Patents

Literature

45 results about "Beam crossing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

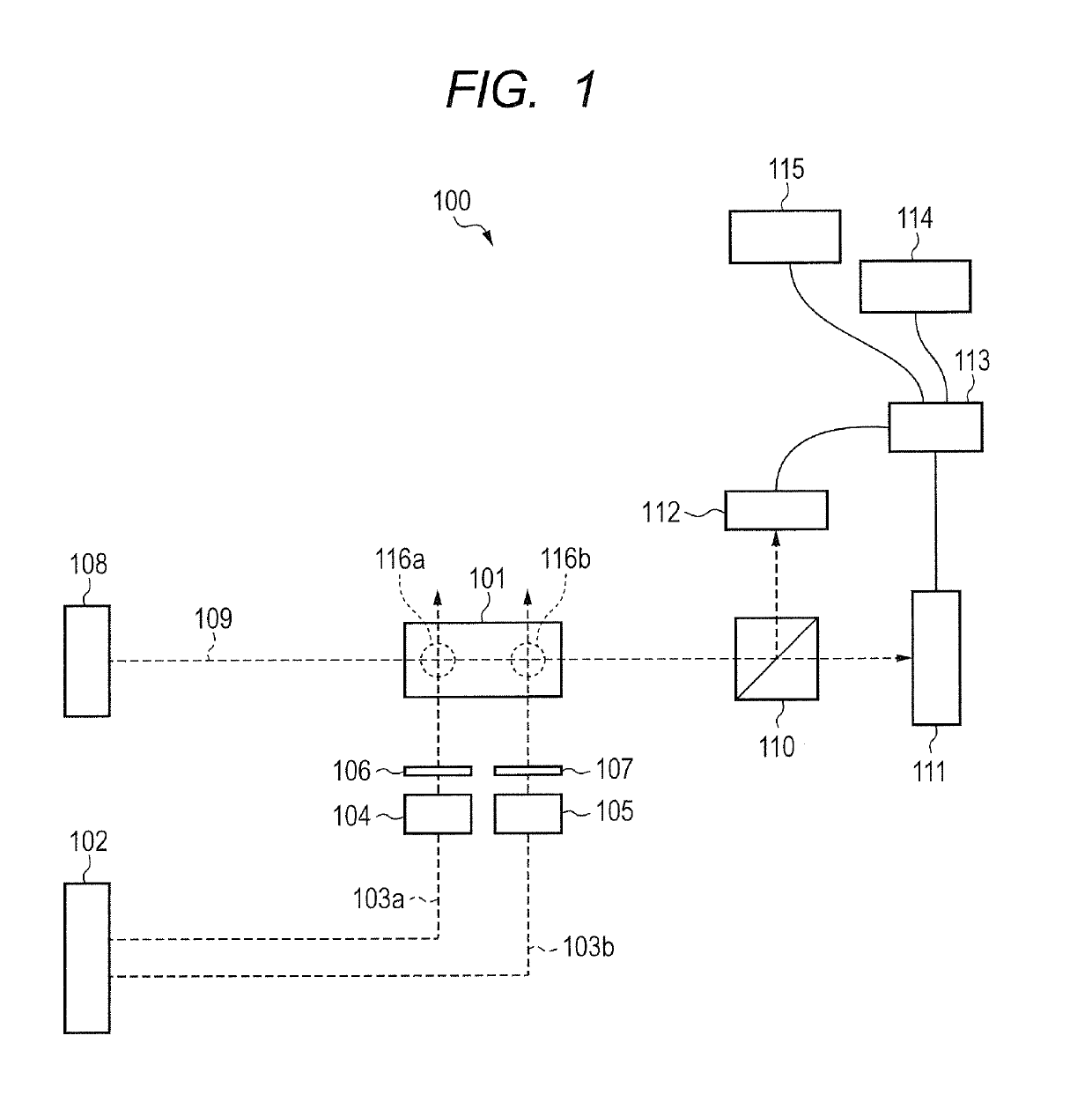

A beam crossing in a particle collider occurs when two packets of particles, going in opposite directions, reach the same point in space. Most of the particles in each packet cross each other, but a few may collide, producing other particles that may be observed in a particle detector. In a linear collider there is only one location where beam crossings occur, while in a modern accelerator ring there are a few locations (LHC, for example, has four); it is at these points that detectors are placed.

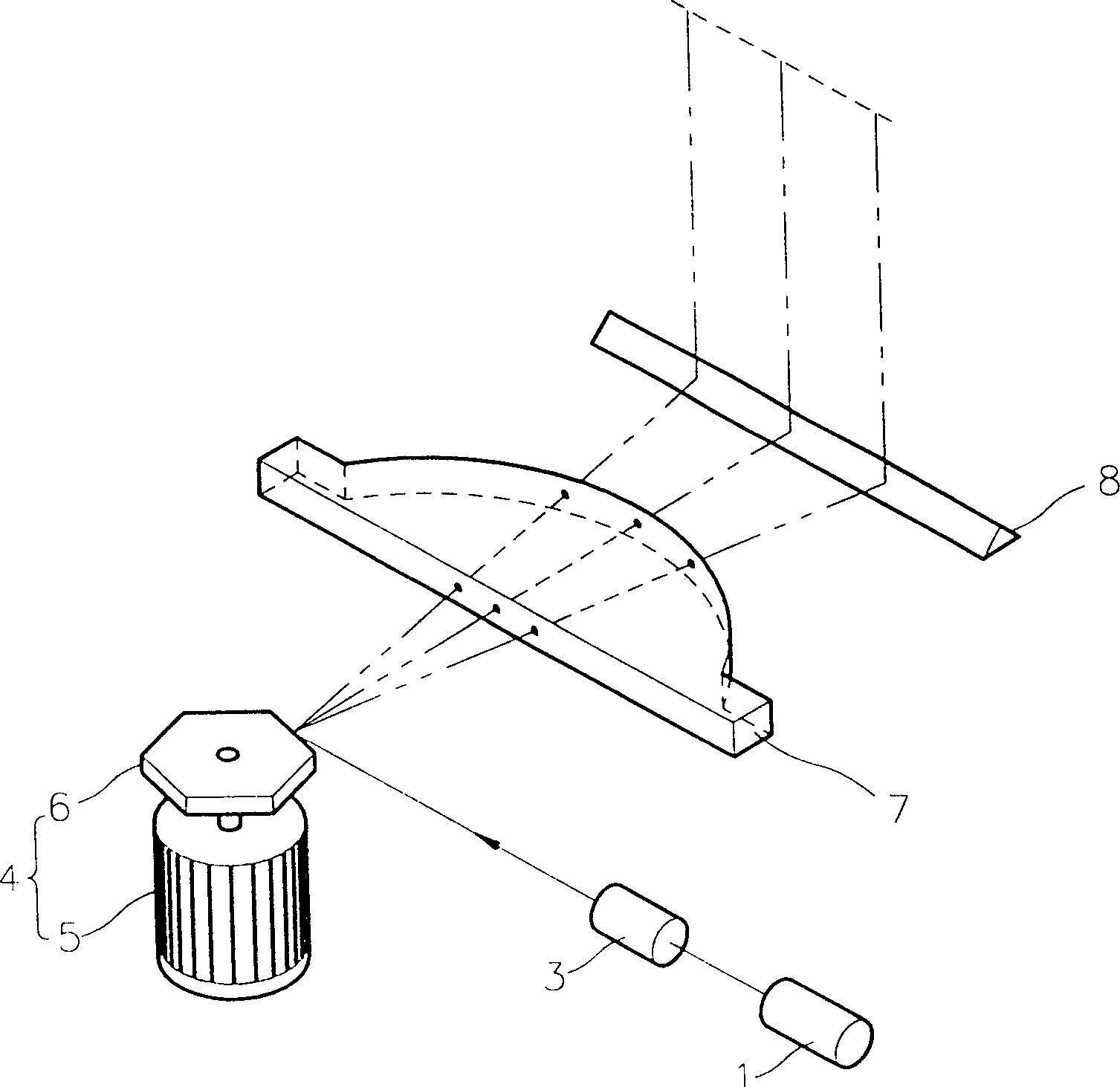

3D point locator system

InactiveUS20050102063A1DistanceReduce distanceComputer controlSimulator controlOperational systemSurvey instrument

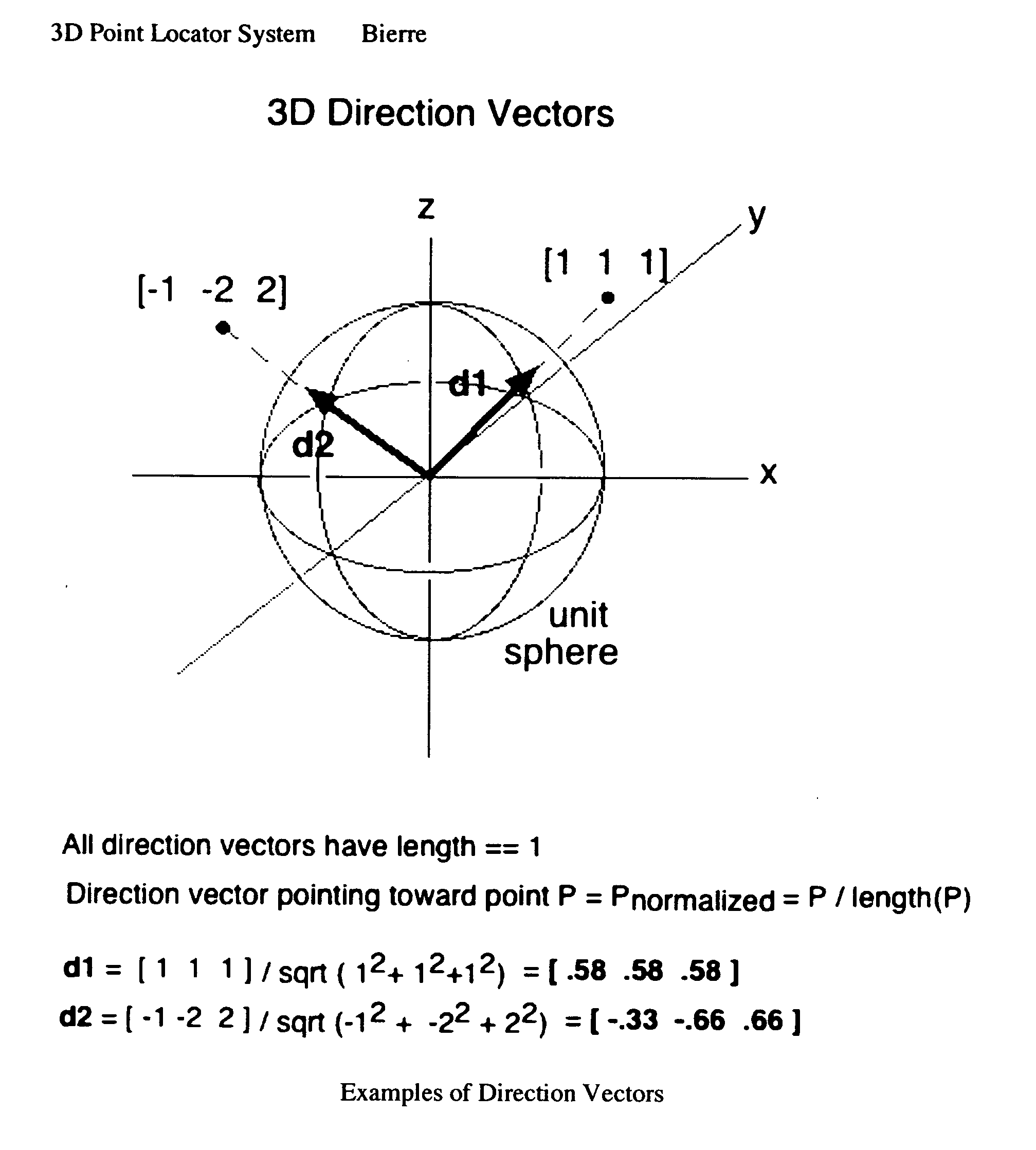

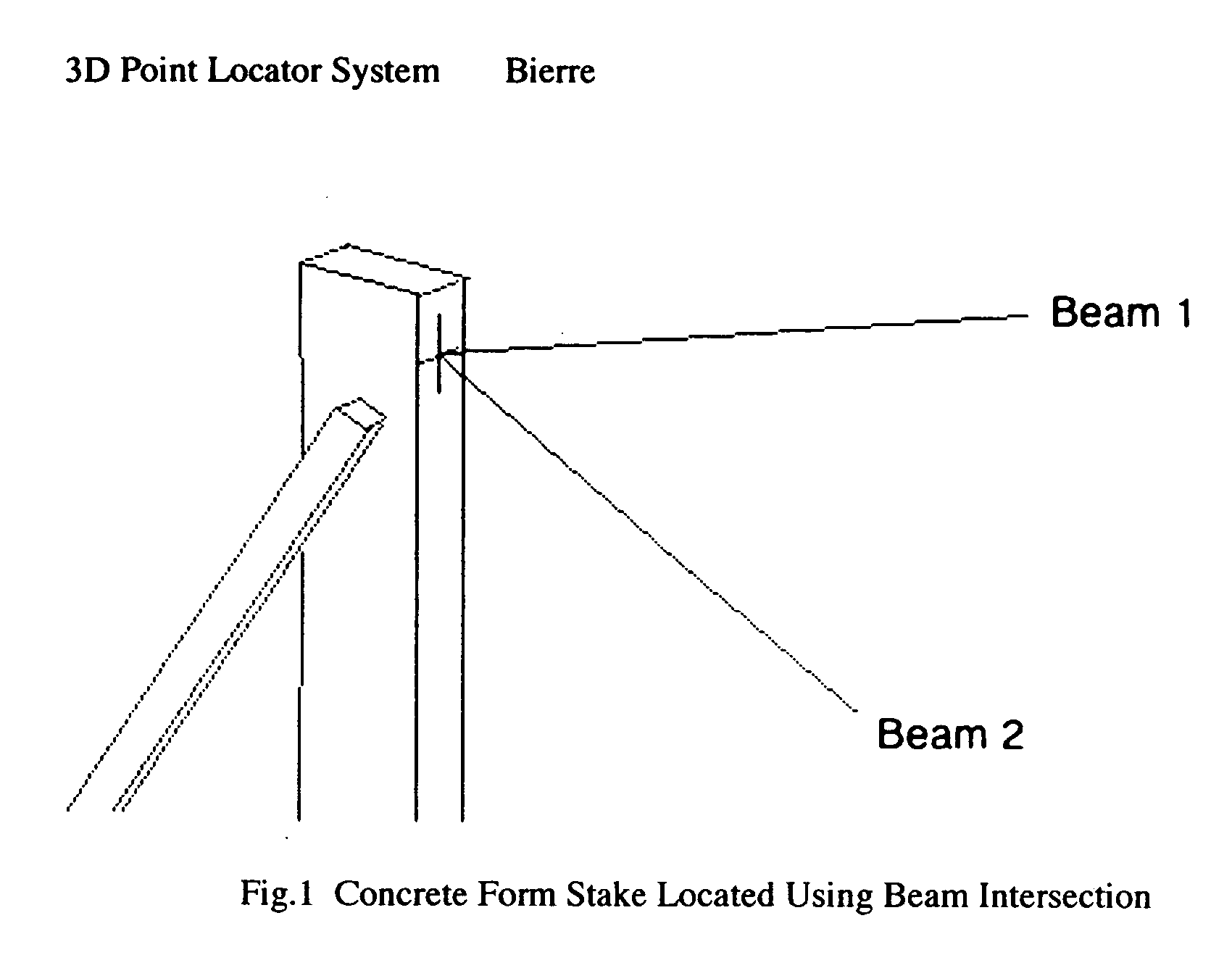

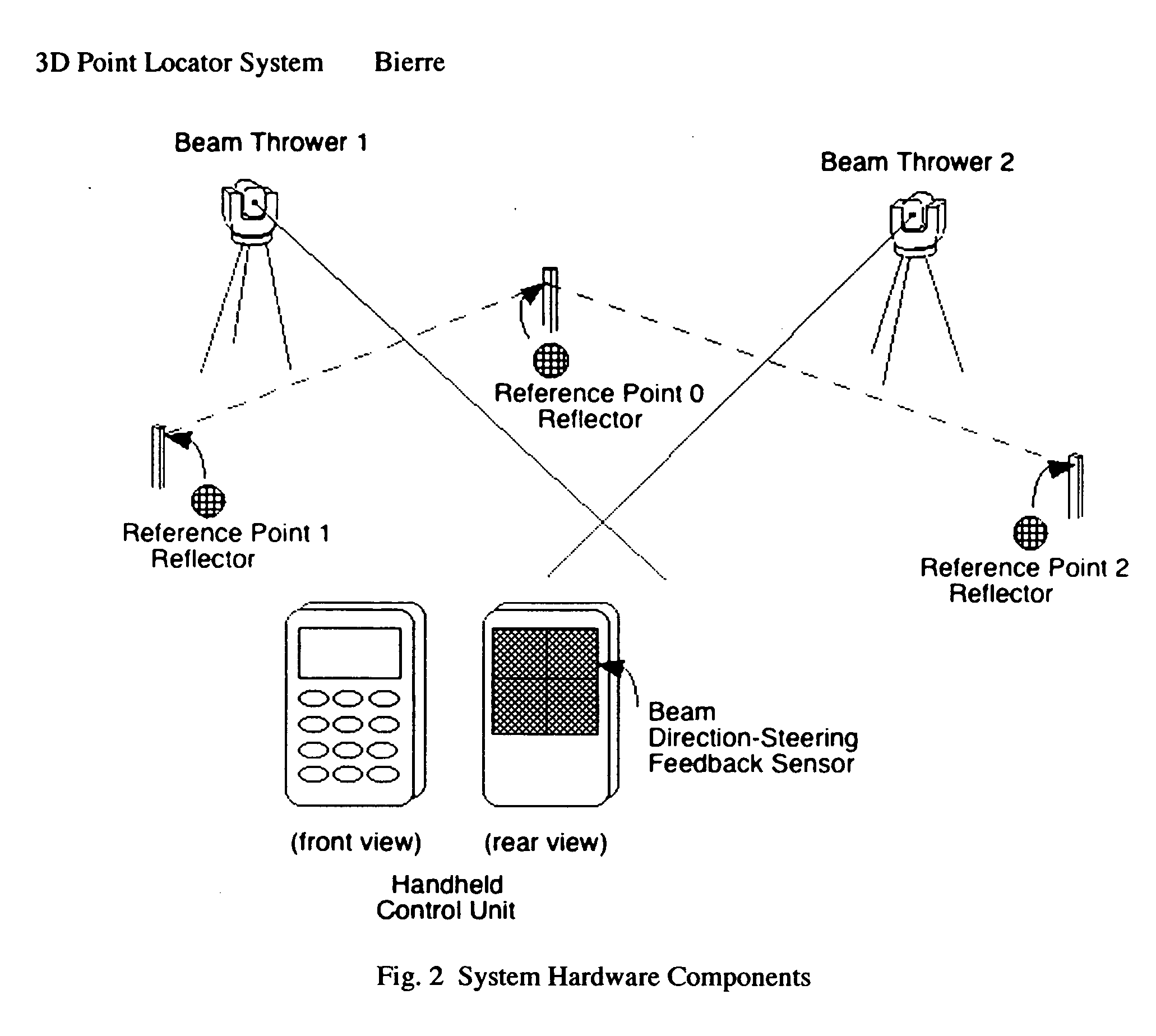

An automated system and method of geometric 3D point location. The invention teaches a system design for translating a CAD model into real spatial locations at a construction site, interior environment, or other workspace. Specified points are materialized by intersecting two visible pencil light beams there, each beam under the control of its own robotic ray-steering beam source. Practicability requires each beam source to know its precise location and rotational orientation in the CAD-based coordinate system. As an enabling sub-invention, therefore, an automated system and method for self-location and self-orientation of a polar-angle-sensing device is specified, based on its observation of three (3) known reference points. Two such devices, under the control of a handheld unit downloaded with the CAD model or pointlist, are sufficient to orchestrate the arbitrary point location of the invention, by the following method: Three CAD-specified reference points are optically defined by emplacing a spot retroreflector at each. The user then situates the two beam source devices at unspecified locations and orientations. The user then trains each beam source on each reference point, enabling the beam source to compute its location and orientation, using the algorithm of the sub-invention. The user then may select a CAD-specified design point using the handheld controller, and in response, the handheld instructs the two beam sources to radiate toward the currently selected point P. Each beam source independently transforms P into a direction vector from self, applies a 3×3 matrix rotator that corrects for its arbitrary rotational orientation, and instructs its robotics to assume the resultant beam direction. In consummation of the inventive thread, the pair of light beams form an intersection at the specified point P, giving the worker visual cues to precisely position materials there. This design posits significant ease-of-use advantages over construction point location using a single-beam total station. The invention locates the point effortlessly and with dispatch compared to the total station method of iterative manual search maneuvering a prism into place. Speed enables building features on top of point location, such as metered plumb and edge traversal, and graphical point selection. The invention eliminates the need for a receiving device to occupy space at the specified point, leaving it free to be occupied by building materials. The invention's beam intersection creates a pattern of instantaneous visual feedback signifying correct emplacement of such building materials. Unlike surveying instruments, the invention's freedom to situate its two ray-steering devices at arbitrary locations and orientations, and its reliance instead on the staking of 3 reference points, eliminates the need for specialized surveying skill to set up and operate the system, widening access to builders, engineers, and craftspeople.

Owner:BIERRE PIERRE

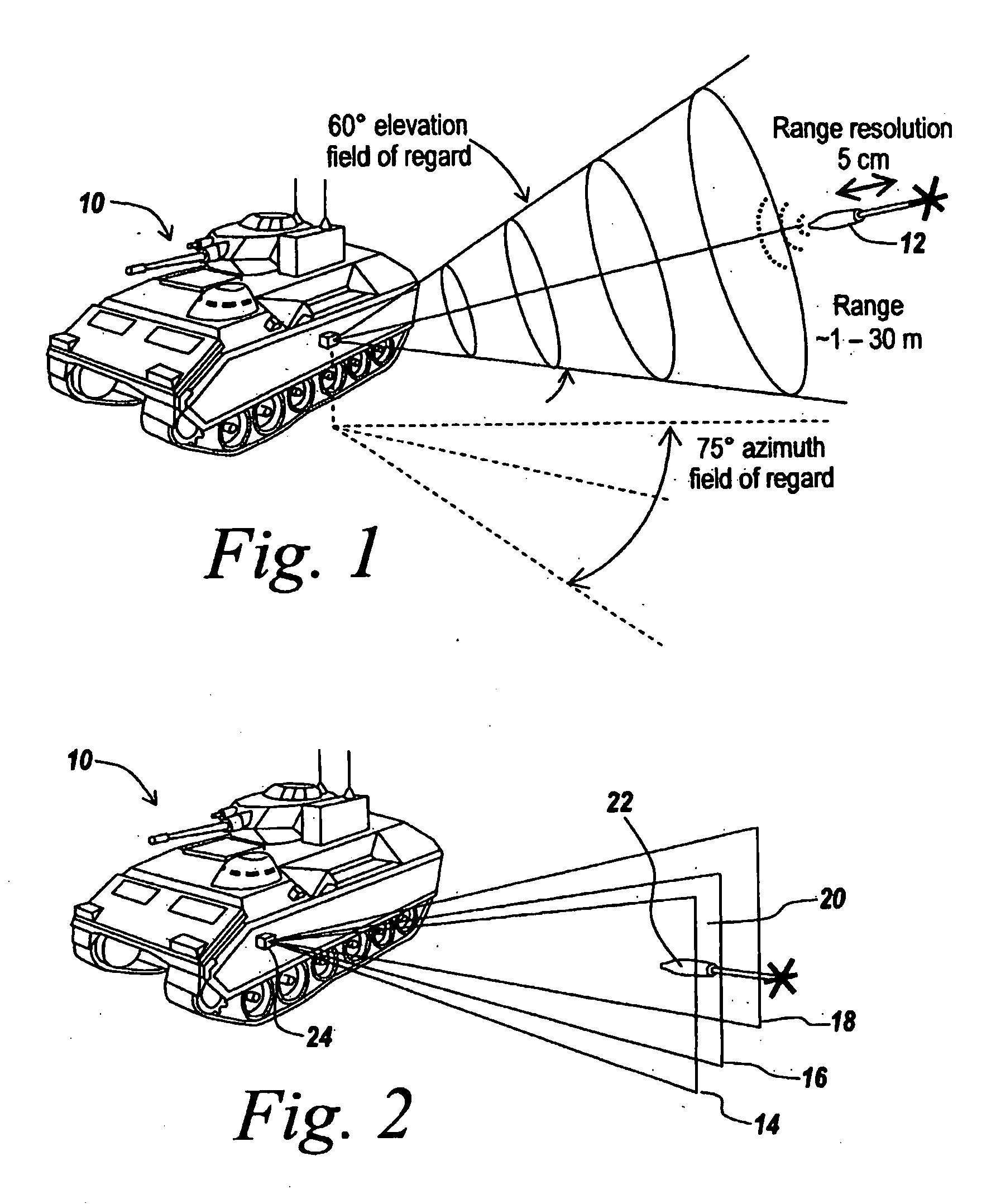

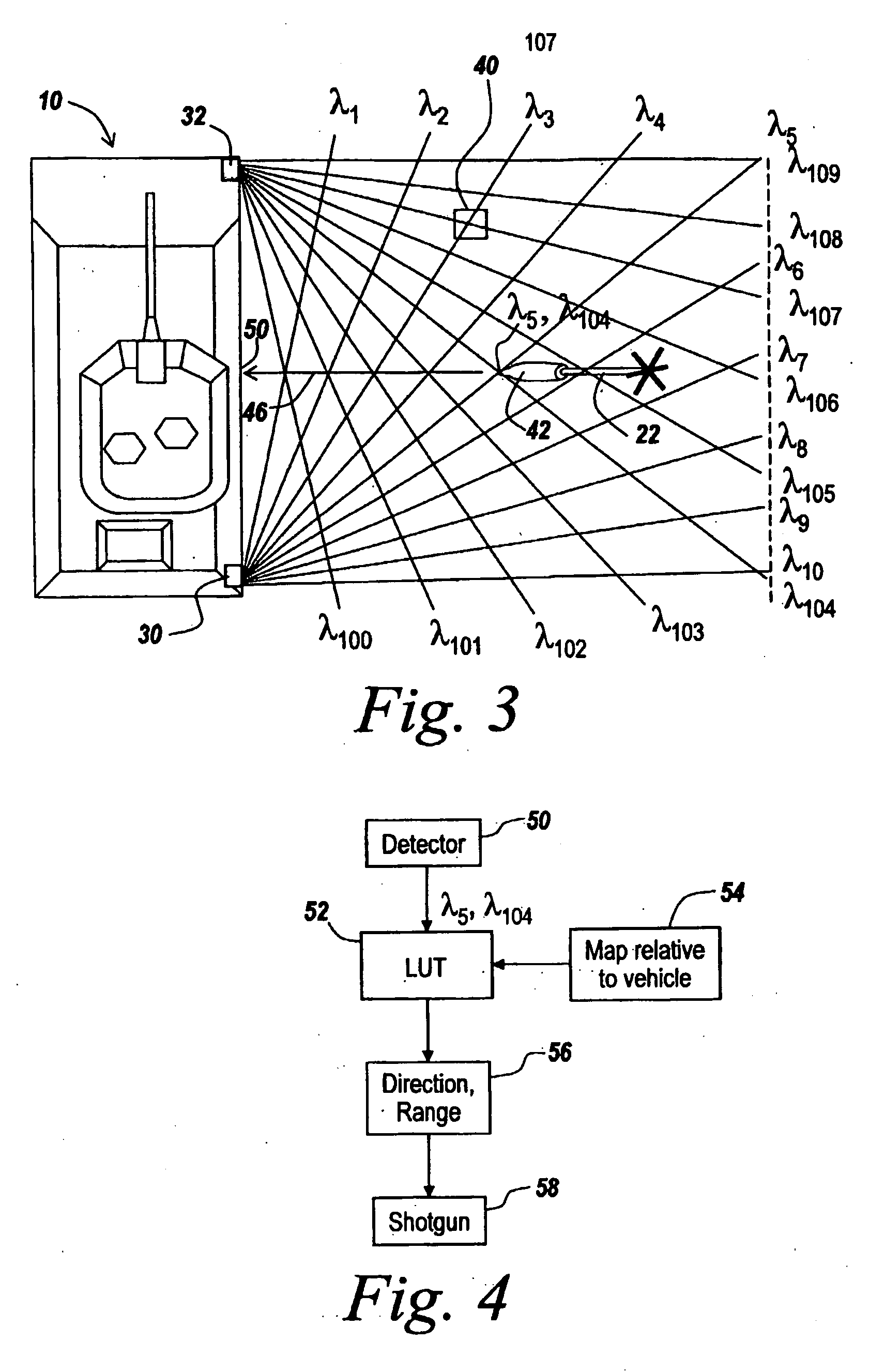

Polyspectral Rangefinder for Close-In Target Ranging and Identification of Incoming Threats

ActiveUS20080273190A1Minimized in sizeHigh resolutionDefence devicesOptical rangefindersLight beamEngineering

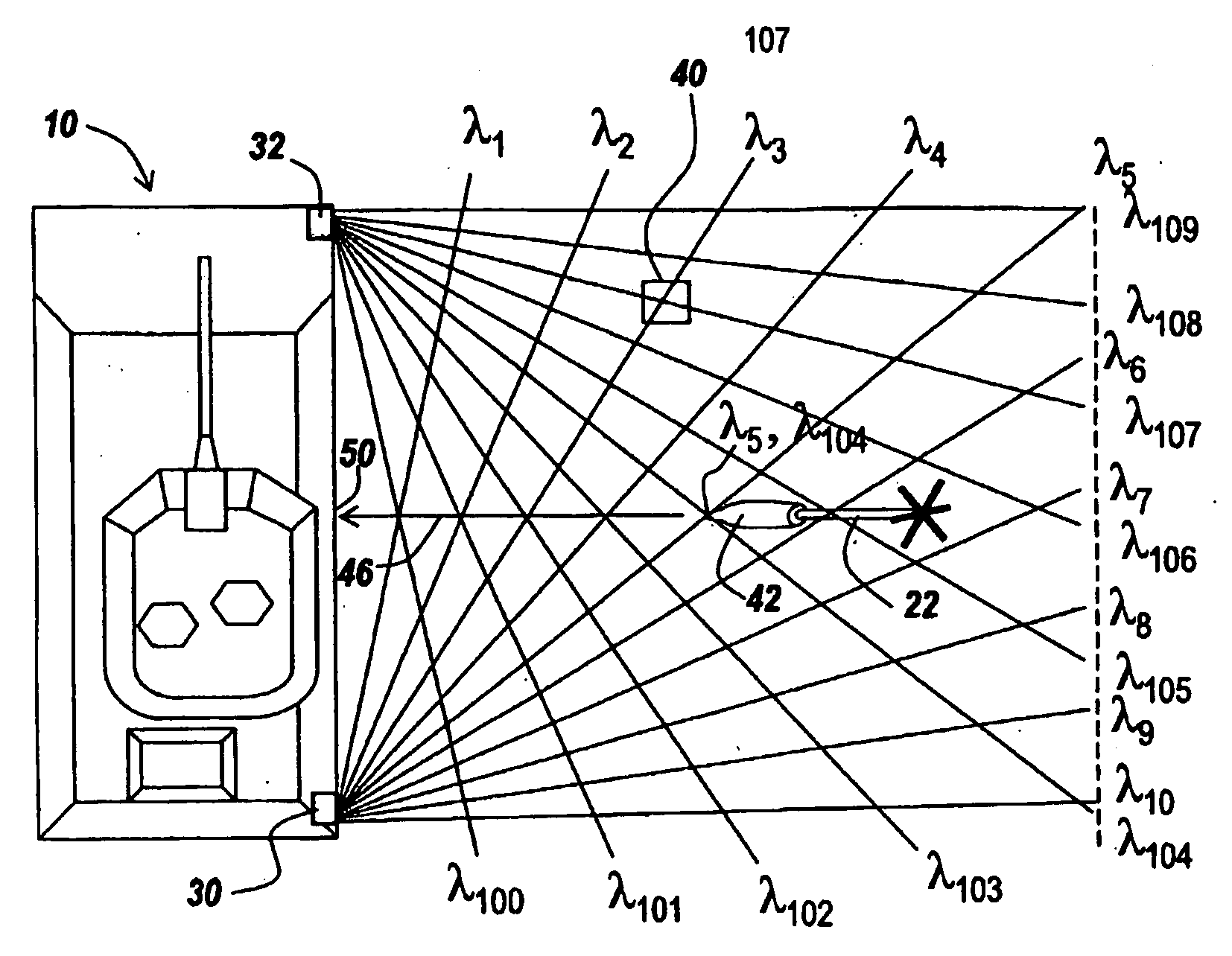

A computationless system 10 is provided for determining the direction of and distance to a target 42, involving bathing an area surrounding an area to be protected with a polyspectral series of narrow fan beams (xi,)ioo) of different colors from at least two spaced-apart projectors 30, 32. The differently colored beams go out at different angles, thus to color-code map the area surrounding the protected space where beams of different colors cross to form color-coded cells. Light 46 reflected back to the area to be protected from a threat 42 has a color code corresponding to the colors associated with beams that cross at the threat, thus to identify by the reflected colors where in space the threat is located.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

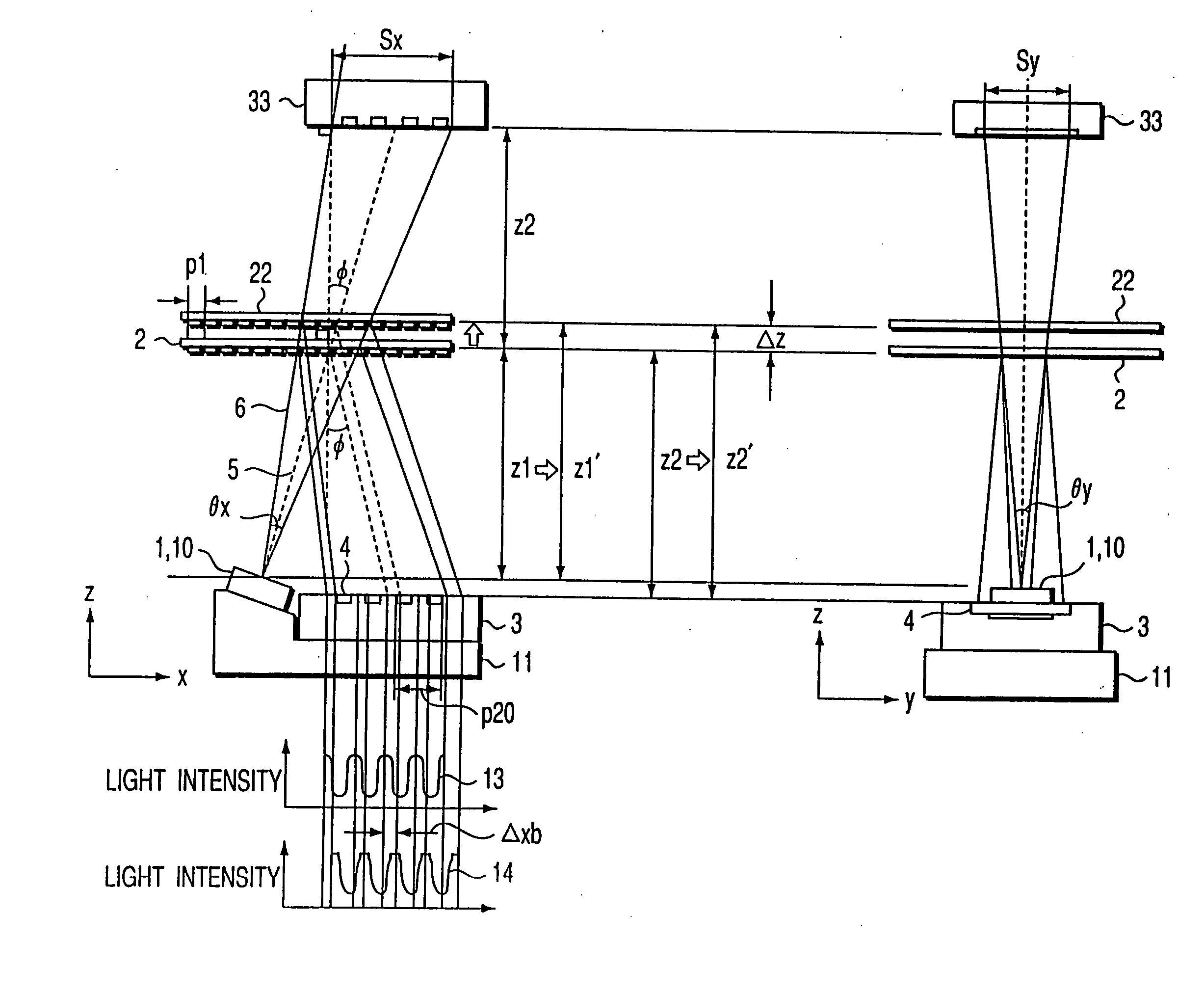

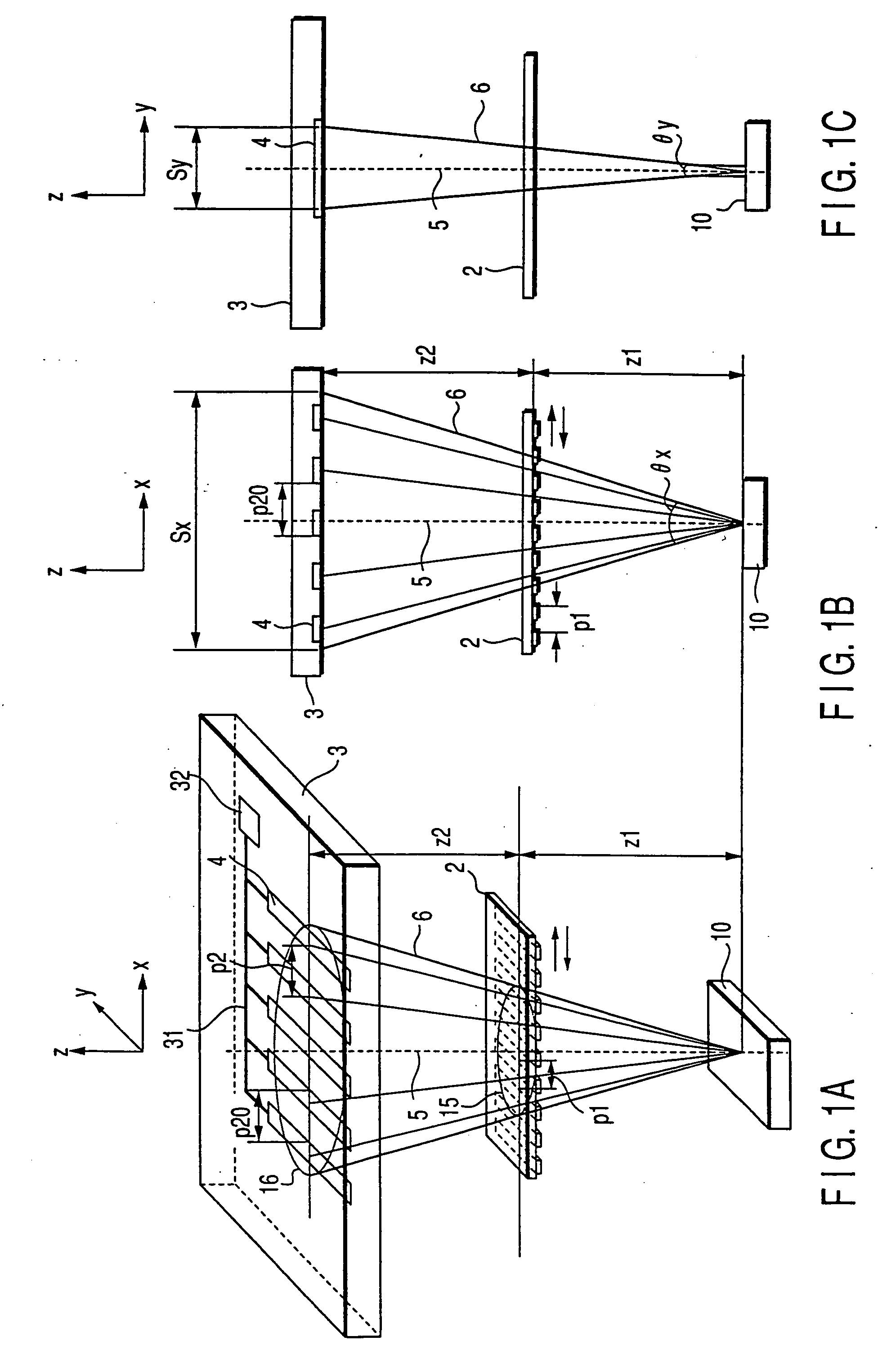

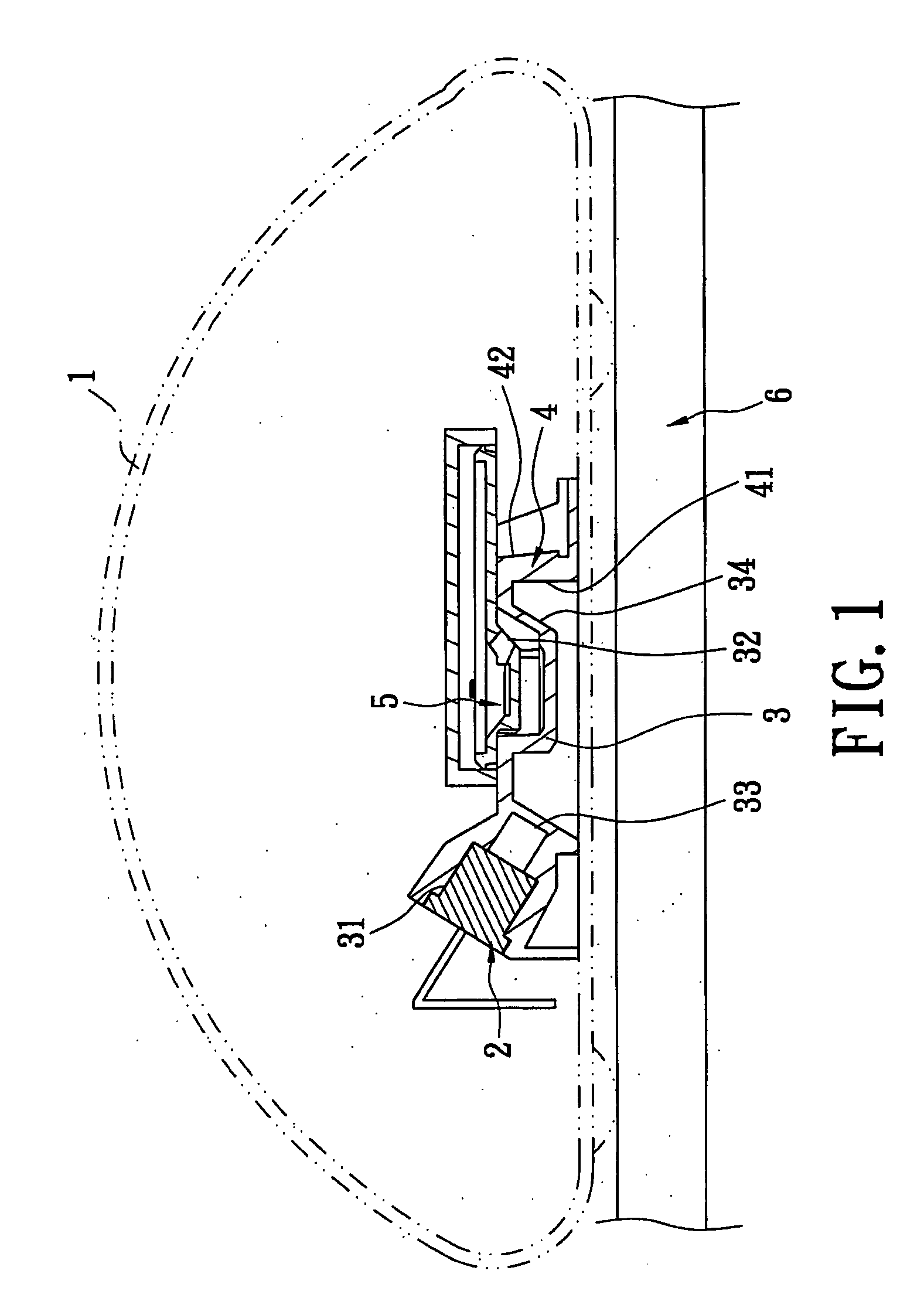

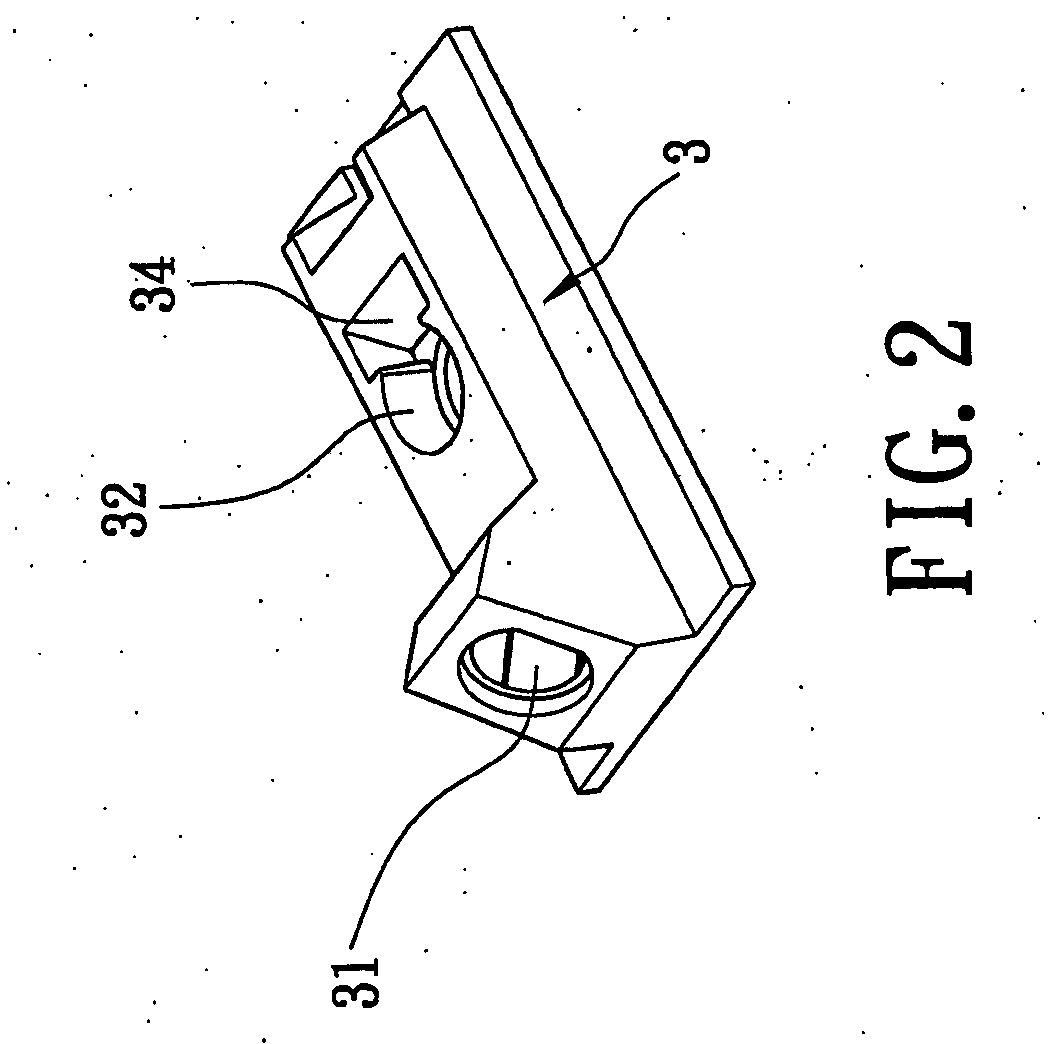

Optical displacement sensor and optical encoder

InactiveUS20050157307A1Prevent pitchSimple designAnalogue/digital conversionElectric signal transmission systemsLight beamLaser light

An optical displacement sensor comprises a surface emitting laser light source, a scale and a photosensor. The surface emitting laser light source emits a light beam having a predetermined shape. The scale is displaceable in such a manner as to cross the light beam emitted from the surface emitting laser light source and has a diffraction grating of a predetermined period formed thereon for forming a diffraction interference pattern from the light beam. The photosensor receives a predetermined portion of the diffraction interference pattern. The photosensor includes light intensity detecting means comprised of a plurality of light receiving areas arranged apart from one another in a pitch direction of the diffraction interference pattern on a light receiving surface at intervals of np1(z1+z2) / z1 where z1 is a distance between a light-beam emitting surface of the surface emitting laser light source and a surface on which the diffraction grating is formed, z2 is a distance between the surface on which the diffraction grating is formed and the light receiving surface of the photosensor, p1 is the pitch of the diffraction grating on the scale, and n is a natural number.

Owner:OLYMPUS CORP

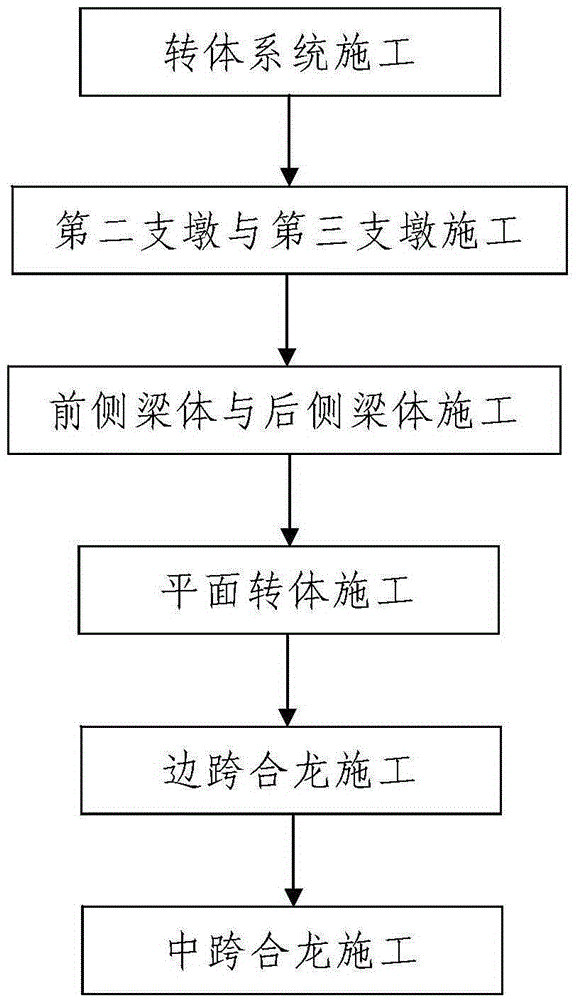

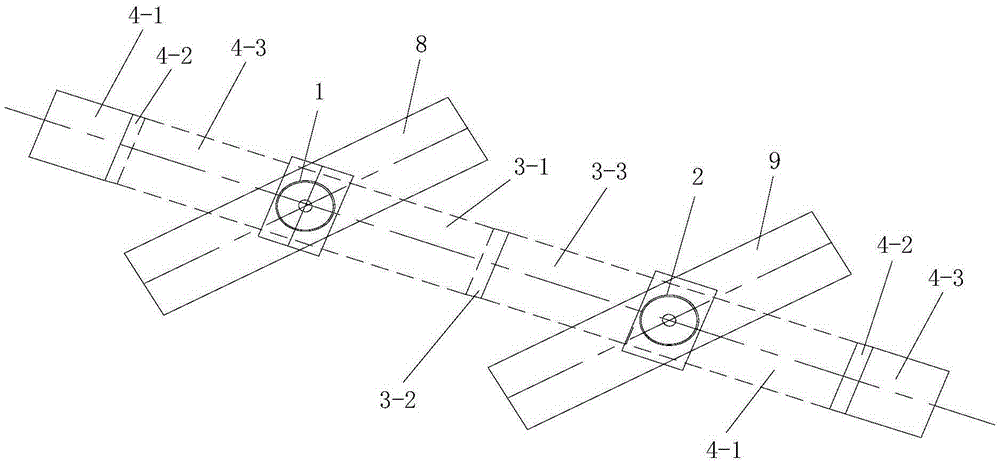

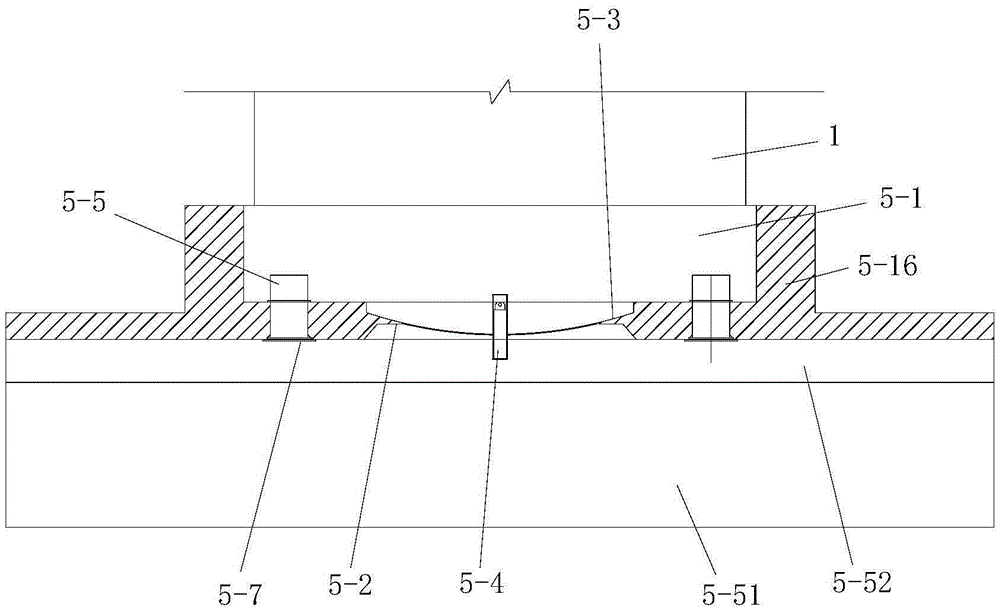

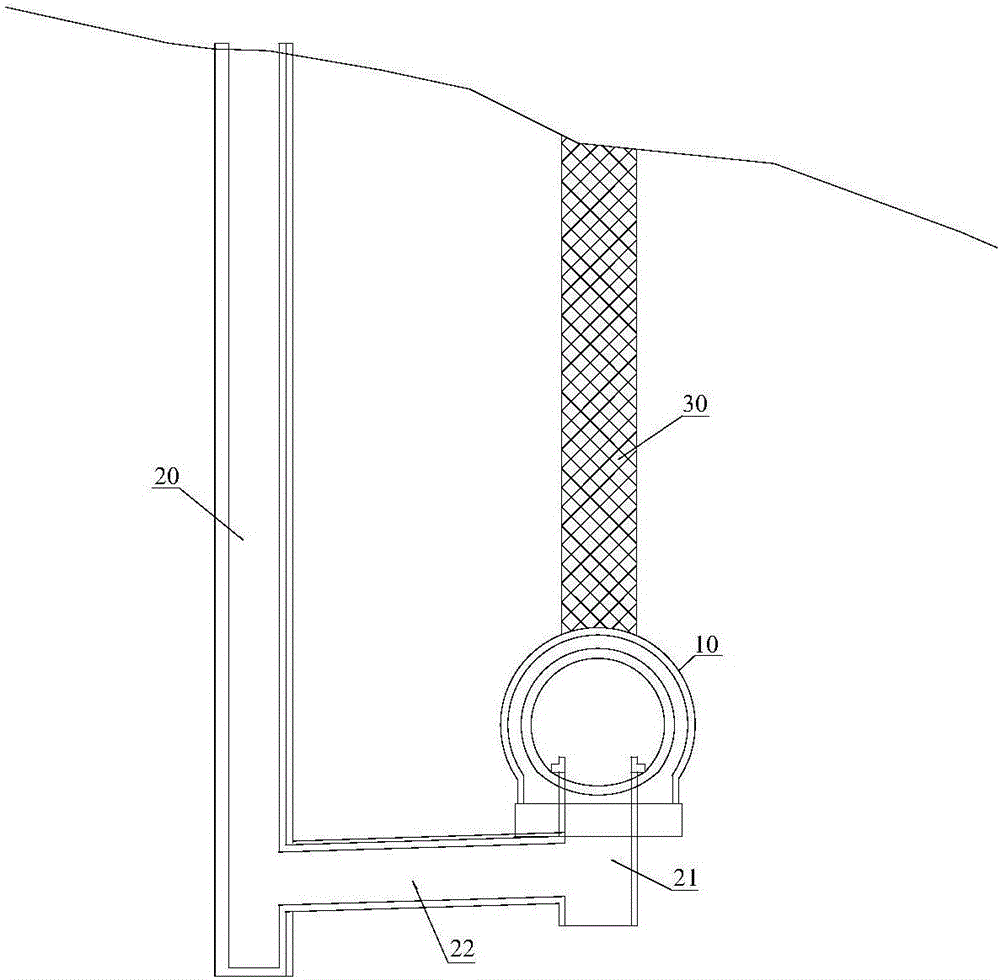

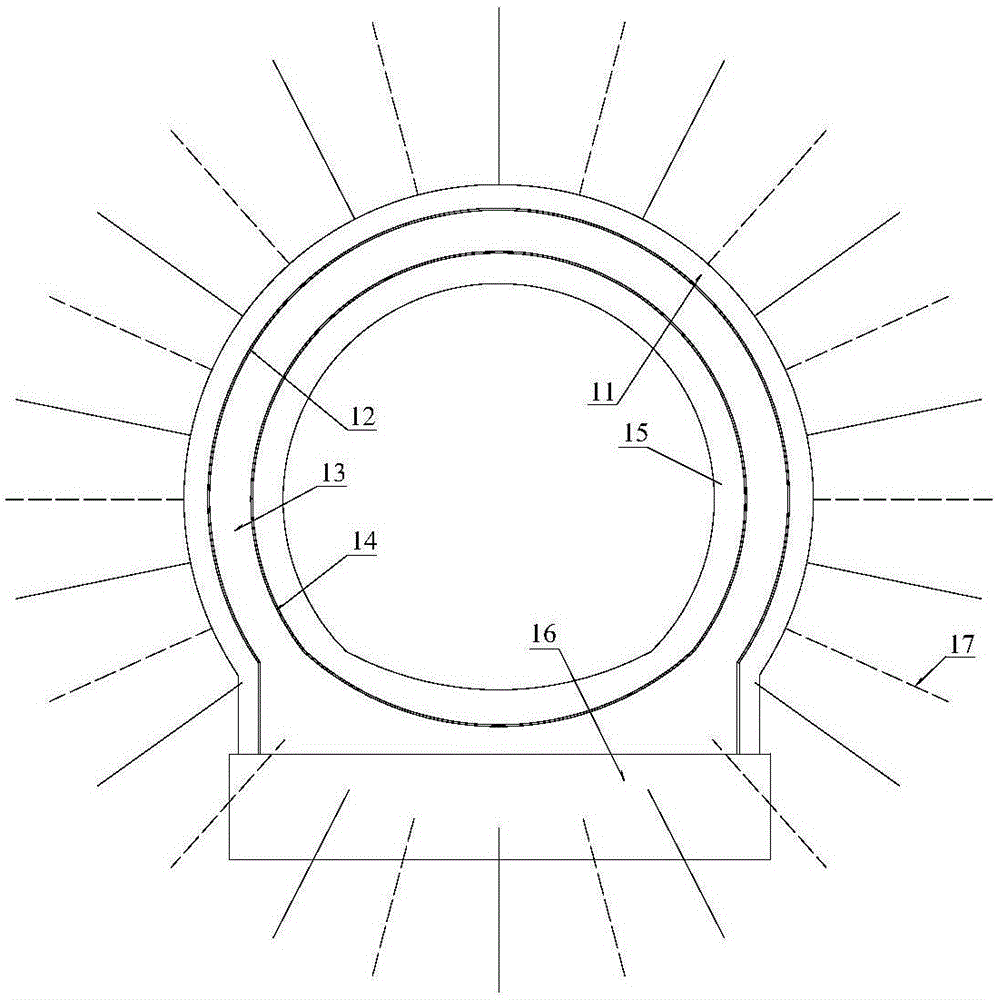

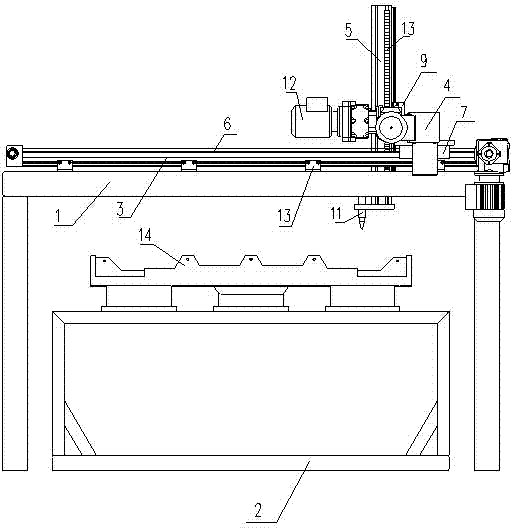

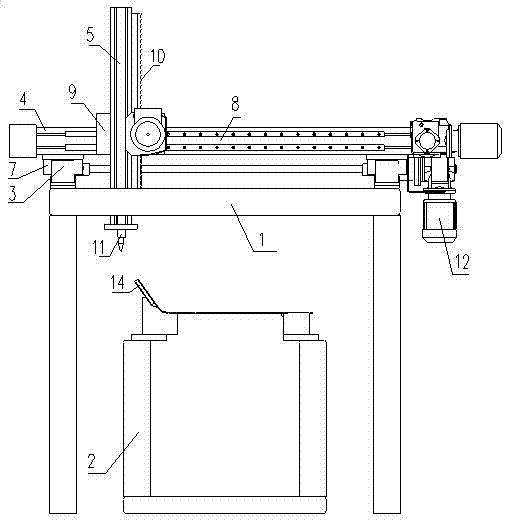

Swivel and closure construction method for large-span continuous beam crossing existing station

ActiveCN105421248AThe method steps are simpleReasonable designBridge erection/assemblyBridge materialsButtressReinforced concrete

The invention discloses a swivel and closure construction method for a large-span continuous beam crossing an existing station. A constructed large-span continuous beam adopts a reinforced concrete box beam crossing the existing station and the front end and the rear end of a span are supported on a second buttress and a third buttress respectively; the swivel and closure construction process comprises steps as follows: step one, swivel system construction: a swivel system is constructed at the bottom of each of the second buttress and the third buttress and comprises a lower support disc, an upper rotating disc, a bridge swivel spherical hinge and a swivel traction system, multiple support legs are arranged at the bottom of the upper rotating disc, and an annular slide way allowing the support legs to slide is formed on a lower bearing platform; step two, construction of the second buttress and the third buttress; step three, construction of a front side beam body and a rear side beam body; step four, plane swivel construction; step five, side span closure construction; step six, mid-span closure construction. According to the method, the steps are simple, the design is reasonable, the construction is simple and convenient, the use effect is good, the swivel and closure construction process of the large-span continuous beam crossing the existing station can be completed simply, conveniently and rapidly, and the construction process is safe.

Owner:NO 1 ENG LIMITED OF CR20G

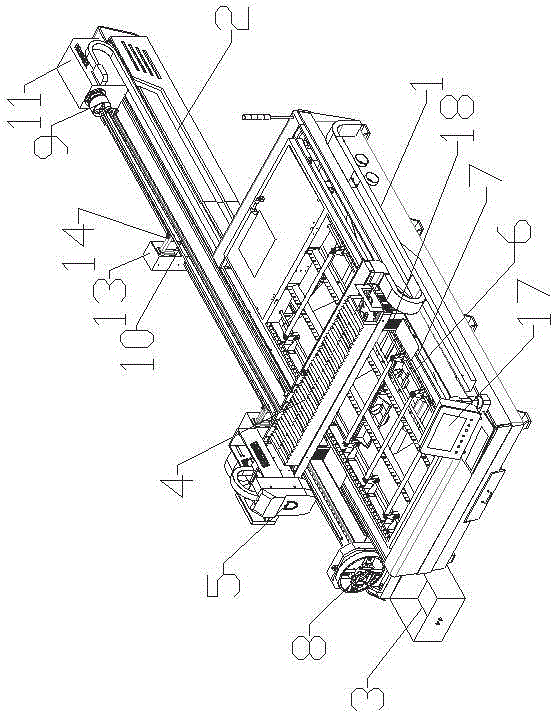

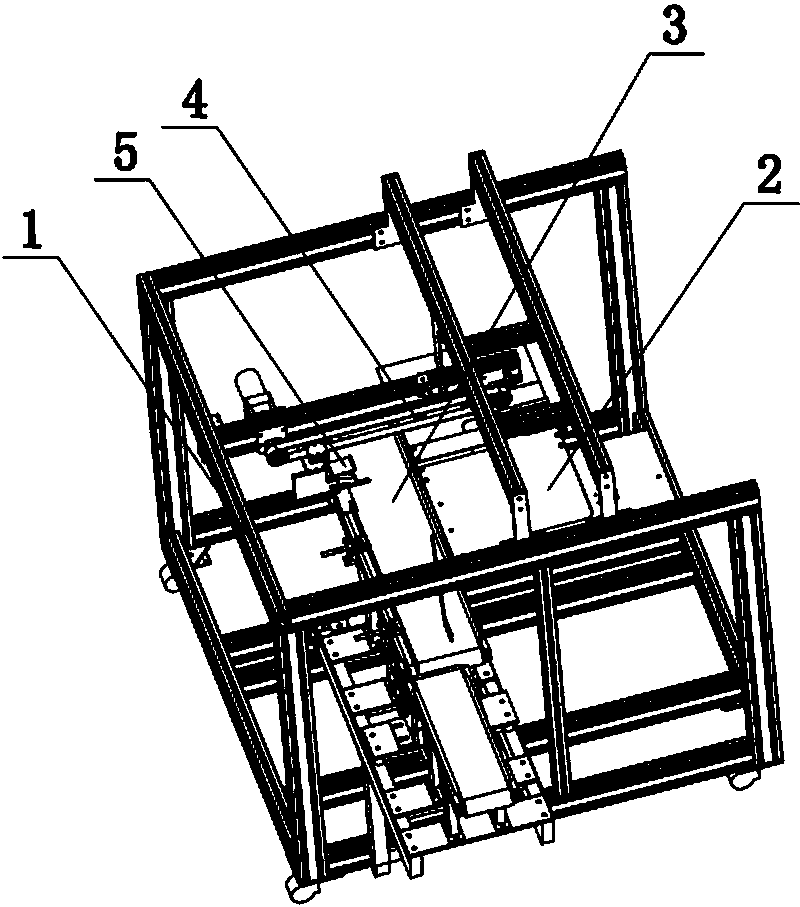

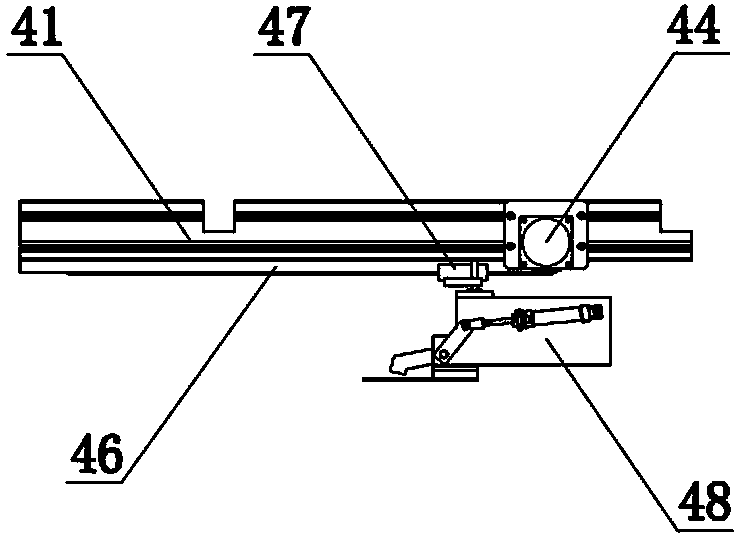

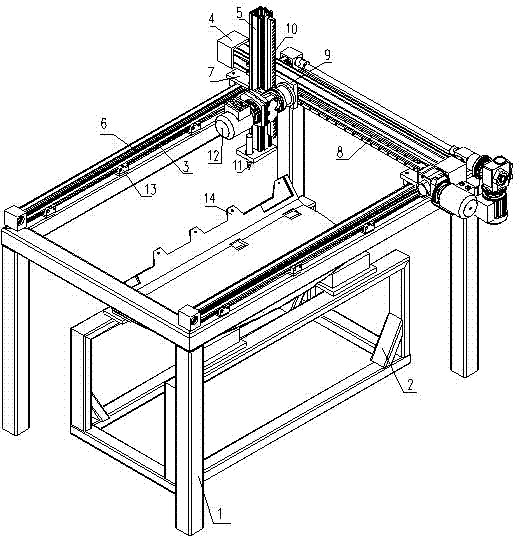

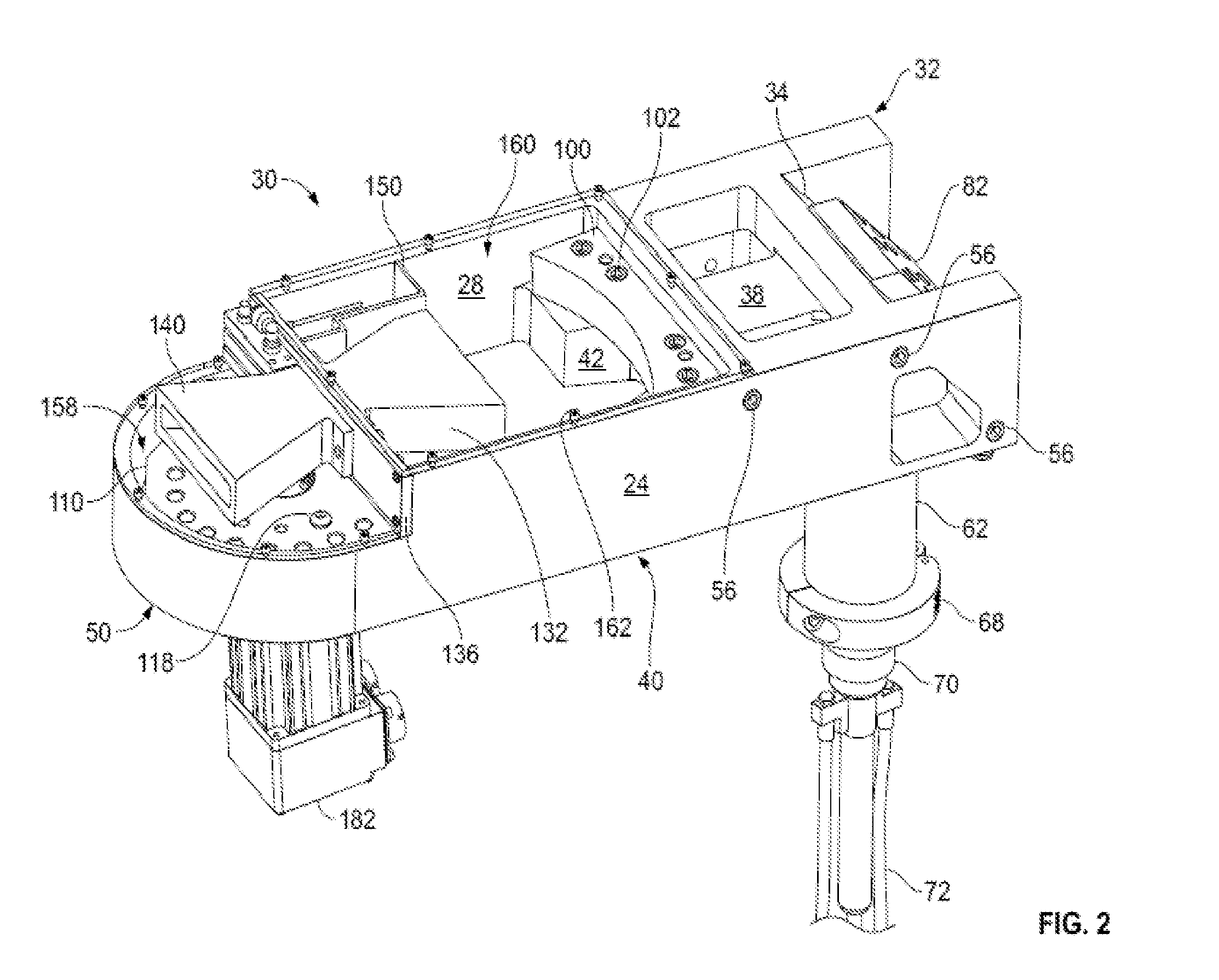

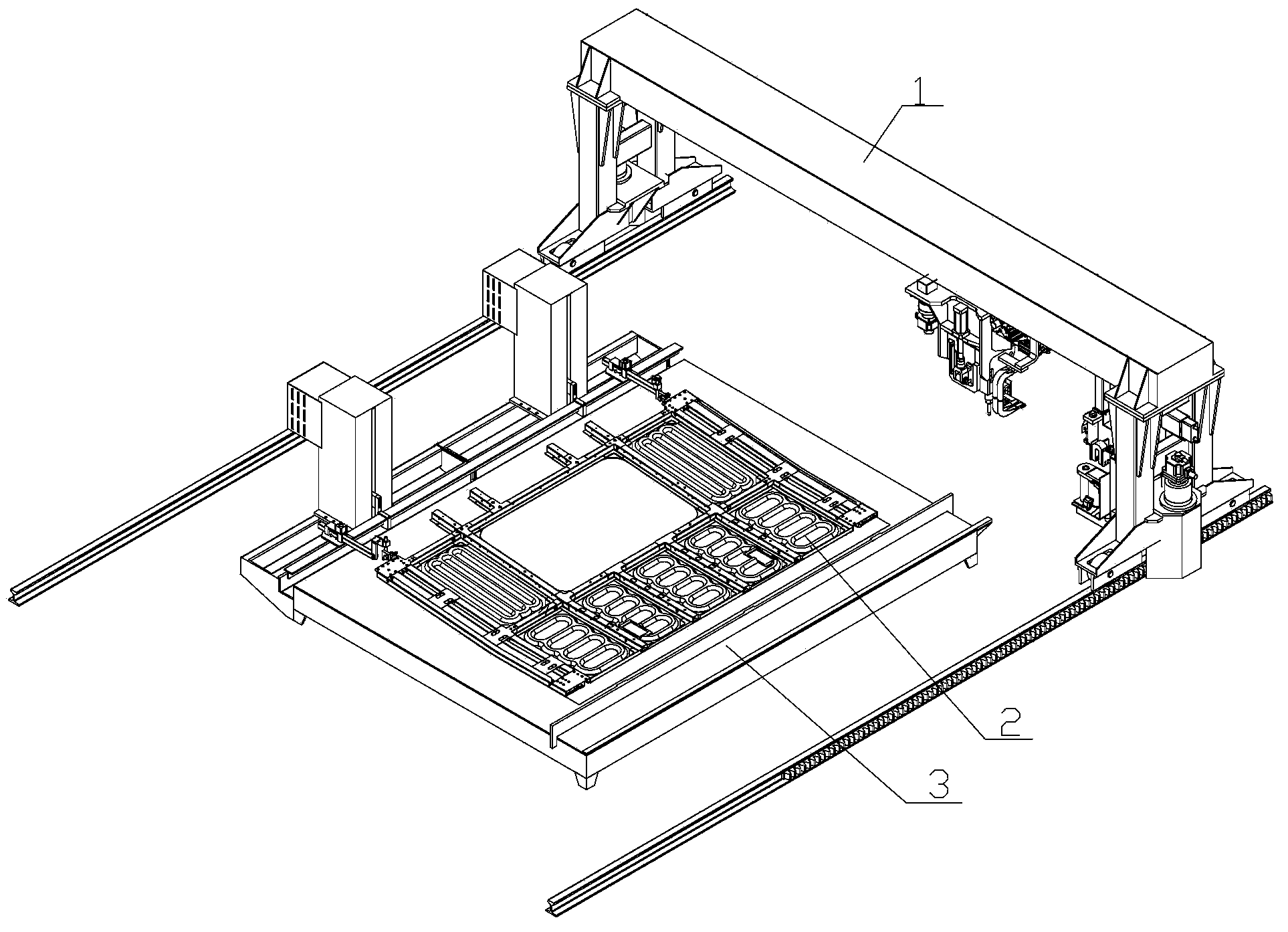

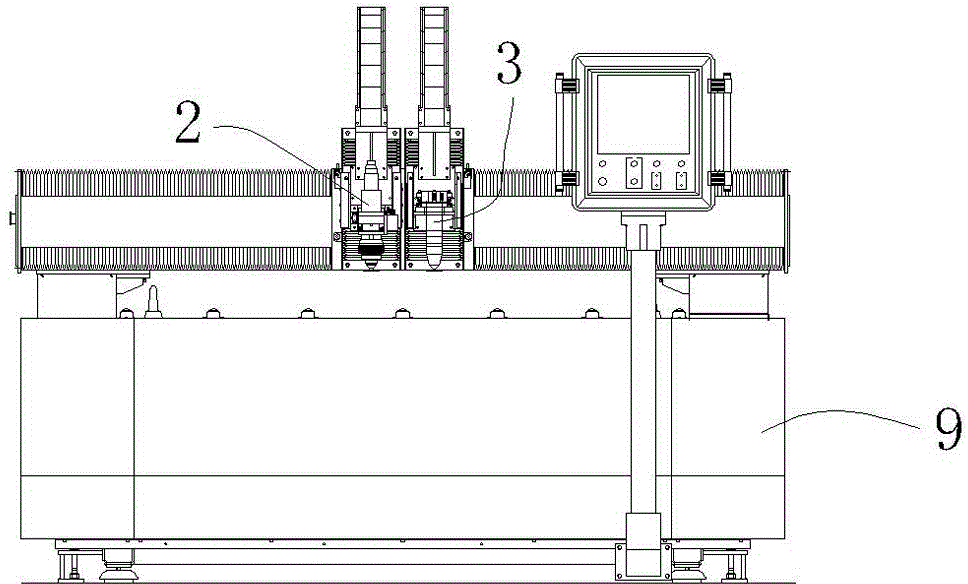

Cutting all-in-one machine for optical fiber laser tube plate

ActiveCN105345278AFunction increaseMeet cutting planeWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerLaser cutting

The invention relates to the laser cutting field, in particular to a cutting all-in-one machine for an optical fiber laser tube plate. The cutting all-in-one machine comprises a PLC (Programmable Logic Controller) unit and a plate rack and a tube rack which are arranged side by side, wherein a beam crossing the plate rack is arranged above the plate rack; one end of the beam is suspended above the tube rack; the upper surface of the beam is provided with a laser head assembly; the two sides of the tube rack are provided with a guide rail and a rack; and a rear chuck and a front chuck are arranged on the tube rack. The cutting all-in-one machine is various in function, can cut not only plates, but also tubes, so that planar and three-dimensional processing needs for cutting are met. The structure is compact, occupied space is reduced in case of keeping the original processing area unchanged, and working efficiency and processing precision are improved.

Owner:JINAN JINQIANG LASER CNC EQUIP

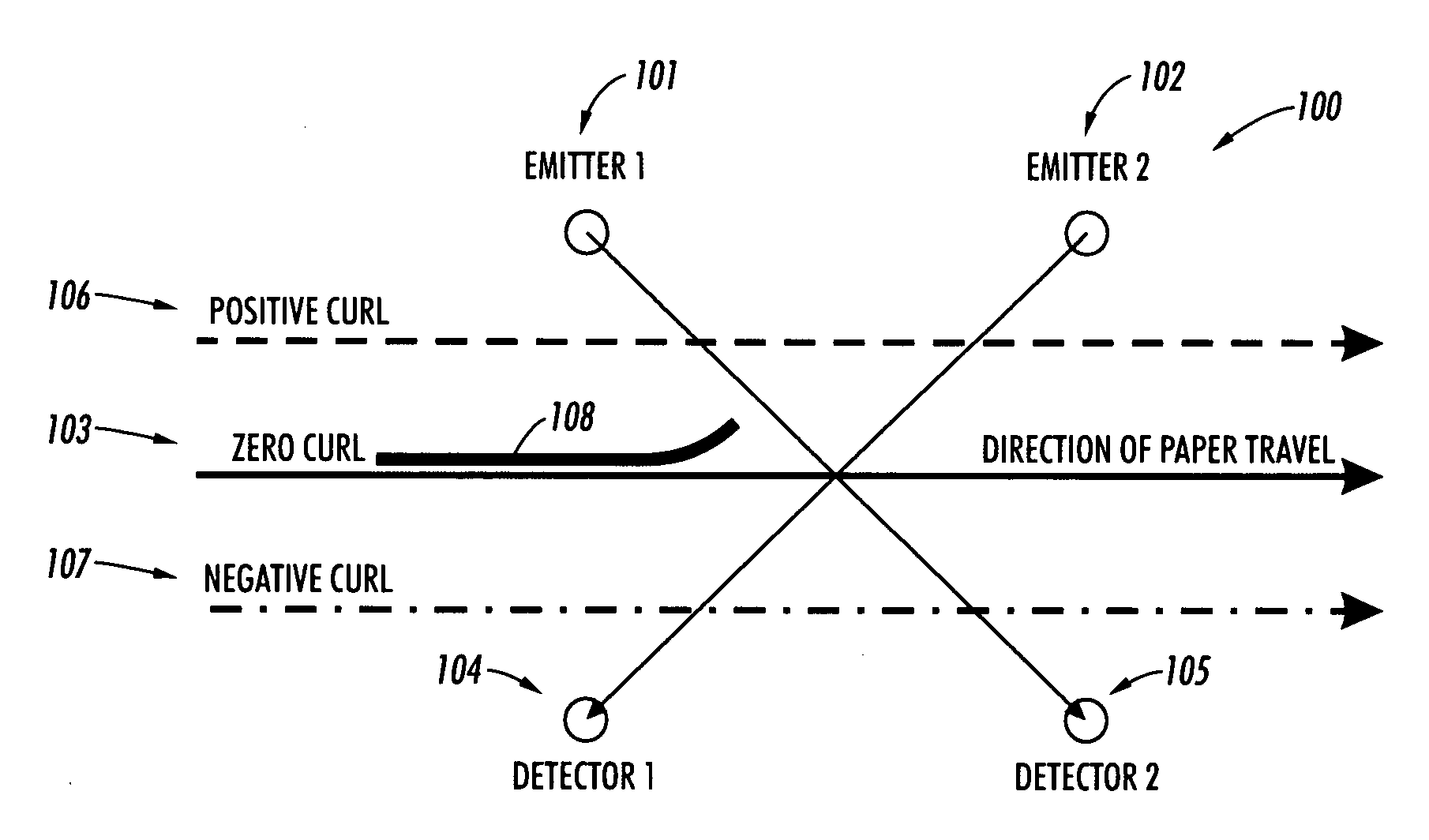

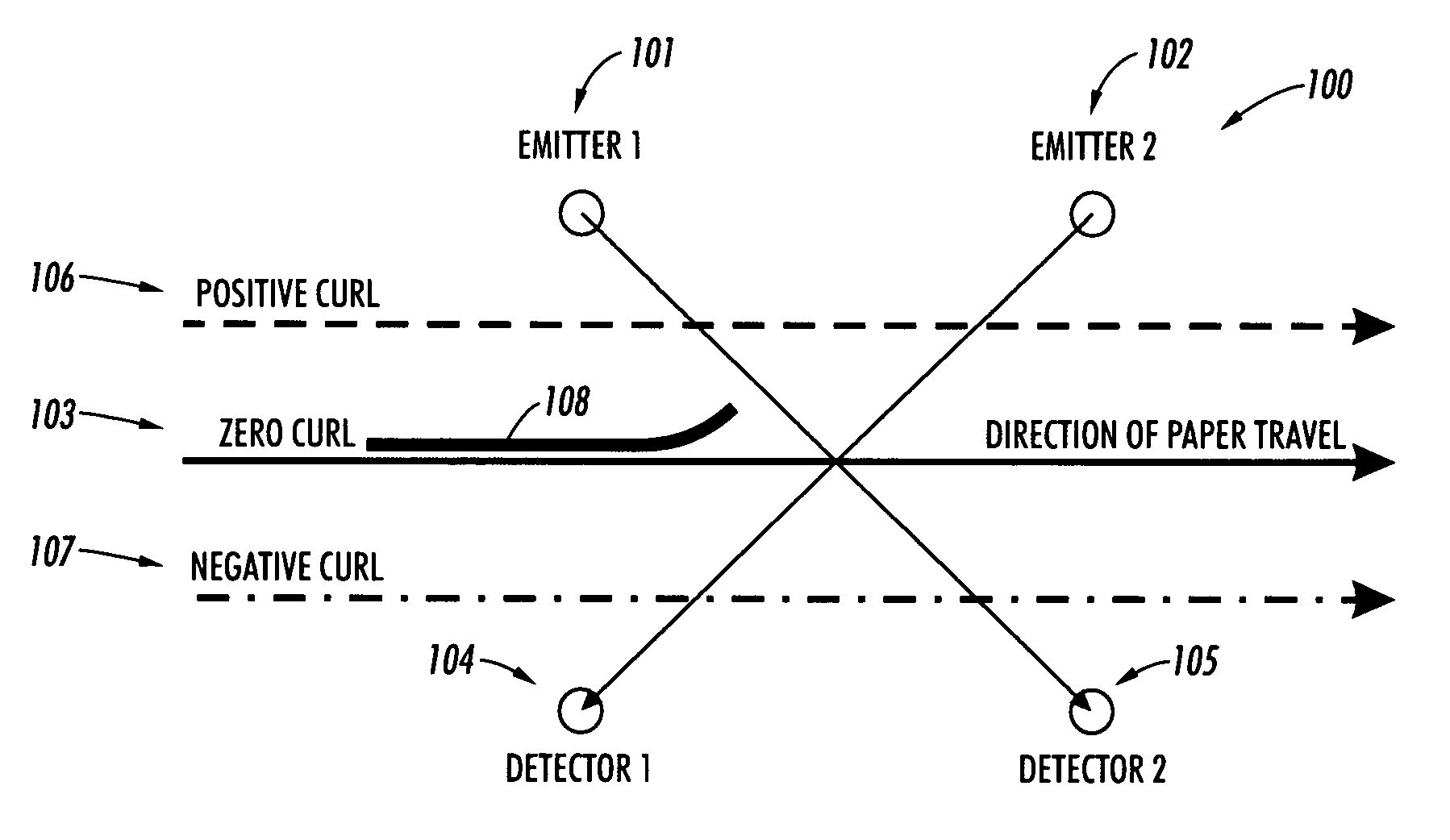

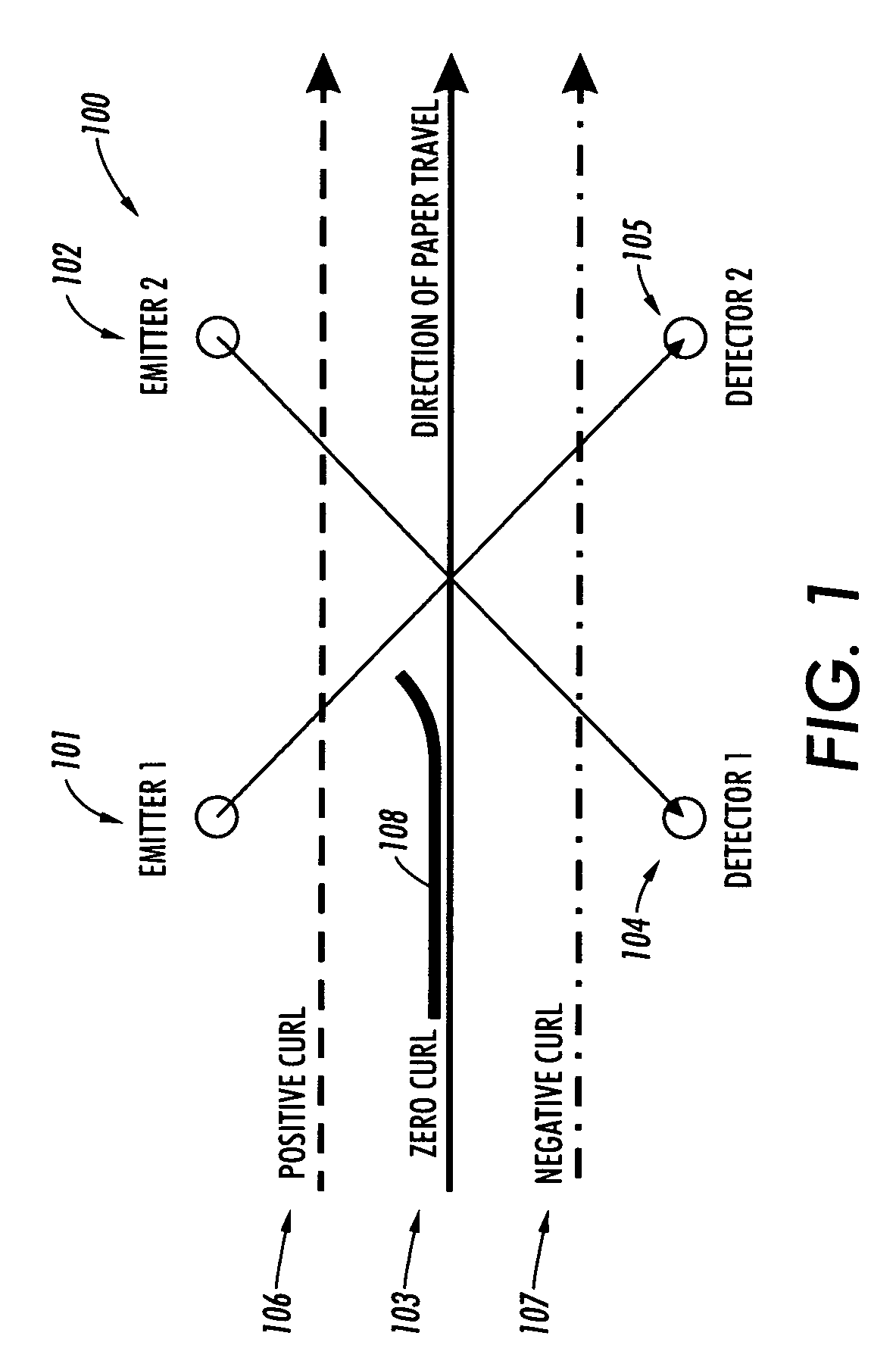

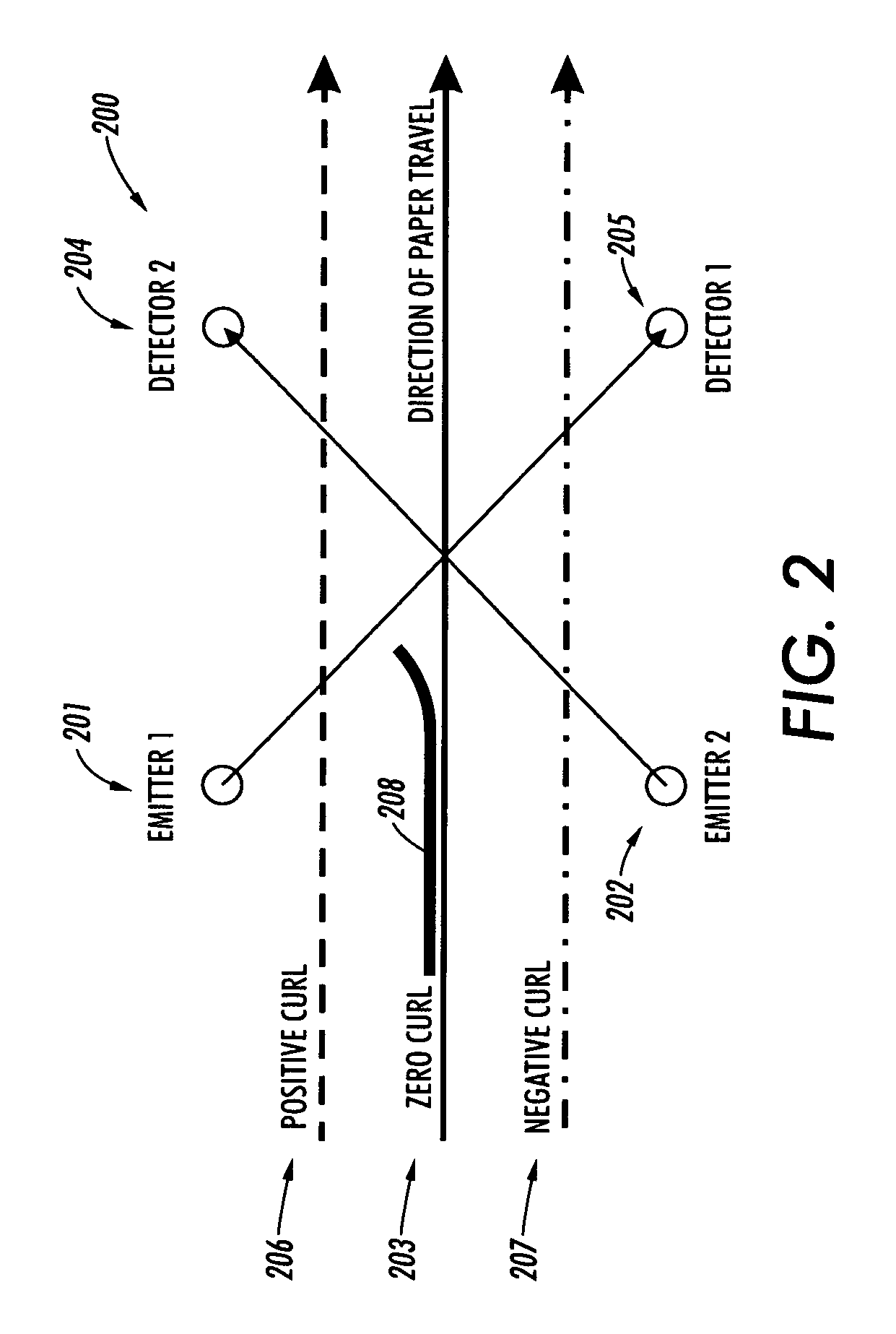

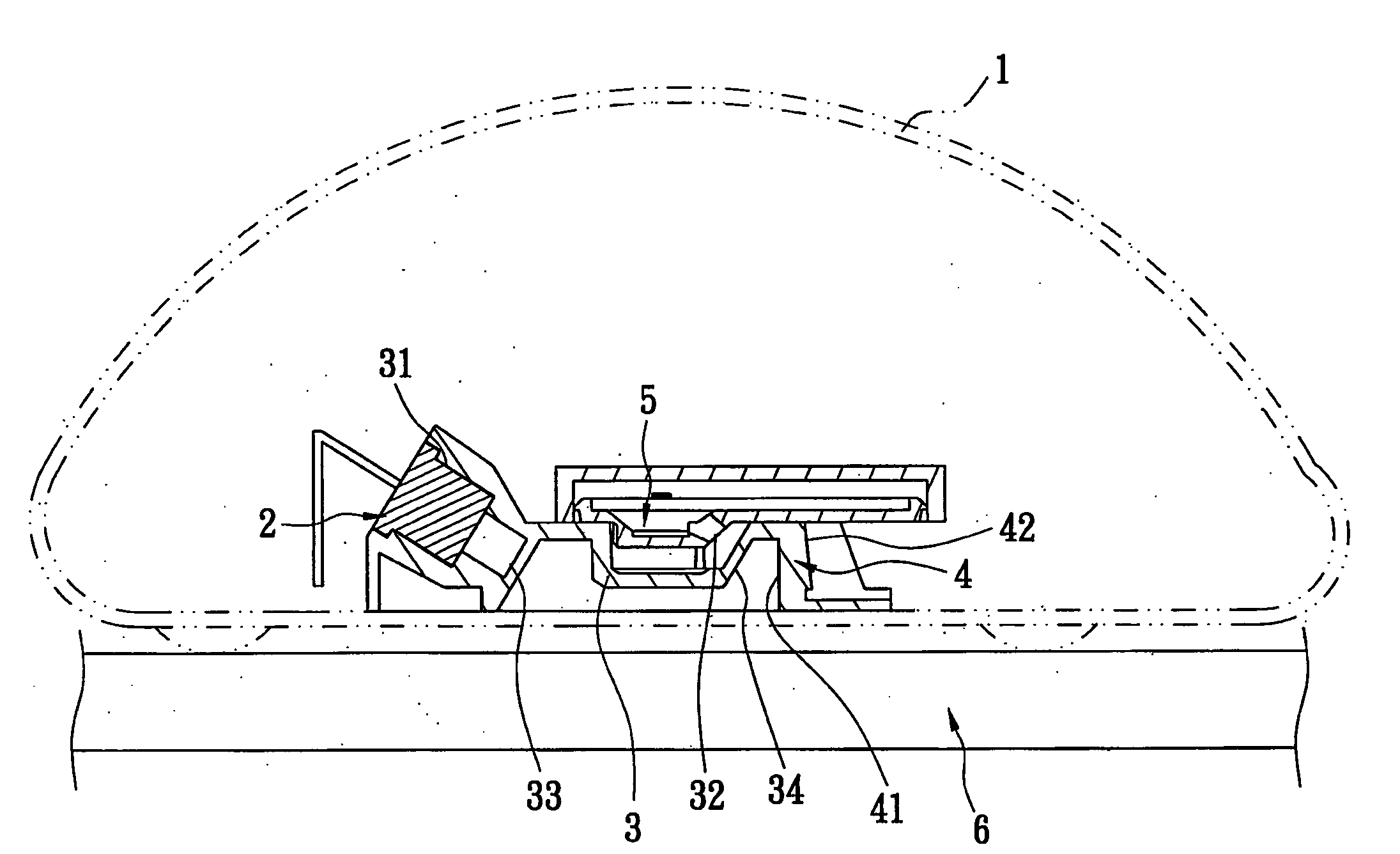

Lead edge sheet curl sensor

InactiveUS20080018913A1Simple methodFunction indicatorsUsing optical meansLeading edgeTransport medium

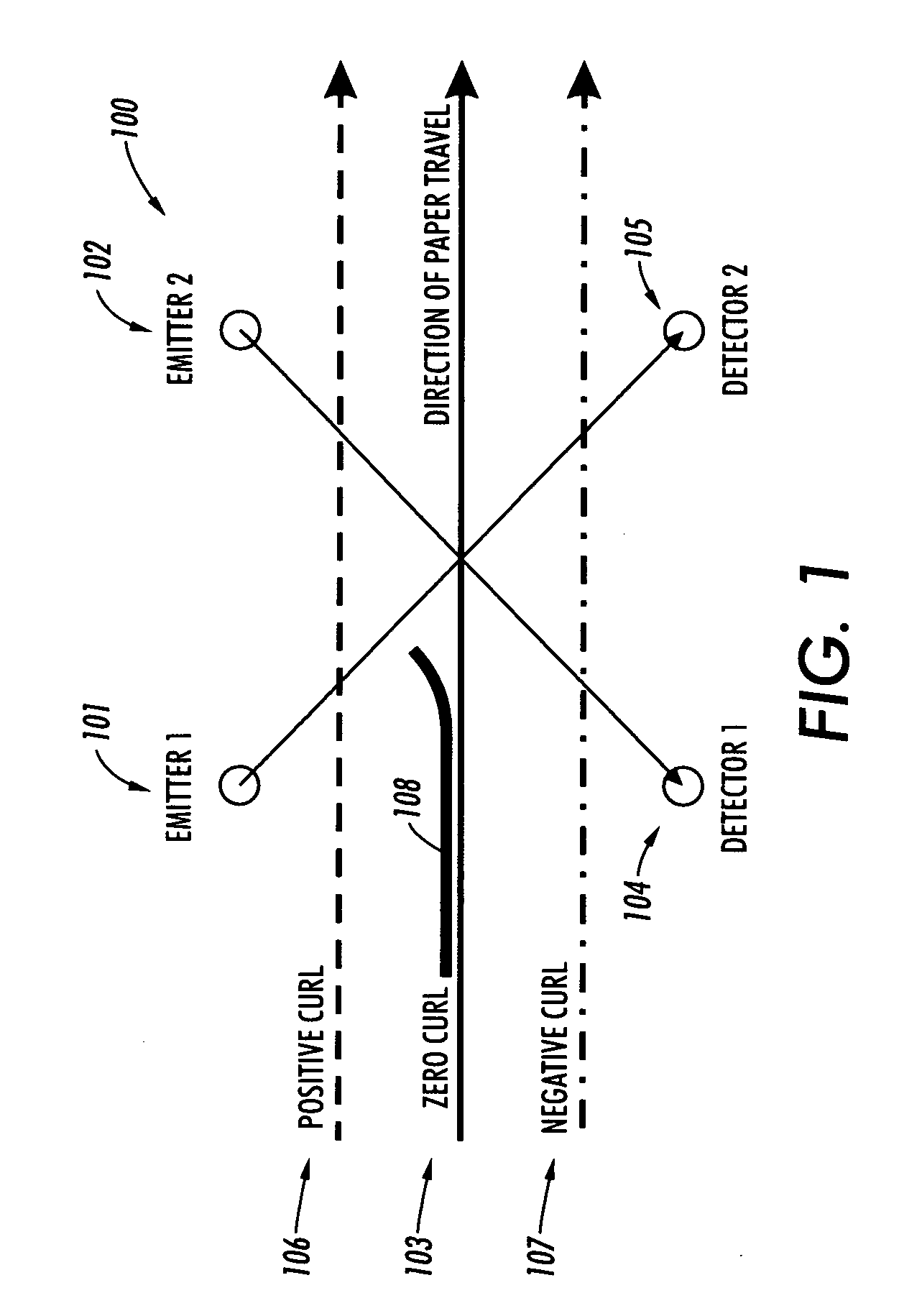

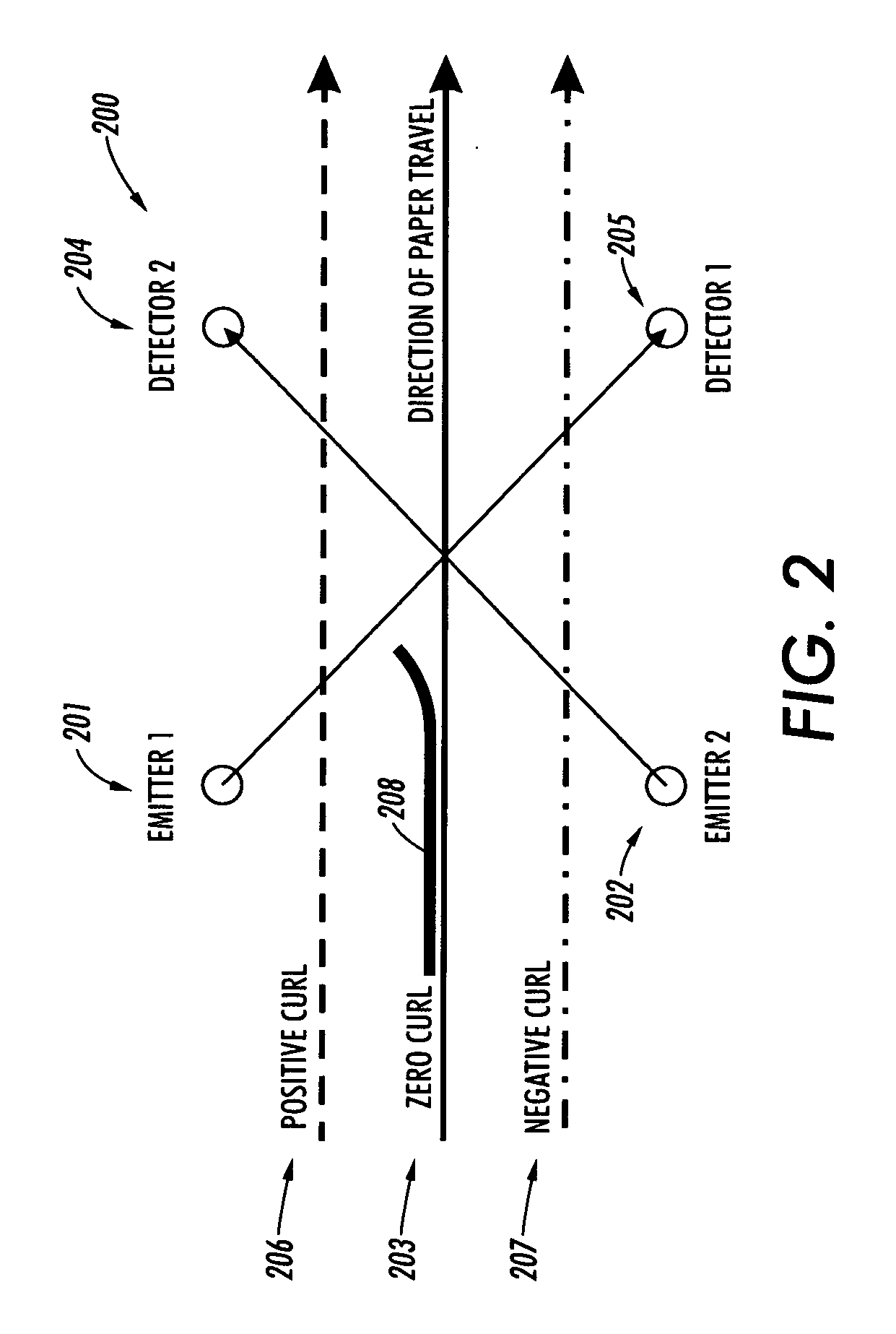

A lead edge sheet curl sensor apparatus and method are disclosed. In general, a first and a second light emitter are aligned wherein the light beams from the first light emitter and second light emitter cross. The first and second light emitter beams cross at the transport media sheet substrate path wherein the transport media sheet substrate path is the path of a media sheet substrate with zero curl. First and second light detectors are aligned to receive the light beams from the first and second light emitters.A media sheet substrate with either positive or negative curl on the lead edge of the sheet substrate interrupts light beams from first and second light emitters, as detected at first and second light detectors. The time delay between the light beam interruptions is proportional to the sheet substrate curl, and the order of interruptions indicates whether the sheet substrate curl is positive or negative.

Owner:XEROX CORP

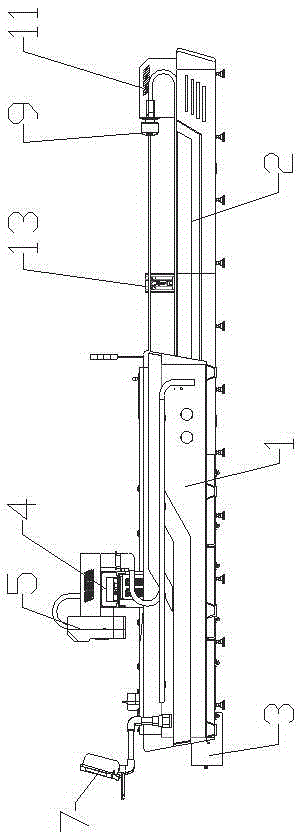

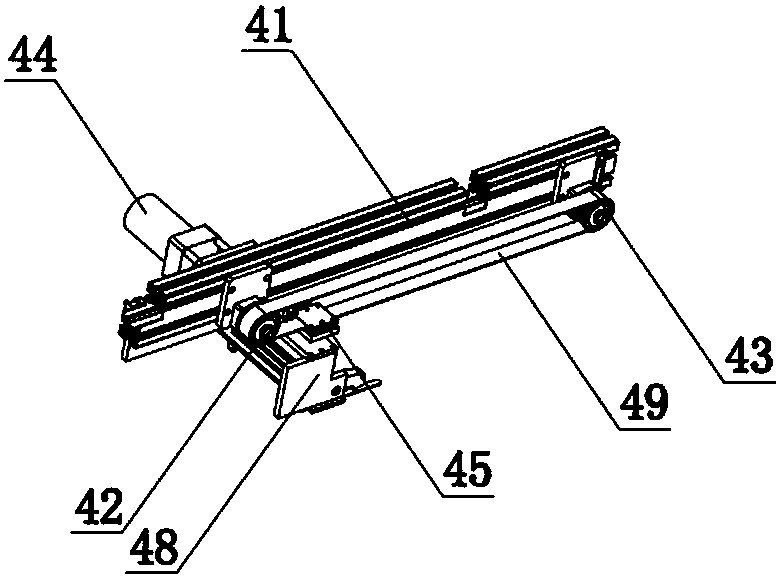

Stocking carrying machine hand device and carrying method thereof

The invention discloses a stocking carrying machine hand device and a carrying method thereof. A cross beam crossing between a workbench and a conveyor belt is arranged on a rack; a sliding rail and a sliding block are arranged on the lower side face of the cross beam; the lower part of the sliding block is connected with a sliding substrate; a fixed shovel plate and a movable pressing plate are arranged on the side of the sliding substrate; the fixed shovel plate is horizontally pasted on the workbench and the working end face of the conveyor belt in a dissociating mode; the two sides of the tail end of the movable pressing plate are coupled onto a pair of rotating shafts on the sliding substrate; one of the pair of rotating shafts is connected with a driving arm; the driving arm is hinged to a telescopic cylinder; a driving belt wheel, a driven belt wheel and a gear belt are arranged on the side face of the cross beam; the driving belt wheel is connected with a positive-negative rotating motor; a motion block is arranged on the lower circulation belt body of the gear belt; the motion block is connected with the sliding substrate. The fixed shovel plate is pasted on the working end face during working, stockings are shoveled and supported integrally from the bottoms, and thus the stockings are prevented from being in disorder during the stocking carrying process.

Owner:ZHEJIANG MENGNA SOCKS & HOSIERY +2

Lead edge sheet curl sensor

Owner:XEROX CORP

Tunnel karst cave and underground water comprehensive treatment structure and construction method

ActiveCN106761918AHigh implementabilityEffective height controlUnderground chambersDrainageKarstEngineering

The invention discloses a tunnel karst cave and underground water comprehensive treatment structure and a construction method so as to effectively ensure the tunnel structure and construction safety and not affect the environment. Out of the range of a tunnel, a tunnel outside drainage vertical well communicated to a water outlet inside the tunnel is arranged from the ground surface, a tunnel inside vertical well is arranged below the tunnel, a drainage transverse channel connected with the tunnel outside drainage vertical well and the tunnel inside vertical well is arranged, the bottom of the tunnel is provided with a bottom beam crossing a karst cave, a whole-seal anti-hydraulic pressure lining is constructed inside the tunnel, and the whole-seal anti-hydraulic pressure lining extends by a certain length back and forth inside the karst cave.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

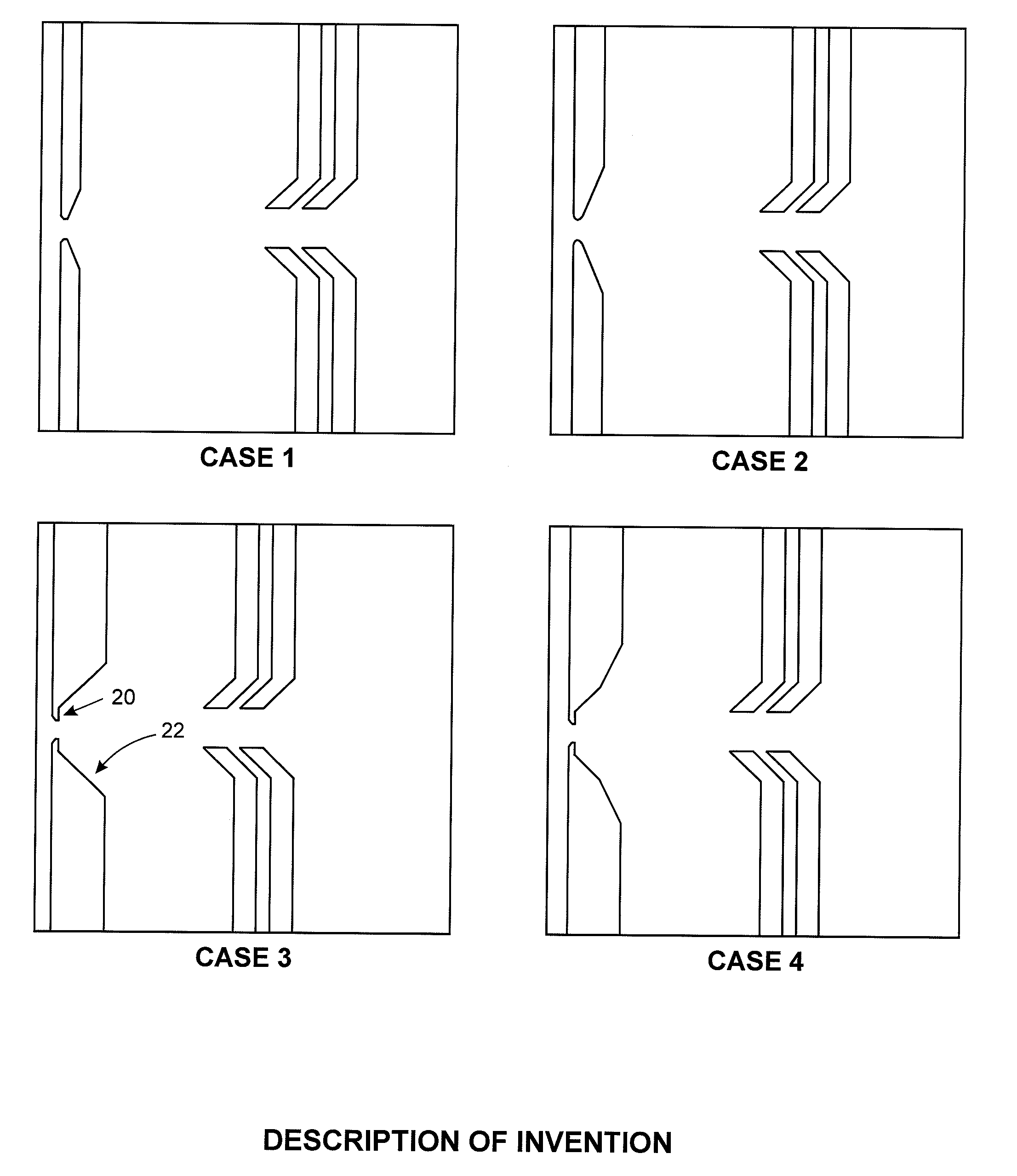

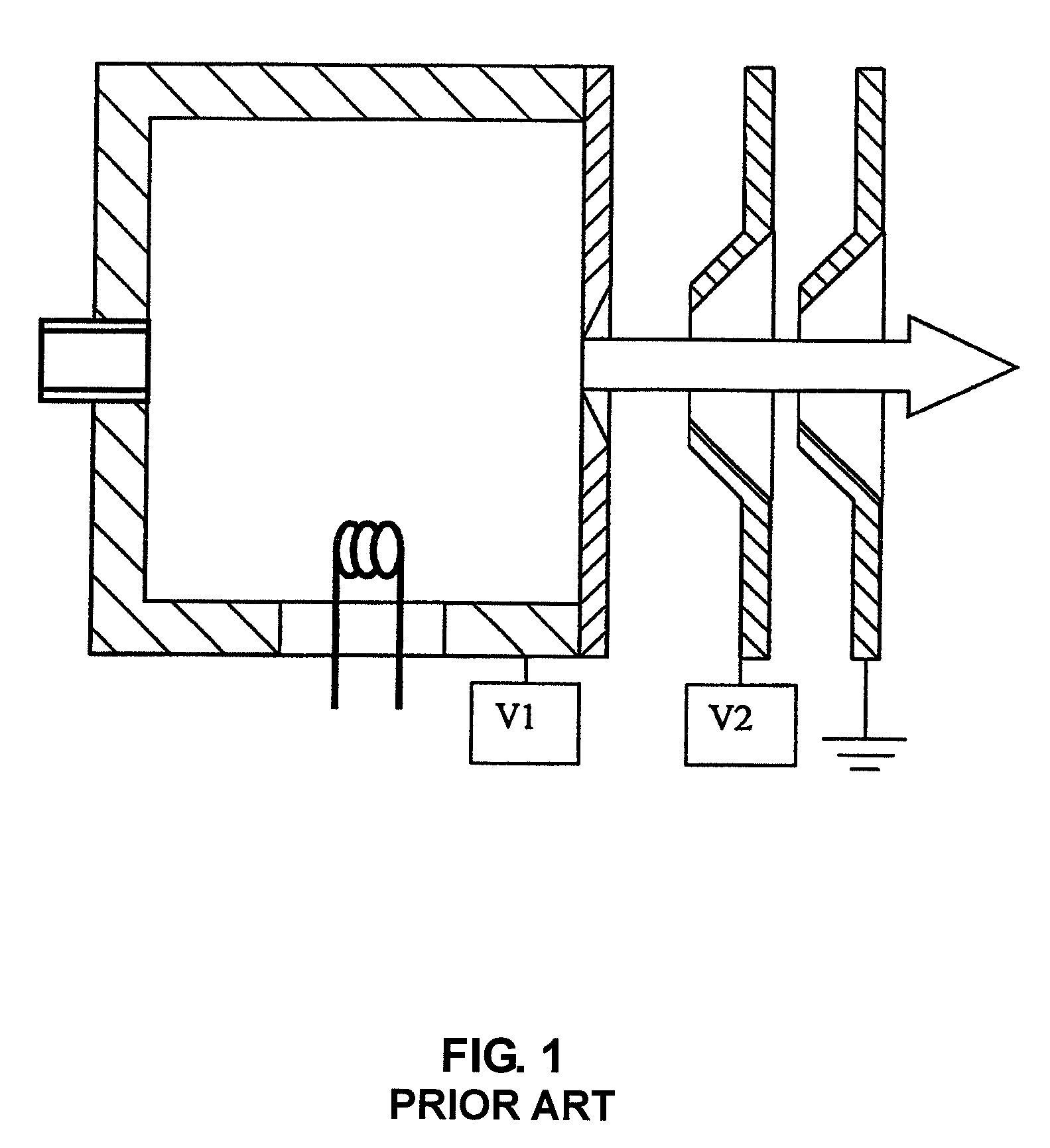

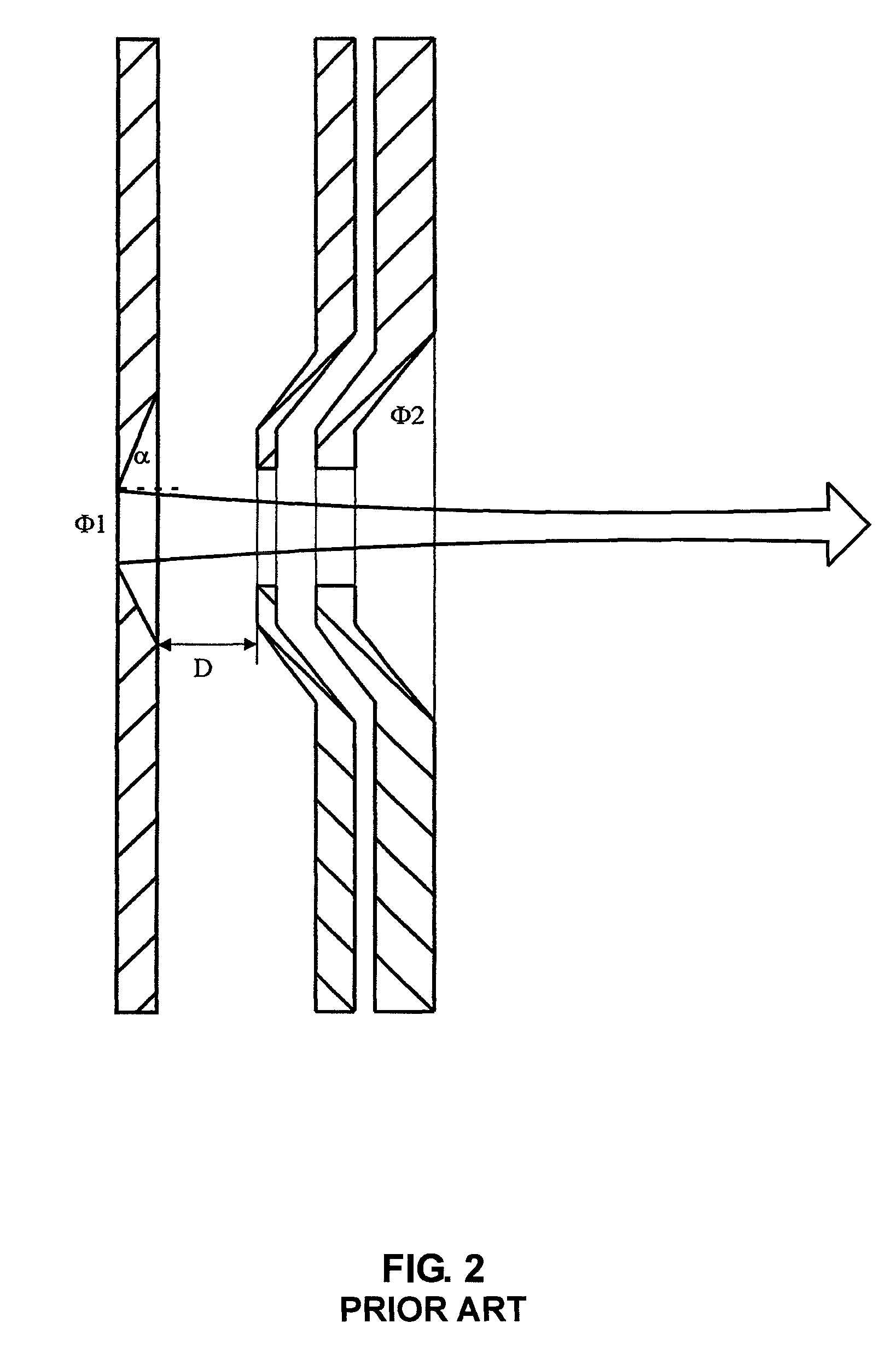

Method and system for extracting ion beams composed of molecular ions (cluster ion beam extraction system)

InactiveUS7928406B2Little valueWide range of energyStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsBeam energyLight beam

A new type of triode extraction system, a Cluster Ion Beam Extraction System, is disclosed for broad energy range cluster ion beam extraction applications while still being applicable to atomic and molecular ion species as well. The extraction aperture plate contours are set to minimize the beam cross over and at the same time shield the source from excess extraction electric fields thus allowing smaller values of the extraction gap. In addition, a novel focusing feature is integrated into these new optics which allows the beam to be either focused or de-focused in the non-dispersive plane by using a bipolar bias voltage of only a few kV over a broad range of beam energy. This is a superior solution to a stand-alone electrostatic lens solution, for example an einzel lens, which would require tens of kV of bias voltage in order to be able to focus an energetic beam.

Owner:SEMEQUIP

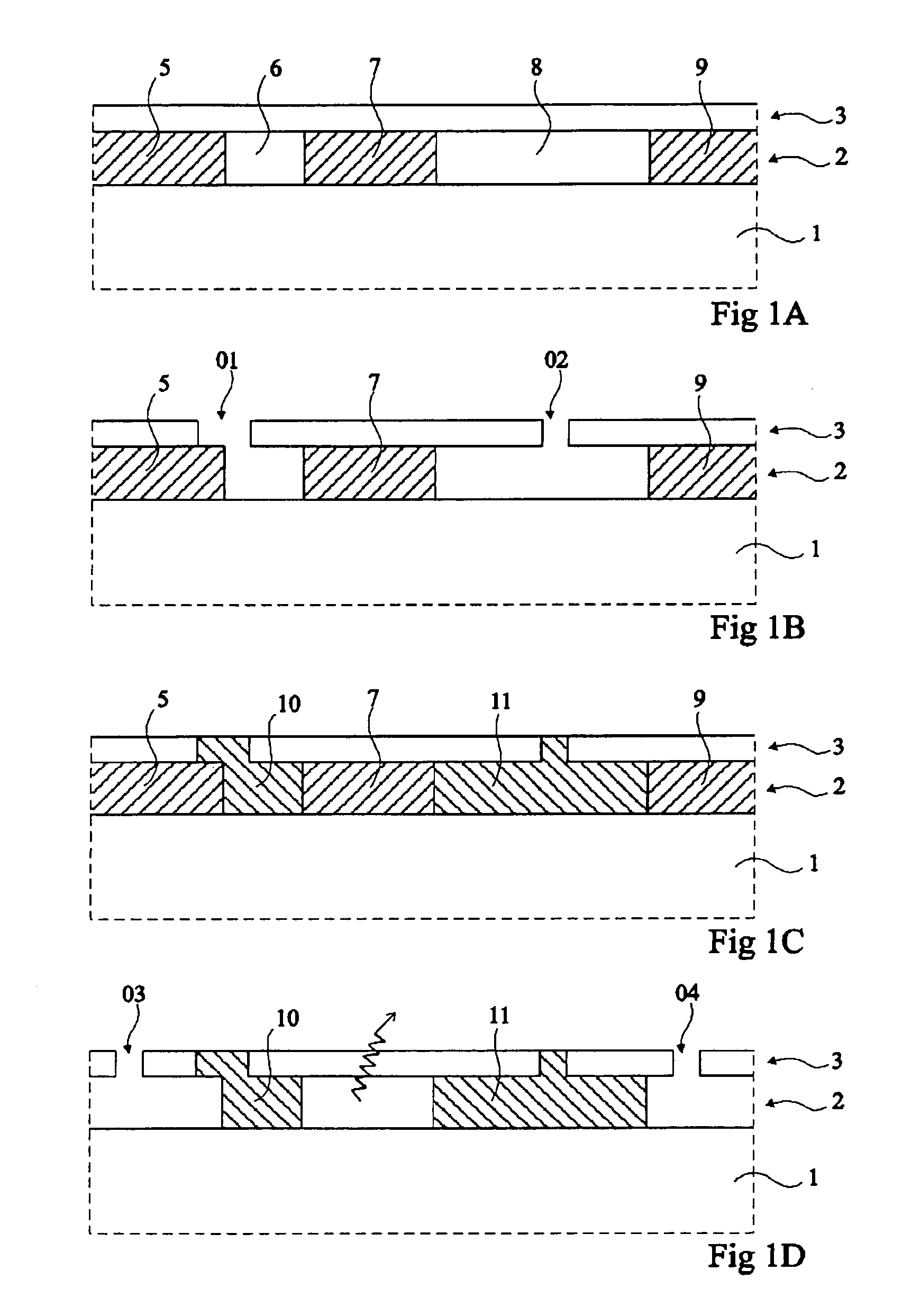

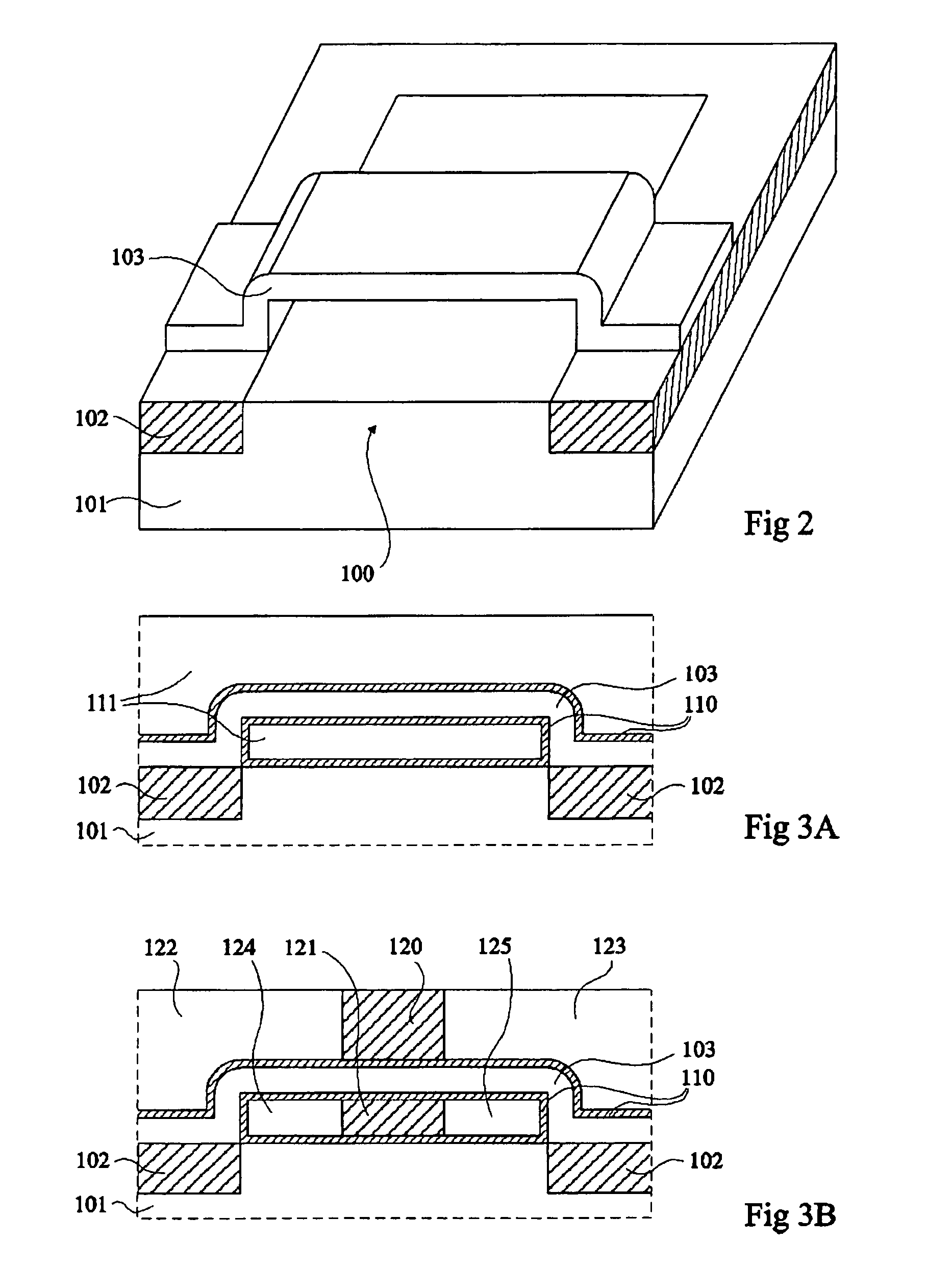

Method for forming, under a thin layer of a first material, portions of another material and/or empty areas

A method for forming a empty area under a layer of a given material, including forming on a substrate a stacking of a photosensitive layer and of a layer of the given material; insolating a portion of the photosensitive layer or its complement according to whether the photosensitive layer is positive or negative with an electron beam crossing the layer of the given material; and removing the portion of the photosensitive layer.

Owner:STMICROELECTRONICS SRL +1

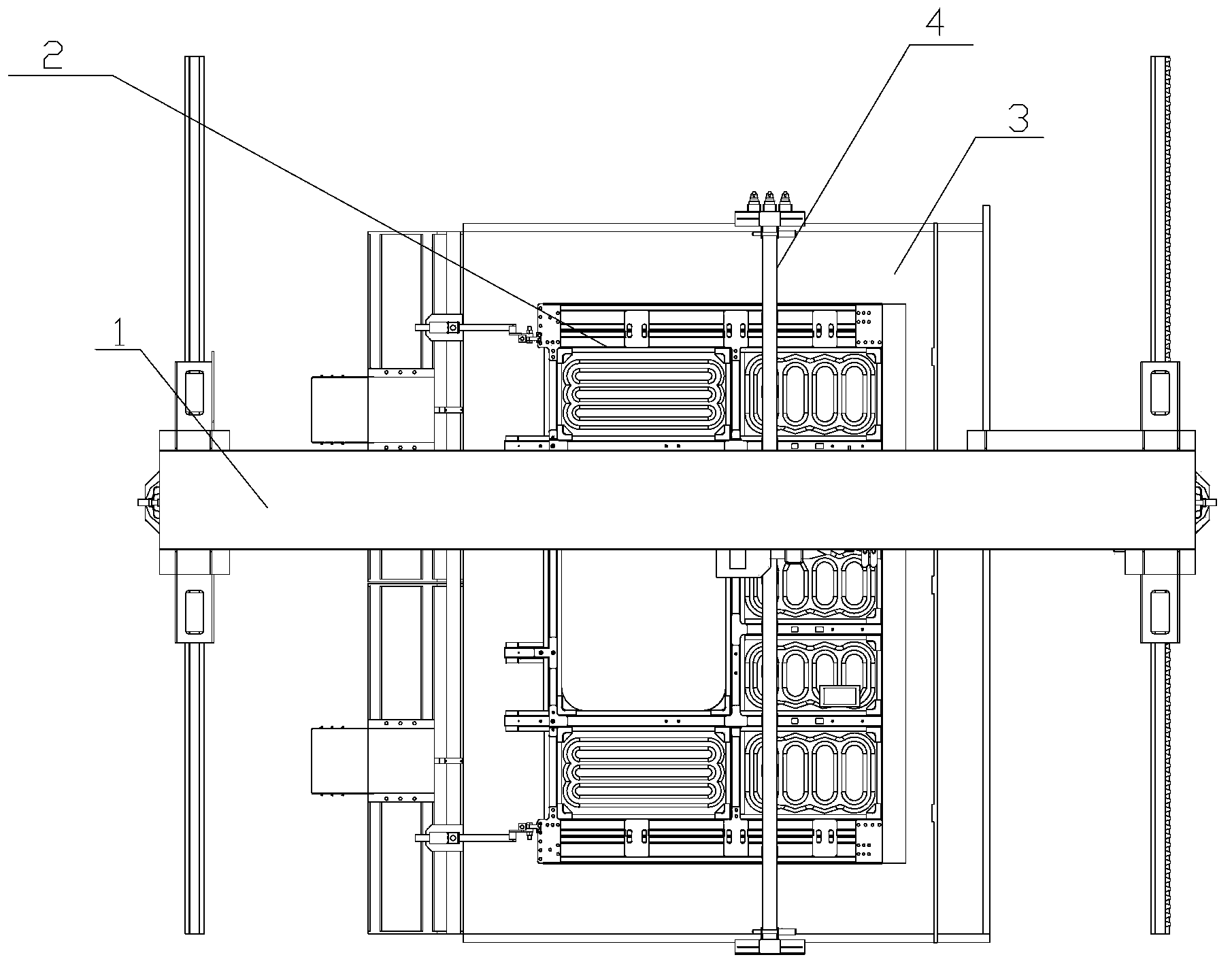

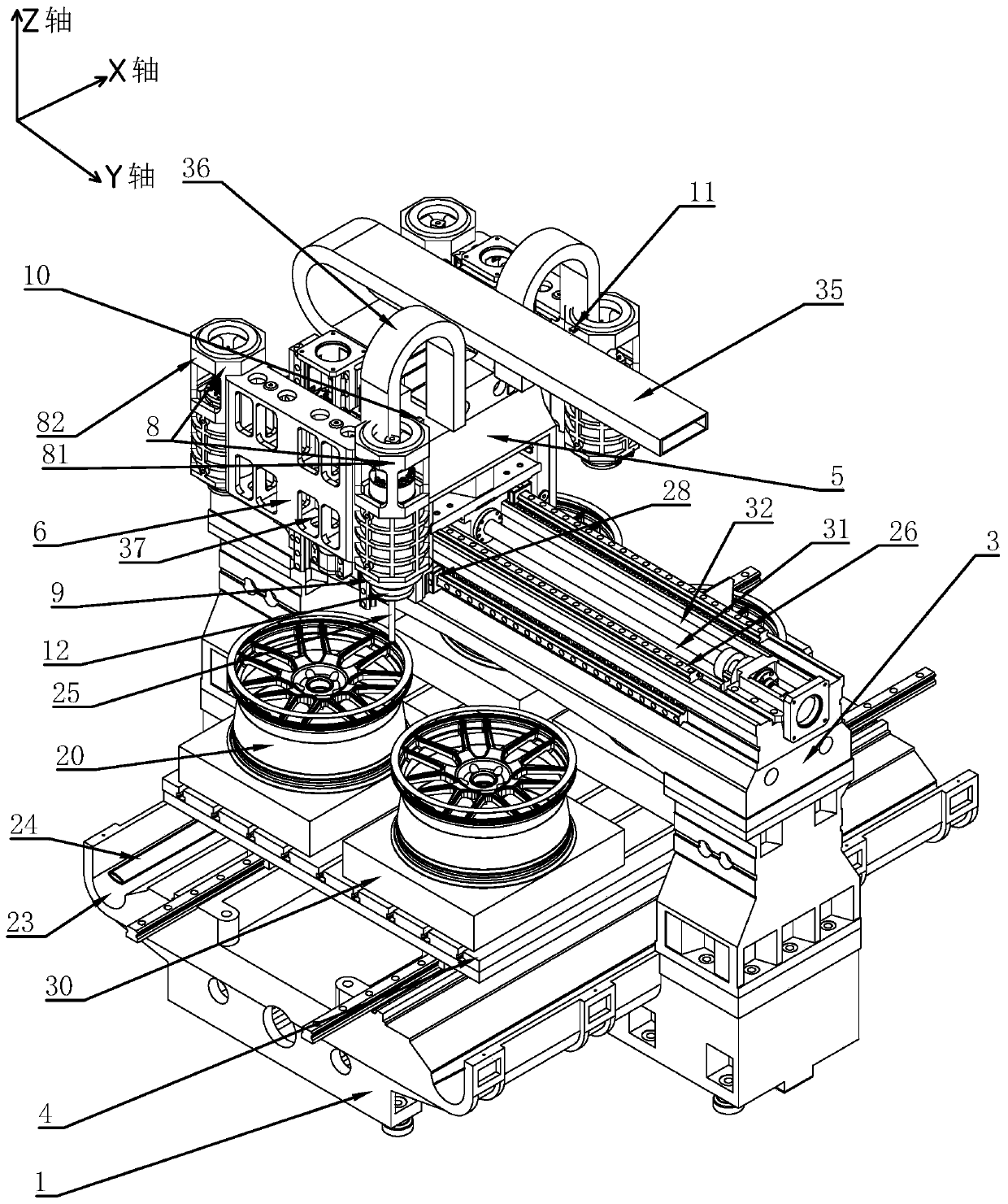

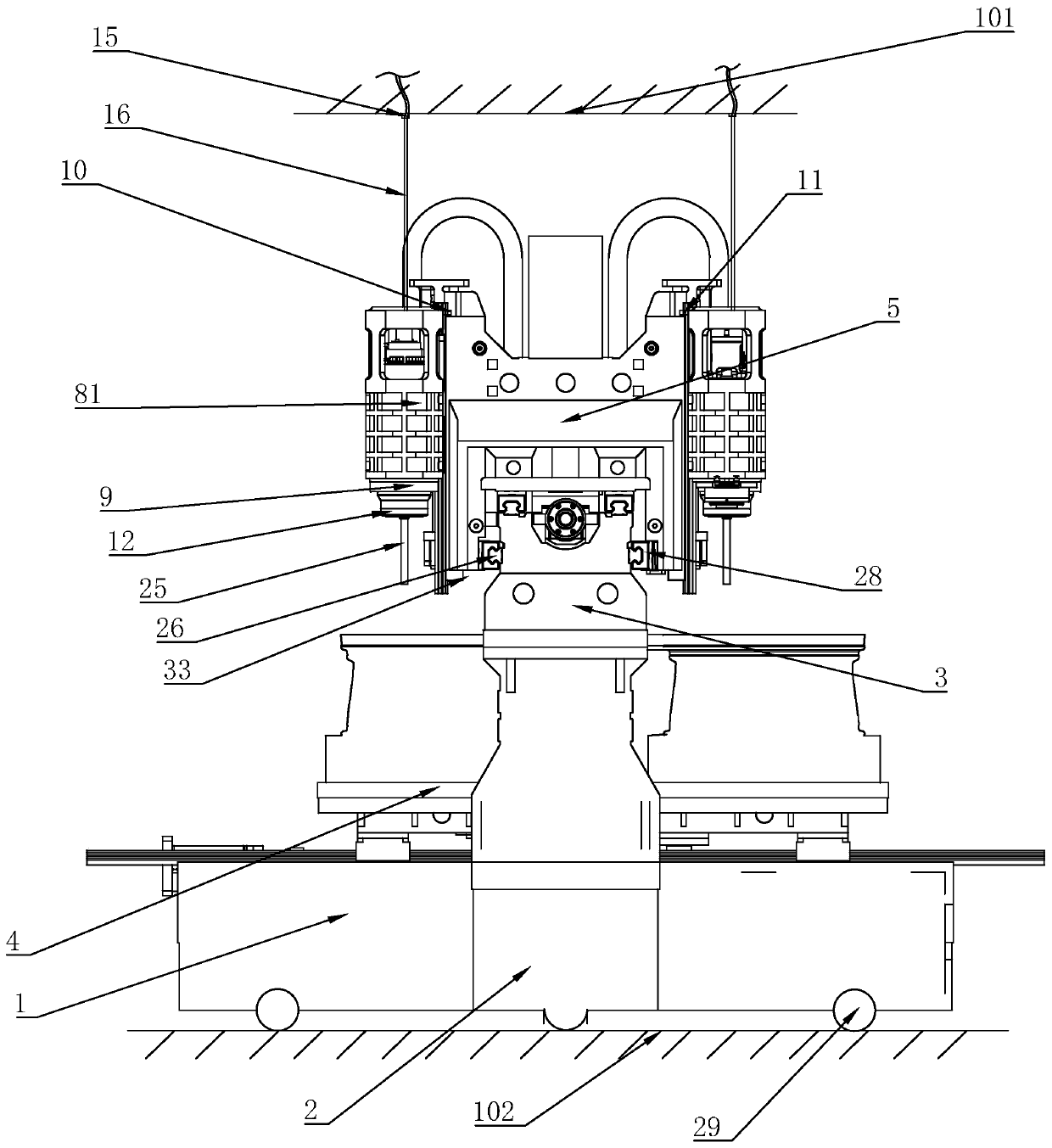

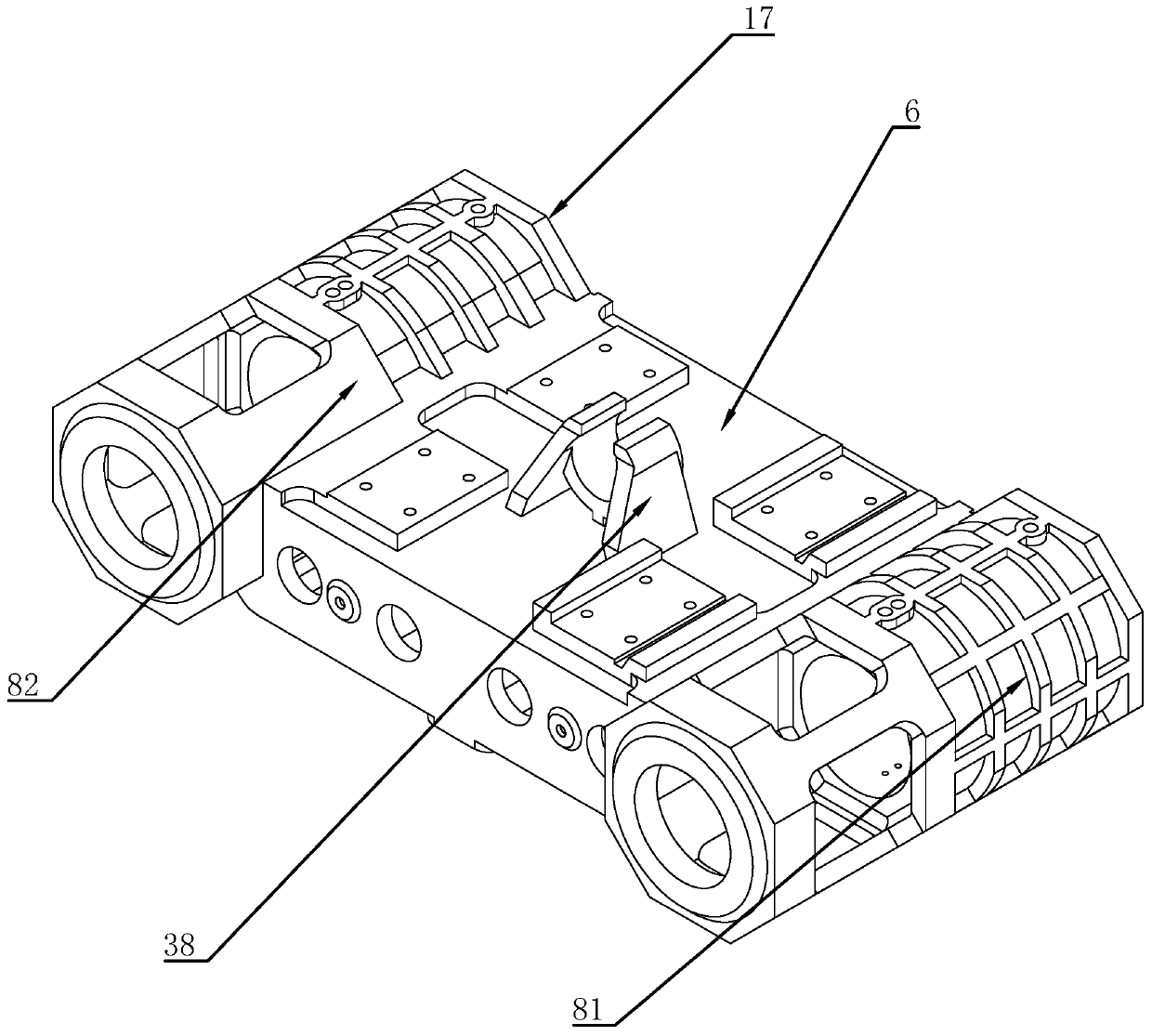

Automatic sealing robot for car baggage holder

InactiveCN104707750ASimple structureLittle servo drive noiseSpraying apparatusSpray nozzleSlide plate

The invention discloses an automatic sealing robot for a car baggage holder, and belongs to the technical field of machining of car components. The automatic sealing robot for the car baggage holder comprises an installation frame, a product positioning frame body and a three-shaft linkage mechanism. The three-shaft linkage mechanism comprises two cross beams, a longitudinal beam crossing the two cross beams and a vertical pillar perpendicular to the cross beams and the longitudinal beam, wherein the two cross beams are arranged at the two ends of the installation frame respectively and both provided with guide rails, the longitudinal beam is connected with the two cross beams through a sliding block corresponding to the guide rails, a sliding rail is arranged on the lateral surface of the longitudinal beam, the vertical pillar is connected with the longitudinal beam through a sliding plate corresponding to the sliding rail, a gear and rack mechanism is arranged between the vertical pillar and the sliding plate, and a glue spraying nozzle is arranged at the lower end of the vertical pillar. The automatic sealing robot for the car baggage holder has the advantages of being simple in structure, being wide in application range and reducing the production cost, overcomes the defects of the installation site and maneuverability of a traditional sealing robot, and is suitable for the specifications of all small car baggage holders.

Owner:ANHUI XINMENG EQUIP CO LTD

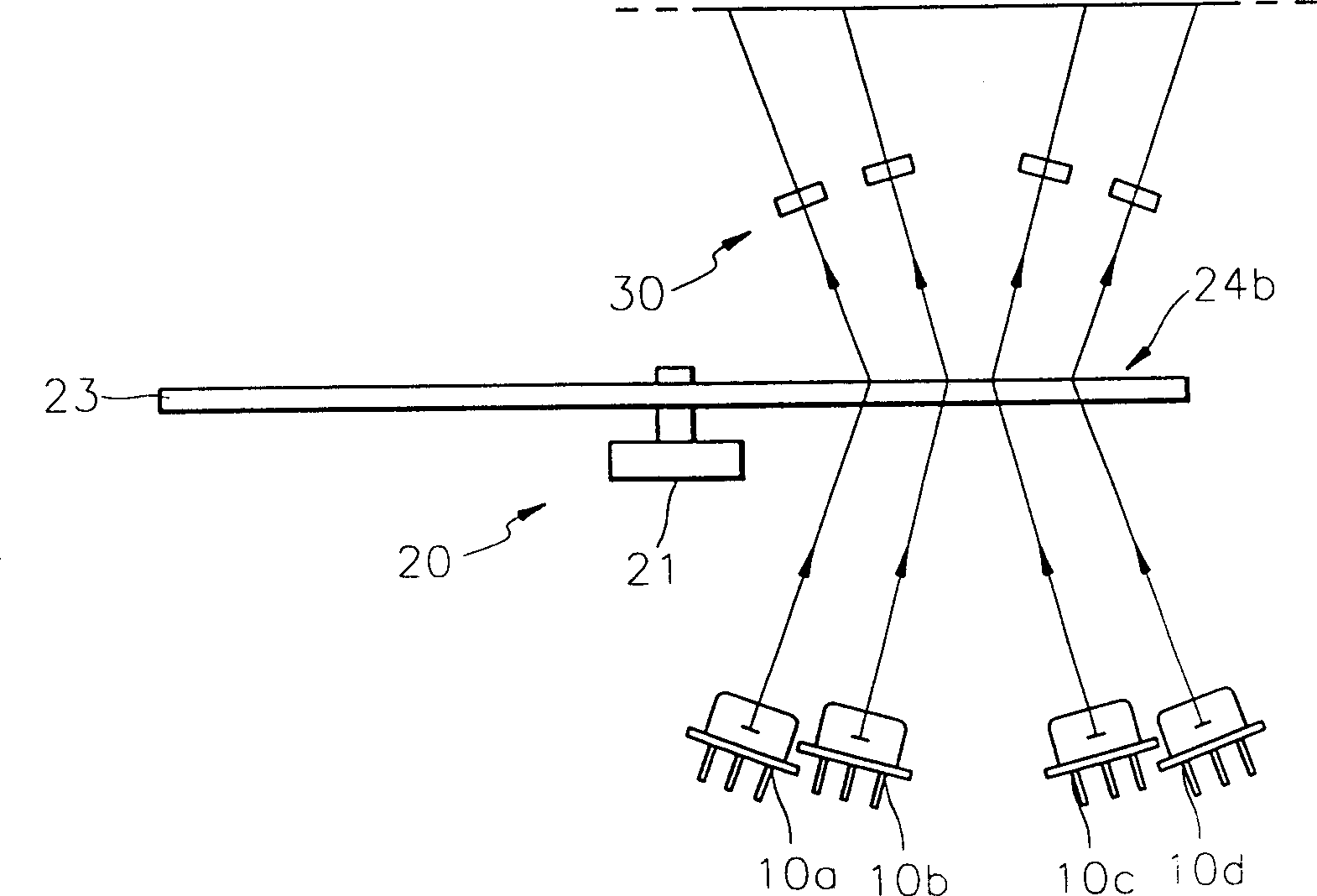

Polygonal laser scanner for coating removal

ActiveUS20110147354A1Other artistic work equipmentsLaser beam welding apparatusLight beamLaser scanning

A laser scanner system for removing a coating from a surface. The system includes a laser source for generating a laser beam; a focusing optic operative to receive, focus and re-direct the laser beam; a rotating multi-faceted mirror for receiving and reflecting the focused laser beam, wherein the rotating multi-faceted mirror repeatedly translates the reflected focused laser beam in one direction along an arc path and through a first focal point, and wherein passage of the laser beam through the first focal point results in divergence of the beam; a reimaging mirror for receiving and reflecting the divergent laser beam toward a work surface, wherein the reimaging mirror produces an image of the first focal point and its path; and wherein the rotating multi-faceted mirror and the reimagining mirror cooperate to produce a beam cross-over region having a minimal cross-sectional area relative to other points along the beam path, and wherein the beam cross-over region is located between the reimaging mirror and the work surface.

Owner:XYREC IP BV

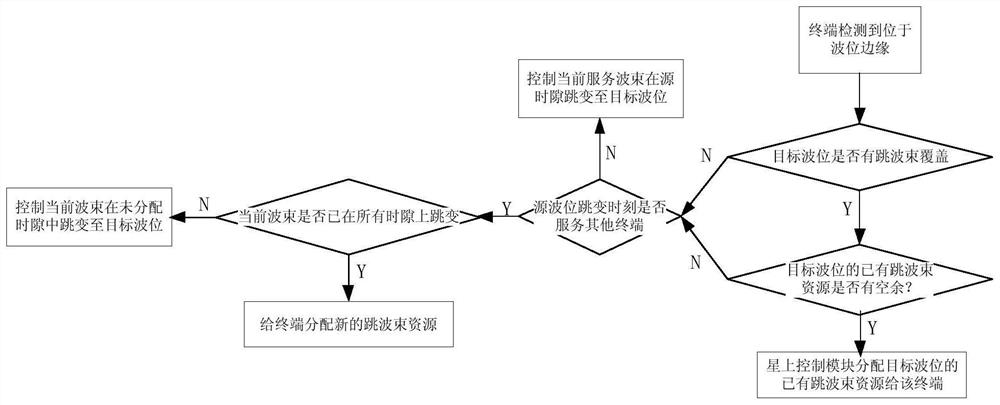

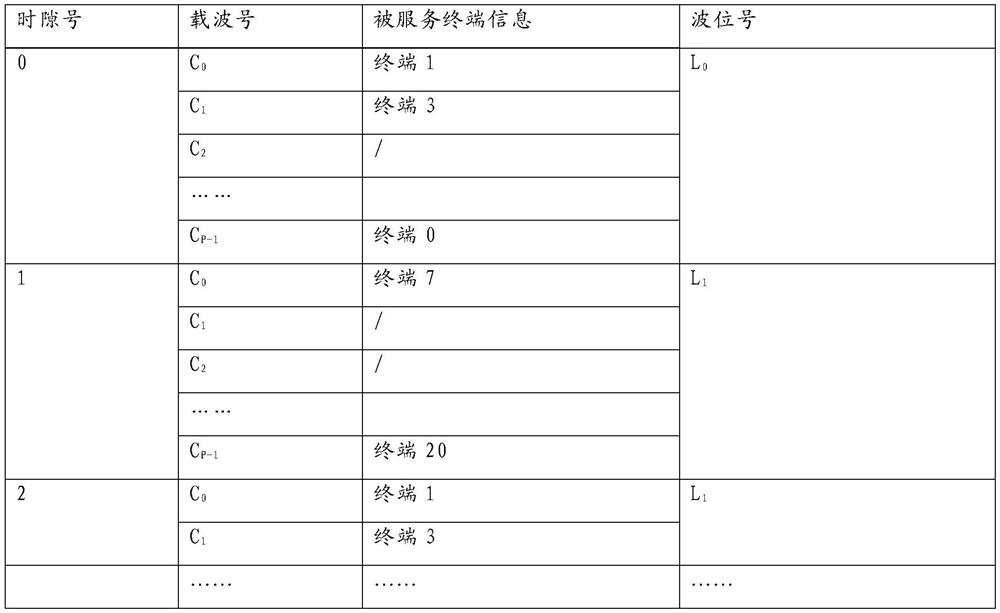

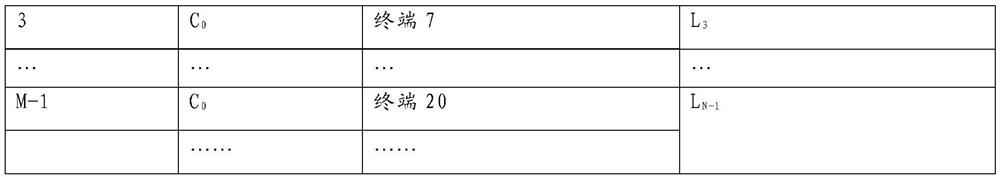

Beam-hopping satellite cross-beam-position resource allocation method

PendingCN113692051AAchieving continuous serviceRealize non-inductive switchingNetwork topologiesTelecommunicationsResource assignment

The invention provides a cross-beam-position resource allocation method for a beam-hopping satellite, which is used for solving the problem of resource allocation when a user terminal moves across a beam position in a satellite beam-hopping scene. The basic idea of the method is that when a user terminal moves to the coverage range of another beam position from one beam position, a satellite control module determines the resources of the mobile terminal according to the beam jump of a source beam position and a target beam position; wherein the principle of resource allocation is to provide non-inductive cross-beam service for the mobile terminal on the premise of not influencing the existing online user terminal. According to the method, a resource allocation scheme during terminal beam crossing is designed for a satellite beam-hopping scene, the implementation principle is simple, the operability is high, and the reliability is relatively high. The method can be applied to a related hopping beam satellite communication system, and has guiding significance for the design of a satellite load.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

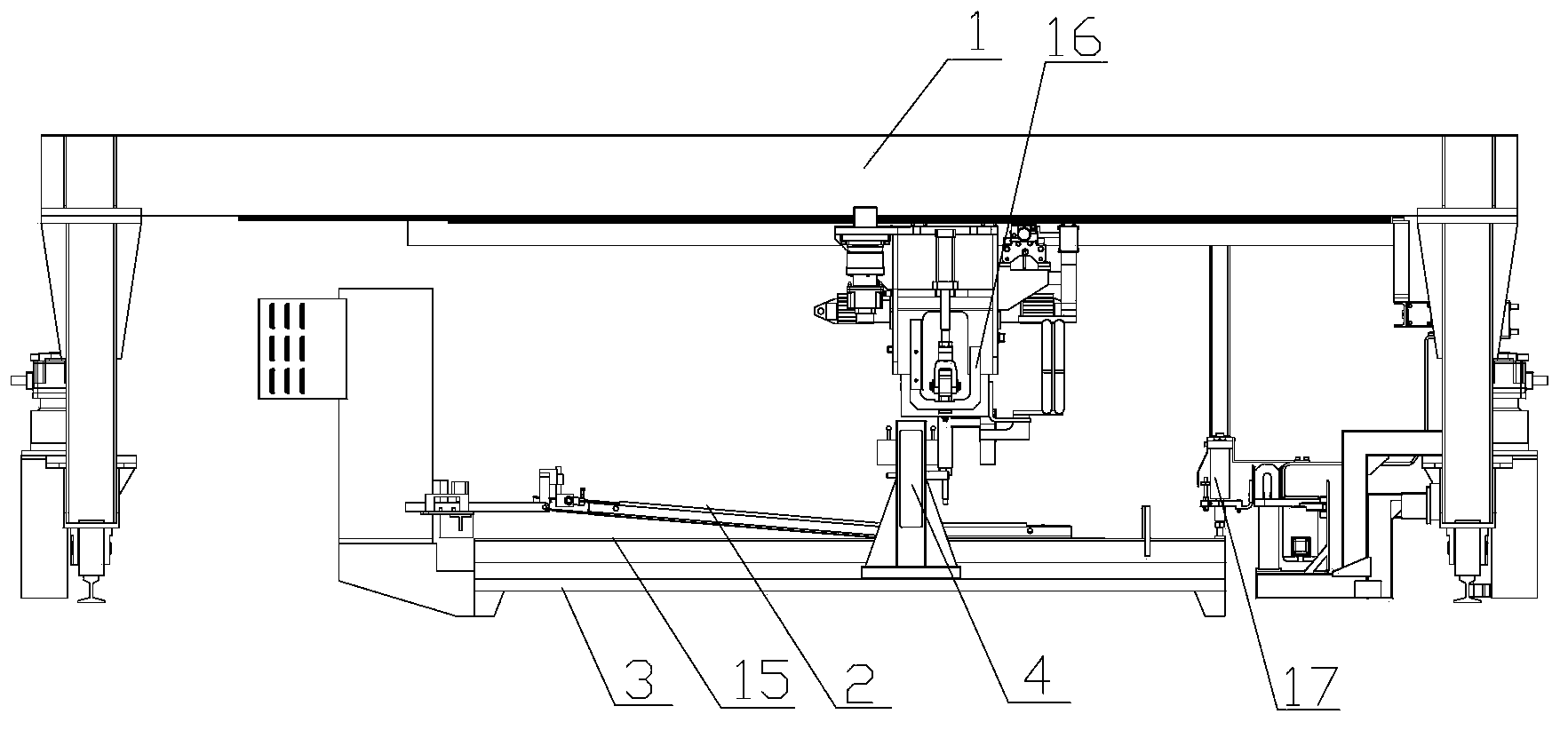

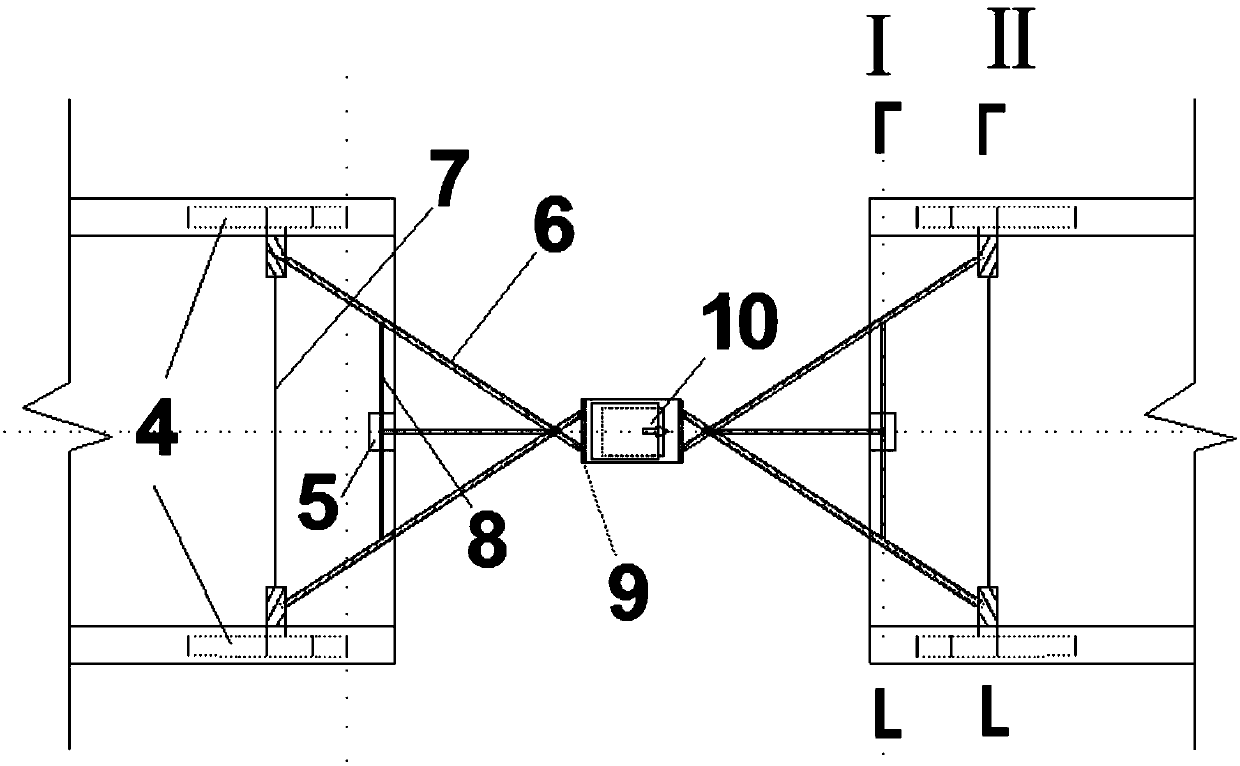

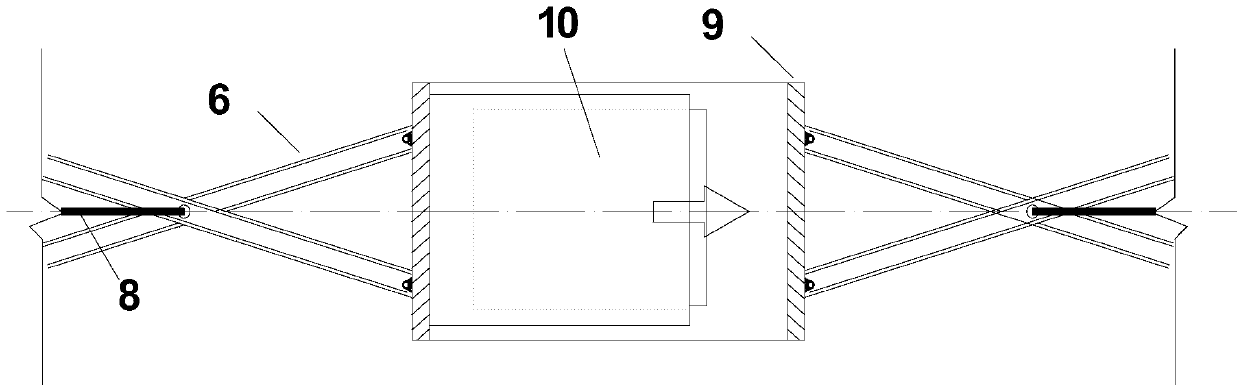

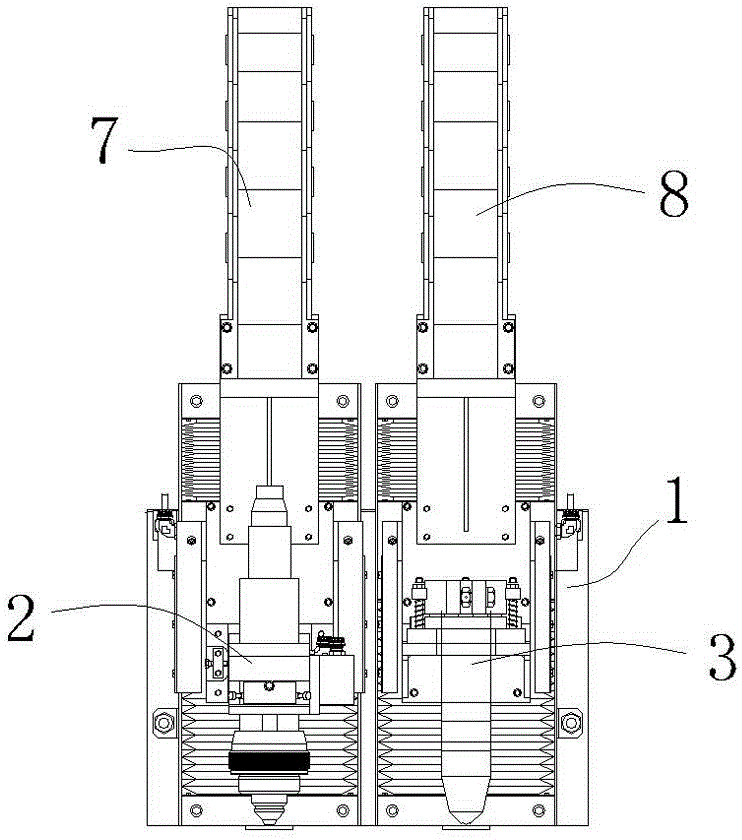

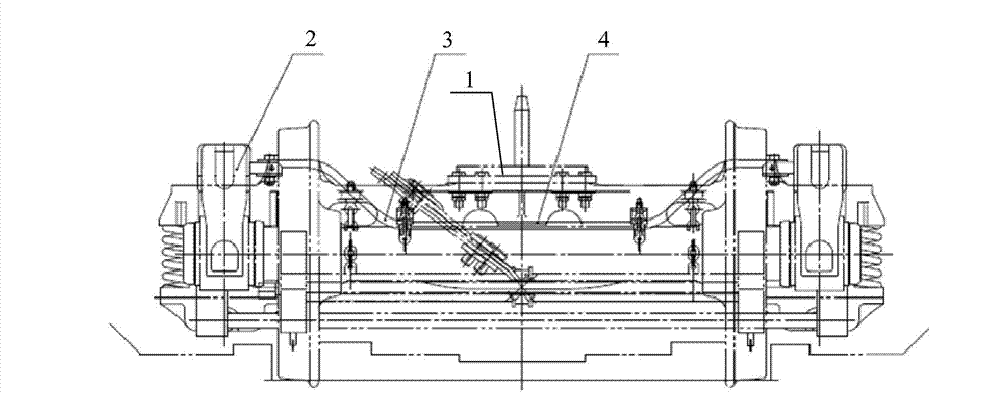

Compressing device for single-side spot welding of stainless steel sidewall, spot welding machine and welding process

ActiveCN103567617AHeight adjustableImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesBeam crossingSpot welding

The invention relates to a compressing device for single-side spot welding of a stainless steel sidewall, a spot welding machine and a welding process. The spot welding machine comprises a welder gantry, a welding platform, and spot welding electrodes. The welding platform is used for holding a sidewall to be welded. The compressing device is disposed on the welding platform and comprises two vertical posts arranged on two sides of the welding platform, and a cross beam crossing over the welding platform and connecting the two vertical posts. The cross beam is provided with a plurality of compressing parts used for compressing the sidewall. The vertical posts are movably connected with the welding platform. A frame and a wallboard are integrally compressed with the compressing device, the frame is tightly attached to the outer face of the wallboard and the platform, corrugated deformation of a workpiece is eliminated by pressure of an air cylinder, the wallboard and the frame form a whole after spot welding, and the whole is higher in rigidity; after compressing force is removed, the outer surface can still be even and flatness is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Optical structure for a laser input device

InactiveUS20080150897A1Accurately determineCathode-ray tube indicatorsInput/output processes for data processingLight beamOptoelectronics

An optical structure of a laser input device includes an input device body; a laser source, inside the input device body to emit a laser light beam which travels linearly along a determined incident path to a work surface; a splitter, having a first interface and a second interface behind the first interface, wherein the first interface and the second interface are in a light reflecting path of the laser light beam and reflect respective axial light beams which have the same frequency and intersect with each other; and a light sensor, located at an intersection of the axial light beams for sensing a light interference strip pattern formed by intersecting the axial light beams. Moving direction and displacement of the input device on a work surface can be determined more precisely by sensing the change of the light interference strip pattern.

Owner:LEAHSIN TECH +1

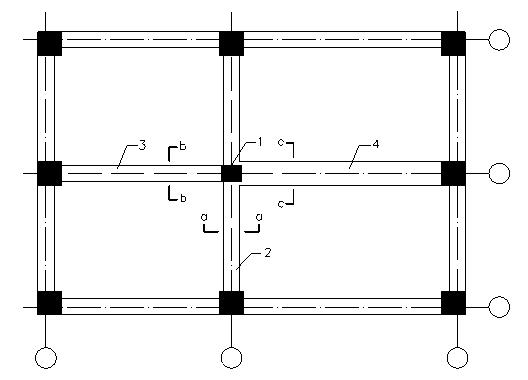

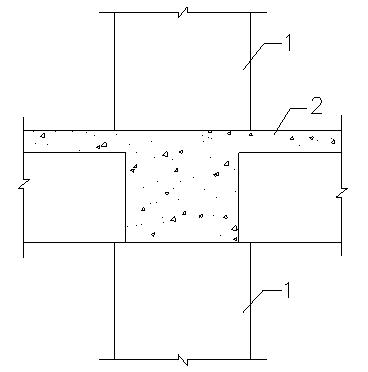

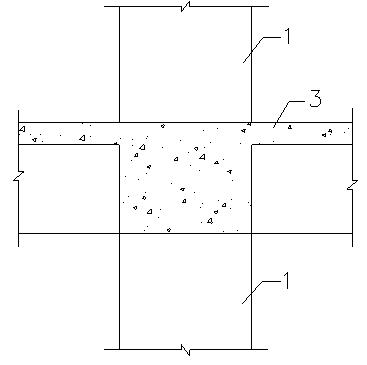

Reinforcement lightweight aggregate concrete flat beam structure

InactiveCN102425231AImprove punching resistanceSolve the problem of overcrowdingShock proofingSocial benefitsSteel bar

The invention relates to a reinforcement lightweight aggregate concrete flat beam structure which comprises a column, a beam and a plate, wherein the beam is a flat beam made of a reinforcing steel bar and lightweight aggregate concrete, the width of the flat beam is more than or equal to the height; and the column is a reinforcement lightweight aggregate concrete column. The reinforcement lightweight aggregate concrete flat beam structure provided by the invention also has better properties of light weight, energy saving, environment friendliness, good durability and the like of the lightweight aggregate concrete under the condition of the advantages of reducing floor height, avoiding pipeline beam crossing and the like, greatly reduces self gravity of the whole building structure and improves earthquake resistant behaviour of the structure while ensuring bearing capacity, and has remarkable economic and social benefits.

Owner:FUZHOU UNIV

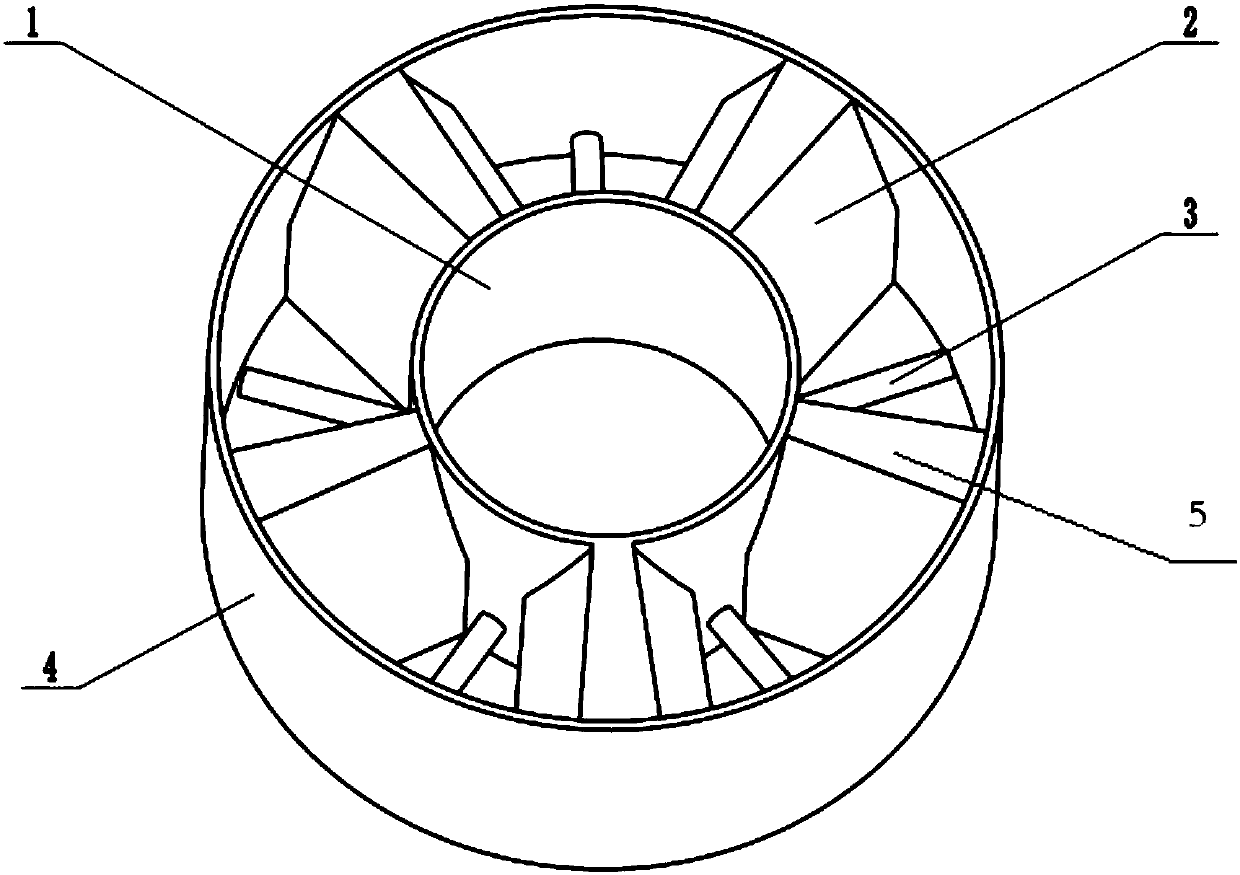

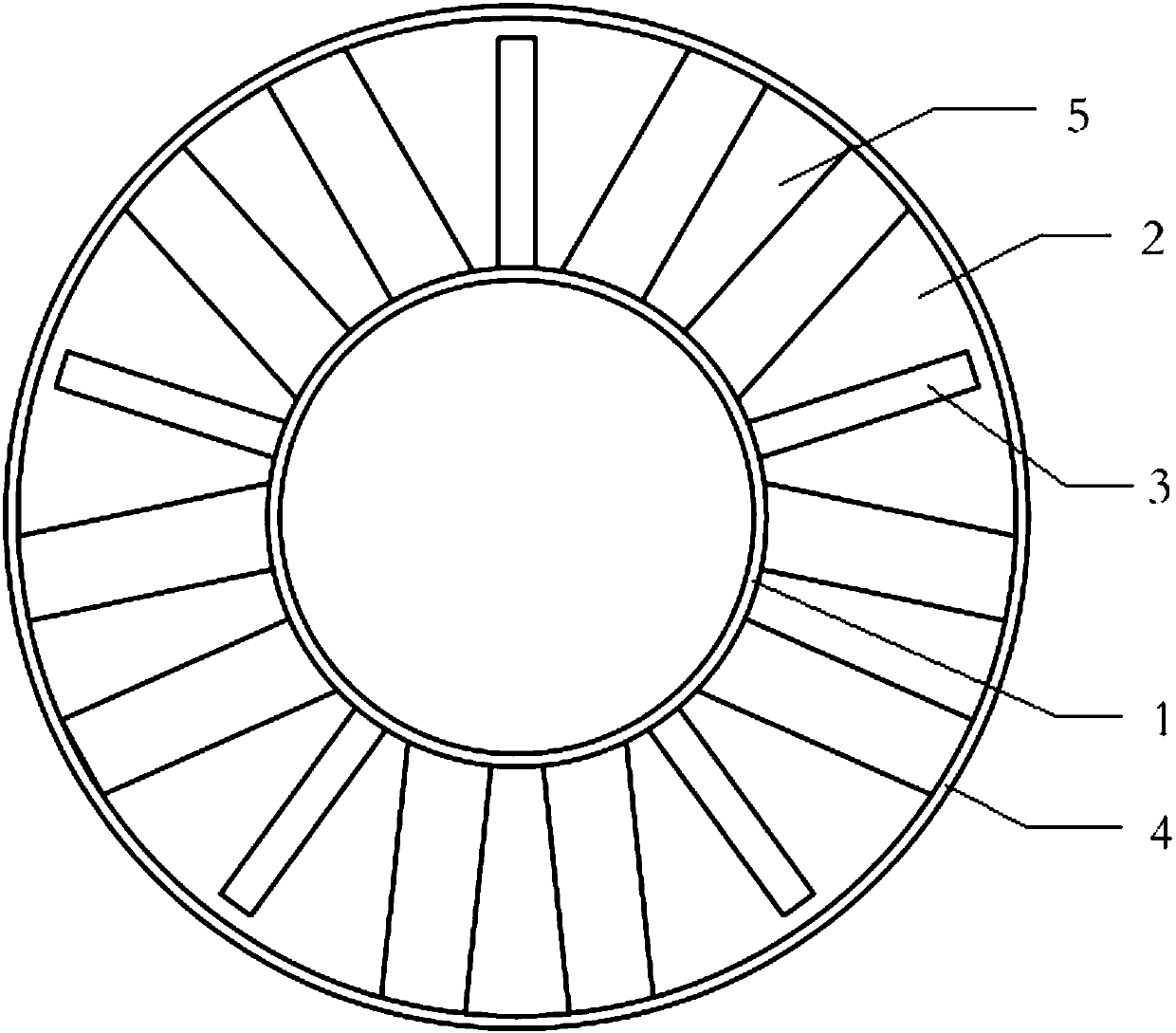

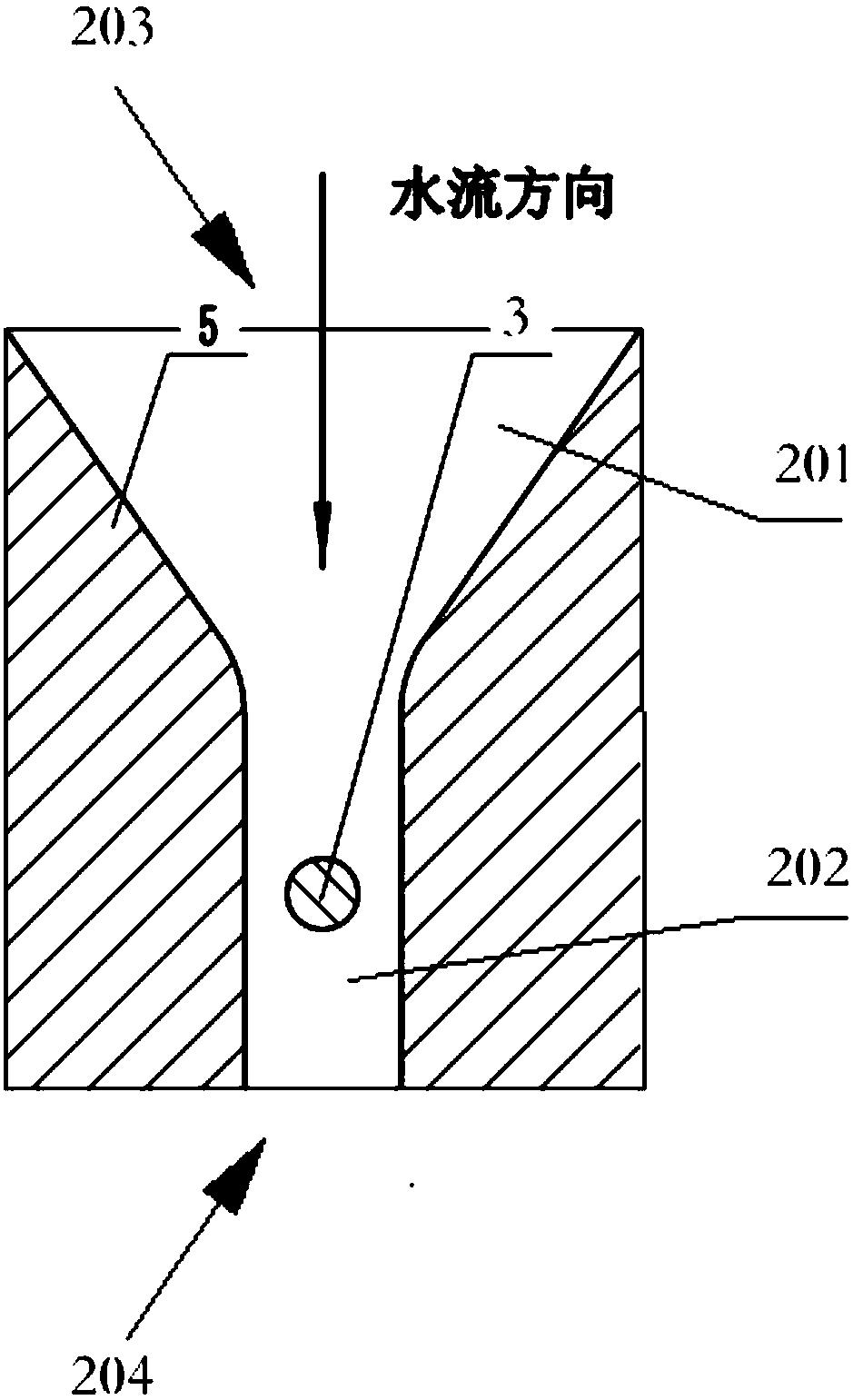

Piezoelectric generating profile instrument damping disc based on Karman vortex street phenomenon

ActiveCN107941198ASolve the speed problemSolve the energy capture problemBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamWater flow

The invention discloses a piezoelectric generating profile instrument damping disc based on Karman vortex street phenomenon. The piezoelectric generating profile instrument damping disc comprises a profile instrument connection support and a speed increase chamber, and also comprises a cantilever beam crossing the speed increase chamber and having one end hanging in air, and an energy-storage unit, a piezoelectric layer is attached to a peripheral part of the cantilever beam, so that water flow passes through the speed increase chamber, and the cantilever beam vibrates for generating and storage is realized to the energy-storage unit. According to the piezoelectric generating profile instrument damping disc, by arranging the cantilever beam in the speed increase chamber, damping is generated during a damping disc working process, a part of energy can be simultaneously recovered, and speed regulation and control as well as energy collection can be simultaneously solved.

Owner:ZHEJIANG UNIV

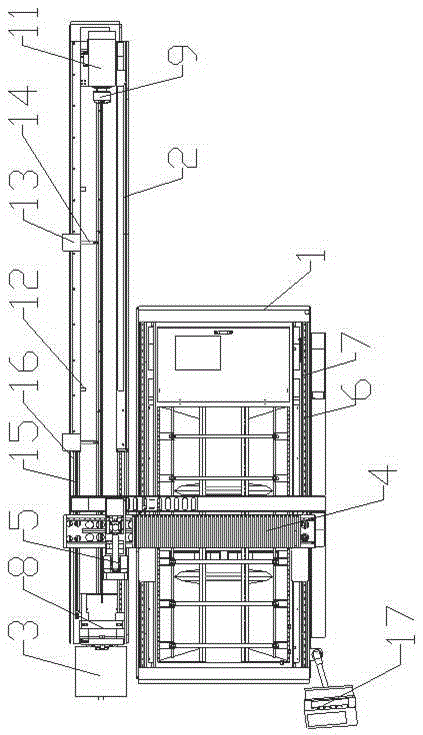

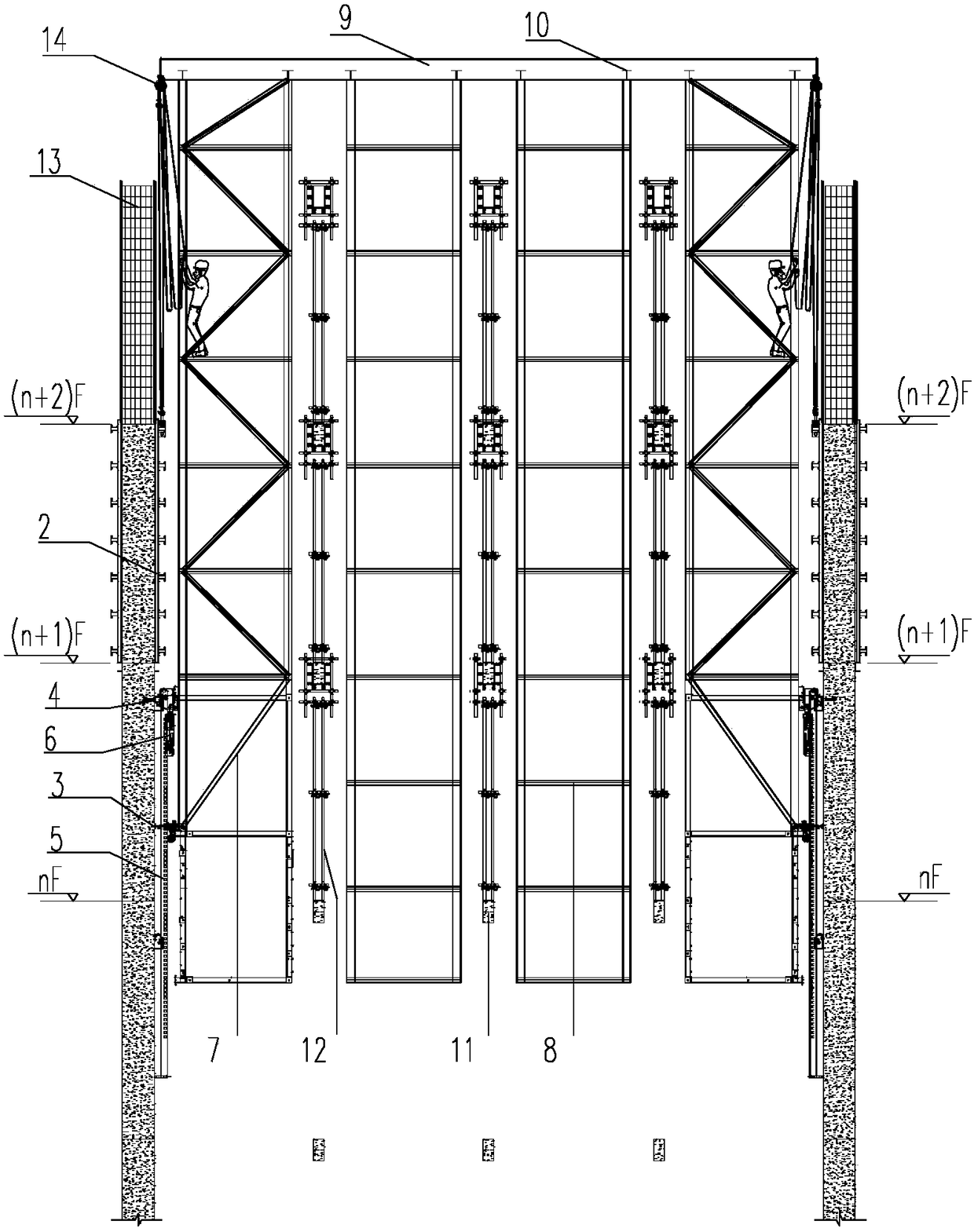

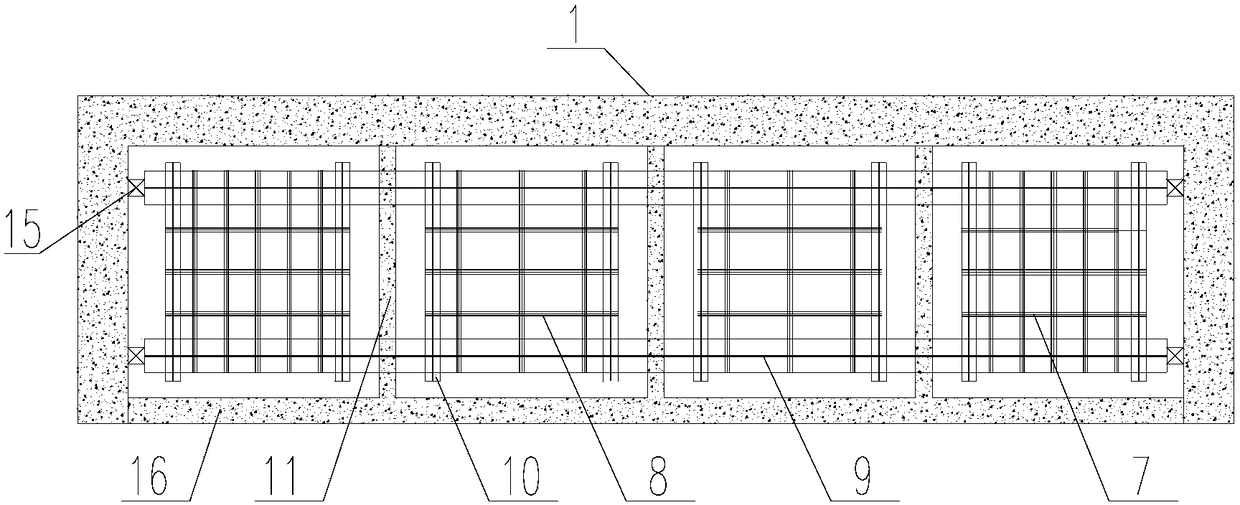

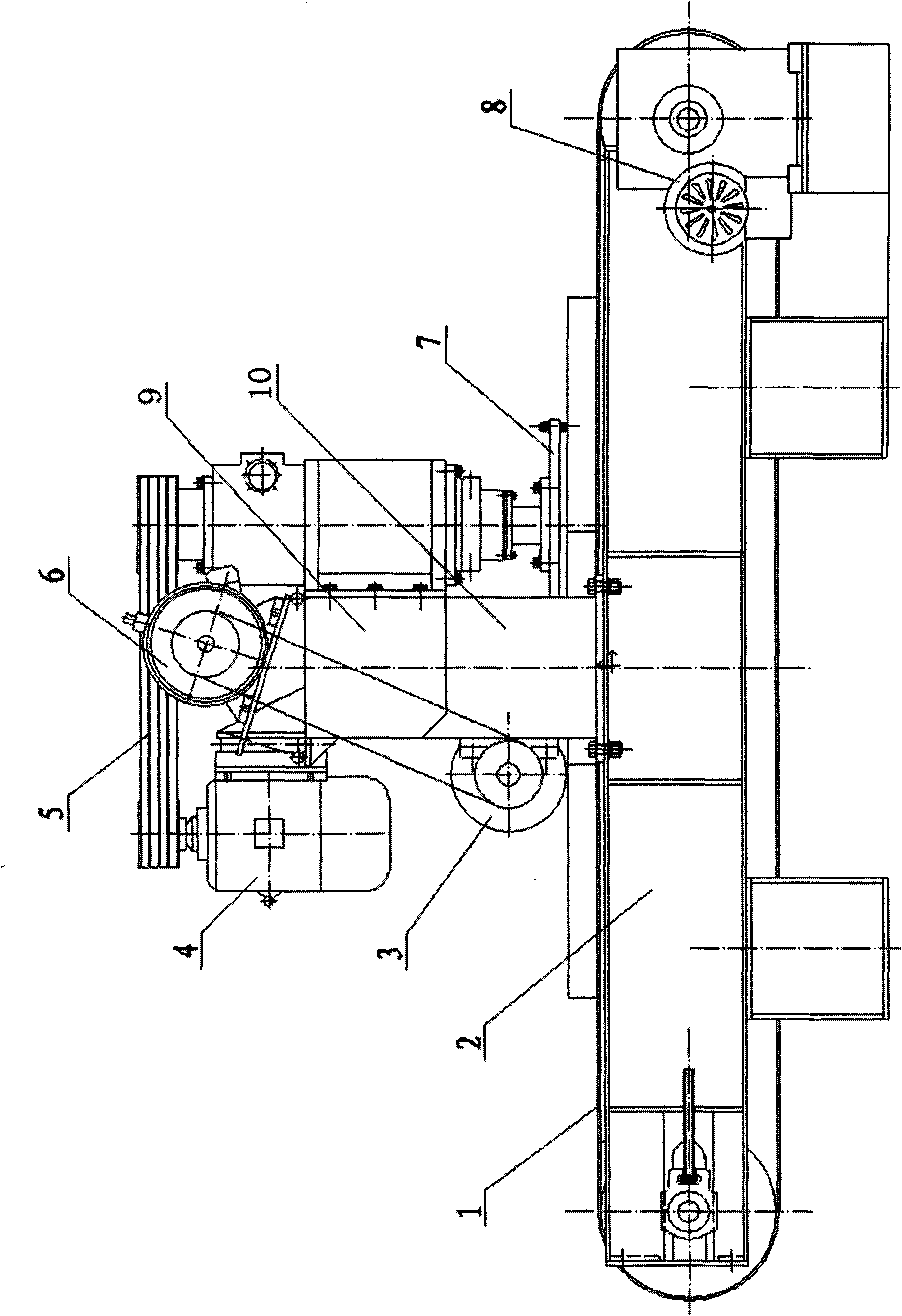

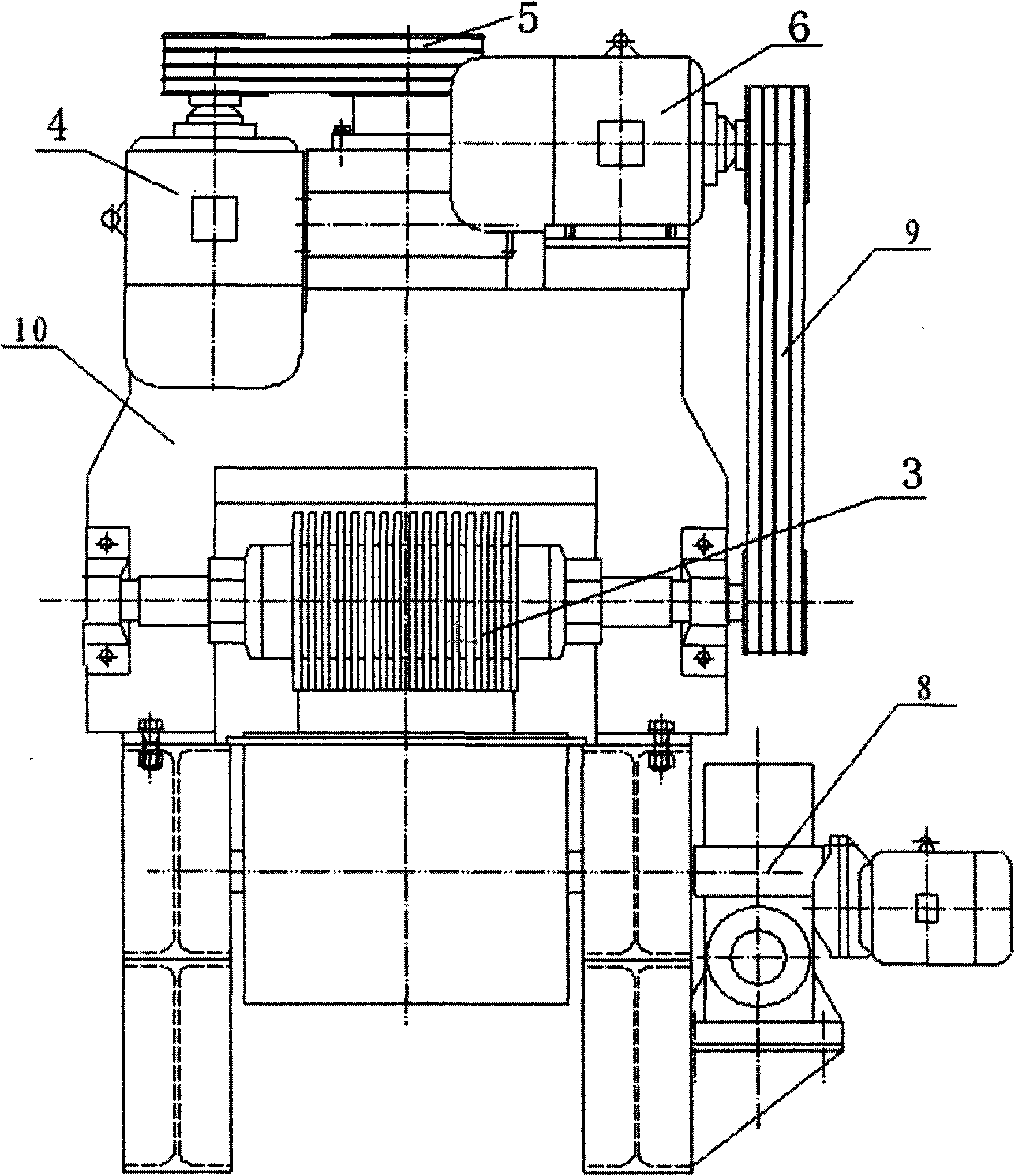

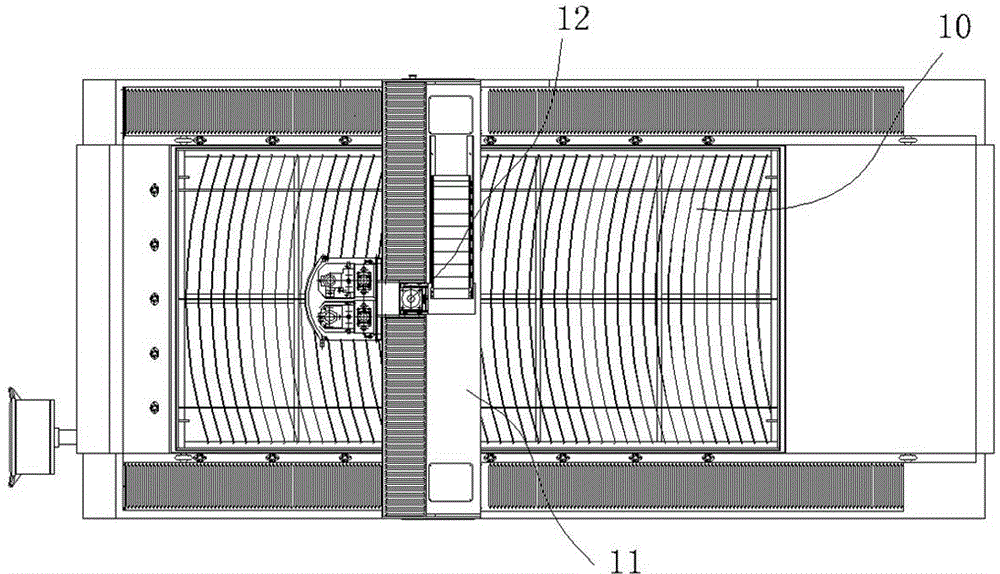

Concrete-overhead-beam crossing self-climbing integrated drum rack system and construction method thereof

PendingCN108286332AConstruction safetyEfficient constructionForms/shuttering/falseworksRebarBeam crossing

The invention provides a concrete-overhead-beam crossing self-climbing integrated drum rack system and a construction method thereof, and belongs to the technical field of building construction. The problem that the elevator shaft construction efficiency of an independent tool type formwork system is low is solved. The system comprises bearing frame bodies, suspending frame bodies, lifting steel beams, large formworks, wall attaching devices, climbing shoes, guide rails and hydraulic systems. The large formworks and the climbing shoes are fixed to the two sides of an elevator shaft shear wall,the hydraulic systems are arranged on the bearing frame bodies, and the guide rails are arranged on the climbing shoes. The lifting steel beams are arranged on the tops of drum racks, the bearing frame bodies and the suspending frame bodies are hung on the lower portions of the lifting steel beams, and the bearing frame bodies are arranged on climbing machine positions at the two ends of an elevator shaft. The method includes the steps that the climbing shoes, the bearing frame bodies, the guide rails, the lifting steel beams and the suspending frame bodies are sequentially installed; construction layer rebars are bound, embedded parts are embedded, the large formworks are installed, concrete is poured, then a former layer of climbing shoes, lifting guide rails and climbing drum racks areinstalled, construction layer rebars are bound and the concrete is poured after climbing is completed, and construction is circulated sequentially.

Owner:SHANGHAI CONSTR NO 1 GRP

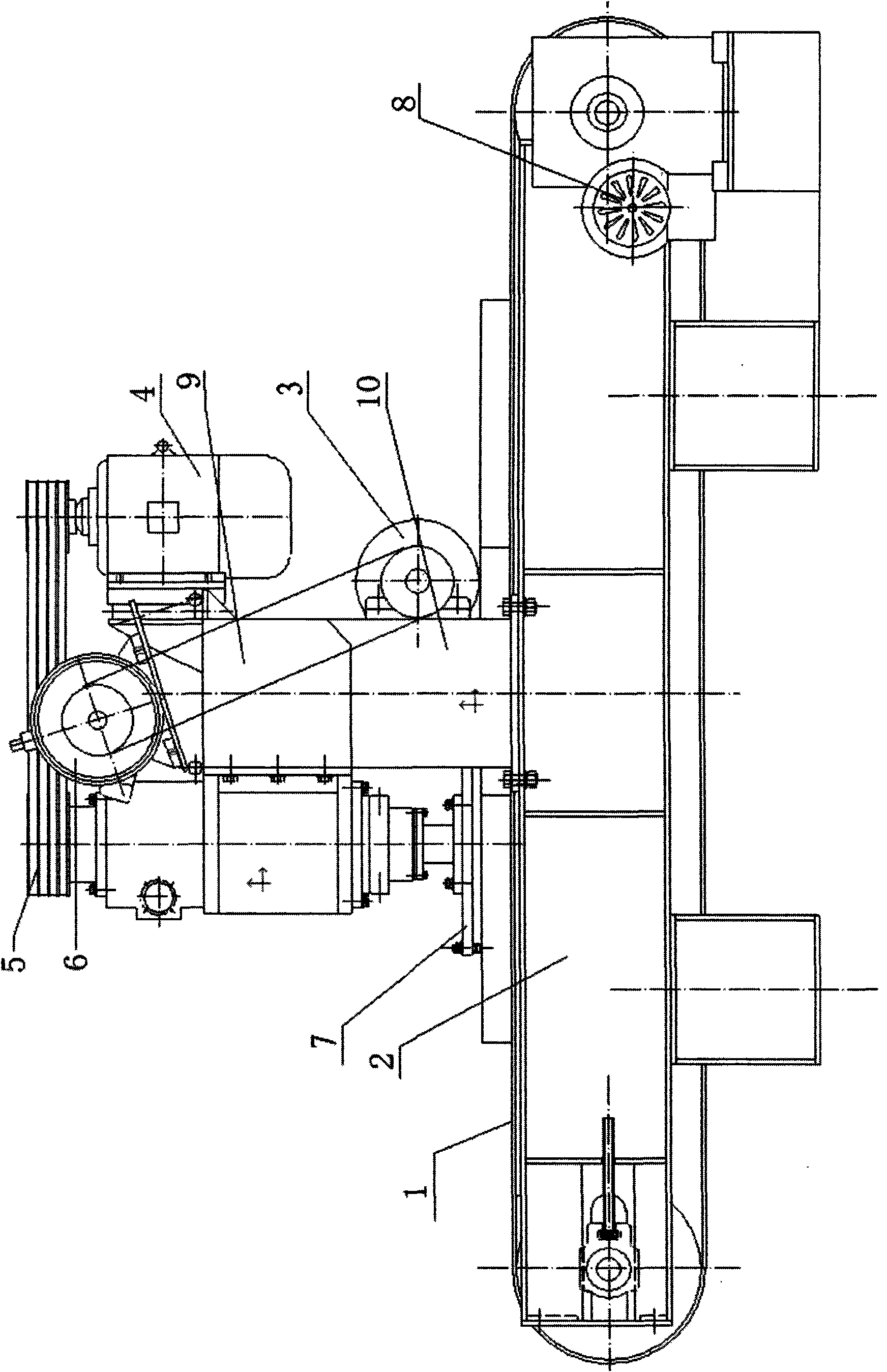

Automatic cement brick strip processing production line

InactiveCN101811328AUniform thicknessImprove work efficiencyStone-like material working toolsPlane surface grinding machinesProduction lineBrick

The invention relates to an automatic cement brick strip processing production line, which belongs to the technical field of building material processing mechanical structures. The automatic cement brick strip processing production line is characterized by consisting of two pieces of identical equipment which are arranged symmetrically, wherein a cement brick feed system adopts a plane conveyor belt structure and comprises a machine frame and a plane conveyer belt which is arranged above the machine frame and driven and controlled by a worm-gear reducing motor; the machine frame is fixedly provided with a beam crossing over the plane conveyor belt; the two pieces of equipment both adopt a dual head structure and comprise a saw bit and a plane millstone which are fixed on the beam; and the saw bit and the plane millstone are driven to rotate by a belt drive system which is connected with the saw bit and the plane millstone respectively and driven by a motor and a belt drive system which is driven by the motor. The automatic cement brick strip processing production line has the advantages of high equipment working efficiency, low processing cost, high quality of the processed strips, and great reduction of the labor intensity of workers.

Owner:李伯信

Concrete continuous rigid frame bridge assembly type partial load prevention pushing device and construction method thereof

PendingCN109610339AThere will be no problem of out-of-sync forceNo torsionBridge erection/assemblyBeam crossingRigid frame

The invention discloses a concrete continuous rigid frame bridge assembly type partial load prevention pushing device which comprises an embedded part, dowel bar pieces and a power system, wherein theembedded part comprises a web embedded part and a roof embedded part; the power system comprises a jack, an oil pump and two bearing plates; the web embedded part and the roof embedded part are buried on a beam crossing two sides in the continuous rigid frame bridge; the two bearing plates are arranged opposite to each other and respectively connected with the embedded part on the beam crossing two sides in the continuous rigid frame bridge by virtue of two sets of the dowel bar pieces; the jack is arranged between the two bearing plates; the oil pump is started, the jack is capable of synchronously applying jacking force to the L-shaped bearing plates on two sides, and the jacking force is uniformly applied to two sides of a closure orifice by virtue of the dowel bar pieces. The pushingdevice disclosed by the invention can be repeatedly used, the synchronism of the jacking force applied onto the beam crossing two sides is ensured, and the problems that the closure push is asynchronous and the structural force is non-uniform are solved.

Owner:HUNAN UNIV OF SCI & TECH

Four-spindle machining center special machine capable of clearing debris automatically

PendingCN110000615AReal-time cleaningWon't splashMetal working apparatusMaintainance and safety accessoriesWorking environmentEngineering

The invention relates to the technical field of machining equipment, in particular to a four-spindle machining center special machine capable of clearing debris automatically. The four-spindle machining center special machine comprises a base and an upper top plate, a standing column is fixedly connected to the base, a cross beam crossing the base is arranged on the standing column, a working table is slidably installed on the base, a sliding seat is slidably installed on the cross beam, a plurality of spindle boxes are installed on the two sides of the sliding seat, the spindle boxes comprisea plurality of spindles, ring flanges are connected to the bottom end faces of the spindles, air outlet holes are formed in the ring flanges, and the spindles are internally provided with ventilationchannels; and the four-spindle machining center special machine further comprises an external air source, the upper top plate is provided with slideways, the slideways are internally and slidably connected with sliding blocks, the external air source is connected with elastic hoses, the elastic hoses penetrate through the sliding blocks and communicate with the ventilation channels in the spindles, air from the external air source passes through the ventilation channels in the spindles from the interiors of the elastic hoses, and finally discharged from the air outlet holes in the ring flanges, a vertical air curtain is produced, debris on a cutter and the working table are cleared in real time, the cleanliness of the working environment is ensured, and the machining accuracy is improved.

Owner:宁波米诺机床有限公司

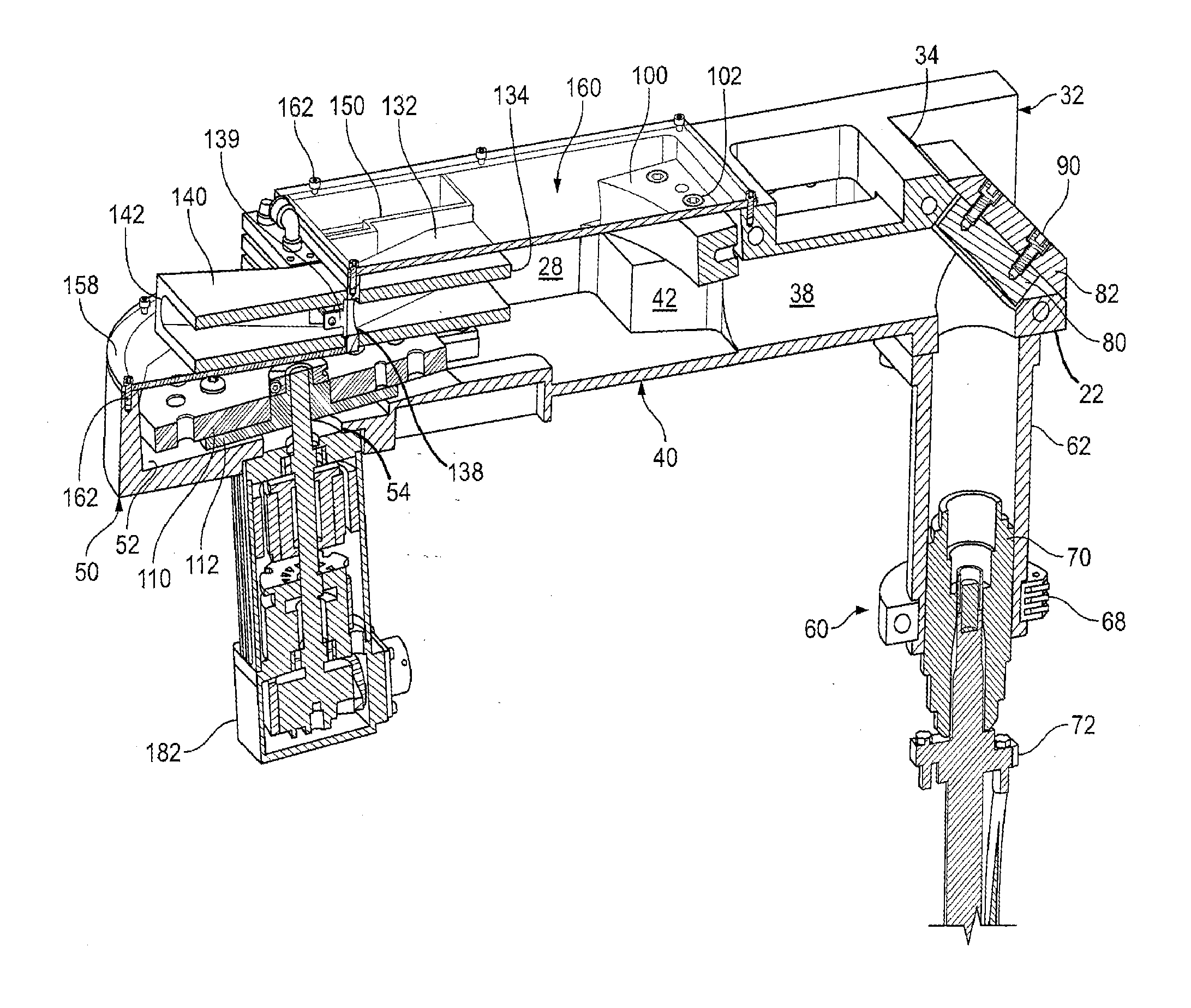

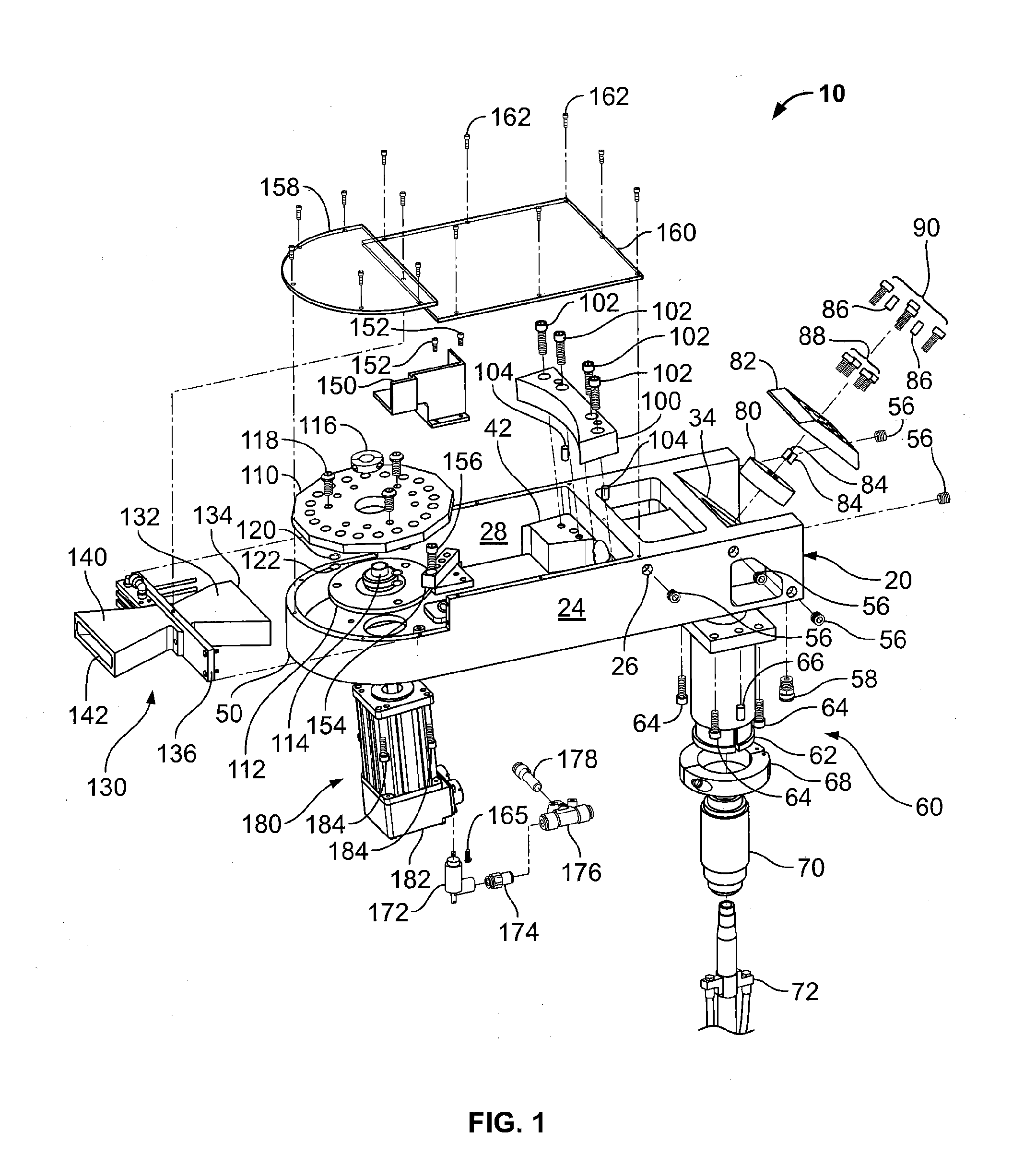

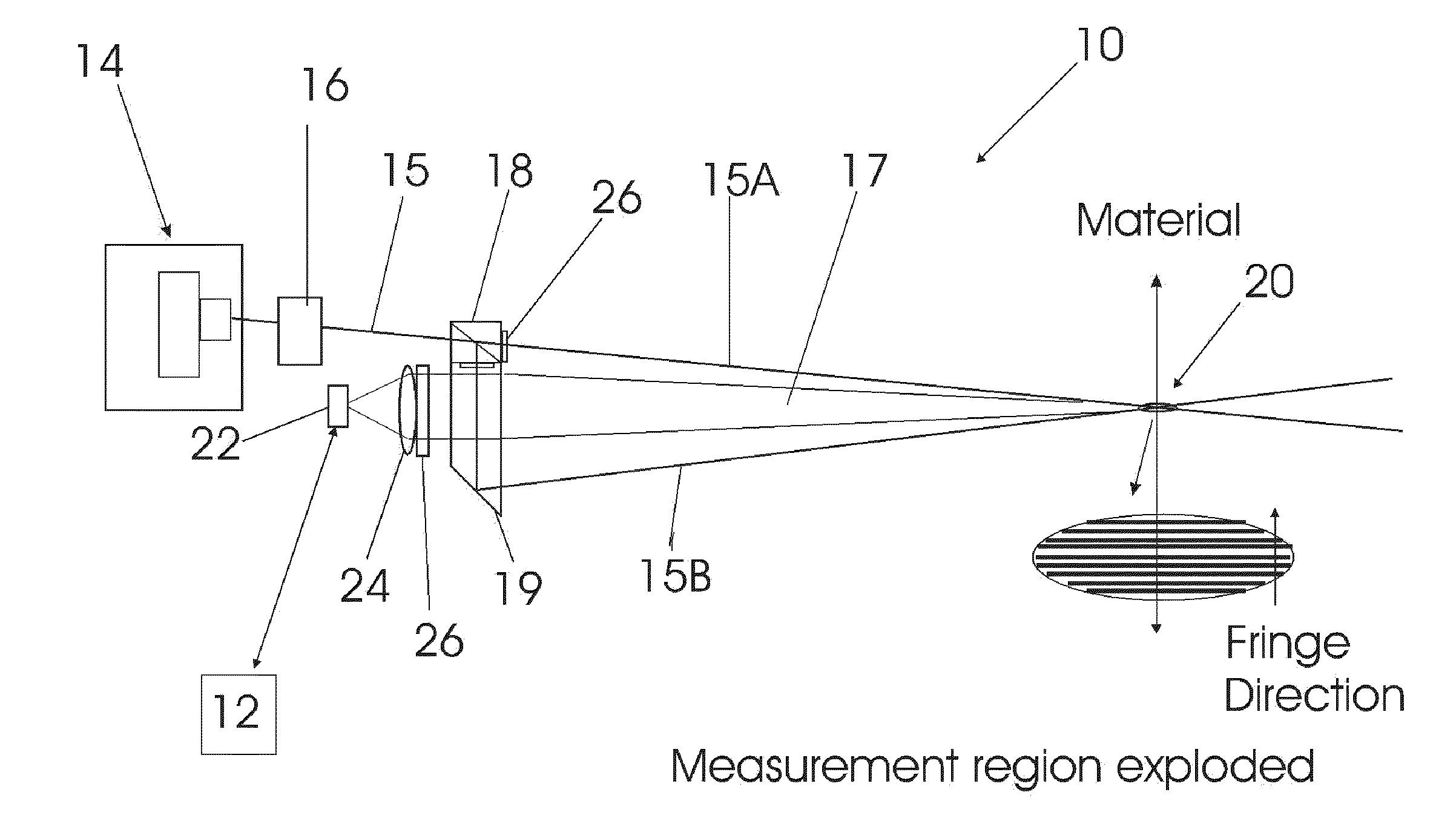

Device and method for measuring parts

ActiveUS20110007301A1Easy to measureAccurate materialsOptical rangefindersDevices using optical meansLight beamBeam crossing

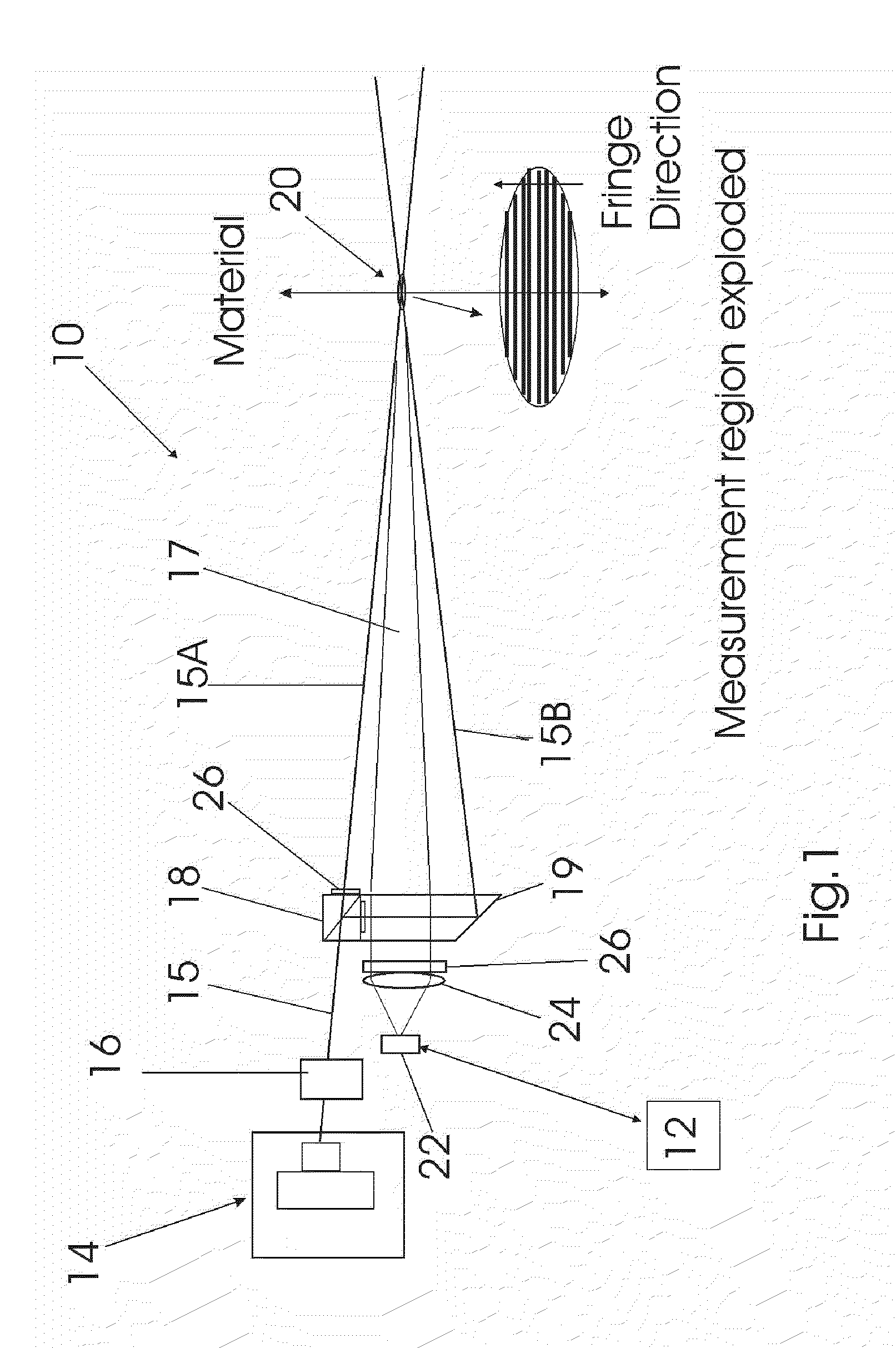

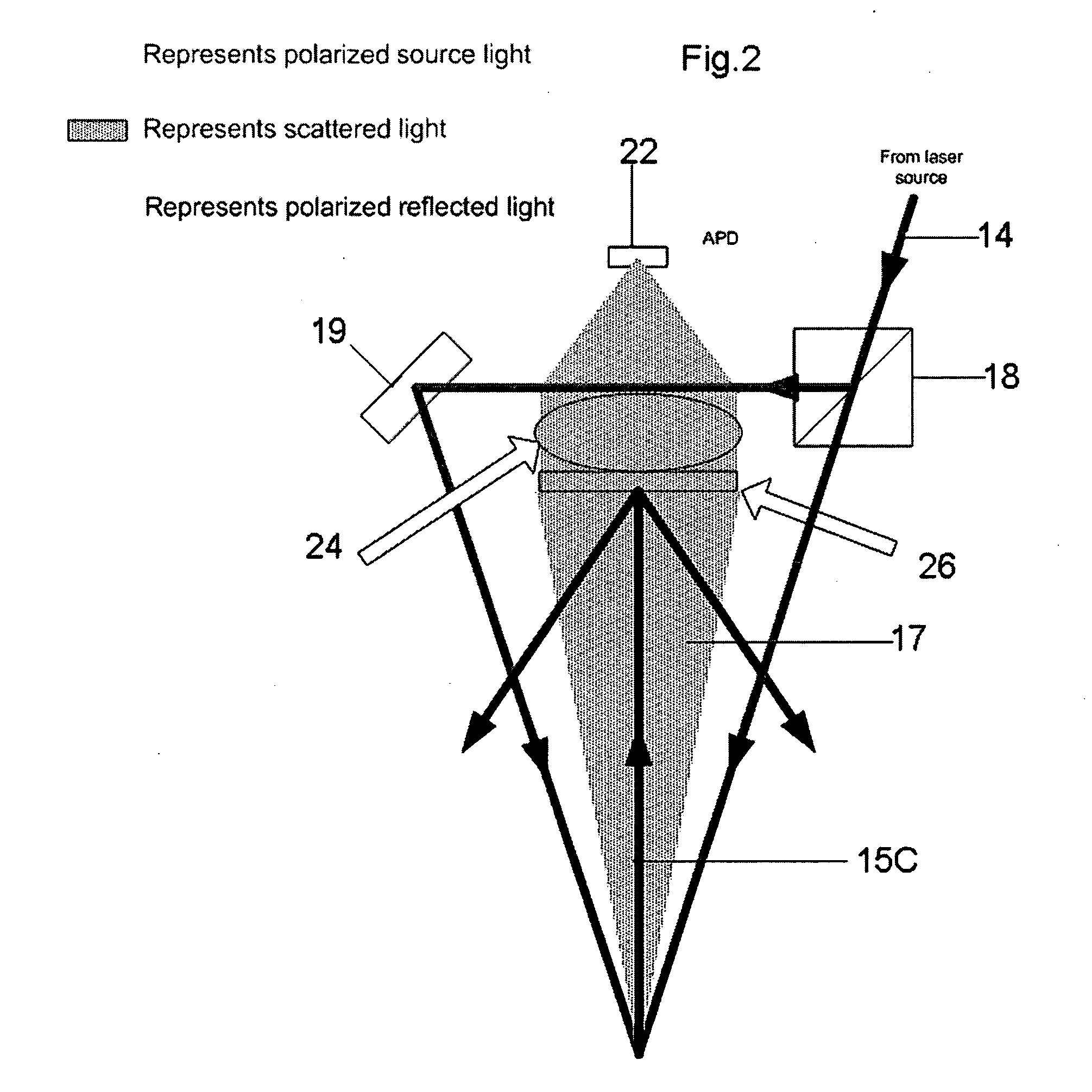

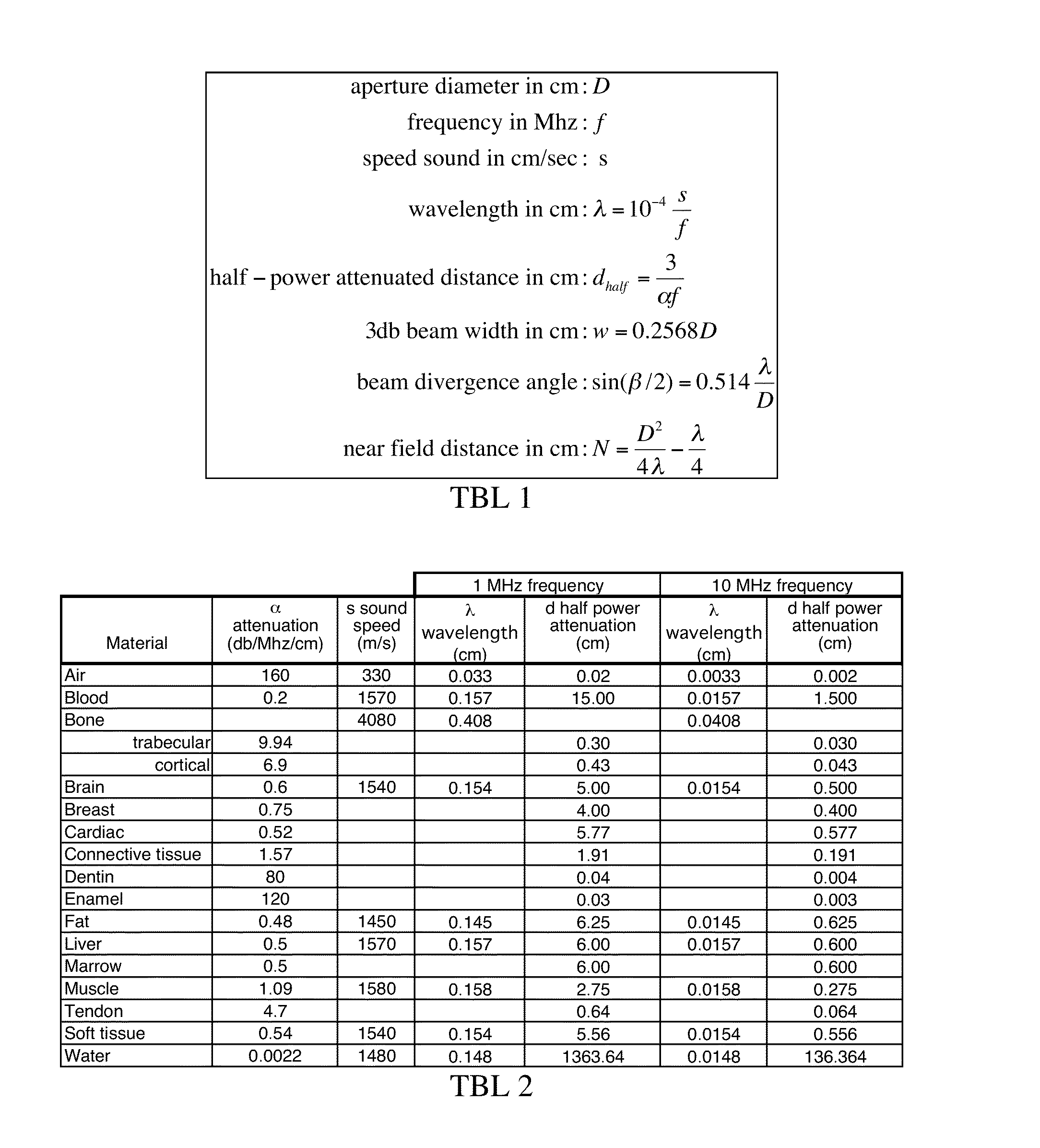

A device and method for measuring moving material includes a processor and operating software associated therewith; a light source for emitting at least two polarized light beams in a manner wherein the beams cross thereby creating an interference region and generate a set of fringes; a sensor aligned relative to the interference region wherein the fringes have a predetermined orientation to the directional movement of the material and wherein the sensor is operably equipped to receive scattered light emanating from the interference region and provide a time varying signal to the processor such that the processor can manipulate and convert the signal to speed and distance and a polarizing filter operably associating a polarizing filter with one of the sensor and the emitting means in a manner to substantially preclude reflected polarized light from the interference region back to one of the sensor and the emitting source.

Owner:NORDSON CORP

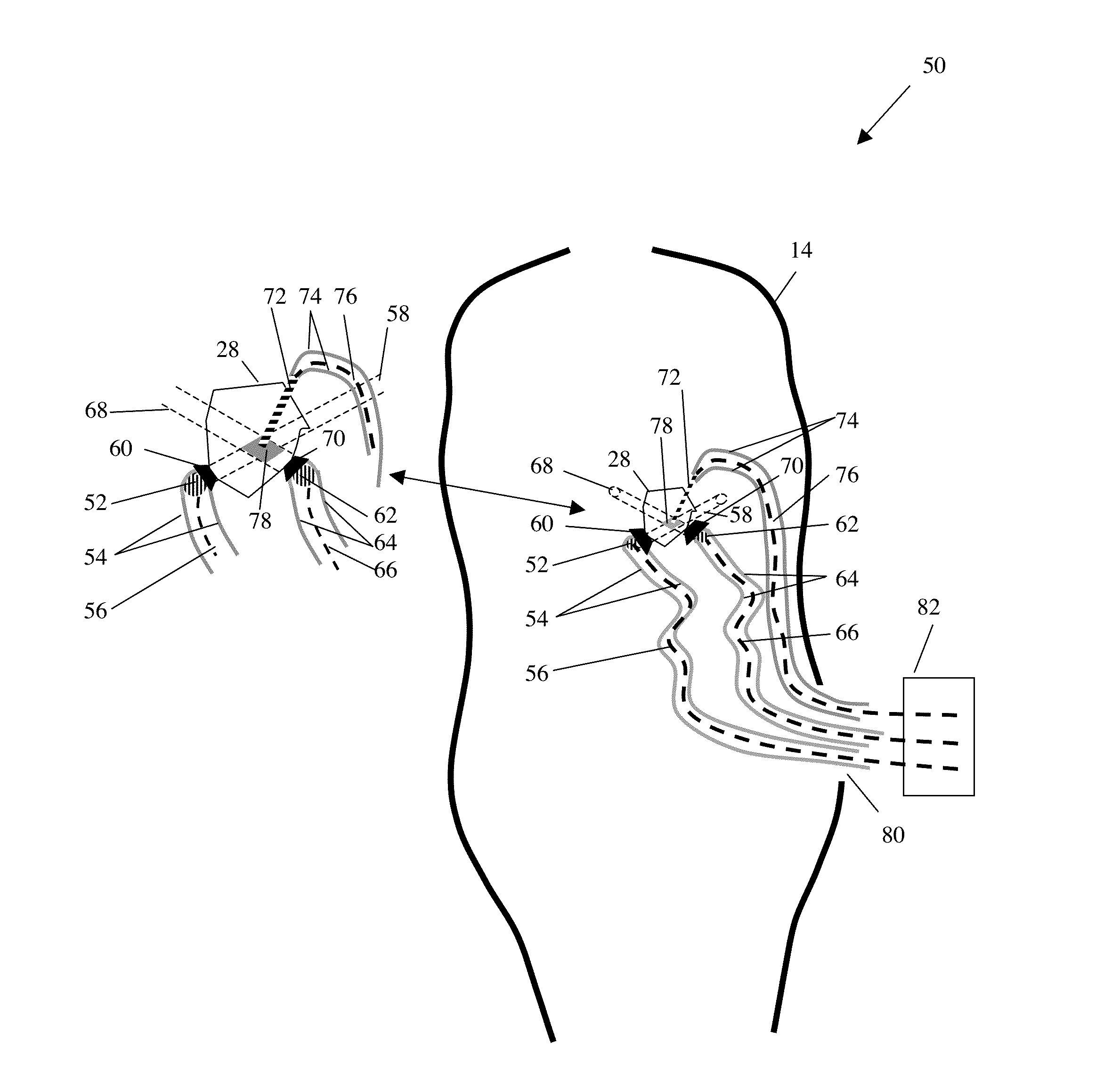

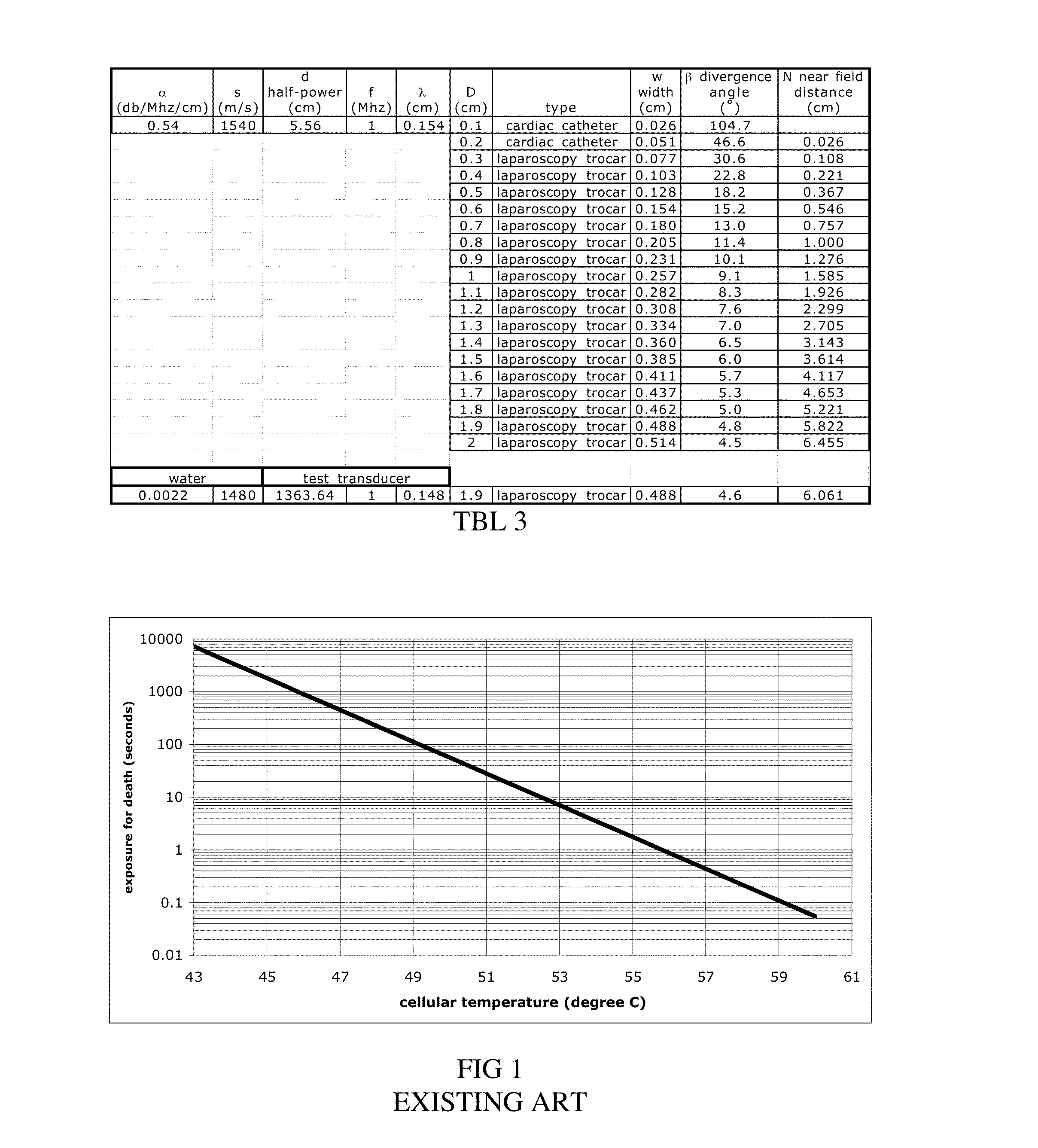

Multi-beam Ultrasound Device

InactiveUS20150141874A1Increase intensityUltrasound therapyChiropractic devicesUltrasound deviceLight beam

A multi-beam ultrasound device with intersecting beams is presented for use in medical therapy and industry. Multiple ultrasound beams interfere constructively and destructively depending on their phase at the target tissue, and this device and its methodology uses phase control for intensity enhancement at the beam intersection. Two among many embodiments are detailed: phase matching where the phases of the beams are determined and controlled to be equal, and phase sweeping where the phases of the beams are purposely varied.

Owner:WILSON KITCHENER CLARK

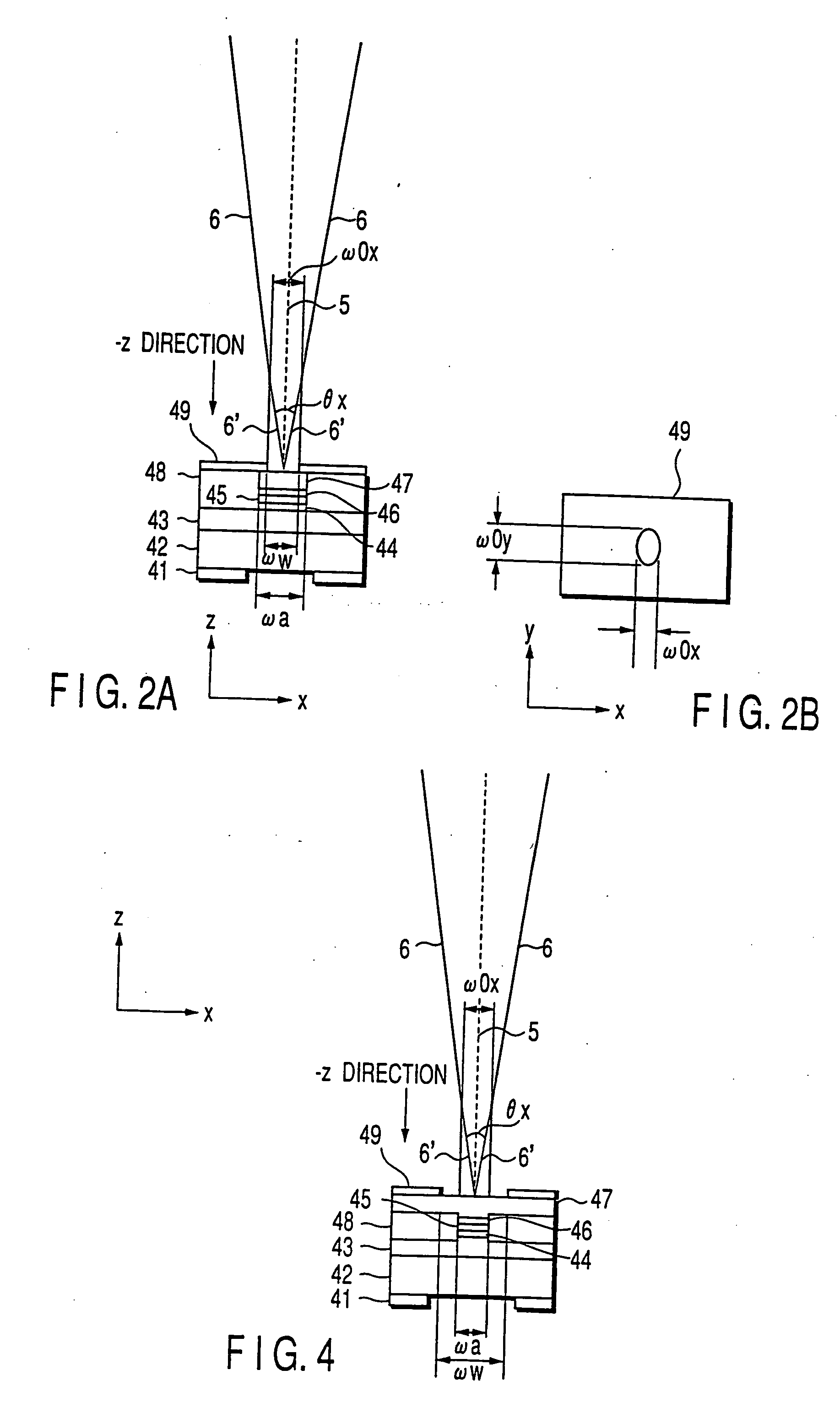

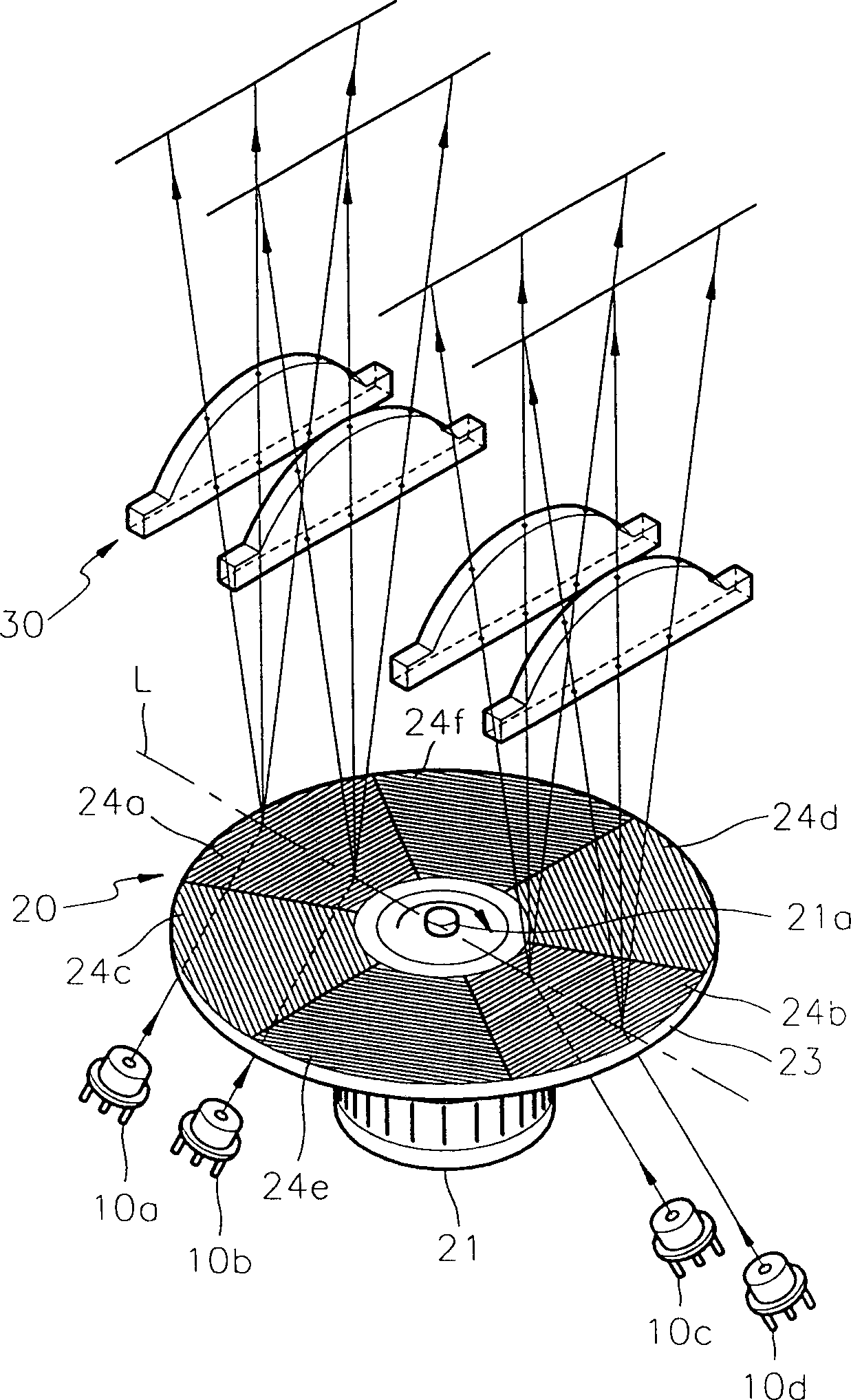

Multibeam scanning apparatus

A multi-beam scanning apparatus including at least two optical sources; a beam deflector including a deflection disc having a plurality of sectors for diffracting and transmitting incident beams, and a driving source for rotating the deflection disc, for deflecting and projecting beams emitted from the optical source; and a beam correcting means installed on a light path, for correcting the beams deflected by the beam deflector.

Owner:SAMSUNG ELECTRONICS CO LTD

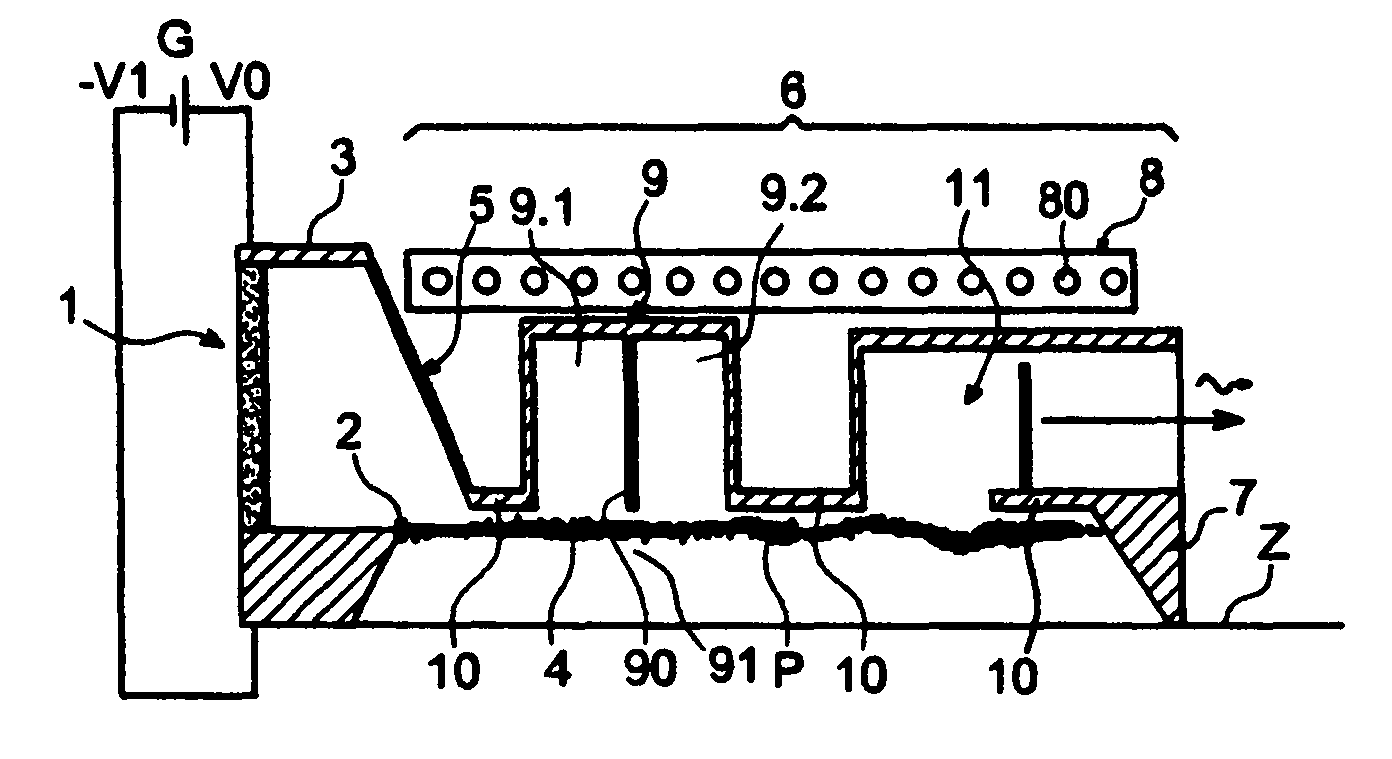

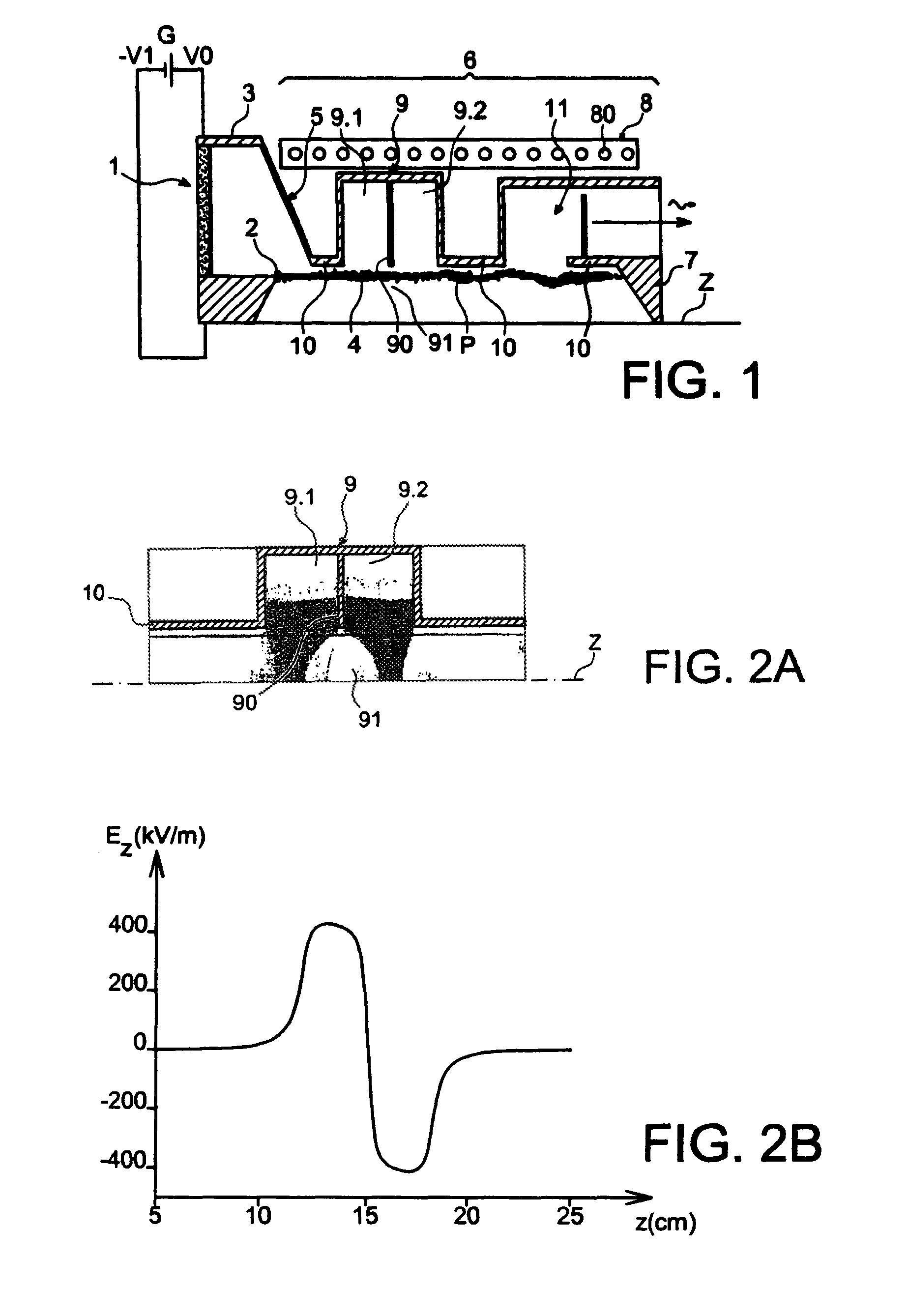

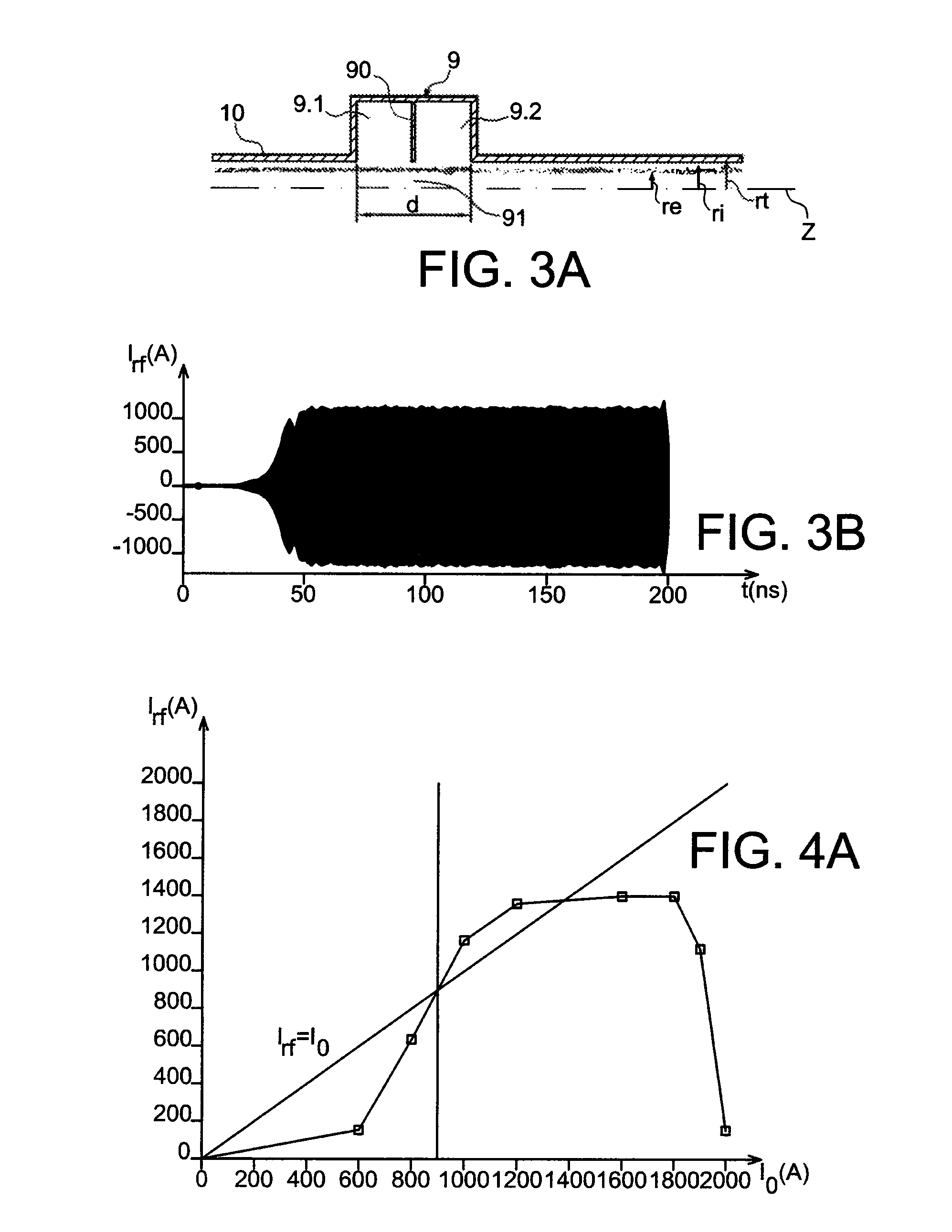

Strong power compact microwave tube

ActiveUS8324809B2Relatively lightweight, compact and inexpensiveMagnetronsKlystronsMicrowave tubeNetwork packet

A microwave tube including: a) an electron gun capable of producing a beam of electrons in the form of a hollow axisymmetrical cylinder in repetitive operation; and b) a body in which the beam is intended to propagate, the body ending with a collector and being provided with means for applying an axial magnetic field for guiding the beam and, upstream from the collector, with a resonant structure crossed by the beam, intended to group the electrons into a succession of packets (P). The resonant structure is formed with two coupled cavities which follow along the axis (Z) of the beam, the coupling being achieved via an inter-cavity region crossed by the beam, this structure having axial symmetry the axis of which is that of the beam and being dimensioned so that the transformation of the electrons in packets is accomplished at a frequency which is that of the π resonant mode of the resonant structure.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Table type laser and plasma cutting all-in-one machine

InactiveCN104858549AAvoid harmRealize the combinationLaser beam welding apparatusEngineeringLaser cutting

A table type laser and plasma cutting all-in-one machine comprises a gantry. A cutting table is arranged on the gantry, a cross beam crossing the cutting table is arranged above the cutting table, and a longitudinal driving device is arranged on the gantry. A transverse moving mechanism capable of moving along the cross beam is arranged on the cross beam, and comprises a seat and a transverse driving mechanism on the seat, a vertical laser cutting head and a vertical plasma cutting head are arranged on the seat, the laser cutting head is connected with the seat through a first lifting device, and the plasma cutting head is connected with the seat through a second lifting device. A laser cover and a plasma cover are further included, the laser cover is connected with the seat through a third lifting device, and the plasma cover is connected with the seat through a fourth lifting device. Plasma cutting and laser cutter are combined, respectively independent lifting protection devices are adopted in the design process, the hurt of cutting arc light, laser radiation and plasma radiation to a human body is avoided, and meanwhile the plasma cutting head and the laser cutting head can be prevented from hindering each other.

Owner:NINGBO JINFENG WELDING & CUTTING MACHINERY MFR

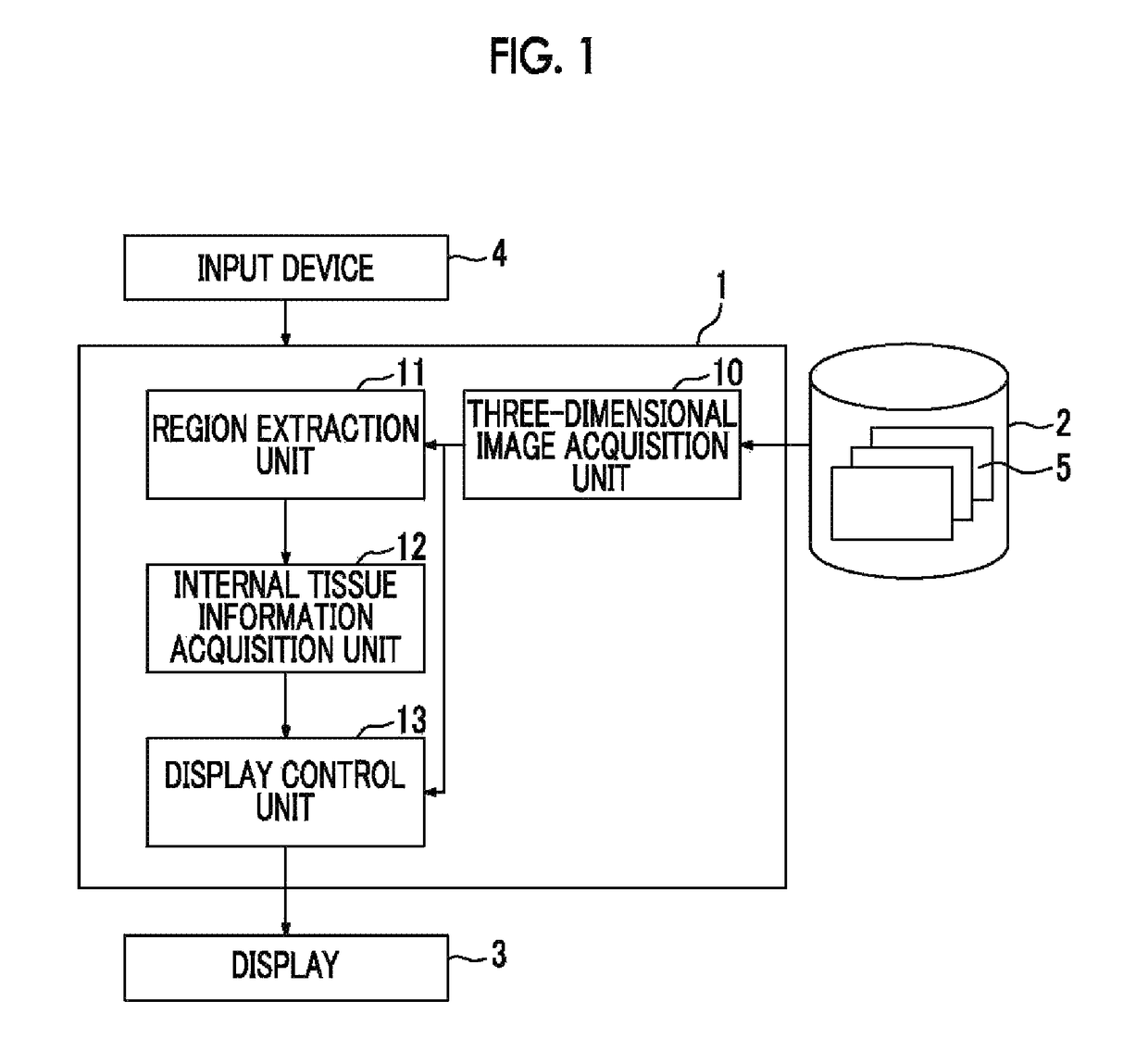

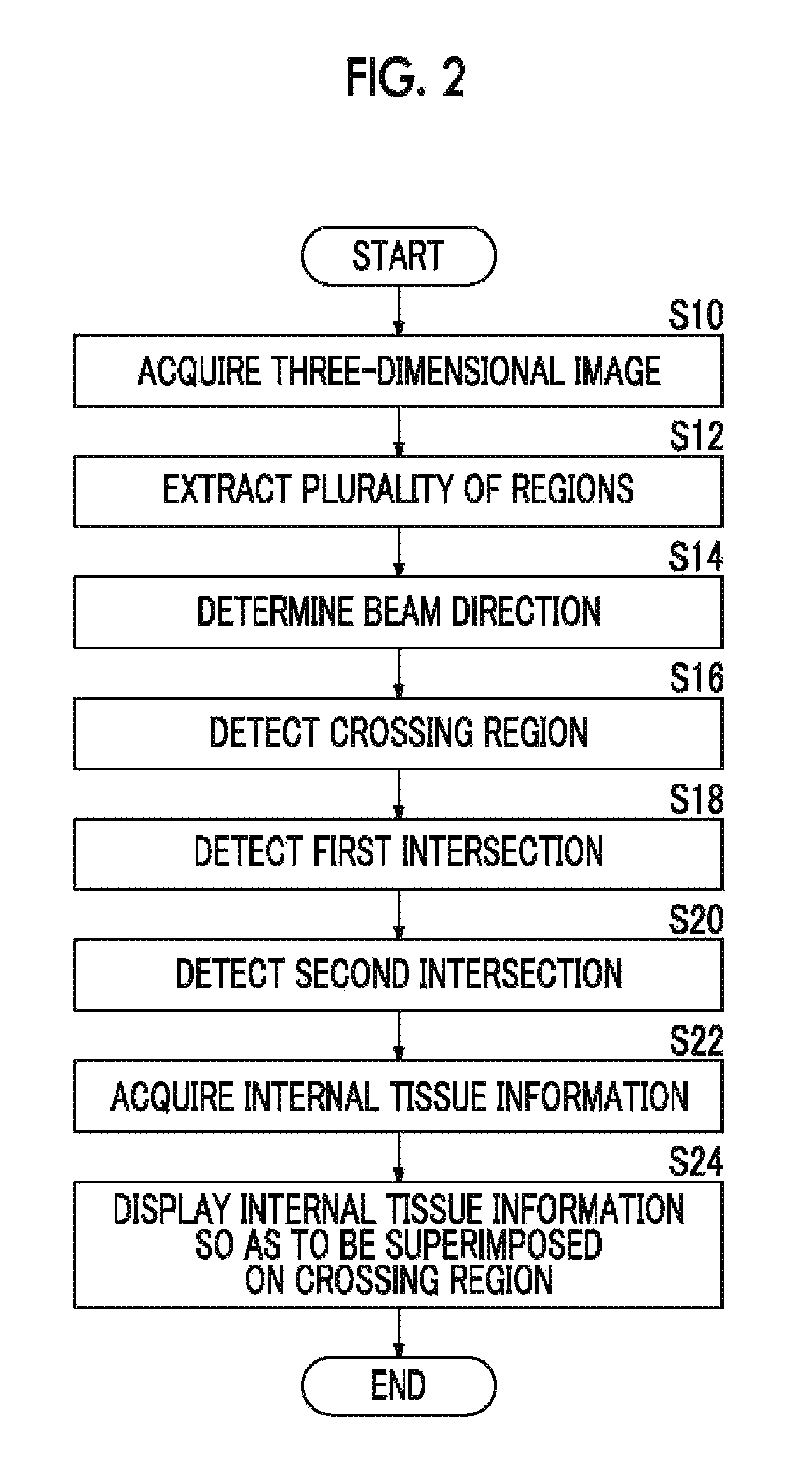

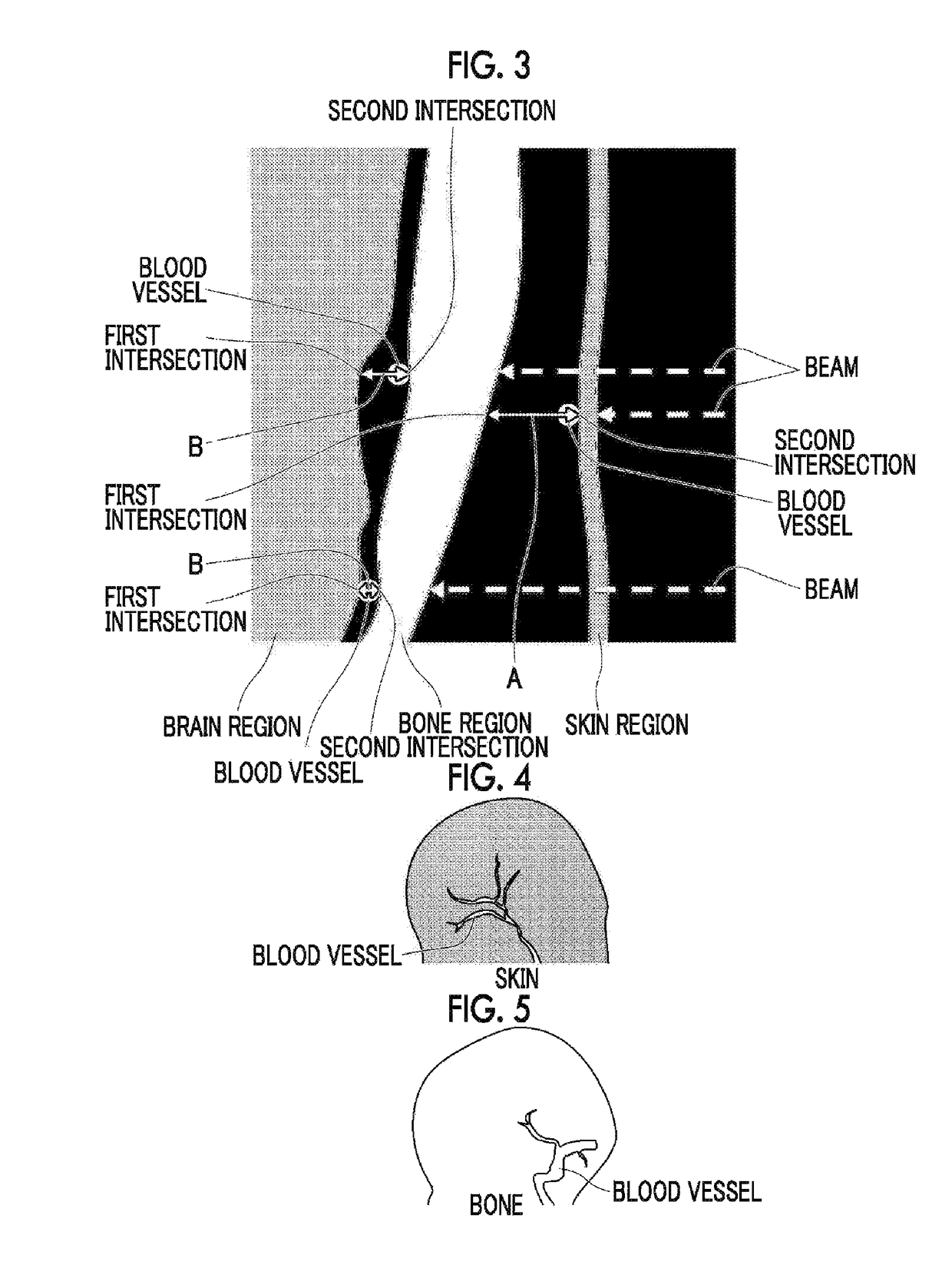

Medical image display control device, method of operation for same, and medical image display control program

InactiveUS10062184B2Image enhancementReconstruction from projectionComputer graphics (images)Light beam

There are provided: a region extraction unit that extracts a plurality of regions from a three-dimensional image of a subject; an internal tissue information acquisition unit that sets, as a crossing region, a region that a light beam used when projecting the three-dimensional image onto the two-dimensional projection plane crosses first among the plurality of regions, sets, as a first intersection, a point on a region crossing the light beam first when the crossing region is excluded, sets, as a second intersection, a point crossing the crossing region when there is an extension in an opposite direction to a traveling direction of the light beam from the first intersection, and acquires information of an internal tissue included between the first and second intersections; and a display control unit that displays the internal tissue information so as to be superimposed on the three-dimensional image.

Owner:FUJIFILM CORP

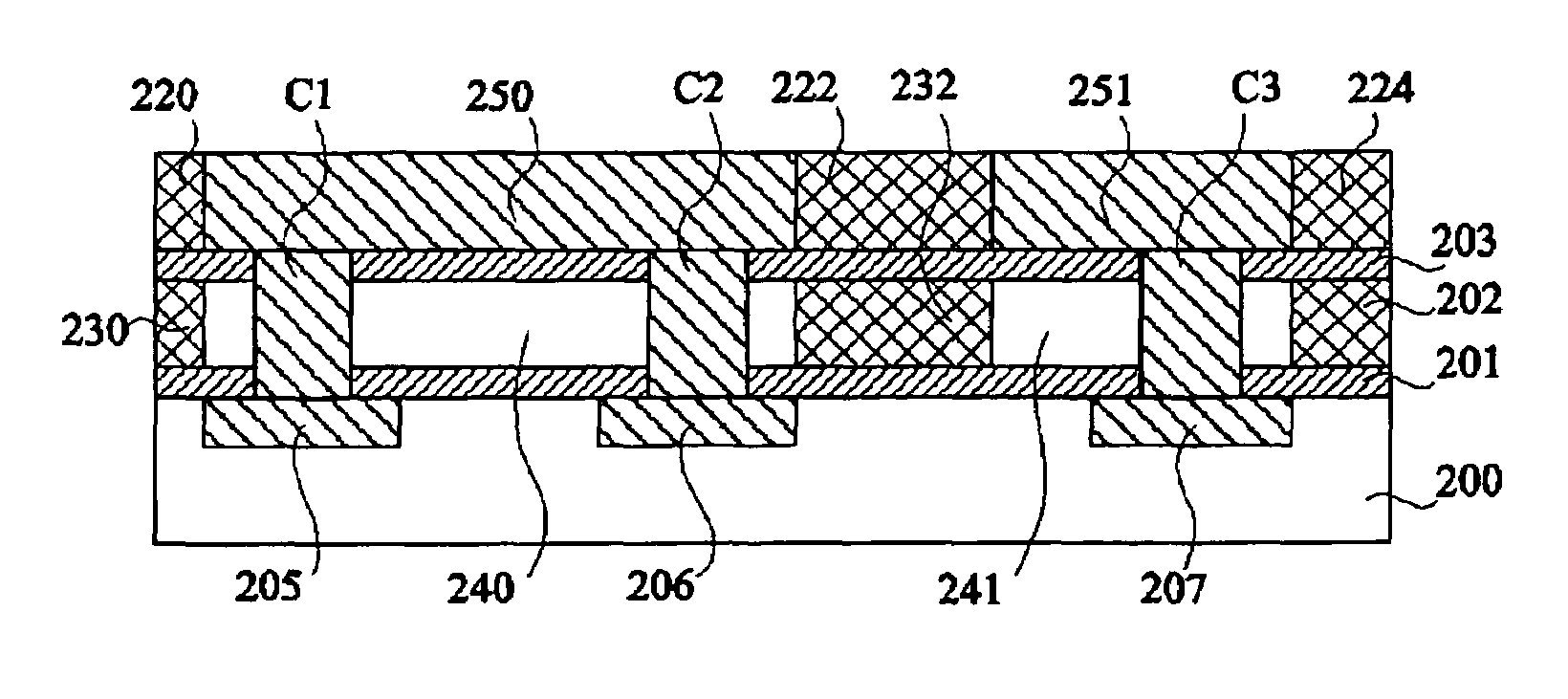

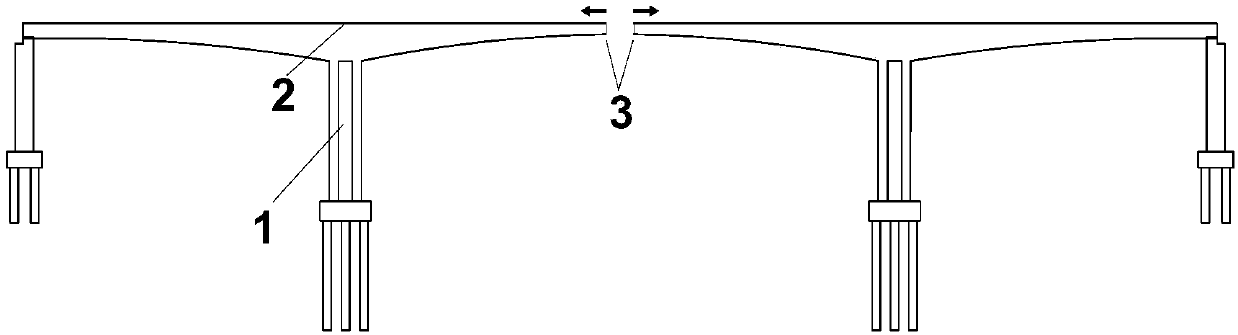

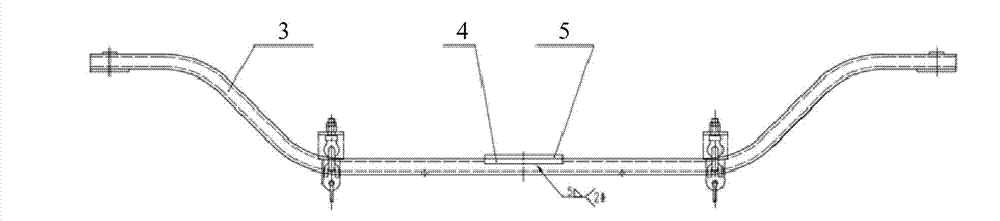

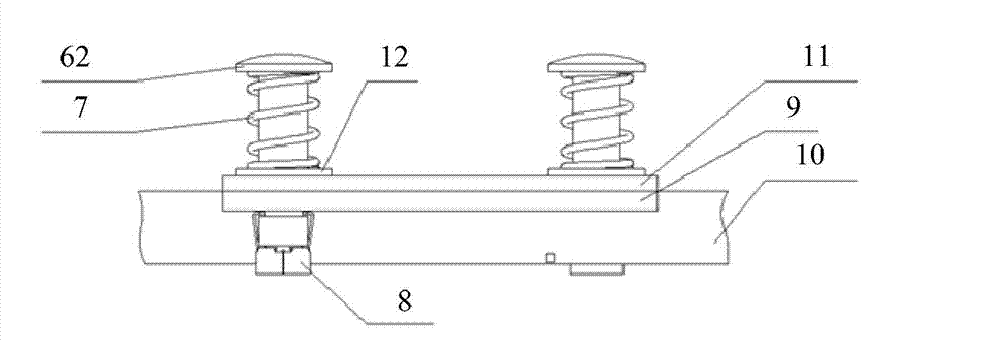

Positioning locking component, beam crossing device and railway wagon

The invention provides a positioning locking component, a beam crossing device and a rail wagon. The positioning lock component includes a guide pin, an elastic ring, and an elastic lock, wherein the guide pin is provided with a rod body and an end head which is arranged at one end of the rod body, the elastic ring with an axial deformation quantity is sleeved on the rod body, the size of the end head is bigger than the size of the rod body and also bigger than the inner diameter of the elastic ring, and the elastic lock with a radial deformation quantity is fixed on one end of the rod body away from the end head. The positioning locking component optimizes the fixing way between a contact pad and an adjusting subplate, cannot result in environmental pollution and deformation of the contact pad, and guarantees the measurement precision of an empty and load vehicle adjustment device.

Owner:CRRC QIQIHAR ROLLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com