Concrete-overhead-beam crossing self-climbing integrated drum rack system and construction method thereof

A concrete and monolithic technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems such as low construction efficiency and potential safety hazards, reduce climbing weight and improve construction efficiency , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

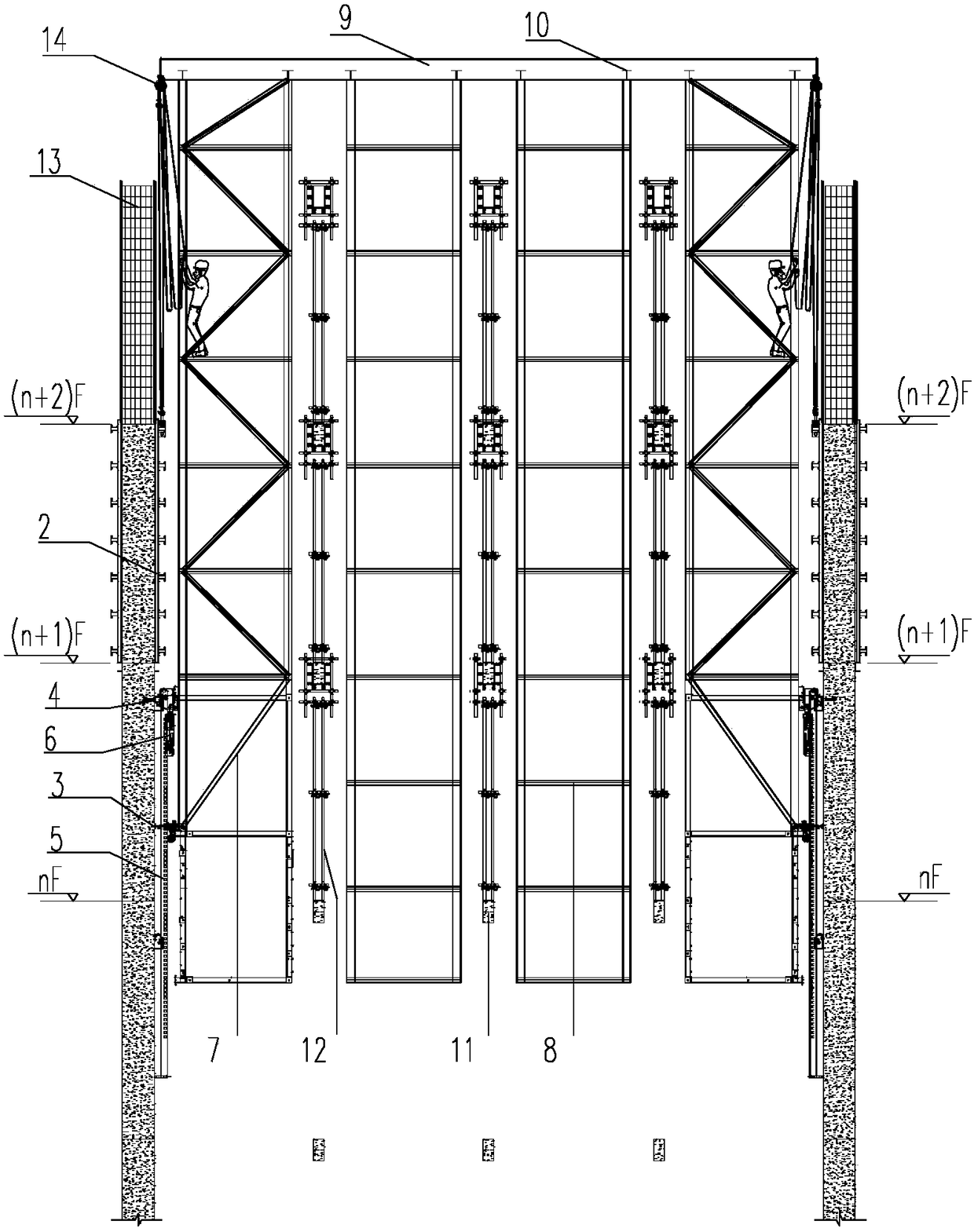

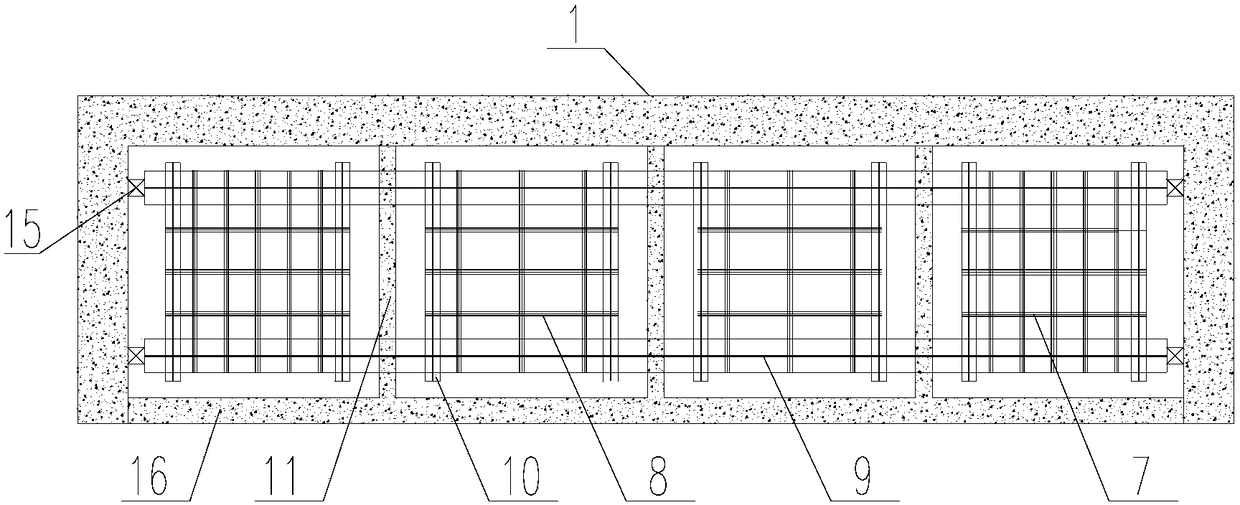

[0031] Combine below figure 1 with figure 2 The composition of the self-climbing monolithic tube frame system of the present invention is described in detail.

[0032] Such as figure 1 with figure 2 As shown, this embodiment discloses a self-climbing monolithic tube frame system over concrete volley beams, including a tube frame (not shown), a large formwork 2, a wall attachment device 3, a climbing shoe 4, a guide rail 5, and a hydraulic system 6. The tube frame includes a load-bearing frame body 7, a lower pylon body 8 and a lifting steel beam (not shown). The large formwork 2 is fixed on both sides of the elevator shaft shear wall 1 by means of tension bolts and installation positioning channel steel. The hydraulic system 6 Set on the creel, the climbing shoe 4 is fixedly connected to the elevator shaft shear wall 1 through embedded parts, and the guide rail 5 is set on the climbing shoe 4; in the construction state, the creel is fixed to the elevator through the climbing s...

Embodiment 2

[0039] Please continue to refer figure 1 with figure 2 This embodiment provides a construction method of a self-climbing monolithic tube frame system over a concrete volley beam, and the construction method includes the following steps:

[0040] Step 1. First install the climbing boots 4 through the embedded parts on the n layer, then install the lower part of the bearing frame 7, the wall attachment device 3 and the guide rail 5, and then install the remaining bearing frame 7 structure from bottom to top, where n is A natural number greater than or equal to 2. The load-bearing frame body 7 is mainly composed of truss layers to ensure its bearing capacity.

[0041] Step 2: After the load-bearing frame body 7 is installed, the longitudinal lifting steel beam 9 is installed first, then the horizontal lifting steel beam 10 is installed, and finally the lower hanging frame body 8 located in the middle of the tube frame is installed.

[0042] Step 3. After all the trusses are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com