Knitting method of tubular knitted fabric

A knitted fabric and tubular technology, which is applied in the knitting field of tubular knitted fabrics, can solve problems such as poor wearing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

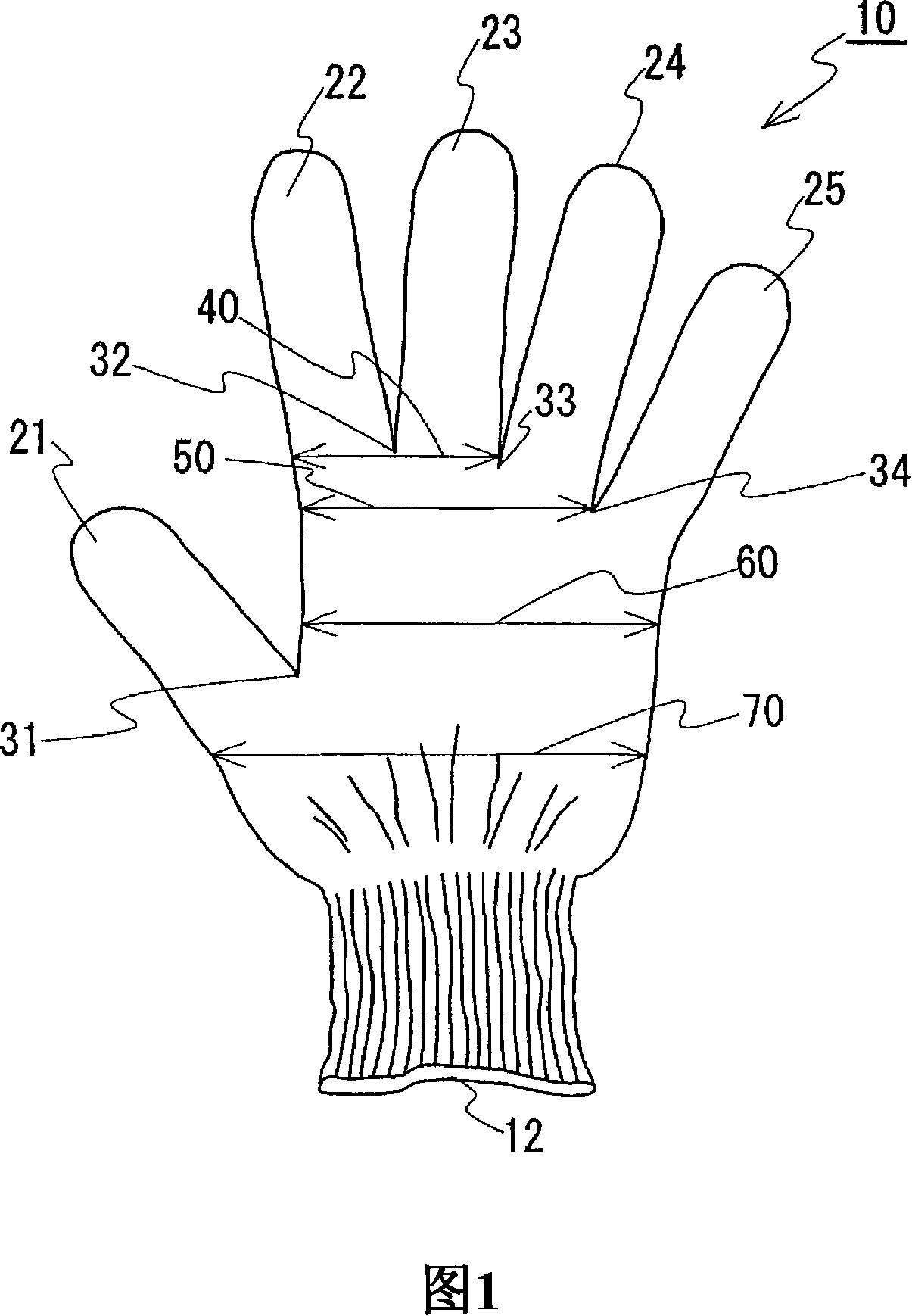

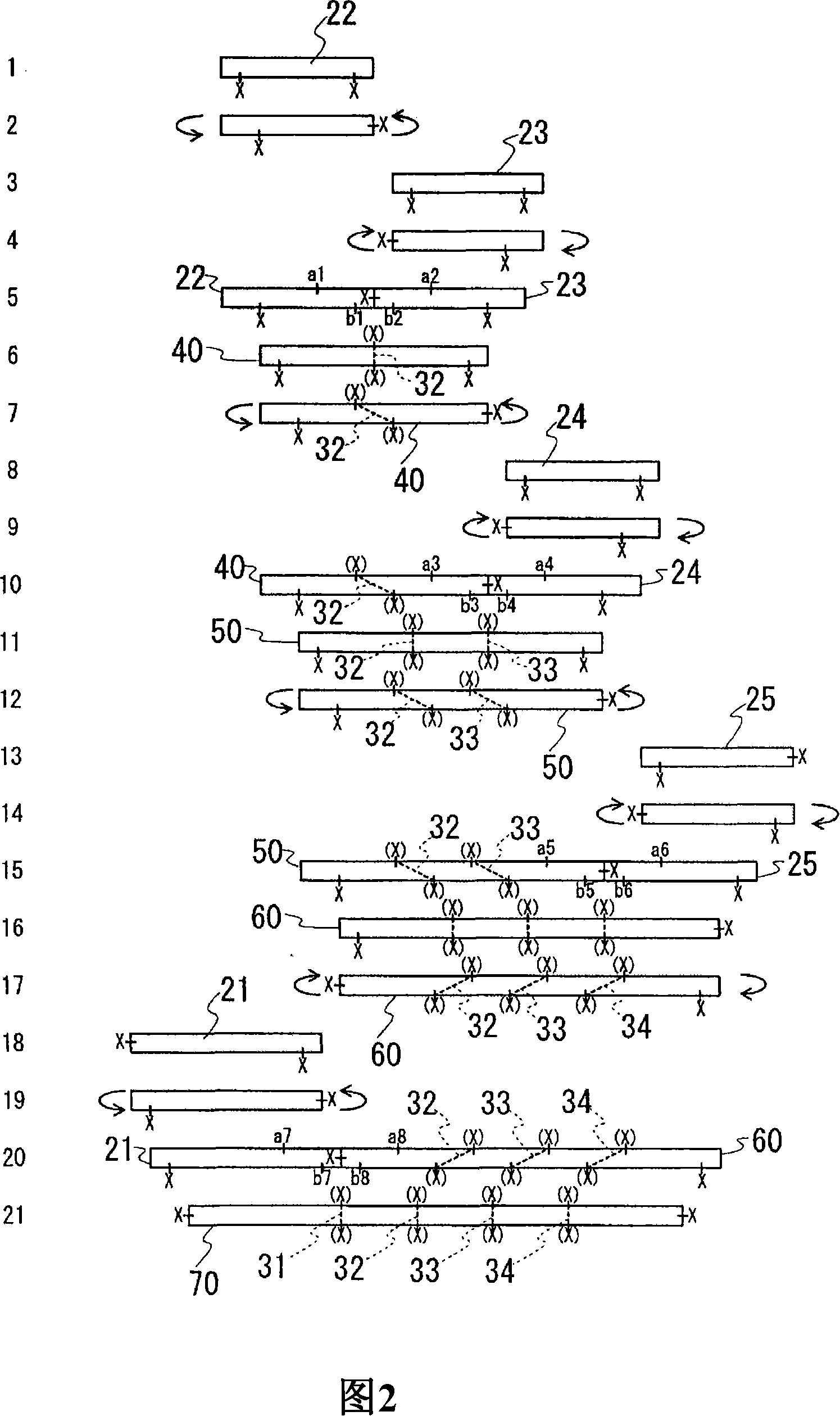

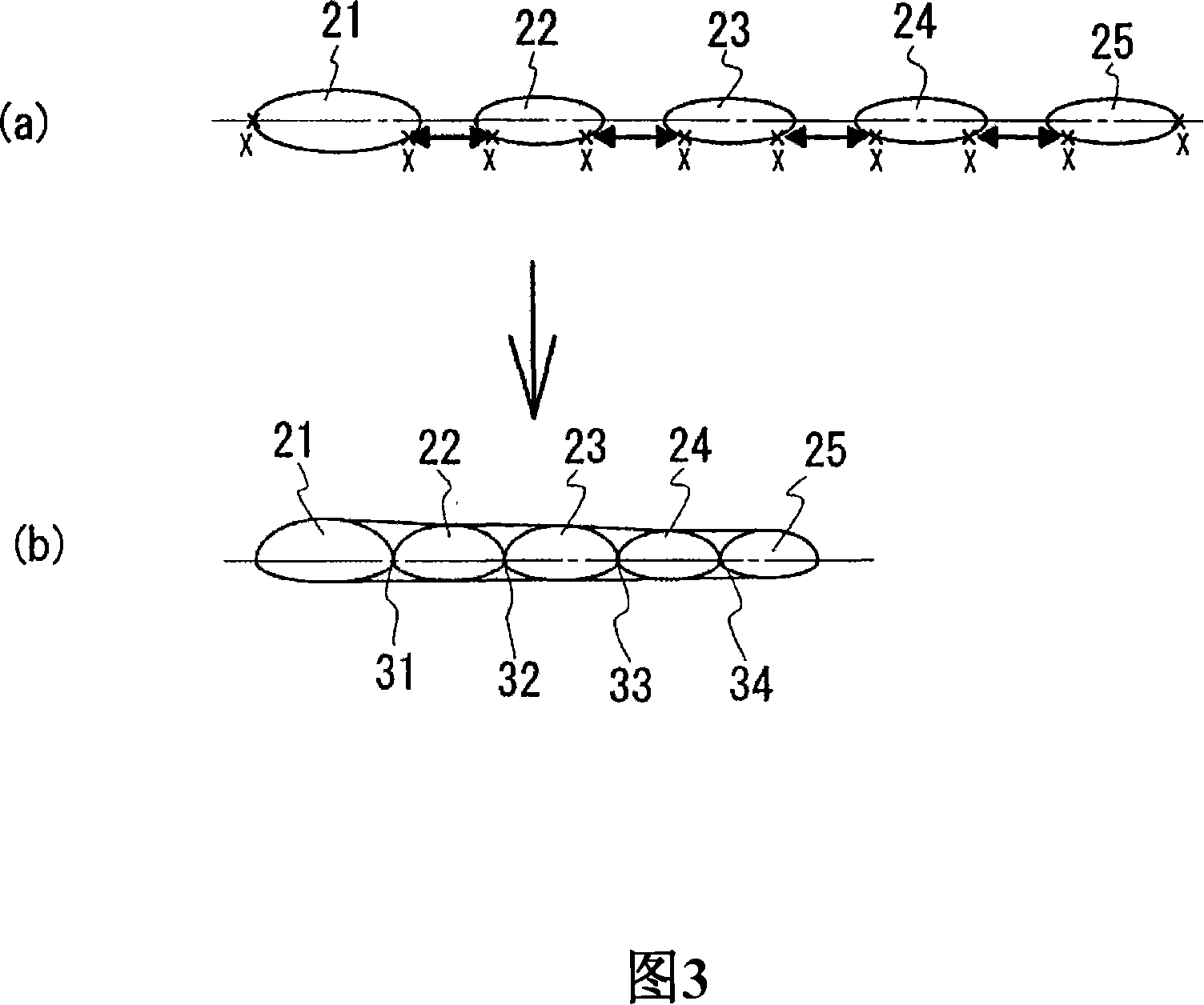

[0109] Fig. 1 is a plan view of a glove having five finger pockets according to a first embodiment. Fig. 2 is a knitting process diagram showing a method of knitting the glove shown in Fig. 1 . Fig. 3 is a cross-sectional view showing a state before and after joining of finger pockets. In the glove 10 of the present embodiment, as shown in FIG. 1 , the front end of the middle finger pocket 23 is the most protruding. Sequentially, the position of the tip of the fingertip is in a descending state.

[0110] And then, form the first root portion 31 between the thumb pocket portion 21 and the index finger pocket portion 22, form the second finger root portion 32 between the index finger pocket portion 22 and the middle finger pocket portion 23, and form the second finger root portion 32 between the ring finger pocket portion. The third finger base 33 is formed between the finger pockets 24 of the ring finger and the fourth finger base 34 is formed between the ring finger pocket 2...

no. 2 approach

[0146] A second embodiment will be described based on the knitting process diagram of FIG. 4 . The second embodiment is also a glove having five finger pockets, and the same components as those in the first embodiment are designated by the same reference numerals, and description thereof will be omitted.

[0147] The second embodiment differs from the first embodiment in that the thumb pocket portion 21 is longer in the knitting width direction of the front side knitted fabric (palm side knitted fabric) than in the knitting width direction of the rear side knitted fabric (back of hand side knitted fabric). The boundary portion X is set in such a manner that the index finger pocket portion 22 is set so that the length in the knitting width direction of the front side knitted fabric (palm side knitted fabric) is the same as the length in the knitting width direction of the rear side knitted fabric (the back side knitted fabric). Boundary X. The boundary portion X of the middle ...

no. 3 approach

[0161] The above-mentioned embodiments are embodiments of gloves, but the knitting method of the present invention can also be applied to the knitted pullover shown in FIG. 6 . In the third embodiment, a common double-bed flat knitting machine is used to knit a tubular body (tubular portion) and a tubular sleeve (tubular portion) independently, and join these body and sleeves to knit a knitted pullover. Condition.

[0162] FIG. 6 shows a plan view of the body and sleeves of the knitted pullover 100 viewed from the front body side. Fig. 7 is a knitting process diagram for knitting the above-mentioned knitted pullover 100 by the knitting method of the present invention, showing the knitting process when the body and sleeves are joined.

[0163] The knitted pullover 100 knitted in the third embodiment is a long-sleeved knitted pullover with a neckline, and has a front body 2 a , a rear body 2 b , left sleeves 3 , and right sleeves 4 . As shown in FIG. 6 , the front body 2 a and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com