Preparation method for mixture of polymer and graphene

A technology of polymer and graphene, which is applied in the field of preparation of polymer-graphene mixture, can solve problems such as corrosion and removal of organic solvents, cost constraints, etc., and achieve the effect of simple and commonly used additives, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

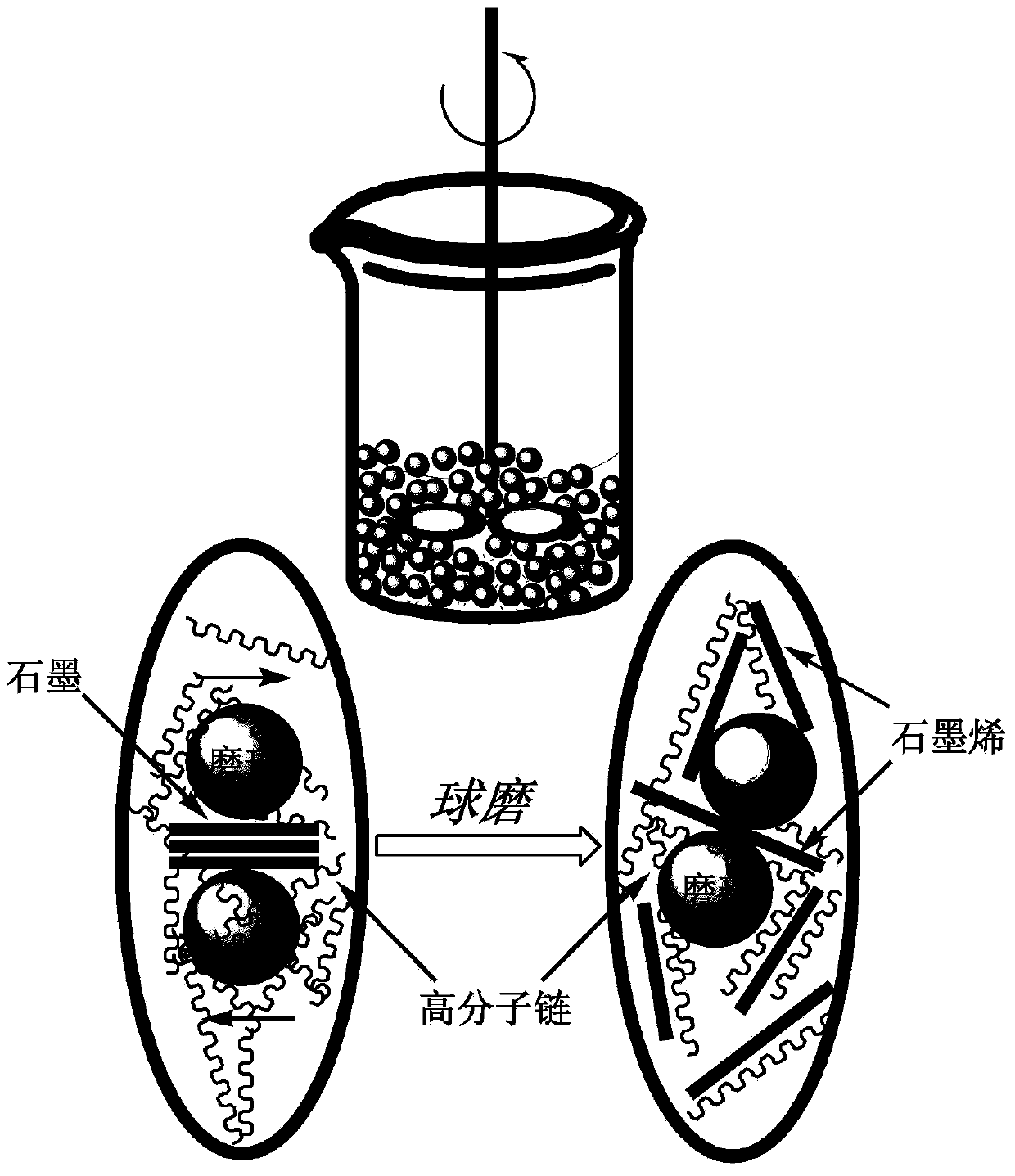

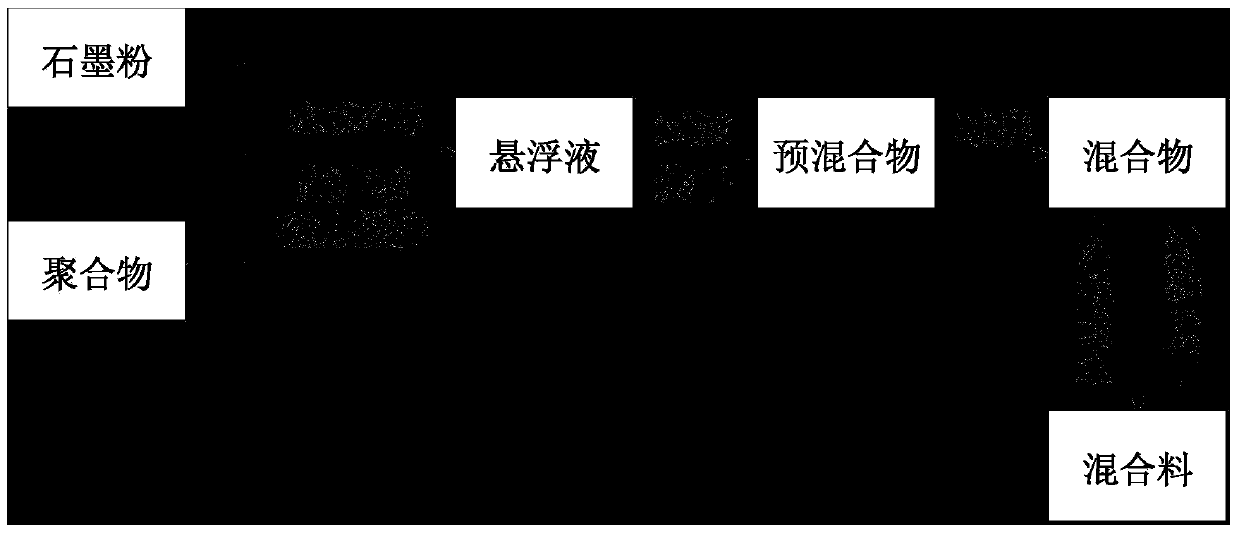

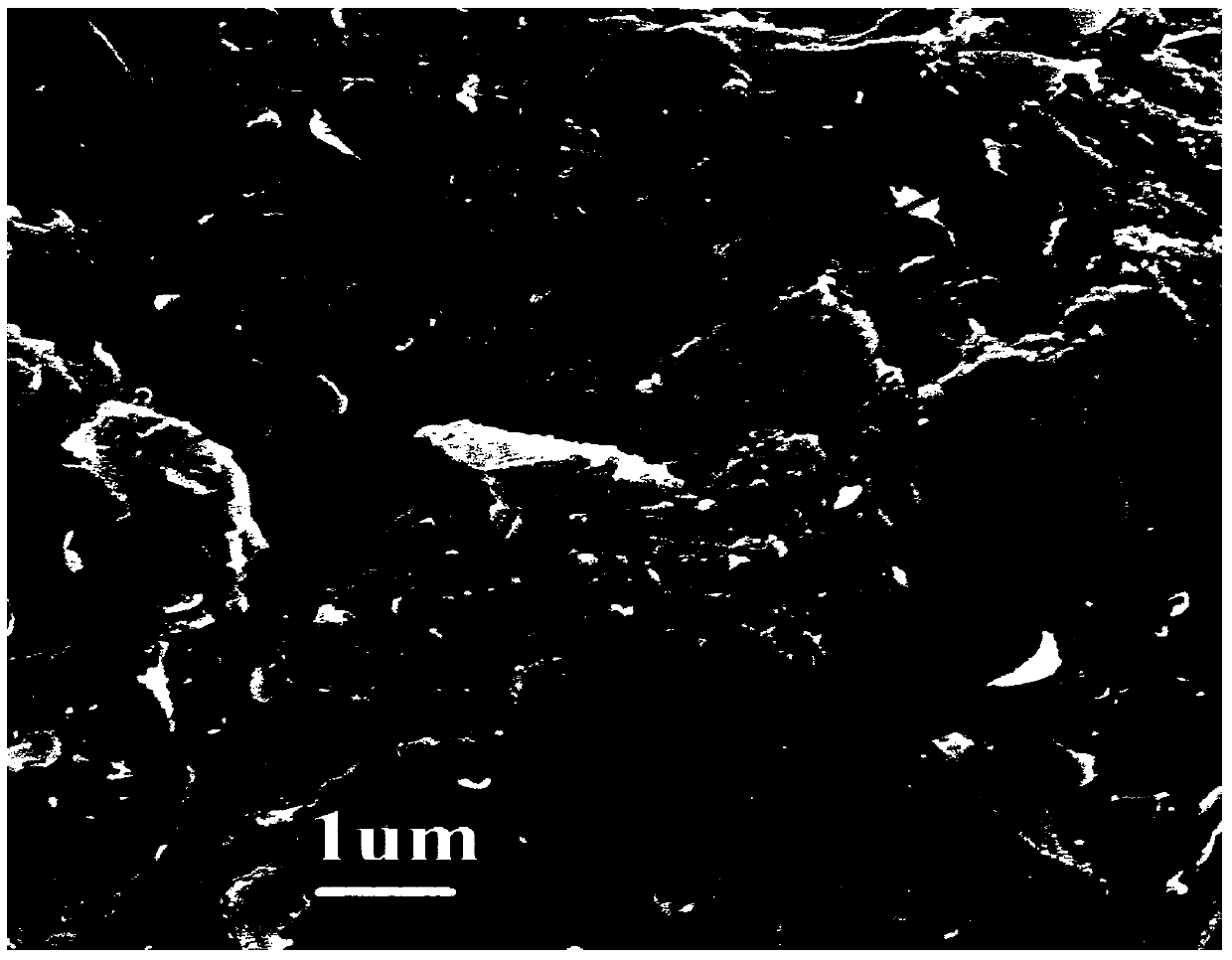

[0032] A kind of preparation method of polymer-graphene mixture, such as Figure 1-2 As shown, it is achieved by the following scheme: Accurately weigh 0.3g of expanded graphite and 29.7g of polyvinyl chloride powder, add them to 500ml of distilled water, and disperse them uniformly by magnetic stirring to obtain a suspension. Filter the suspension, take the solid and dry it to obtain a uniform powder, which is the polyvinyl chloride-graphite powder pre-mixture. The pre-mixture is moved to a stirring ball mill ball mill tank with a volume of 400ml equipped with zirconia balls, the mass ratio of zirconia balls to expanded graphite is about 2000:1, and the ball mill is stirred at a speed of 200 rpm for 6h to obtain Powdered polyvinyl chloride-graphene nano-hybrid. The mixture and the grinding balls are added to water for cleaning, and the solids obtained by filtering the cleaning solution after taking out the grinding balls are dried to obtain the powdery polyvinyl chloride-gra...

Embodiment 2

[0034] A preparation method of a polymer-graphene mixture, which is realized by the following scheme: Accurately weigh 0.15g of earthy graphite and 29.85g of polyethylene powder, add them to 500ml of absolute ethanol, and disperse them uniformly by ultrasonic method to obtain a suspension liquid. Filter the suspension, take the solid and dry it to obtain a uniform powder, which is the polyethylene-graphite powder pre-mixture. After the pre-mixture is evenly divided into 4 parts, each part is put into a polytetrafluoroethylene ball mill tank with a volume of 100ml together with steel balls. In each part, the mass ratio of steel balls to earthy graphite is about 2400:1. Planetary ball milling at a speed of 240 rpm for 80 hours to obtain a powdery polyethylene-graphene nanometer mixture. Add the mixture together with the grinding balls into water for cleaning, take out the grinding balls, filter the solids from the cleaning solution, and dry them to obtain the powdery polyethylene...

Embodiment 3

[0036] A preparation method of a polymer-graphene mixture is realized by the following scheme: Accurately weigh 3.0g of flake graphite and 97.0g of polypropylene powder, add them to 2000ml of distilled water, and uniformly disperse them by magnetic stirring to obtain a suspension. Filter the suspension, take the solid and dry it to obtain a uniform powder, which is the polypropylene-graphite powder pre-mixture. The pre-mixture is moved to the horizontal ball mill ball mill tank of 5000ml with a volume of agate balls, the mass ratio of agate balls to flake graphite is about 600:1, and ball milled for 50h at a speed of 300 revs / min to obtain powdery aggregate Propylene-graphene nanohybrids. Add the mixture together with the grinding balls to absolute ethanol for cleaning, take out the grinding balls, filter the solids from the cleaning liquid, and dry them to obtain the powdery polypropylene-graphene nano mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com