Compressing device for single-side spot welding of stainless steel sidewall, spot welding machine and welding process

A pressing device and single-sided spot welding technology, which is applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as cracking of solder joints, failure to meet flatness requirements, and large deformation of plates, so as to improve flatness and movement The effect of smoothing and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

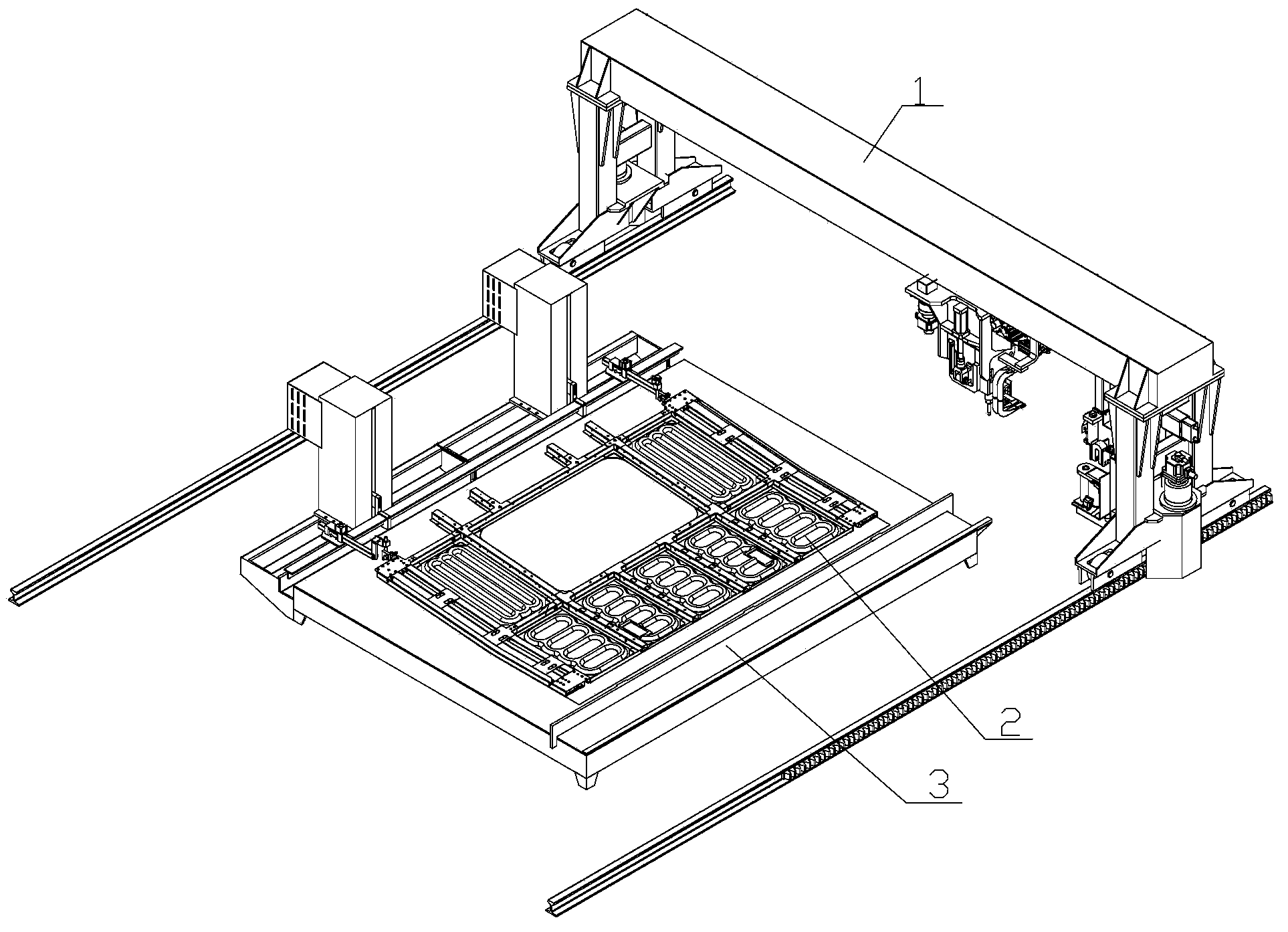

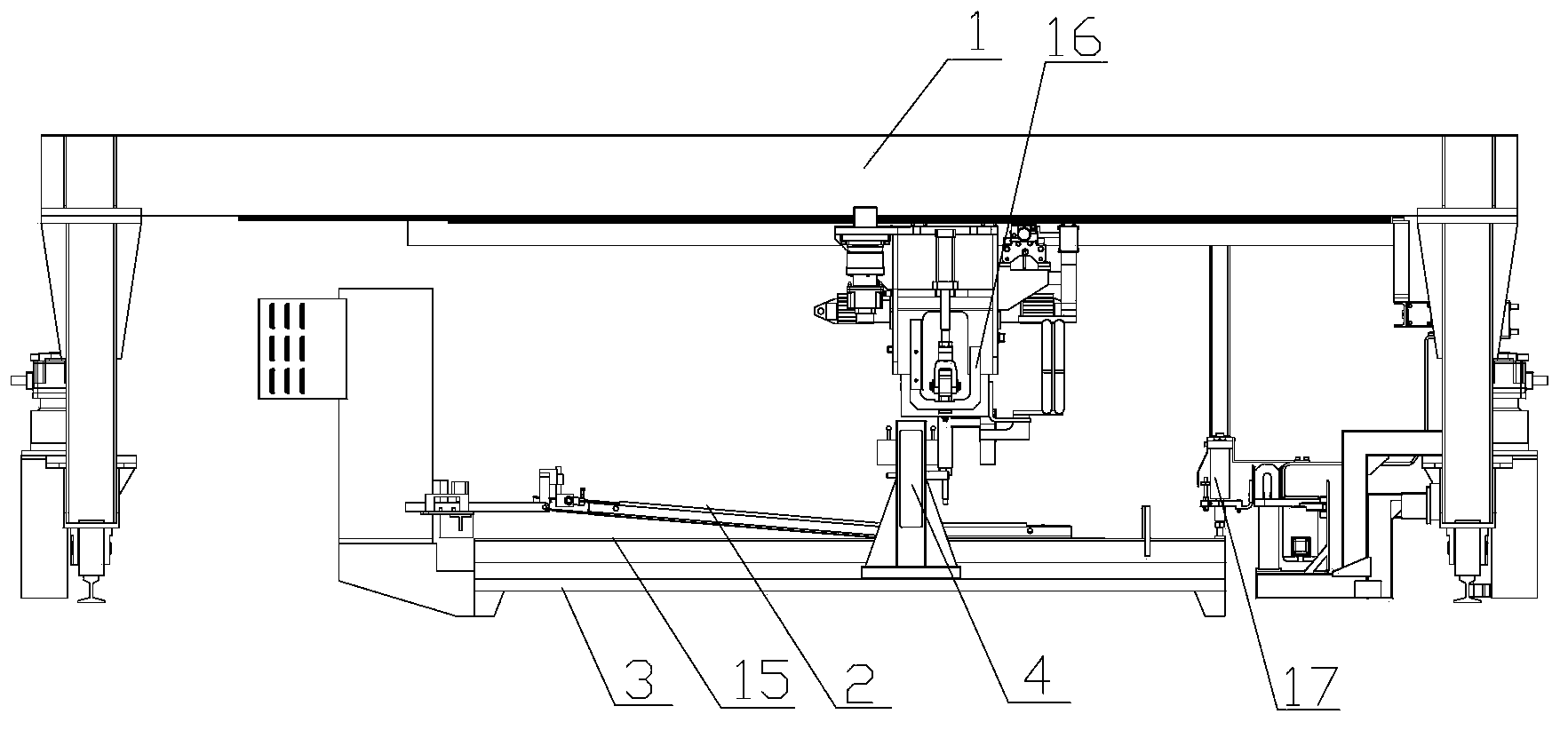

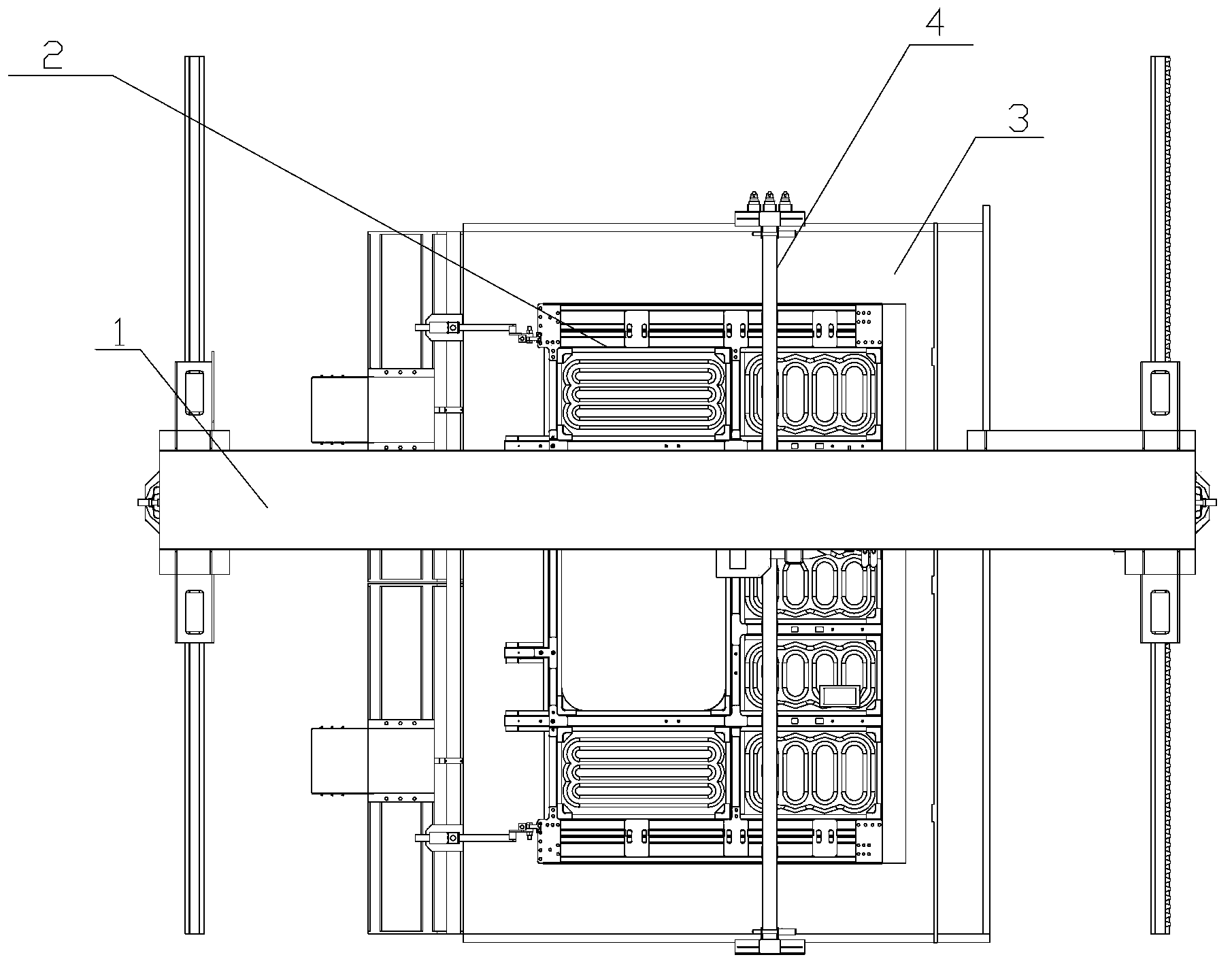

[0035] Such as figure 2 with image 3 Shown, a kind of spot welding machine of the present invention comprises welder gantry 1, welding platform 3, hold-down device 4 and spot welding electrode, and the uppermost layer of welding platform 3 is copper platform 15, and the upper electrode 16 that spot welding is used and the auxiliary electrode 17 are fixed on the welder gantry 1, the auxiliary electrode 17 is connected with the copper platform 15, the side wall 2 to be welded is placed on the uppermost copper platform 15 of the welding platform 3, and the pressing device 4 is used for pressing the side wall2.

[0036] Such as Figure 4 As shown, the pressing device 4 includes a column 6 positioned on both sides of the welding platform 3 and a crossbeam 5 connecting the two columns 6, the crossbeam 5 spans the top of the welding pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com