Patents

Literature

105results about How to "No torsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

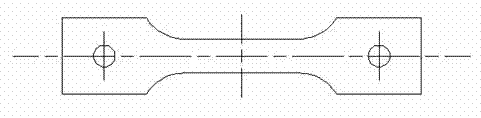

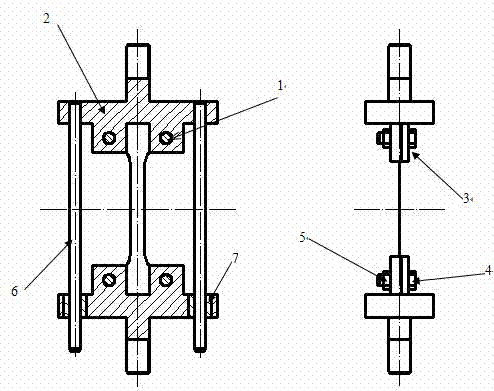

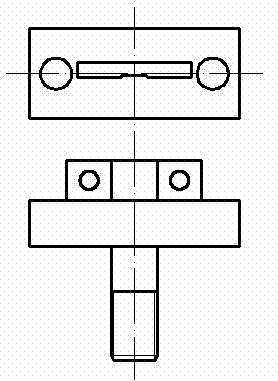

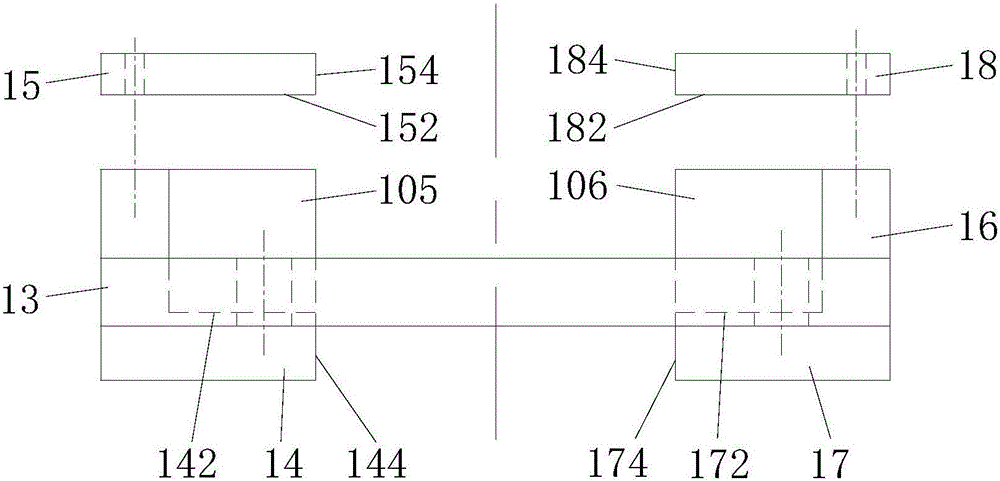

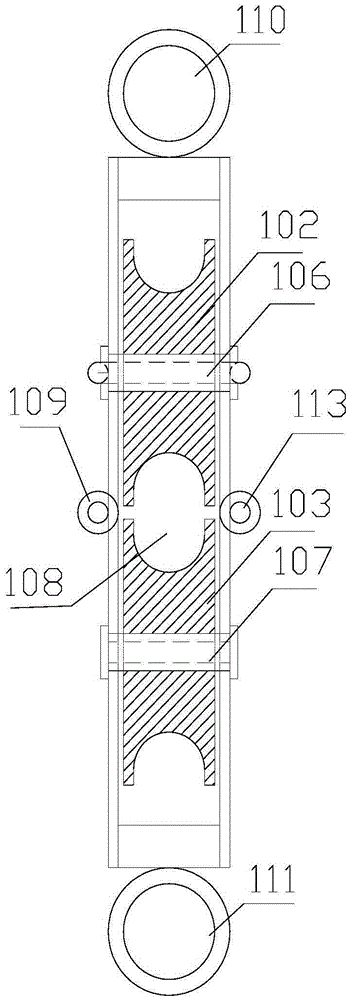

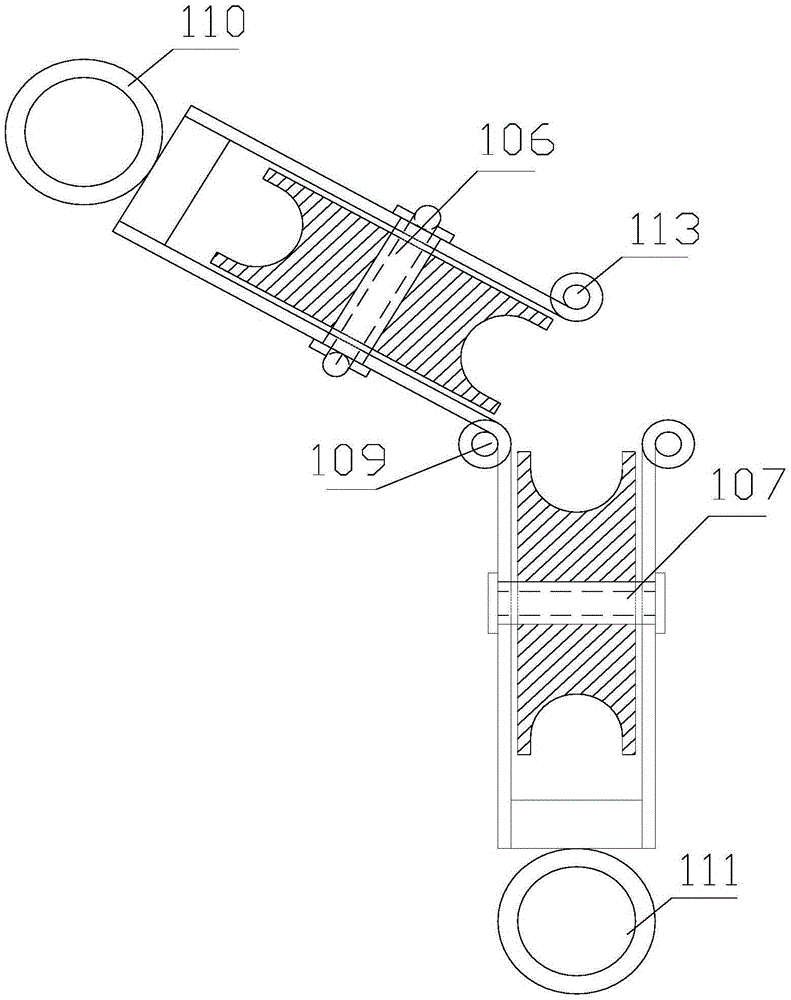

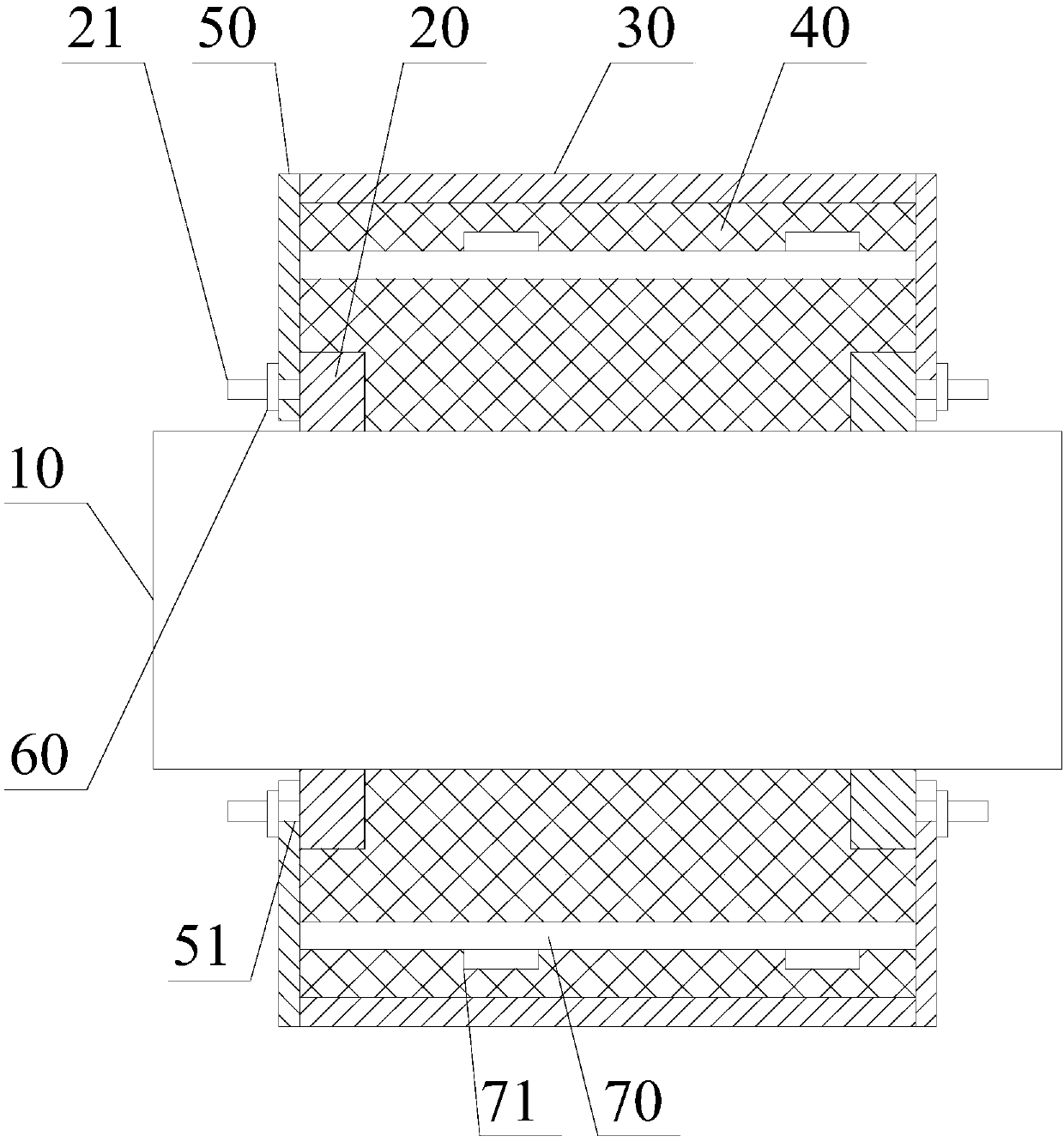

Tensile test special fixture used for sheet metal or metal foil and using method

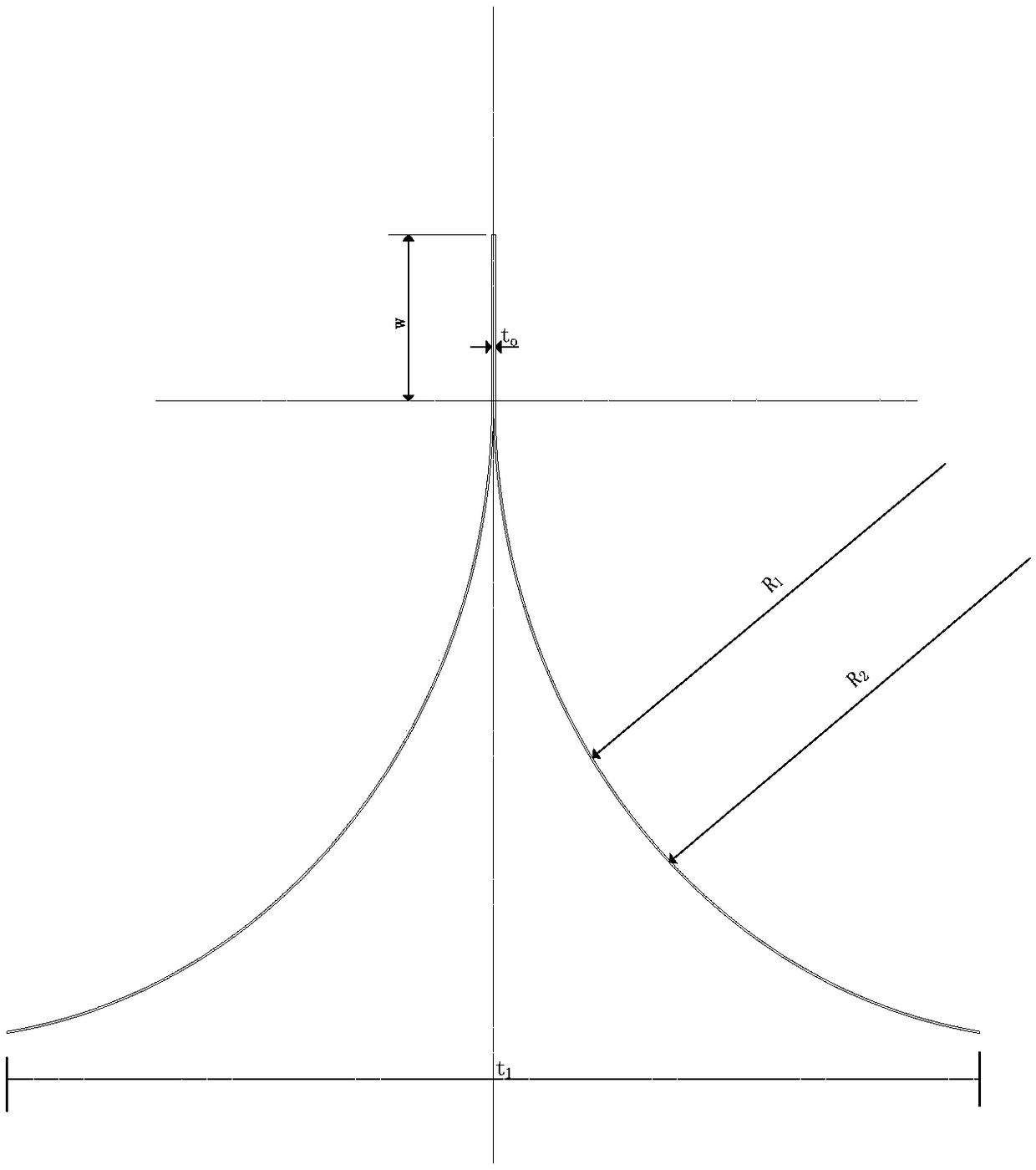

The invention relates to a tensile test special fixture used for sheet metal or metal foil. The tensile test special fixture comprises an upper clamping head, a lower clamping head, two sets of guide post guide sleeves and threads through which the upper clamping head is connected with a stretcher stretching head base seat, wherein the upper clamping head comprises a T-type clamping component, a small clamping component and two pairs of bolts and nuts, and the upper clamping head is same to the lower clamping head in structure. Through holes are reserved in the upper clamping head and the lower clamping head along the direction parallel to the sample tensile direction, an upper guide sleeve is installed in the lower clamping head through hole, and the upper clamping head through hole is connected with the guide sleeves through guide posts. Bolt holes are reserved in the T-type clamping component and the small clamping component which are in the upper clamping head along the direction perpendicular to the sample tensile direction, and samples are clamped due to the fact that the two groups of bolts penetrate through the reserved holes of the clamping components. The tensile test special fixture used for the sheet metal or the metal foil is simple in structure and convenient to install and clamp, and overcomes various difficulties when the sheet metal and the metal foil are stretched.

Owner:JIANGSU UNIV

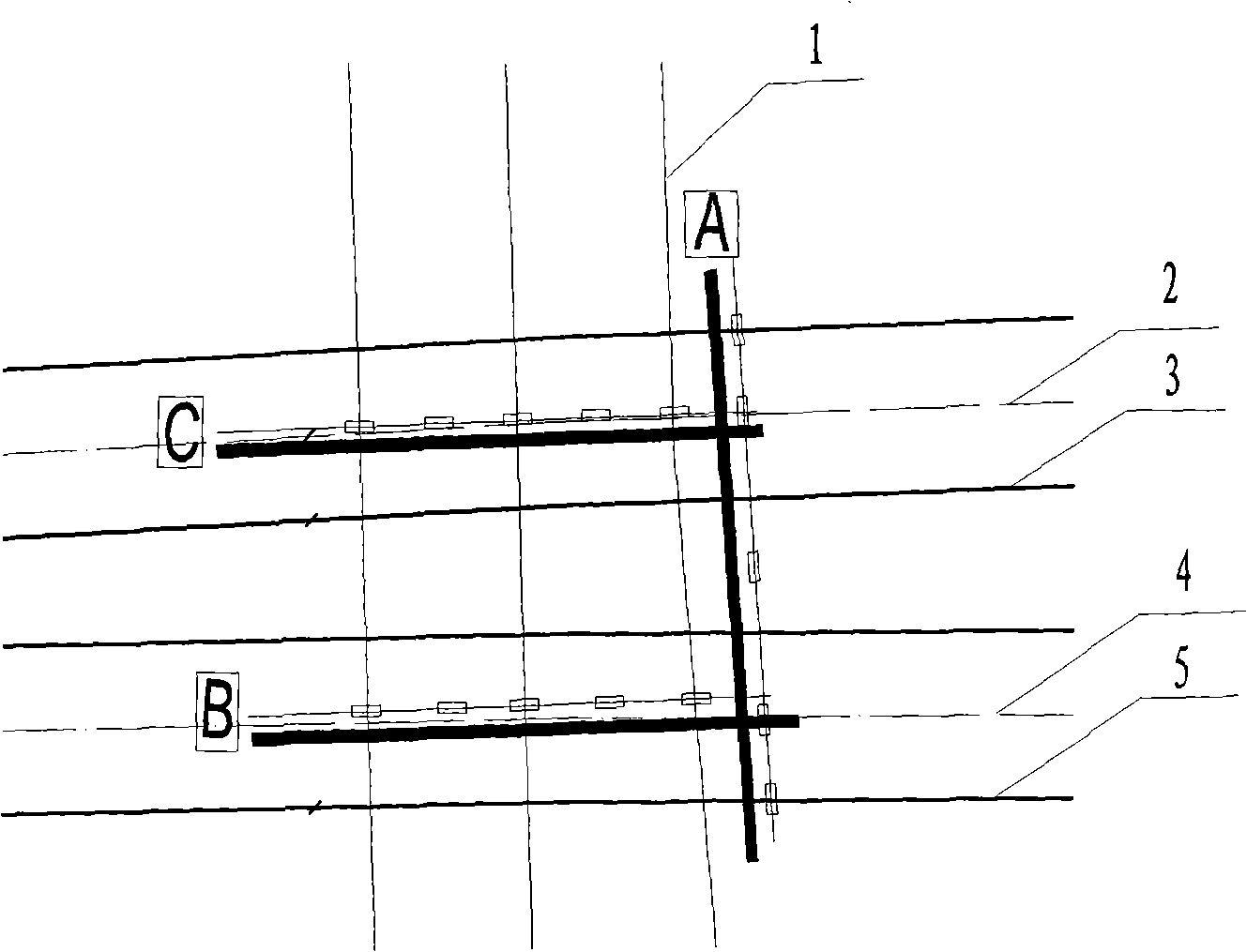

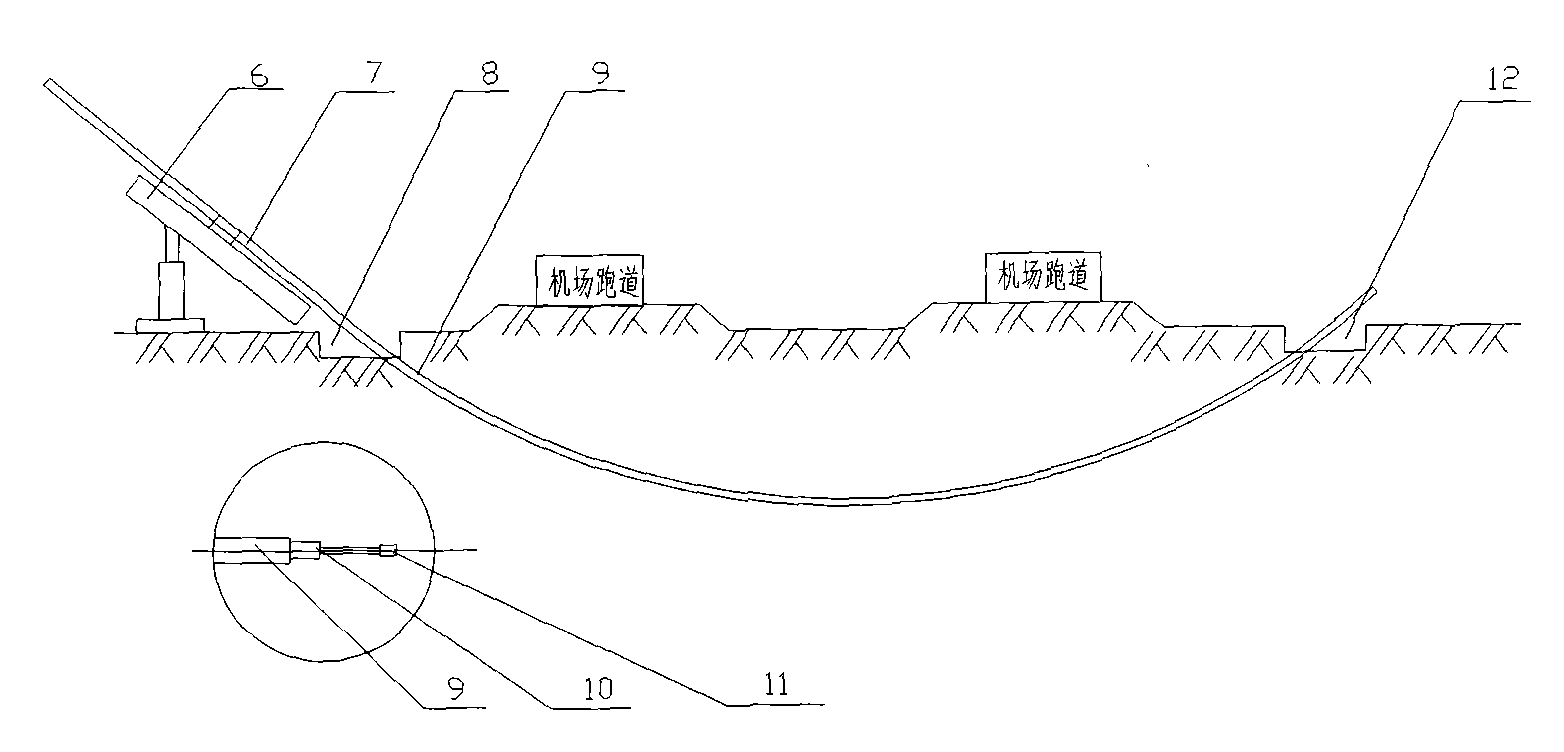

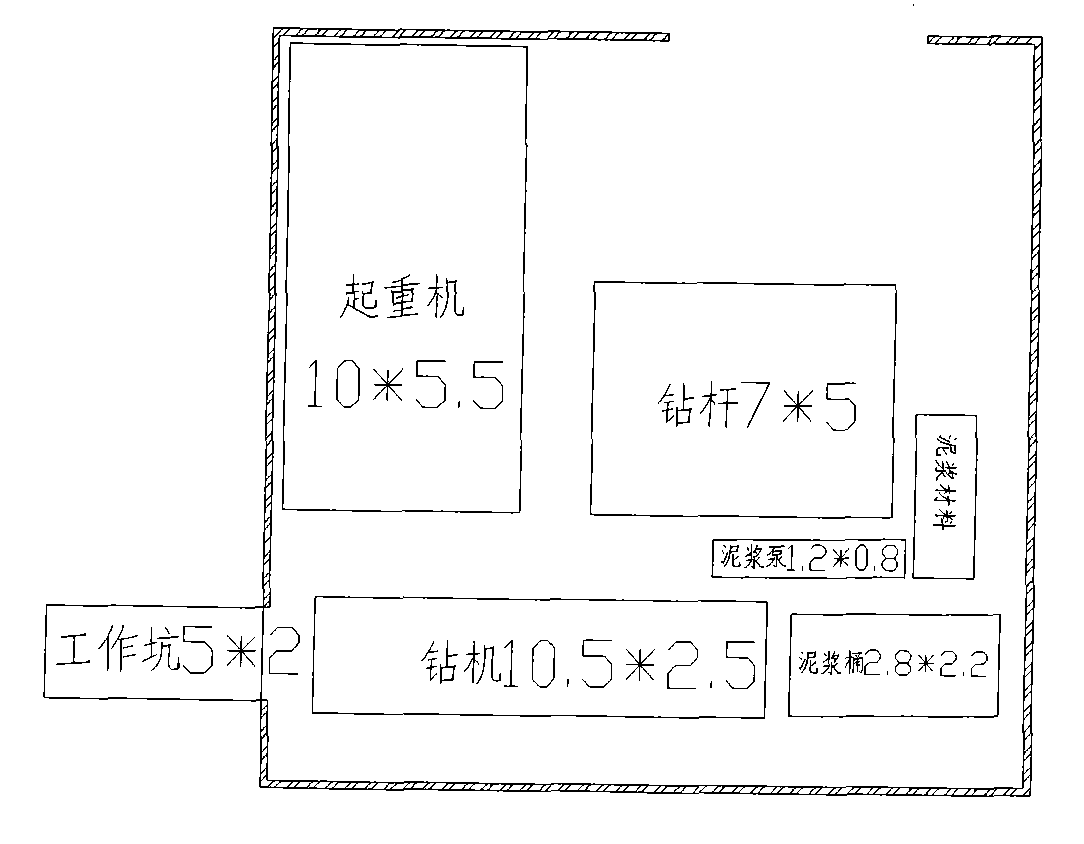

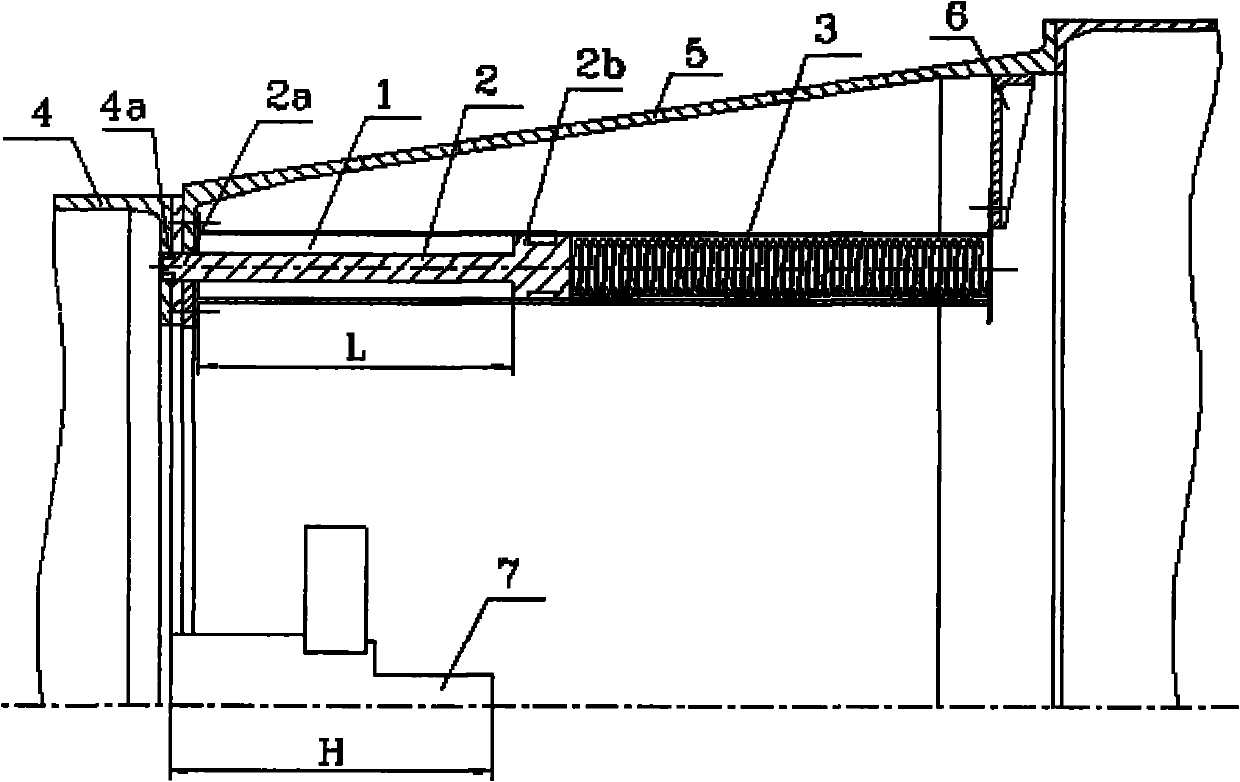

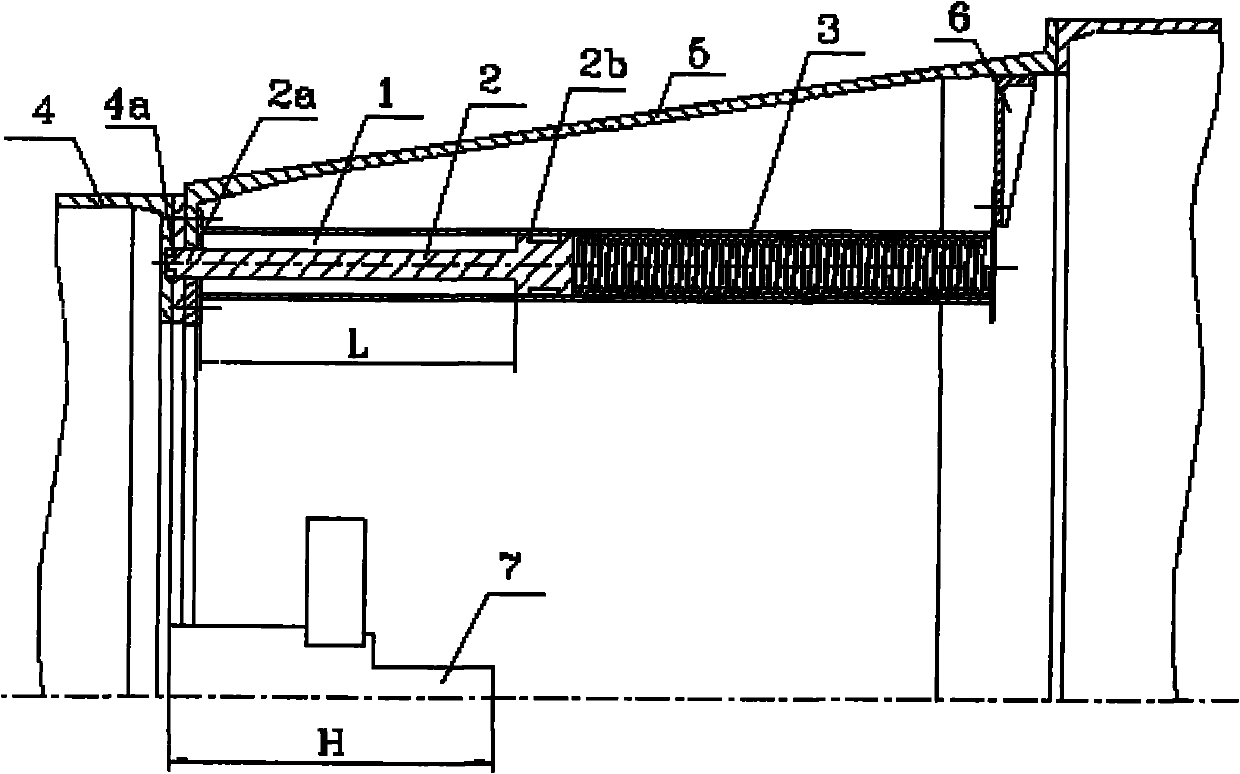

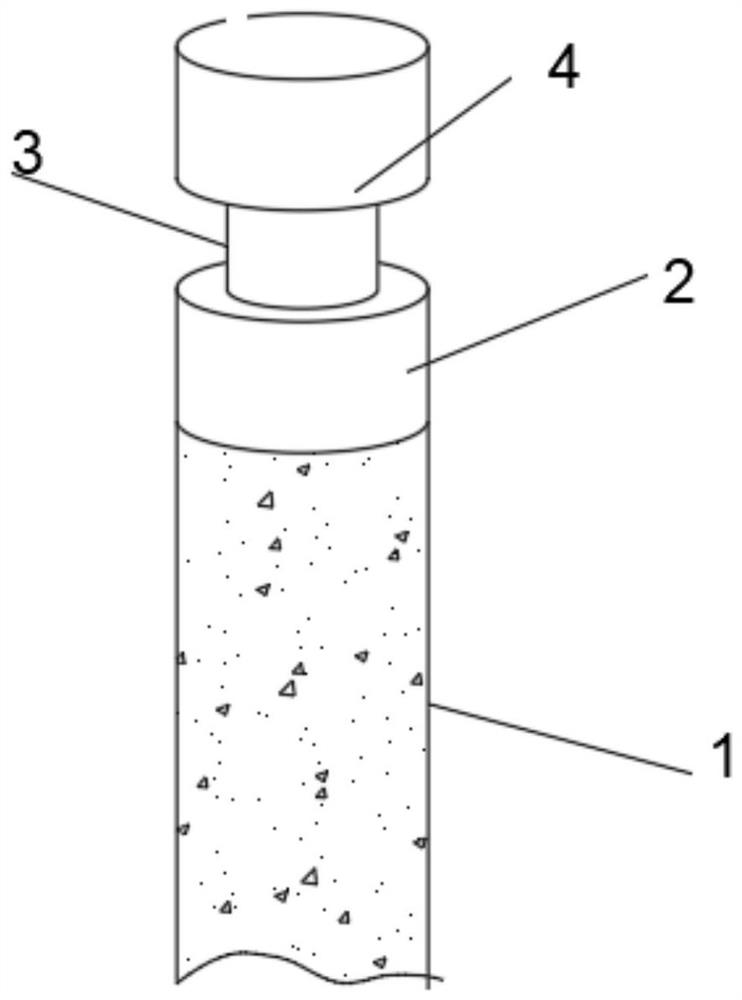

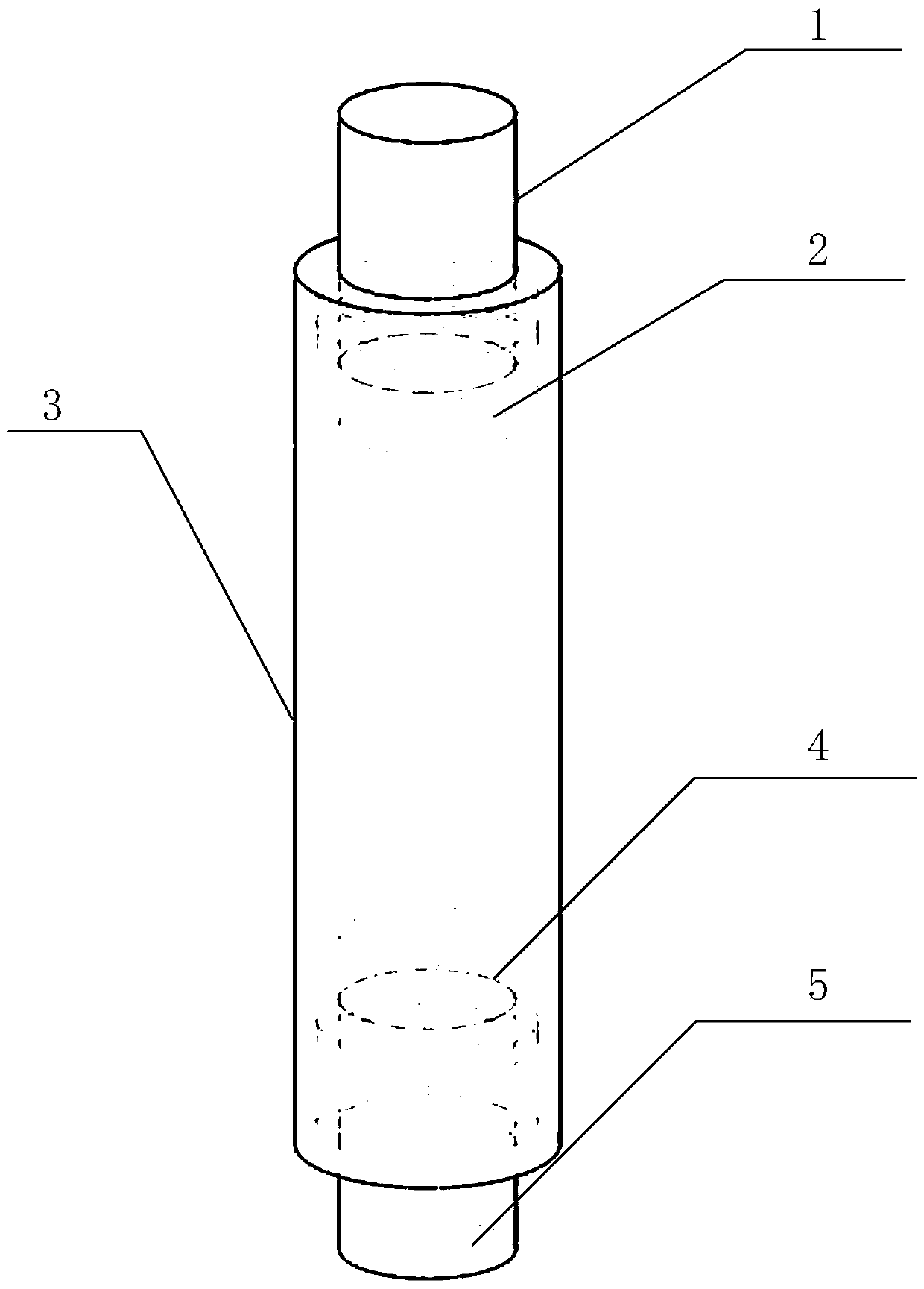

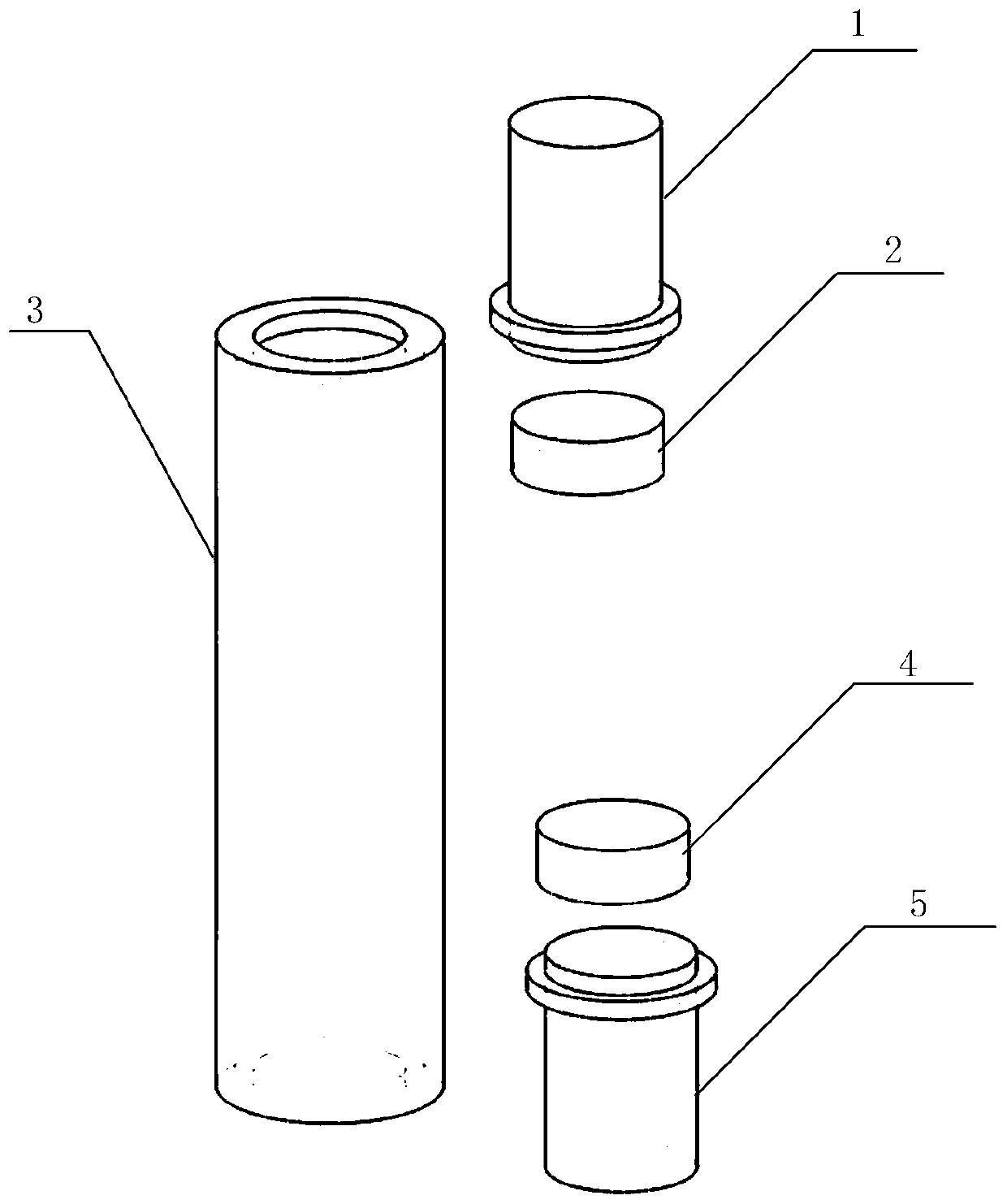

Construction method for embedding inclinometer tube

InactiveCN101575860ASolve the embedding problemAccurate placementFoundation testingEngineeringEarth surface

The invention relates to the fields of monitoring and construction, in particular to a construction method for embedding an inclinometer tube suitable for monitoring the earth surface settlement. The construction method arranges the inclinometer tube in a sleeve according to the embedding track of the inclinometer tube, uses a sleeve type drag pipe when the inclinometer tube is drawn into a pore path, i.e., the sleeve and the inclinometer tube are drawn out of the pore path together by drawing the sleeve with the interior containing the inclinometer tube, instead of directly drawing the inclinometer tube, and then mud is filled in the gap between the sleeve and the inclinometer tube fully, the sleeve is stripped off and the inclinometer tube is put in the right position. The construction method can lead the inclinometer tube to be put in the right position accurately without twisting and does not affect the accuracy of monitoring.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

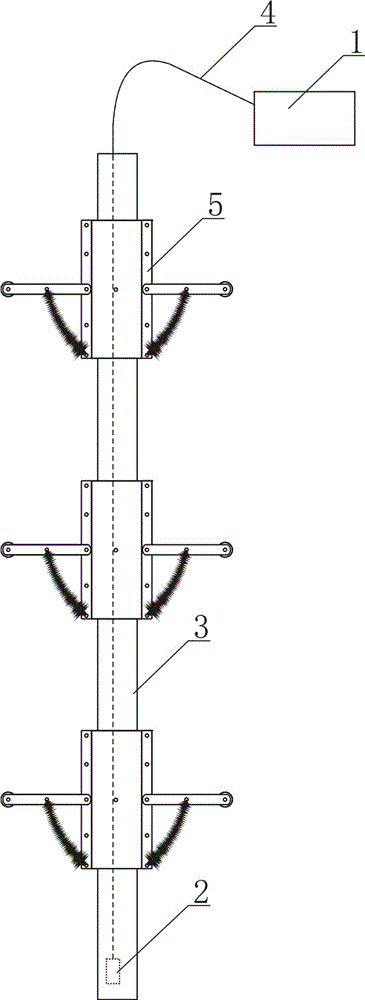

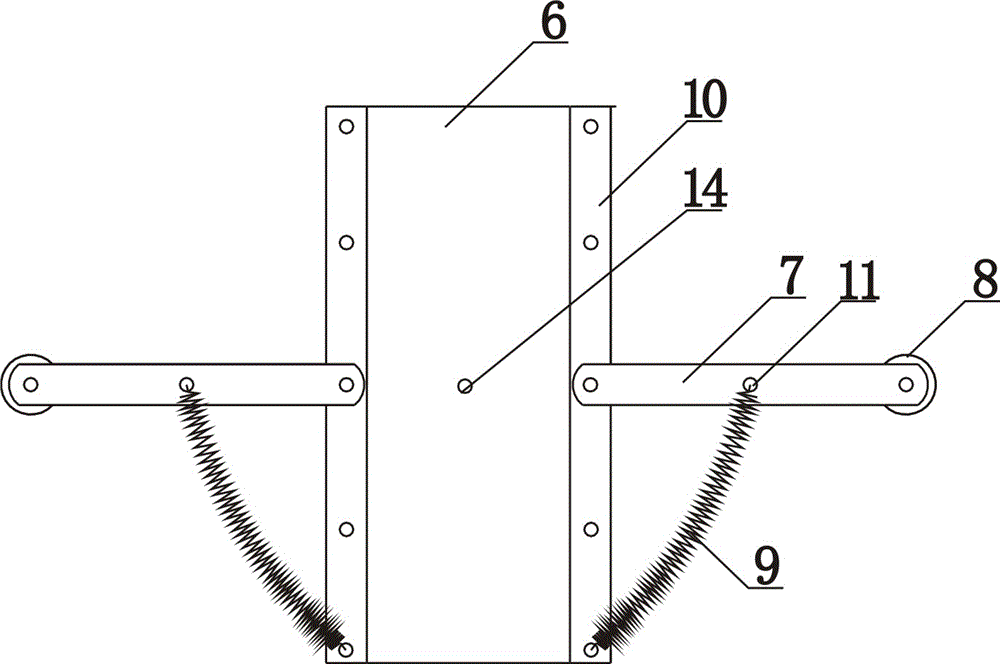

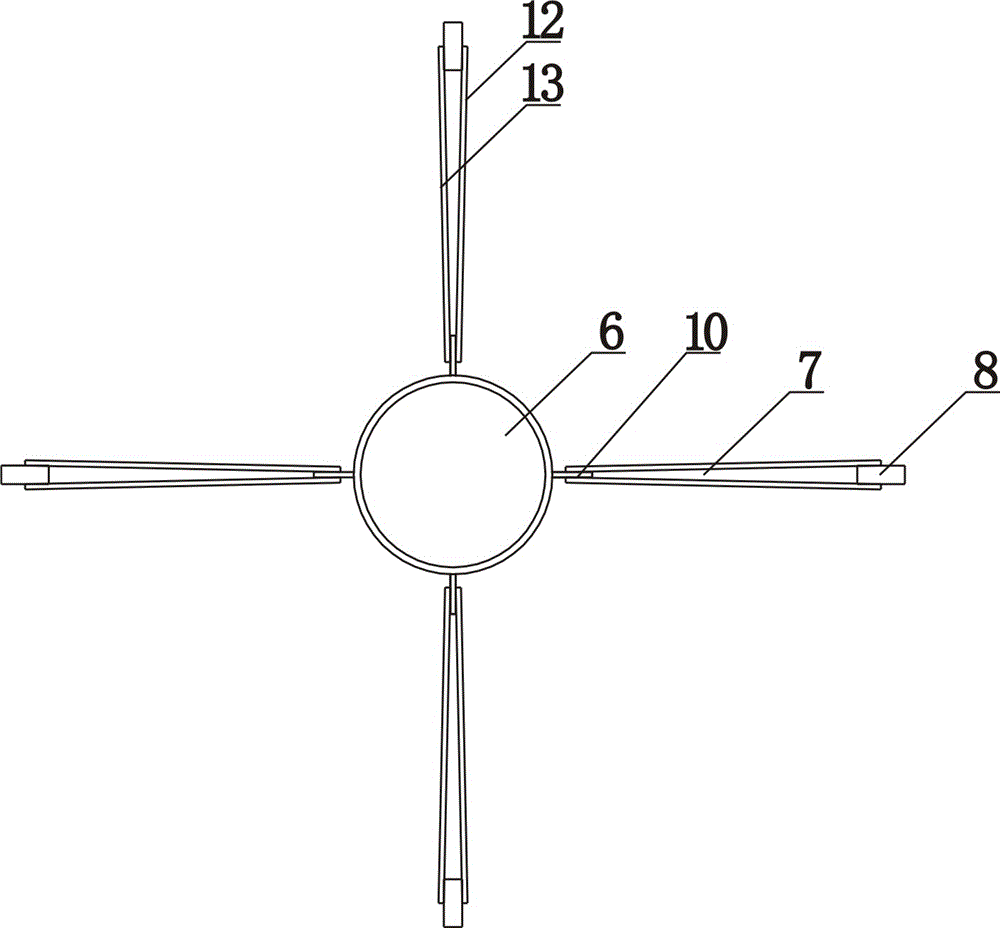

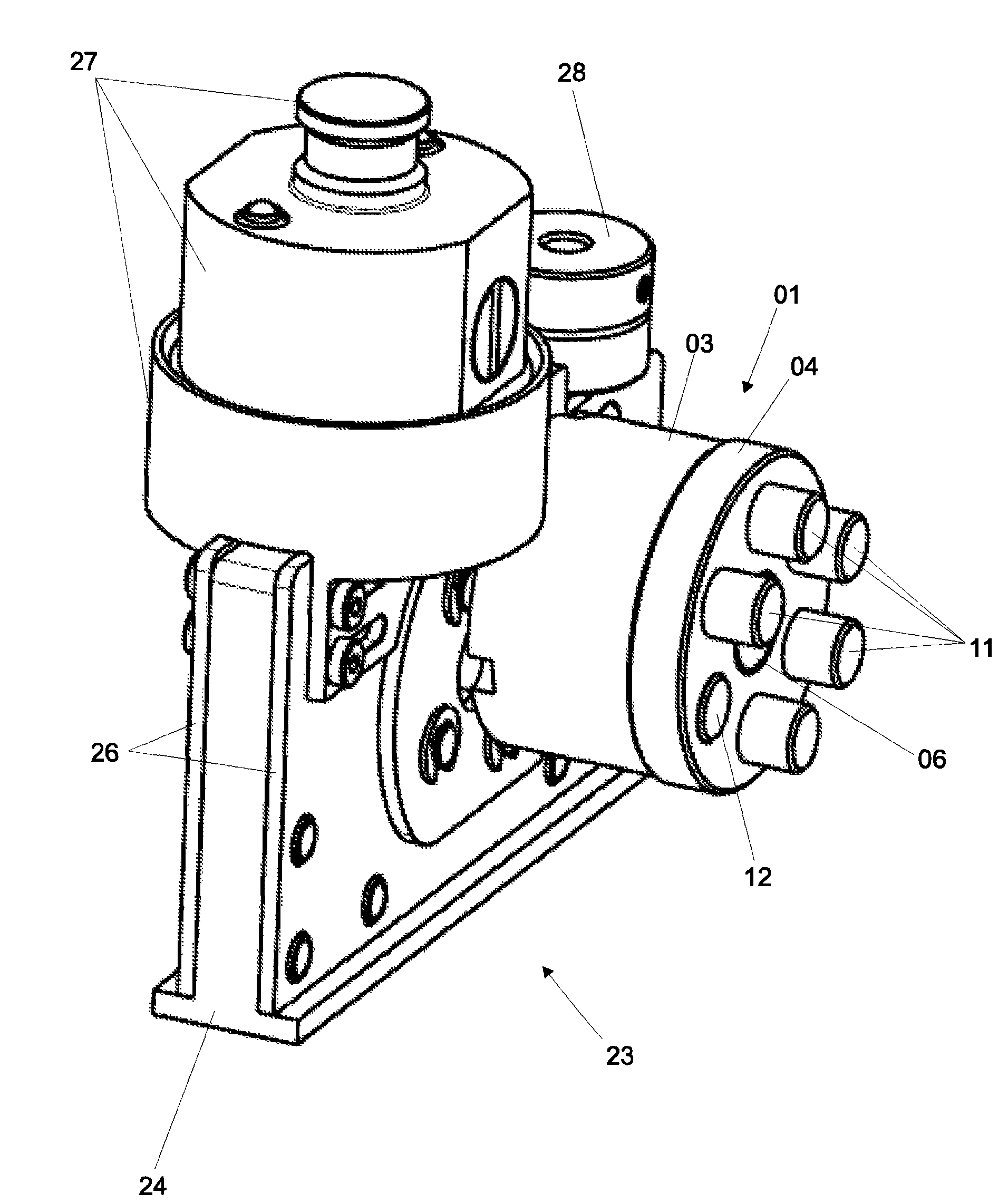

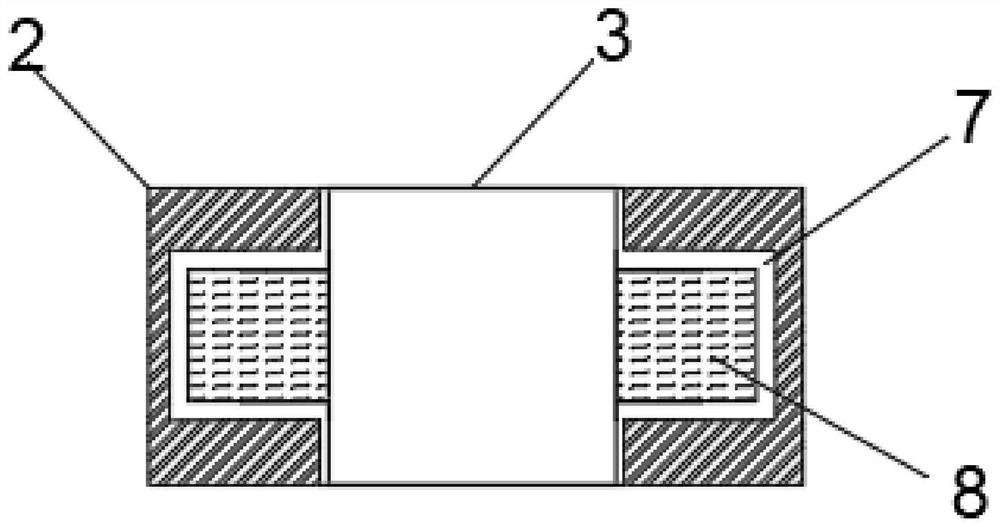

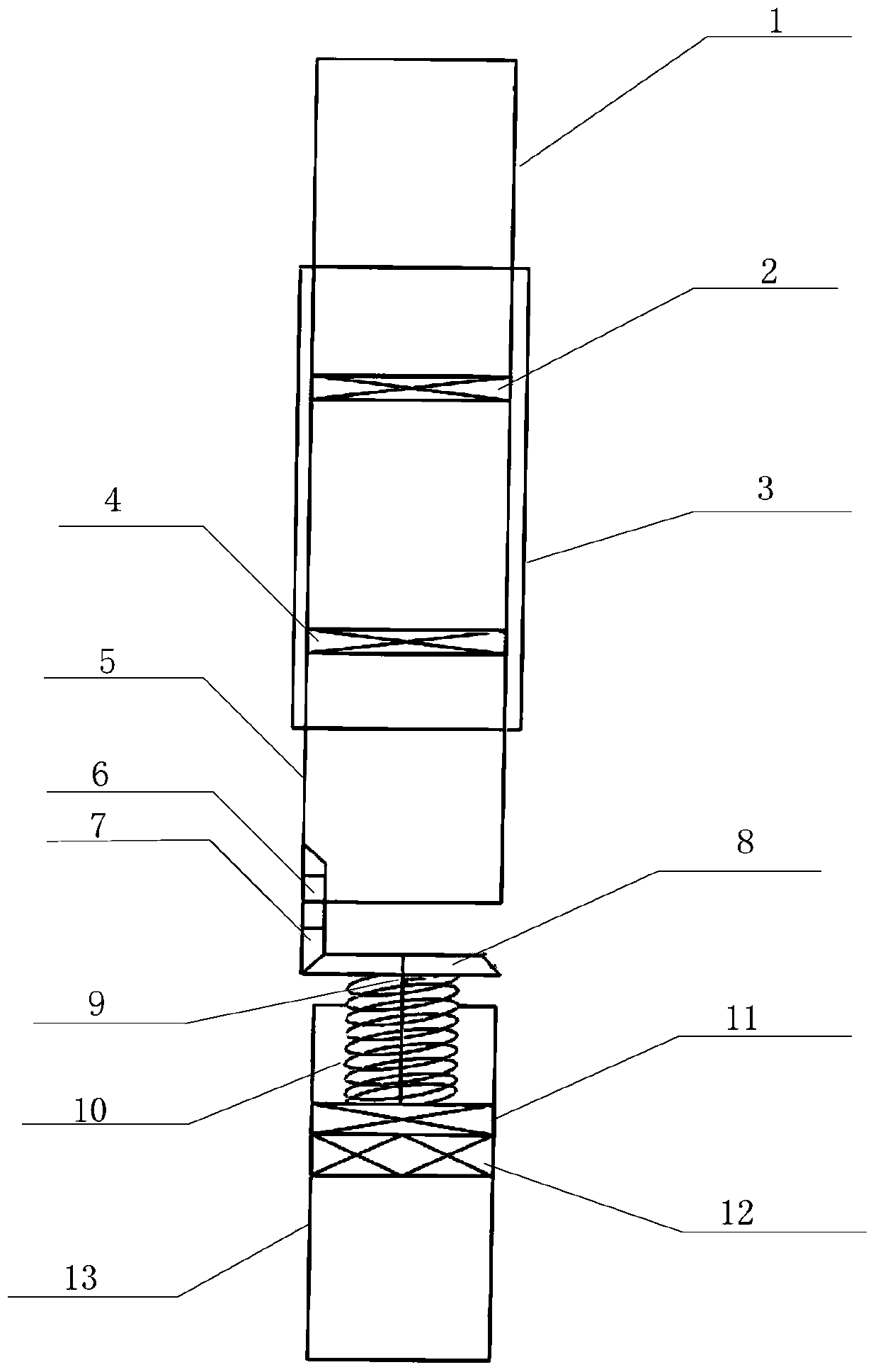

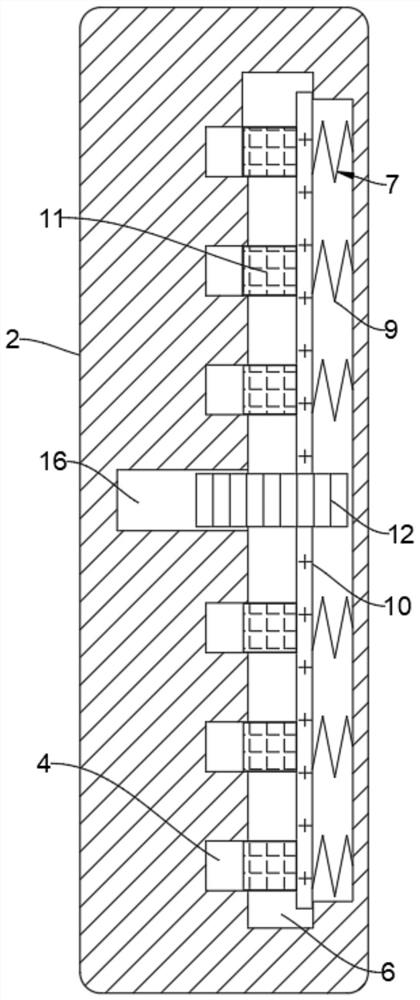

Inclination detection device for tubular pipe and inclinometer tube centring and locating assembly thereof

The invention discloses an inclination detection device for a tubular pipe and an inclinometer tube centring and locating assembly thereof. The inclination detection device for the tubular pipe comprises an inclination detection reading device, an inclination detection probe, the inclinometer tube and a cable used for lifting and pulling the inclination detection probe, and further comprises the inclinometer tube centring and locating assembly, wherein the inclination detection probe slides along a tubular groove in the inclinometer tube through rollers; and the inclination detection probe is connected with the inclination detection reading device through the cable. The inclinometer tube centring and locating assembly is characterized by comprising a locating sleeve, four locating rods, pulleys and springs, wherein the locating sleeve is mounted on the inclinometer tube in a sleeving manner; and the four locating rods are distributed in the circumferential direction of the locating sleeve to form a cross-shaped structure. The inclinometer tube centring and locating assembly guarantees that central positions of the inclinometer tube and the tubular pipe overlap, guarantees that the inclination detection probe does not twist and incline in the horizontal direction inside the inclination detection probe, guarantees that the detection data of the inclination of the tubular pipe is accurate and reliable, and has the characteristics of high measurement accuracy and convenient operation.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP SURVEY & DESIGN INST

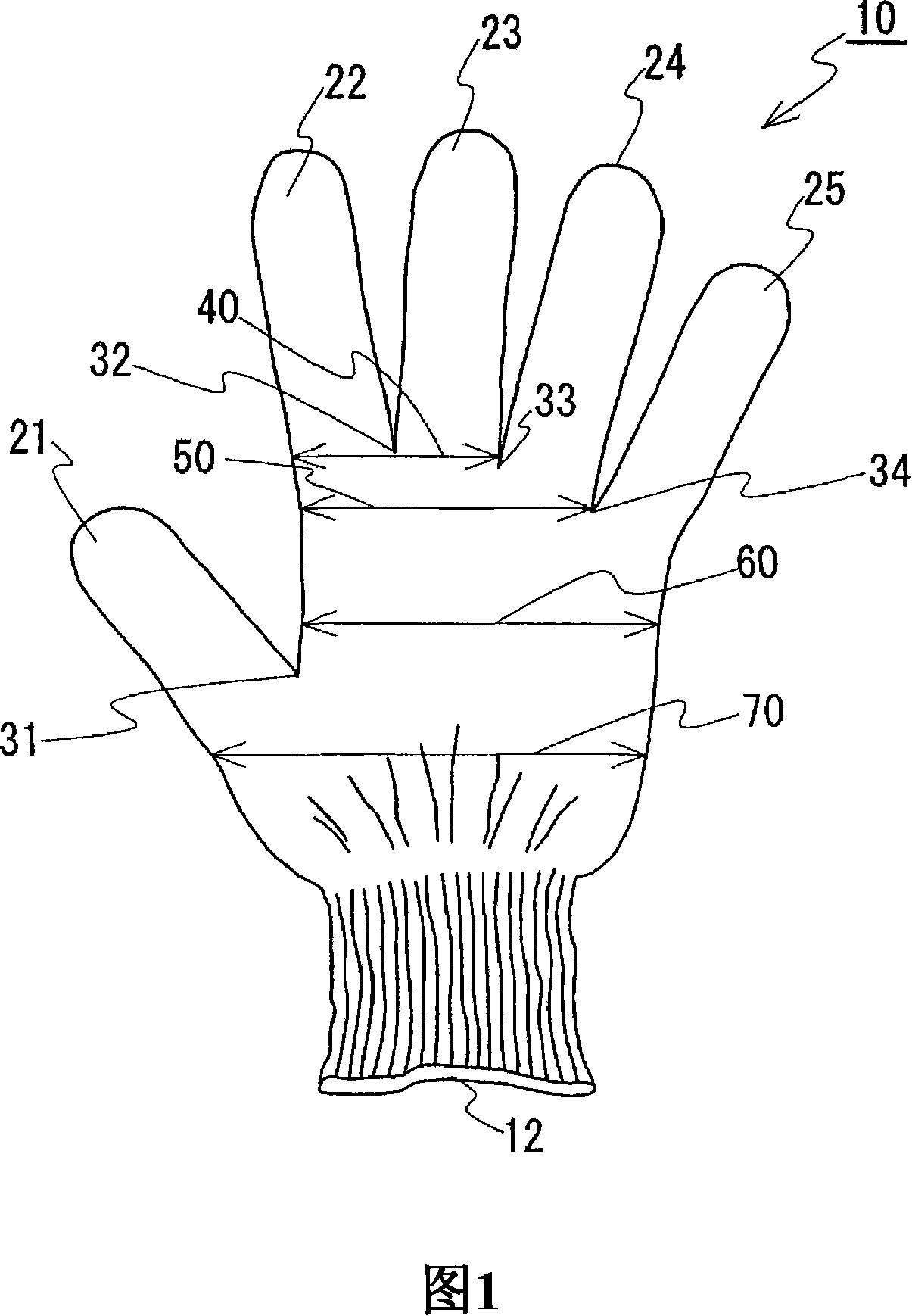

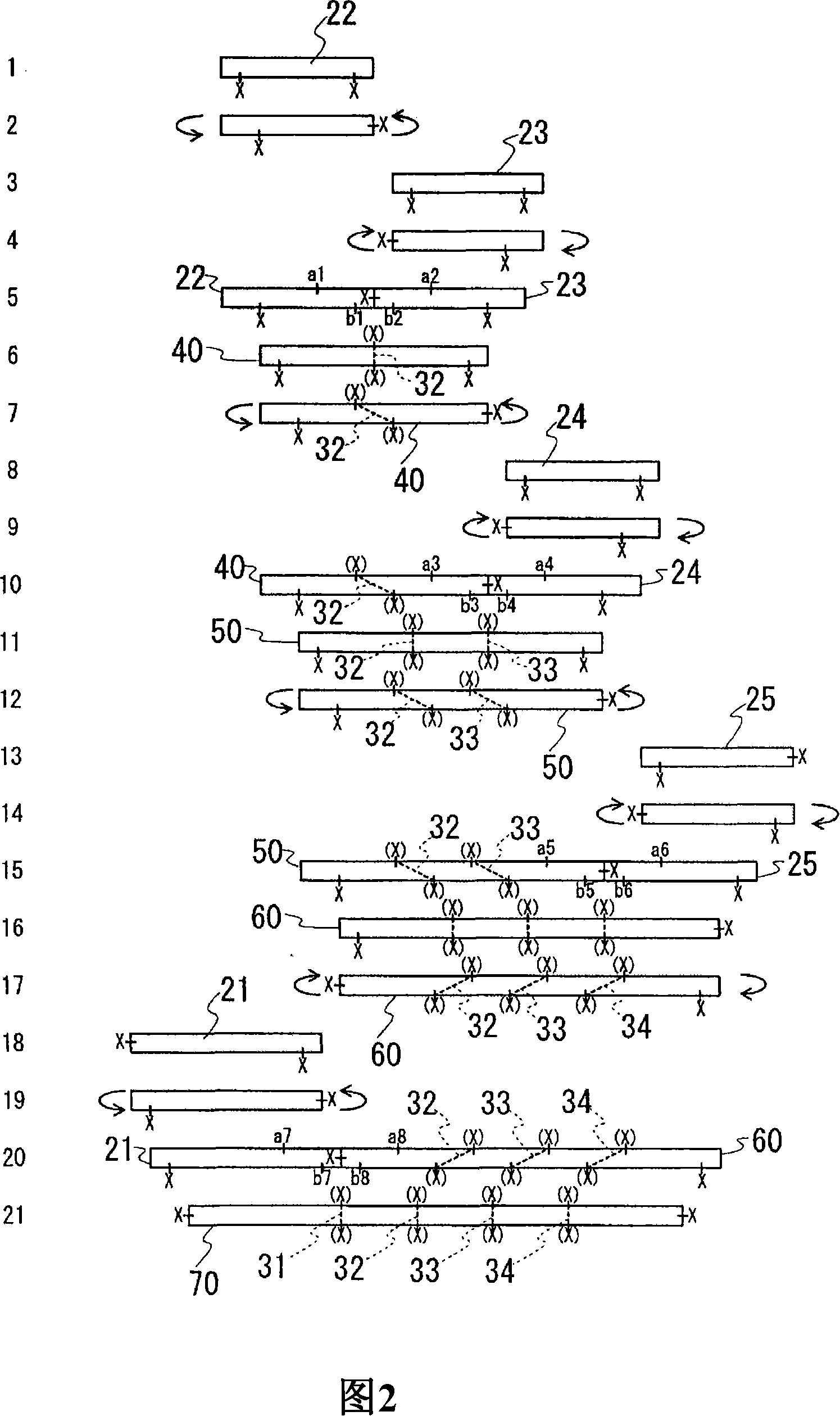

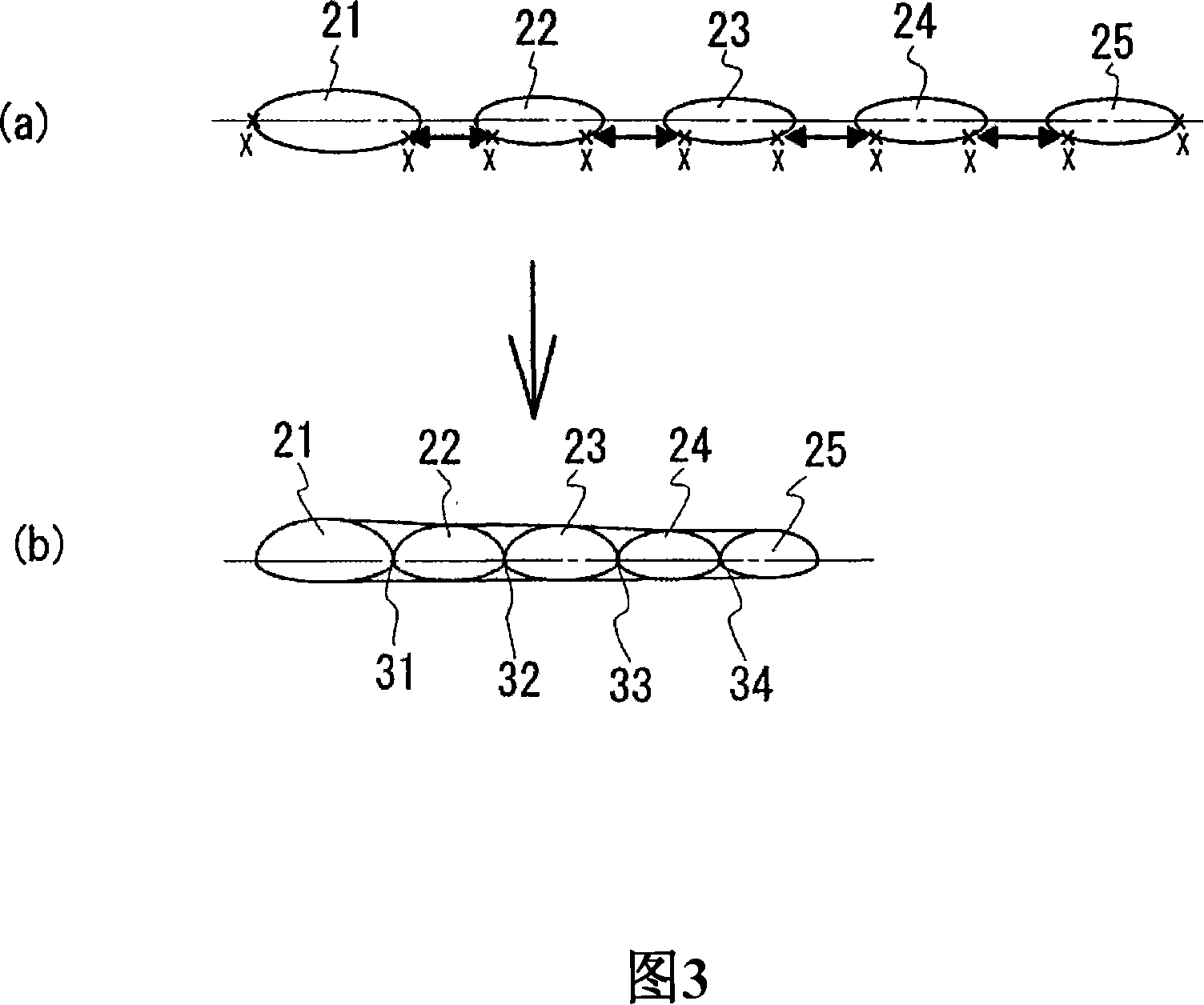

Knitting method of tubular knitted fabric

A knitting method provides an easy-to-wear knitted tubular knitted fabric which gives little stretching feeling and exhibits high fitness upon wearing by joining at least three tubular parts. The method of a tubular knitted fabric using a flat knitting machine having at least a pair of front and back needle beds extending in a transverse direction and disposed opposite to each other in a cross direction, at least either of which is racked in the transverse direction so that loops can be transferred between the front and back needle beds comprises an operation of joining two tubular parts at a boundary of front and back knitted fabrics to form a tubular part is repeated; wherein the boundary is set so that the front knitted fabric and the back knitted fabrics are different in length in a knitting width direction immediately before joining for at least one tubular part; the tubular part in which the front and back knitted fabrics are different in length in the knitting width direction and the boundary to be joined is not positioned between the front and back needle beds is rotated so that the boundary is positioned between the front and back needle beds; and two adjacent tubular parts having the boundaries opposed to each other between the needle beds are joined while holding the boundary in between after the rotation.

Owner:SHIMA SEIKI MFG LTD

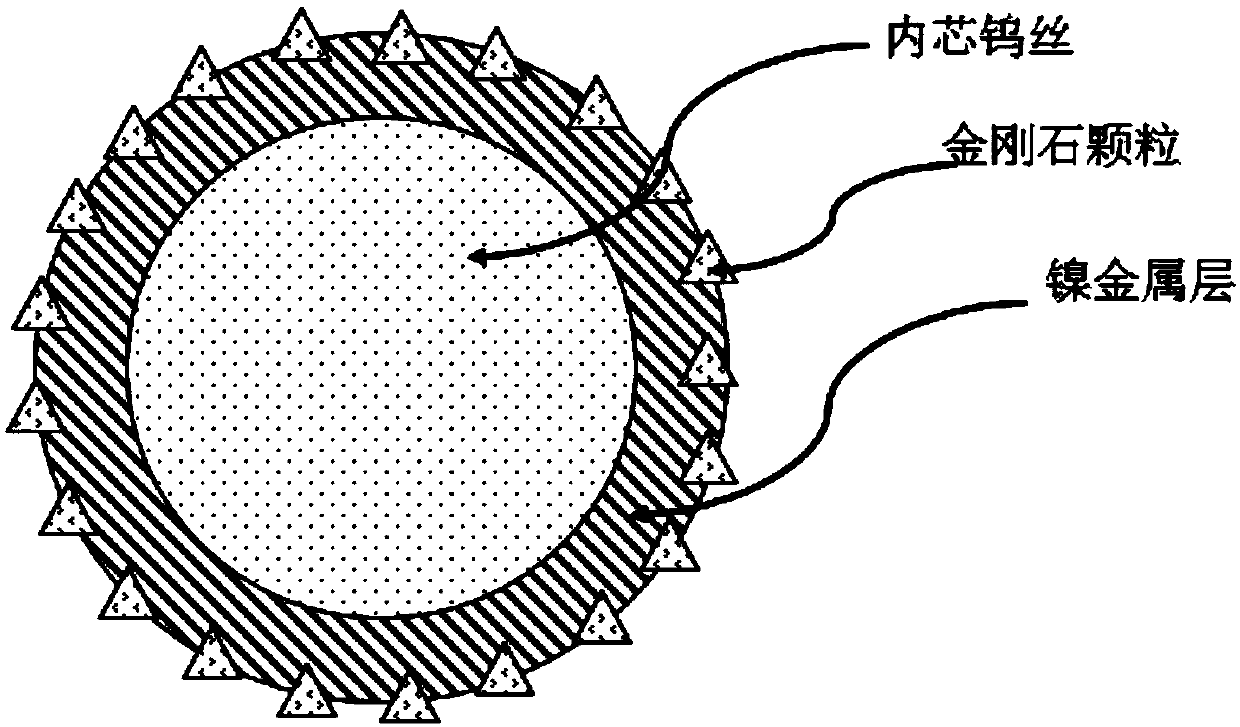

Diamond wire saw and preparation method thereof

PendingCN109591210ANo torsionIncrease productivityWorking accessoriesFine working devicesTungstenElectrolyte

The invention belongs to the technical field of a cutting wire saw, specifically relates to a diamond wire saw and a preparation method thereof. In the diamond wire saw provided by the invention, theintermediate core is tungsten, the surface layer is covered with a metal plating layer or a resin layer, the surface of the metal plating layer or the resin layer is fused with diamond particles. Thepreparation method is as follows: a tungsten wire is combined and pulled by multi-pass sliding drawing and non-sliding drawing to obtain a tungsten wire with a diameter of 0.008-0.065mm; and then, thedrawn tungsten wire passes through an electrolyte containing diamond particles to obtain an electroplated diamond wire saw; or the above drawn core wire passes through a resin solution containing diamond particles to obtain a resin diamond wire saw after being cured. The diamond wire saw with the core body prepared by the invention has a diameter of 0.01-0.085mm and a strength greater than or equal to 4000 MPa, so the diamond wire saw can effectively improve the cutting quality and cutting efficiency in the application aspect of the cutting line.

Owner:盛利维尔(常州)金属材料有限公司 +1

Head-body separation device with guide function

The invention provides a head-body separation device with a guide function, comprising a guide assembly and a thrust assembly, wherein the guide assembly and the thrust assembly are arranged in a cylinder body and respectively comprise a guide push rod and a thrust spring which are arranged in the cylinder body; the front end of the guide push rod extends out of a front cover of the cylinder bodyand is used as a thrust end pushing against the head, namely the rear end of an aircraft, a piston which is matched with the inner diameter of the cylinder body is arranged at the rear end of the guide push rod, a compression spring which is arranged in a cylinder body chamber is arranged between the piston and a rear cover of the cylinder body, and the rear cover of the cylinder is fixed on the inner wall of a separation body through a base. The maximum stroke L of the guide push rod is smaller than the maximum compression amount 5mm-10mm of the spring. The maximum stroke L of the guide pushrod is greater than the maximum length H about 5mm-10mm of a protruding structure on the rear end surface of the aircraft. The front end of the guide push rod is sunk in a groove at the rear end of the aircraft.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

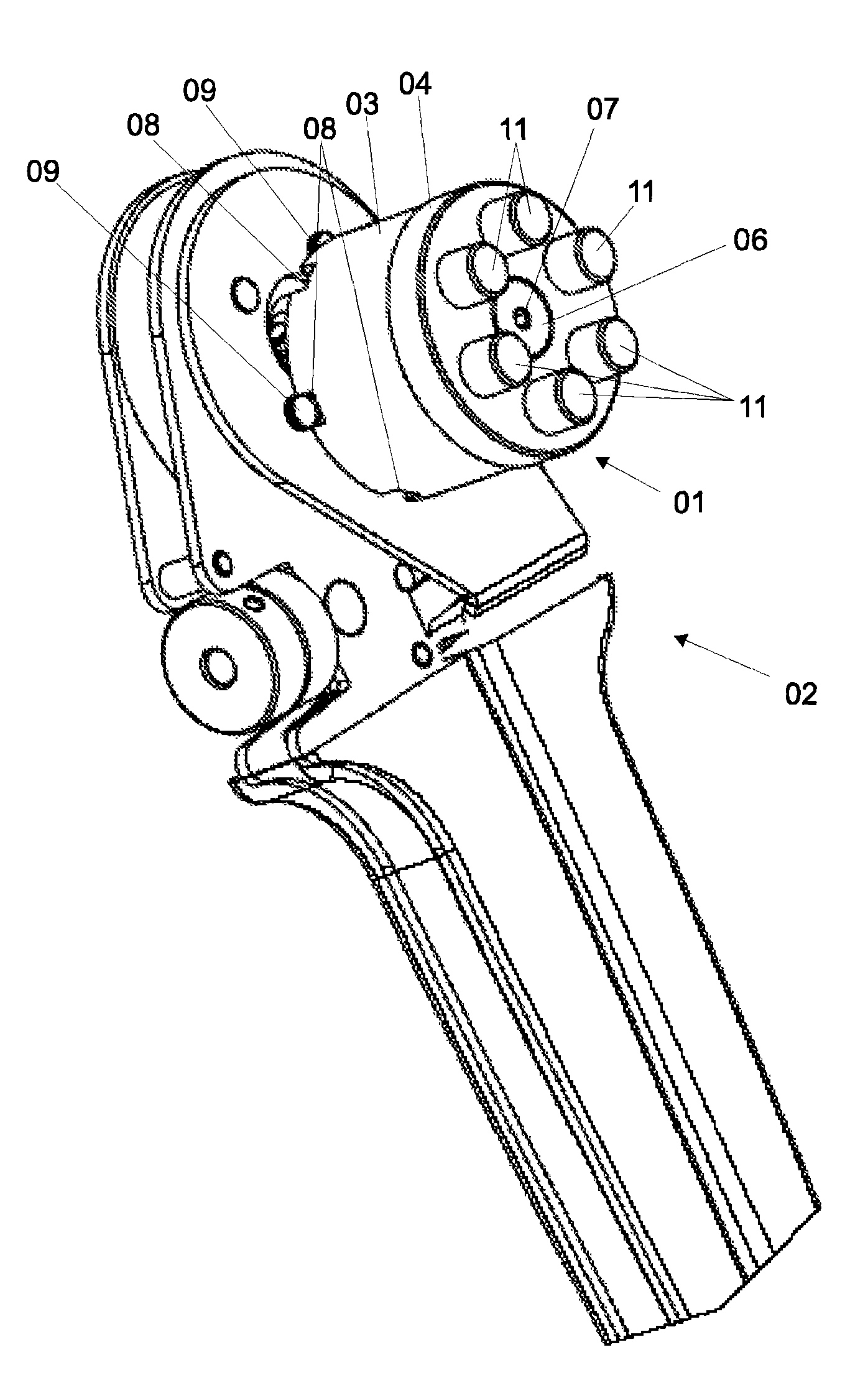

Positioning device for crimping tools

The invention relates to a positioning device for crimping tools. Such positioning devices are suitable for the positioning of an element that is to be pressed relative to the pressing elements of the crimping tool, which are formed by notching elements, crimping plungers or the like. According to the invention, the positioning device (Ol) comprises a support head (03) which is rotatable with respect to the crimping tool (02, 23). A plurality of positioning elements (11, 12) are peripherally arranged in said support head and can be individually displaced in an axial manner in the direction of the crimping tool (02, 23) between an initital position and a working position. The invention also relates to a crimping tool, for example a crimping pliers or a crimping insert for a crimping machine.

Owner:RENNSTEIG WERKZEUGE

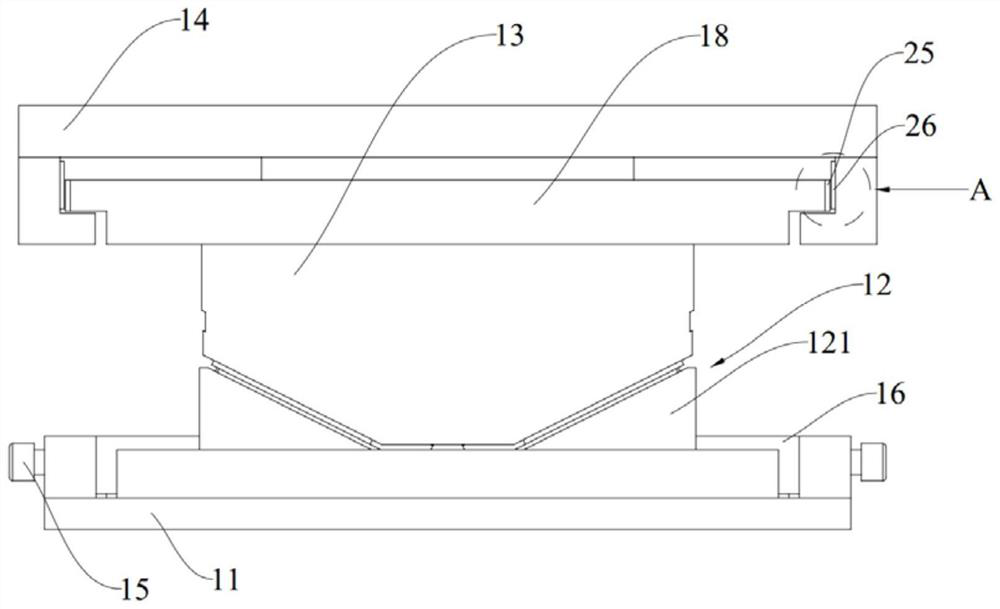

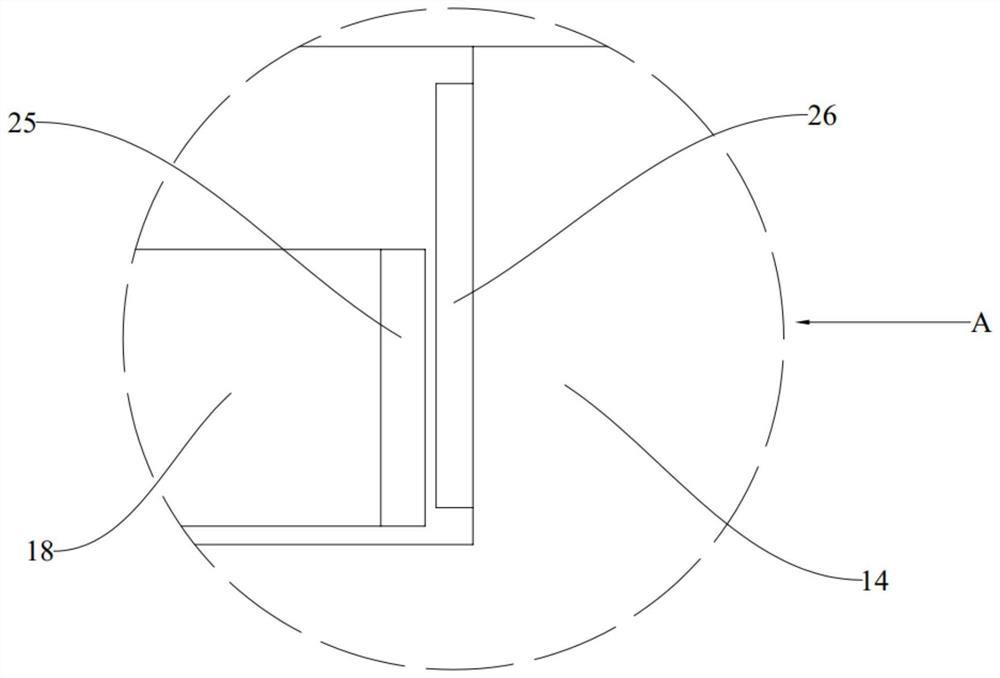

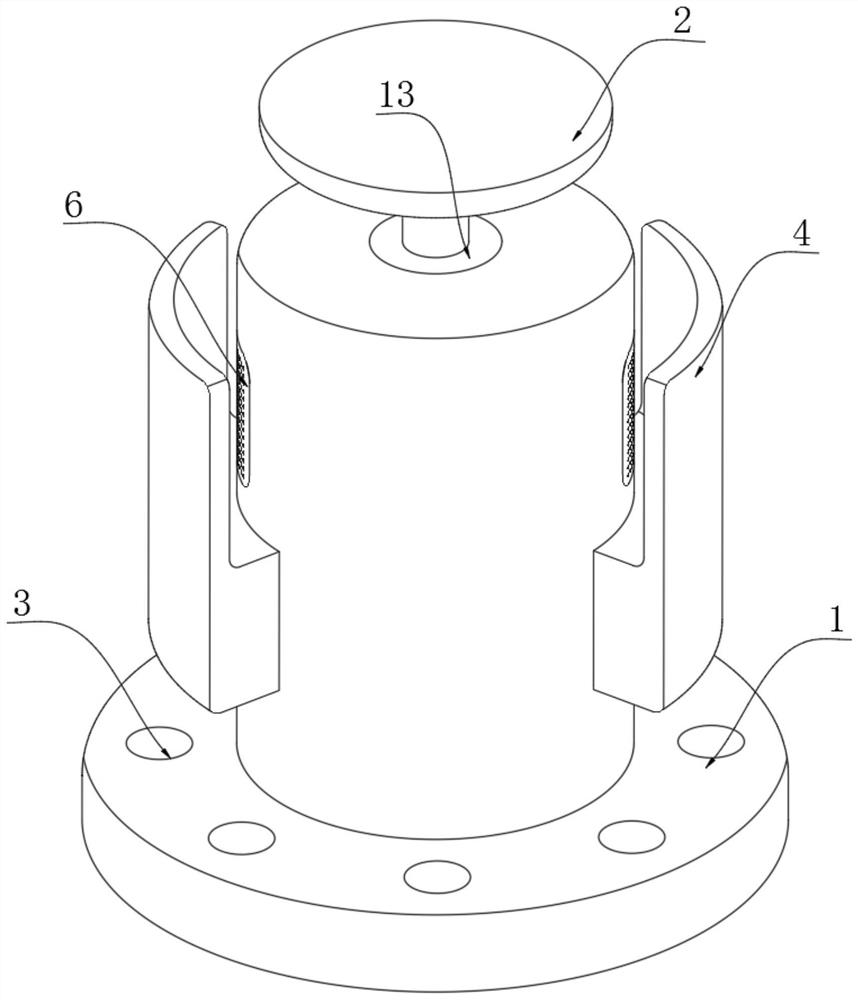

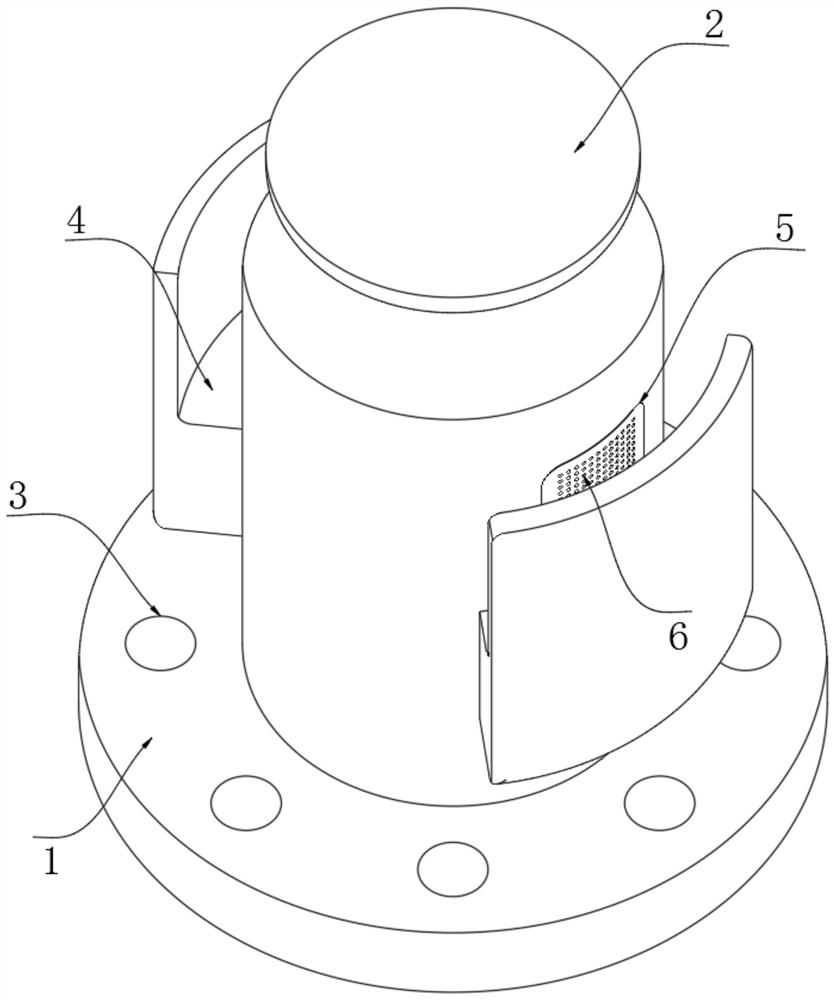

Folding type support disk

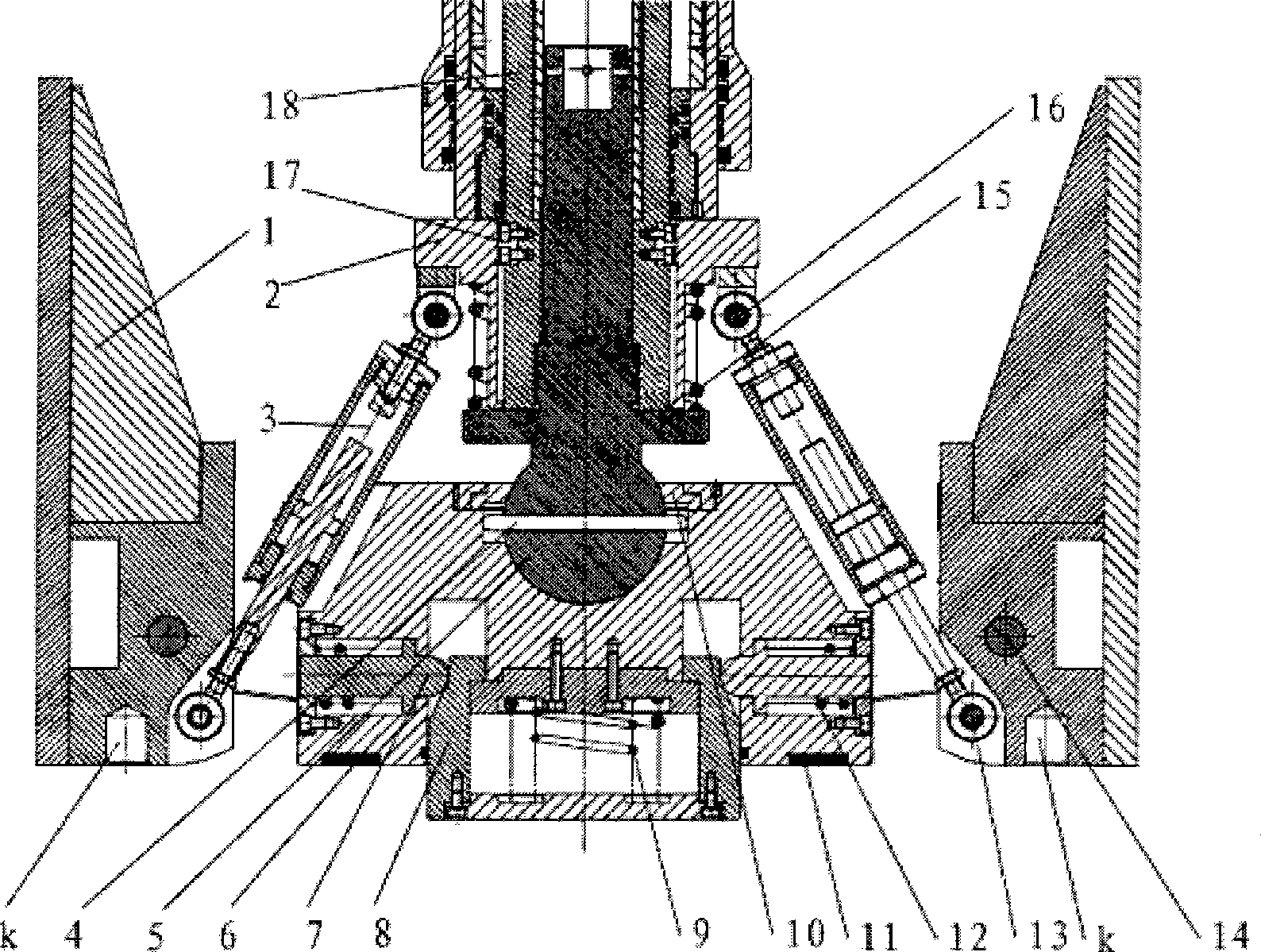

InactiveCN101391598AIncrease the effective working areaIncrease frictionVehicle cleaning apparatusMaterial resourcesEngineering

The invention belongs to support structures, in particular to a folding support plate. The folding support plate comprises a piston which is connected with a vehicle, two or more pull rod sliding bases are arranged on the side wall of the piston and can be slid up and down along the side wall of the piston, the pull rod sliding bases are hinged with pull rods, a base is arranged below the piston, a ball head of the piston is fixedly connected on the top surface of the base, slopes are arranged on the positions which are corresponding to the pull rods and arranged on the side wall of the base, lugs are arranged on the side wall below the slopes, folded plates are fixed on the lugs through rotary shafts and hinged with the pull rods through lower shafts, and the folded plates can be rotated by taking the rotary shafts as the shafts under the action of the pull rods. The folding support plate has the effects that: 1. the effective working area of the support plate can be increased through the folding mode, thereby allowing the vehicle to carry the larger support plate under the situation of not increasing the additional space, having no need of carrying a bulky stow wood and saving manpower and material resources; and 2. the support plate can realize the automatic one-time leveling of the ground slope by relying on the sliding bases.

Owner:BEIJING INST OF SPACE LAUNCH TECH

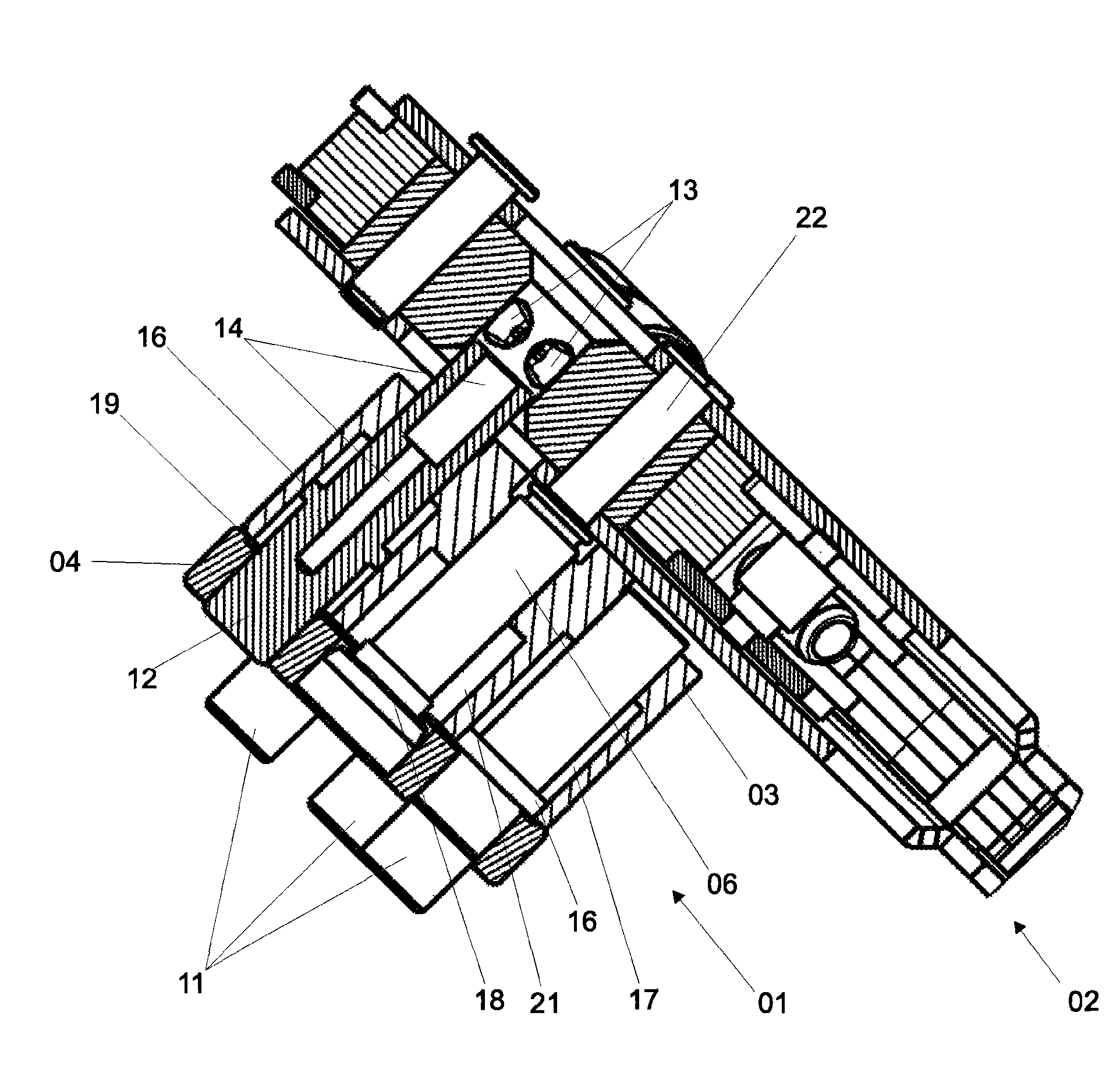

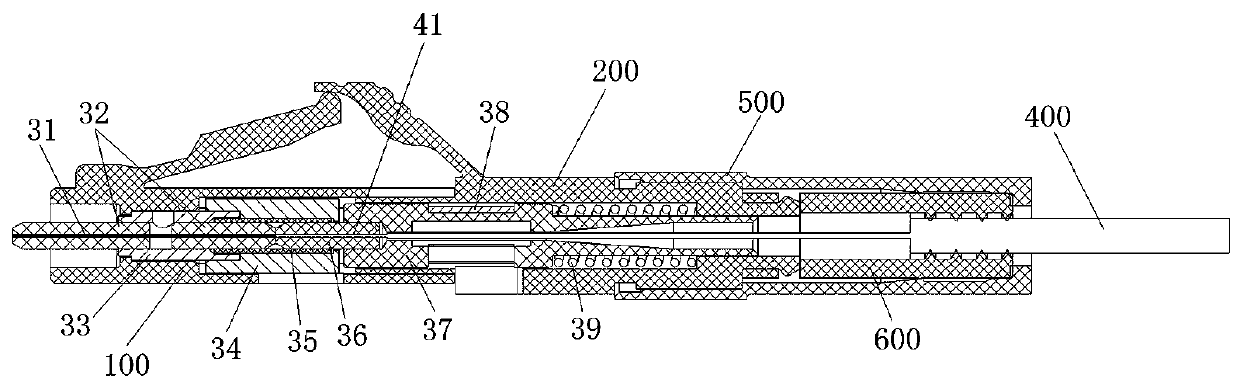

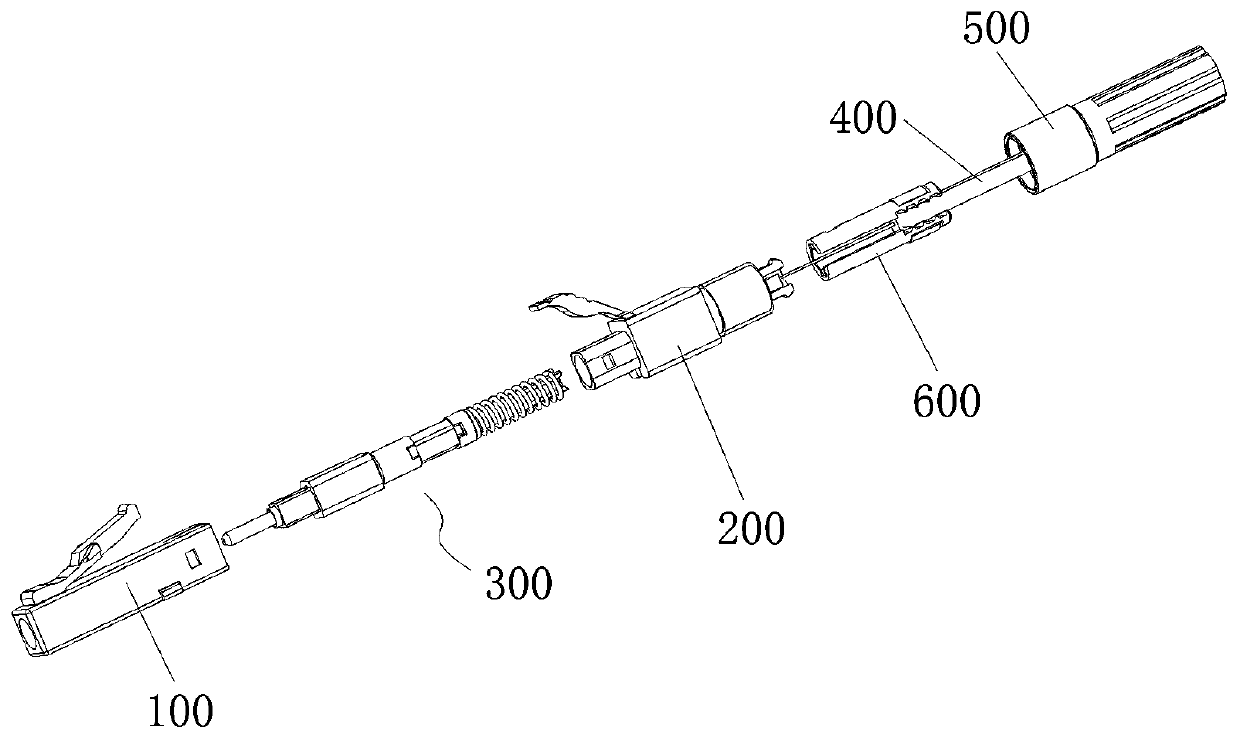

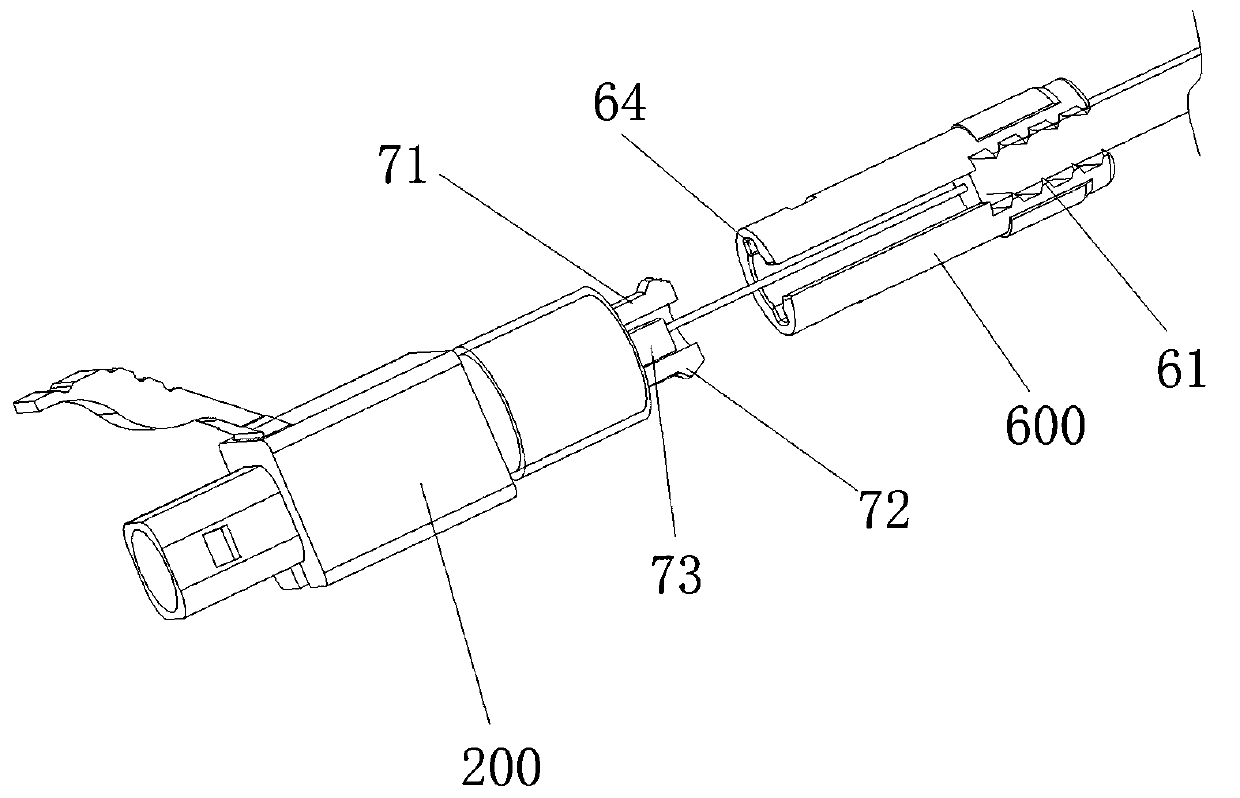

Optical fiber connector for field construction

ActiveCN110208913ANo torsionCoupling accuracy influenceCoupling light guidesEngineeringOptical fiber connector

The invention provides an optical fiber connector for field construction. The optical fiber connector comprises a connector shell, wherein the front end of the connector shell is a plug-in end, and the rear end of the connector shell is a wiring end; an embedded optical fiber and a mounting sleeve are arranged in the connector shell; an optical cable press-fitting structure is also arranged on theconnector shell and comprises a tail clamp; the tail clamp and the connector shell are assembled together in a circumferential rotation-stopping manner through a circumferential rotation-stopping structure; an elastic arm is arranged on one of the tail clamp and the connector shell; a bulge is arranged on the outer side of the elastic arm; a plug-in part which is in plug-in fit with the bulge toform front and back axial stop fit is arranged on the other of the tail clamp and the connector shell; and the optical cable press-fitting structure also comprises a connecting nut which is spirally assembled at the rear part of the connector shell and is sleeved outside the tail clamp. The tail clamp is fixed relative to the connector shell, so that the connecting optical fiber in the optical cable cannot be twisted during assembly, and the influence on the coupling accuracy of the embedded optical fiber and the connecting optical fiber is avoided.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

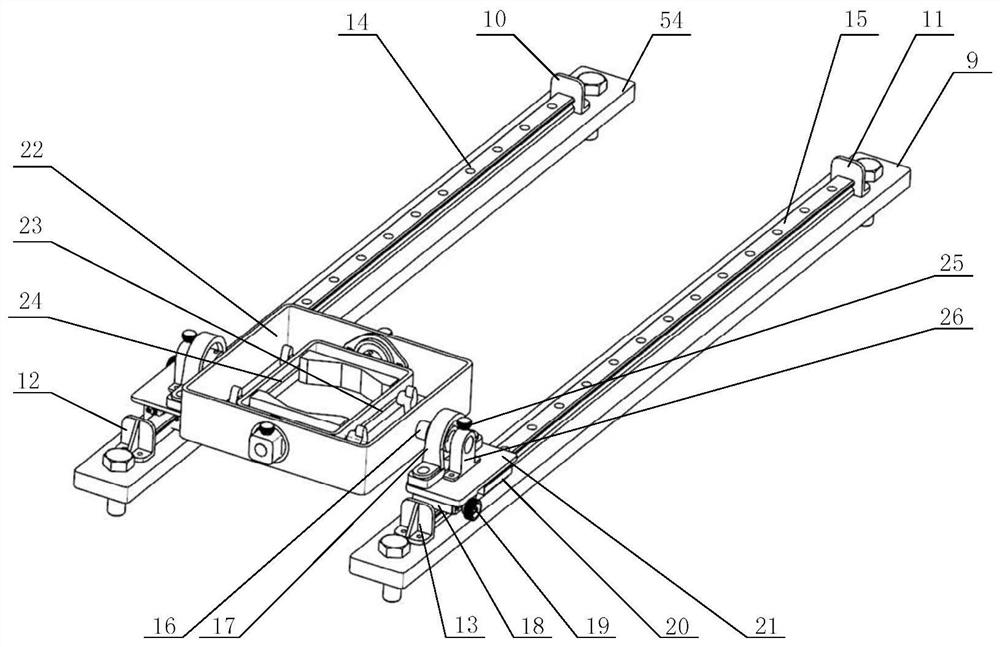

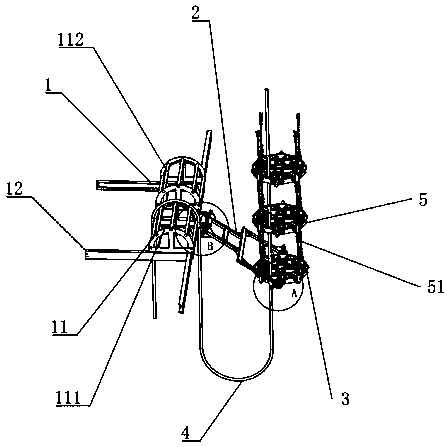

Two-dimensional linear air float guide rail type mechanical arm gravity compensation device

ActiveCN103878788ASolve the problem of gravity compensationMeet deformation effectsManipulatorEngineeringDrive motor

The invention relates to a mechanical arm gravity compensation device, in particular to a two-dimensional linear air float guide rail type mechanical arm gravity compensation device which solves the problem that a space mechanical arm is designed according to a space weightless environment ball, if gravity compensation is not carried out in a ground experiment, a drive motor can not normally operate, and even the mechanical arm is damaged. According to the two-dimensional linear air float guide rail type mechanical arm gravity compensation device, the upper end of a first suspension rope is fixedly connected with a first suspension center, two second linear air float guide rails are arranged side by side in parallel, a first linear air float guide rail is arranged between the two second linear air float guide rails, the two ends of the first linear air float guide rail are in sliding connection with the two second linear air float guide rails respectively, the upper end of a second suspension rope is connected with the first linear air float guide rail through a movable sliding block, the lower end of a third suspension rope is connected with the middle portion of a mechanical arm, and the lower end of a fourth suspension rope is connected with the right end of the mechanical arm. The two-dimensional linear air float guide rail type mechanical arm gravity compensation device is used for space mechanical arm gravity compensation.

Owner:HARBIN INST OF TECH

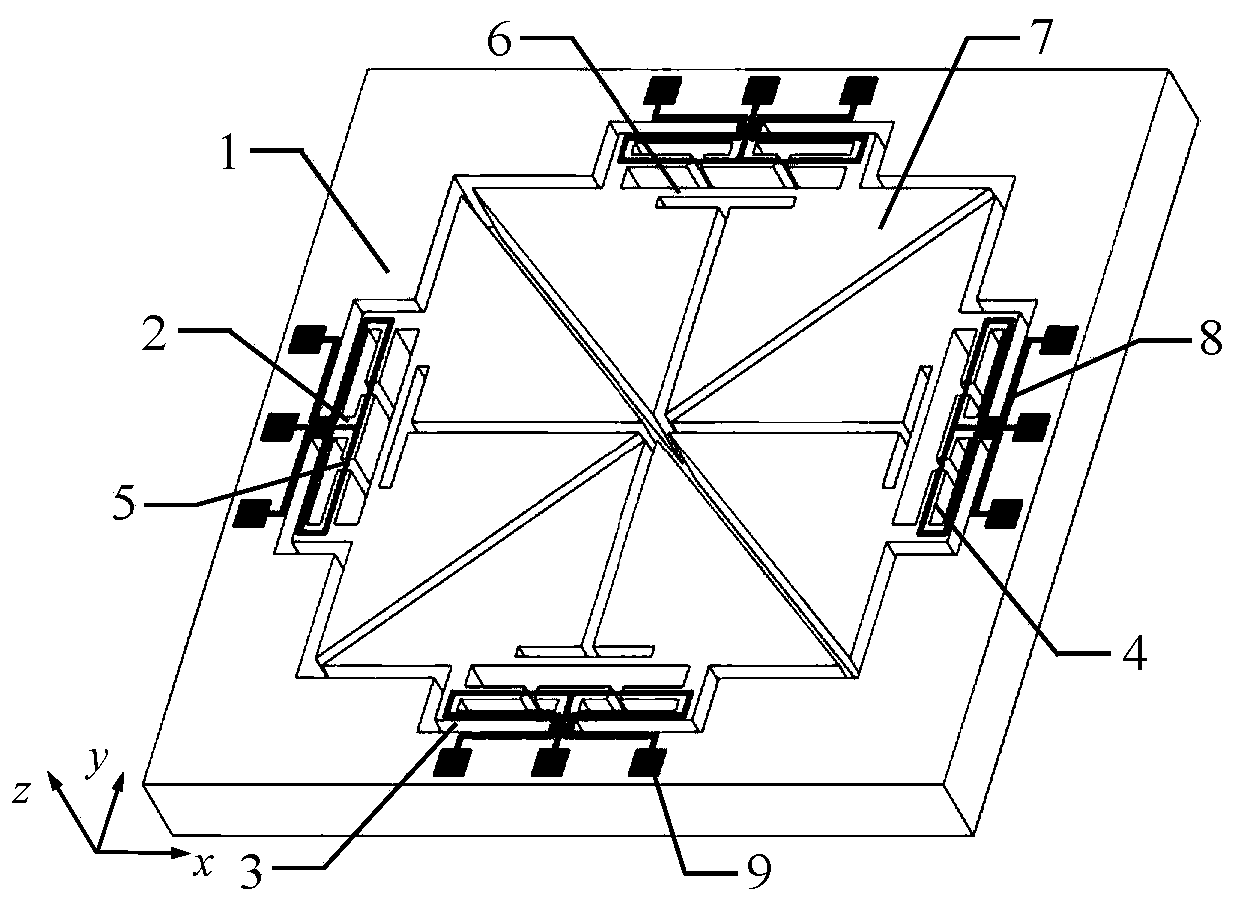

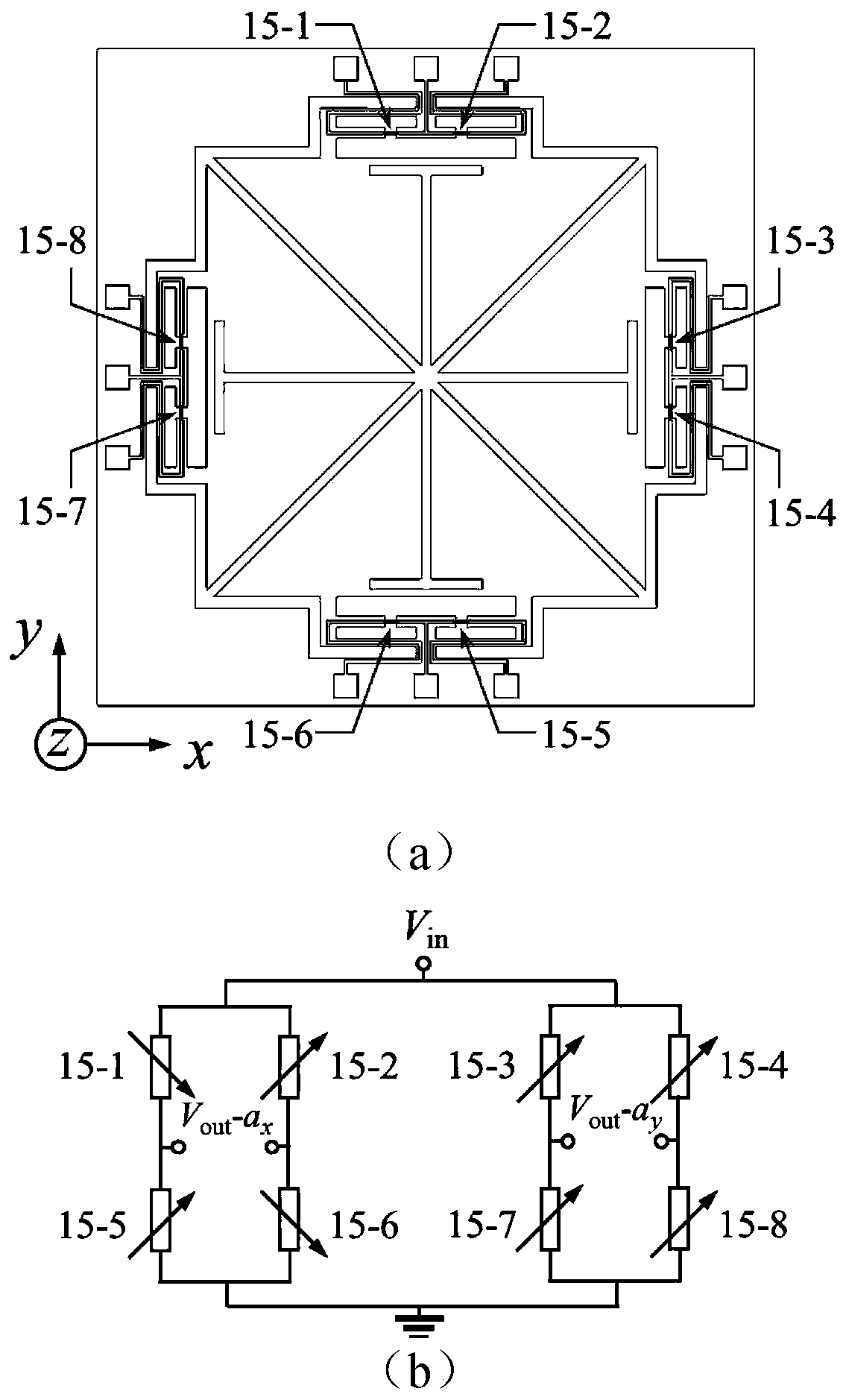

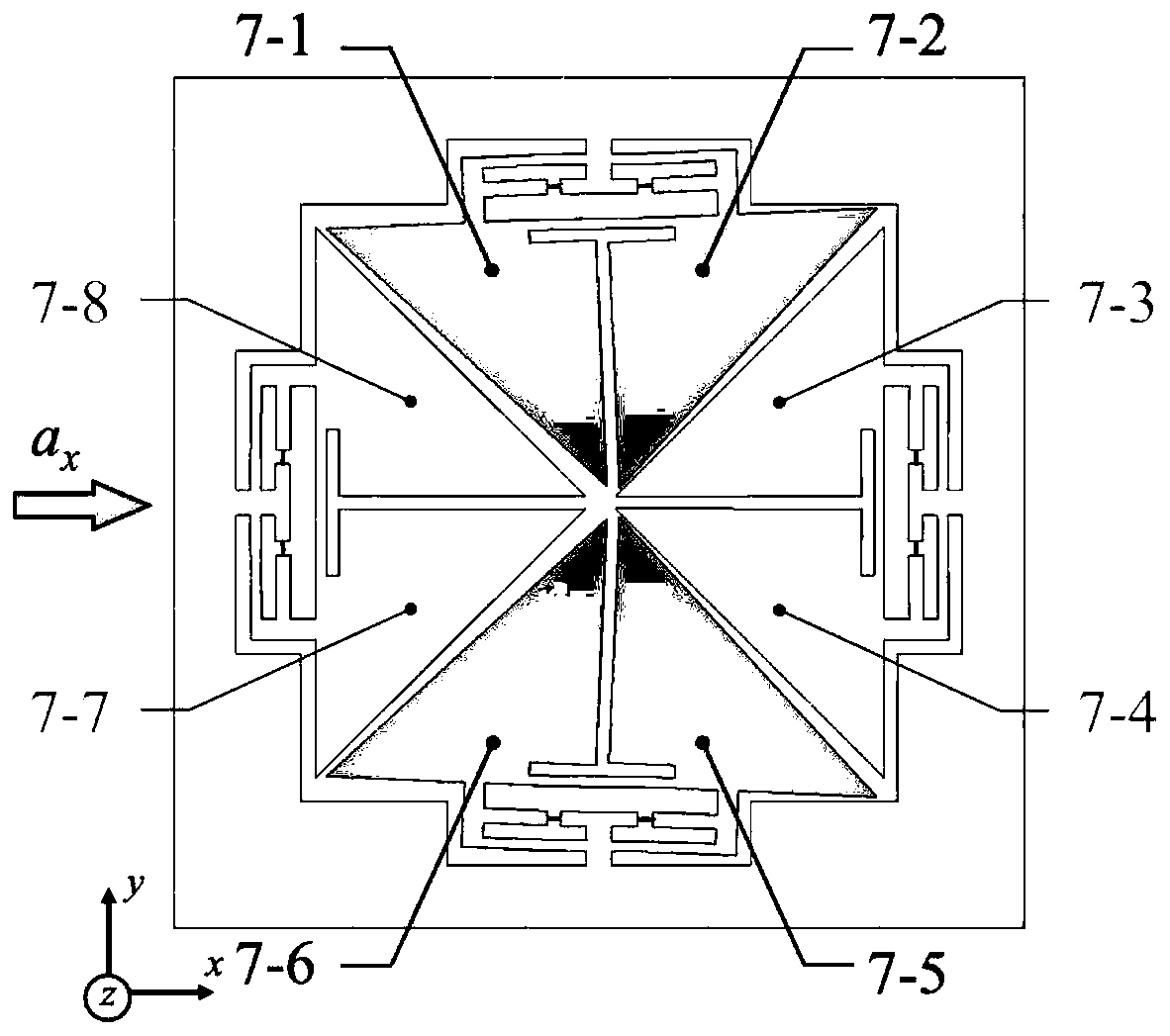

In-plane biaxial piezoresistive acceleration sensor chip and preparation method thereof

ActiveCN110371921AFlexible structureThickness dimension controlTelevision system detailsAcceleration measurement using interia forcesFull bridgeEngineering

The invention discloses an in-plane biaxial piezoresistive acceleration sensor chip and a preparation method thereof. A chip is made of an SOI silicon wafer, and comprises a chip outer frame. A fixingisland is arranged in the middle of each side of the chip outer frame, a supporting beam is of an L-shaped structure, one end of a long section of the supporting beam is fixed to the chip outer framethrough the fixing islands, the other short section of the supporting beam is sequentially connected with an extending beam and a mass block, and a sensitive piezoresistive micro beam is arranged ina gap between the tail end of the extending beam and the fixing islands. All the eight mass blocks are connected through hinge beams to be square. A piezoresistor on the sensitive piezoresistive microbeam is connected with a bonding pad through a metal lead to form a Wheatstone full-bridge circuit. The extension beam is used as an intermediate structure for connecting the sensitive piezoresistivemicro-beam, the support beam and the mass blocks, and transmits the change of the motion state of the mass blocks to the sensitive piezoresistive micro-beam. According to the piezoresistive acceleration sensor chip, the supporting element and the sensitive element are separated, the dynamic performance and the application range of the piezoresistive acceleration sensor are improved, the preparation method is simple, and the reliability is high.

Owner:XI AN JIAOTONG UNIV

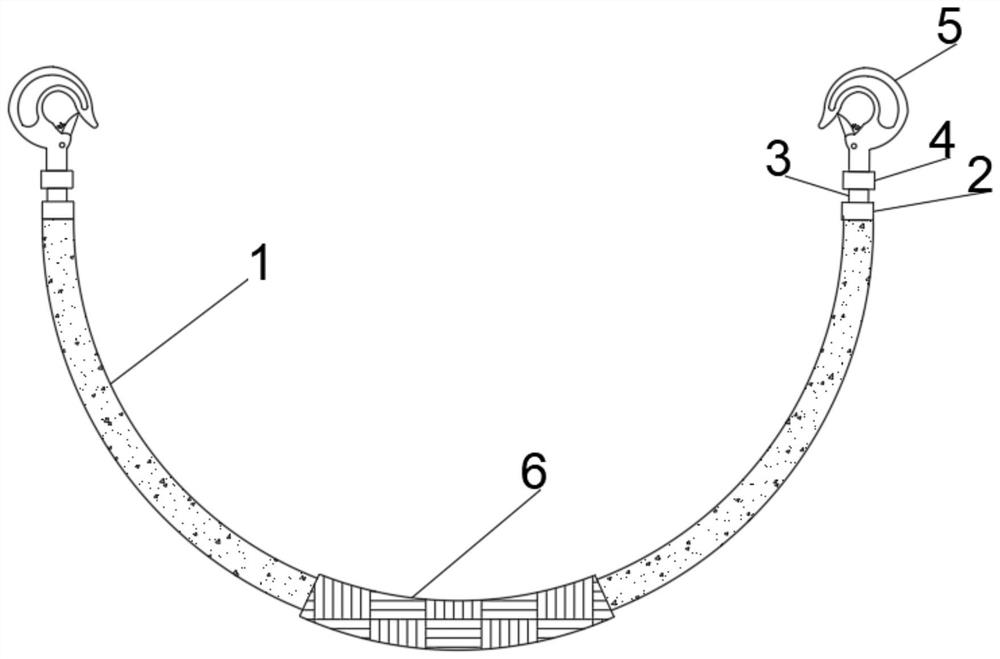

Synthetic fiber lifting belt and mounting method thereof

InactiveCN111874795AExtended service lifePlay a protective effectLoad-engaging elementsInsulation layerEngineering

The invention relates to the technical field of fiber lifting belts, and discloses a synthetic fiber lifting belt and a mounting method thereof. The synthetic fiber lifting belt comprises a lifting belt body, fixing pieces are arranged at the two ends of the lifting belt body, sleeve rods are connected to the upper ends of the fixing pieces, the peripheries of the sleeve rods are sleeved with sleeves, lifting hooks are fixedly connected to the tops of the sleeves, a protective sleeve is fixedly sewn to the periphery of the lifting belt body, and a bearing seat is arranged in each fixing piece.According to the synthetic fiber lifting belt and the mounting method thereof, the lifting hooks are arranged, the lifting hooks are detachable, the specifications of the lifting hooks can be conveniently and rapidly replaced when different objects are lifted, the lifting hooks can be rotatably connected with the fixing pieces through the sleeve rods, the appearance of the lifting belt body is conveniently prevented from being twisted when the lifting belt body is used, a nylon reinforcing layer is arranged in the lifting belt body, the structural strength can be increased, in addition, a high-temperature-resistant heat insulation layer and a high-temperature-resistant protective layer are additionally arranged on the surface of the protective sleeve, so that the lifting belt body can bear high temperature, and the application range is expanded.

Owner:TAIXING CHENGUANG RIGGING

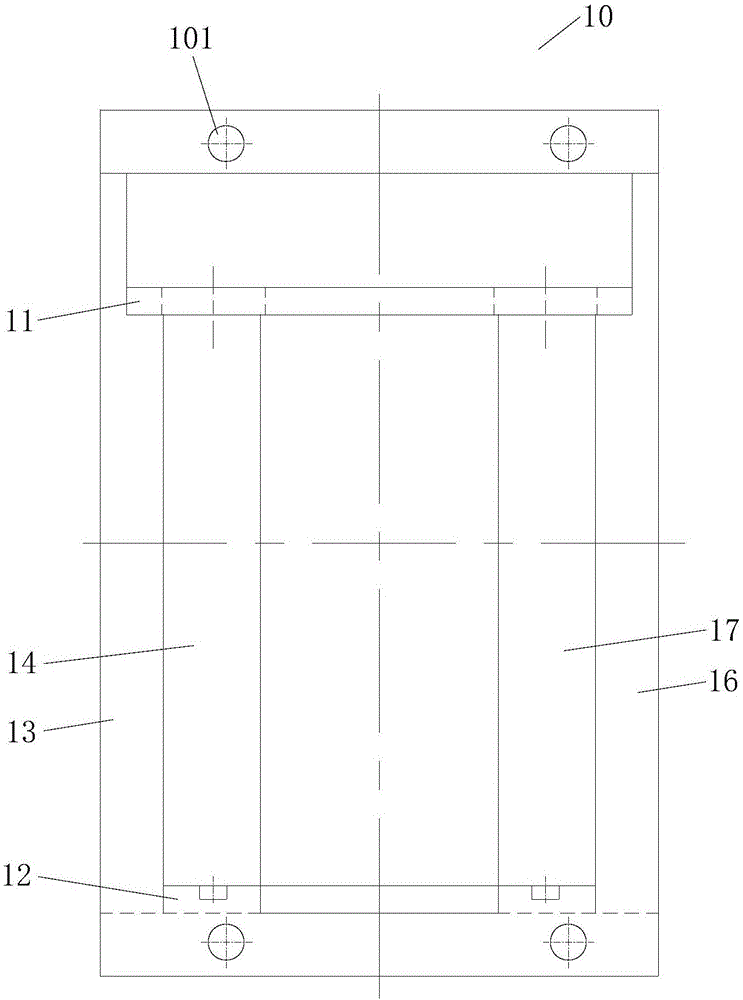

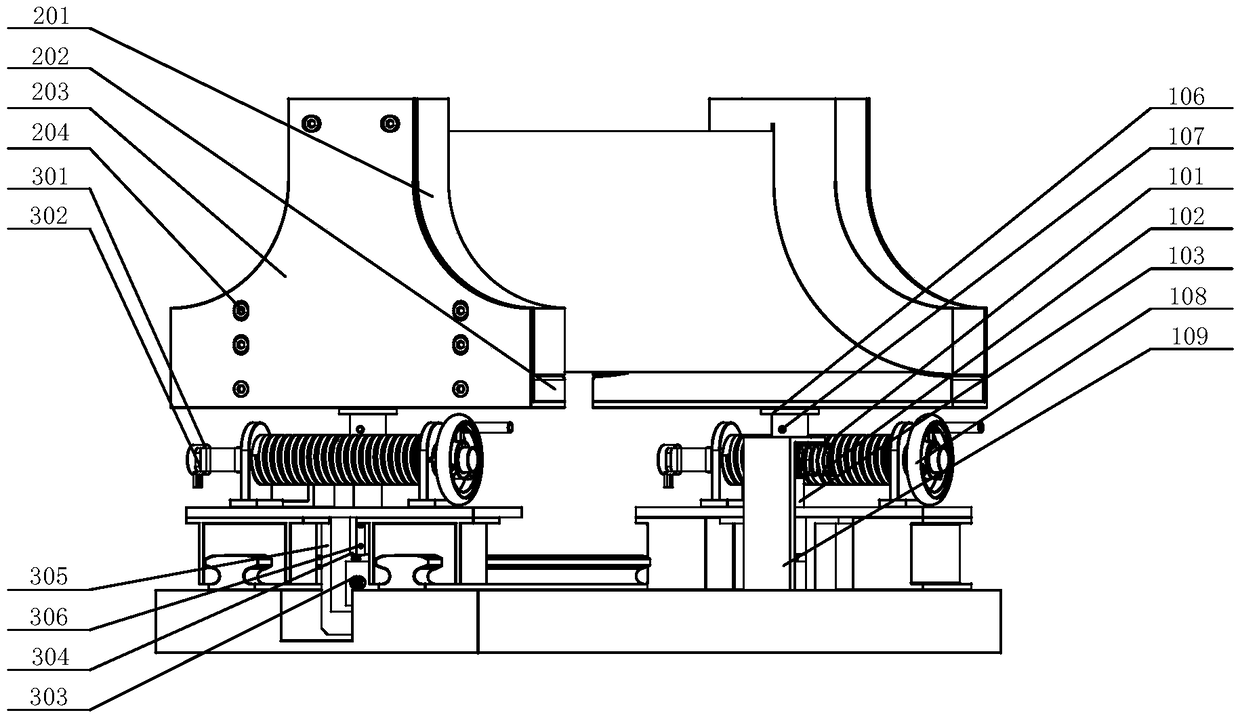

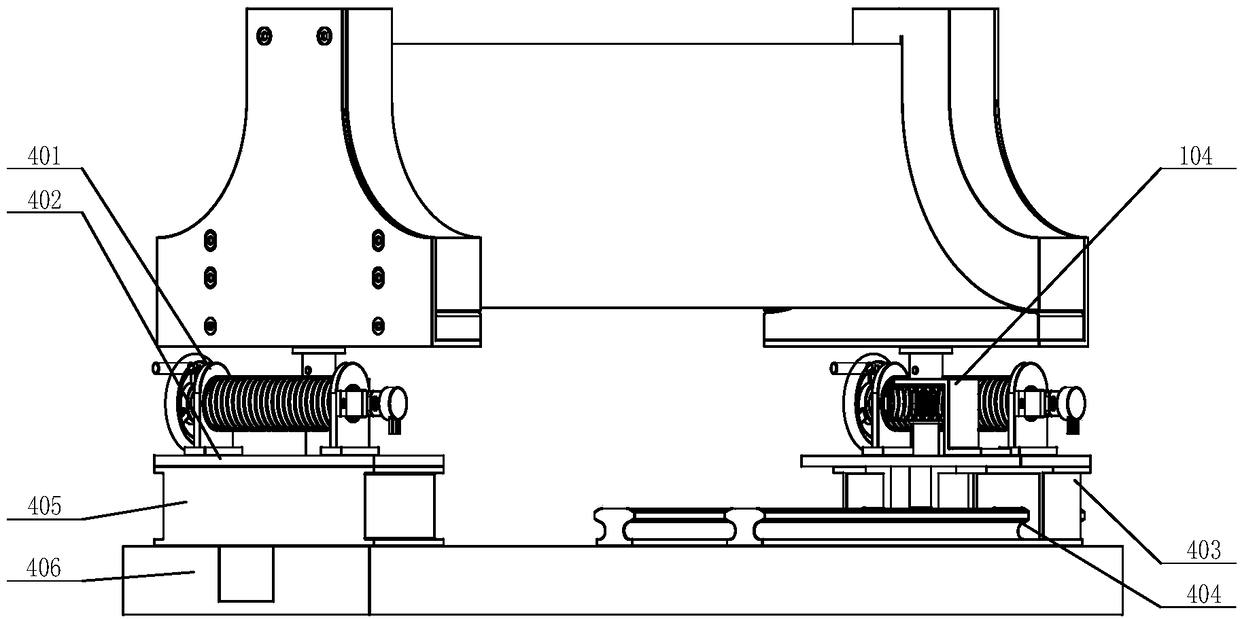

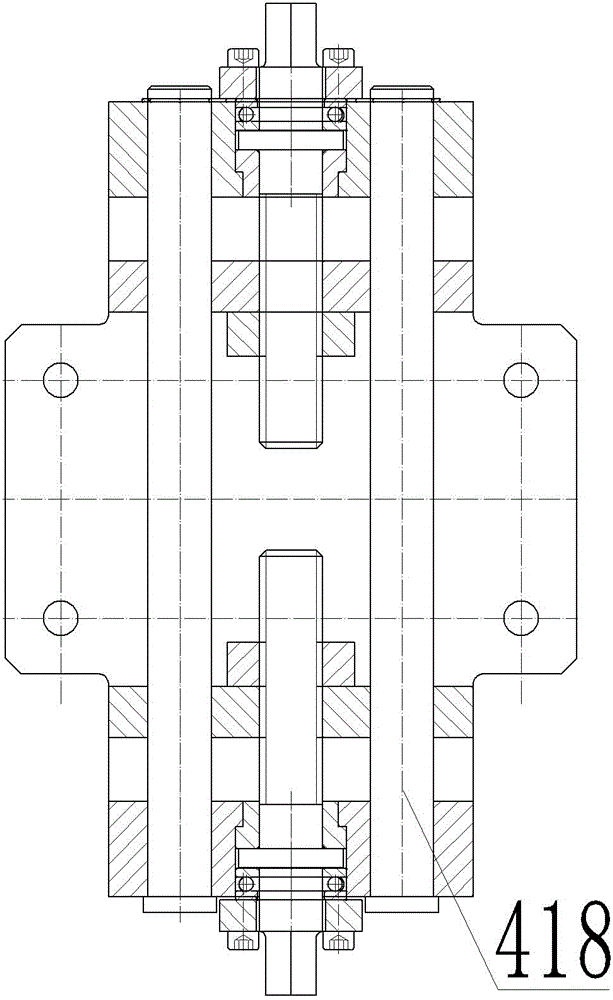

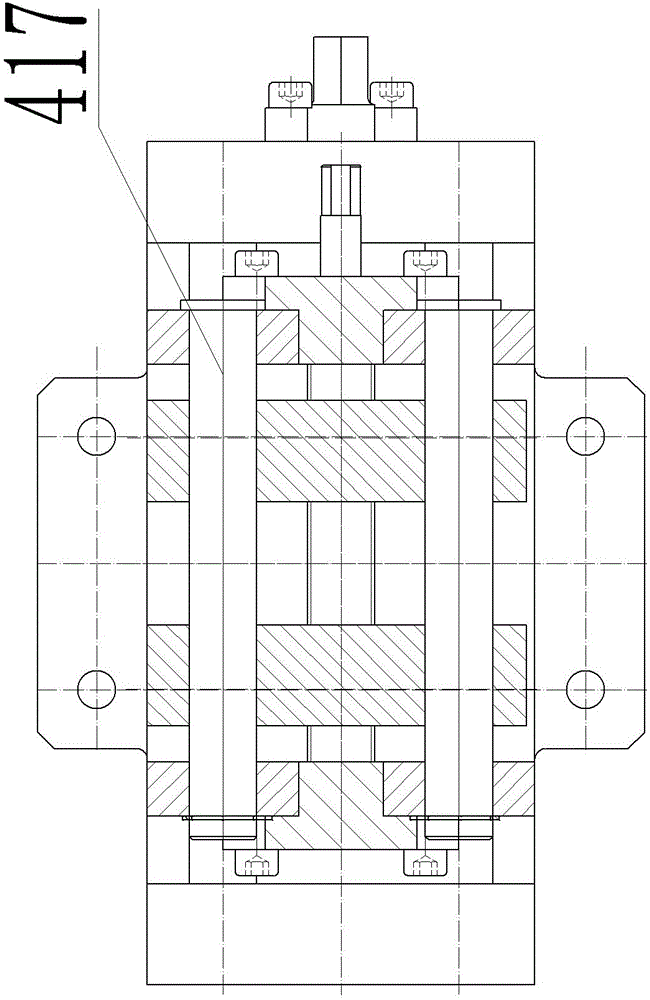

Guiding and guarding clamping device and rolling machine

ActiveCN106670244AHigh strengthIncrease stiffnessGuiding/positioning/aligning arrangementsRoll mill control devicesEngineeringMechanical engineering

The invention provides a guiding and guarding clamping device and a rolling machine. The guiding and guarding clamping device comprises a framework, an adjusting mechanism comprising two screws and a guiding and guarding mechanism comprising an upper guiding and guarding box and a lower guiding and guarding box, wherein the framework comprises an upper cross beam and a lower cross beam which are opposite, a first side wall and a second side wall which are opposite, a first front pressing plate and a first rear pressing plate which are vertically connected to the first side wall, and a second front pressing plate and a second rear pressing plate which are vertically connected to the second side wall; a first sliding groove is defined by the first side wall, the first front pressing plate and the first rear pressing plate, and a second sliding groove is defined by the second side wall, the second front pressing plate and the second rear pressing plate; first and second external threads are separately arranged at the upper and lower parts of each screw; the two ends of the upper guiding and guarding box are separately arranged in a manner capable of sliding in the first sliding groove and the second sliding groove and are in surface contact with the first sliding groove and the second sliding groove; the two ends of the lower guiding and guarding box are separately arranged in a manner capable of sliding in the first sliding groove and the second sliding groove and are in surface contact with the first sliding groove and the second sliding groove; and the screws rotate and drive the upper and lower guiding and guarding boxes to slide in a face-to-face manner or back-to-back manner. The guiding and guarding clamping device has large bearing capability.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

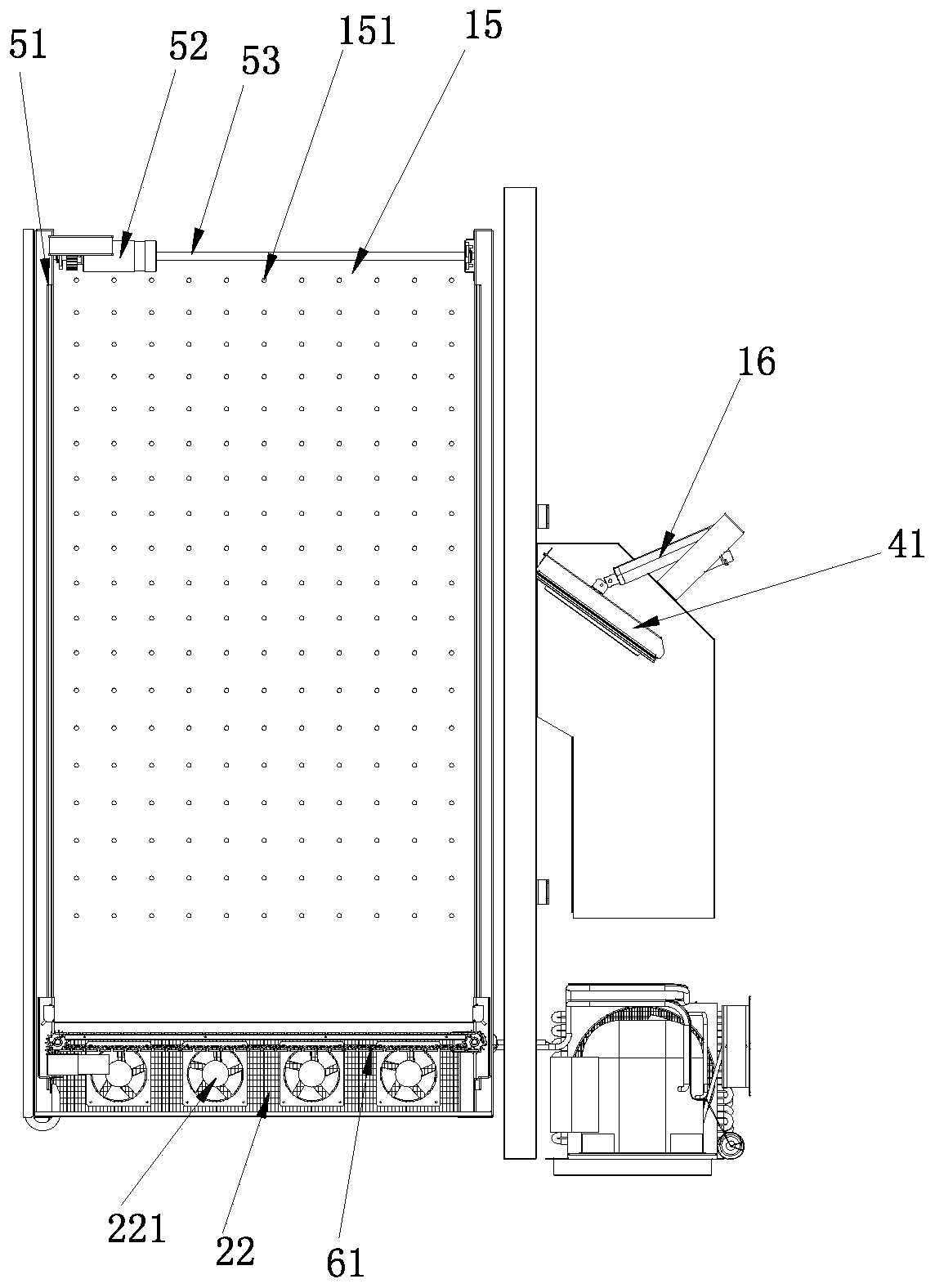

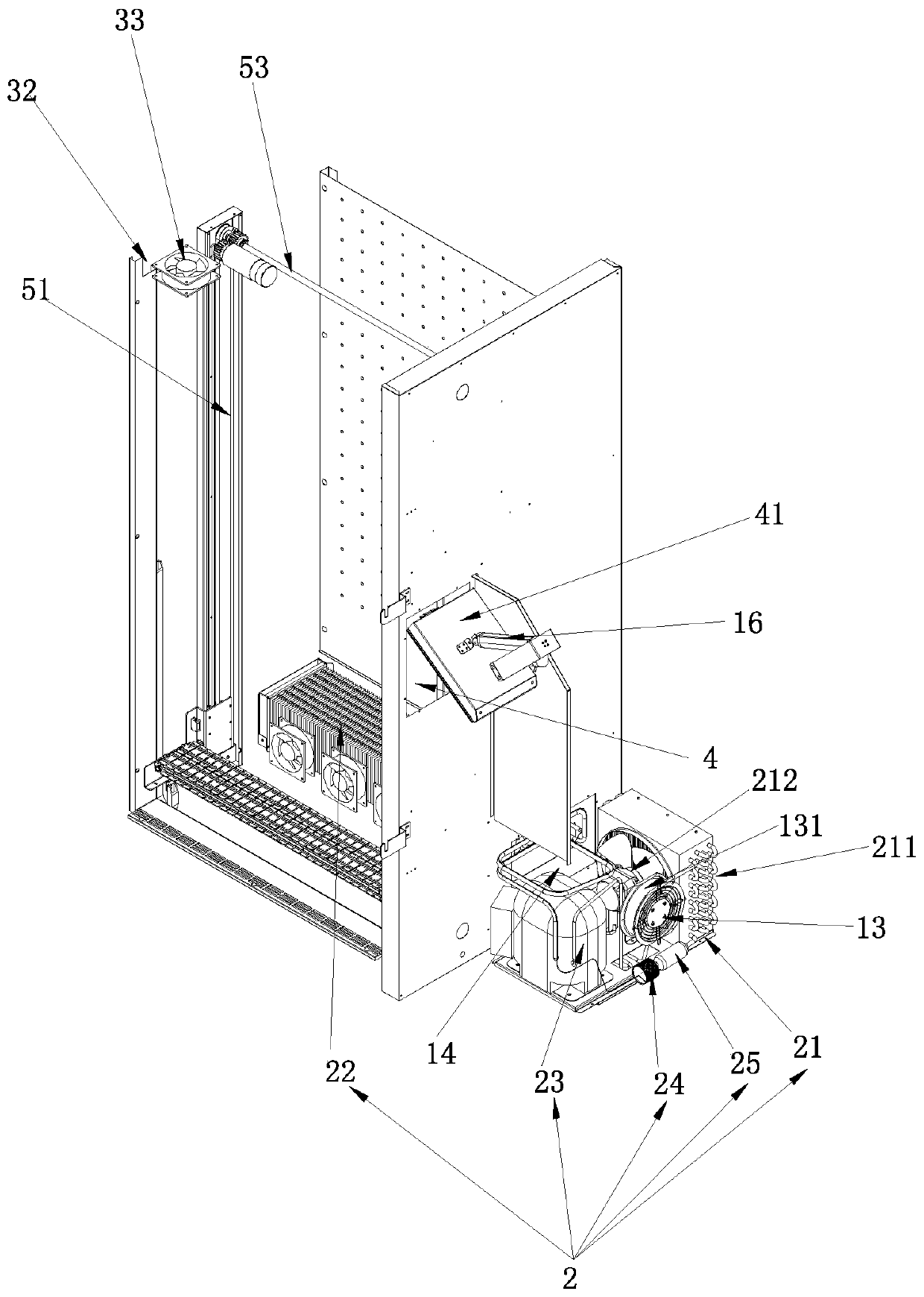

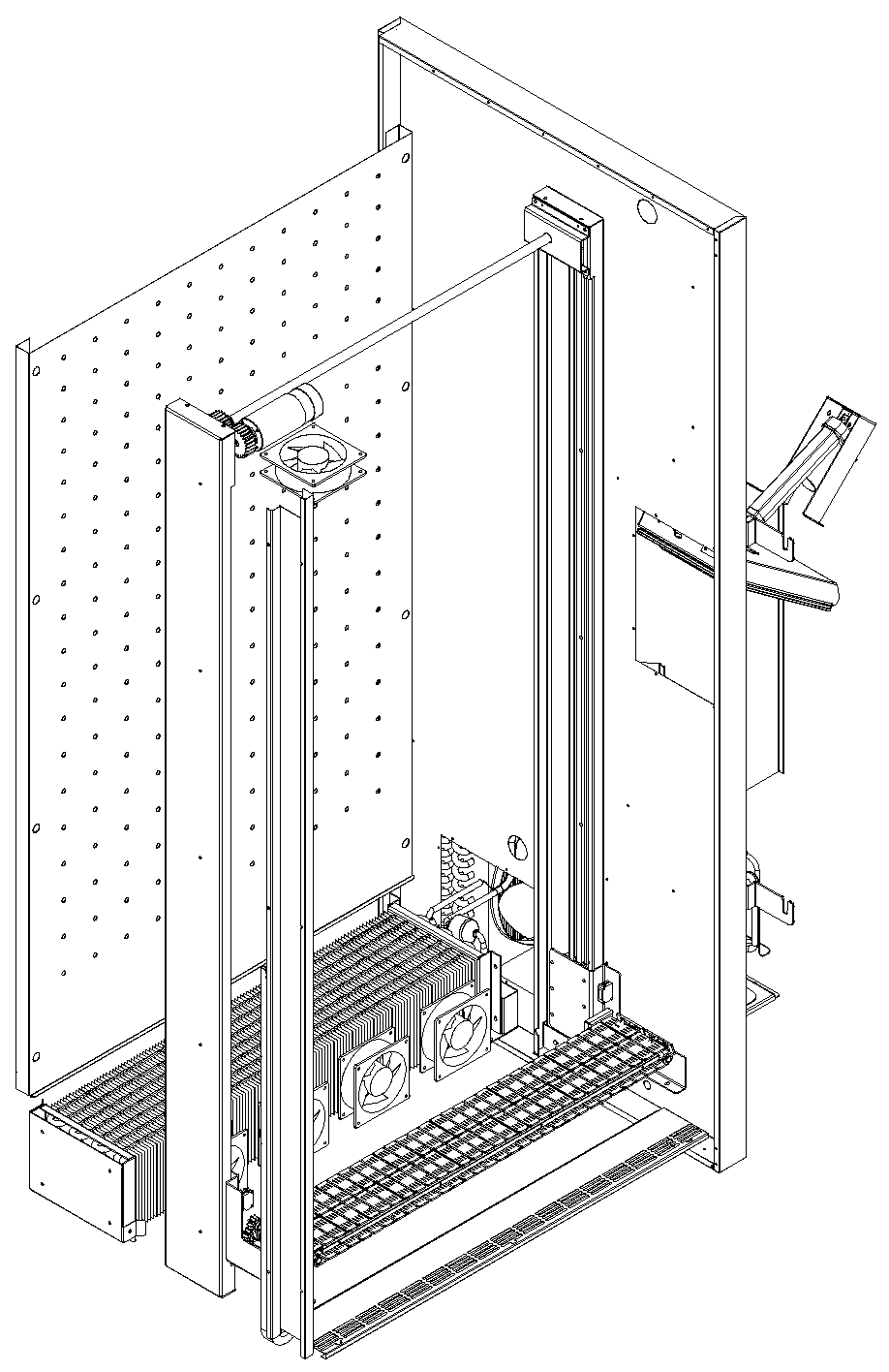

Frozen vending machine

PendingCN110853231AReduce heat exchangeReduce cooling lossLighting and heating apparatusCoin-freed apparatus detailsEngineeringElectrical and Electronics engineering

The invention discloses a frozen vending machine. A wind screen device comprises two air outlet chambers, an air channel and a fan; two air outlet chambers are respectively located at two opposite ends of the doorway; the air outlet chambers are located at the inner side of an opening and closing door; opposite sides of the two air outlet chambers are respectively provided with air outlet holes; the two air outlet chambers communicate with each other through the air channel; the fan is arranged on the air outlet chambers or the air channel; the air outlets of the two air outlet chambers form wind screens which are in butt joint with each other under the action of the fan; a shipping port is arranged on a box body; a goods channel and a shipping platform are in butt joint; the shipping platform is in butt joint with a shipping port through a lateral moving device; the shipping port is provided with a sealing door; various belt transmission mechanisms are located on both sides of the boxbody; a transmission shaft is connected between various belt transmission mechanisms; the transmission shaft is in transmission connection with a rotary driving member; at least one belt transmissionmechanism is in transmission connection with the shipping platform; and the shipping platform has a vertical movement stroke under the driving of the belt transmission mechanisms. The frozen vendingmachine provided by the invention is applied to the technical field of vending machines.

Owner:HUNAN XINGYUAN TECH CO LTD

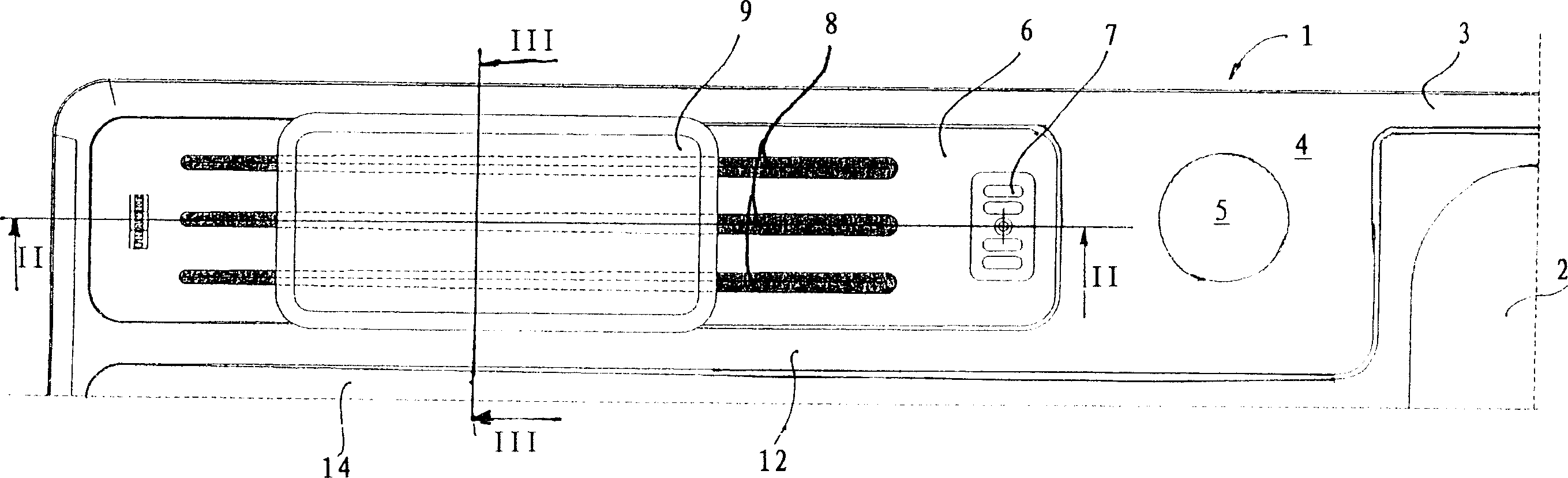

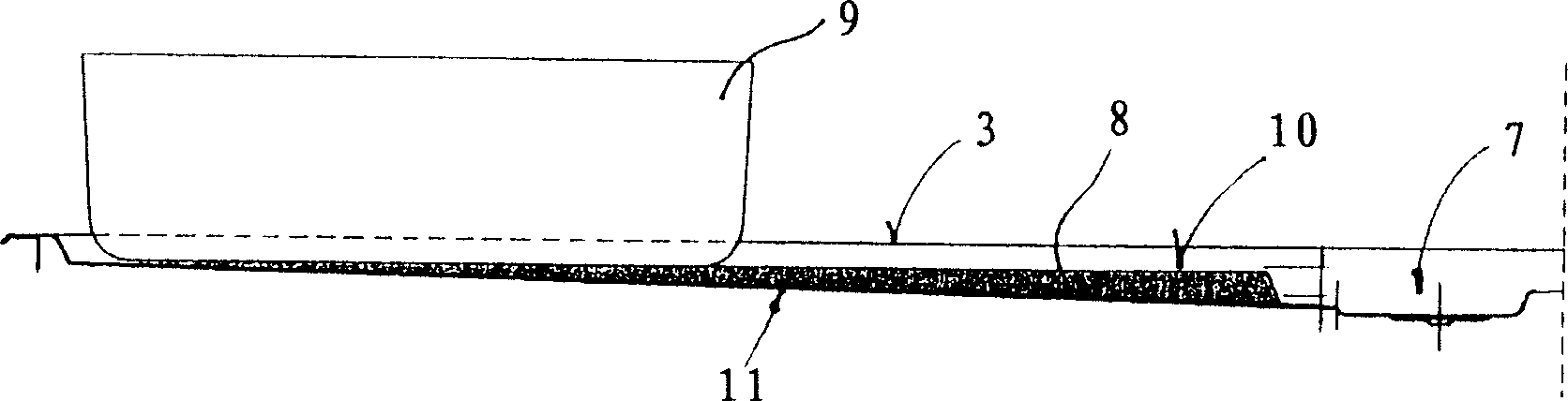

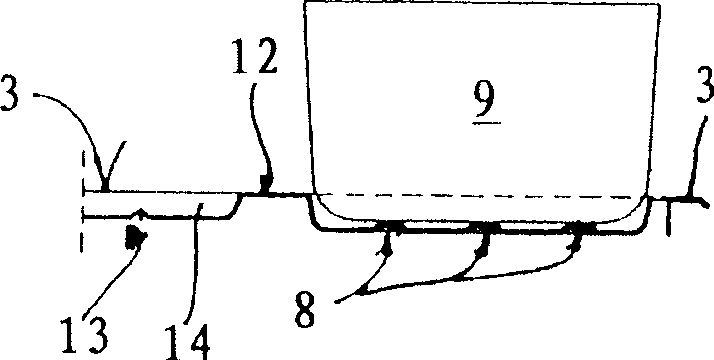

Kitchen sink with drain surface

The invention relates to a kitchen flume which comprises a pool and a water control pool provided with one corrugated portion inclined towards one water outlet, wherein the pool and the water control pool are surrounded by one edge. The upper side of the corrugated portion is provided with a distribution profile parallel with the edge at horizontal direction, therefore, the corrugated portion can support the guiding element on the edge, and the bottom of the corrugated portion is inclined relative to the edge, therefore, the outlet water can be discharged.

Owner:FRANKE TECH & TRADEMARK LTD

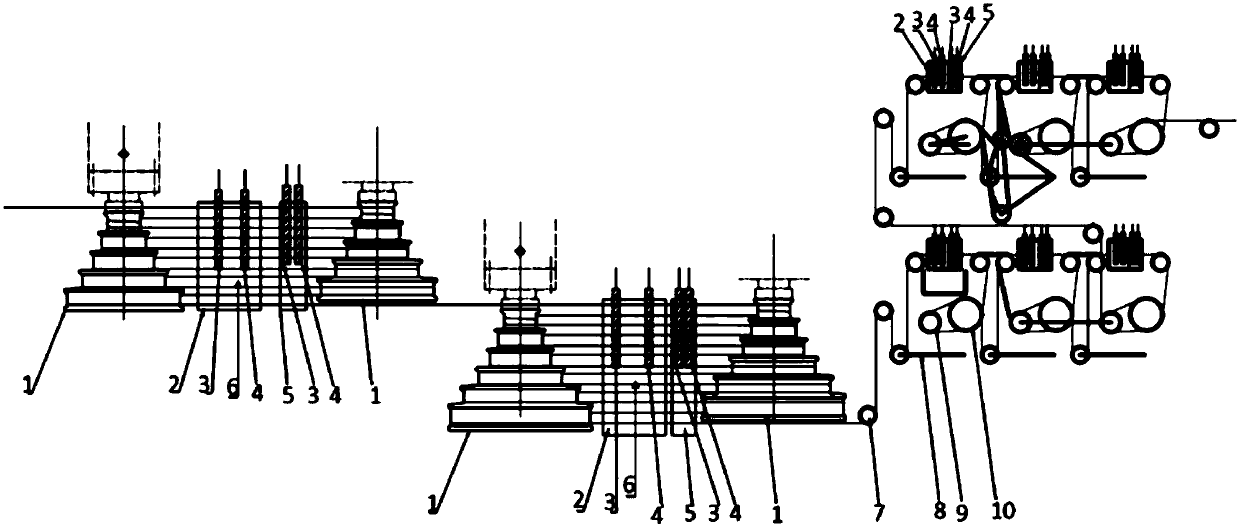

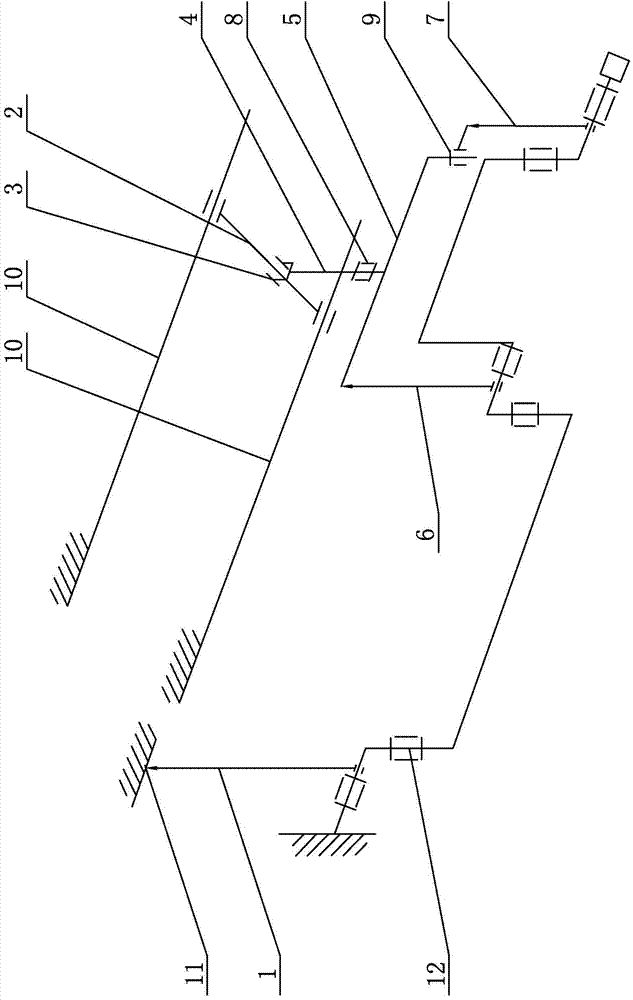

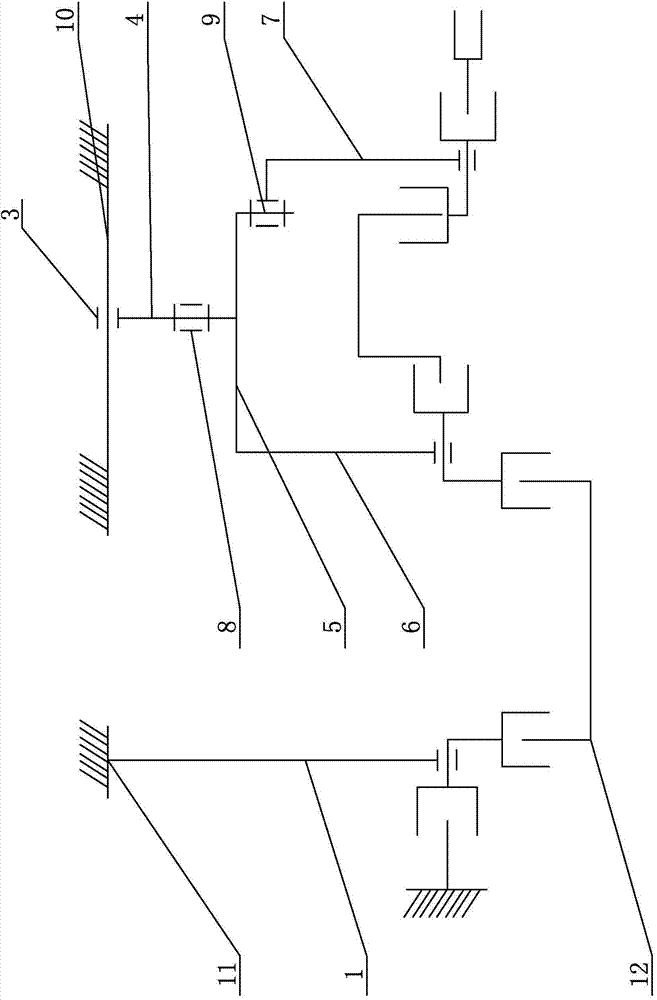

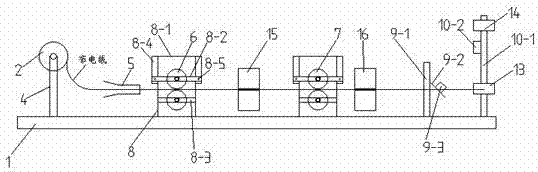

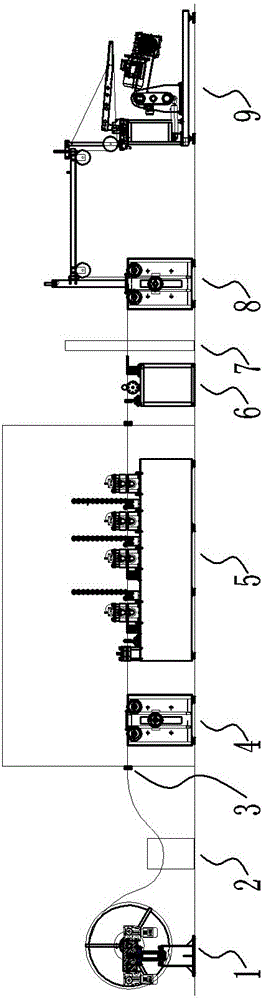

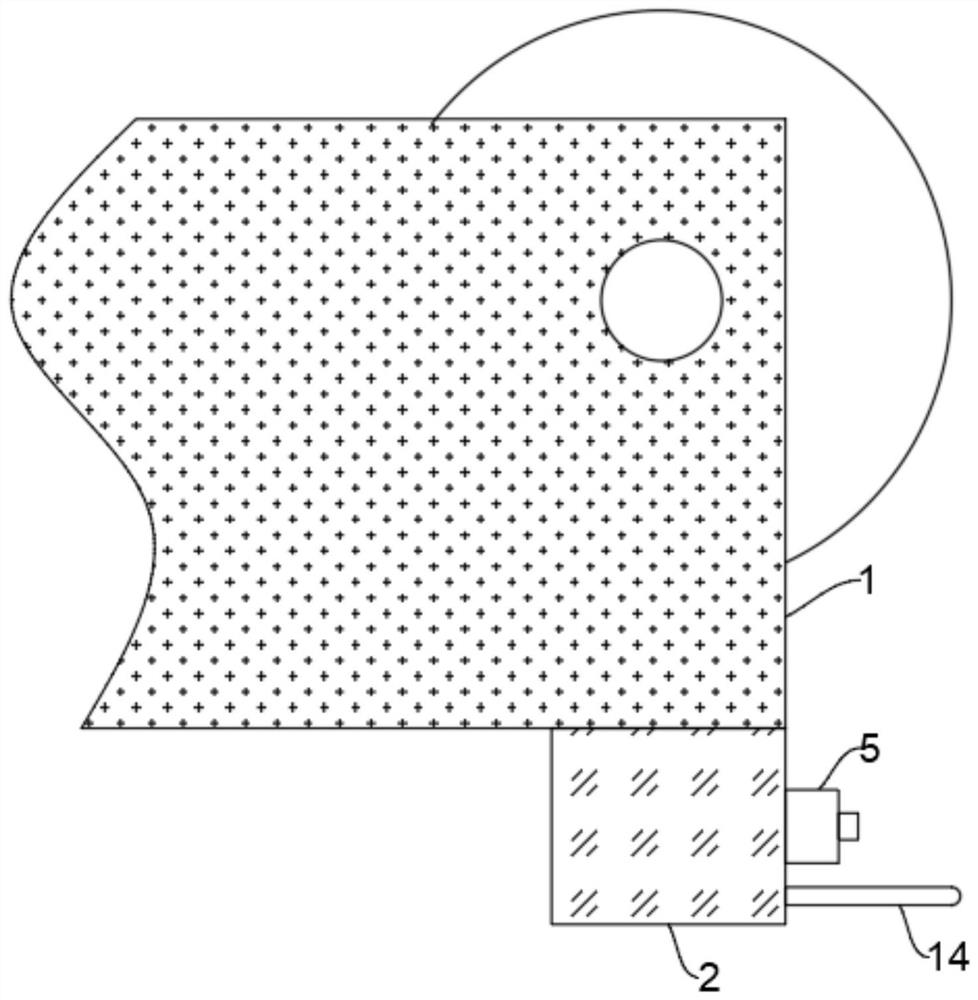

Integrated machine for automatically aligning, shearing and measuring distance of cotton covered wire

InactiveCN107204588AReduce consumptionReduce volumeApparatus for cutting/splicing cablesUsing optical meansEngineeringUltimate tensile strength

The invention relates to an all-in-one machine for automatic straightening, distance measuring and cutting of electric wires. In order to solve the problems of time-consuming and labor-intensive, waste of materials and certain damage to materials in existing construction methods, the automatic straightening, measuring and The integrated distance and cutting machine includes a machine base, on which a tension wire reel is arranged, the tension wire reel is driven by a wiring motor, the output end of the tension wire reel is provided with a straightening mechanism, and the output end of the straightening mechanism is provided with a The distance measuring mechanism, the output end of the distance measuring mechanism is provided with a shearing mechanism, the control device for controlling the tension coil 2, the straightening mechanism, the distance measuring mechanism, and the opening and closing of the shearing mechanism, and the signal input between the distance measuring mechanism and the computer terminal connection, and the tension wire reel, straightening mechanism and shearing mechanism are connected with the signal output terminal of the computer. The all-in-one machine has a simple structure, is convenient to use, can be used in various occasions, has high work efficiency, and reduces the labor intensity of workers.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

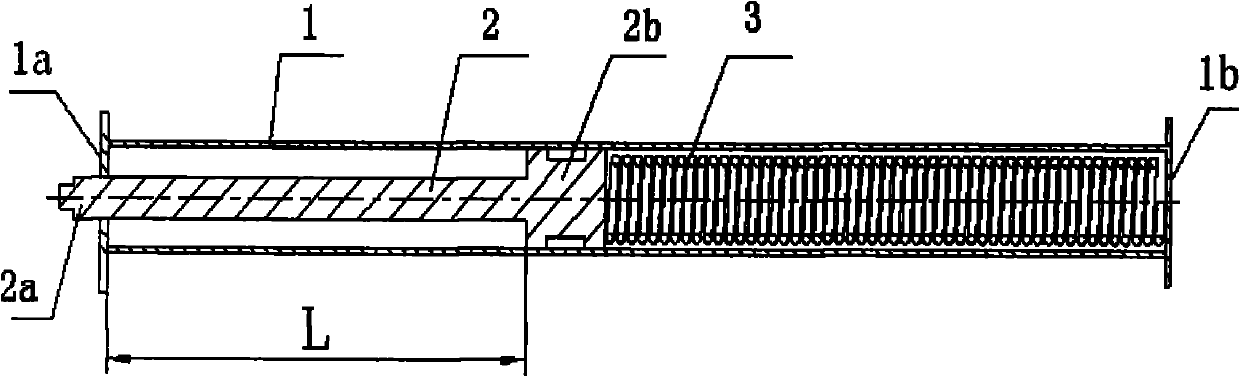

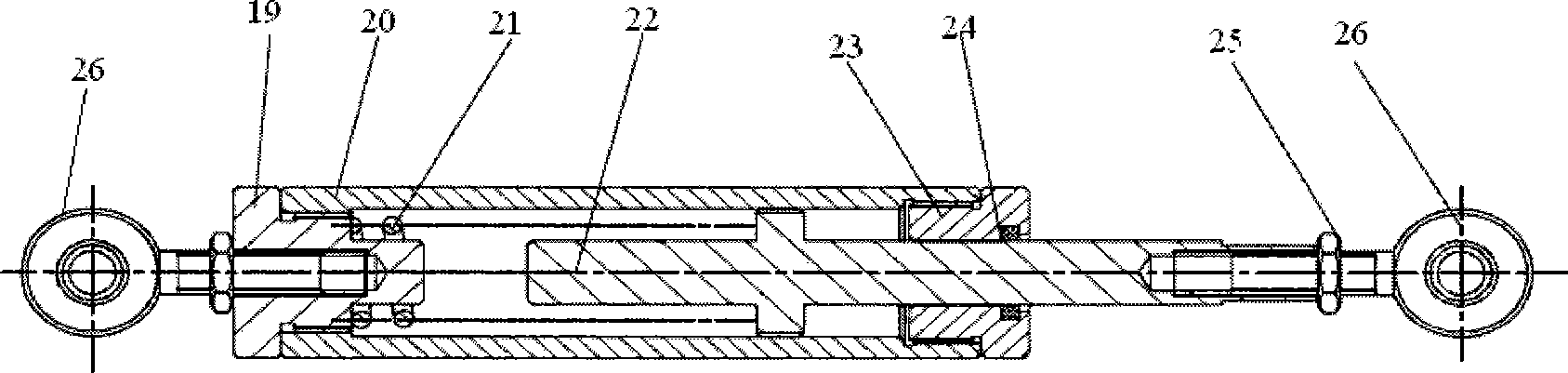

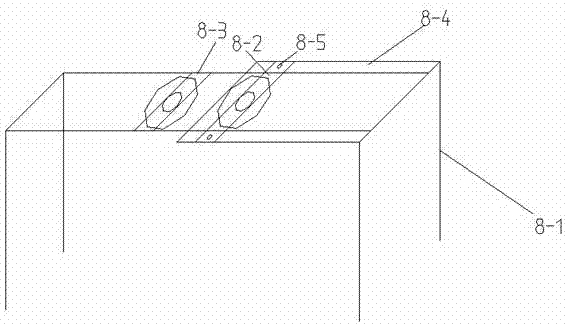

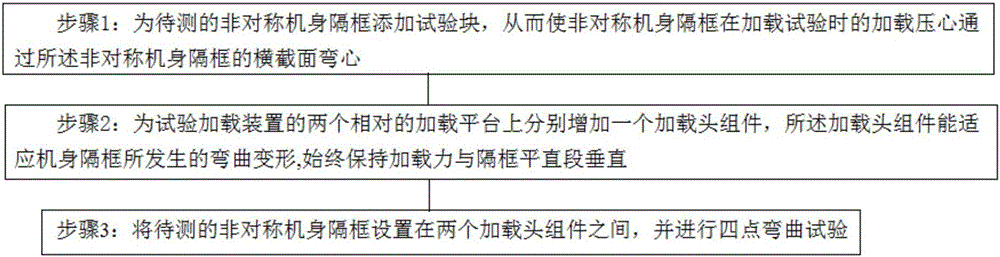

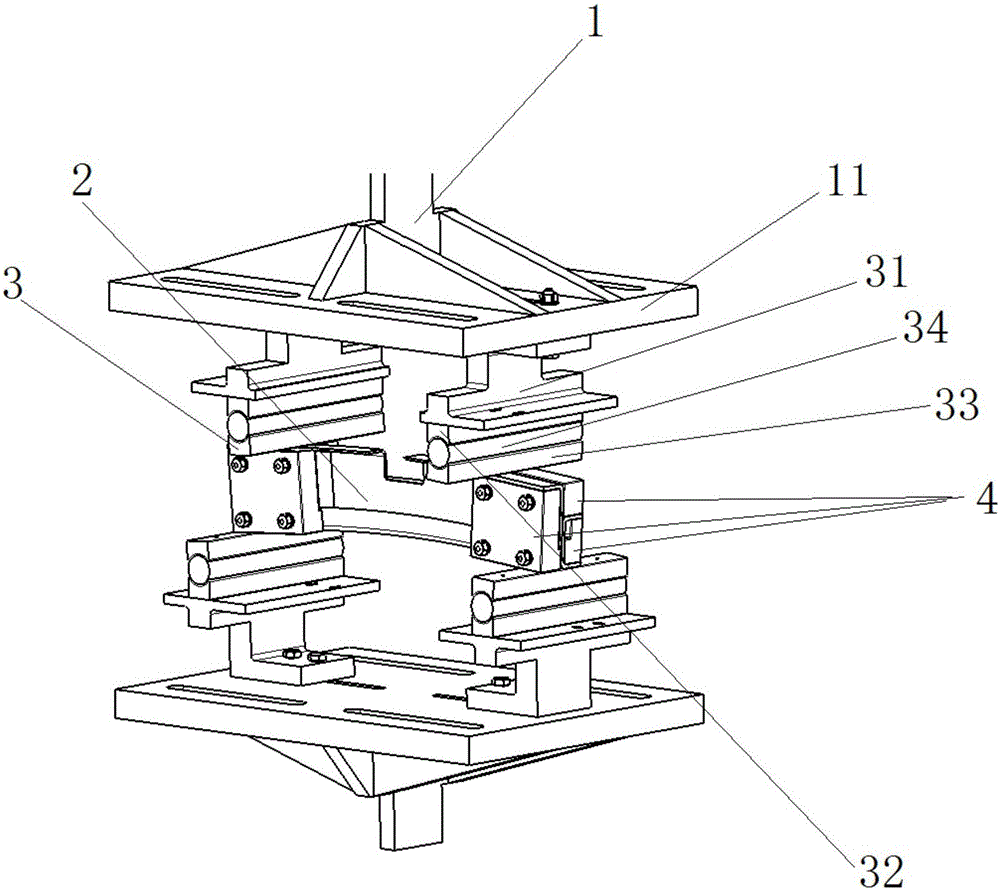

Asymmetric fuselage bulkhead four-point bending testing method and device

ActiveCN106240842ATo achieve the purpose of measuring asymmetric eccentric structureSimple methodGround installationsNon symmetricFour point flexural test

The invention discloses an asymmetric fuselage bulkhead four-point bending testing method and device. The asymmetric fuselage bulkhead four-point bending testing method includes the following steps that 1, a test block is additionally arranged on a to-be-tested asymmetric fuselage bulkhead; 2, one loading head assembly is additionally arranged on each of two opposite loading platforms of a test loading device, the loading head assemblies can adapt to bending deformation of the fuselage bulkhead, and it is always kept that loading force is vertical to the straight section of the bulkhead (the same below); 3, the to-be-tested asymmetric fuselage bulkhead is arranged between the two loading head assemblies, and a four-point bending test is carried out. According to the asymmetric fuselage bulkhead four-point bending testing method, the loading pressure center of the asymmetric fuselage bulkhead in a loading test is bent through the cross section of the asymmetric fuselage bulkhead, bending deformation of the asymmetric fuselage bulkhead is adjusted in the mode that the loading head assemblies deform in the force carrying process in the loading process, and the purpose of measuring the asymmetric eccentric structure is achieved.

Owner:CHINA AIRPLANT STRENGTH RES INST

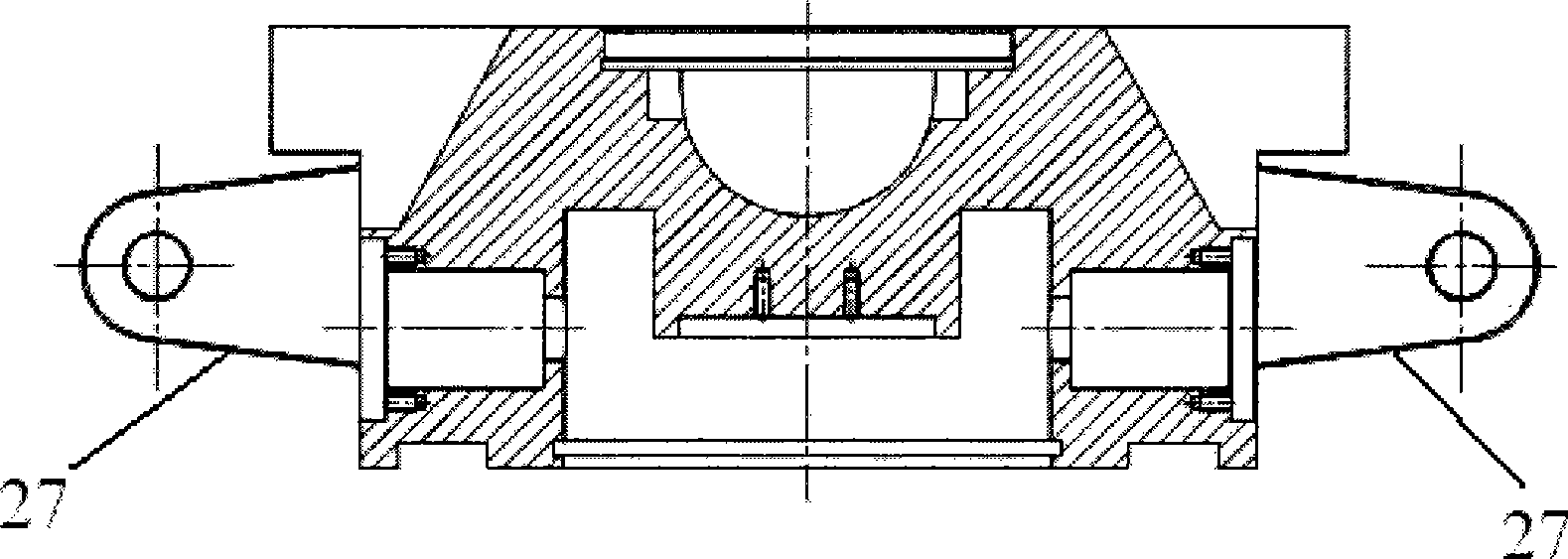

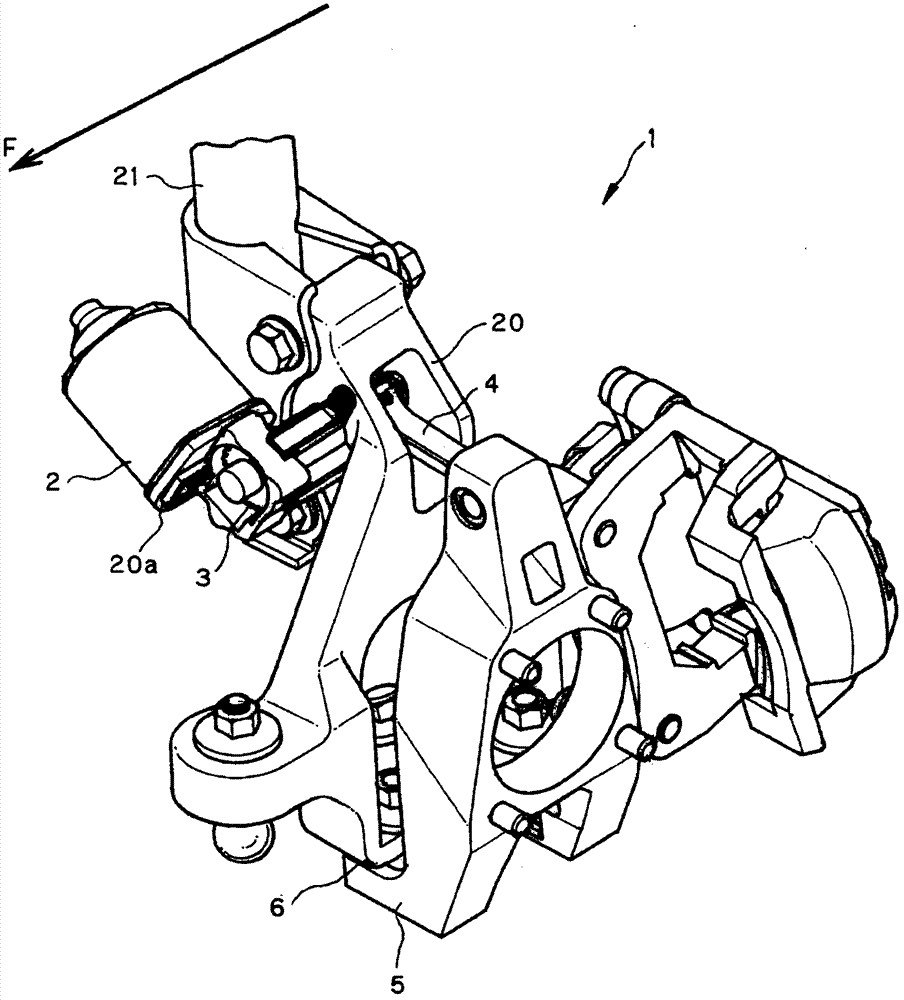

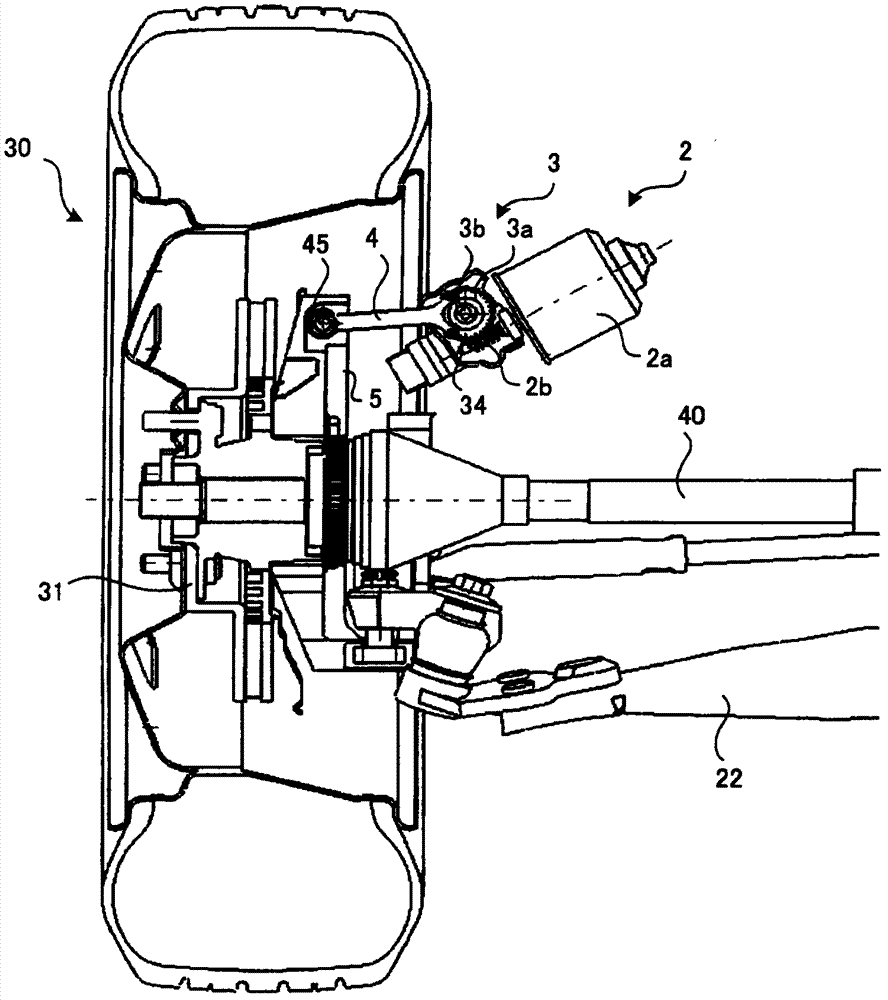

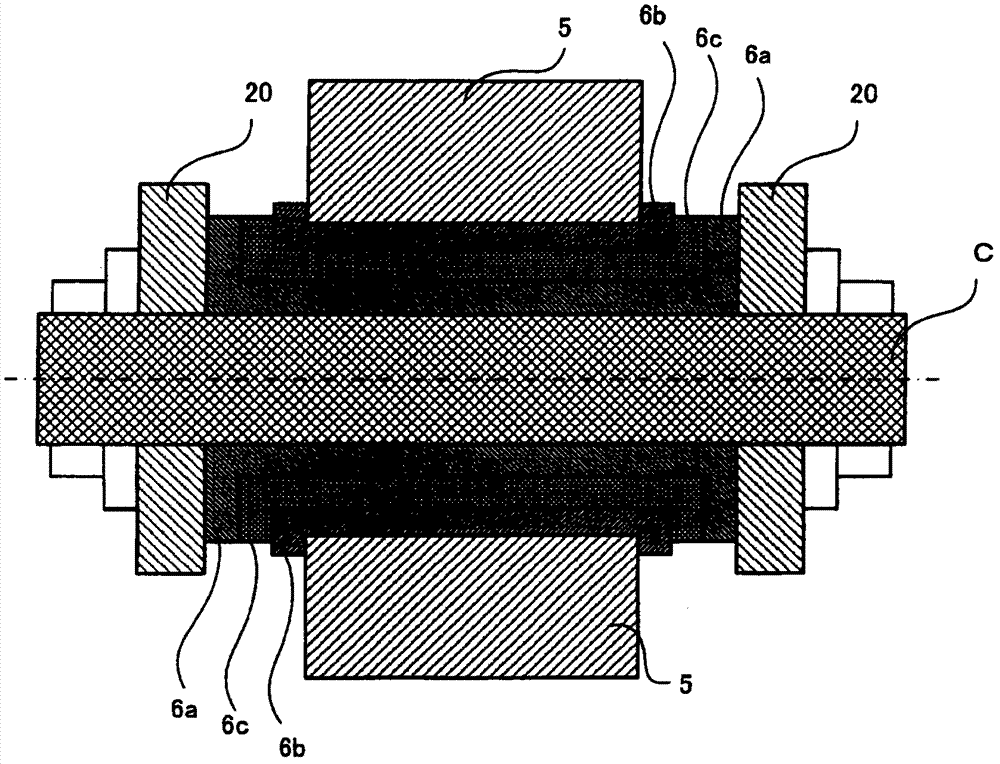

Camber angle changing mechanism

InactiveCN102083642BReduce in quantitySimple structureSteering partsInterconnection systemsCamber angleEngineering

Owner:EQUOS RES

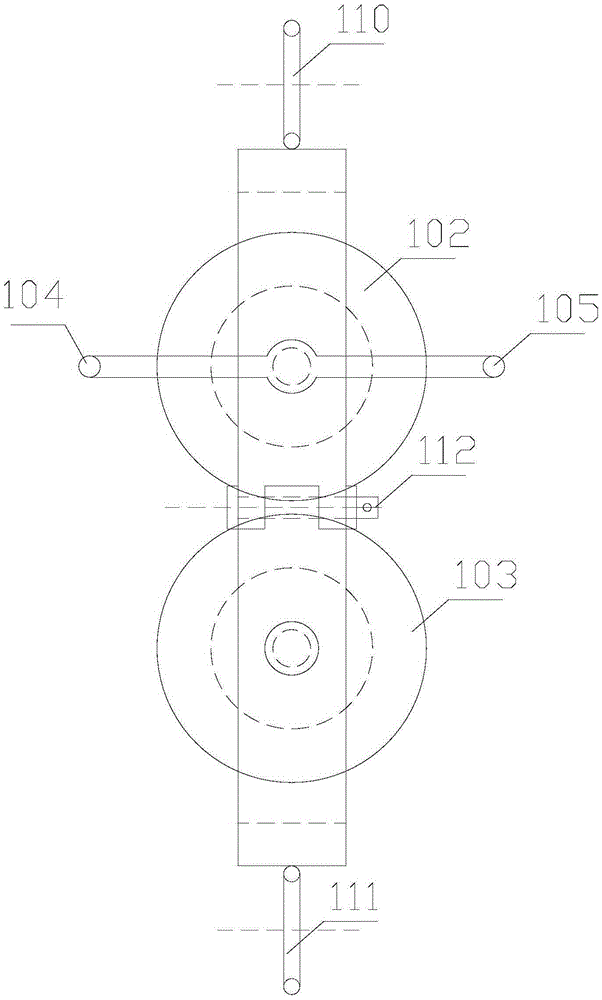

Tackle for net weaving in high-voltage power transmission wire construction

ActiveCN105429055APrevents slipping off the tackleReduce frictionPortable liftingApparatus for overhead lines/cablesHigh pressureHigh voltage

The invention provides a tackle for net weaving in high-voltage power transmission wire construction. The tackle includes a tackle main body frame, an upper pulley, a lower pulley and a front connecting ring; the upper pulley is fixed to the upper half part of the tackle main body frame through a first bearing; the lower pulley is fixed to the lower half part of the tackle main body frame through a second bearing; the axial direction of the first bearing is parallel to the axial direction of the second bearing; a gap formed between the upper pulley and the lower pulley is used for accommodating a supporting rope; the front connecting ring is fixedly welded to the first bearing; and the front connecting ring is used for connecting a traction rope for net weaving. According to the tackle of the invention, the two rolling pulleys are adopted, so that friction between the rolling pulleys and the rope can be decreased; the two pulleys are arranged sequentially along a vertical direction, and the gap is formed between the upper pulley and the lower pulley, and the supporting rope can be arranged in the gap, and therefore, the supporting rope will not slip away from the tackle; the net traction rope is arranged in the front connecting ring, and therefore, the direction of a force borne by an O-shaped lock is consistent with the direction of the supporting rope, and the tackle will not rotate and is smooth when pulling the net traction rope.

Owner:STATE GRID CORP OF CHINA +3

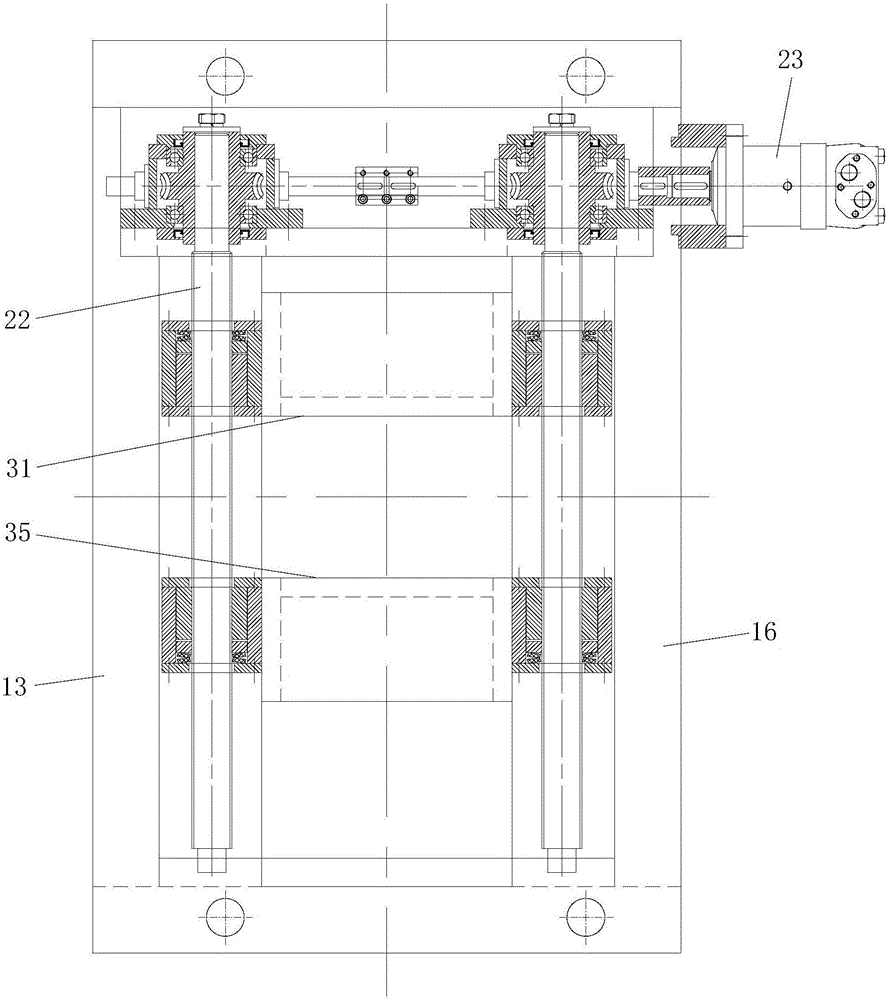

Precision Y-shaped rod pure bending torque experiment device

ActiveCN109459322AImprove accuracySmall bending angle intervalMaterial strength using steady bending forcesPure bendingTorque sensor

Owner:ANHUI UNIVERSITY

Strip material roll shearing roll extruding mechanism

ActiveCN106334721ADoes not affect continuous processingHigh speedMetal rolling arrangementsHobbingEngineering

The invention discloses a strip material roll shearing roll extruding mechanism. The strip material roll shearing roll extruding mechanism comprises an uncoiler, a welding machine, a storing material tensioning gear, a roll shearing roll extruding unit, a length detection camera system, a measuring pile, an outlet storing material pendulous device, and a recoiling machine which are arranged in sequence; a flat guide roller is arranged between the welding machine and a inlet storing material device, and a flat guide roller is also arranged between the roll shearing roll extruding unit and the length detection camera system; the roll shearing roll extruding unit is composed of a tension pad, a vertical guide roll, and four hobbing press racks which are arranged in sequence; a unit is arranged between each pair of hobbing press racks; two guiding devices are arranged in front of the two hobbing press racks close to the vertical guide roll respectively; hobbing cutting tools are arranged on the hobbing press racks close to the vertical guide roll; and roll extruding cutting tools are arranged on the rest hobbing press racks. Raw materials of automobile sealing strip skeletons are subjected to uncoiling using the uncoiler firstly. The strip material roll shearing roll extruding mechanism is capable of ensuring continuous processing of automobile sealing strip skeletons in installation of new strip steel coiling blocks; the tension pad is capable of protecting the surfaces of the automobile sealing strip skeletons from scratches, adjusting automobile sealing strip skeleton tension, and ensuring the type of coil is qualified.

Owner:重庆安驰芯金属制品有限公司

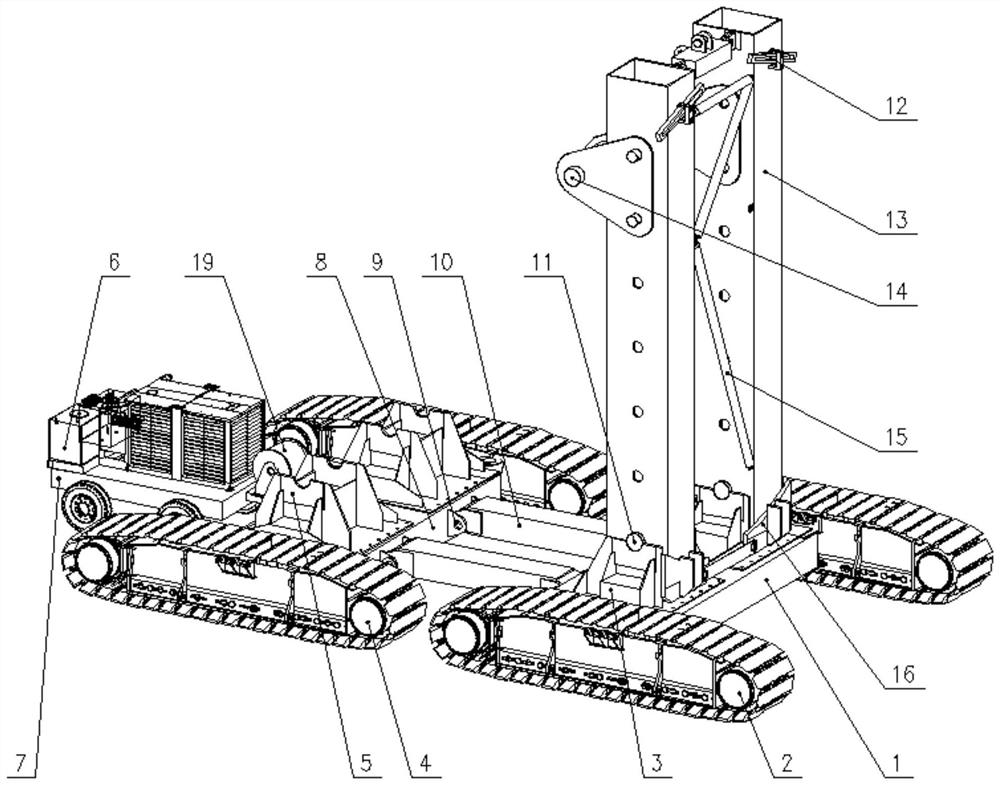

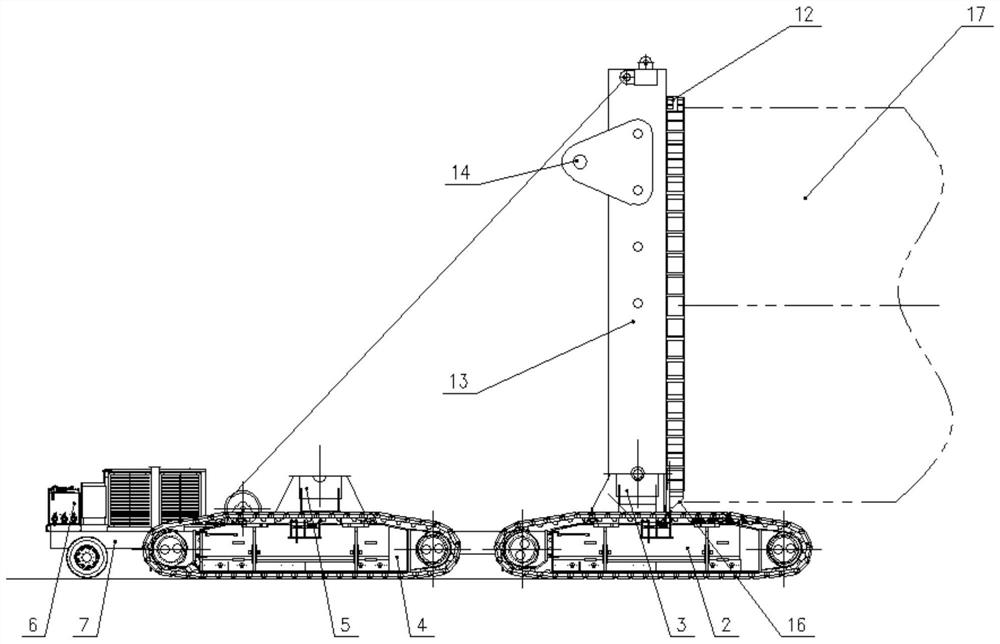

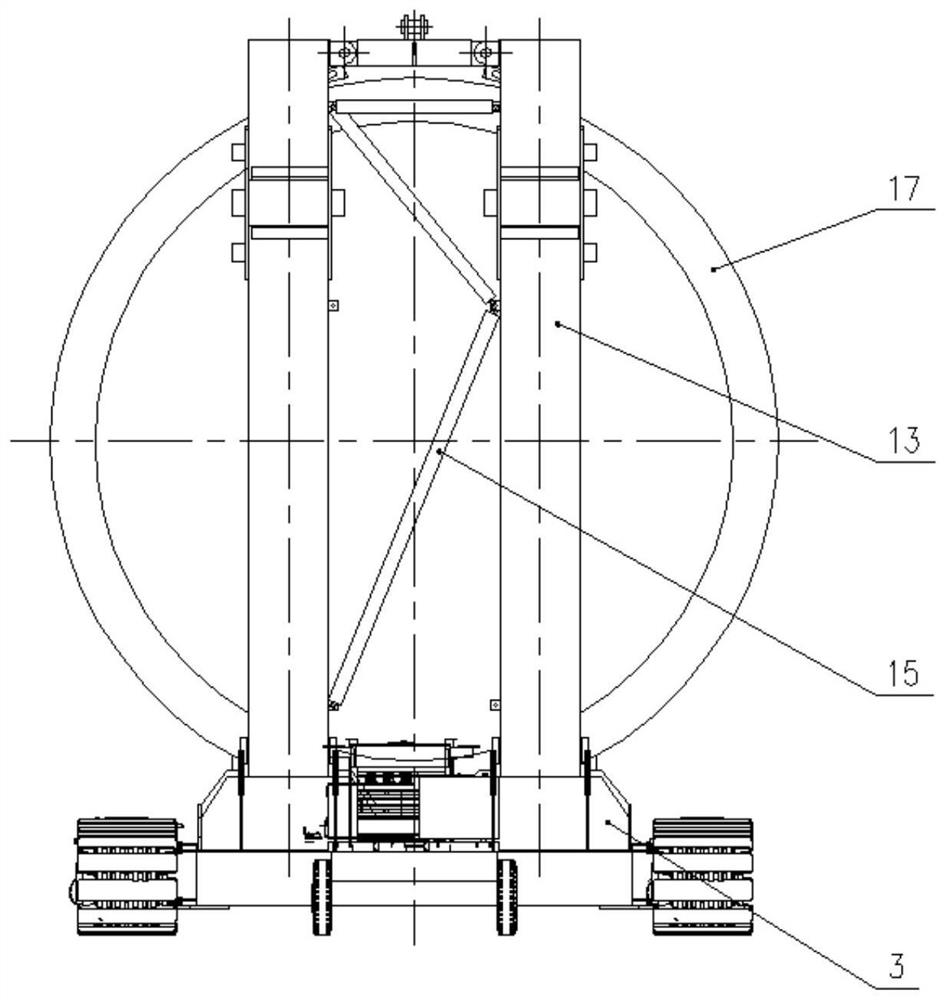

Follow-up turnover equipment for hoisting equipment and follow-up turnover hoisting method

PendingCN112374367AReduce hoisting costsImprove versatilityCargo handling apparatusPassenger handling apparatusRolling chassisManufacturing engineering

The invention relates to the technical field of engineering machinery, and provides follow-up turnover equipment for hoisting equipment and a turnover hoisting method. The follow-up turnover equipmentcomprises a travelling chassis, front turnover supporting seats, rear turnover supporting seats and a turnover platform, wherein the front turnover supporting seats, the rear turnover supporting seats and the turnover platform are separately arranged on the travelling chassis; the two front turnover supporting seats are arranged, and the two front turnover supporting seats are correspondingly arranged at the front end of the travelling chassis; the two rear turnover supporting seats are arranged, and the two rear turnover supporting seats are correspondingly arranged at the rear end of the travelling chassis; the turnover platform comprises hoisting pressing rods and two platform main beams connected together, one ends of the platform main beams are provided with platform supporting seats, and the other ends are provided with supporting shafts; and the hoisting pressing rods are arranged at the ends, close to the platform supporting seats, of the platform main beams, the supporting shafts and the front turnover supporting seats are correspondingly arranged, and the platform supporting seats and the rear turnover supporting seats are correspondingly arranged. The equipment is simple in structure, high in efficiency, good in stability and safer.

Owner:大连益利亚科技发展有限公司

Flexible mechanical arm device capable of actively and passively adjusting rigidity

ActiveCN110450161ANo collisionSimple structureProgramme-controlled manipulatorJointsReduction driveGear wheel

The invention discloses a flexible mechanical arm device capable of actively and passively adjusting rigidity. A first electromagnet fixed to one end of a first mechanical arm is included and arrangedin a cylinder cavity. A second electromagnet repelling to the first electromagnet is arranged in the cylinder cavity and arranged at one end of a second mechanical arm. A spline-shaped elastic element is arranged at the other end of the second mechanical arm and connected with a second bevel gear through a first bevel gear. The face, away from the second mechanical arm, of the second bevel gear is connected with one end of a spring. A center shaft is arranged on the axis of the spring, one end of the center shaft is connected with the second bevel gear, and the other end of the center shaft is connected with a harmonic reducer. The other end of the spring is arranged on the harmonic reducer. The harmonic reducer is arranged on a third mechanical arm through a brushless direct current motor. According to the flexible mechanical arm device, the mechanical arm structure is optimized, and changes of rigidity from zero to infinite can be achieved.

Owner:SICHUAN UNIV

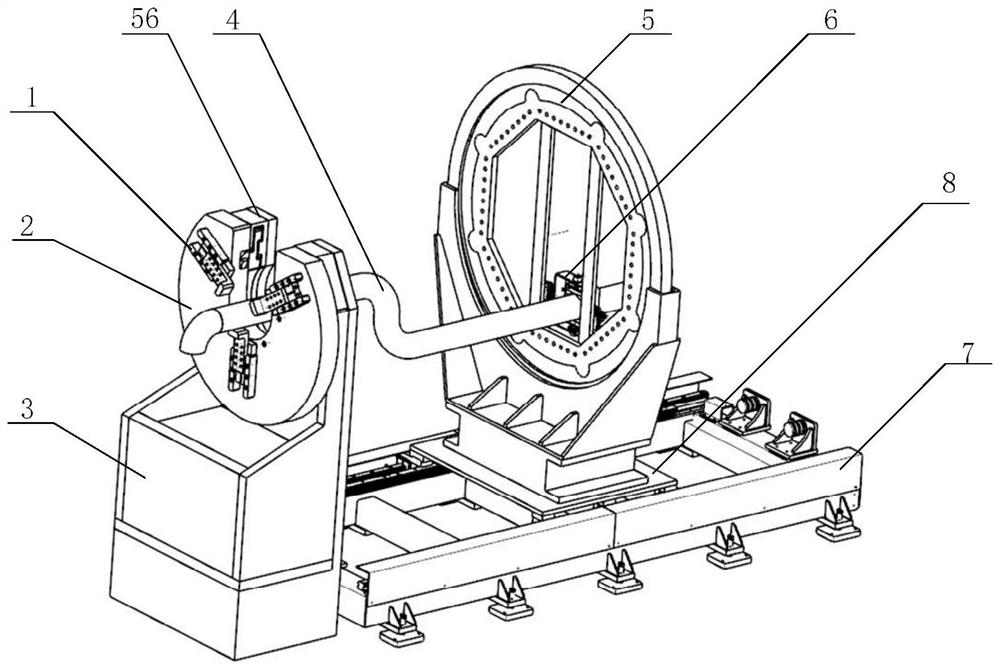

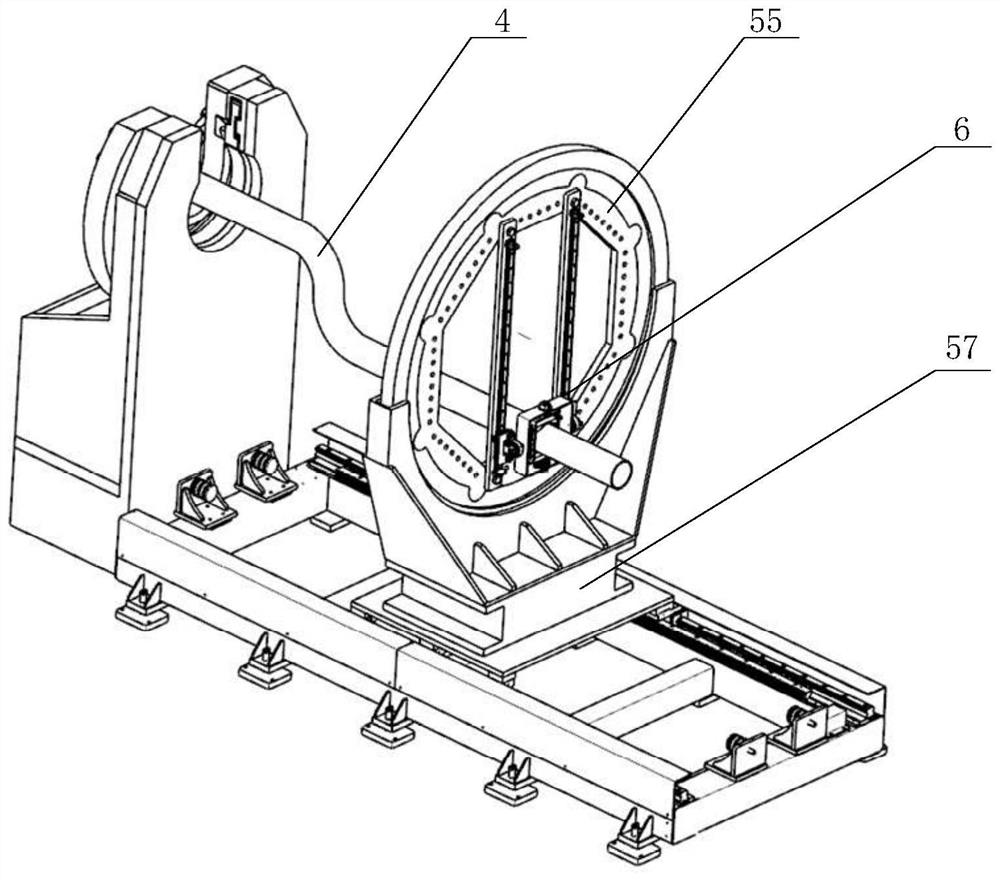

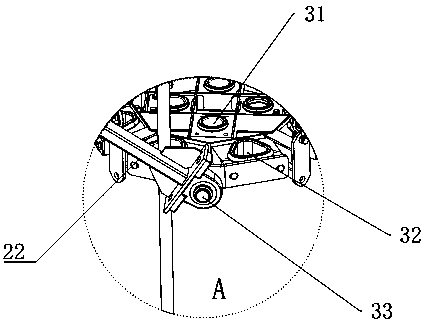

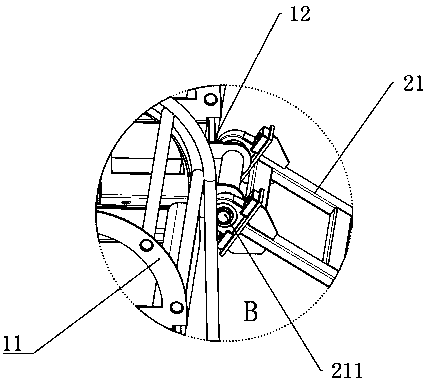

Flexible clamping tool for rotary positioning of bent pipe

ActiveCN112605601ANo torsionRealize flexible clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlide plate

The invention discloses a flexible clamping tool for rotary positioning of a bent pipe. The flexible clamping tool comprises an open type positioner, an R-shaped positioner, a clamping tool and a rail. The open type positioner is used for clamping the to-be-welded nearby area of the bent pipe and conducting rotary positioning. The R-shaped positioner is used for clamping the other end of the bent pipe and carrying out rotary positioning. The clamping tool is flexibly adjusted on the R-shaped positioner and clamps the bent pipe. The R-shaped positioner is installed on the top of the rail through a sliding plate, freely slides and can adapt to the bent pipes with different lengths. By means of the flexible clamping tool for rotary positioning of the bent pipe, flexible clamping and automatic rotary positioning of the multi-bend bent pipe can be achieved, and the automation level of welding of the multi-bend bent pipe is improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

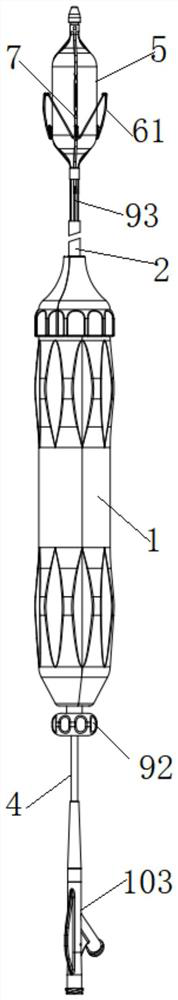

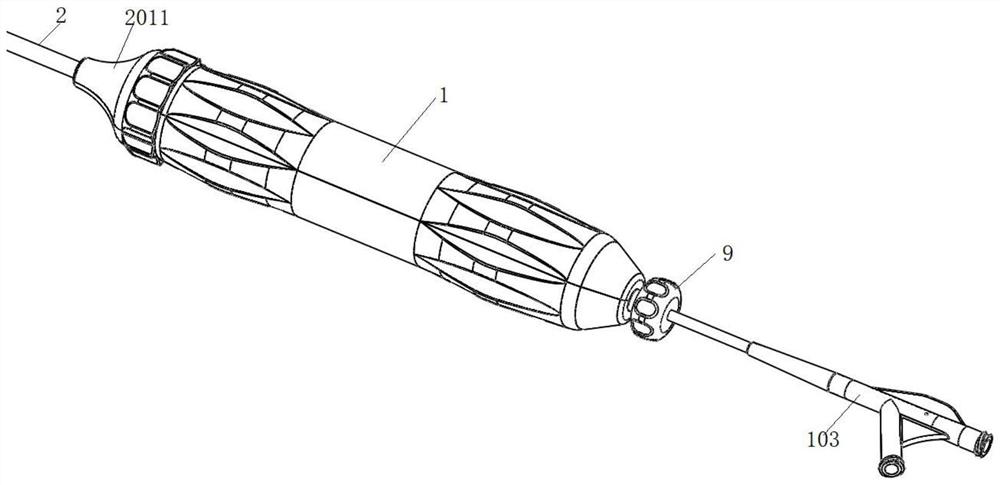

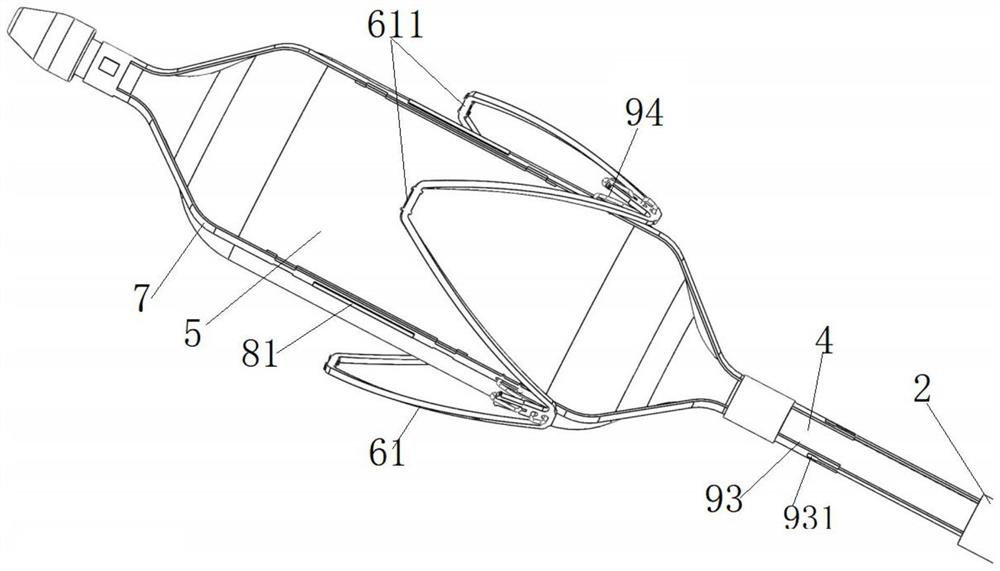

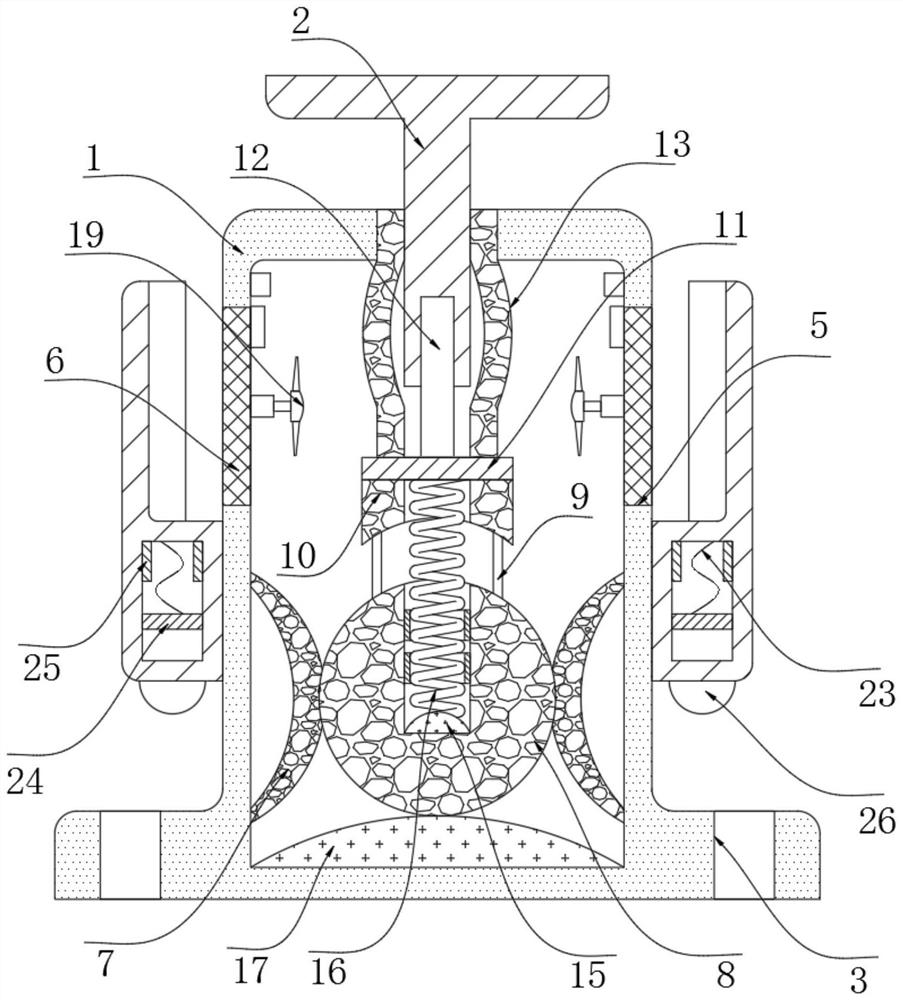

Cutting type balloon dilatation device

PendingCN112263773AReduce damageReduced mobilityBalloon catheterSurgeryBiomedical engineeringKnife blades

The invention discloses a cutting type balloon dilatation device. The cutting type balloon dilatation device comprises a balloon, a positioning support, a catheter, an inner tube and at least one blade. Due to the fact that the blade is arranged on the peripheral wall face of the balloon, when a hard guide wire arranged in the inner tube in the penetrating mode guides the cutting type balloon dilatation device to move towards a lesion position, even if a calcification area exists at an opening of the lesion position, the balloon slides and stretches into the opening, and the balloon does not touch the calcification area while not inflated; and then the balloon is inflated with gas, because the blade is arranged outside the balloon, before the balloon is filled with gas, the blade firstly encounters the calcification area, by moving or rotating the catheter, the calcification area is by the blade, so that the calcification area is reduced, and even if the balloon is filled with gas andthe balloon is in contact with the calcification area, the probability that the balloon moves forwards or backwards instantly along the calcification area is reduced, and then the probability that theadjacent organ tissue is damaged is reduced.

Owner:SHANGHAI HEALING MEDICAL DEVICES CO LTD

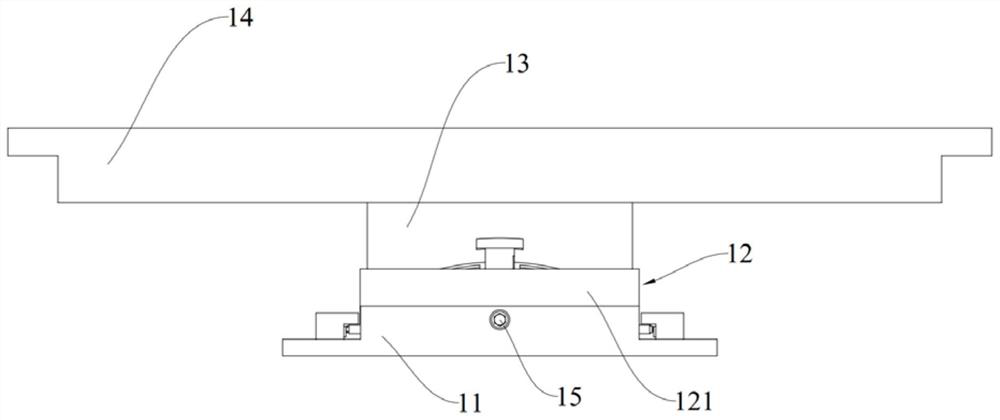

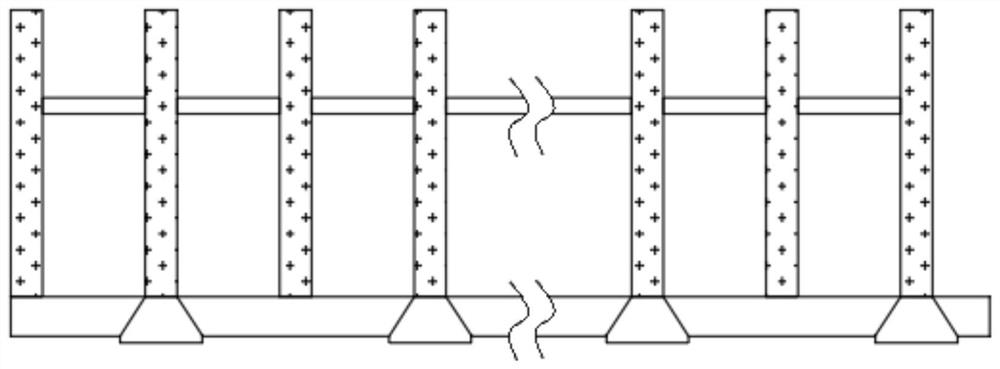

Magnetic suspension support

PendingCN112323547AAssembly Error GuaranteeEnsure integrity and smoothnessRailway tracksMagnetic suspension systemStructural engineering

The invention belongs to the technical field of magnetic levitation, and discloses a magnetic levitation support which comprises a lower support plate, a position adjusting piece, a middle support plate and an upper support plate. The middle seat plate is arranged on the position adjusting piece, and the position adjusting piece can move in the transverse bridge direction so as to adjust the height of the middle seat plate and / or the position of the middle seat plate in the transverse bridge direction; the upper seat plate is arranged on the middle seat plate in a sliding mode and can slide inthe bridge direction. When the position of a vacuum pipeline or a lower supporting structure changes in the installation process or the subsequent use process of a magnetic suspension system line, the integrity and smoothness of the line in the bridge direction can be guaranteed through relative sliding between the upper base plate and the middle base plate; the integrity and smoothness of a linein the vertical direction and the transverse bridge direction can be guaranteed by adjusting the position adjusting pieces, and the train operation safety is guaranteed.

Owner:成都西交华创科技有限公司 +3

Saddle structure with cable twisting limiting function

PendingCN110707633AAvoid installationAvoid entanglementElectrical apparatusMachines/enginesElectromagnetic interferenceTower

The invention discloses a saddle structure with a cable twisting limiting function. The structure comprises a transition saddle, a limiting swing arm and a first cable separation assembly, the transition saddle and the limiting swing arm are hinged to the two ends of the limiting swing arm respectively, so the first cable separation assembly swings only in the vertical direction. The transition saddle comprises a support and a cable bridge used for carrying a cable, the support is installed on a tower drum, the limiting swing arm is hinged to the support, and a plurality of branching holes areformed in the first cable separation assembly. The suspension cable is isolated and clamped by the cable separation assembly, so that the cables are prevented from being wound and collided during yawing, and damage and electric leakage caused by mutual friction of cable sheaths are avoided. When the cable is arranged, a three-phase one-group arrangement mode is adopted, electromagnetic interference is reduced, current transmission quality is ensured, the limiting swing arm ensures that the cable only moves up and down and does not twist or swing, and stress of the cable is effectively reducedwhile abrasion of the cable is further avoided.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

Axle protection structure

InactiveCN107662452APrevent penetrationImprove securityShaftsAxle unitsInterference fitWear resistant

The invention discloses an axle protection structure, which comprises an axle, a fixed ring, a protective tube, a filling layer and a connecting flange; One side of the shaft extends axially outward to form a plurality of fixed rods; the fixed rods on the two fixed rings are located on the sides of the two fixed rings away from each other; the connecting flange is sleeved on the axle, and a through hole is opened on the connecting flange , the fixed rod goes through the through hole; the connecting flange is fixed on the fixed ring through the nut threaded with the fixed rod; the protective tube is set on the axle, and the two ends of the protective tube are respectively fixedly connected with the two connecting flanges; Between the outer surface of the axle and the inner surface of the protection cylinder, the filling layer is wear-resistant rubber. The invention can slow down the loss of driving force of the vehicle after the axle breaks, and prevent the fragments produced by the breakage of the axle from penetrating the fuel tank.

Owner:CHONGQING ZHANRUI AUTOMOBILE FITTING FACTORY

Cleaning vehicle water saving and spraying mechanism and using method thereof

ActiveCN111790539ASave waterControl positionSpraying apparatusRoad cleaningWater savingWater storage

The invention belongs to the field of municipal engineering, and particularly relates to a cleaning vehicle water saving and spraying mechanism and a using method thereof. The cleaning vehicle water saving and spraying mechanism comprises a cleaning mechanism, the cleaning mechanism is connected with a water spraying shell, the water spraying shell is internally provided with a water storage chamber, the side wall of one side of the water storage chamber is provided with a plurality of water outlets, the water outlets communicate with spray heads, the side walls of the water outlets are provided with a control cavity, the control cavity is internally provided with a control mechanism, and the outer side of the water spraying shell is provided with a touch switch assembly. According to thecleaning vehicle water saving and spraying mechanism and the using method thereof, by arranging the touch switch assembly, it can be achieved that after a touch connection rod makes contact with a vertical rod of a fence, the vertical rod pushes the touch connection rod, and thus, the touch connection rod drives a sector gear to rotate, accordingly, the sector gear drives a first rack which is inengagement connection with the sector gear to slide, communication of the water outlets is achieved through cooperation of the first rack and the control mechanism, thus, water is only sprayed onto the portions provided with vertical rods, and water resources are greatly saved.

Owner:HUBEI WUHUAN SPECIAL PURPOSE VEHICLE

Auxiliary assembler for vehicle damping rubber

PendingCN113124079ALow frequency and small vibration avoidanceReduce excessive impact damageSpring motorHigh internal friction springsStructural engineeringMechanical engineering

The invention discloses an auxiliary assembler for vehicle damping rubber. The auxiliary assembler for the vehicle damping rubber comprises a dust-proof cover and an upper connecting body, wherein multiple lower connecting holes are formed in the lower end of the dust-proof cover in a penetrating mode; two protection tables are symmetrically fixed to the side wall of the dust-proof cover; alarm mechanisms are arranged in the two protection tables; two window grooves are formed in the side wall of the dust-proof cover in a penetrating mode; filter screens are fixed to the inner walls of the two window grooves correspondingly; two pieces of mounting rubber are fixed to the inner wall of the dust-proof cover; and main buffer rubber is fixed to the side walls of the two pieces of mounting rubber jointly. The auxiliary assembler for the vehicle damping rubber provided by the invention has the advantages that by arranging a buffer spring, the upper connecting body can move up and down in the operation vibration process, so that a pressing plate and upper pressing rubber are driven to move downwards, and deformation of the buffer spring is mainly caused in the initial stage of movement; and then low-frequency small-amplitude vibration can be effectively avoided by utilizing the spring characteristics of the buffer spring, so that low-frequency stability which cannot be obtained by conventional rubber cushioning is obtained.

Owner:TONGCHENG SUPER RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com