Air purification equipment for biological treatment of kitchen waste

An air purification equipment and biological treatment technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of oil and gas volatilization, environmental pollution, polluted resources, etc., to achieve high recovery rate, great environmental protection benefits, good handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

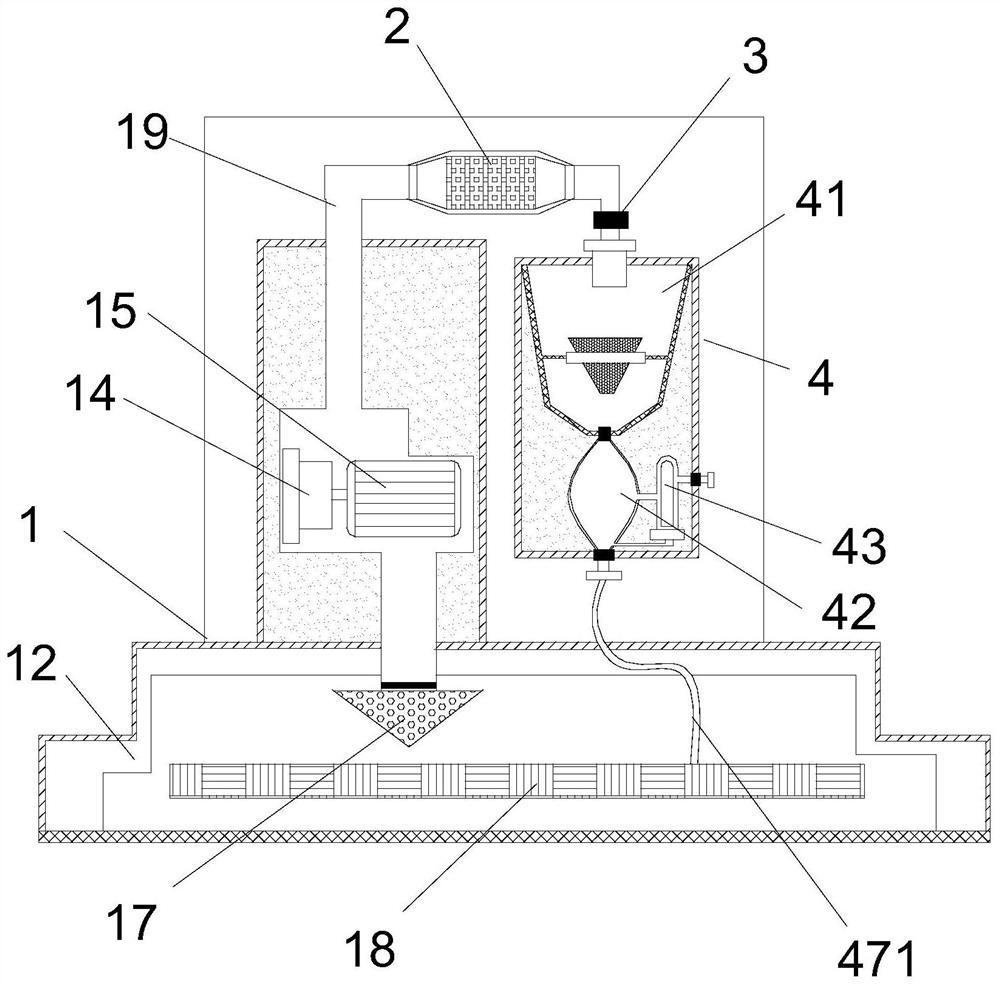

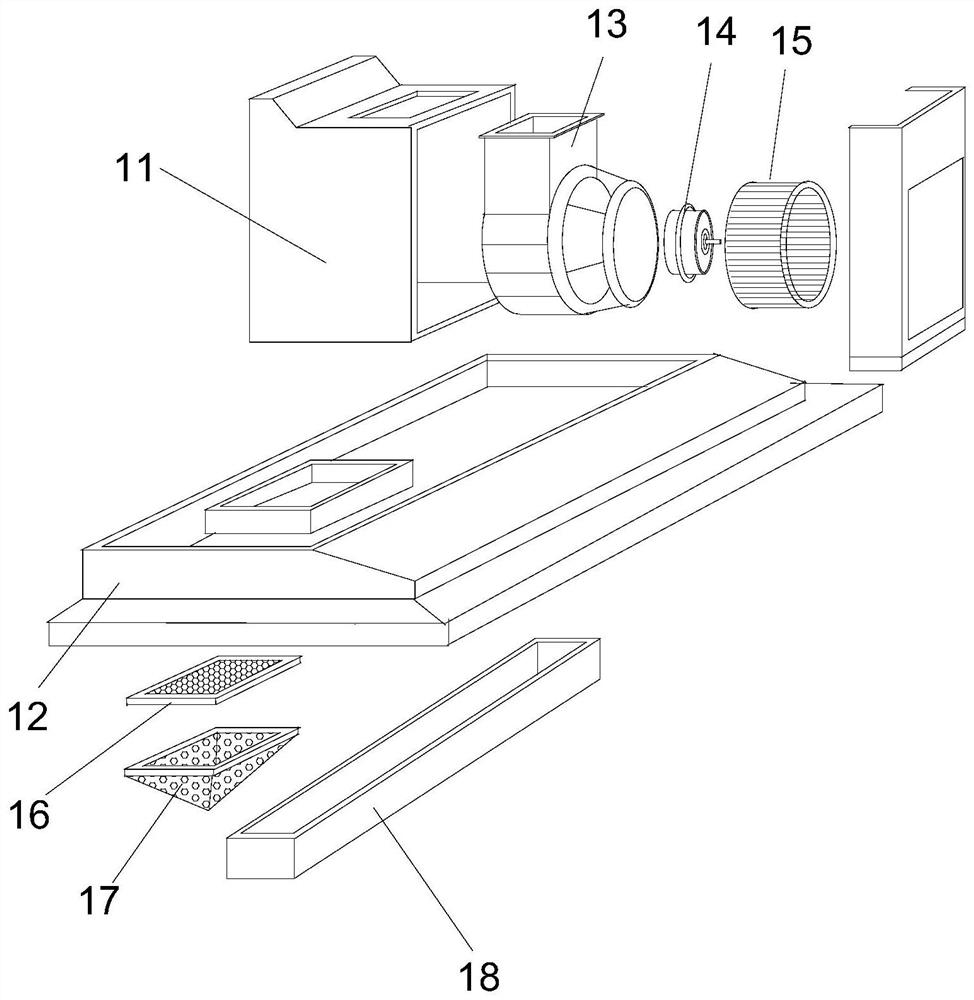

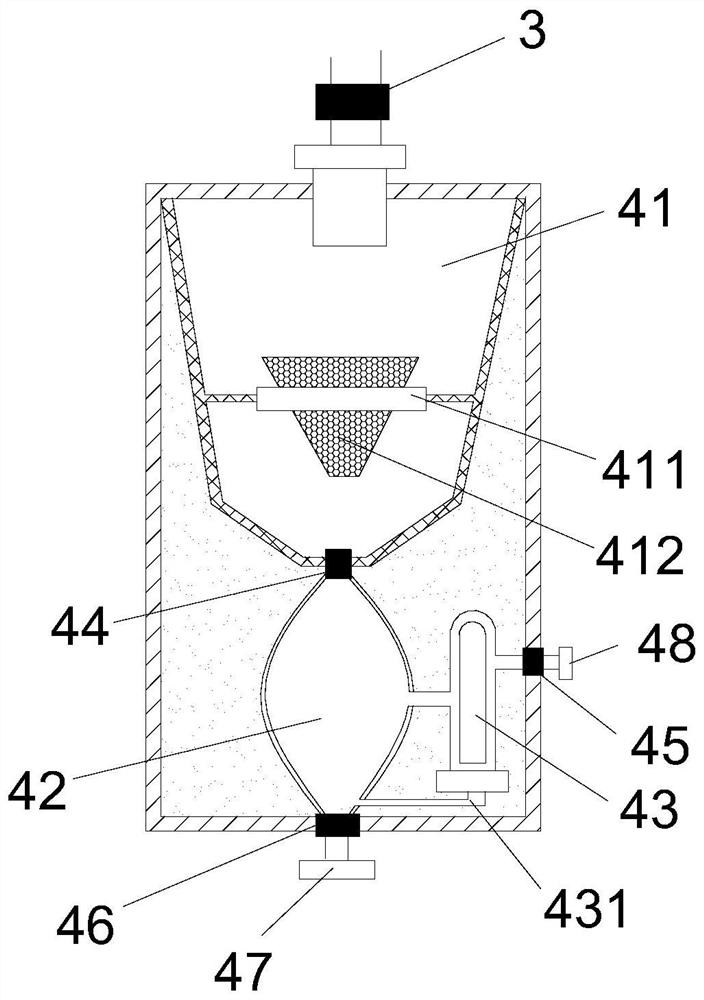

[0055] like figure 1 and figure 2 As shown, this embodiment provides an air purification device for biological treatment of food waste, which is installed in a drying room for biological treatment of food waste to perform air purification treatment. The air purification equipment includes a smoke collection assembly 1. The smoke collection assembly 1 includes a smoke collection cover 12 and a bellows box body 11. A wind cabinet 13, a motor 14 and a wind wheel 15 are arranged in the bellows box body 11. The outlet of the wind cabinet 13 and the exhaust The inlet of the flue 19 is communicated; the air purification equipment also includes: a three-way catalytic converter 2, an oil-gas condenser 4, a first one-way valve 3, a first stop valve 44, a second stop valve 45, a third stop valve 46, and the controller 100 . The untreated gas collected by air purification equipment is hereinafter referred to as flue gas.

[0056] Wherein, the three-way catalytic converter 2 is used to...

Embodiment 2

[0079] This embodiment provides an air purification device for biological treatment of kitchen waste. The difference between this embodiment and Embodiment 1 is:

[0080] like Image 6 As shown, in this embodiment, a first air compressor 5 is provided between the outlet of the three-way catalytic converter 2 and the inlet of the oil-gas condenser 4, and the first air compressor 5 is a screw air compressor. In Embodiment 1, the air is driven by the wind wheel 15 in the wind cabinet 13 , discharged into the oil-gas condenser 4 , and the gas backflow is suppressed by the first one-way valve 3 . However, in this implementation, after the first air compressor 5 is used, the pressure value in the oil-gas condenser 4 can be further increased, so as to facilitate the full liquefaction and recovery of oil and gas, and improve the efficiency of liquefaction recovery.

Embodiment 3

[0082] This embodiment provides an air purification device for biological treatment of kitchen waste. The difference between this embodiment and Embodiment 2 is:

[0083] like Figure 7 As shown, in this embodiment, a cooling system 6 is further provided outside the oil-gas condenser 4, such as Figure 8 As shown, the cooling system 6 includes a circulation pipeline 61 , an evaporator 62 , a second compressor 63 , a condenser 64 , a liquid storage tank 65 , a dry filter 66 , a solenoid valve 67 and an expansion valve 68 .

[0084] Refrigerant is set in the liquid storage tank 65, and under the drive of the compressor, the refrigerant flows through the evaporator 62, the second compressor 63, the condenser 64, the liquid storage tank 65, the dry filter 66, and the solenoid valve in sequence along the circulation pipeline 61. 67 and expansion valve 68 to complete the refrigeration cycle. The cooling system 6 is electrically connected with the controller 100, and the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com