Tunnel karst cave and underground water comprehensive treatment structure and construction method

A comprehensive treatment and groundwater technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of blind blocking, long construction period, difficult blocking, etc., to ensure construction safety, fast and convenient construction, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

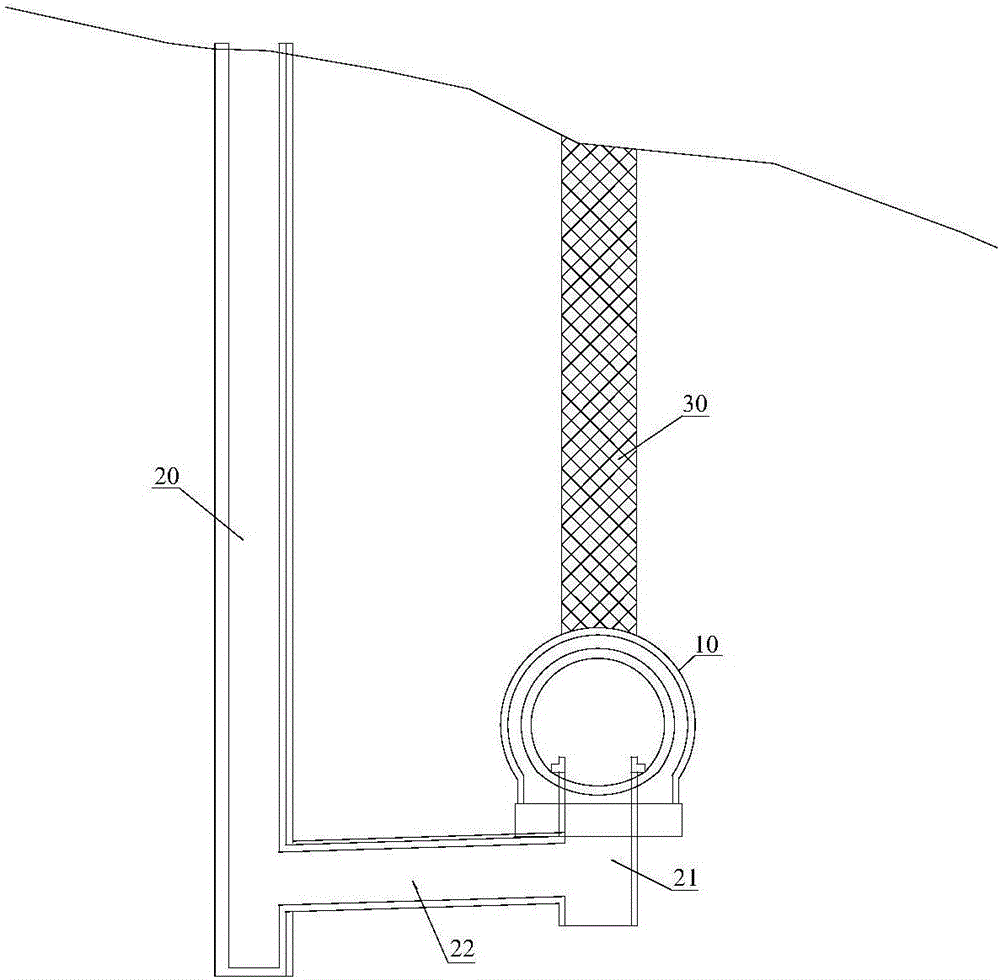

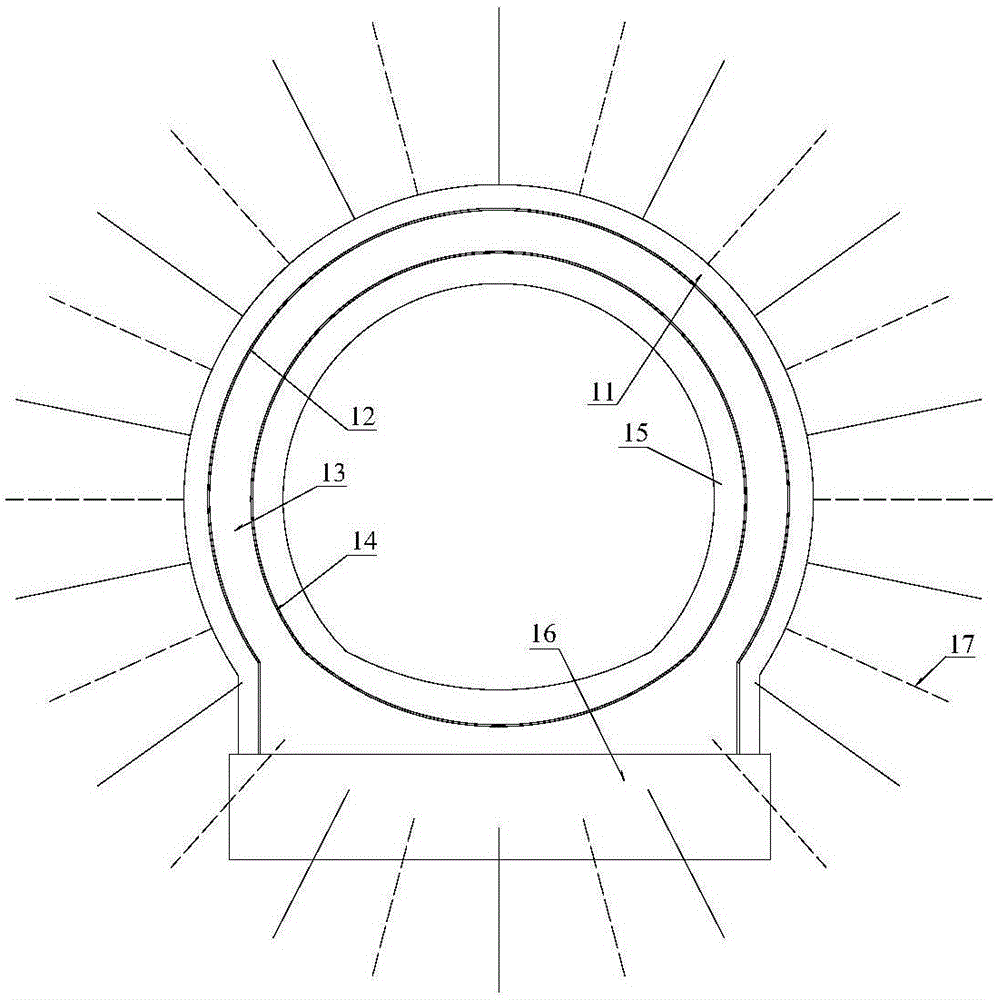

[0021] refer to figure 1 , the tunnel karst cave and groundwater comprehensive treatment structure of the present invention includes the karst cave 30 above the surrounding rock 10 revealed during the excavation process. The outside of the surrounding rock 10 is provided with an external drainage shaft 20 connected to the ground, an internal vertical shaft 21 is provided below the surrounding rock 10, and a horizontal drainage channel 22 connecting the external drainage shaft 20 and the internal vertical shaft 21 is provided. The surrounding rock 10 A fully-sealed anti-water pressure lining is constructed on the outside, and the fully-sealed anti-water pressure lining extends for a certain length before and after the karst cave 30.

[0022] The present invention adopts sealing and draining combined technical measures. A drainage shaft is set outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com