Connecting structures for protective boots for chemical protective clothing

A chemical protection and connection structure technology, applied in protective clothing, clothing, applications, etc., can solve problems such as jamming, falling off, and uncontrollable inflow of chemical substances, and achieve the effect of reducing pain, reducing friction area, and easy wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the connection structure of the protective boots for chemical protective clothing according to the embodiment of the present invention will be described with reference to the accompanying drawings. When describing the present invention, detailed descriptions of related well-known common functions or configurations are omitted.

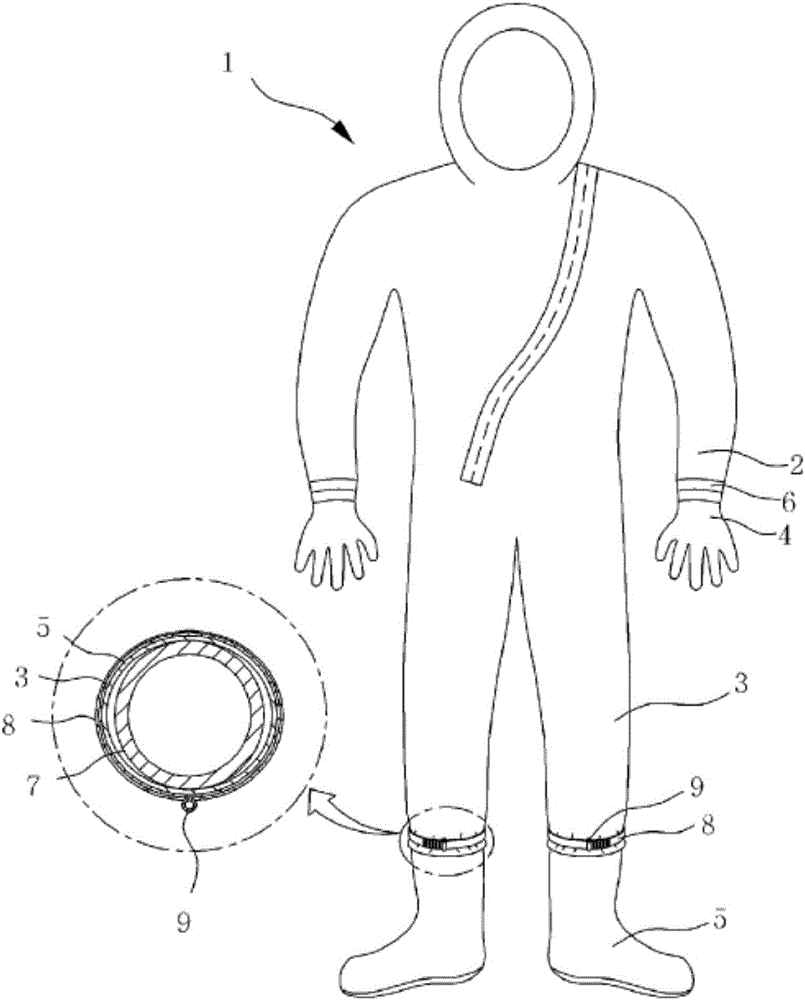

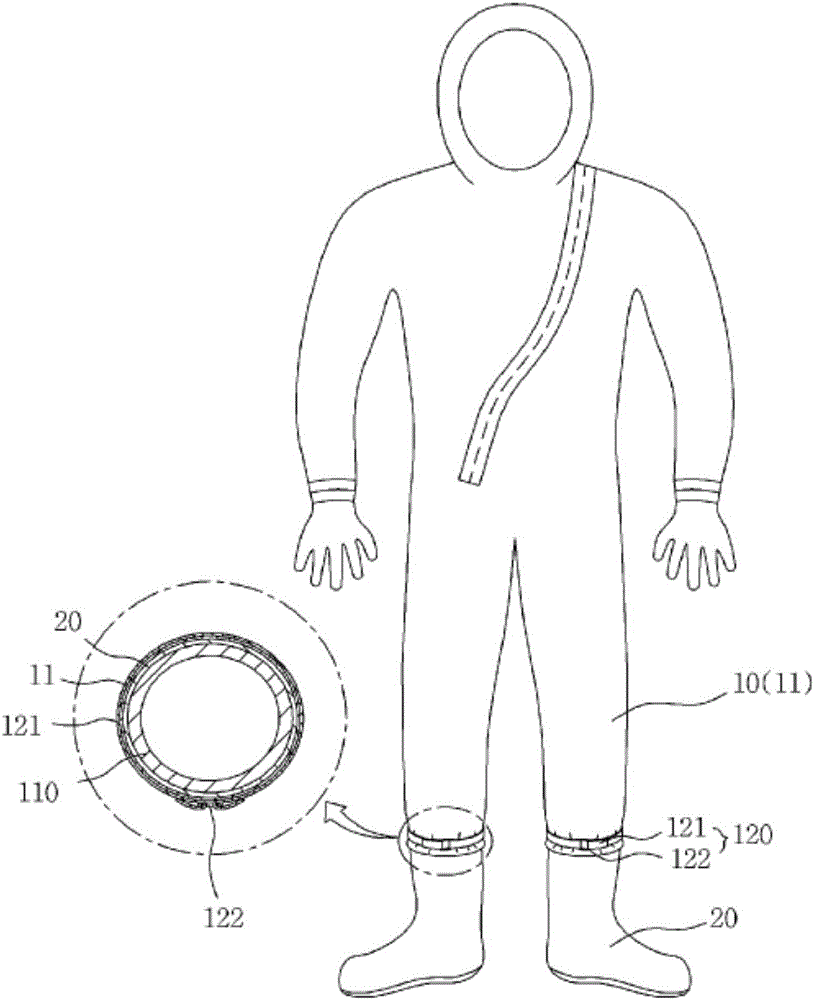

[0048] Such as image 3 As shown, the connection structure of the protective boots for chemical protective clothing according to the present invention is to fix the protective boots 20 and the lower garment 11 of the protective clothing 10 as one, and includes a ring 110 and a binding belt 120 .

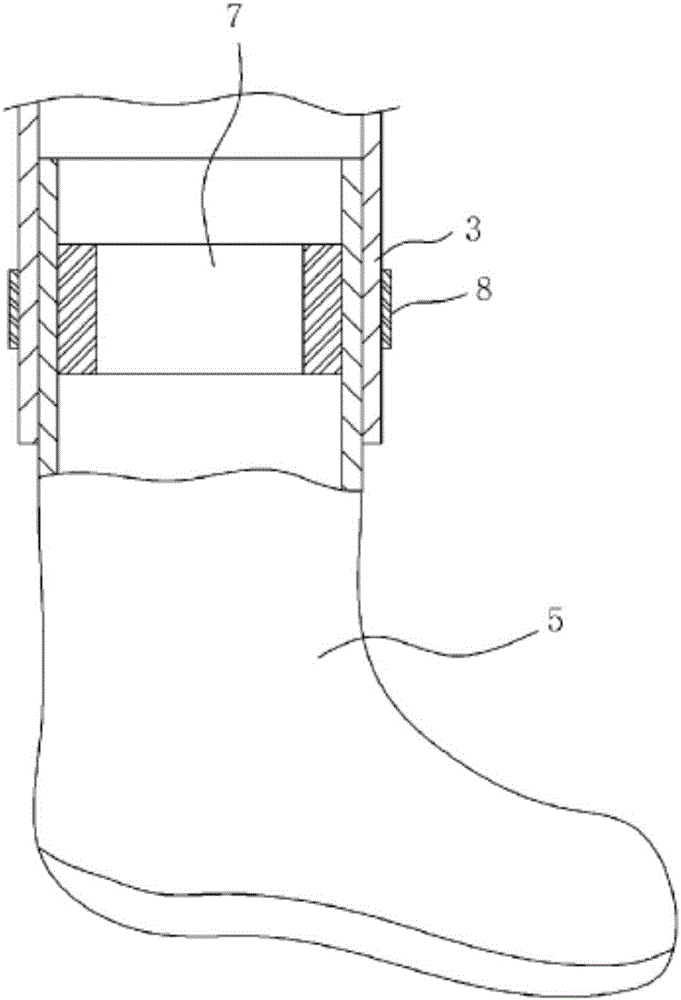

[0049] Such as image 3 and Figure 4 As shown, the ring 110 is embedded in the inner peripheral surface of the protective boot 20 and is pressed by the binding belt 120 described later. The width of the entrance of the protective boot 20 is generally larger in the left-right direction than in the front-rear direction. In order to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com