Automatic cement brick strip processing production line

A cement brick and production line technology, which is applied to the automatic cement brick stripe processing production line and the production line field of stripe processing on the surface of cement bricks, can solve the problems of poor stripe quality, high cost of finished products and high breakage rate, and achieve high stripe quality. , The effect of low processing cost and low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

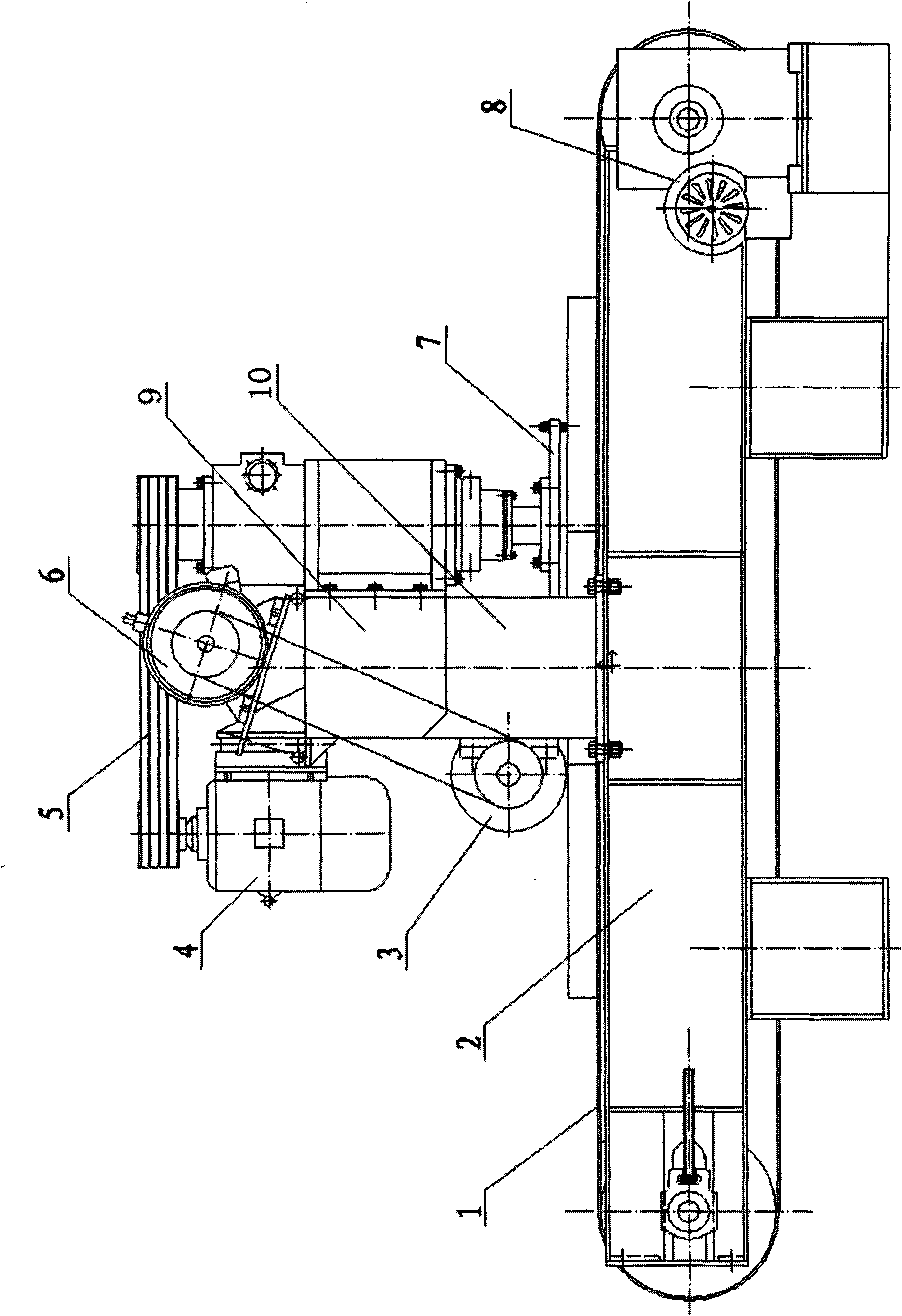

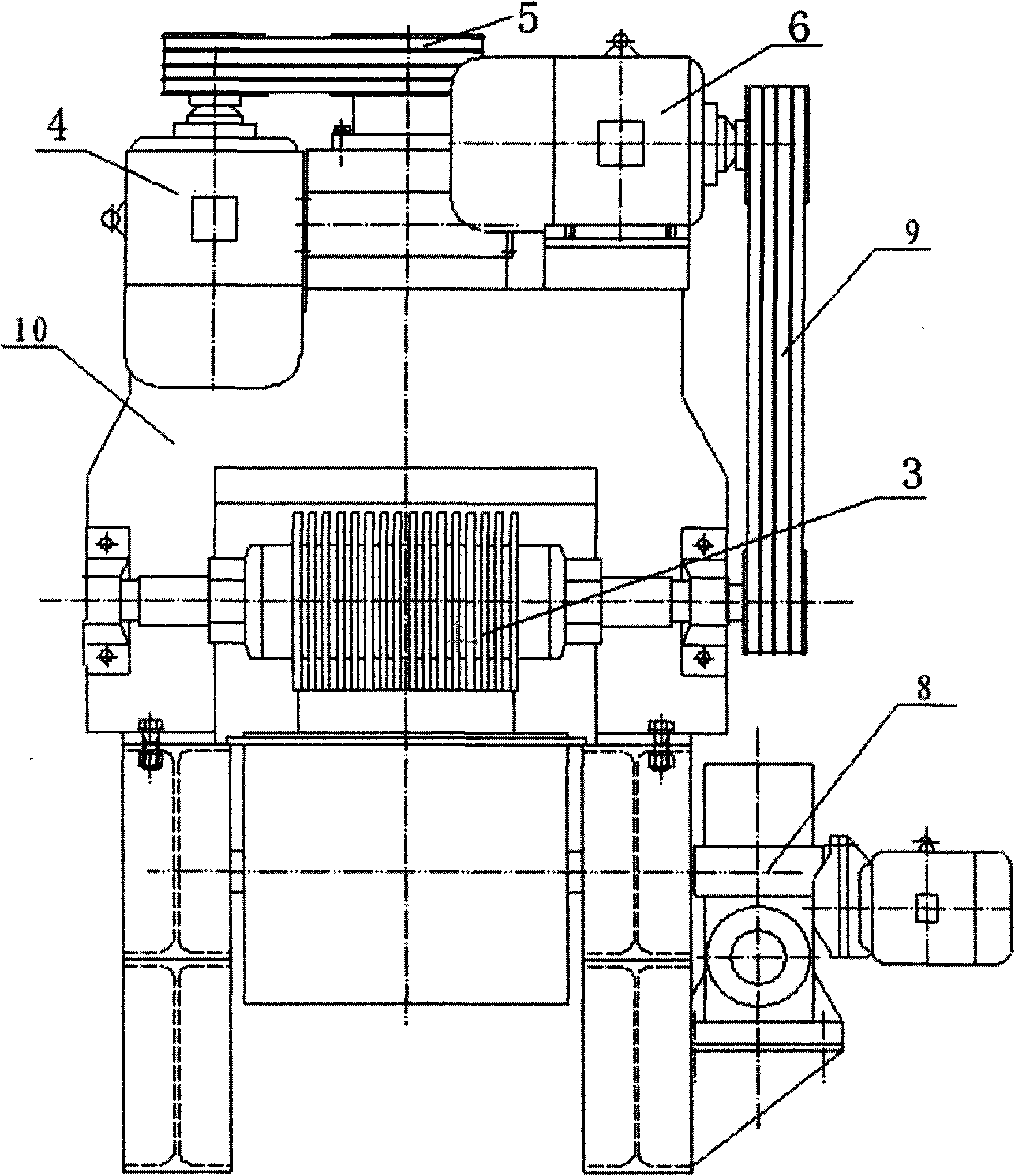

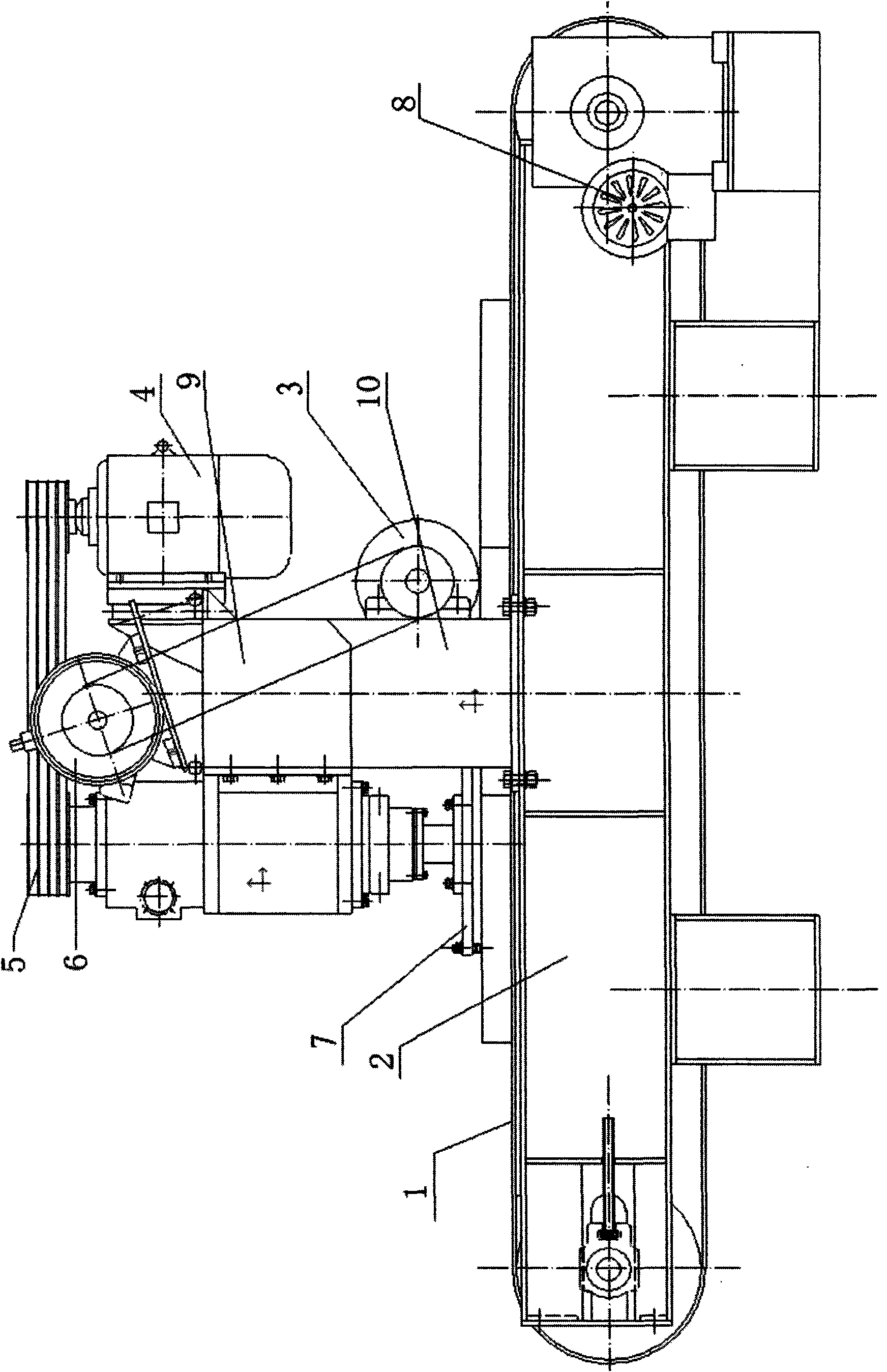

[0015] A reference to an automatic cement brick stripe processing production line in this embodiment Figure 1-3 , composed of two identical equipment with symmetrically arranged heads. Since the cement brick blank is casted into a plastic mold, the back is uneven and the thickness is uneven. This plan adopts two identical equipment with symmetrically arranged heads. The first one processes the back flat first. , and make the thickness uniform; the second machine will process stripes on the front. The cement brick feeding system adopts a plane conveyor belt structure, including a frame 2 and a plane conveyor belt 1 driven and controlled by a worm gear motor 8 above it. The crossbeam 10 of the two equipments adopts a double-head structure, which includes the saw blade 3 and the plane grinding disc 7 fixed on the beam 10. The transmission system 9 and the belt transmission system 5 driven by the motor 4 are driven; the belt transmission system 9 and the belt transmission system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com