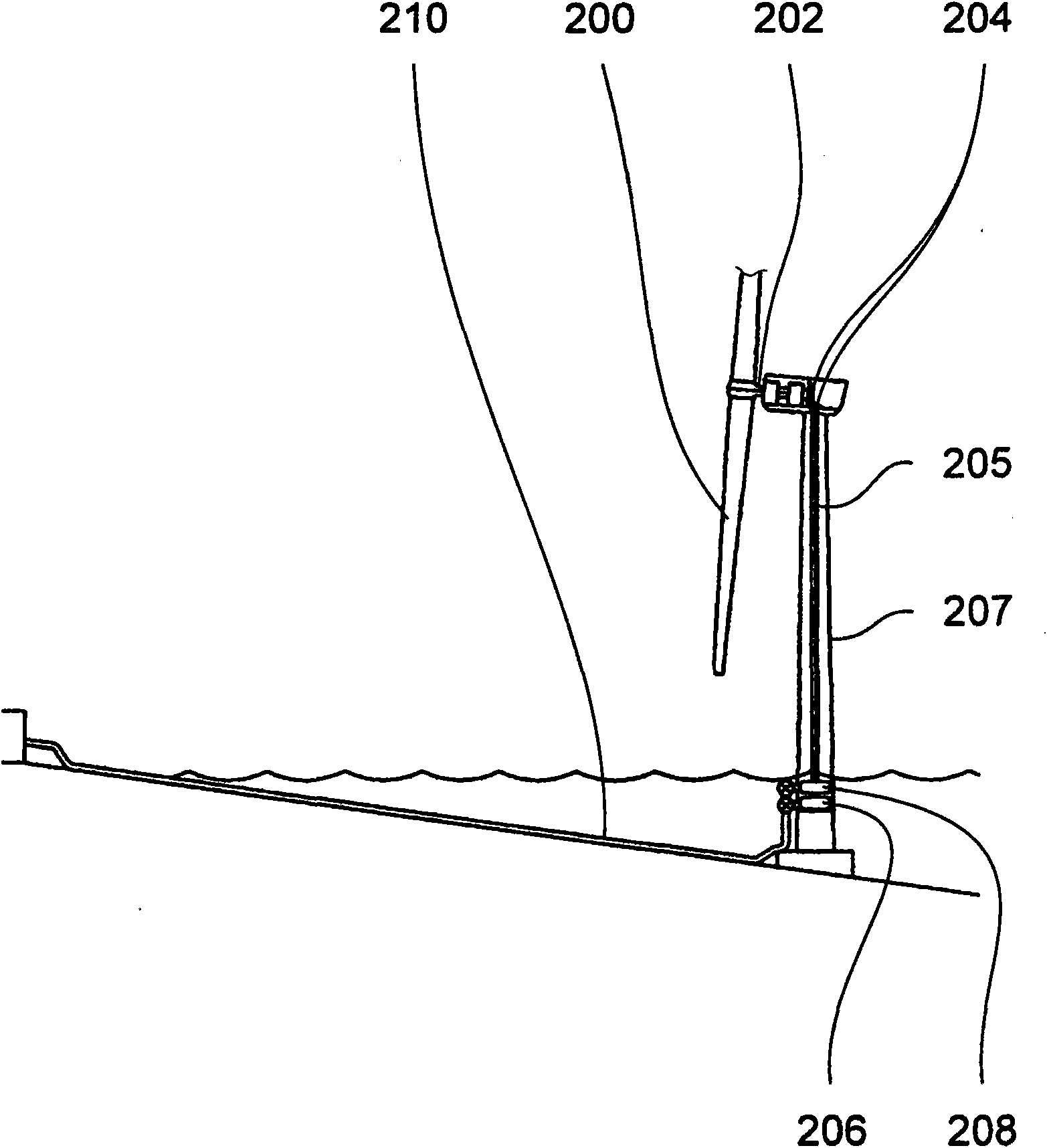

Renewable energy fluid pump to fluid-based energy generation

InactiveCN101855447AReduce maintenance costsReduce pollutionWorking fluid for enginesEnergy industryWater turbineReverse osmosis

A wind or water turbine mounted atop a support tower or tethered underwater drives a hydro-pumping system. The turbine converts wind or water energy into a driving torque applied to the hydro-pump. The hydro-pump forces water through a pipe transmission system to an onshore facility. On shore, the resultant pressurized fluid-flow propels a hydroelectric generating system to produce electricity or may first be used in a Reverse Osmosis desalinization process and the byproduct in part used to propel a hydroelectric generating system to produce electricity. The cold-water discharge from the hydroelectric generating system and / or from the desalinization process is used for onshore district or power plant cooling purposes.

Owner:DEHLSEN ASSOC LLC

Method for treating antibiotic dregs by adopting thermophilic microbial agent

ActiveCN103695337AHigh degree of reductionNo secondary pollutionBacteriaSolid waste disposalMicroorganismThermomicrobia

The invention provides a method for treating antibiotic dregs by adopting a thermophilic microbial agent. The thermophilic microbial agent is added into the antibiotic dregs, so that the antibiotic dregs are reduced, and the antibiotic residues in the dregs are reduced. Under an aerobic fermenting condition, the antibiotic dregs are reduced by over 85%, and the removal rate of the antibiotic residues in the dregs reaches over 90%. The method has the advantages that the degree of reducing the antibiotic dregs is high, and the residue removal rate is high. The reduced dregs are then incinerated, so that the incinerating cost is greatly saved. The method is simple, easy to operate, small in occupied area, low in investment cost and free from secondary pollution to the environment, and has the remarkable economical, social and environment-friendly benefits.

Owner:北京绿源科创环境技术有限公司

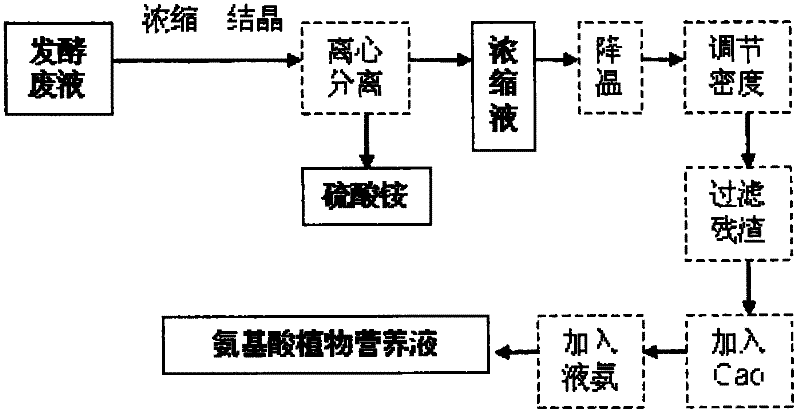

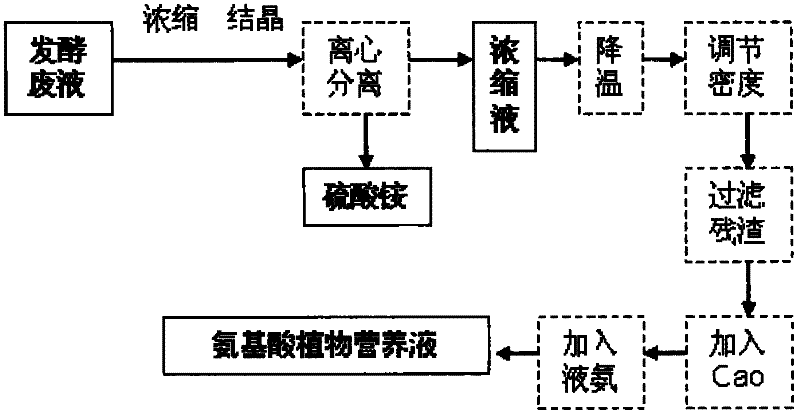

Production method of amino acid plant nutrient solution

InactiveCN102173881AImprove the level of comprehensive utilizationSolve the worries of developmentClimate change adaptationBioloigcal waste fertilisersMonosodium glutamateSulfate radicals

The invention discloses a production method of an amino acid plant nutrient solution. The method comprises the following steps: extracting thalli from the fermentation effluent of MSG (monosodium glutamate) to evaporate and concentrate, and crystallizing to separate and obtain ammonium sulfate and a concentrate; treating the concentrate with CaO and liquid ammonia, fixing sulfate radicals, and adjusting the pH value to obtain the amino acid plant nutrient solution. By adopting the production method, the wastewater treatment problem of the MSG fermentation industry can be solved fundamentally, the wastewater can be converted into the amino acid plant nutrient solution, and the environmental benefit, economic benefit and social benefit are significant.

Owner:LINGHUA GROUP INCORPORATED COMPANY

Full fly ash building brick and its manufacturing method and special additive

A flyash brick for building is prepared from the flyash (90-96 wt.%) and the composite additive (4-10 wt%) containing water glass, alkaline oxide or the alkaline compounds, bentone, and iron oxide. Its advantages are high strength and low cost.

Owner:山西民兴实业有限公司

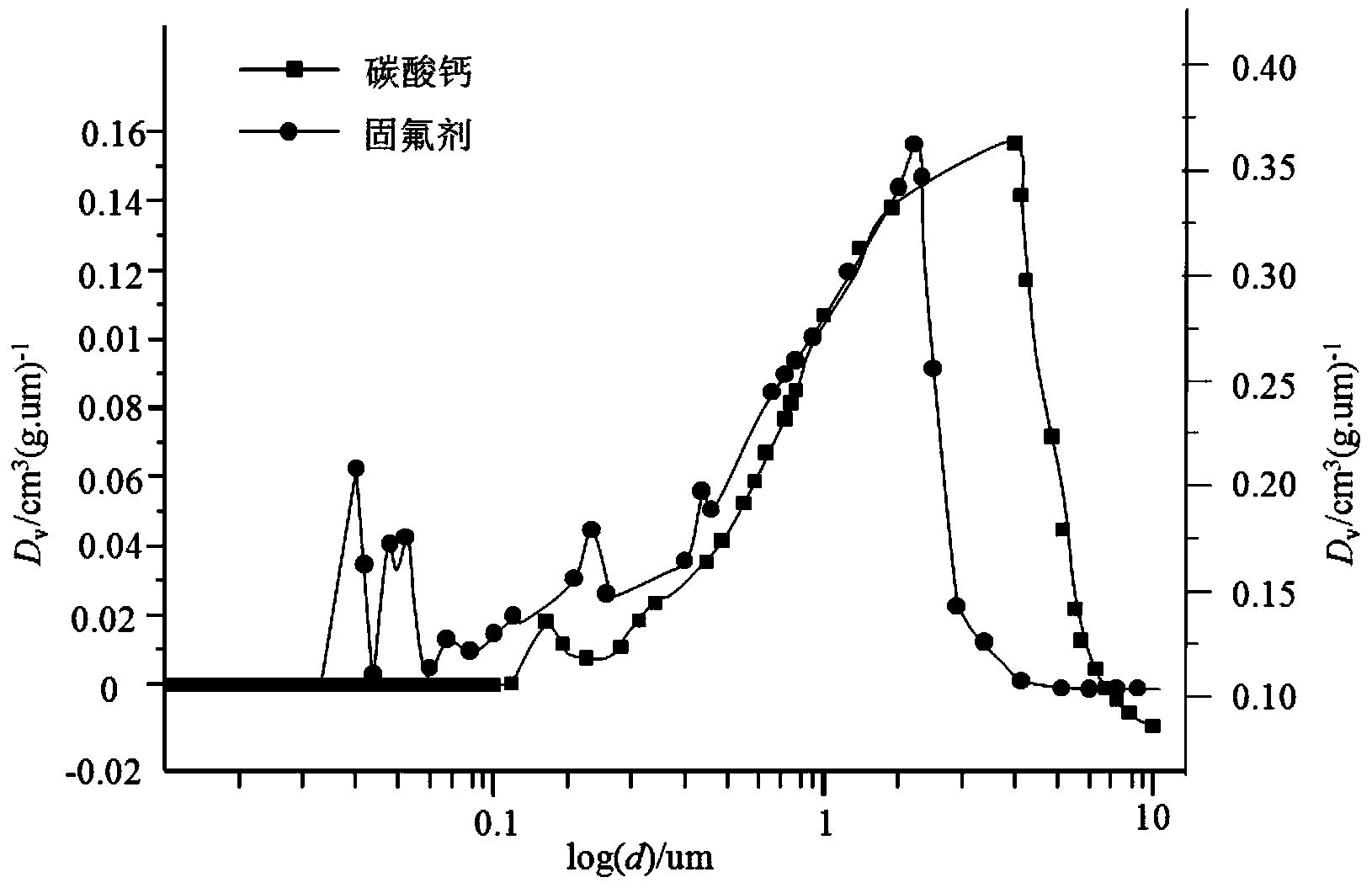

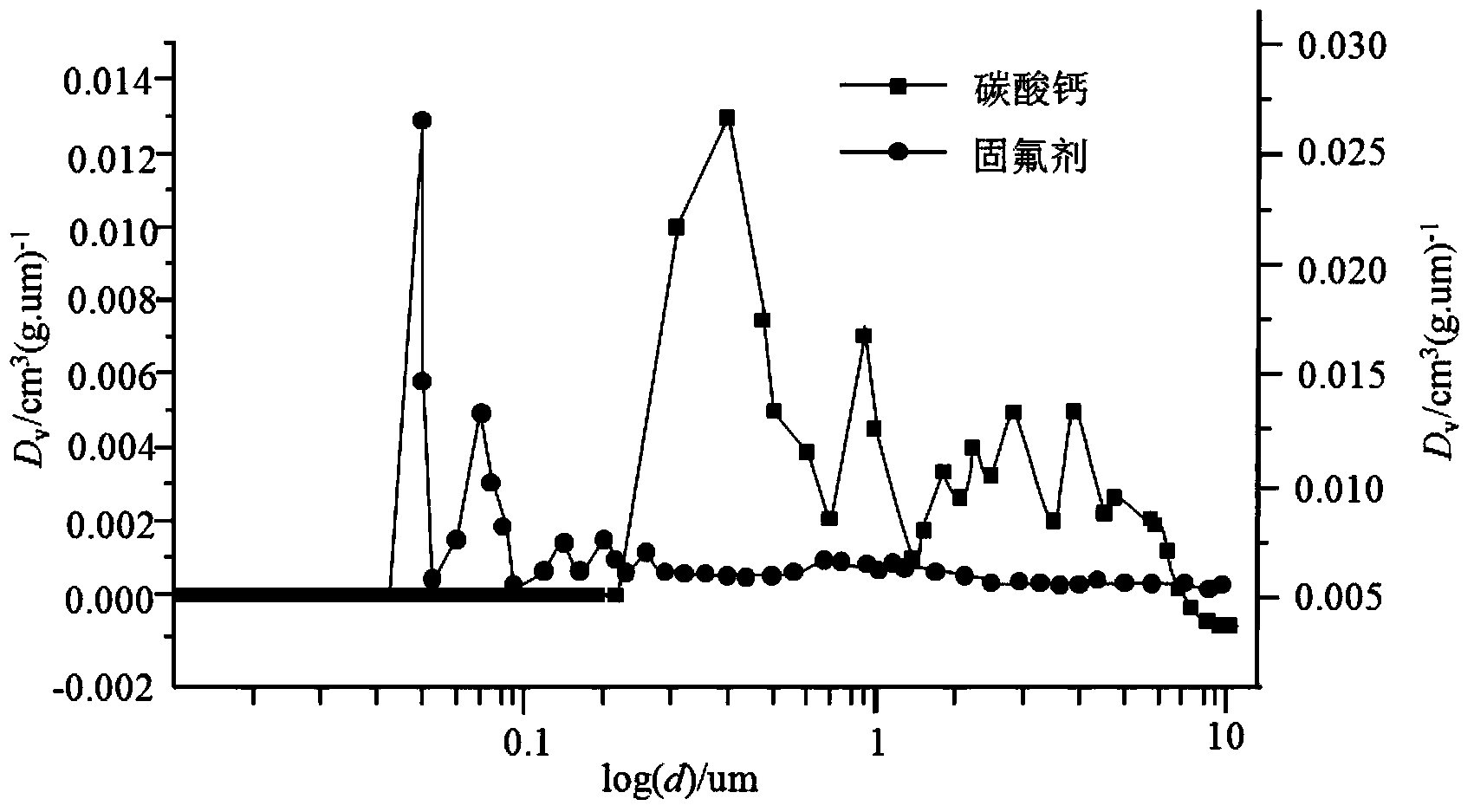

Fluoride solidifying agent for treating fluorine pollution caused by burning coal and preparation method and application method thereof

ActiveCN103923721AImprove microscopic void structureLarge hole volumeSolid fuelsPorosityPotassium carbonate

The invention discloses a fluoride solidifying agent for treating fluorine pollution caused by burning coal. The fluoride solidifying agent is prepared by the following steps of respectively weighing calcium magnesium acetate, aluminum sulfate, sodium carbonate and potassium carbonate according to the molar ratio of ca2+, Al3+, Na+ to K+, wherein the molar ratio is 30: 1.5: 3: 2-4.5; evenly mixing the calcium magnesium acetate, the aluminum sulfate, the sodium carbonate and the potassium carbonate; grinding the mixture through a 180 mesh-300 mesh screen; adding water with the weight 6-12 times that of the mixture into the mixture; heating the mixture to the temperature of 70 DEG C-90 DEG C; stirring the mixture for two to six hours; drying the mixture at the temperature of 100 DEG C-120 DEG C; grinding the mixture through the temperature of 70 DEG C-90 DEG C. Compared with the calcium carbonate serving as the traditional fluoride solidifying agent, porosity and specific surface area of the fluoride solidifying agent are increased greatly, fluoride can be solidified effectively during coal burning, and fluoride content in high-temperature smoke is reduced effectively. Compared with the calcium magnesium acetate serving as the fluoride solidifying agent independently, effect in removing fluoride in high-temperature smoke is more remarkable. Furthermore, the preparation method of the fluoride solidifying agent is simple, and raw material price and production cost are low. The method for solidifying fluoride during coal burning by utilizing the fluoride solidifying agent is easy to implement.

Owner:沃德费默循环经济科技发展(北京)有限公司

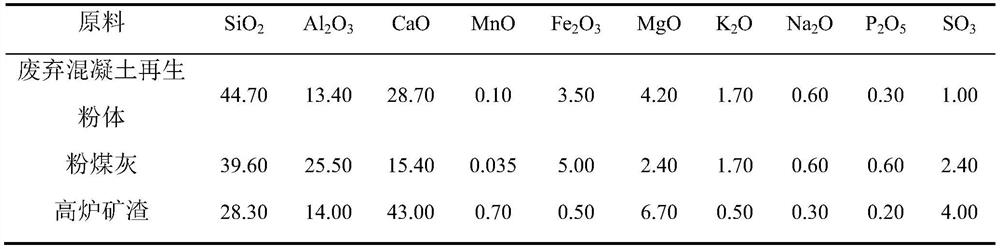

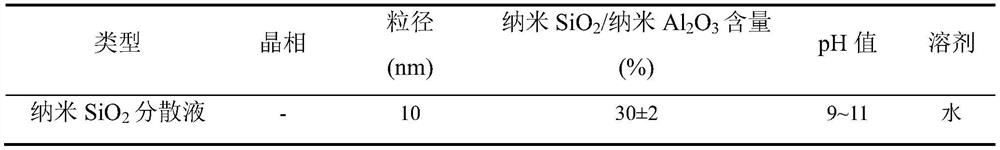

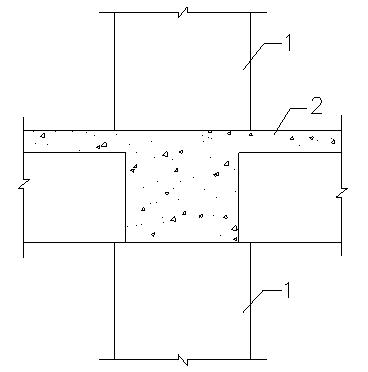

Modified high-strength geopolymer cementing material and preparation method thereof

The invention relates to a modified high-strength geopolymer cementing material and a preparation method thereof. The geopolymer cementing material is prepared by using waste concrete regenerated powder, blast furnace slag and fly ash as precursors, using a nano SiO2 aqueous dispersion or a nano Al2O3 aqueous dispersion for modification, and using a mixed solution of a sodium silicate solution and sodium hydroxide as an alkali activator. The waste powder generated in the waste concrete recycling process is consumed to prepare the geopolymer cementing material with high strength under the normal-temperature curing condition. The geopolymer cementing material is a green building material, and has the advantages of being high in early strength, excellent in durability and the like. High-added-value utilization of the waste concrete powder is achieved. The preparation method is also simple and easy to operate and has a wide application prospect.

Owner:SOUTHEAST UNIV

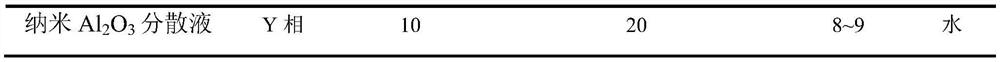

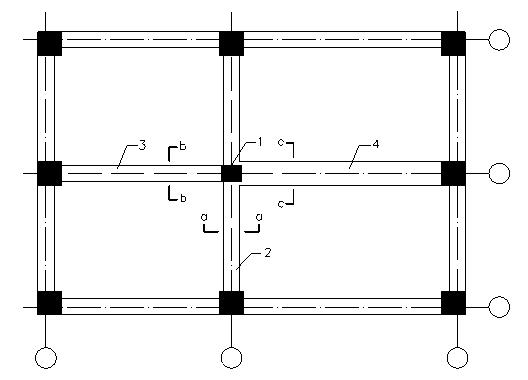

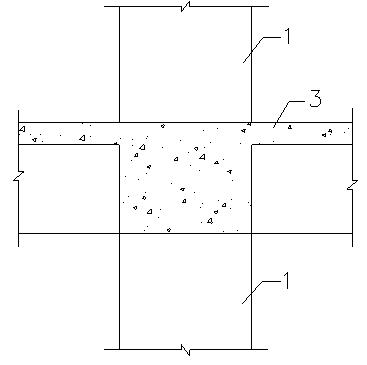

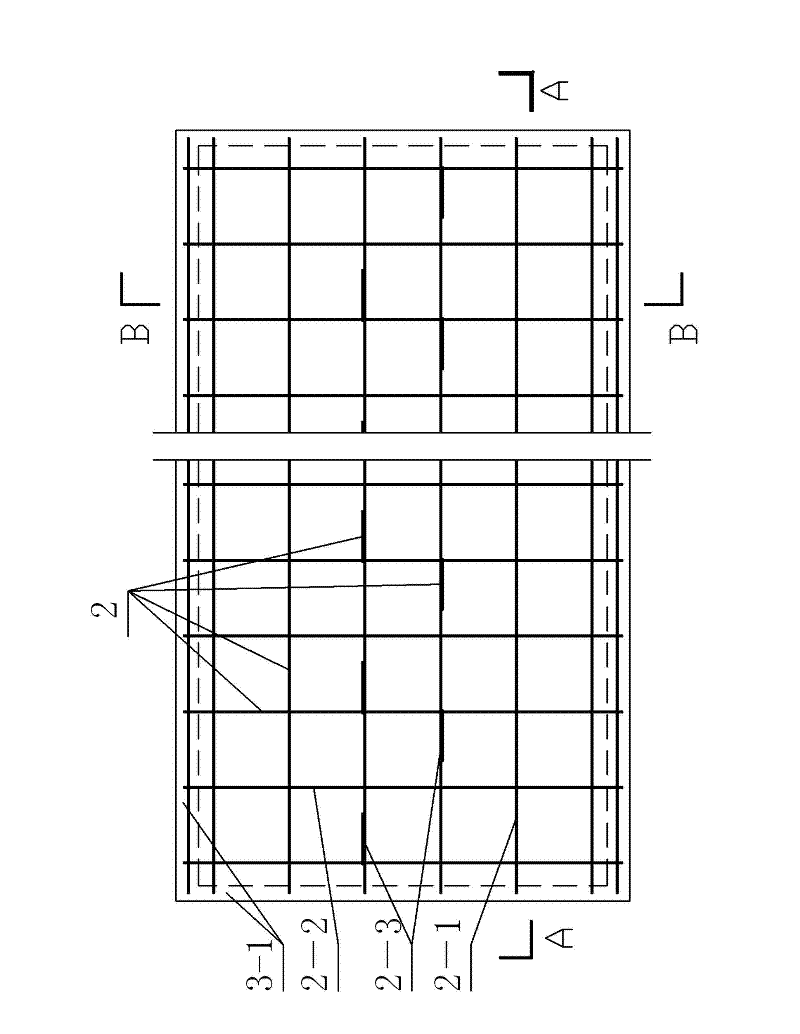

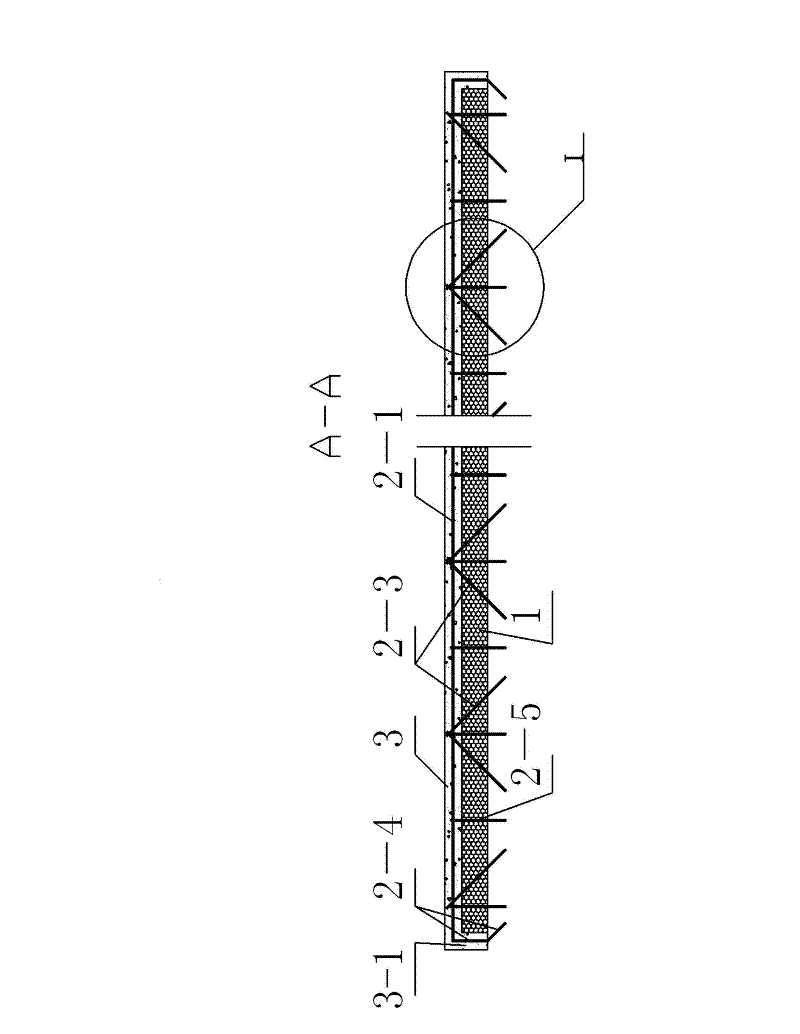

Reinforcement lightweight aggregate concrete flat beam structure

InactiveCN102425231AImprove punching resistanceSolve the problem of overcrowdingShock proofingSocial benefitsSteel bar

The invention relates to a reinforcement lightweight aggregate concrete flat beam structure which comprises a column, a beam and a plate, wherein the beam is a flat beam made of a reinforcing steel bar and lightweight aggregate concrete, the width of the flat beam is more than or equal to the height; and the column is a reinforcement lightweight aggregate concrete column. The reinforcement lightweight aggregate concrete flat beam structure provided by the invention also has better properties of light weight, energy saving, environment friendliness, good durability and the like of the lightweight aggregate concrete under the condition of the advantages of reducing floor height, avoiding pipeline beam crossing and the like, greatly reduces self gravity of the whole building structure and improves earthquake resistant behaviour of the structure while ensuring bearing capacity, and has remarkable economic and social benefits.

Owner:FUZHOU UNIV

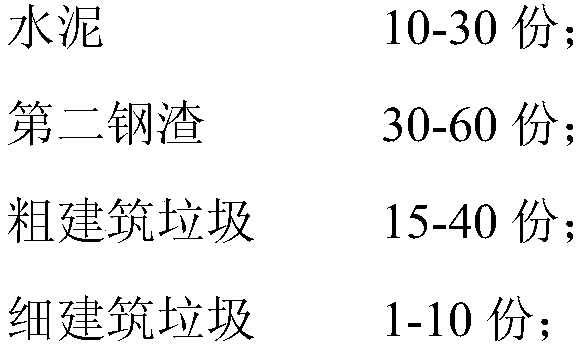

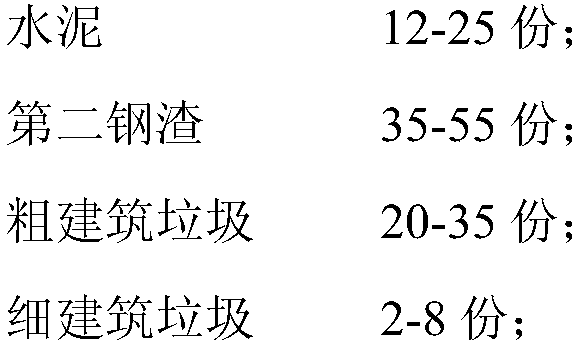

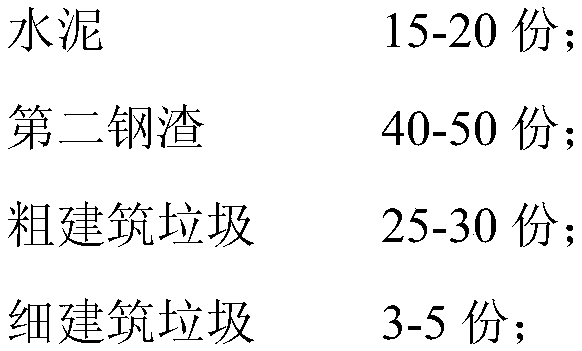

Water permeable brick and preparation method thereof

InactiveCN109456000AAvoid shortageExpansion and utilization of new avenuesSingle unit pavingsPaving gutters/kerbsBrickSurface layer

The invention provides a water permeable brick material, which sequentially comprises a surface layer material and a bottom layer material from top to bottom, wherein the surface layer material comprises a facing material, a surface layer water reducer and surface layer water; the facing material is prepared from the following components in parts by weight: 10-30 parts of cement, 60-85 parts of first steel slag and 1-10 parts of fine construction waste; the addition amount of the surface layer water reducer is suitable; the addition amount of the surface layer water is suitable; the bottom layer material comprises a bottom material, a bottom layer water reducer and bottom layer water; the bottom material is prepared from the following components in parts by weight: 10-30 parts of the cement, 30-60 parts of the first steel slag, 15-40 parts of coarse construction waste and 1-10 parts of fine construction waste; the addition amount of the bottom layer water reducer is suitable; and the addition amount of the bottom layer water is suitable. The invention further provides a preparation method of the water permeable brick. The water permeable brick and the preparation method thereof provided by the invention solve the problem of insufficient supply of electric furnace steel slag and expands a new way of utilization of the construction waste.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

Cement porous polymer composite heat insulation plate

The invention relates to a cement porous polymer composite heat insulation plate. The cement porous polymer composite heat insulation plate is characterized by comprising an efficient heat insulation layer, a three-dimensional rigid skeleton and a cement concrete layer using a porous polymer as light aggregate, wherein the three-dimensional rigid skeleton is connected between the cement concrete layer and the efficient heat insulation layer and respectively embedded into the cement concrete layer and the efficient heat insulation layer so as to form an integrated plate member. The heat insulation performance of the integrated plate member can be promoted, the mechanical strength of the integrated plate member can be improved, the surface density and the weight of the integrated plate member are reduced, and meanwhile, the requirements of fireproof, shockproof, durable and wall rendering construction are met; and moreover, punching shear resistance and bending resistance of the integrated plate member can be improved, and the mechanical property required by template engineering is met.

Owner:永格(福建)建筑科技有限公司

Self-compacting concrete and preparation method thereof

ActiveCN112707685ALow water absorptionHigh strengthSolid waste managementStructural engineeringSodium silicate

The invention provides self-compacting concrete and a preparation method thereof, and belongs to the technical field of building materials. The preparation method provided by the invention comprises the following steps of: sequentially drying, crushing and ball-milling engineering muck to obtain engineering muck micro-powder; sequentially mixing the engineering muck micro-powder, first cement, sodium silicate and first water and carrying out granulating and curing to obtain baking-free muck particles; crushing and screening construction waste in sequence to obtain recycled fine aggregate; mixing the baking-free muck particles, the recycled fine aggregate, second cement, fly ash, mineral powder, silica fume, second water, a concrete defoaming agent and a water reducing agent, and then sequentially carrying out molding, demolding and curing to obtain the self-compacting concrete. According to the invention, the characteristic of high fluidity is obtained by utilizing the grain shape centrality (the grain shape coefficient approaches 1) and low water absorption rate of the baking-free muck particles, and the baking-free muck particles and the recycled fine aggregate are combined for use to complement each other, so that the brand-new self-compacting concrete with higher strength is obtained.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

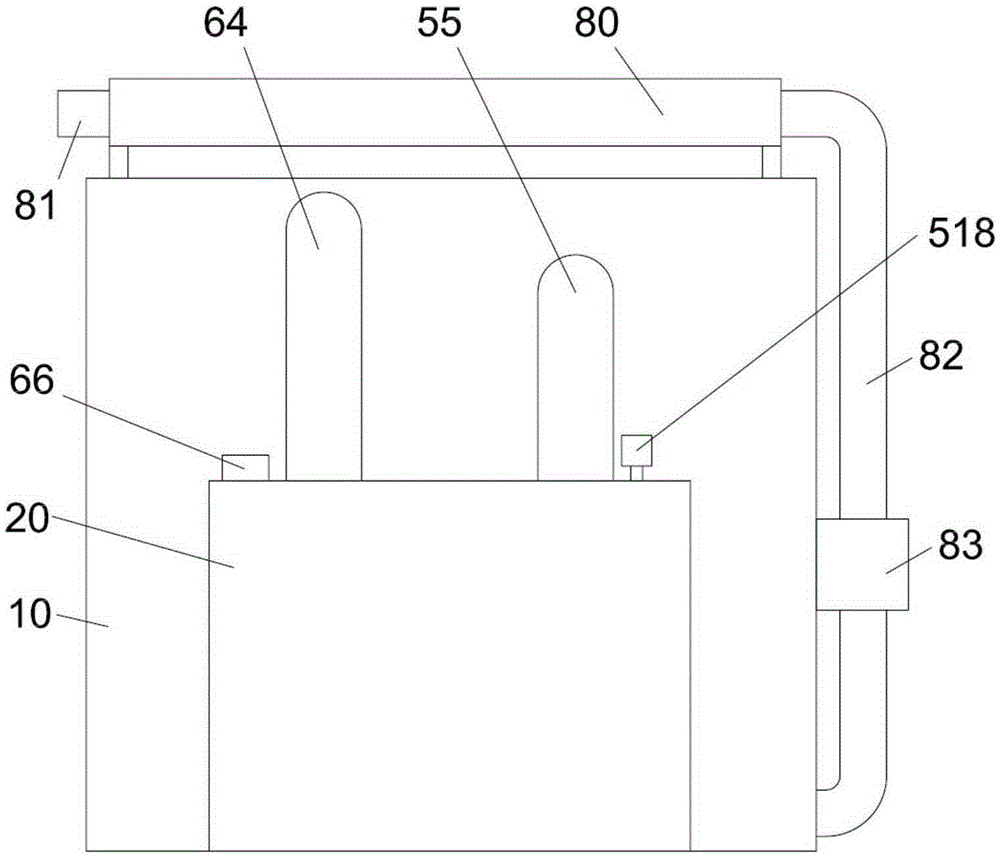

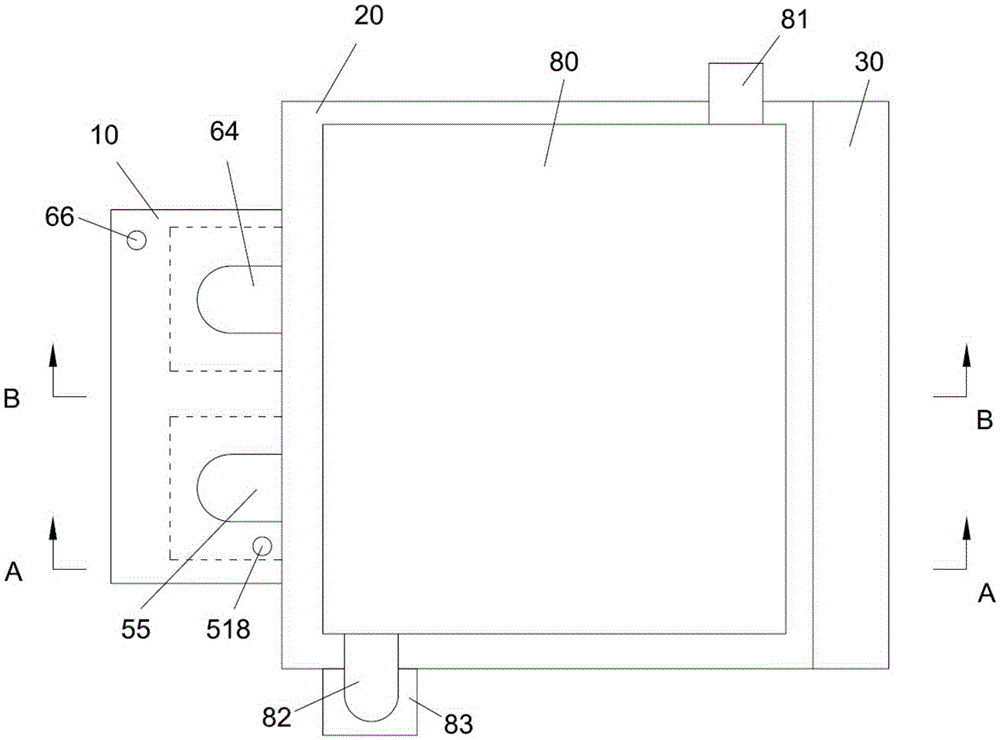

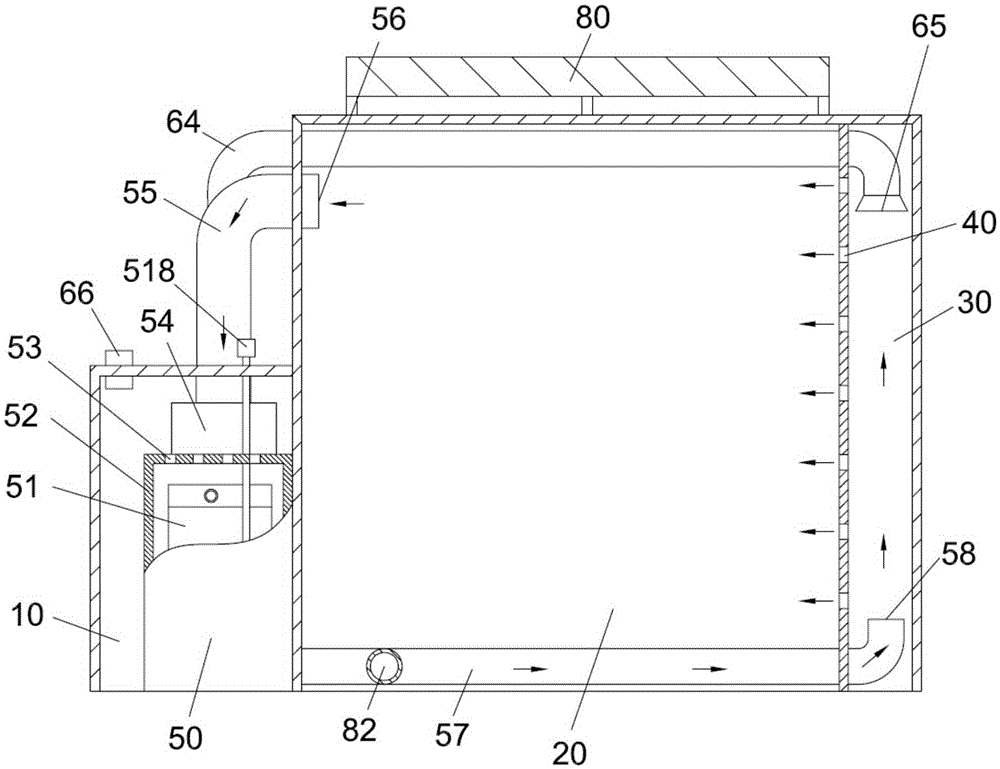

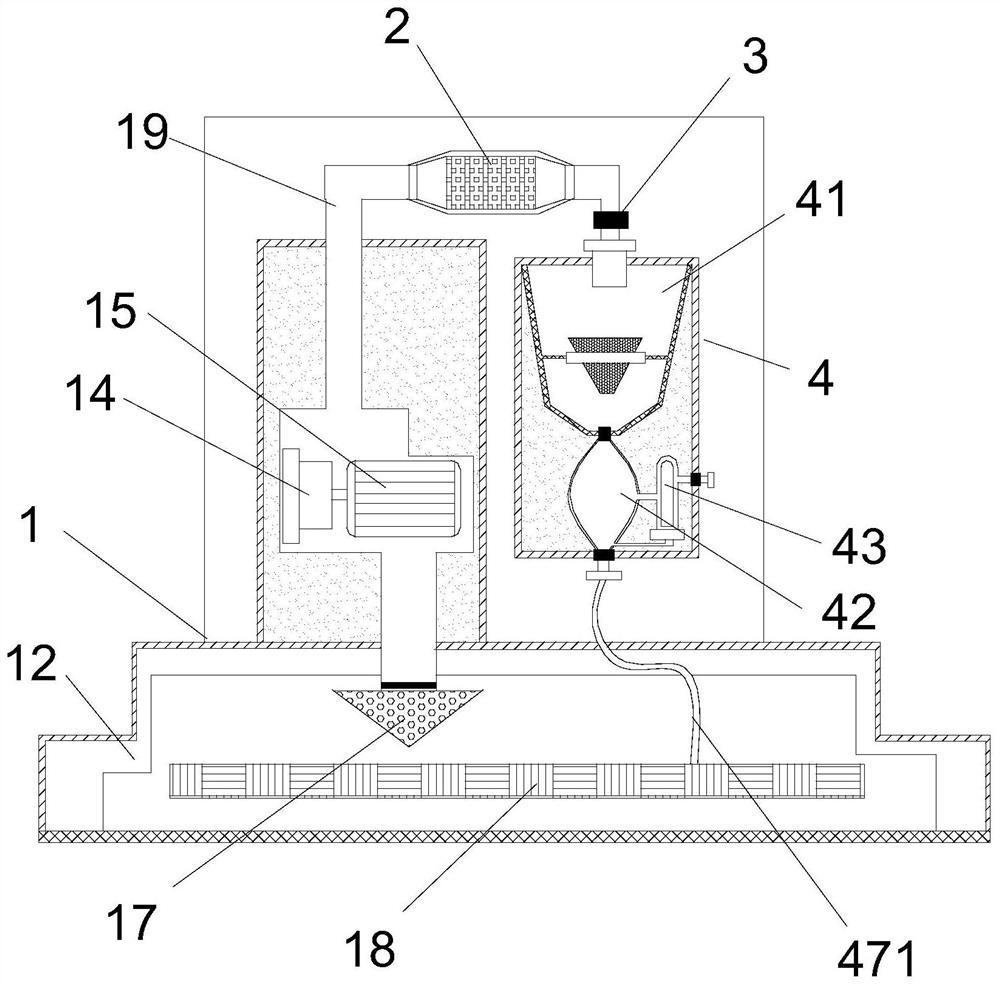

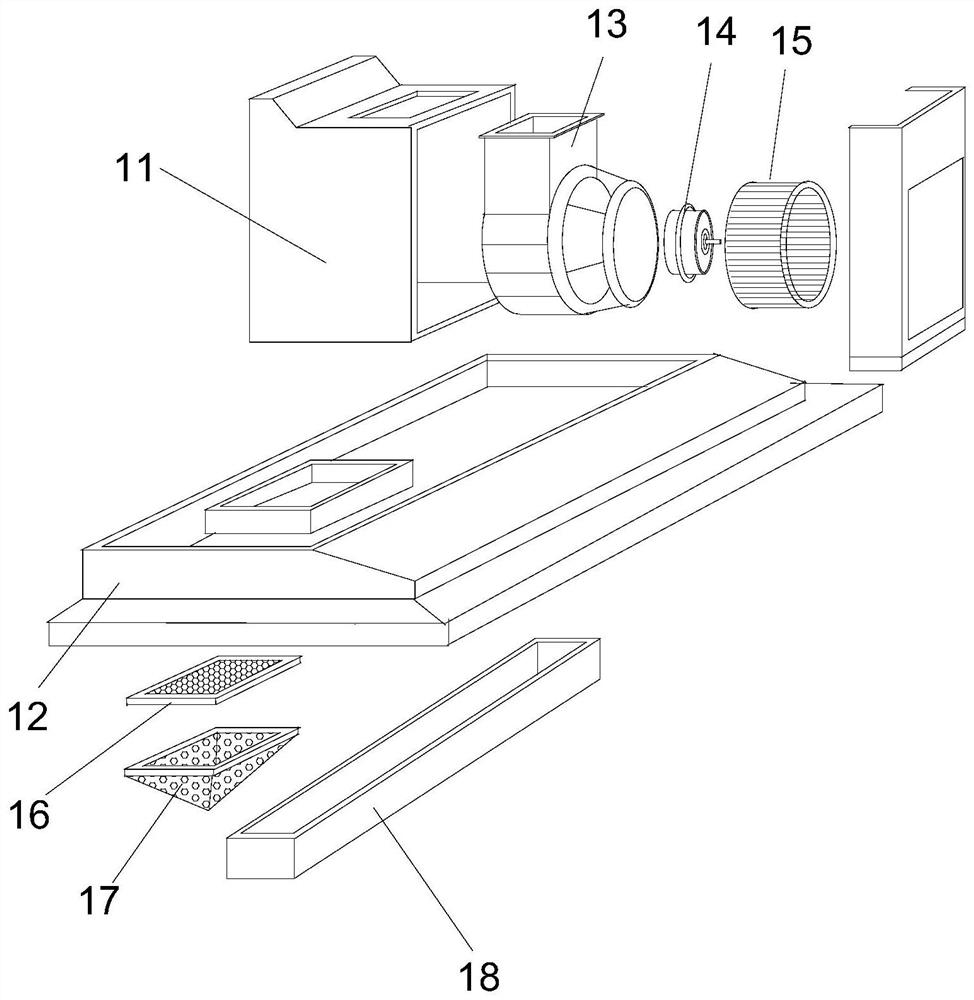

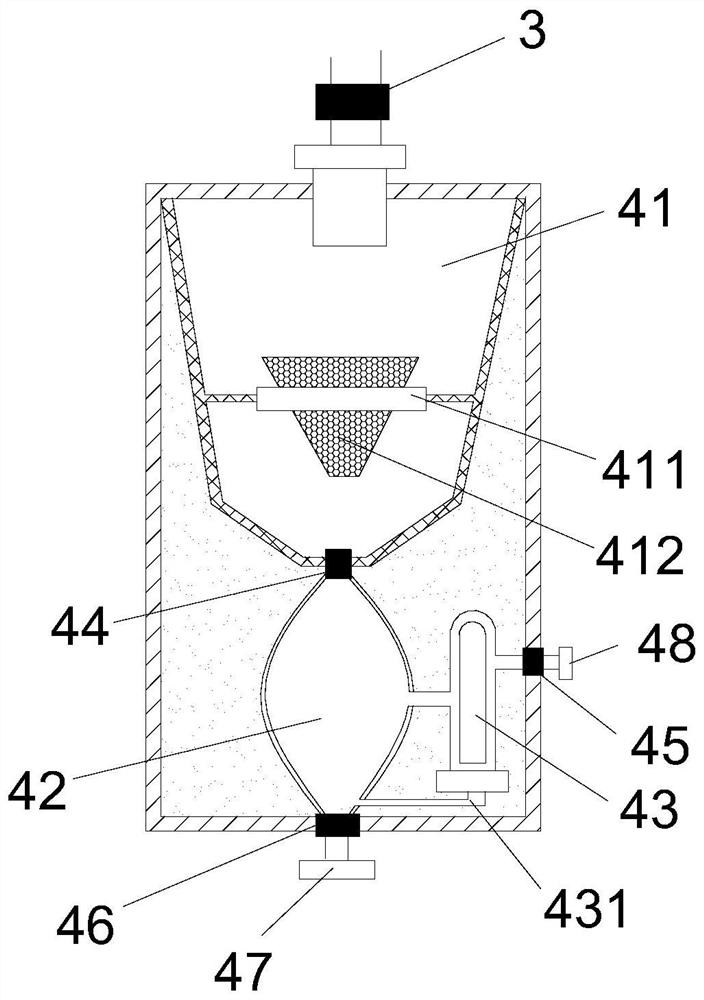

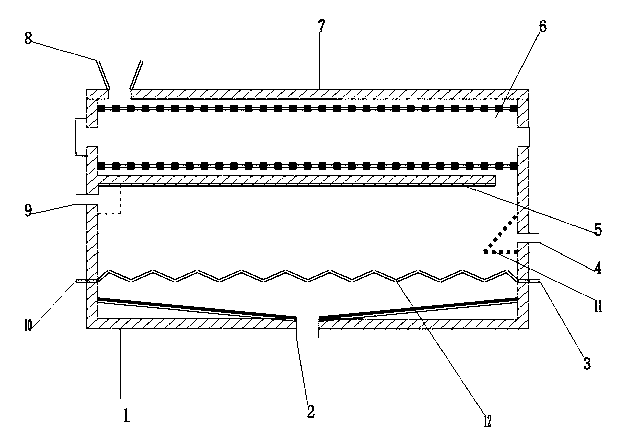

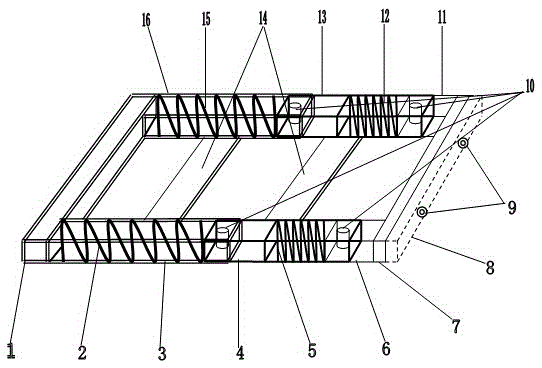

Dehumidification drying equipment and method controlled by new energy assistance and wide temperature section

ActiveCN105403003AStrong regional adaptabilityGuaranteed uptimeDrying gas arrangementsDrying machines with local agitationSolar air collectorNew energy

The invention discloses dehumidification drying equipment and a dehumidification drying method controlled by new energy assistance and wide temperature section. The dehumidification drying equipment comprises a dehumidification room and a drying room, wherein the dehumidification room is arranged at one side of the drying room, an air supply room is arranged at the other side of the drying room, blowing holes are formed in the common wall of the air supply room and the drying room, and a dehumidification device and a drying device are arranged in the dehumidification room. The dehumidification drying equipment further comprises a solar air collector arranged at the top of the drying room, a collector air inlet is formed at one side of the solar air collector, a collector exhaust duct connected with an exhaust duct B is arranged at the other side of the solar air collector, and a collector electromagnetic regulating valve used for regulating exhaust air rate is arranged on the pipeline of the collector exhaust duct. According to the invention, new energy assistance and wide temperature section automatic regulation are added on the basis of conventional energy resources, so that dehumidification drying can be carried out on different varieties of grains, forest products and traditional Chinese medical materials needing different drying temperature.

Owner:王正宇

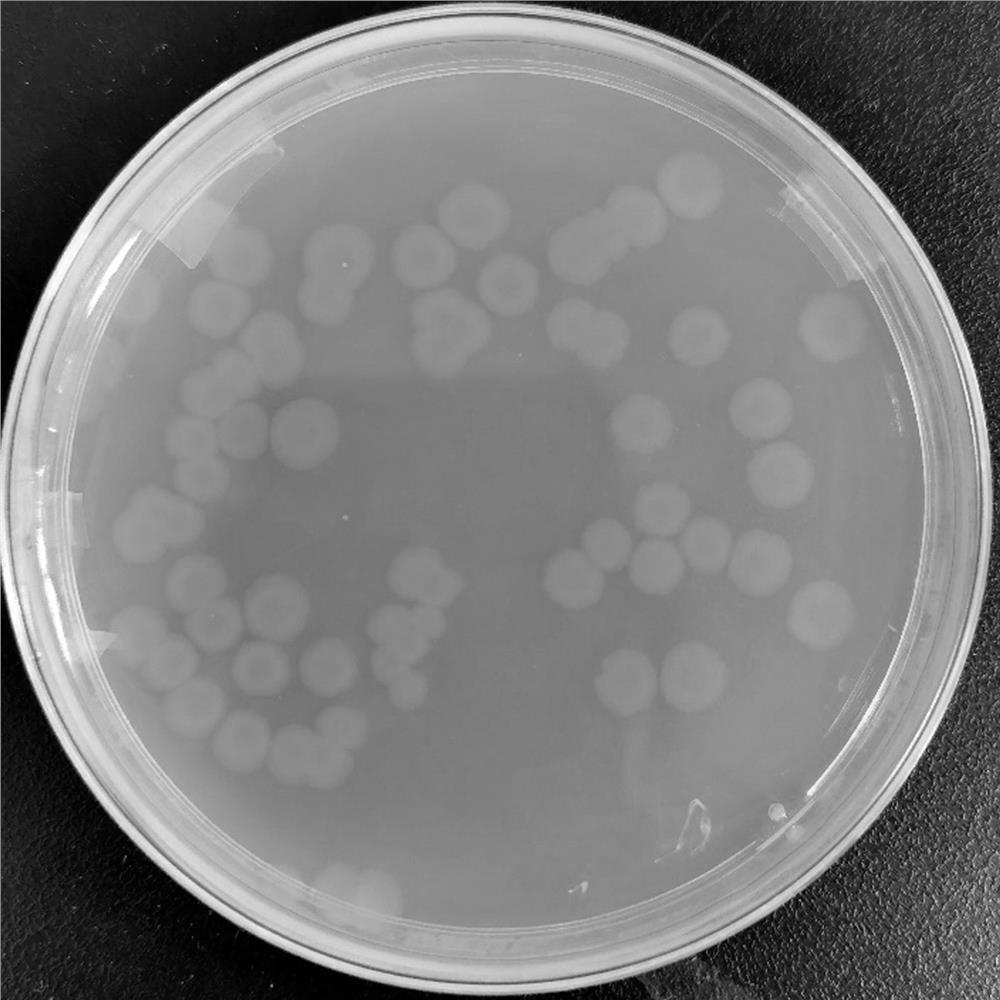

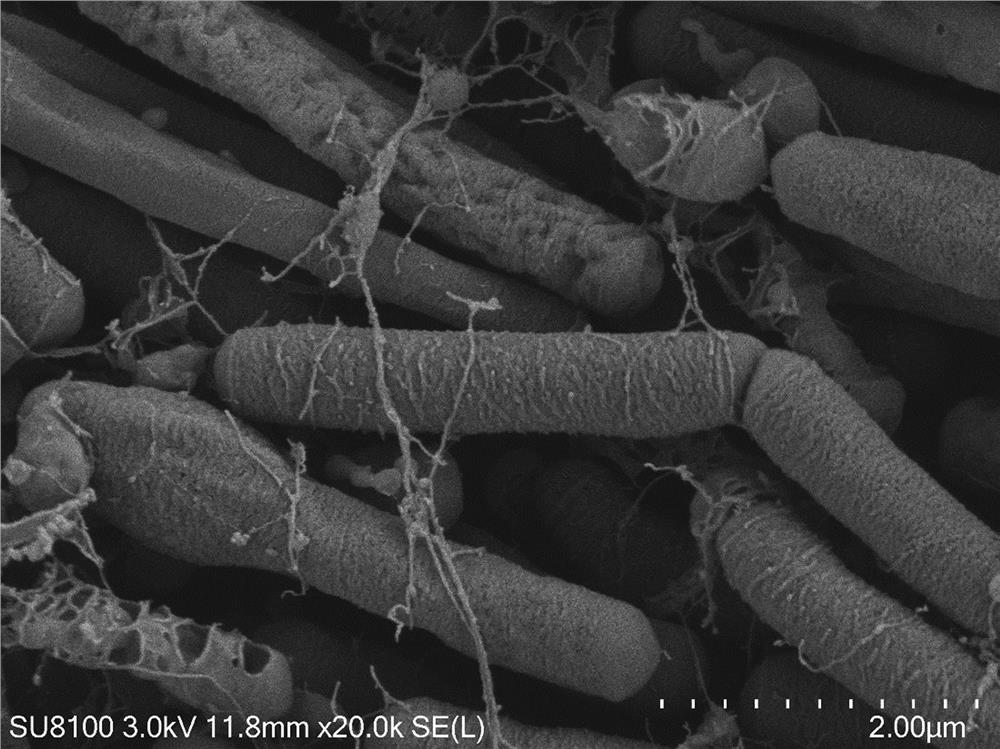

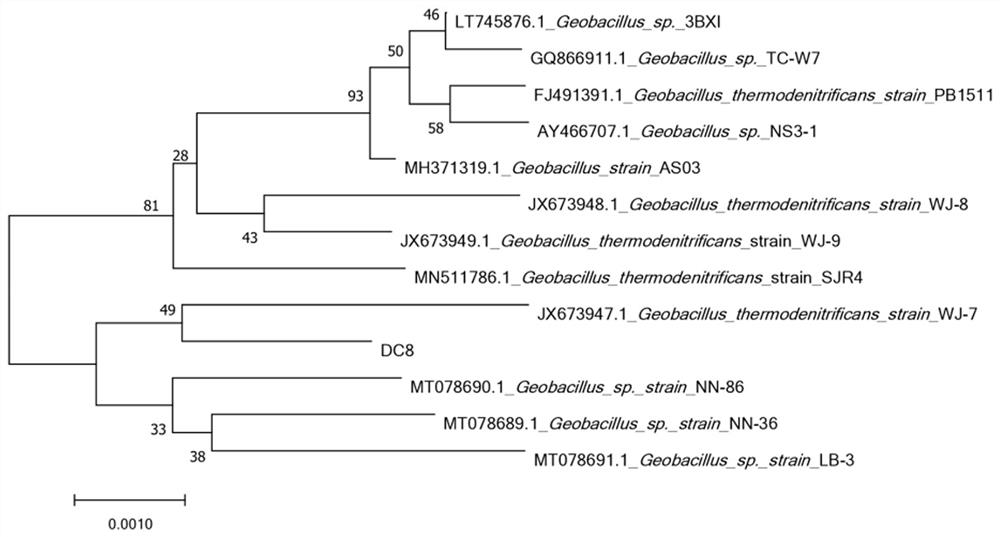

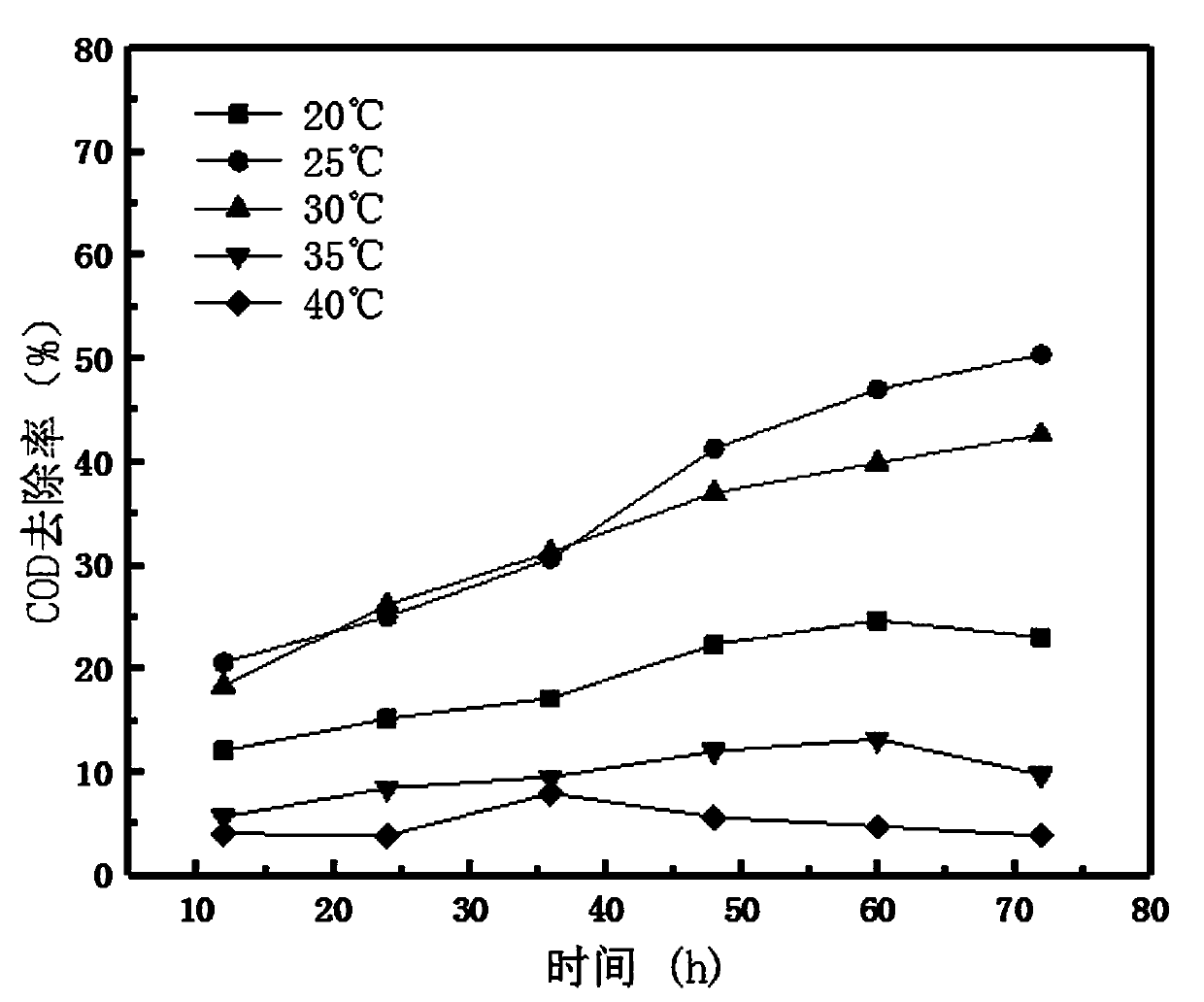

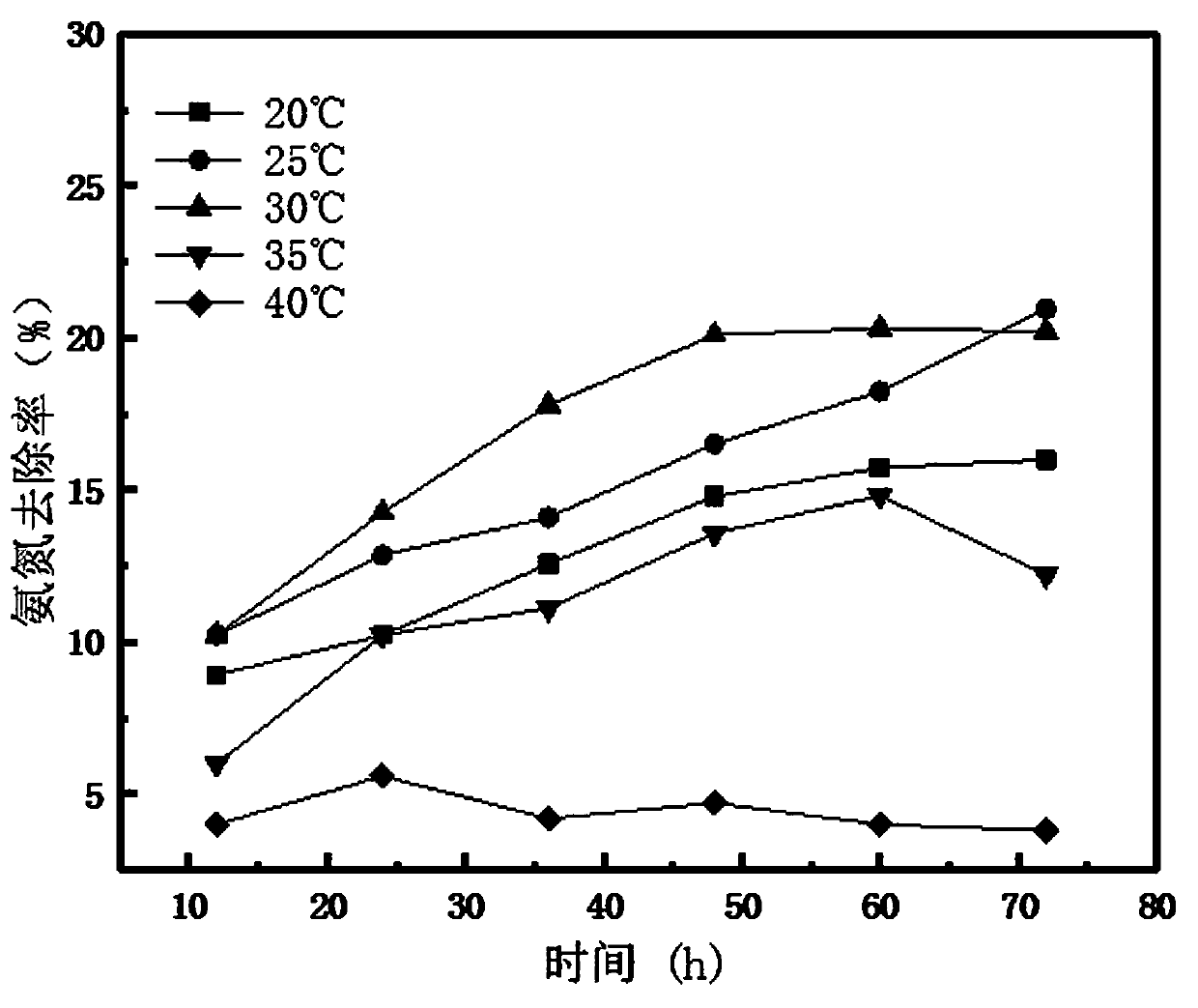

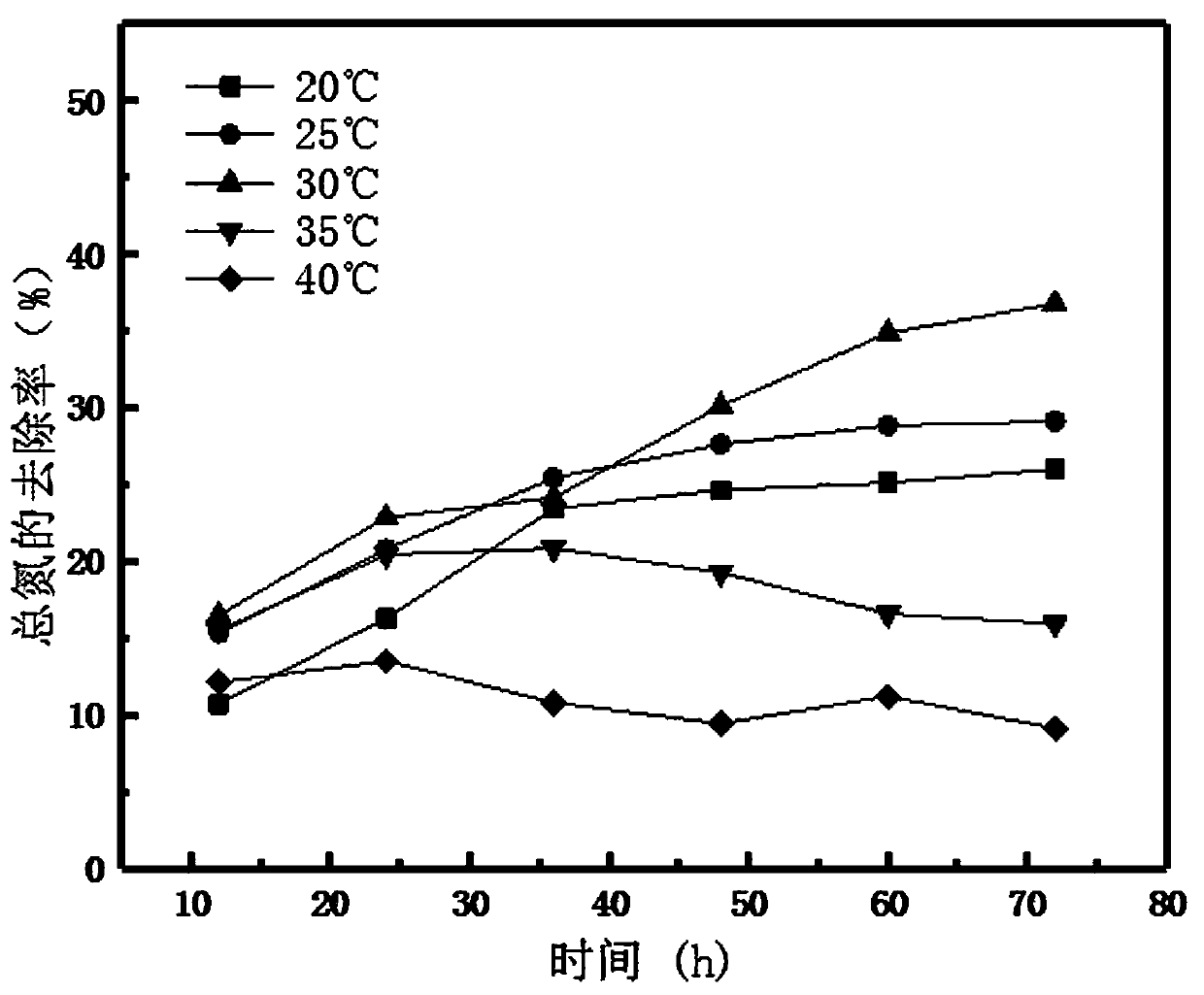

Geobacillus thermodenitrificans DC8 strain and application thereof

PendingCN114164133AFlat surfaceNeat edgesBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a geobacillus thermodenitrificans DC8 strain and application thereof, the geobacillus thermodenitrificans DC8 strain is preserved in China General Microbiological Culture Collection Center (CGMCC) on August 30, 2021, and the preservation number is CGMCC No.23318. The strain provided by the invention has the capability of degrading excess sludge to extract protein in a high-temperature environment, and the protein extraction rate can reach 29.7%. Protein in sludge can be effectively utilized by utilizing the strain, the reduction and degradation effect of residual sludge is improved, and the strain has a good application prospect. According to the invention, an efficient bacterium source is provided for the reduction of the residual sludge of a sewage plant, the functional application of the geobacillus thermodenitrificans is widened, and the geobacillus thermodenitrificans has a relatively high practical value.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Flotation reagent for improving flotation indexes of sphalerite

The invention relates to a flotation reagent for improving flotation indexes of sphalerite and belongs to the field of metal mineral beneficiation. The special flotation reagent is prepared by mixing the following solutions by volume percent: 5-20% of a 1-1.5 wt% ammonium dibutyl dithiophosphate solution, 5-15% of a 8-10 wt% sodium(potassium)amyl xanthate solution, 30-40% of a 8-10 wt% sodium O-ethyl dithiocarbonate solution and the balance of a 8-10 wt% sodium n-butyl-xanthate solution. The flotation reagent is high in zinc recovery rate and low in consumption and cost, and has an obvious beneficiation effect on fine sphalerite.

Owner:YILIANG CHIHONG MINING IND

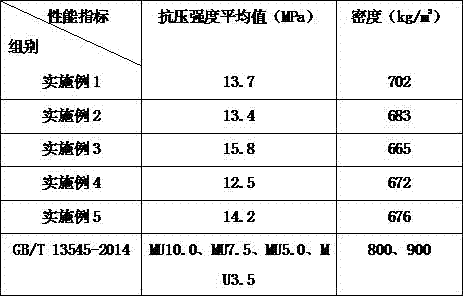

Floating-bead containing ageing-resistant hollow brick and preparation technology thereof

The invention discloses a floating-bead containing ageing-resistant hollow brick and a preparation technology thereof, and relates to the field of manufacturing of hollow bricks. The hollow brick comprises the following raw materials in parts by weight: 80-120 parts of composite portland cement, 40-70 parts of blast furnace slag, 20-40 parts of purple sand shale, 10-30 parts of floating beads, 10-30 parts of modified quartz powder, 5-25 parts of silicon carbide fibers, 2-10 parts of calcium stearate, 1-10 parts of an anti-cracking agent, 1-10 parts of an early strength agent, 1-5 parts of a water reducing agent, and 1-5 parts of a water-repelling agent. The preparation technology comprises the following steps: conveying the raw materials together to a mixer to perform uniform mixing with stirring; then conveying the obtained mixture to an ageing room to perform ageing; extruding the obtained materials into a mould to perform molding; and finally performing drying, solarization and curing to obtain the hollow brick. The preparation technology of the hollow brick provided by the invention is simple, and low in energy consumption. The hollow brick prepared by the preparation technology has high compressive strength, good ageing resistance and a long service life, so that buildings built with the hollow bricks have good earthquake resistance, and are green and environmentally friendly.

Owner:明光市泰丰新材料有限公司

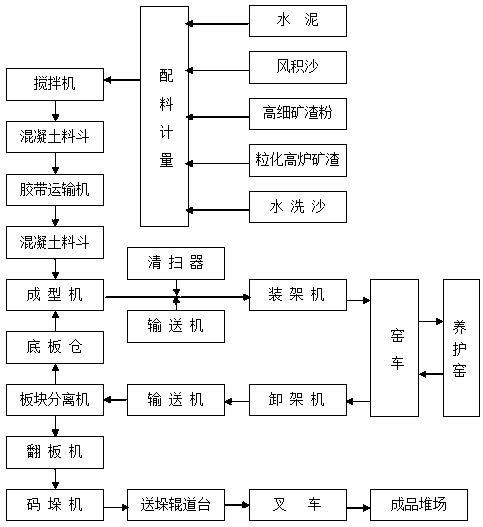

Pavement brick produced from industrial waste residues and production method thereof

InactiveCN111302728ARealize resourcesImprove the ecological environmentSolid waste managementCeramicwareBrickSlag

The invention discloses a pavement brick produced from industrial waste residues and a production method thereof, belongs to the field of building materials, and solves the problems that natural resources used as the building materials are increasingly exhausted and the resource utilization rate of the industrial waste residues is insufficient. The pavement brick comprises the following components: granulated blast furnace slag or converter steel slag, superfine slag powder or fly ash, aeolian sand, washed-out sand and cement. The production method comprises the following steps: adding granulated blast furnace slag or converter steel slag, aeolian sand, washed-out sand and water into a stirrer, uniformly stirring, adding cement and high-fine slag powder or fly ash, uniformly stirring, adding the pigment, uniformly stirring, adding water, uniformly stirring to obtain a mixture, conveying the mixture to a forming machine, vibrating, extruding and forming the mixture into a pavement brickblank, and putting the pavement brick blank into a curing kiln, carrying out steam curing for at least 8 hours, and taking out of the kiln. The industrial waste residues are adopted to replace natural raw materials to serve as one kind of aggregate, so that the quality of the pavement brick is guaranteed and the hygroscopicity of the pavement brick is improved.

Owner:嘉峪关祁连山水泥有限公司

Method for production of acid from phosphogypsum by utilizing electrolytic-aluminium waste cathode carbon blocks

ActiveCN109279582ALow early strengthDetrimental effects favor inhibitionSulfur compoundsCement productionDecompositionPhosphogypsum

The invention discloses a method for applying electrolytic-aluminium waste cathode carbon blocks in combined production of sulfuric acid and cement from phosphogypsum. The method comprises the following steps: smashing the phosphogypsum, carrying out drying and dehydrating so as to obtain hemihydrate gypsum, crushing the electrolytic-aluminium waste cathode carbon blocks into a powder material, mixing the powder material with the hemihydrate gypsum, clay and bauxite, carrying out on-line drying, after completion of drying, carrying out integrated grinding so as to obtain a phosphogypsum cementraw material, preheating the raw material, delivering the preheated raw material into a hollow rotary kiln for decomposition and calcination, subjecting generated SO2-containing gas to gas-solid separation, carrying out dedusting and purifying, then delivering obtained gas into a sulfuric acid system so as to prepare a finished sulfuric acid product, subjecting the raw material to high-temperature calcination so as to obtain a cement clinker, blending the cement clinker with certain amounts of coal cinder and fly ash, and carrying out grinding with a ball mill so as to obtain the cement. Themethod provided by the invention realizes reutilization of the electrolytic-aluminium waste cathode carbon blocks and the phosphogypsum, eliminates the influence of wastes on the environment, saves the cost of occupied land, seepage prevention treatment and the like for waste residue storage at the same time, and has significant economic and environmental benefits.

Owner:山东汇泰再生资源有限公司

Treatment method for abamectin fermentation wastewater

InactiveCN110563159AImprove purification efficiencyEasy to operateWater treatment parameter controlFungiSocial benefitsWastewater

The invention relates to a treatment method for abamectin fermentation wastewater. According to the invention, Geotrichum candidum is improved in purification efficiency during treatment of abamectinthrough pretreatment of Geotrichum candidum and control of temperature, pH value and inoculum size in the treatment process; and the method is simple to operate and low in cost, and has obvious economic benefits, social benefits and environmental protection benefits.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Air purification equipment for biological treatment of kitchen waste

PendingCN113522019ASimple structureEasy to handleDispersed particle filtrationVapor–liquid separatorAir cleaning

The invention belongs to the technical field of environmental protection equipment, and particularly relates to air purification equipment for biological treatment of kitchen waste. The air purification equipment comprises a smoke collection assembly, a three-way catalyst, a switching pipeline, a first air compressor, an oil gas condenser, a first one-way valve, a first stop valve, a second stop valve, a third stop valve, a cooling system and a controller. The smoke collection assembly comprises a smoke collecting hood and an air bellow body, and an air cabinet, a motor and a wind wheel are arranged in the air bellow body. The oil gas condenser internally comprises an oil condensing cavity and an oil collecting cavity; a condensation promoting carrier for promoting liquefaction and condensation of oily gas-phase substances in the smoke is arranged in the center of a cavity body of the oil condensing cavity; the oil condensing cavity is communicated with the oil collecting cavity, an exhaust port is formed in the side wall of the oil collecting cavity, a first gas-liquid separator is installed at the exhaust port, and an oil discharging port is formed in the bottom of the oil collecting cavity; the air purification equipment has good harmful gas purification and oil gas liquefaction recovery performance, the liquefaction recovery rate of volatile oil gas is very high, and the energy-saving and environment-friendly performance is outstanding.

Owner:安徽坤健生物科技有限公司

High-strength light hollow brick and preparation process thereof

The invention discloses a high-strength light hollow brick and a preparation process thereof, and relates to the field of hollow bricks. The hollow brick is prepared from the following raw materials in parts by weight: 70 to 130 parts of dehydrated river mud, 50 to 110 parts of blast furnace slag, 30 to 70 parts of kaolin, 10 to 30 parts of expanded perlite, 5 to 25 parts of glazed hollow bead, 5 to 25 parts of red porcelain shale, 5 to 15 parts of ceramic fiber, 5 to 15 parts of shell charcoal powder, 4 to 12 parts of calcium formate, 4 to 8 parts of hydroxyethyl methyl cellulose, 3 to 7 parts of methyl methacrylate, and 5 to 15 parts of cement-based permeable crystallization type water-proofing agent, wherein the water content of the dehydrated river mud is 15 to 25 percent; the hollow brick is 40 percent in hole ratio; the hole pattern is a rectangular hole pattern; the hollow brick is prepared by mixing materials, aging, casting, molding, dicing, drying, airing with sunlight and maintaining. The high-strength light hollow brick has the advantages of low raw material cost, simple preparation process, energy saving, environmental friendliness, high pressure resistance and low density.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Preparation method of high-performance bamboo leaf matter carbonized Cr adsorbent

InactiveCN107081130AHigh selectivity of adsorptionHigh specific surface areaOther chemical processesWater contaminantsSorbentPerchloric acid

The invention discloses a preparation method of a high-performance bamboo leaf matter carbonized Cr adsorbent. According to the method, fresh leaves of sympodial bamboo are subjected to point removal and base removal treatment and are then carbonized; next, perchloric acid, sodium hydroxide solution and acrylonitrile alcoholic solution are sequentially used for performing modification and optimization treatment on the carbonized bamboo leaves; the croadmixture brown black flay high-performance bamboo leaf matter carbonized Cr adsorbent can be obtained. The bamboo leaves are prepared into adsorption Cr removal materials through chemical and hydrothermal modification; the specific surface area of the adsorption materials can be improved; the pore structures of the adsorption materials are improved; the adsorption volume and the adsorption efficiency are improved; meanwhile, the surface chemical groups of the adsorption materials can be obviously improved; the adsorption selectivity on the Cr can be obviously enhanced. The bamboo leaf matter carbonized Cr adsorption removal materials maintain the thin sheet shapes of the bamboo leaves, so that the solid-liquid separation after the adsorption is convenient; waste materials are changed into beneficial materials; the environment-friendly effect is achieved; the high application prospects and obvious economic and environment benefits are realized.

Owner:青岛威瑞德环境科技有限公司 +1

Rapid environmental-friendly energy-saving glass crushing and melting device

InactiveCN102838265AIncrease profitImprove energy savingGlass furnace apparatusExhaust valveAgricultural engineering

The invention discloses a rapid environmental-friendly energy-saving glass crushing and melting device, which comprises an outer shell, a reject valve, a flow discharge valve, an upper cover board, a feeding hopper, an exhaust valve, a cathode rod, a grinding partition board, a crushing roller and an anode rod, wherein the outer shell is arranged on the outer side of an inner device, the reject valve is arranged on the lower side of the outer shell and is communicated with an inner inclined hopper, the flow discharge valve is arranged on one side of the outer shell and is communicated with an inner glass fluid filter screen, the upper cover board is arranged on the upper sides of the outer shell and the crushing roller, the feeding hopper is arranged on the upper side of the outer shell and is communicated with a space on the upper side of the crushing roller, the cathode rod is arranged on one side of the outer shell and is connected with one end of a heating rod in the inner side, the grinding partition board is arranged on the lower side of the crushing roller and both ends of the grinding partition board are respectively connected with the inner sidewalls of the outer shell, the crushing roller is arranged on the upper side in the outer shell, the lower side of the upper cover board and the upper side of the grinding partition board, and the anode rod is arranged on one side of the outer shell and is connected with one end of the heating rod in the inner side. The rapid environmental-friendly energy-saving glass crushing and melting device, provided by the invention, has the advantages of advanced technical characteristic, convenience, fastness and practicability, crushing, melting and purification, high efficiency, energy conservation and environmental friendliness, low production cost and high comprehensive benefit.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Unique solid and safe anti-collision frame

The invention relates to an unique solid and safe anti-collision frame, wherein two ends of a rear bumper tube are respectively connected with a left rear tube and a right rear tube; the rear end of the left rear tube is connected with the left end of the rear bumper tube; the rear end of a left middle tube is accommodated within the front end of the left rear tube; the rear end of the left middle tube is placed at the front end of the left rear tube; the rear end of a left front tube is accommodated in the front end of the left middle tube; the rear end of the left front tube is placed on the internal side of the front end of the left middle tube; the front end of the left front tube is connected with the rear side of a front bumper tube; the two ends of the rear side of the front bumper tube are respectively connected with front ends of the left front tube and the right front tube; a front slowing bumper is arranged on the front side of the front bumper tube; the front end of the right front tube is connected with the rear side of the front bumper tube; the rear end of the right front tube is placed in the left middle tube; the rear end of the right front tube is accommodated in the internal side of the front end of the right middle tube; the rear end of the right middle tube is placed in the front end of the right rear tube; machine bumpers are respectively arranged between the left and right rear tubes and between the left and right middle tubes; the rear end of the right middle tube is accommodated in the front end of the right rear tube; the rear end of the right rear tube is connected with the front side of the rear bumper tube; a left rear spring is arranged in the left rear tube; a left front spring is arranged in the left middle tube; inductive heads are arranged at the two ends of the front slowing bumper; inductive bolts are arranged in the left rear tube, the right rear tube, the left middle tube and the right middle tube; the right front spring is arranged in the right middle tube; and the right rear spring is arranged in the right rear tube.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

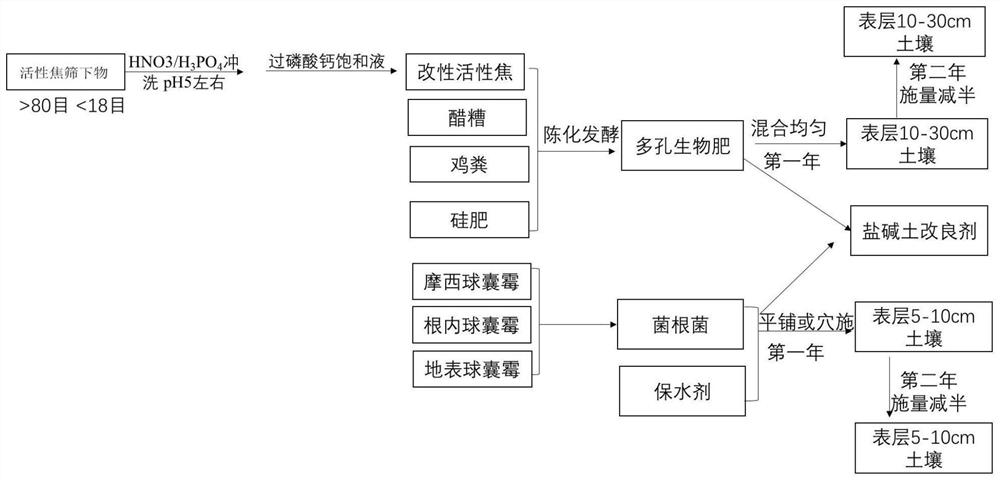

Active coke-based saline-alkali soil improver and preparation method thereof

PendingCN112876320AImprove fertilityImprove macroporous microporous structureSuperphosphatesExcrement fertilisersAlkali soilGlomus versiforme

The invention belongs to the field of soil improvement, and particularly relates to an active coke-based saline-alkali soil improver and a preparation method thereof. The improver is composed of a porous biological fertilizer and a strain inoculant which are independently packaged, wherein the porous biological fertilizer is obtained by mixing, aging and fermenting an active coke mixture, vinegar residues and chicken manure according to the weight ratio of 1: (0.2-5): (0.2-1); the active coke mixture is obtained by fully mixing active coke screen underflow subjected to homogenization pretreatment and acidification impurity removal with a calcium superphosphate saturated solution and a silicon fertilizer according to the solid weight ratio of 1: (0.5-5): (0.2-1) by utilizing alternating-frequency magnetic coupling ultrasonic grading mechanical stirring; and the strain fungicide is composed of mycorrhizal fungi and a water-retaining agent according to the weight ratio of (0.1-1): (1-5), the mycorrhizal fungi are obtained by compounding glomus mosseae, glomus intraradices and glomus versiforme according to the weight ratio of 1: (0.2-2): (0.5-5) and propagating in local soil, and the inoculated product is a rhizosphere mixture composed of spores, hyphae and mycorrhizal fragments.

Owner:SHANXI UNIV

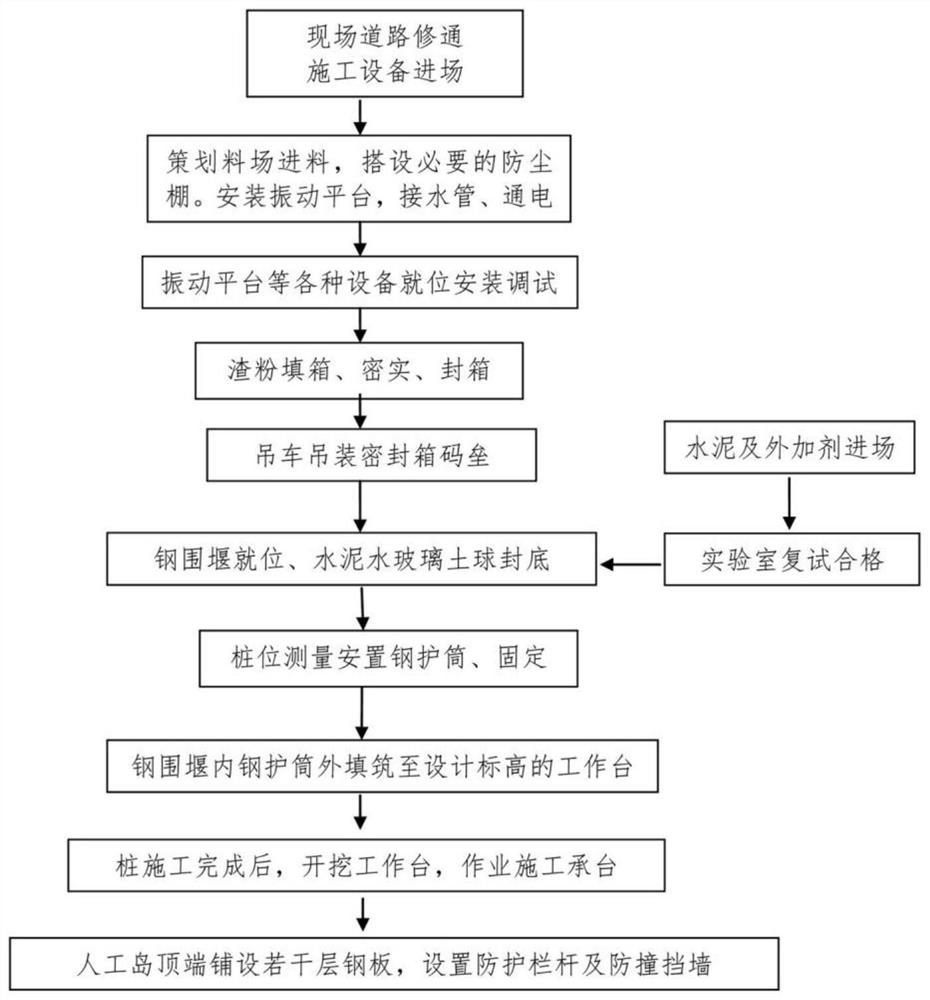

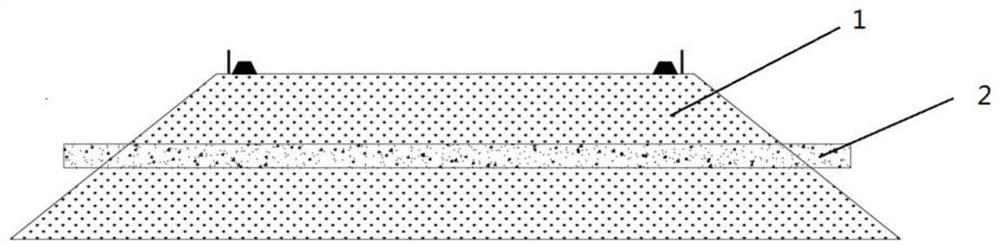

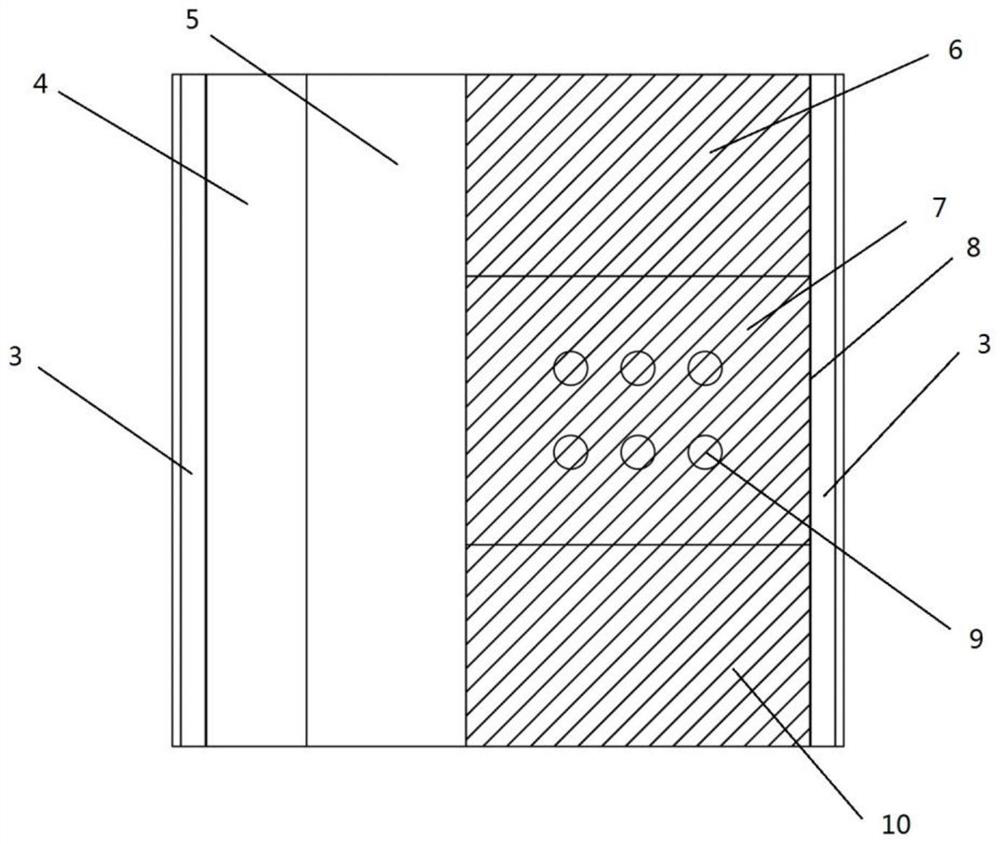

Method for building artificial island and pile foundation bearing platform workbench through waste boxing and stacking

ActiveCN111910607AReduce workloadImprove efficiencyArtificial islandsUnderwater structuresSlagArchitectural engineering

The invention relates to a method for building an artificial island and a pile foundation bearing platform workbench through waste boxing and stacking. The method is characterized by comprising the following steps that garbage slag powder is filled into sealed boxes, and vibrating and compacting are carried out on the garbage slag powder by using a vibrating table to form permanent sealed boxes; the sealed boxes are hoisted into water by using a crane to form the artificial island in a stepped stacking manner, wherein a plurality of water pipes are preset at the lower part of the artificial island; a steel cofferdam is fixed at a preset position, and the sealed boxes are stacked around the outer wall of the steel cofferdam to form the artificial island; bottom sealing needs to be conductedin the steel cofferdam, it is guaranteed that dry operation is conducted after water pumping, and cement water glass soil balls are adopted for bottom sealing; and pile positions are preset in the steel cofferdam, steel pile casings are inserted into the pile positions, outer walls of steel pile casings are used for filling of the workbench, and after pile construction is completed, excavation isfacilitated for bearing platform construction. According to the method, water construction is changed into land construction, use of large equipment is facilitated, efficiency is improved, quality and safety are easy to control, and the construction cost is effectively reduced.

Owner:北京建材地质工程有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com