Patents

Literature

276results about How to "Reduce friction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

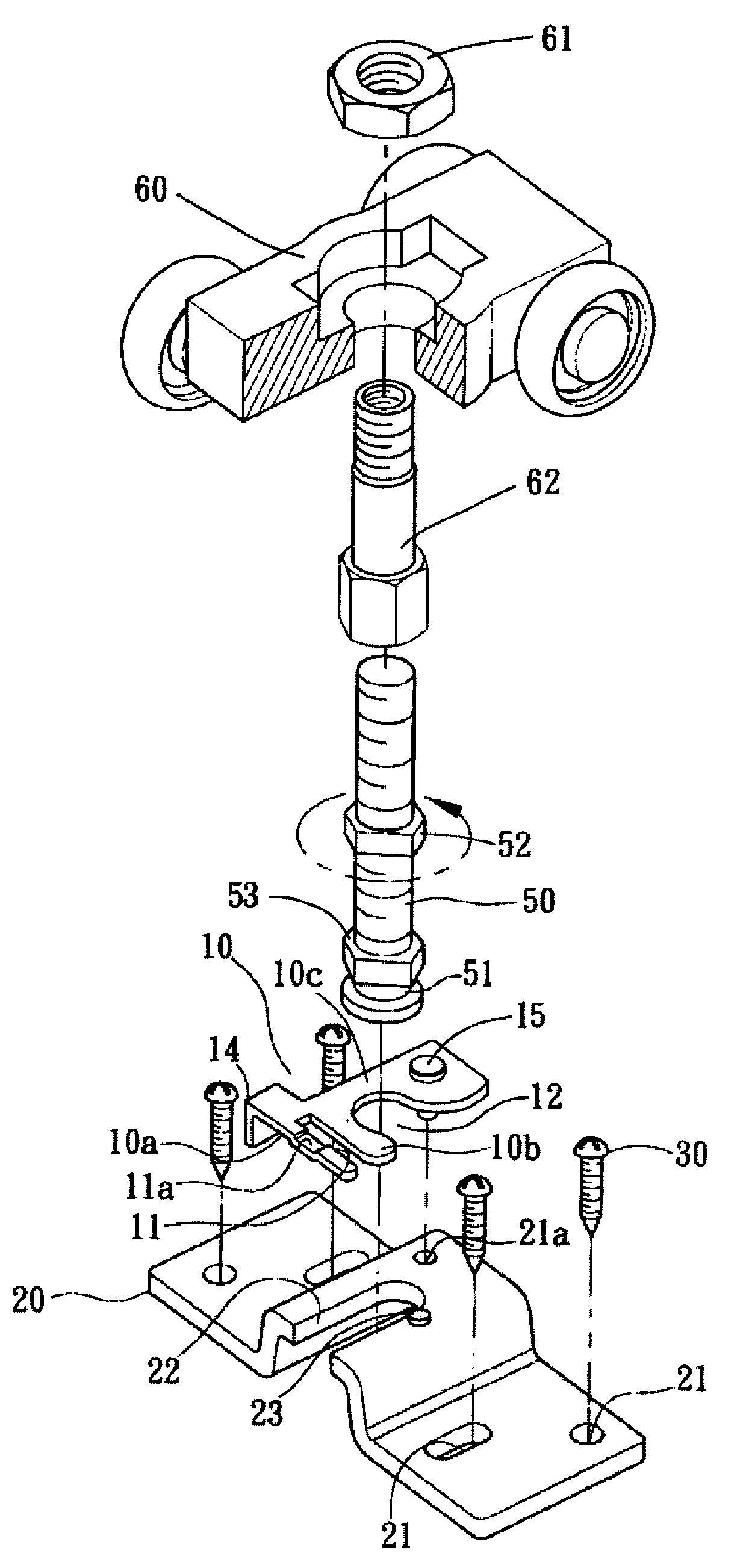

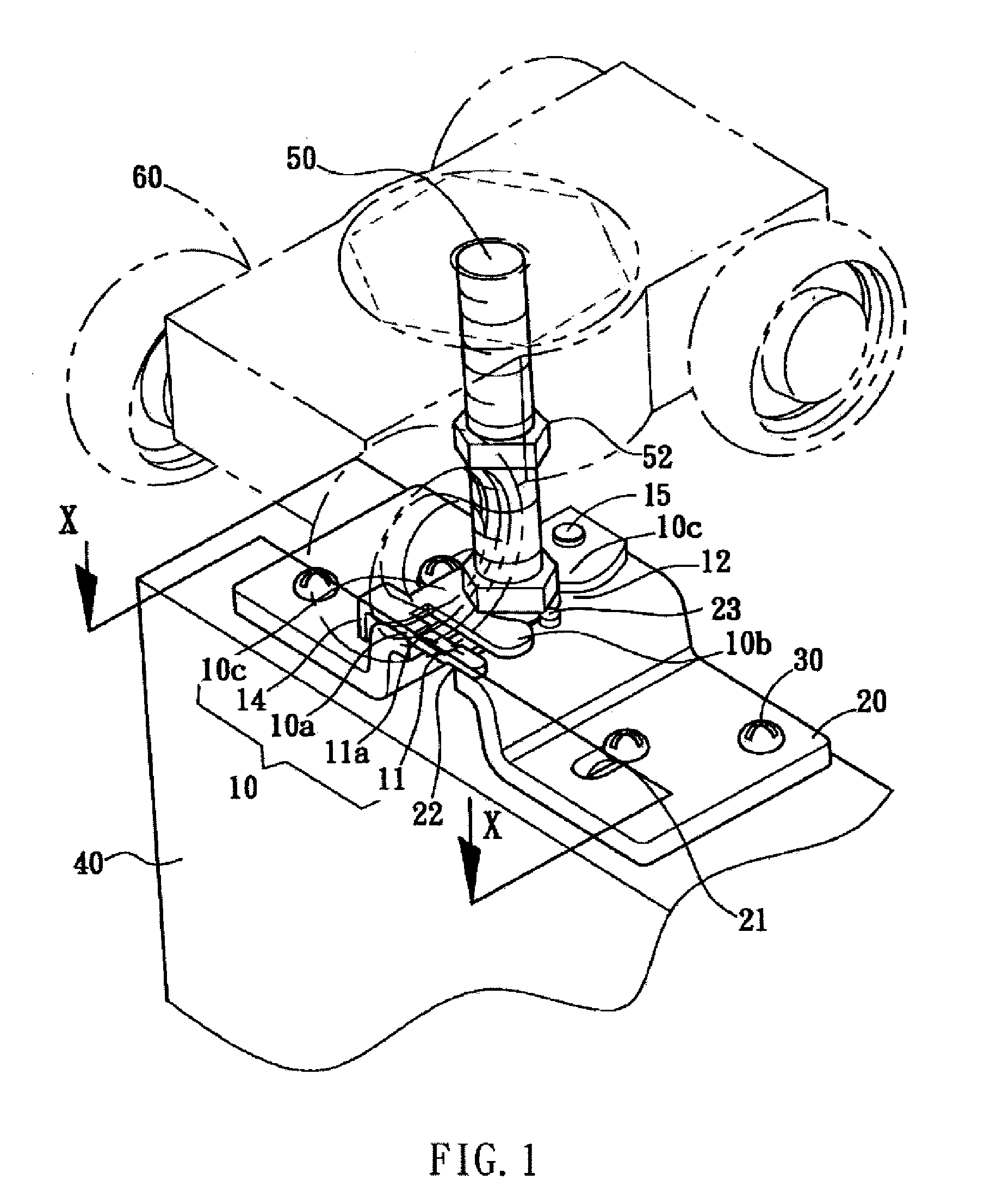

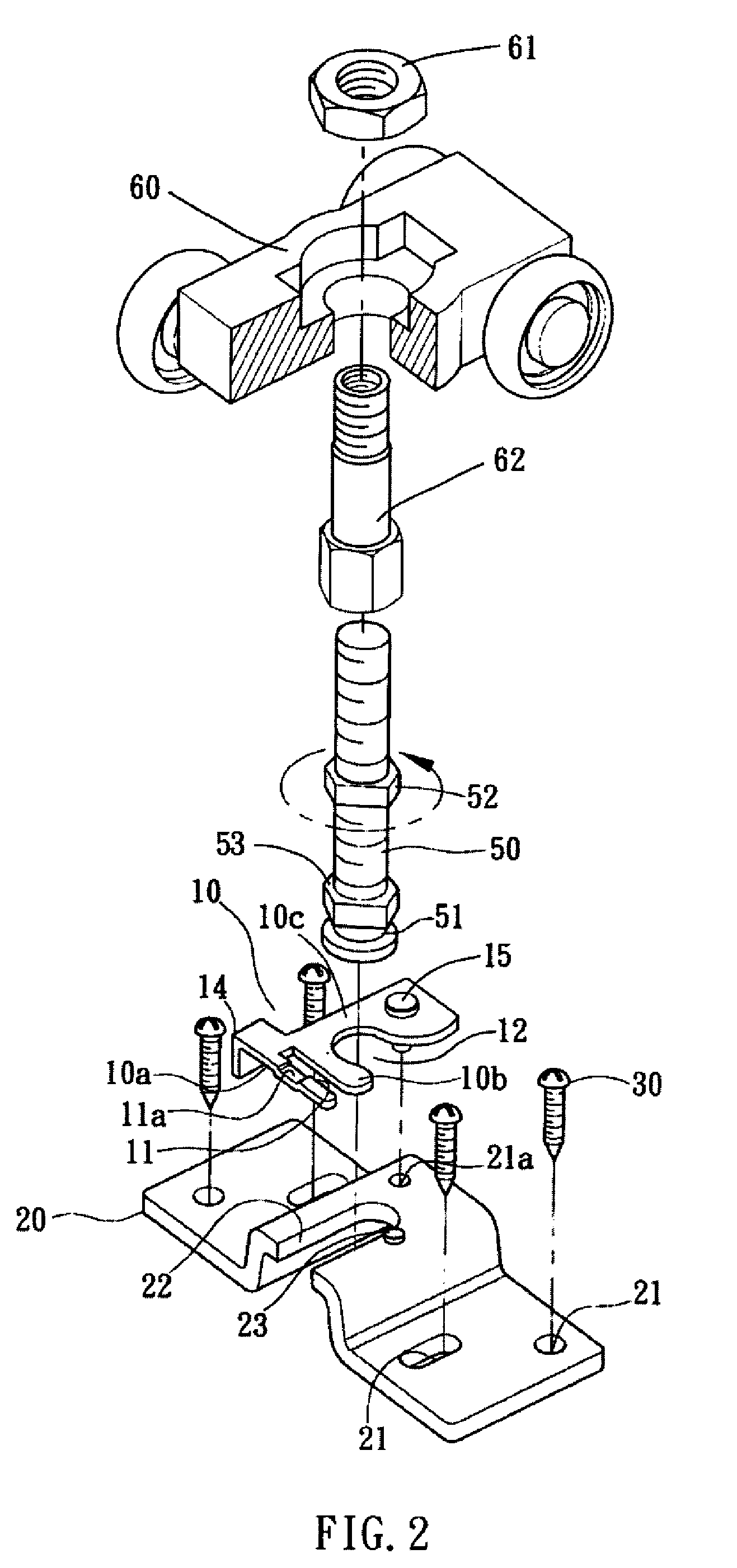

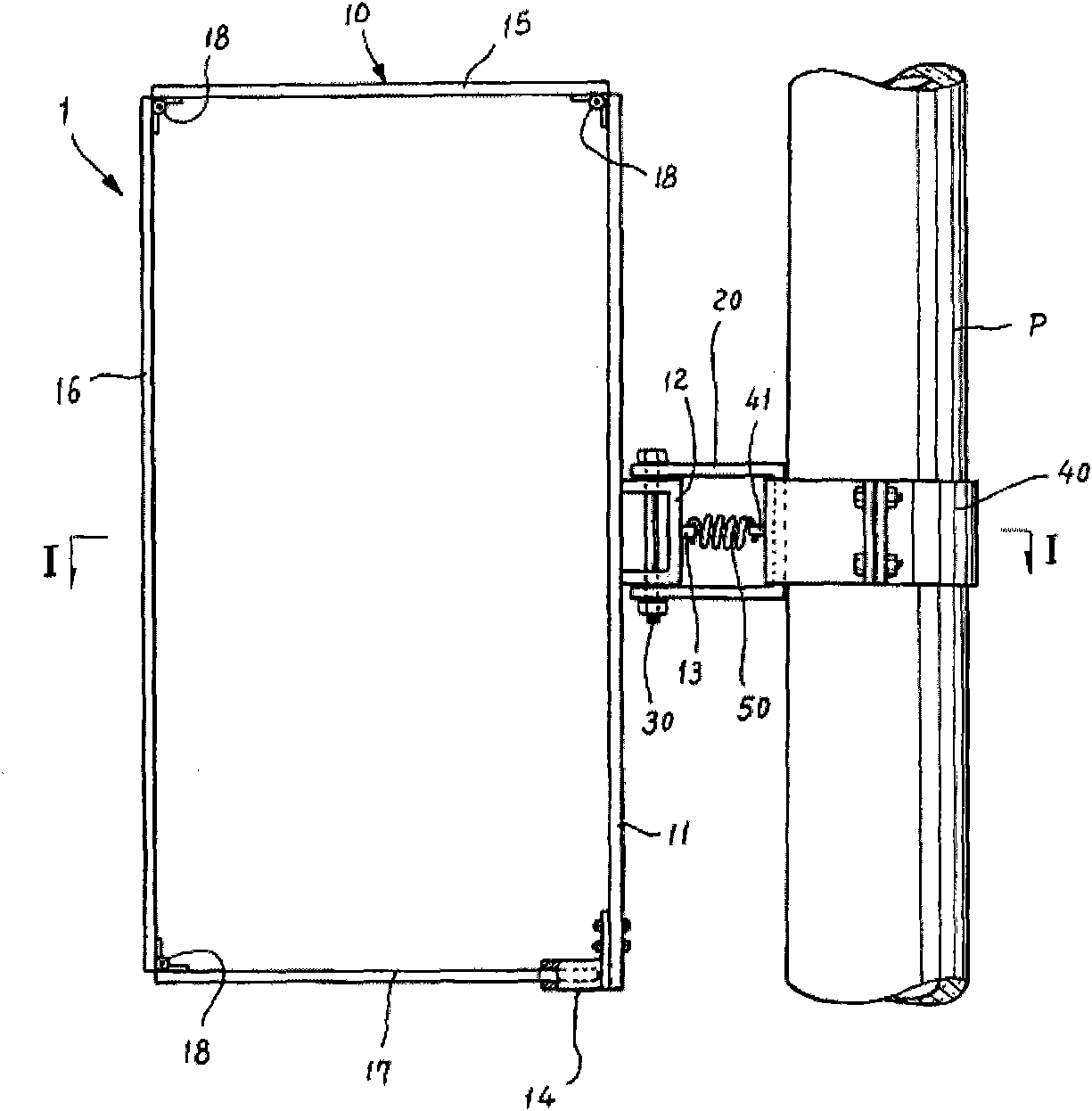

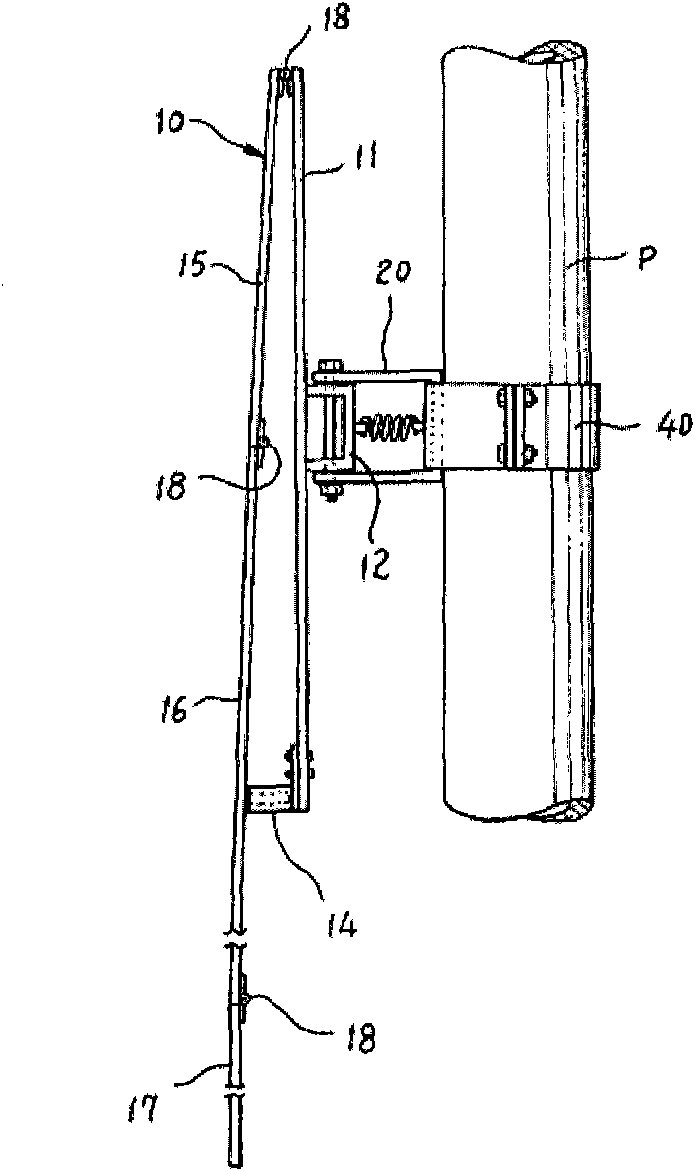

Positioning member for preventing detachment of axle

InactiveUS20090289463A1Prevent disengagementPrevent undesired separationBuilding locksWing suspension devicesRotational axisEngineering

A positioning member is coupled to a mounting plate, which defines a plurality of holes for receiving screws for connection with an end of an external object. An upper adjustment nut sets a distance between a roller seat and the mounting plate and to provide a securing function by cooperating with a roller seat nut and a roller seat bolt. The mounting plate forms in a central portion thereof an elongate slot for slidably receiving a neck of the axle therein. The positioning member includes a plate-like body forming a straight slot and an inclined slot for leading the neck therein and is provided with a rivet or a resilient fork-like fastener at one side of the inclined slot opposite to the straight slot to be fit into the a positioning hole defined beside the elongate slot for serving as a rotational axis of the positioning member.

Owner:ONLY INDAL CORP

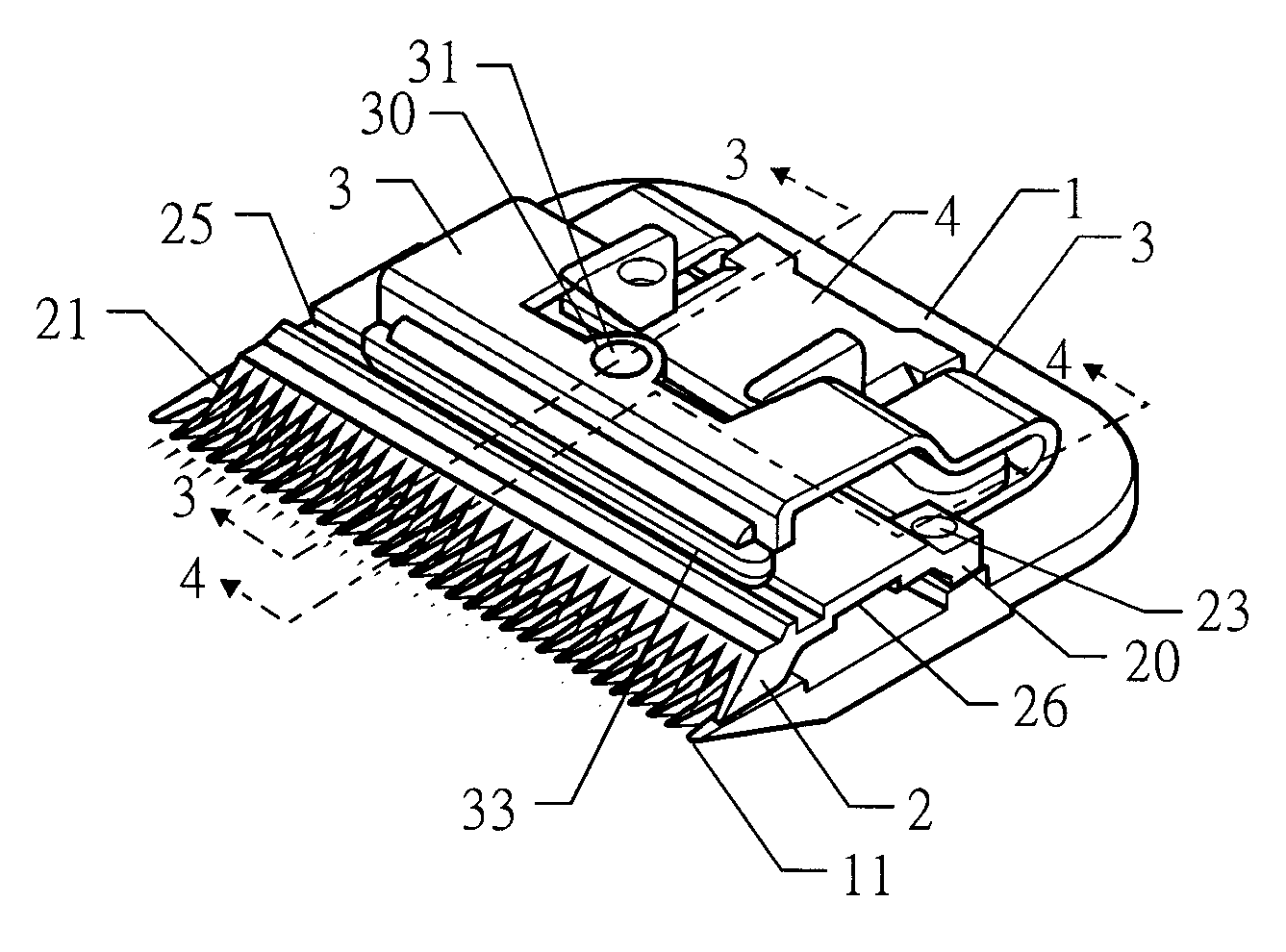

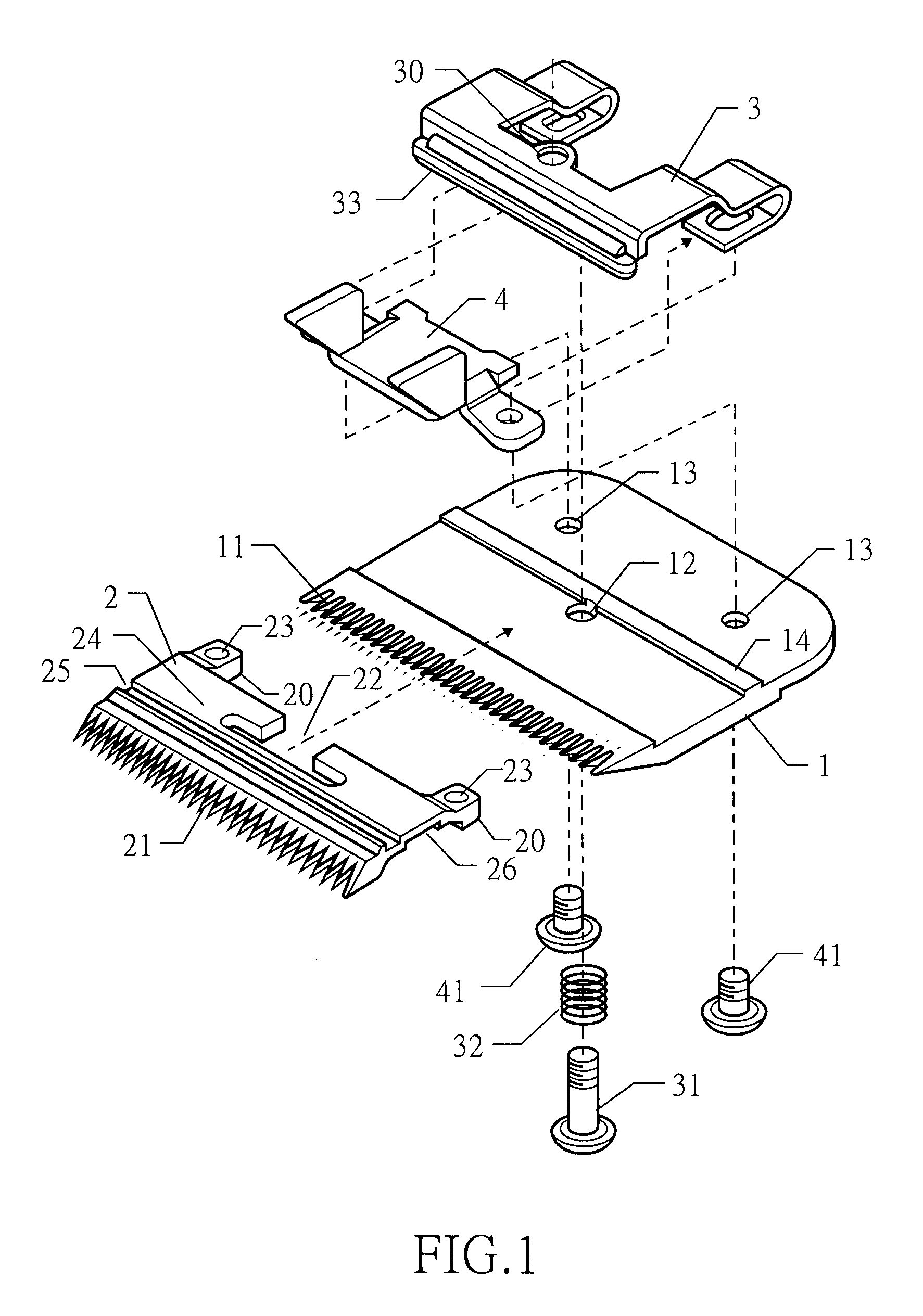

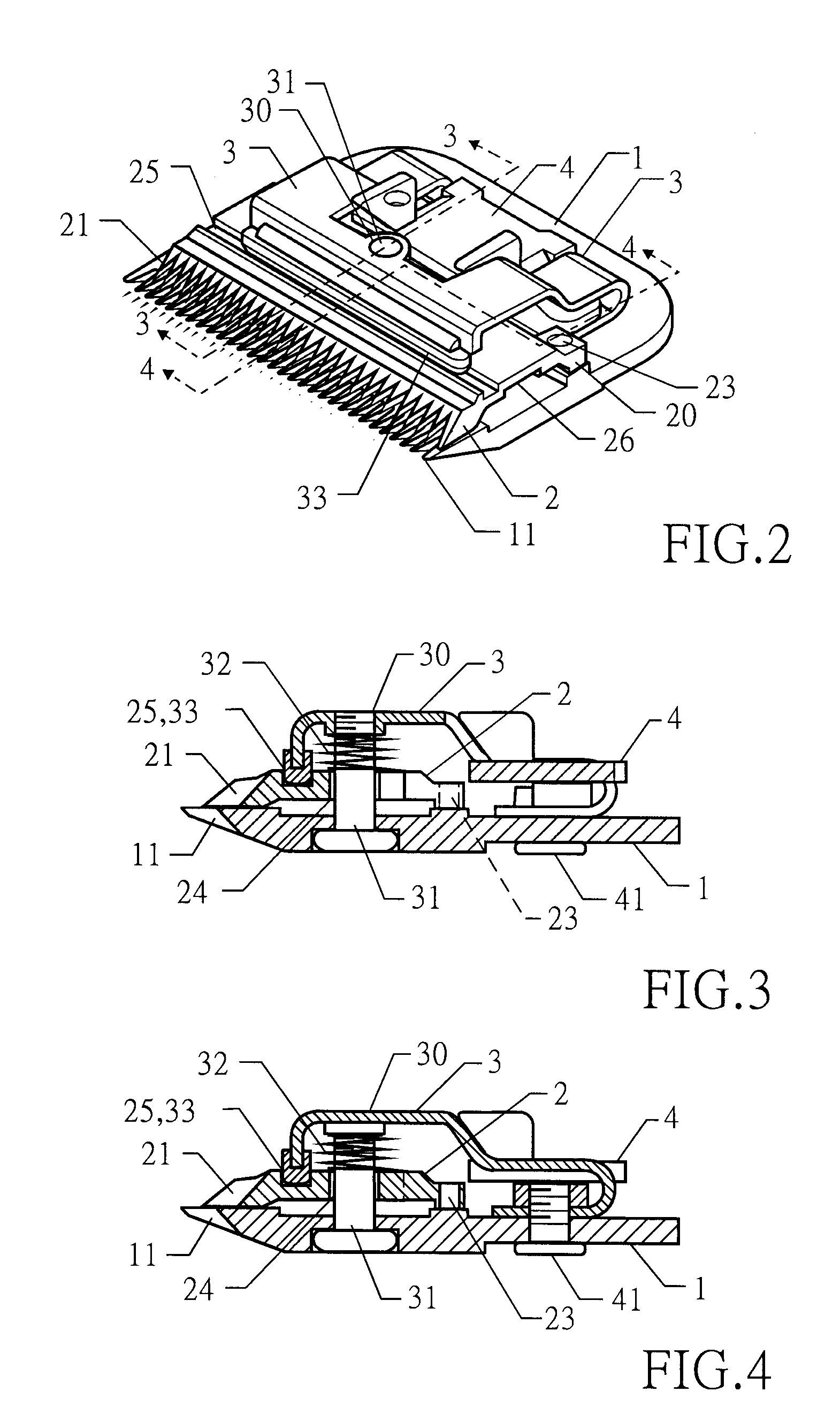

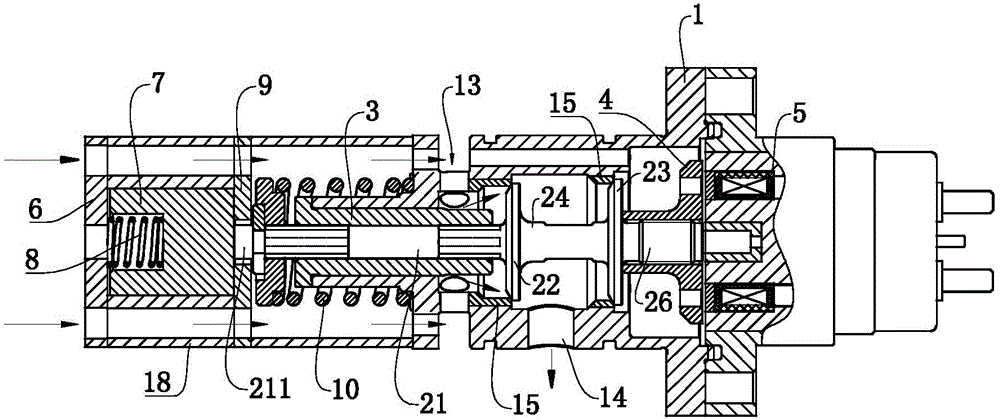

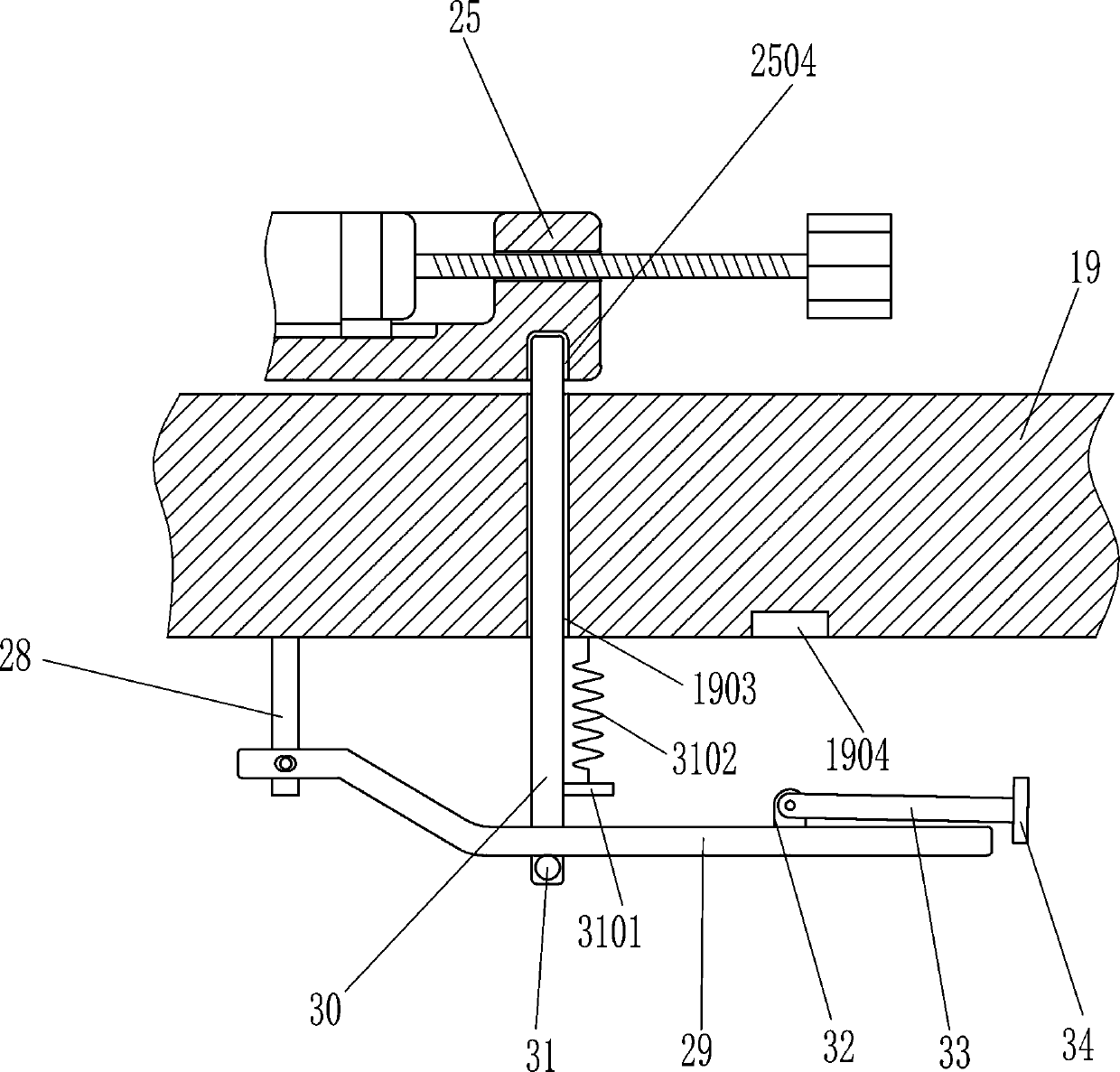

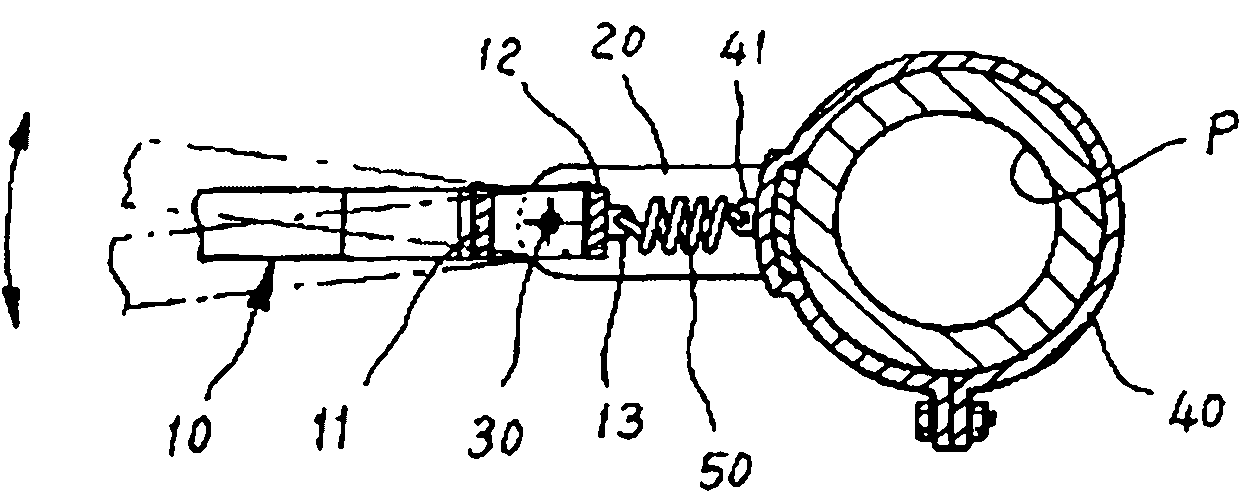

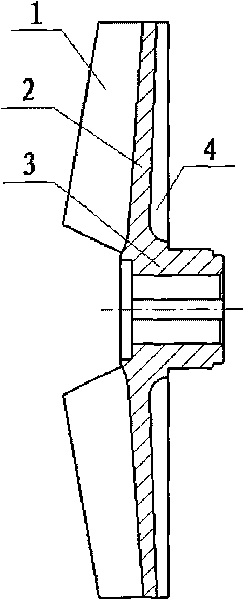

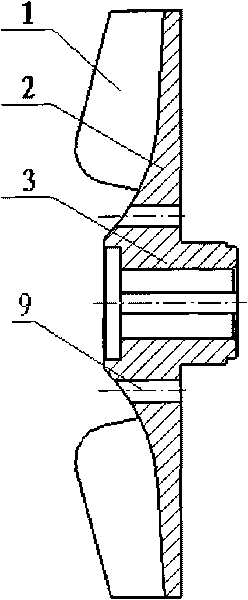

Pressure adjustable knife set for electromotive hair cutter

InactiveUS20110061241A1Reduce friction areaEasy to understandMetal working apparatusEngineeringFront edge

A pressure adjustable knife set for an electromotive hair cutter comprises: a fixed knife, a movable knife, and a pressure adjust unit; a front edge of the fixed knife having a cutting edge; the fixed knife being formed with a penetrating hole for passing through the adjustable screw of the pressure adjusting unit; a front edge of the movable knife being formed with a cutting edge; a lower side of the movable knife being formed with a supporting leg; the supporting leg being formed with a plurality of heat dissipating holes with a further function of reduction of the friction area of the supporting legs; the movable knife being formed with a penetrating trench; and a fixing plate being installed between the fixed knife and the pressure adjusting unit; an adjustable screw passing through a penetrating hole of the fixed knife, the movable knife and the pressure adjusting unit.

Owner:JIAN JHENG MAU

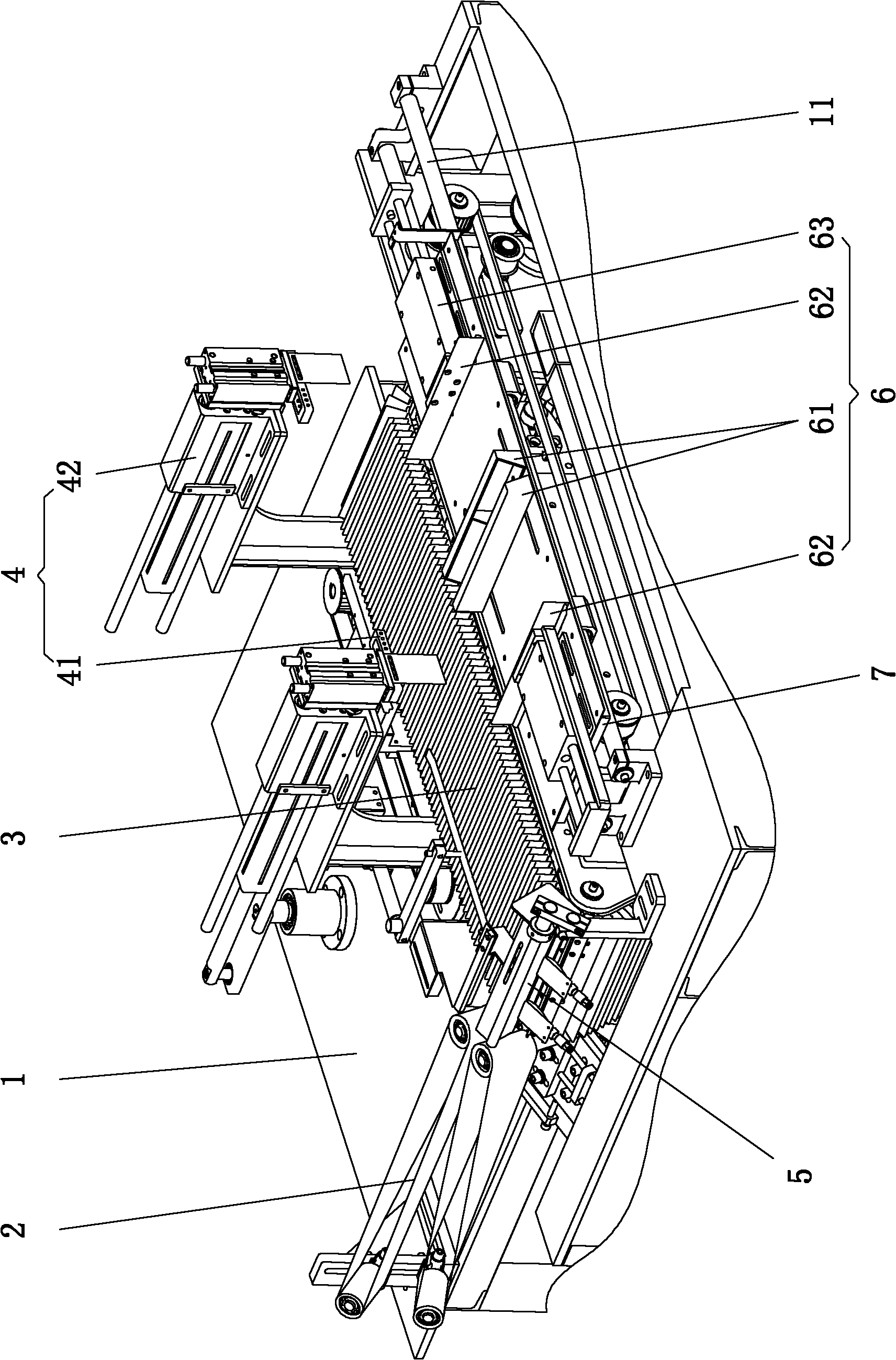

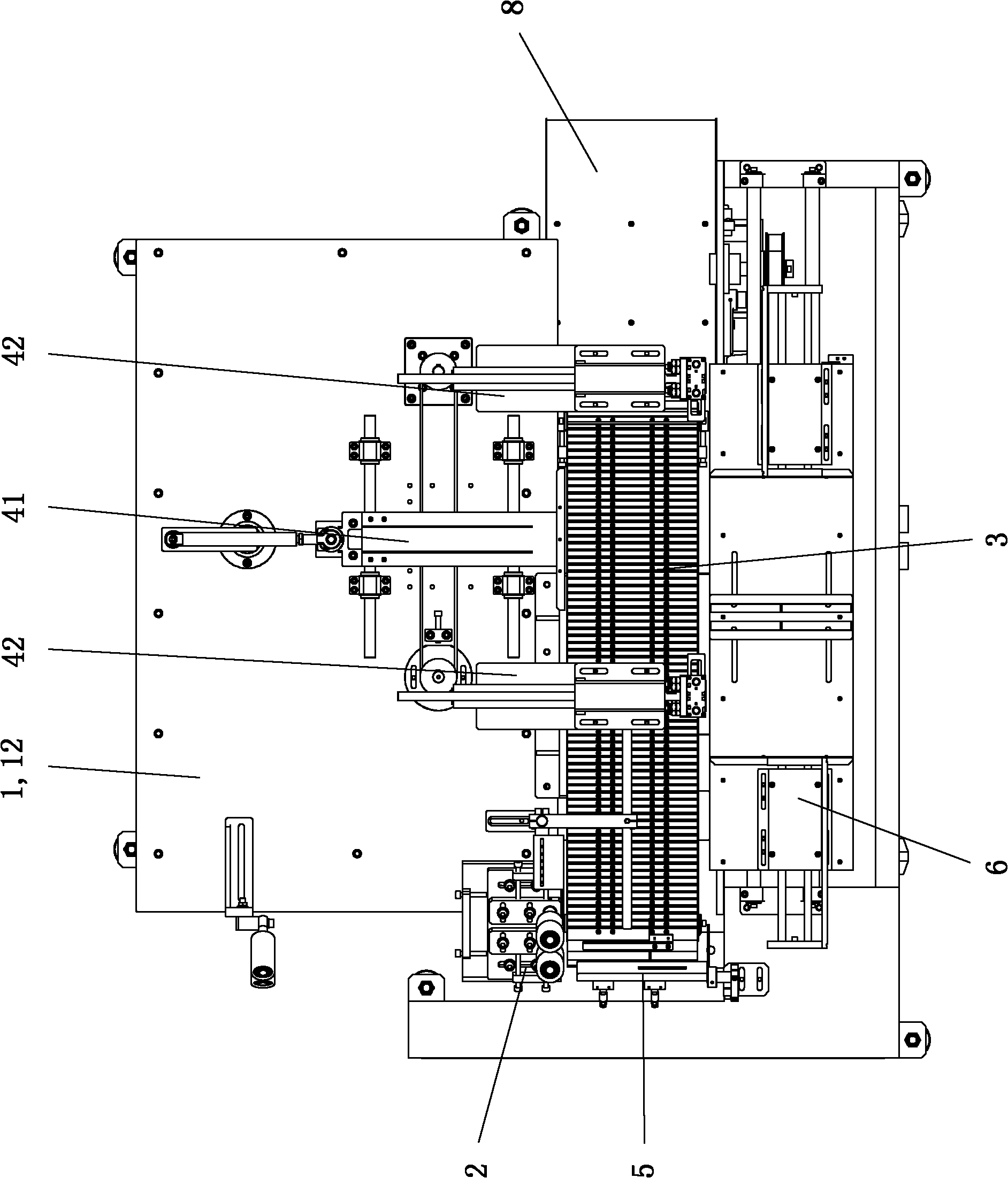

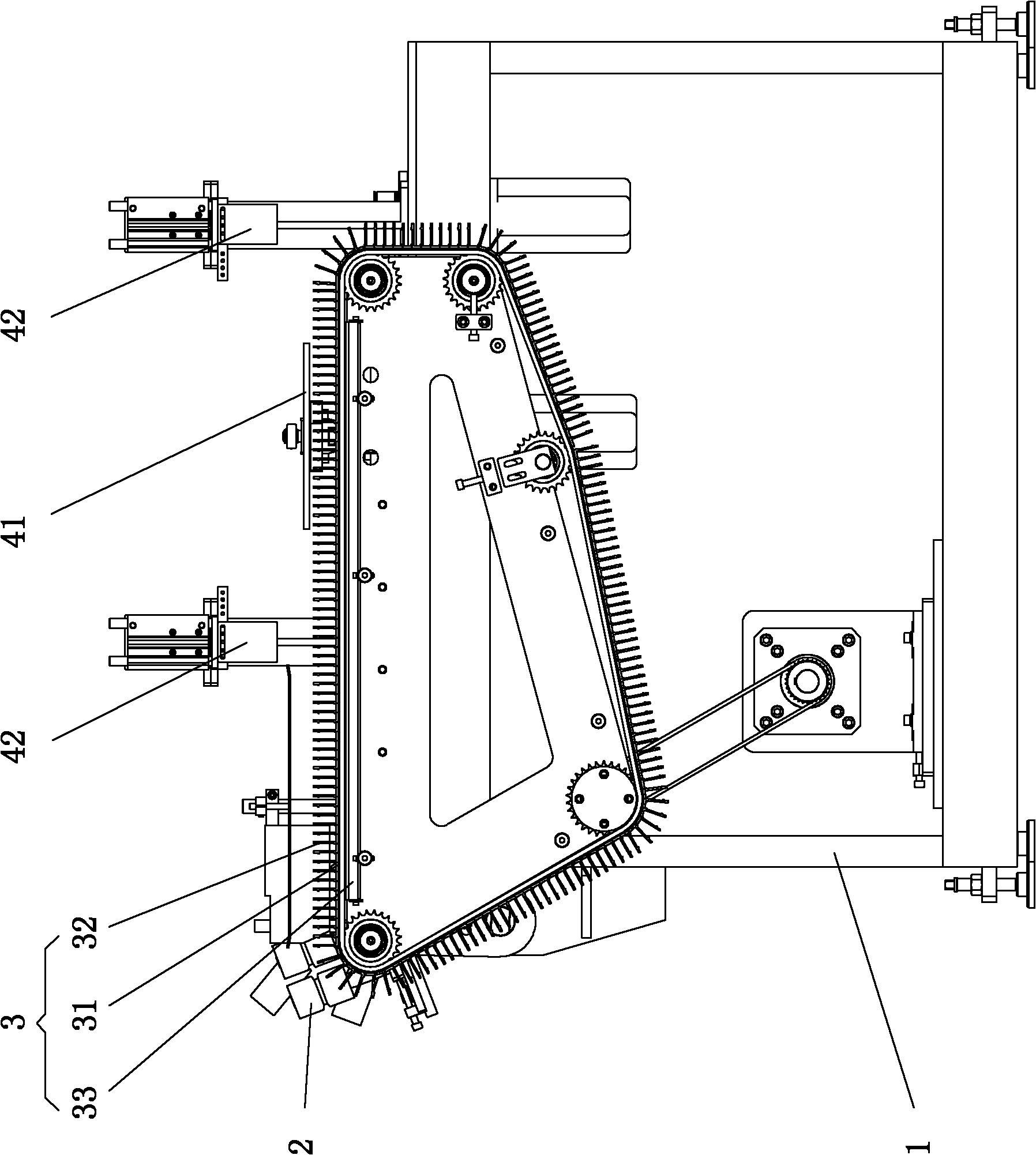

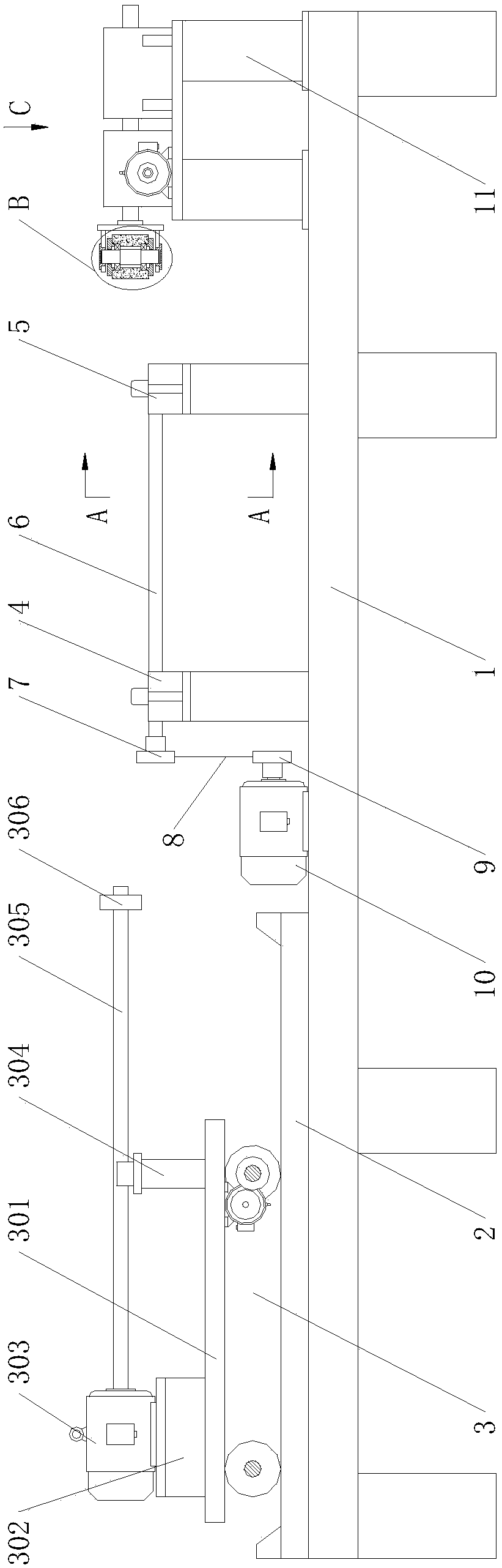

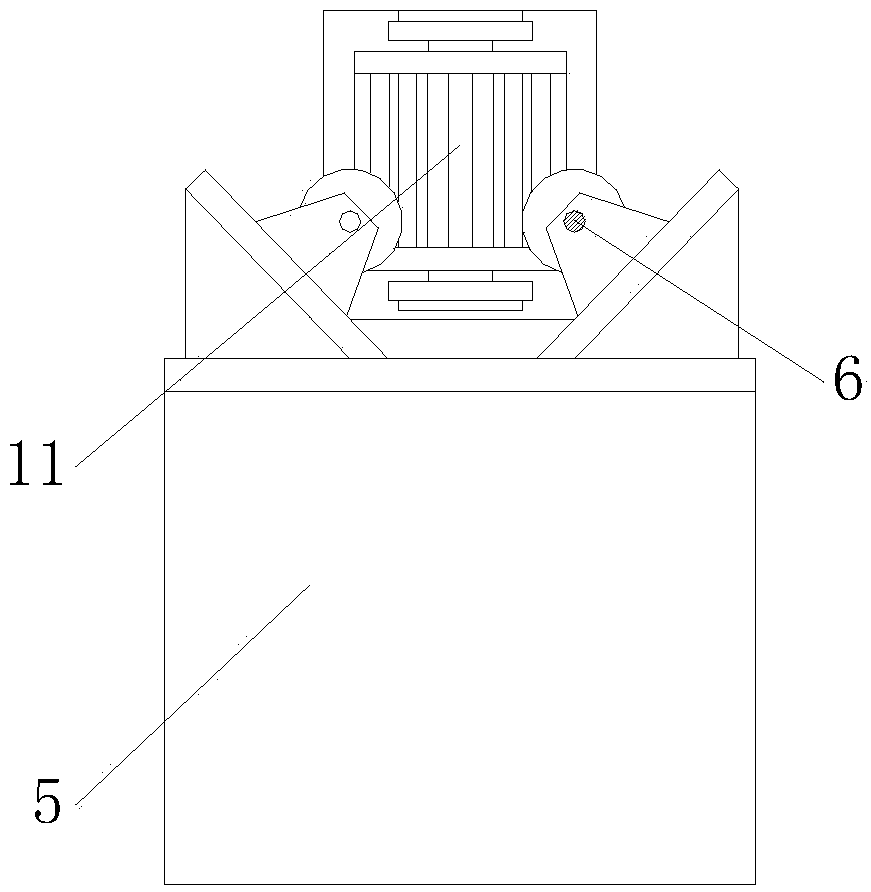

Thin straight-piece product stacking machine

ActiveCN103043253APrevent from causingPrevent upward movementPackagingStack machineIndustrial engineering

The invention relates to a thin straight-piece product stacking machine. The thin straight-piece product stacking machine is provided with a machine frame, a feeding mechanism arranged on the machine frame, a piece arranging mechanism and a pushing hand mechanism. A limiting mechanism is arranged at the position of the piece arranging mechanism corresponding to the feeding mechanism, and the pushing hand mechanism is arranged on one side of the piece arranging mechanism and is provided with a small package pushing hand and two bagging pushing hands symmetrically arranged on the left side and the right side of the small package pushing hand. Two compaction mechanisms are controllably slidably arranged at the position of the other side of the piece arranging mechanism corresponding to the pushing hand mechanism, the sliding direction of the two compaction mechanisms and the moving direction of the piece arranging mechanism are consistent, each compaction mechanism is provided with an adjustable fixed compaction plate and a slidable compaction plate, and the center distance between the small package pushing hand and each bagging pushing hand is matched with the distance between the two compaction mechanisms. The thin straight-piece product stacking machine can adapt to accurate piece arrangement and high-speed stacking of thin straight-piece products, works stably and is high in working efficiency and reasonable in design.

Owner:ANQING HENG CHANG MACHINERY

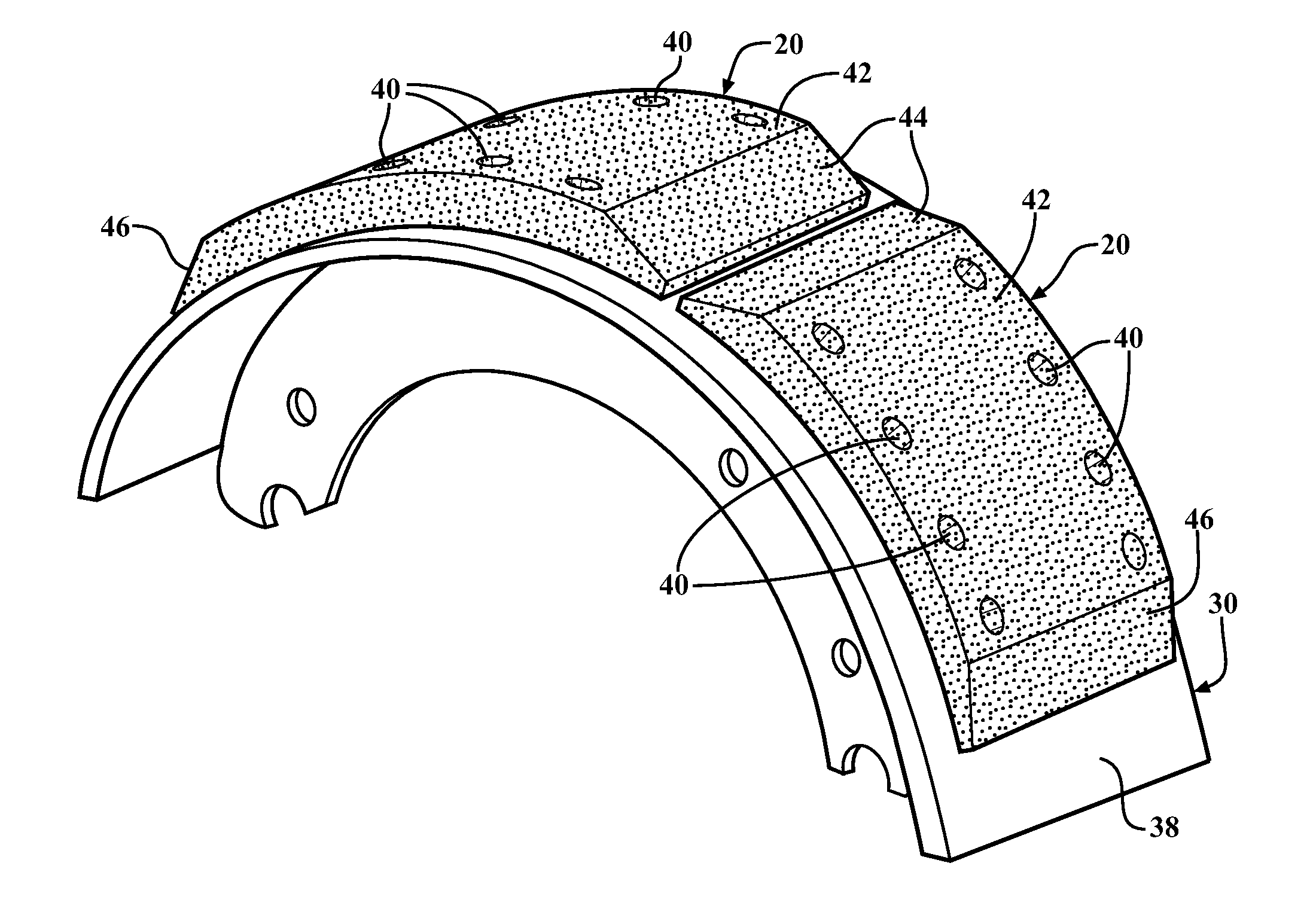

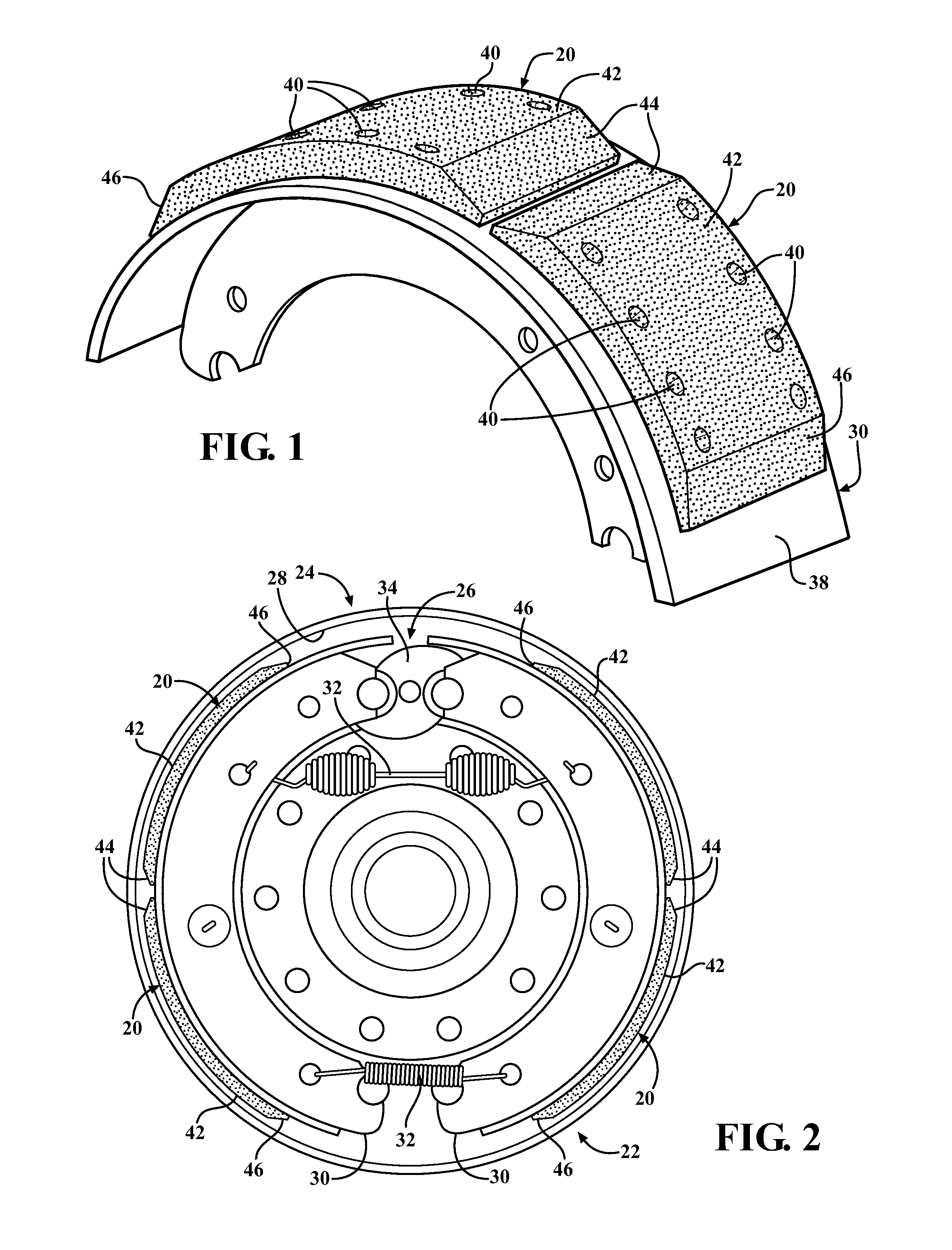

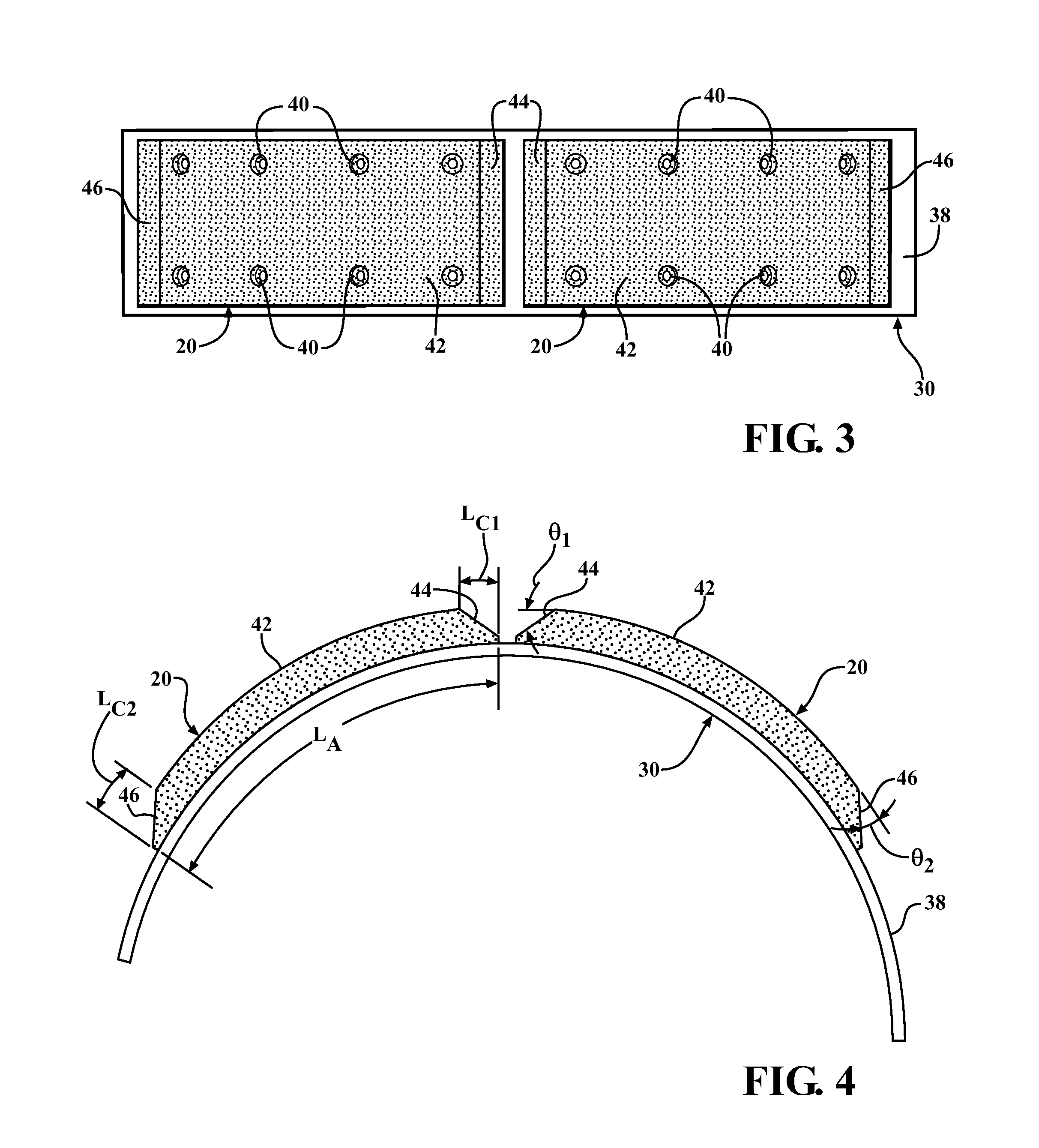

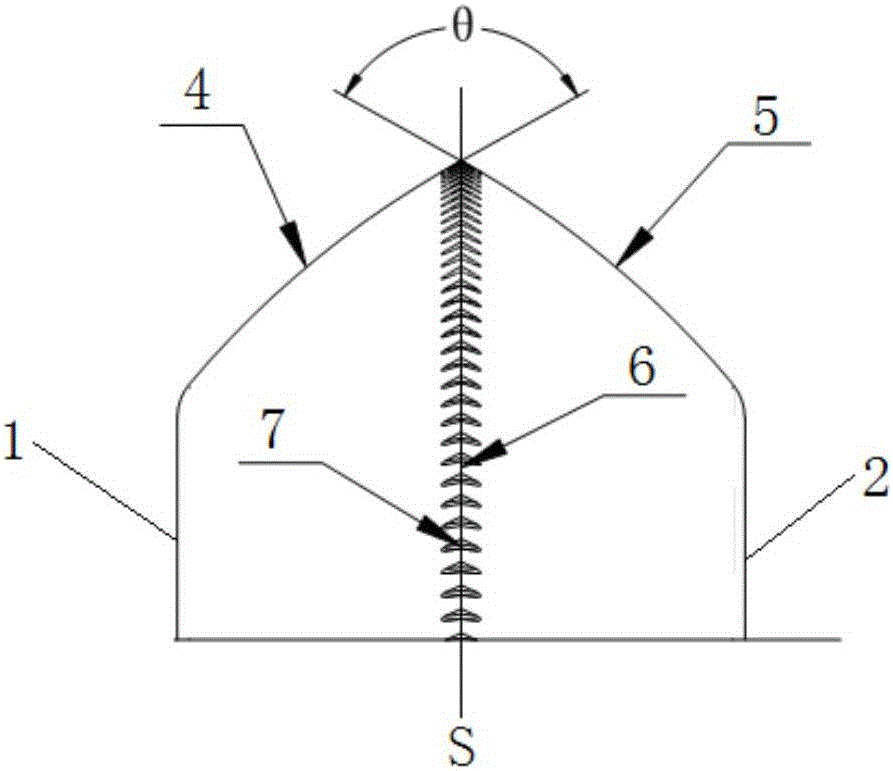

Brake lining for a drum brake assembly

ActiveUS20130134001A1Reduce brake vibration and noiseBrake performance be not compromiseBraking membersDrum brakesDrum brakeBrake lining

An improved drum brake assembly for reducing braking vibrations and noise. The improved assembly includes a pair of shoes, each extending through an arc and presenting an outer shoe surface. A pair of brake linings of a friction material are coupled to the outer shoe surface. Each of the brake linings has an upper surface and a pair of oppositely facing chamfered edges. Each chamfered edge has an arc length of no less than one inch and is disposed at an angle of between ten and twenty-five degrees from the tangent of the upper surface where it meets the chamfered edge.

Owner:FEDERAL MOGUL PROD US LLC

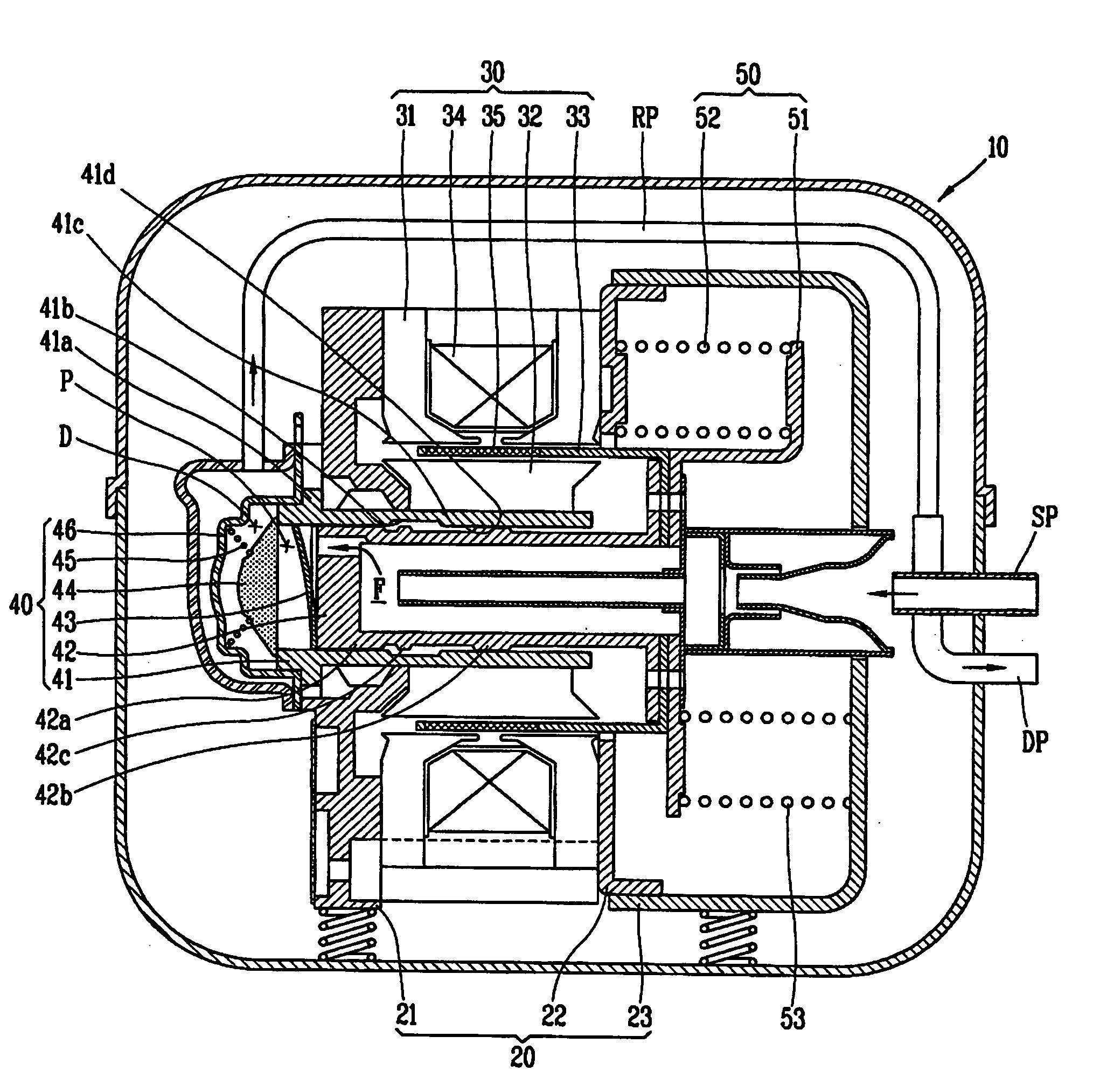

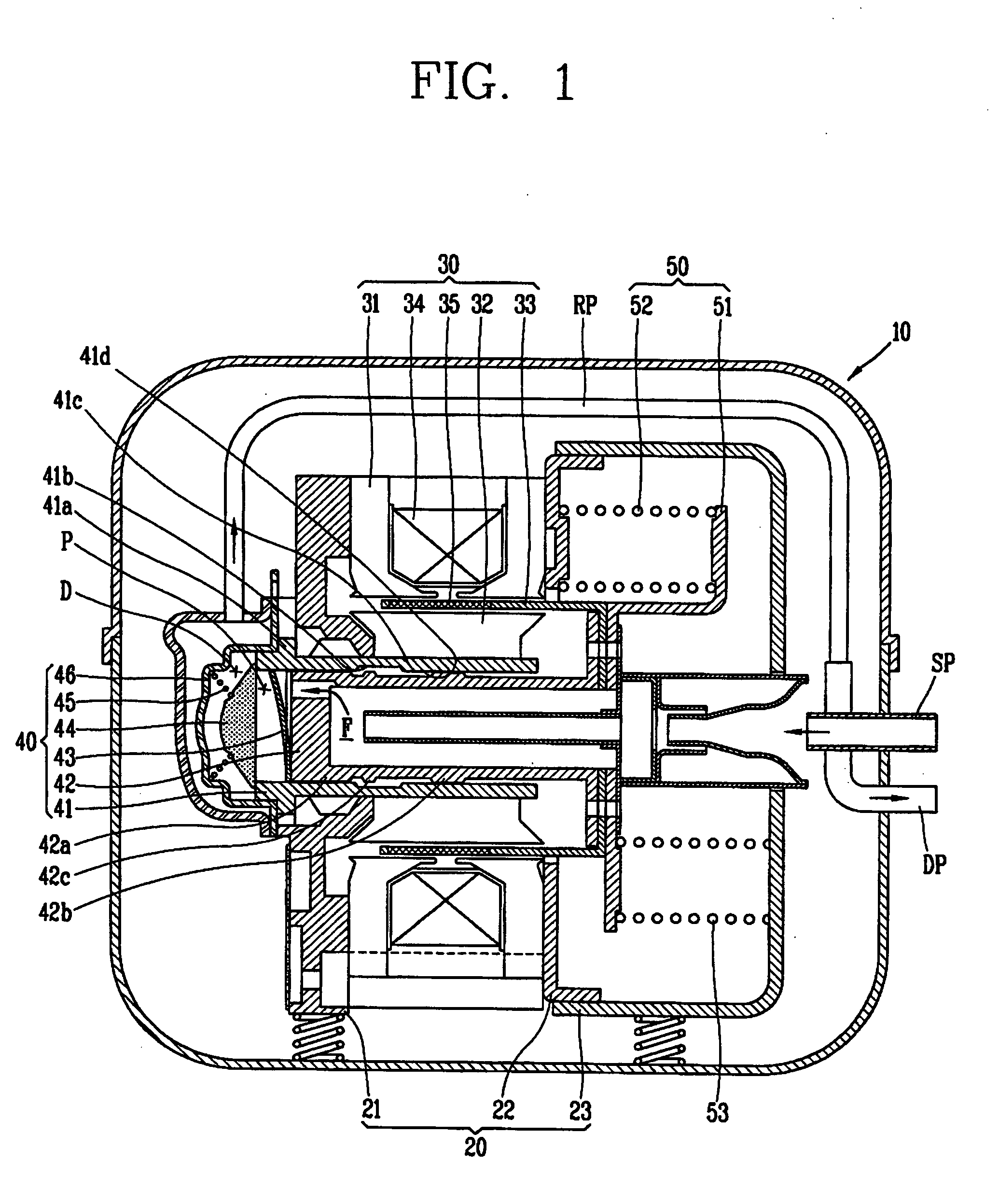

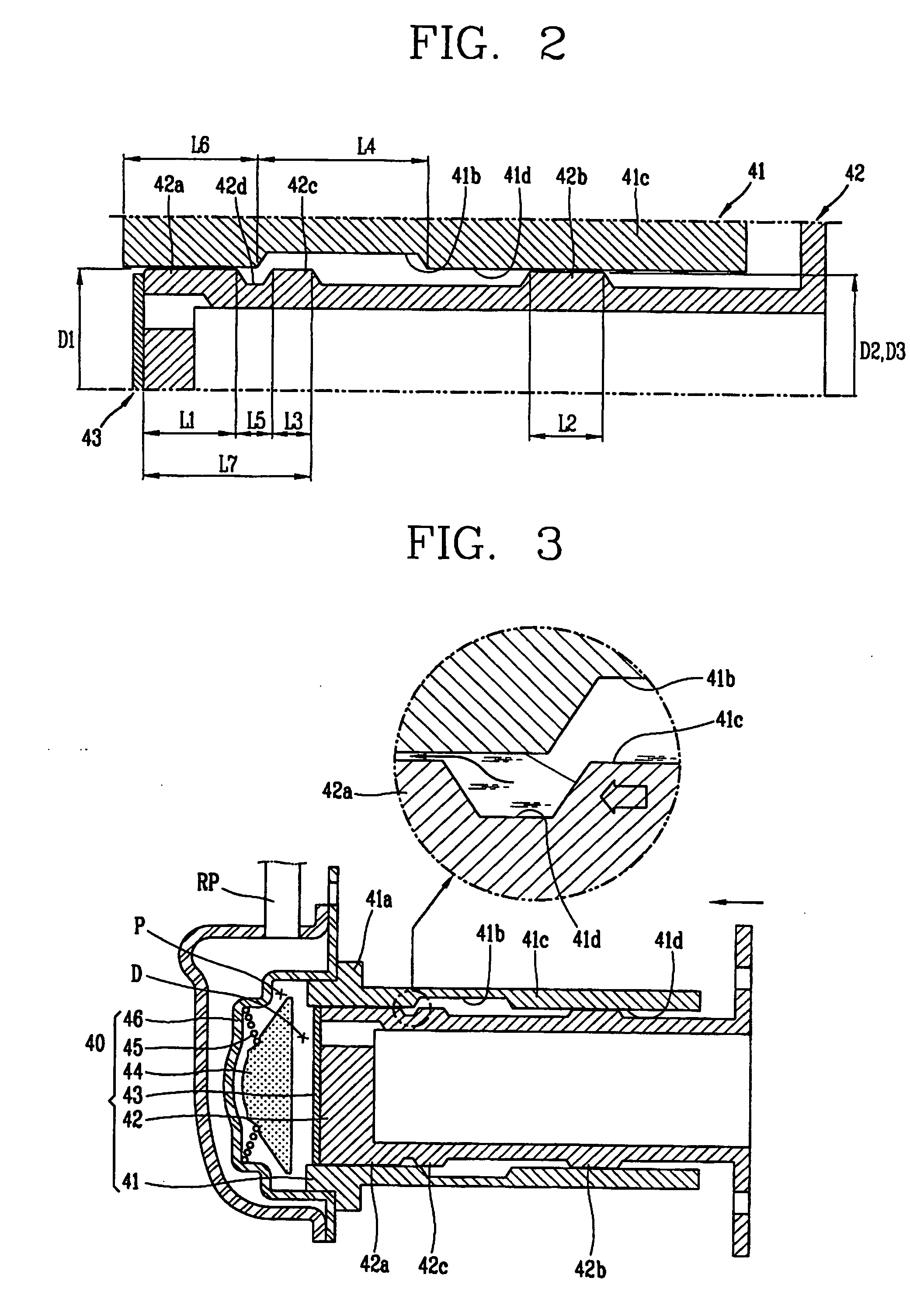

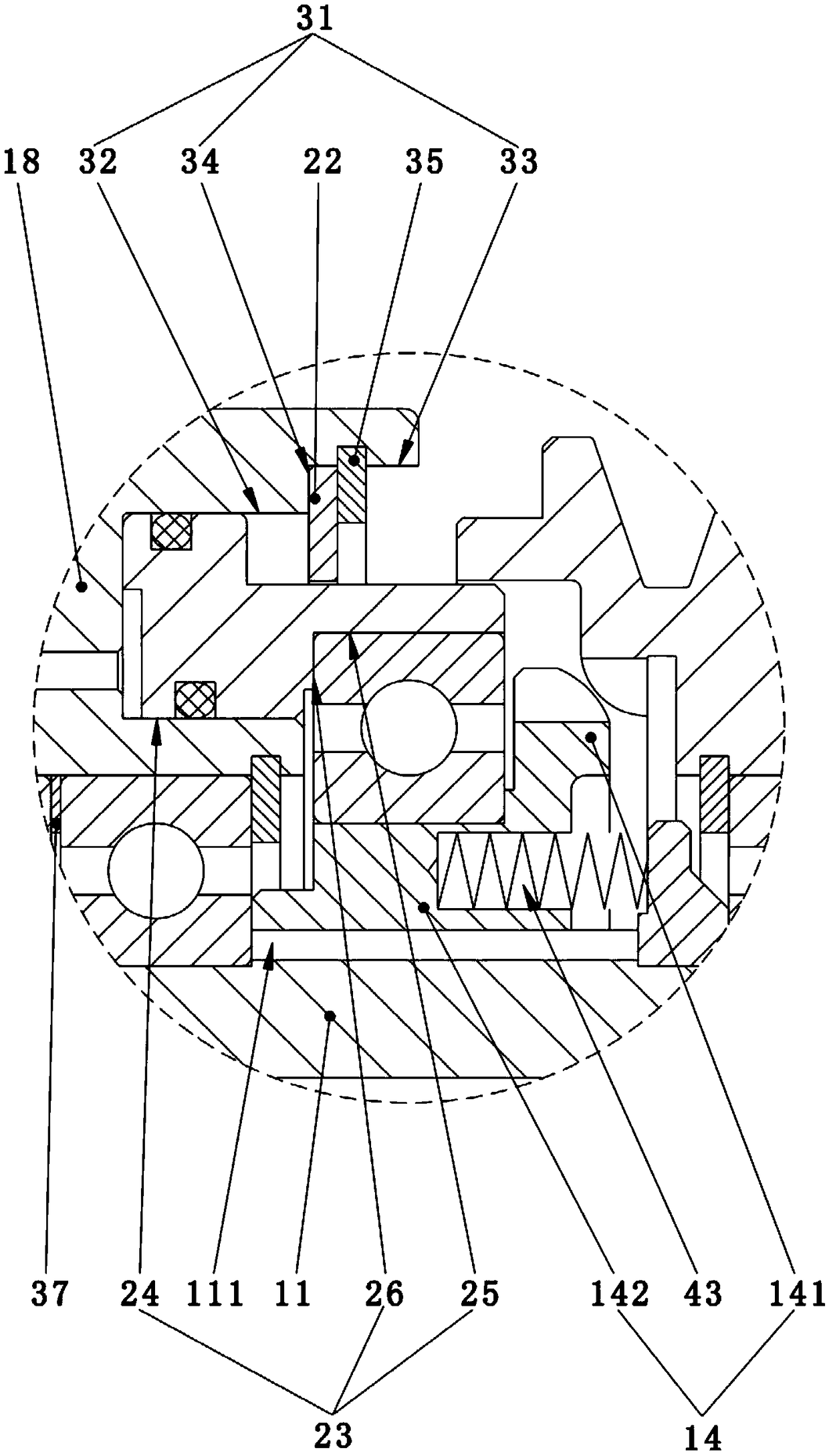

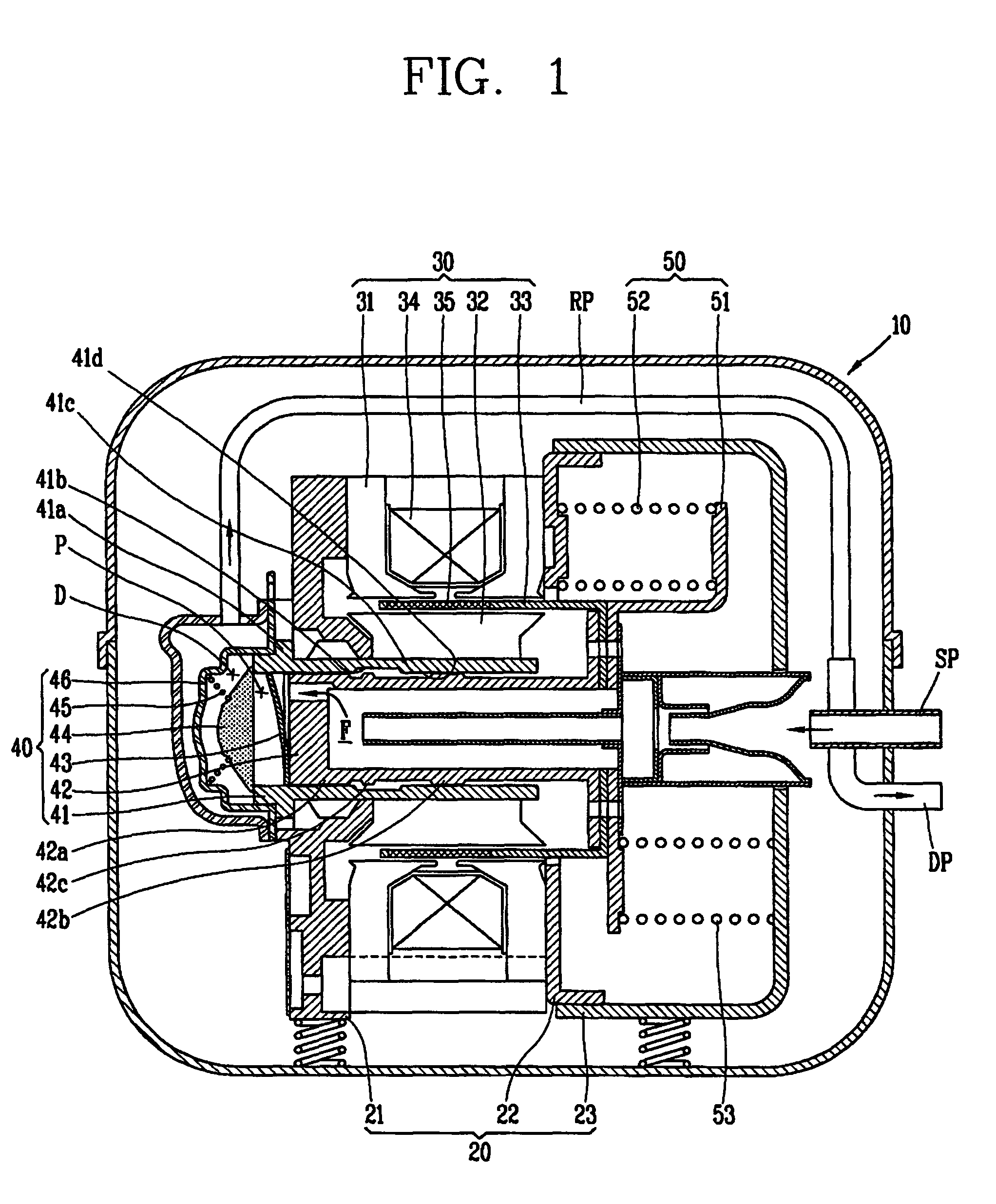

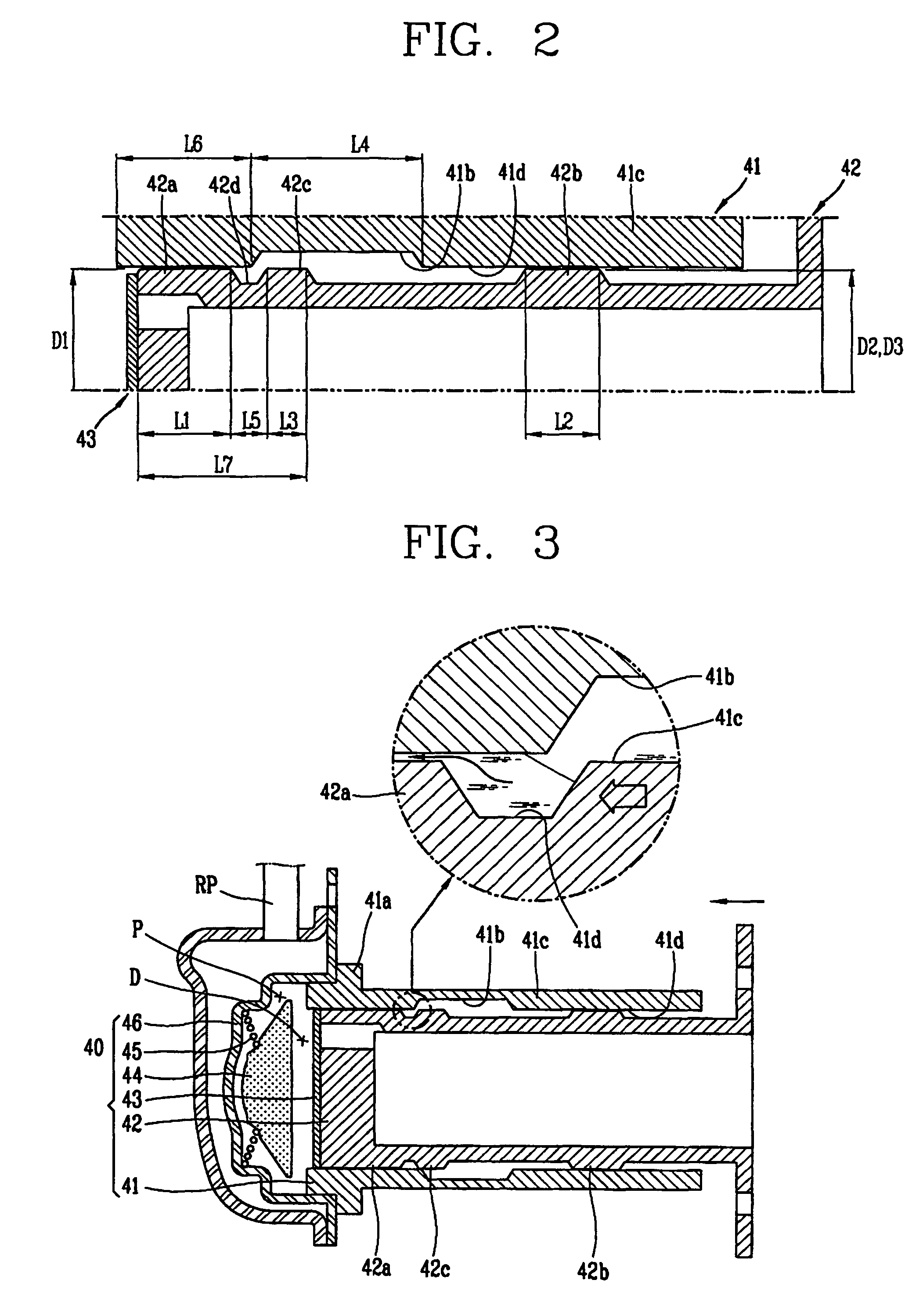

Reciprocating compressor

ActiveUS20090101003A1Decrease frictional areaEasy to assemblePositive displacement pump componentsPlungersEngineeringReciprocating compressor

A reciprocating compressor comprises: a cylinder having an oil pocket on an inner circumferential surface of a piston insertion hole for inserting a piston with a predetermined width and depth; and a piston having a bearing portion protruding so as to slidably contact an inner circumferential surface of the piston insertion hole, and inserted into the piston insertion hole of the cylinder, wherein the bearing portion is formed to have a length shorter than that of the oil pocket of the cylinder. Accordingly, a frictional loss between the cylinder and the piston is reduced.

Owner:LG ELECTRONICS INC

Gas injection valve with buffer mechanism

ActiveCN105042177AReduced collision wearQuick responseValve members for absorbing fluid energySlide valveVALVE PORTFastener

Owner:WEIFANG LICHUANG ELECTRONICS TECH

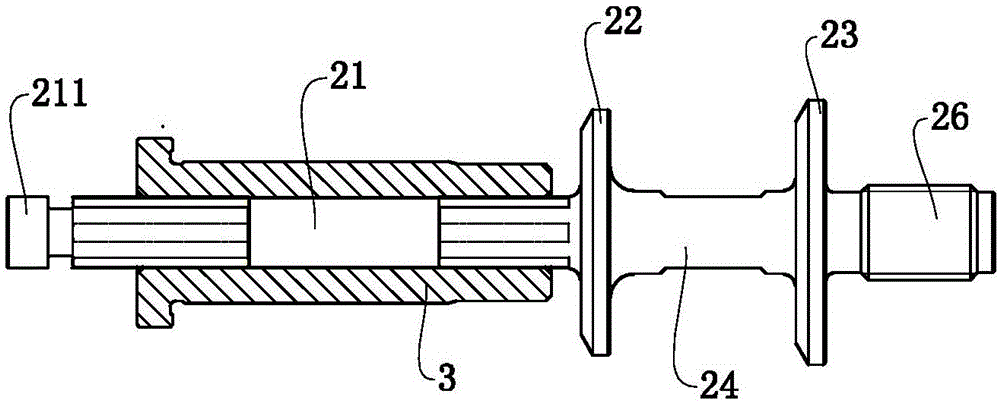

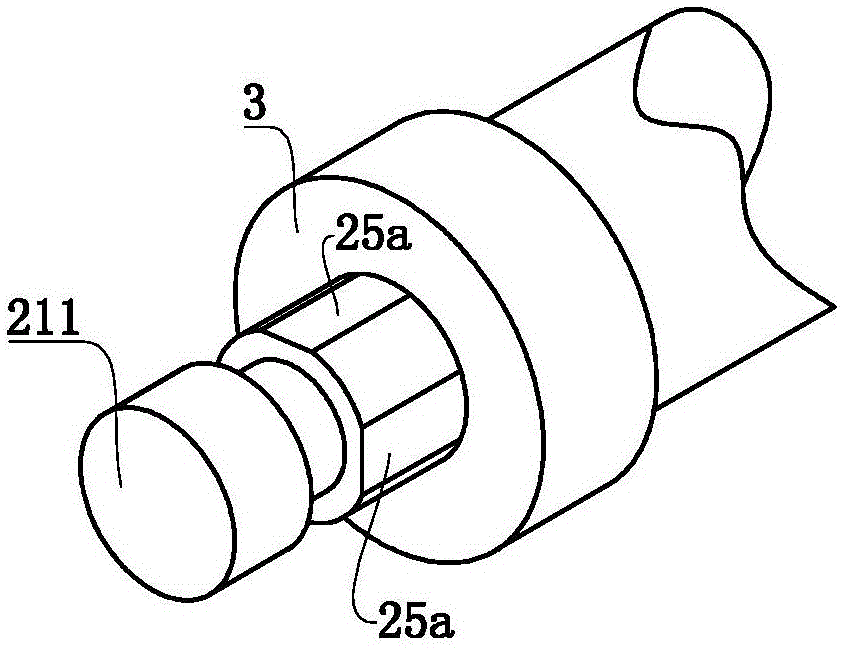

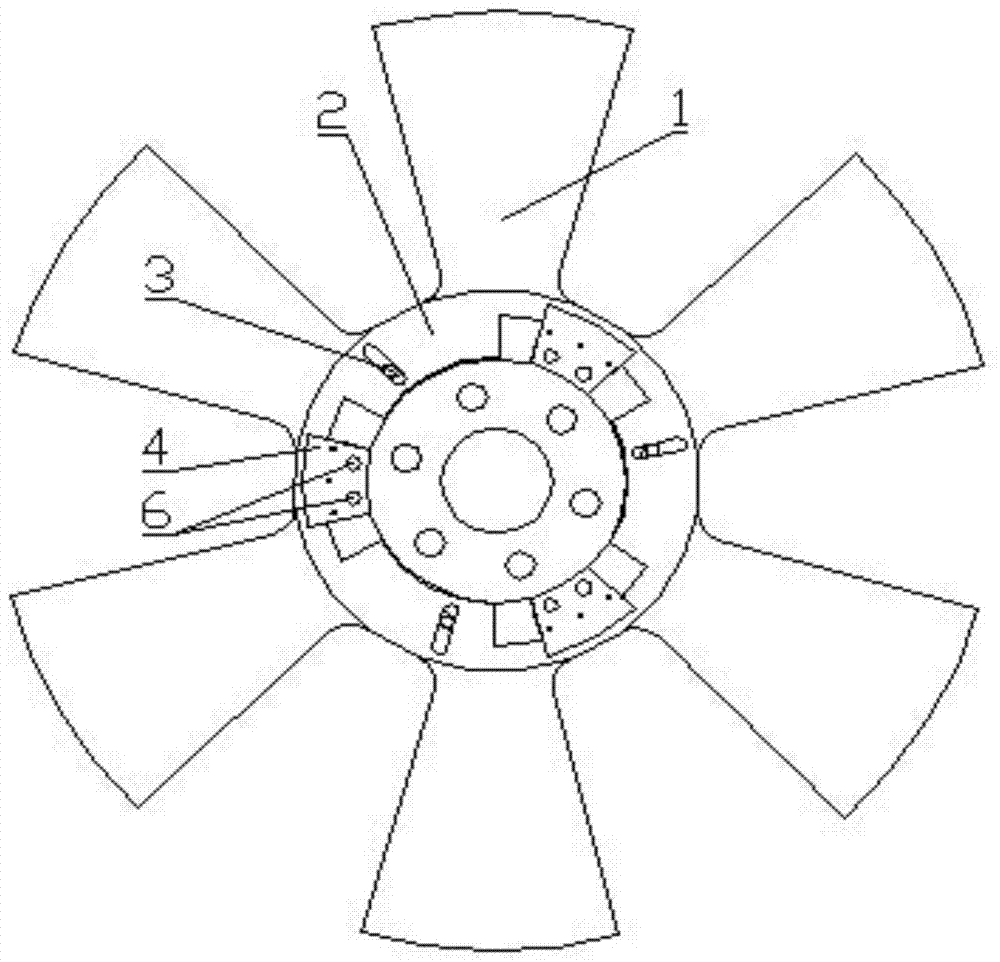

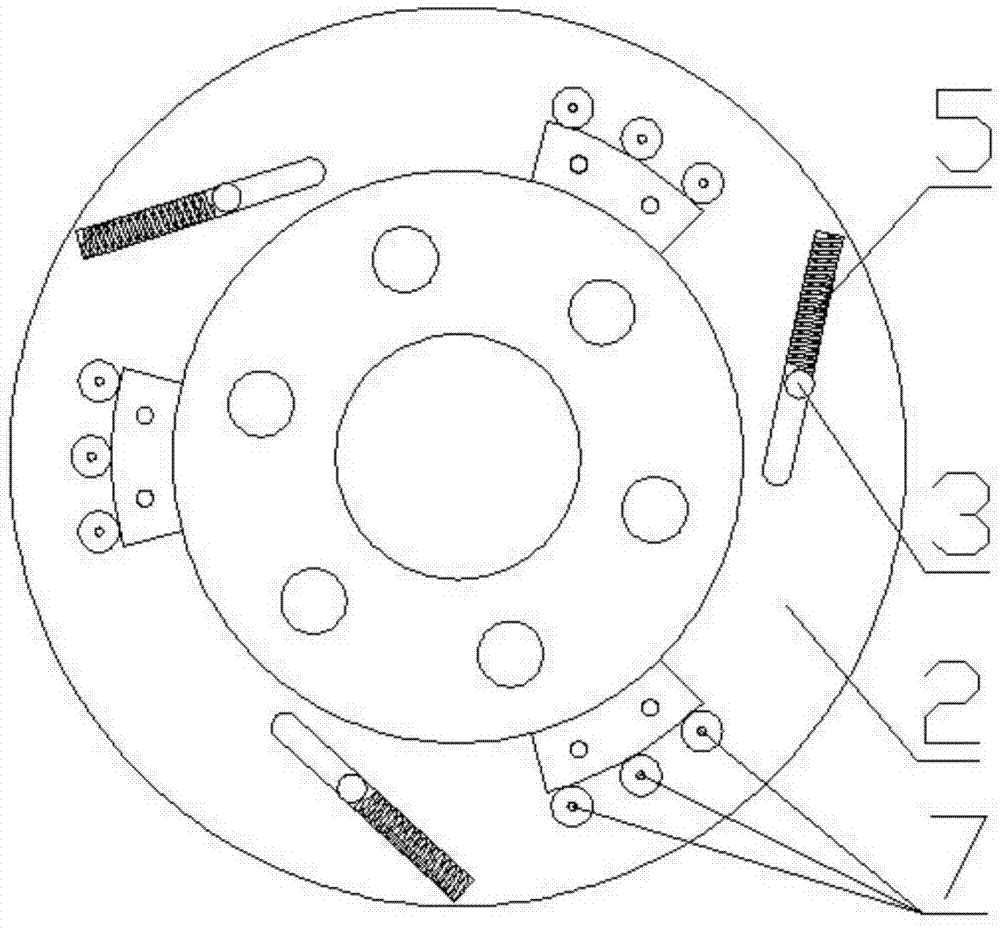

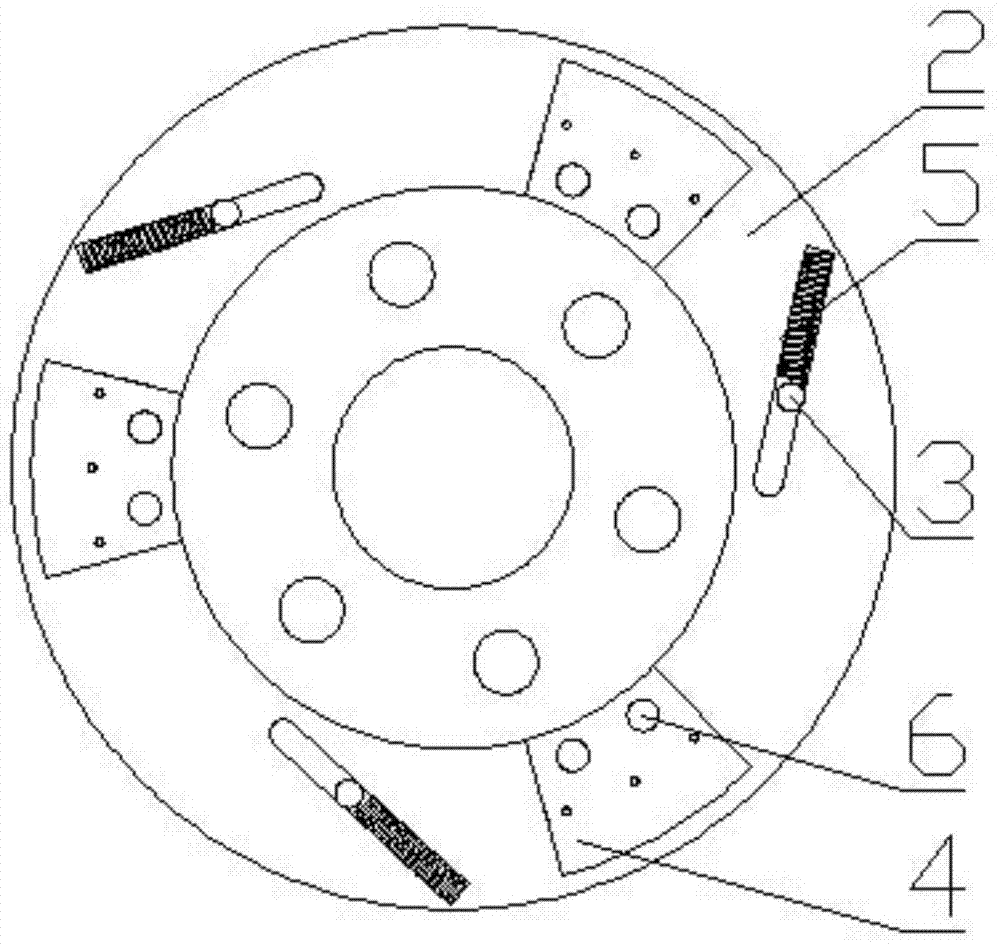

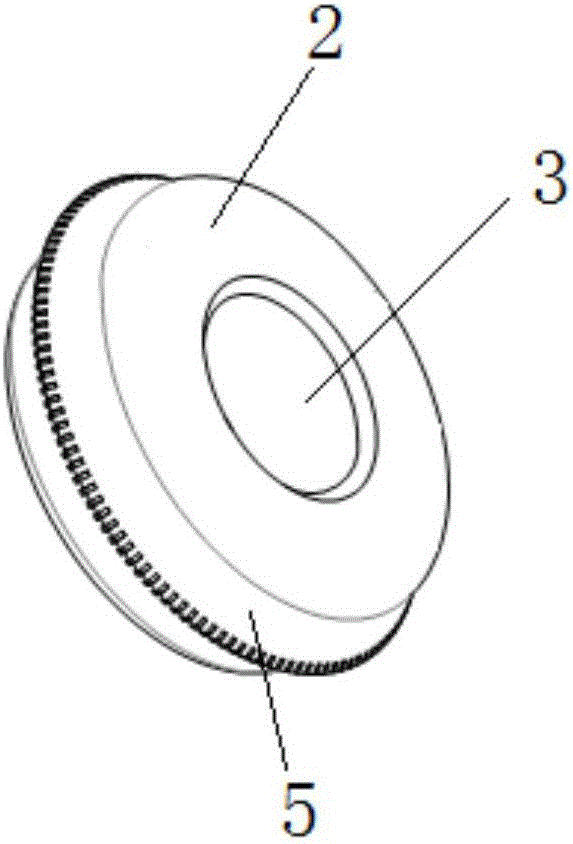

Anti-drag device capable of adjusting wheel spoke hole area automatically

ActiveCN104742640AImprove bindingEasy to installWheel protectionEngineeringFuel economy in automobiles

The invention discloses an anti-drag device capable of adjusting the wheel spoke hole area automatically, and relates to an anti-drag device capable of changing the hole area between spokes automatically according to the automobile speed. The anti-drag device solves the problem that the wind drag coefficient of a wheel and fuel consumption are enlarged when an automobile is driven at high speed due to the fact that air eddy is generated in a wheel cavity or positions nearby with the existence of a hole between the spokes. The anti-drag device is composed of a supporting frame, foliated cover plates and connecting transmission parts arranged between the supporting frame and the foliated cover plates, the supporting frame is fixed on a wheel hub and is located between a brake disc flange and the wheel hub, and the foliated cover plates are capable of rotating around the supporting frame. The anti-drag device does not work when the automobile speed is lower so that heat generated by frequent braking of the automobile can be emitted effectively and cannot influence the automobile. The anti-drag device is capable of decreasing the hole area between the wheel spokes automatically along with the increase of the automobile speed until the wheel hole is close to entirely closed, so that the wind drag coefficient of the automobile wheel is reduced greatly, fuel consumption is reduced, and the automobile fuel economy is improved.

Owner:JILIN UNIV

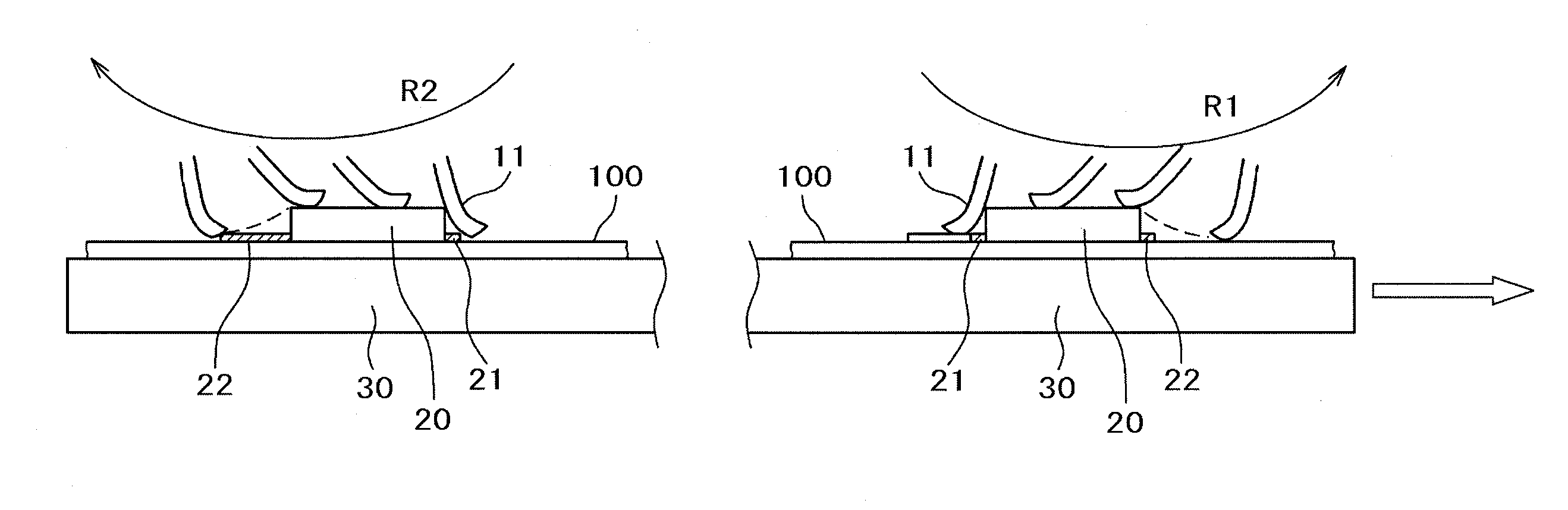

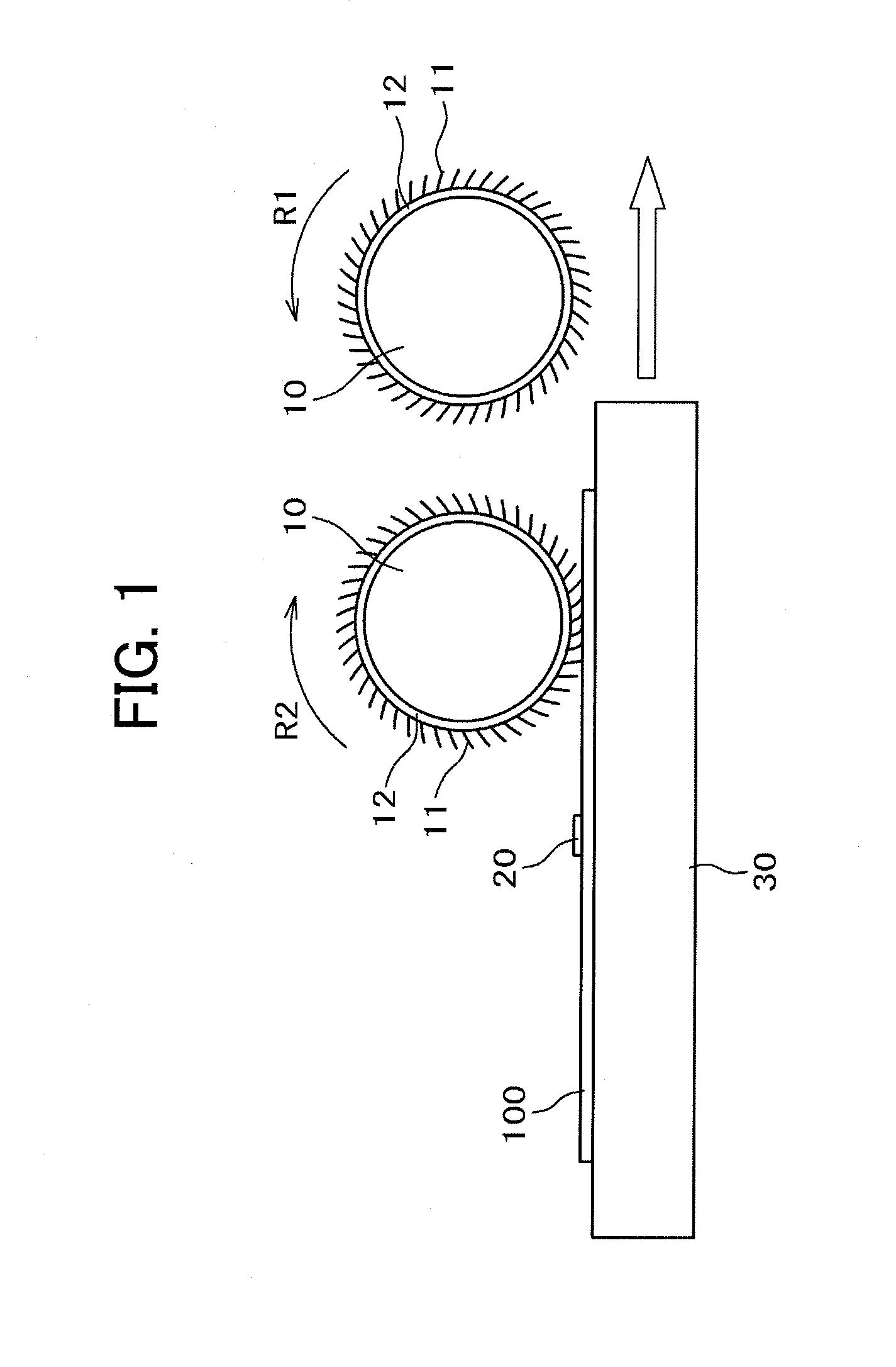

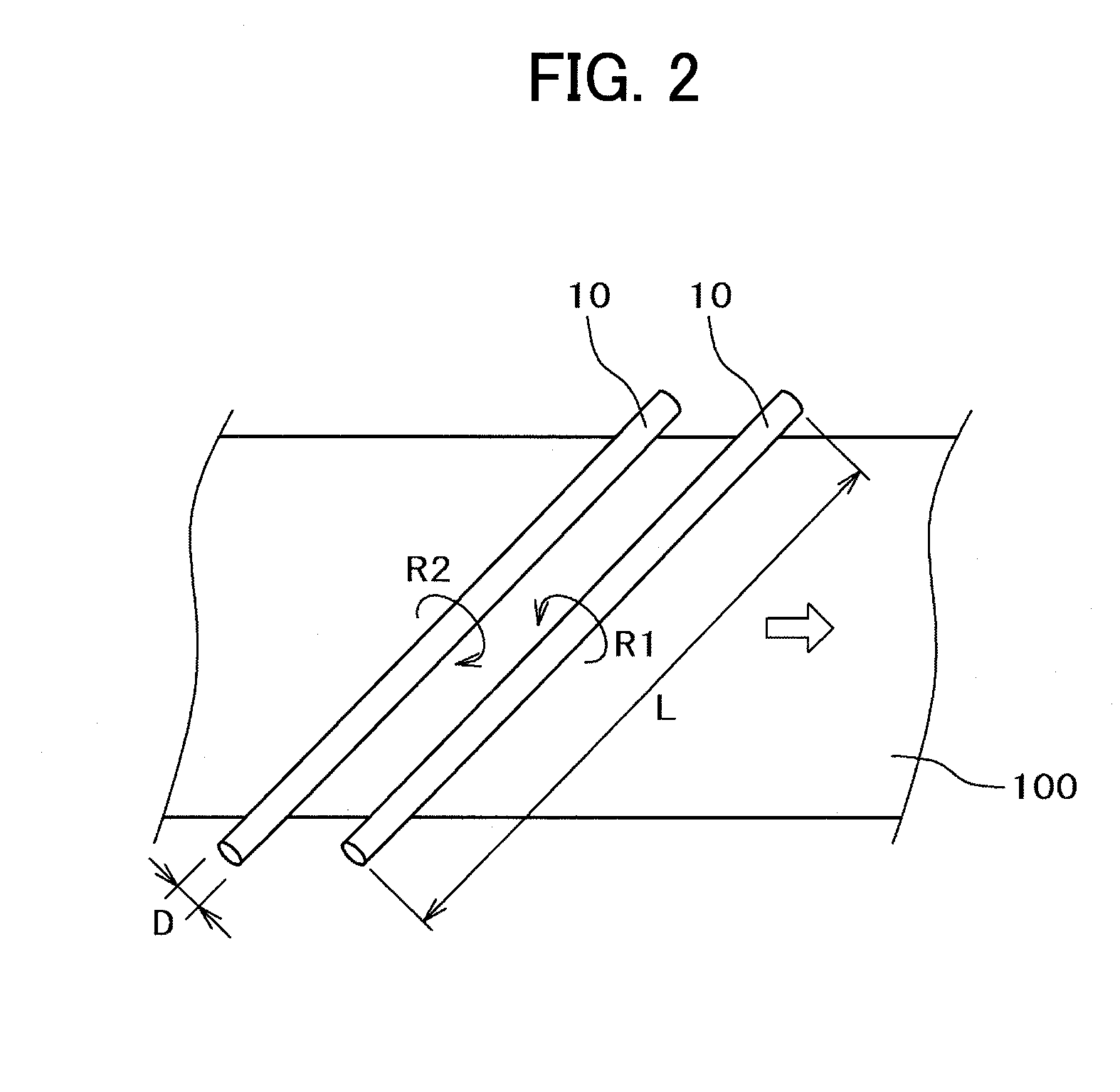

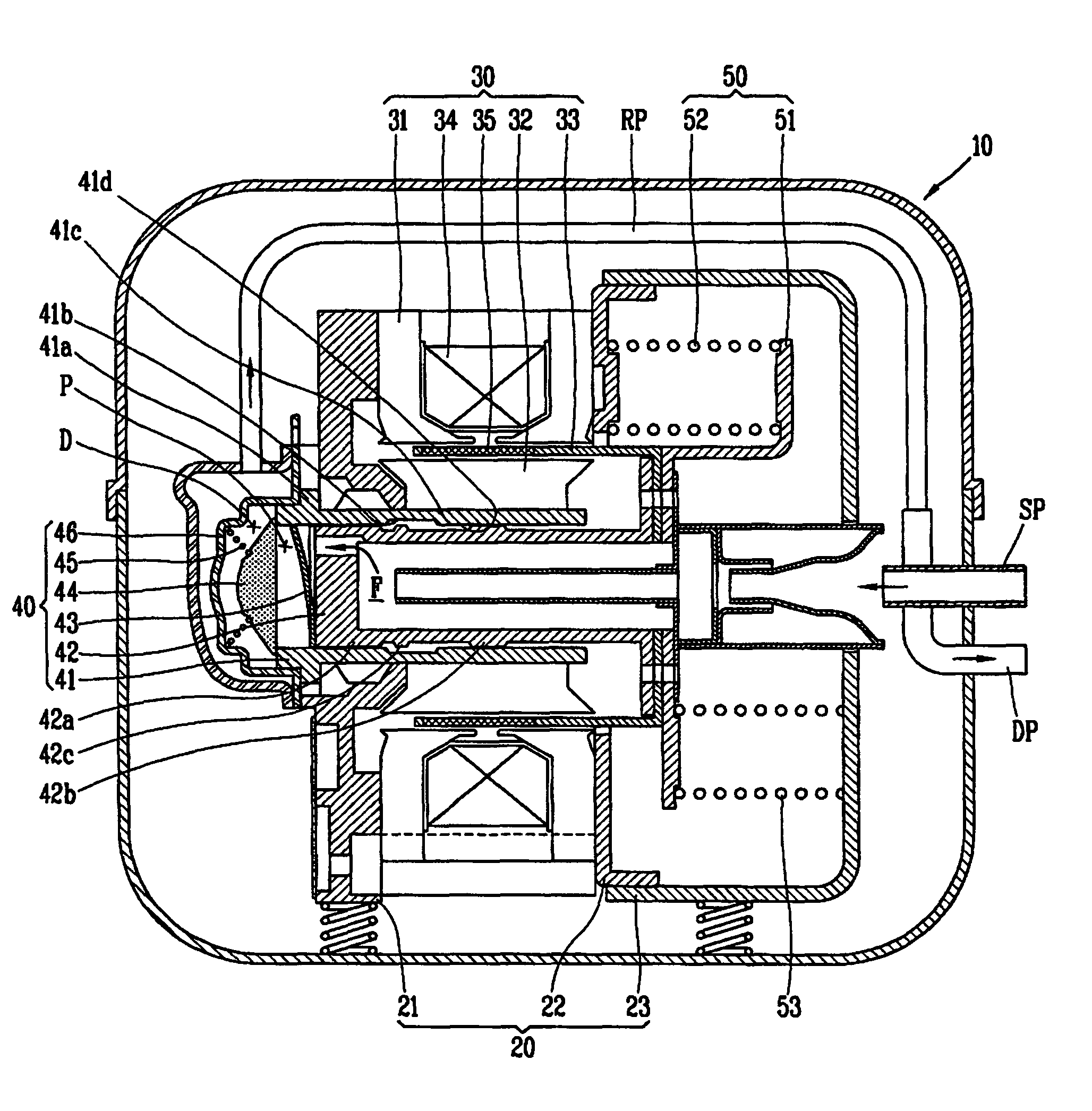

Manufacturing method of liquid crystal display device

InactiveUS20110292332A1Improve directionExclude influenceNon-linear opticsLiquid-crystal displayEngineering

The present invention prevents an unrubbed portion caused by asperities formed on a surface of an alignment layer of a TFT substrate or a counter substrate. A TFT substrate is disposed on a rubbing stage and a projecting portion is formed on a surface of the TFT substrate by TFT wiring. The projecting portion on the surface causes an unrubbed portion, that is, a rubbing shadow particularly at the downstream of rubbing. In a rubbing step, two rubbing rollers that rotate in different directions are provided and the TFT substrate is rubbed in contact with the two rubbing rollers that rotate in different directions, which eliminates the influence of the rubbing shadow. Thus light leakage is prevented in black display.

Owner:HITACHI DISPLAYS +1

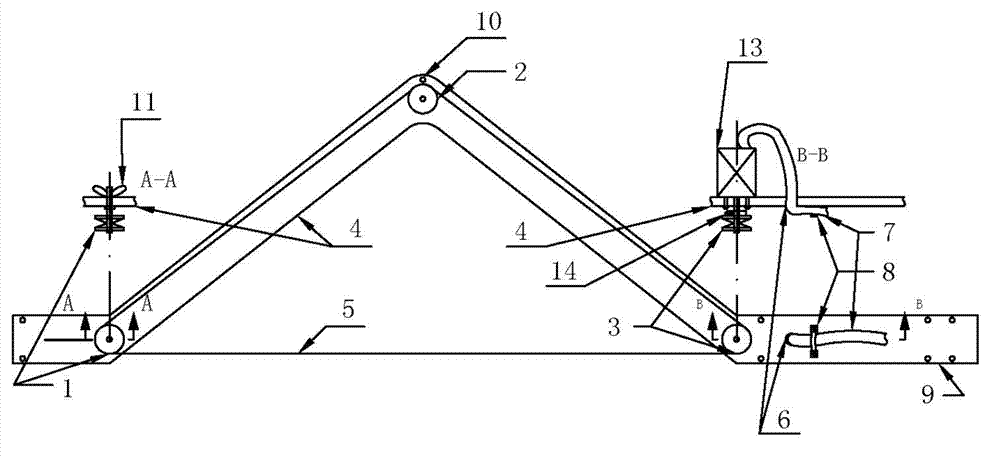

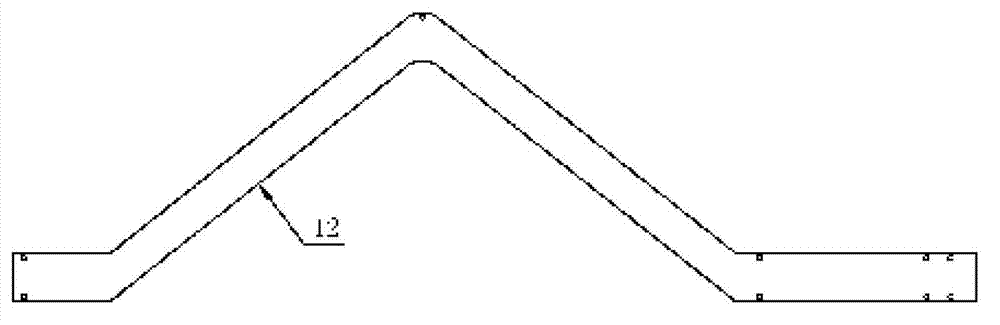

Electric wire-cutting fruit tree pruning machine

The invention discloses an electric wire-cutting fruit tree pruning machine, which comprises a bracket mechanism, a transmission mechanism and a wire saw. The bracket mechanism includes a bottom bracket, a bracket cover and an extending handle, wherein the bracket cover is in press fitting with the bottom bracket through bolts and fixing holes, and the extending handle is disposed at one side of the bottom bracket. The transmission mechanism comprises a tension wheel, a guide wheel, a power wheel and a motor, wherein the motor is fixed at the back surface of the bottom bracket, and the tension wheel, the guide wheel and the power wheel are distributed at three corners of the bottom bracket. The annular wire saw is fitted over the tension wheel, the guide wheel and the power wheel, and the bottom edge of the wire saw is a cut edge. By using a steel wire for cutting, the inventive machine has small ineffective cutting frictional area, reduces power consumption, is light in overall weight and low in noise, can easily cut off the thick branches which cannot be cut off by the conventional pruning machine, is flexible to use, and can replace the large-sized machine such as chain saw and electric saw.

Owner:SOUTH CHINA AGRI UNIV

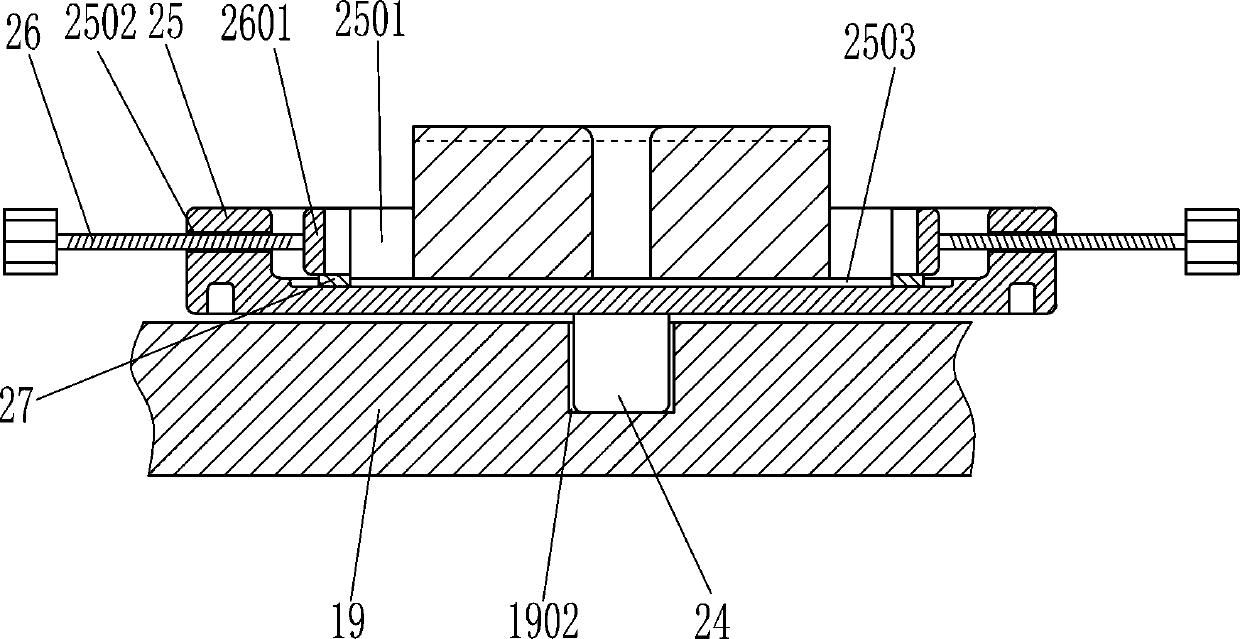

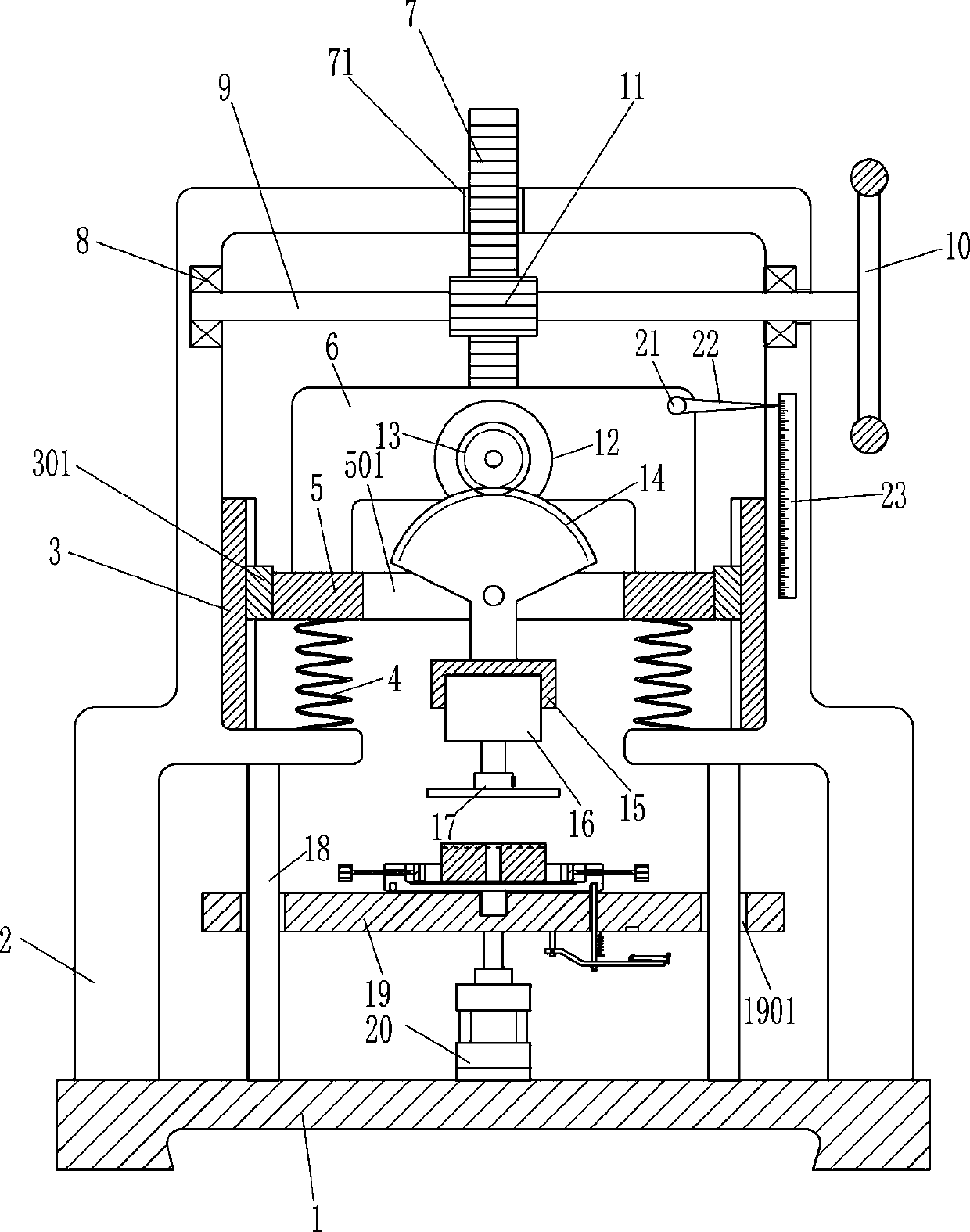

Lower die grinding machine for bracket punching die

ActiveCN109590857AAvoid fatigueReduce friction areaGrinding drivesGrinding machinesEngineeringHand held

The invention relates to a grinding machine, in particular to a lower die grinding machine for a bracket punching die. Therefore, the technical aimof the invention is to provide the lower die grindingmachine for the bracket punching die, wherein the lower die grinding machine for the bracket punching die is capable of preventing physical strain and improving grinding efficiency. According to thetechnical scheme, the lower die grinding machine for the bracket punching die comprises a base, a frame, sliding rails, first sliding blocks, first springs, a transverse bracket, a U-shaped plate, a rack, bearings, a shaft rod, a turntable, a first gear, a servo motor and the like. The frame is fixed on the top of the base which plays a supporting role, the two sliding rails are correspondingly installed on the upper parts of the left wall and the right wall in the frame, and the sliding rails are slidably connected with the first sliding blocks. According to the lower die grinding machine, asector gear drives a mounting seat to swing, so that a grinding disc can be tilted through a rotating motor, the friction area during grinding of the grinding disc and a lower die can be reduced, anda worker is not required to grind the die with a hand-held grinding stone, so that physical strain is prevented, and the grinding efficiency is improved.

Owner:台州旭龙业五金制品有限公司

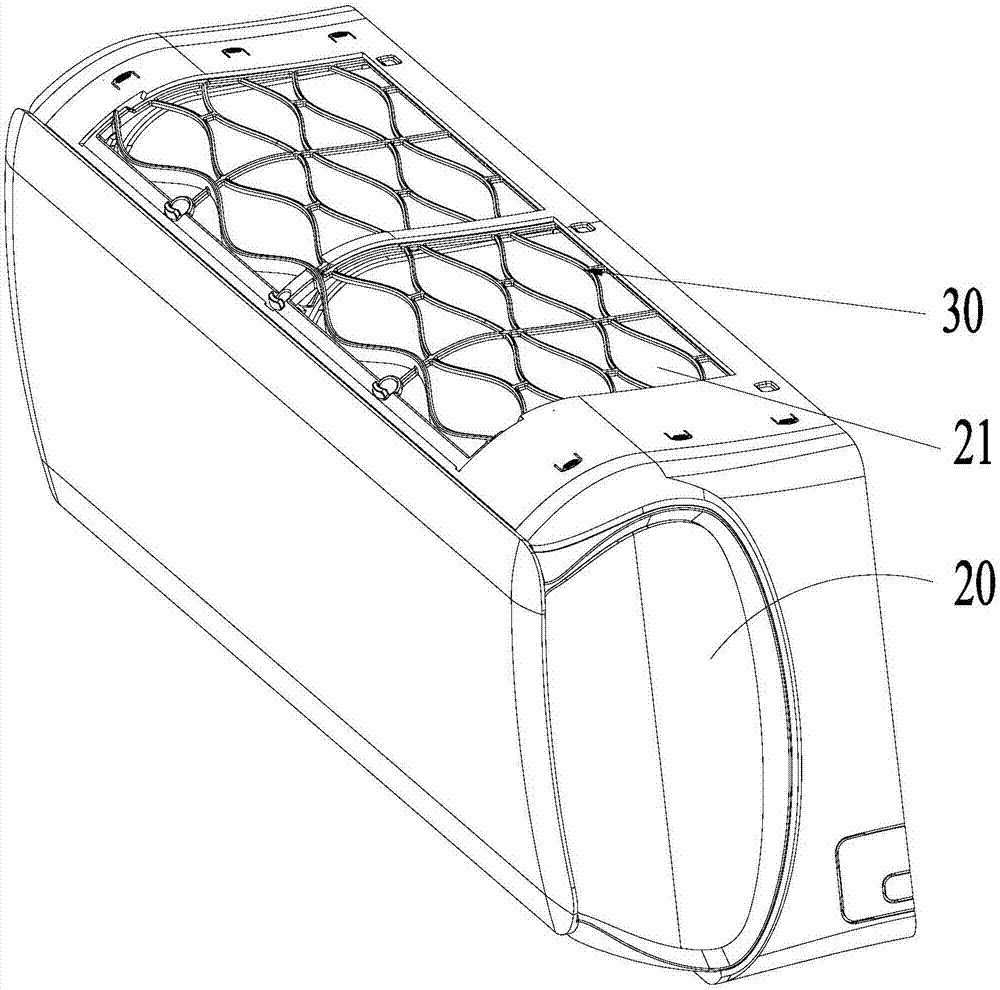

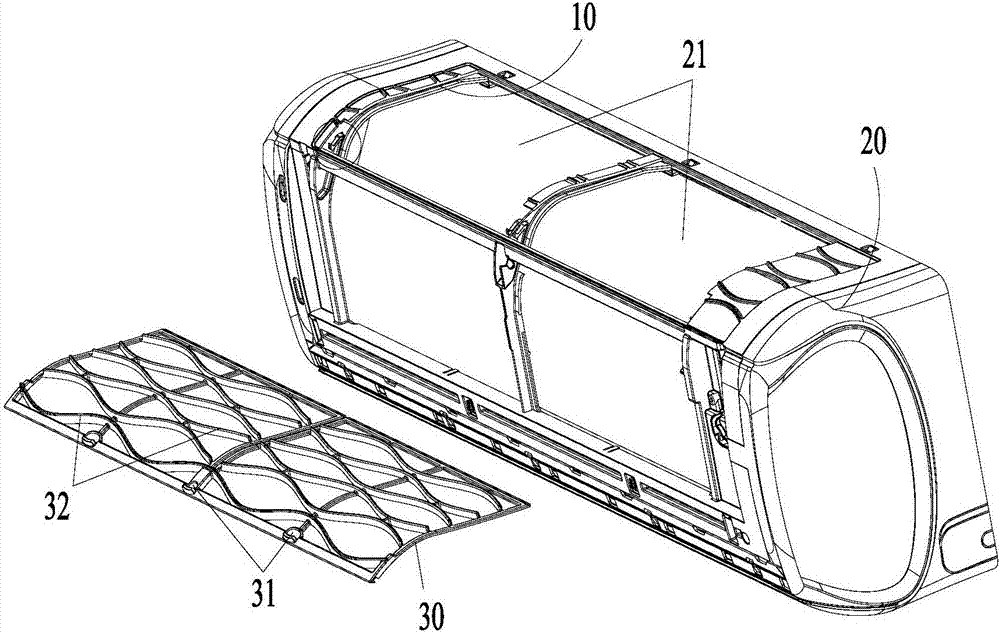

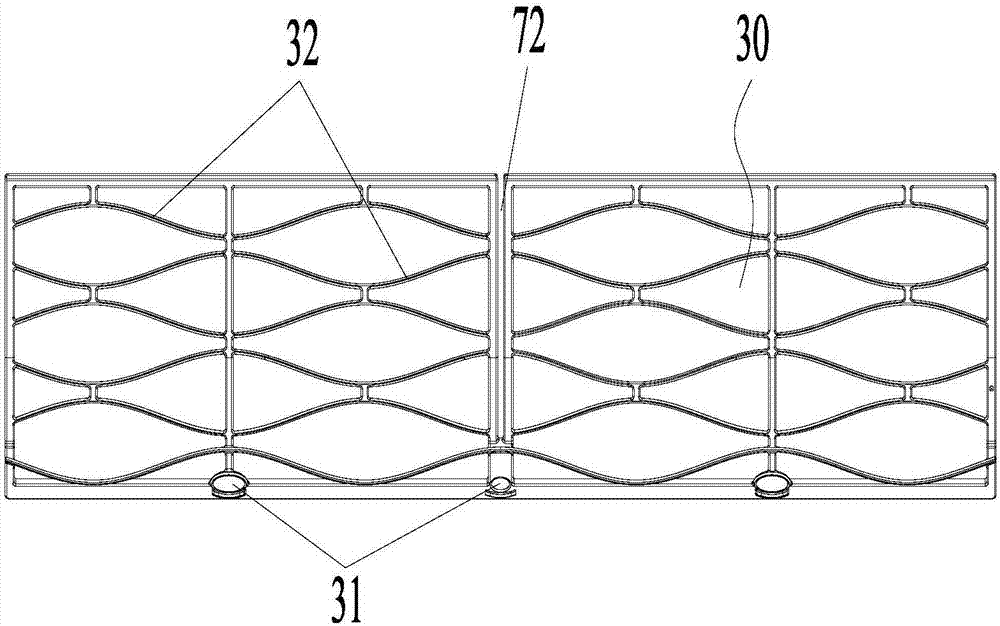

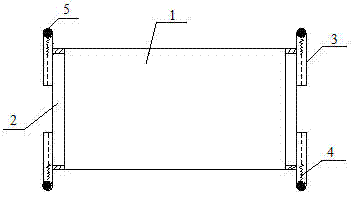

Filter net assembly and air conditioner

InactiveCN107178893AReduce frictionBetter and smoother installationLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

The invention provides a filter net assembly and an air conditioner. The filter net assembly comprises an installation frame and a filter net. The installation frame is used for being connected with an air conditioner body. The filter net is detachably arranged on the installation frame. The installation frame and the filter net are connected through a clamped connection type sliding groove assembly which comprises a sliding groove part and a clamped connection sliding part. The sliding groove part is arranged on the installation frame and comprises a groove portion and an anti-disengagement portion. The anti-disengagement portion is arranged on an opening of the groove portion and provided with a passing groove. The clamped connection sliding part comprises a connection portion and a clamped connection portion which are connected. One end of the connection portion is connected with the filter net, the other end of the connection portion is connected with the clamped connection portion, the connection portion is detachably installed in the passing groove, the clamped connection portion is movably installed in the groove portion, and the anti-disengagement portion prevents the clamped connection portion from being disengaged from the groove portion. By applying the technical scheme, the problem that a filter net of an air conditioner in the prior art is difficult to detach and install is solved.

Owner:GREE ELECTRIC APPLIANCES INC

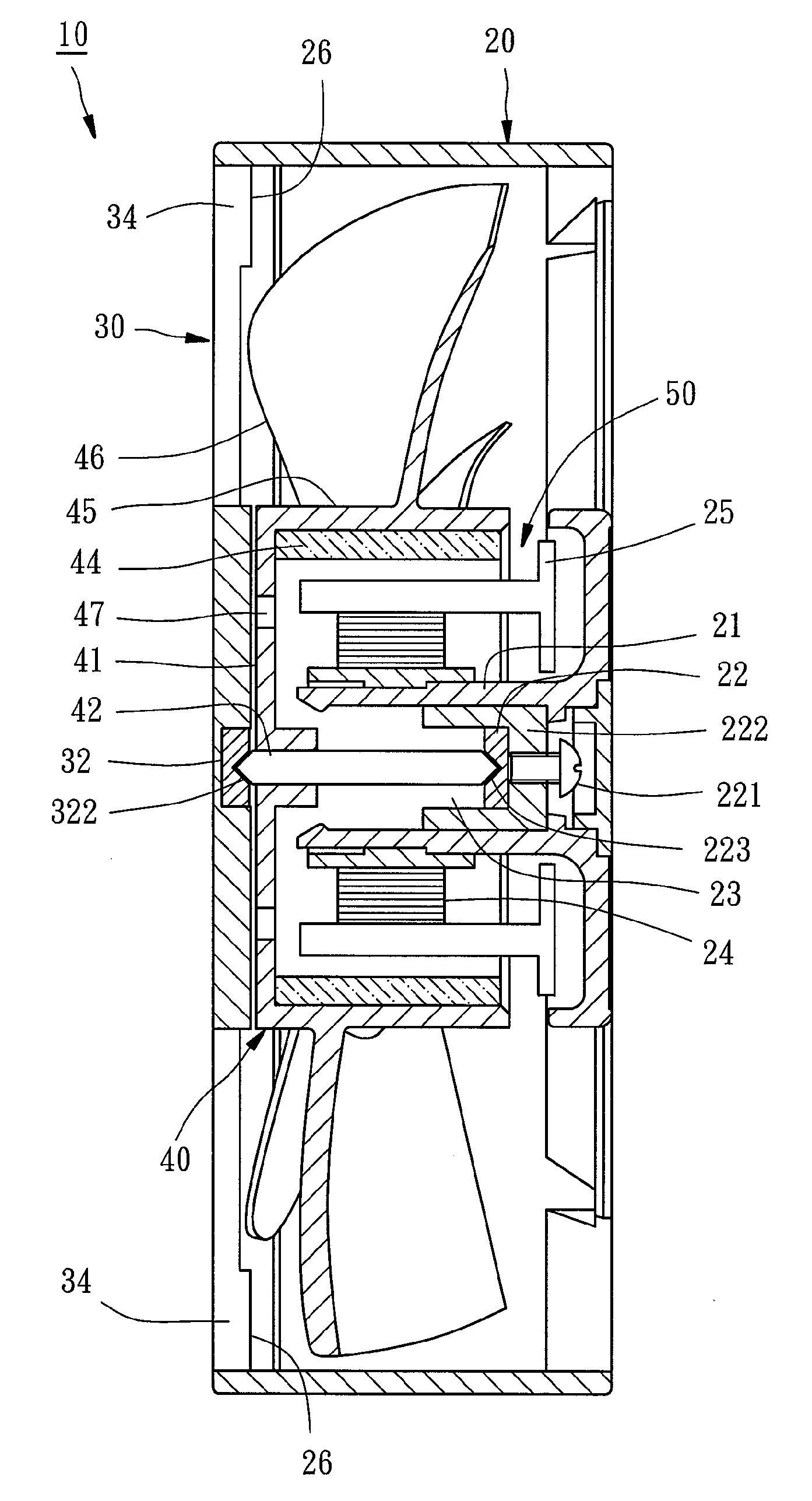

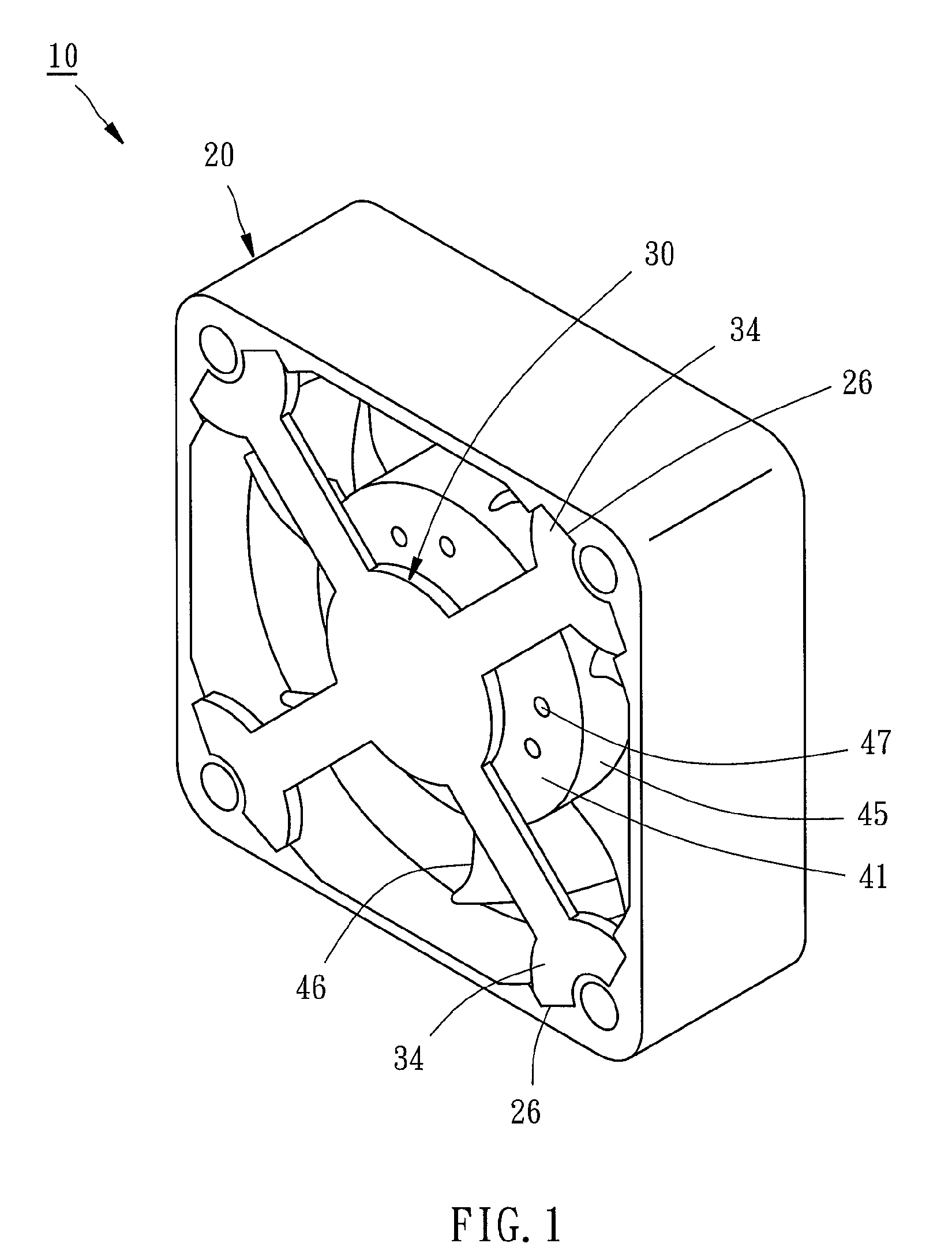

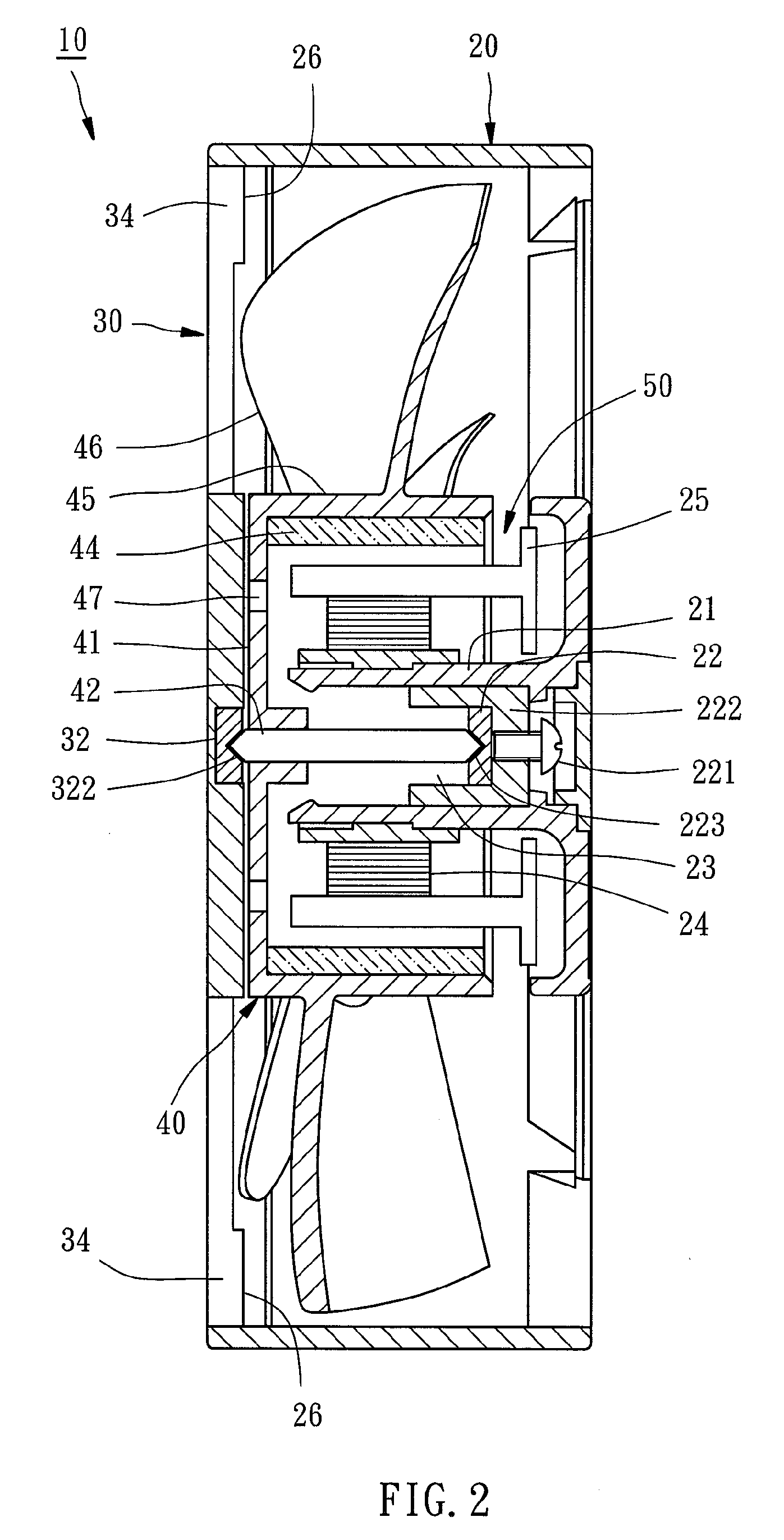

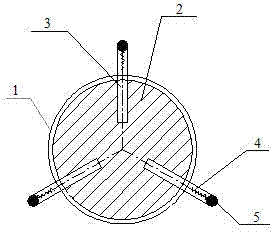

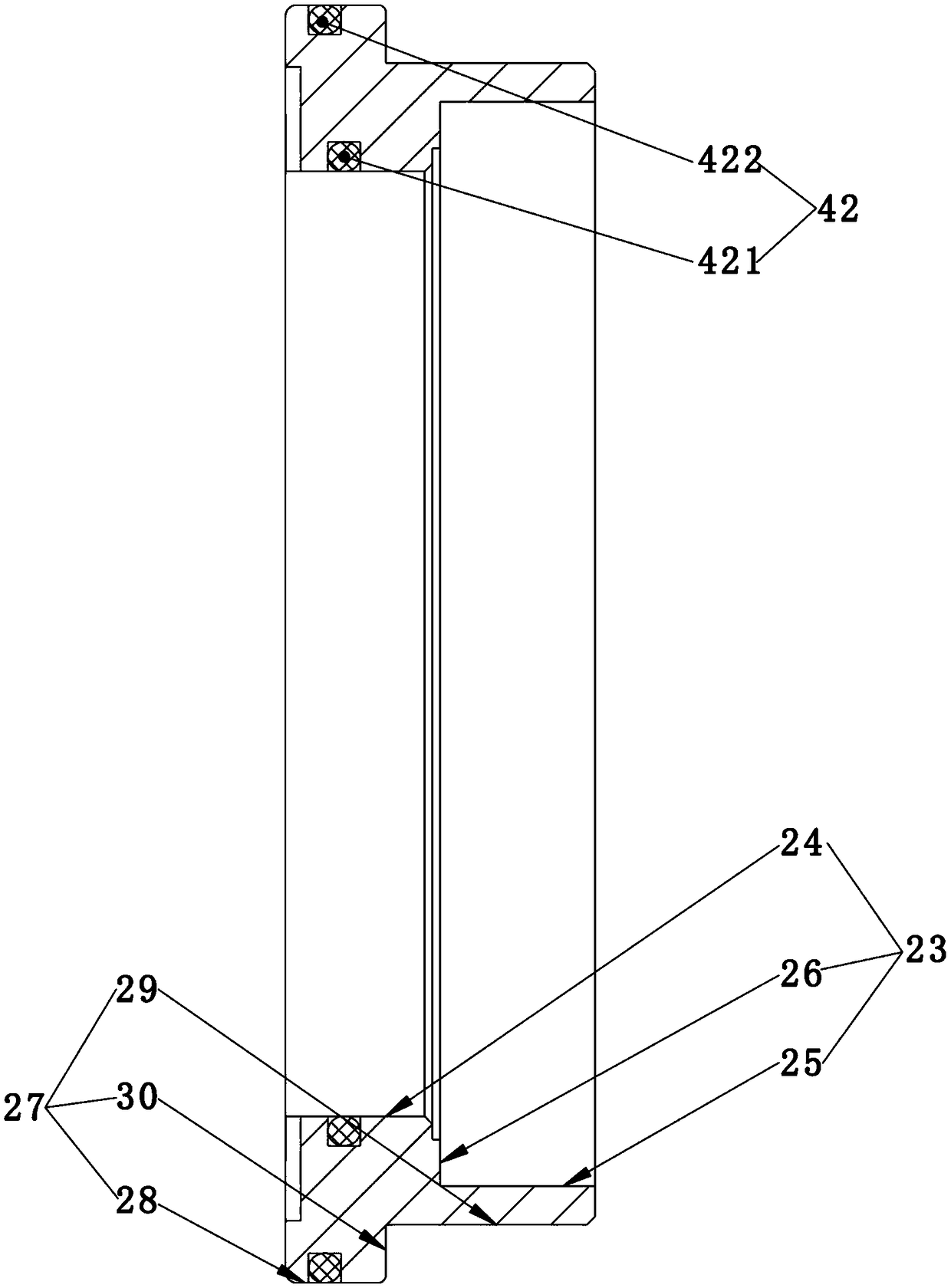

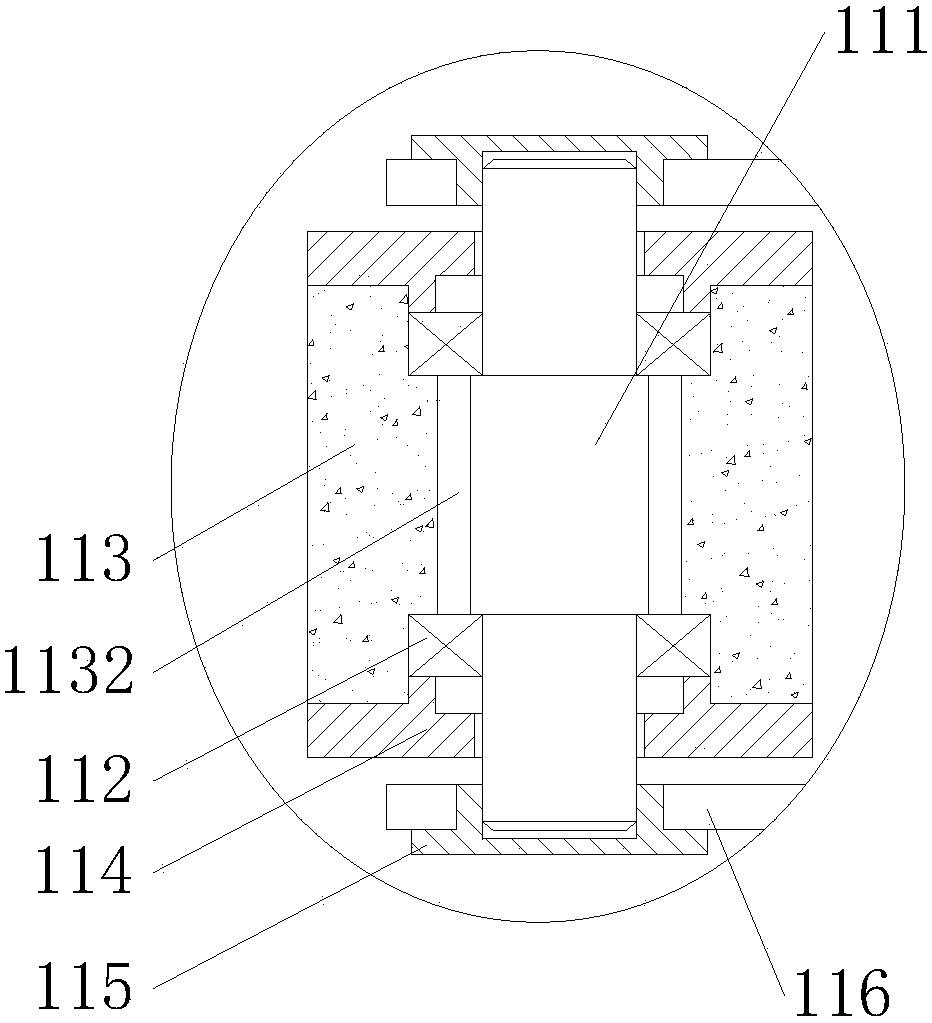

Magnetic floating shaft set and apparatus using same

InactiveUS20080036321A1Improve efficiencyExtend working lifePump componentsShaftsEngineeringConductor Coil

A magnetic floating shaft set is disclosed to include two guides kept apart from each other at a distance in such a manner that one guide is movable relative to the other guide to adjust the distance between the two guides, a shaft set in between the two guides with the two distal ends thereof respectively facing the two guides, a magnetic member mounted on the shaft, and a winding coaxially mounted around the shaft for generating a magnetic field to induce the magnetic member and to further cause floating of the shaft between the two guides and rotation of the magnetic member on the shaft.

Owner:YU CHIEN CHUN

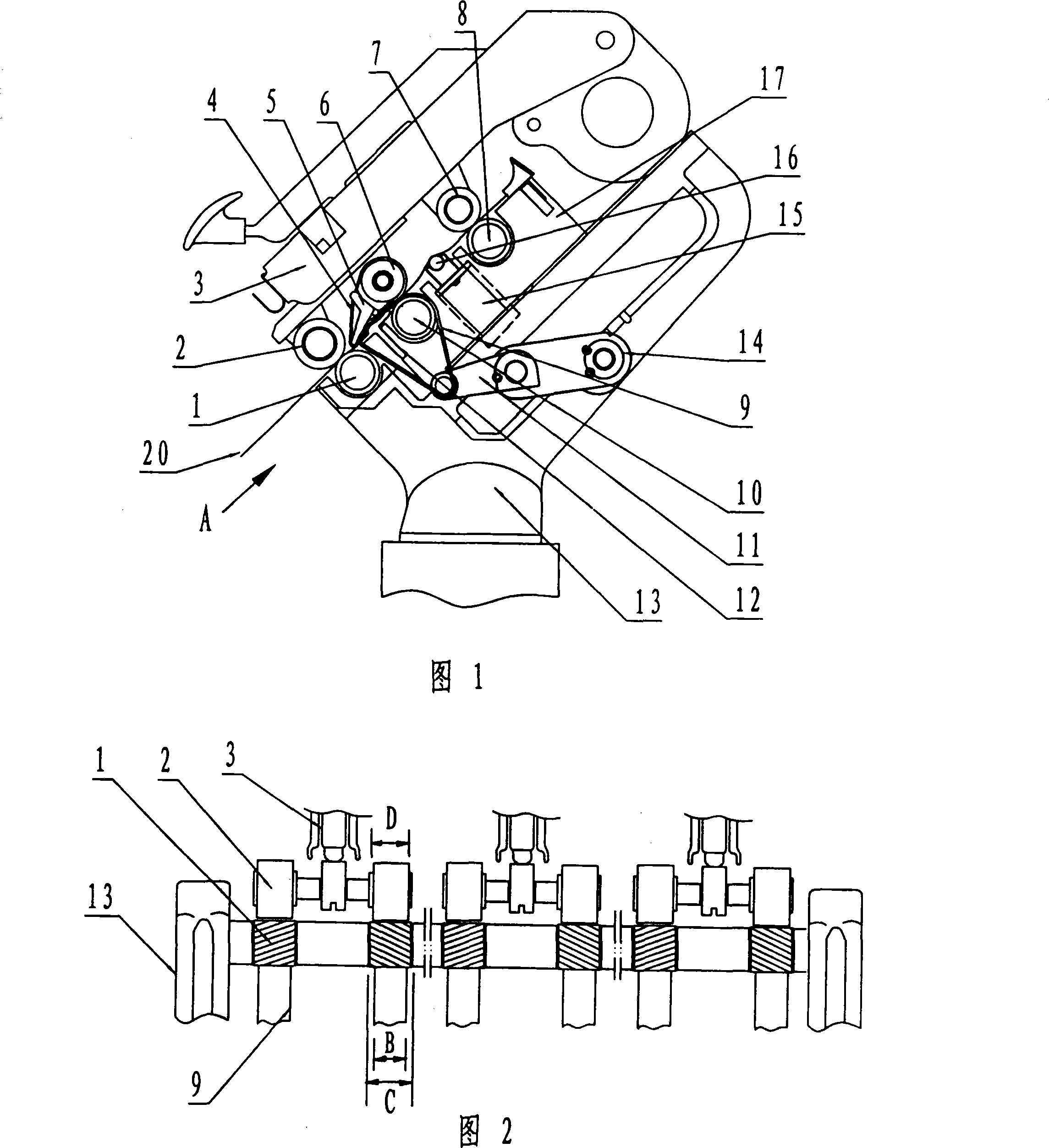

Drafting assembly of spinning machine

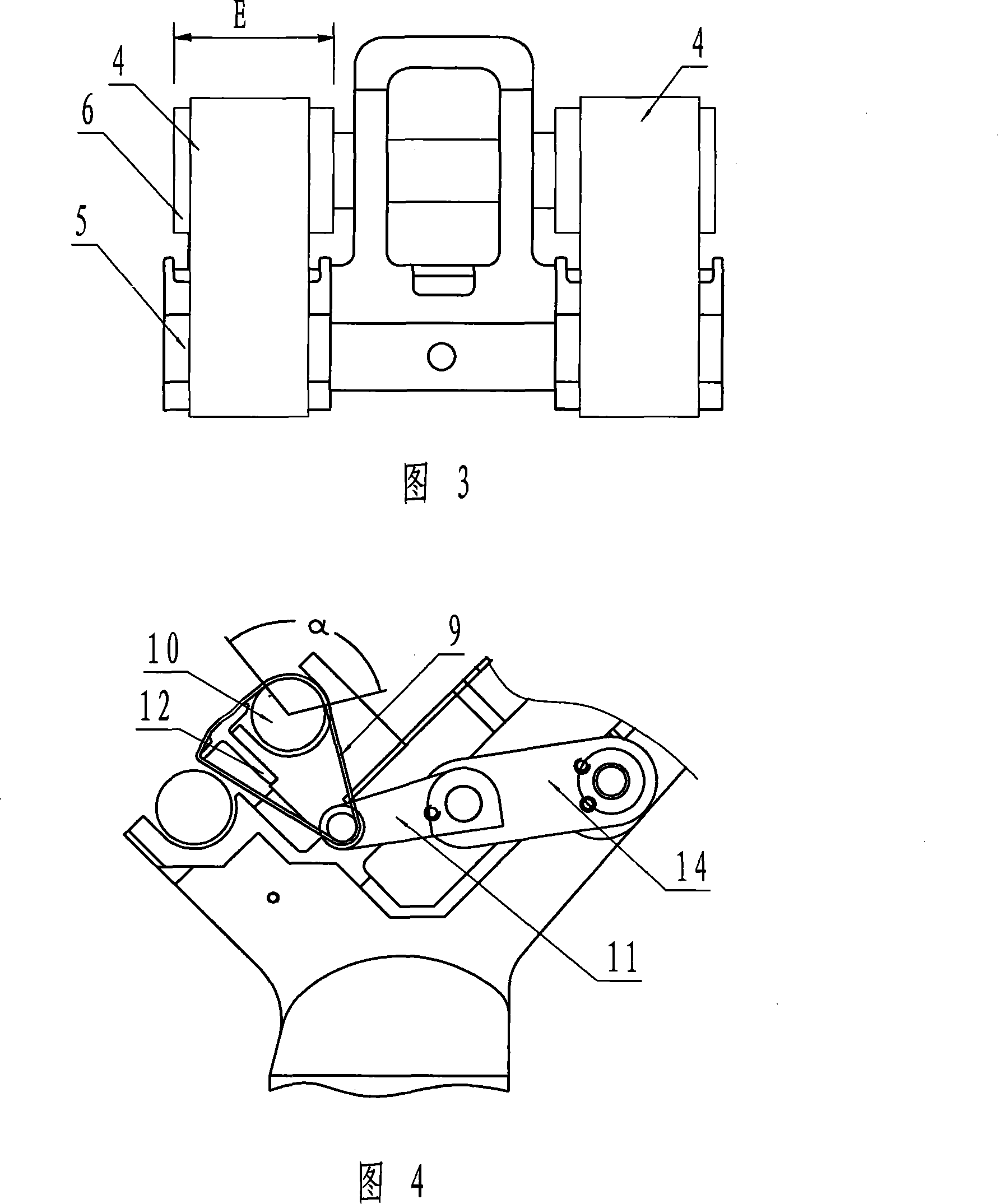

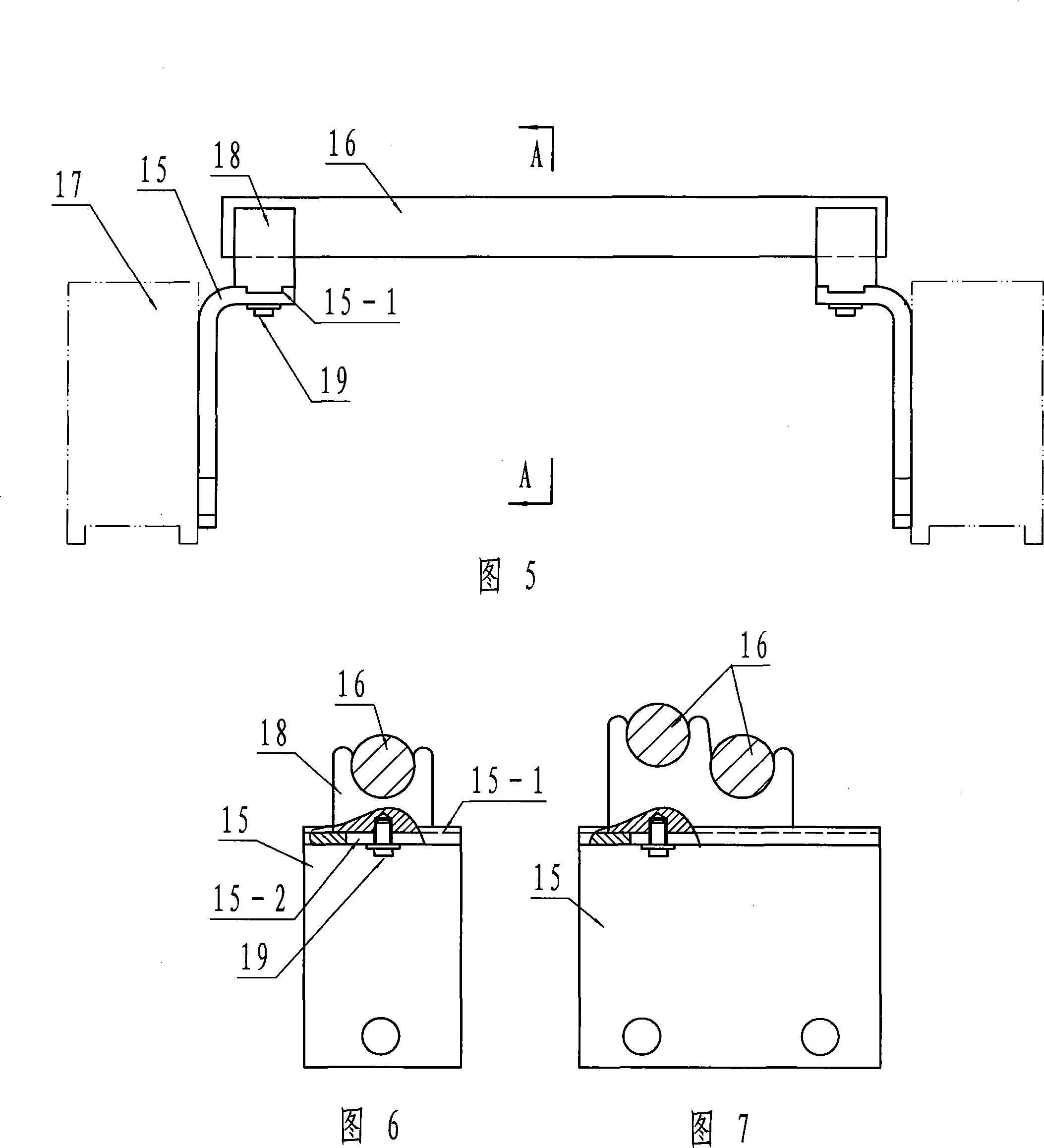

The invention relates to a drafting device of a spinning machine, belonging to the spinning technical field, comprising a cradle, a plurality of rollers, a front lower roller, a front upper rubber roller, a back upper rubber roller, a back lower roller and a main drafting component, wherein, the front lower roller and the front upper rubber roller are arranged at the front section of a drafting area, the back upper rubber roller and the back lower roller are arranged at the back area of the drafting area, and the main drafting component is arranged at the central section of the drafting area, the main drafting component comprises a middle upper roller, an upper pin, an upper leather collar, a middle lower roller, a lower pin and a lower leather collar. After improvement, the working position dimension D of the front upper rubber roller and the back upper rubber roller are 15 to 28 millimeters, the working position dimension C of the front lower roller and the middle lower roller and the back lower roller are 15 to 32 millimeters, the width dimension B of the upper leather collar and the lower leather collar are 14 to 27.5 millimeters, the width dimension E of the middle upper roller is 15 to 30 millimeters. The drafting device of the spinning machine has the advantages of reducing the friction area and the driving power, improving the operation stability of the drafting component, saving lots of consumable materials, effectively reducing the production cost and improving the quality of resultant yarn.

Owner:HEBEI TAIHANG TEXTILE MACHINERY CO LTD

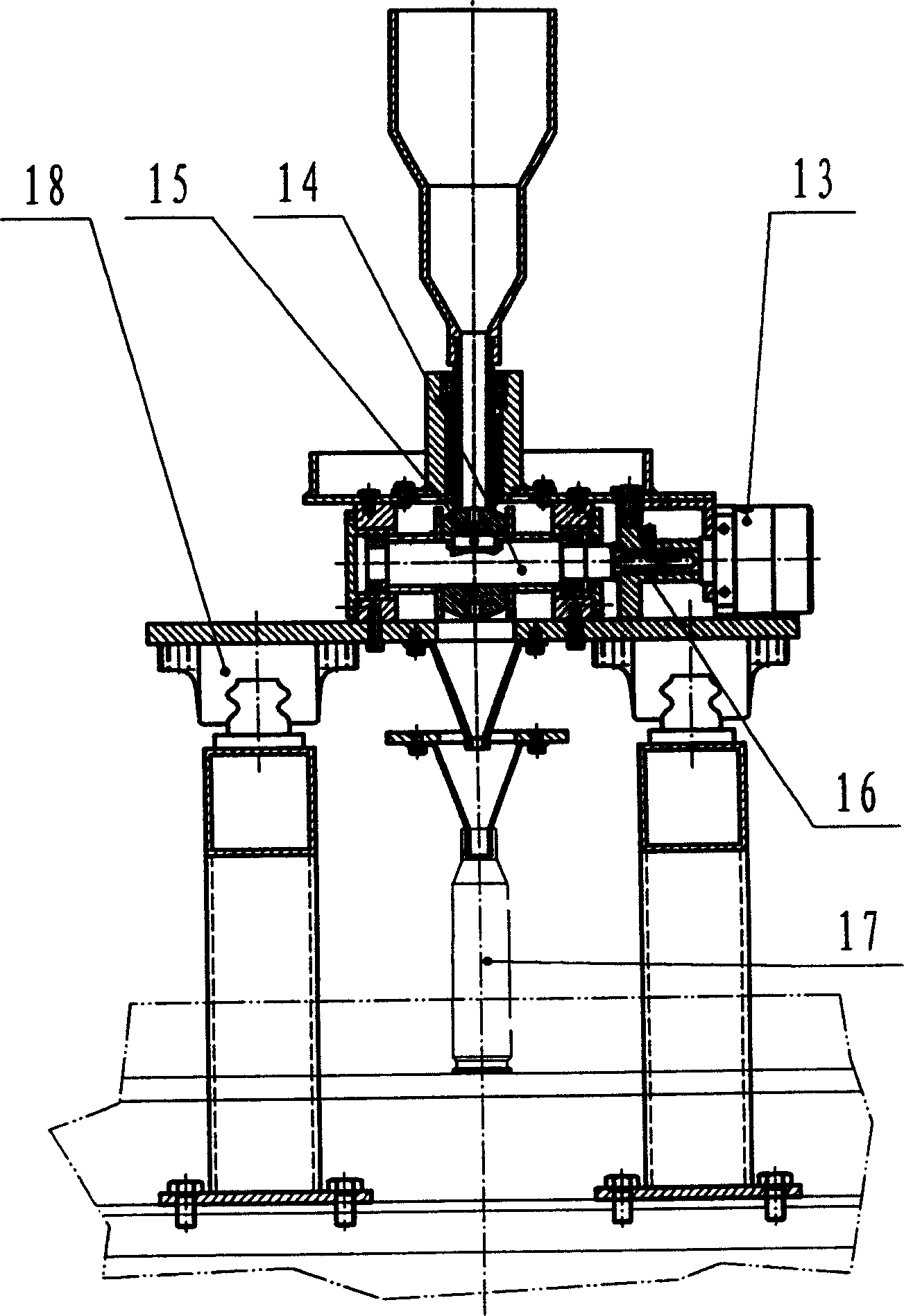

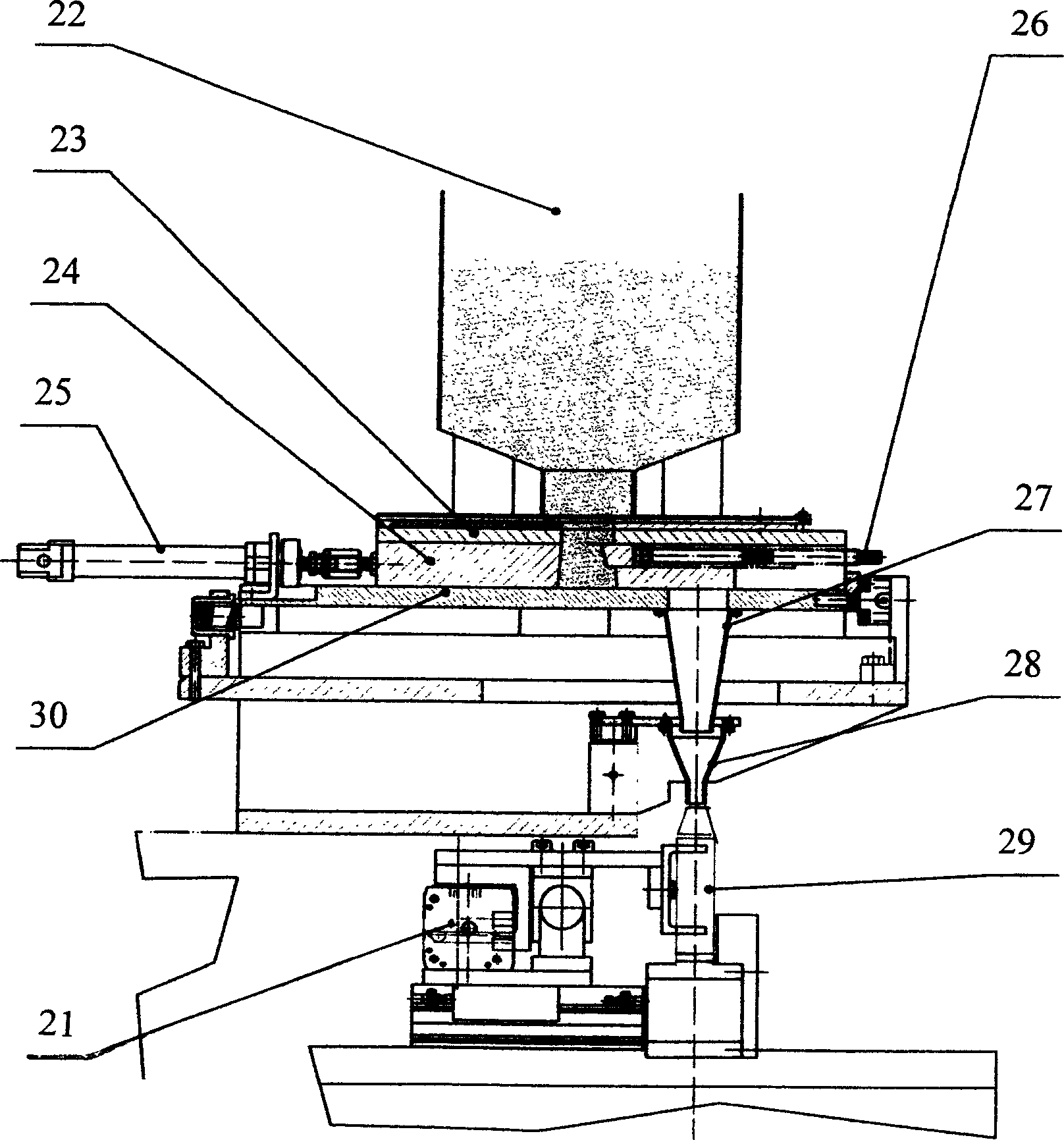

Explosion-proof spherical rotation measuring filling device

An explosive loading device with ball rotary metering in explosive proof type is prepared as setting seal sleeve and bunker cover under bunker, setting fixed base and swing air cylinder on base plate, erecting ball on rotary shaft of air cylinder and opening a pair of metering holes at the same periphery on ball being closely contacted with seal sleeve, fixing diaphragm vibration air cylinder and recoil vibration absorber at two ends of base plate, setting fixed hopper on base plate and movable hopper and its lifting control air cylinder under fixed hopper and checking linear guide rail on base plate on track.

Owner:SICHUAN KERUITE SPECIAL EQUIP DEV

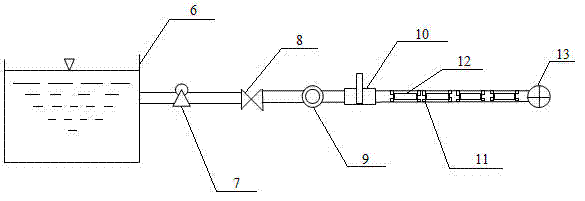

Pipeline hydraulic conveying machine tool and application thereof

Provided are a pipeline hydraulic conveying machine tool and application of the pipeline hydraulic conveying machine tool. A spring is installed in a support body; the spring is elastically connected with a universal wheel; one end of the support body is connected with an inner wall of a hydraulic conveying pipeline in rolled and supported modes; the support body is fixedly connected onto one end face of a sealing cover; the other end face of the sealing cover is sealed on one end face of a material filling container; and the other end face of the material filling container is also sealed by the sealing cover fixedly provided with the support body, and the material filling container is installed in the hydraulic conveying pipeline to form the pipeline hydraulic conveying machine tool. The application of the pipeline hydraulic conveying machine tool is that a water source is communicated with a conveying pipeline, and a water drawing device, an electrically operated valve, a putting device, a brake device and a receiving device are sequentially arranged on the conveying pipeline. The pipeline hydraulic conveying machine tool is energy-saving and environment-friendly; and with the adoption of the pipeline hydraulic conveying machine tool, delivery scope of materials is expanded, delivery resistance of the materials is reduced, safety and stability of material conveying systems are guaranteed and the service life is prolonged.

Owner:TAIYUAN UNIV OF TECH

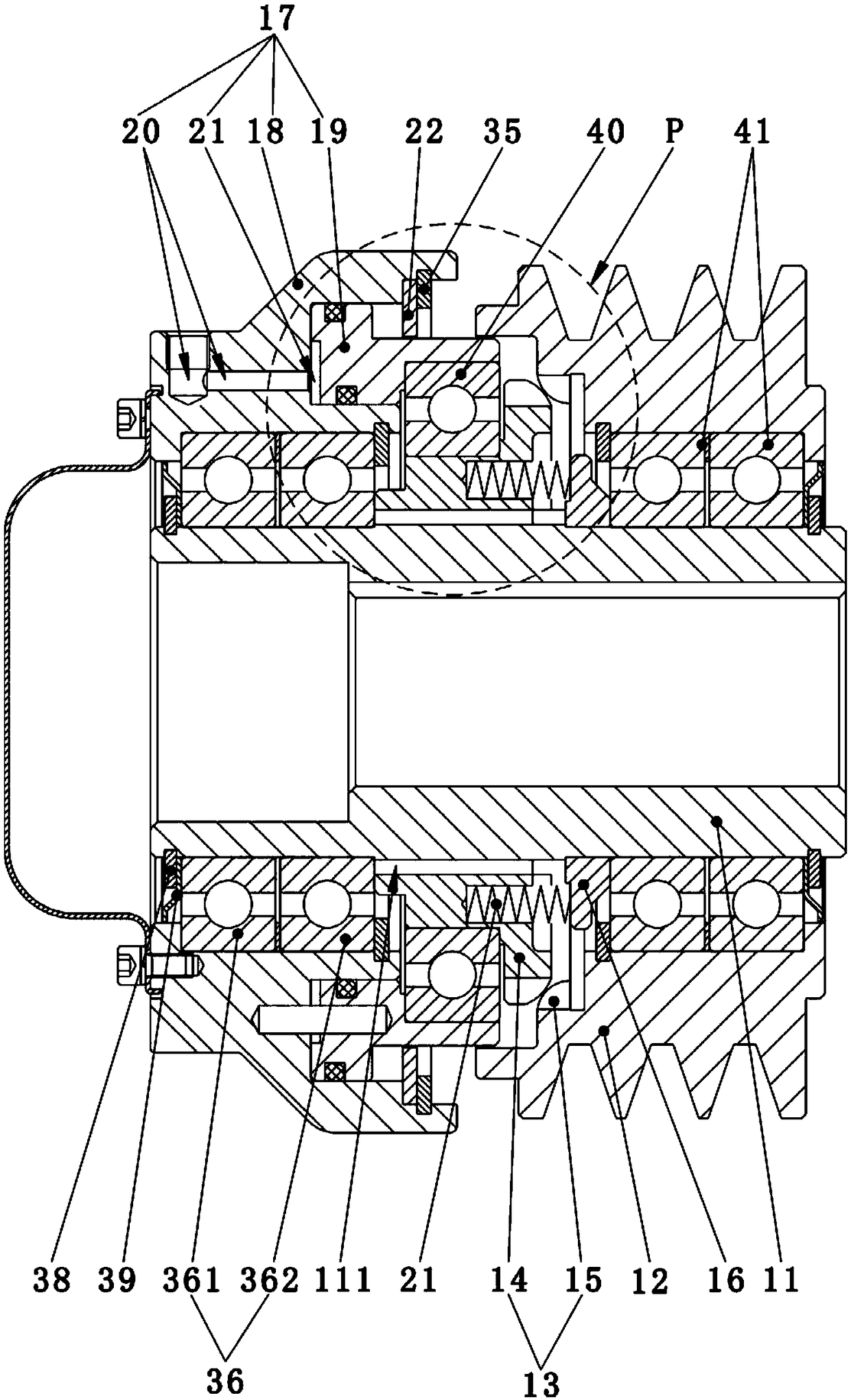

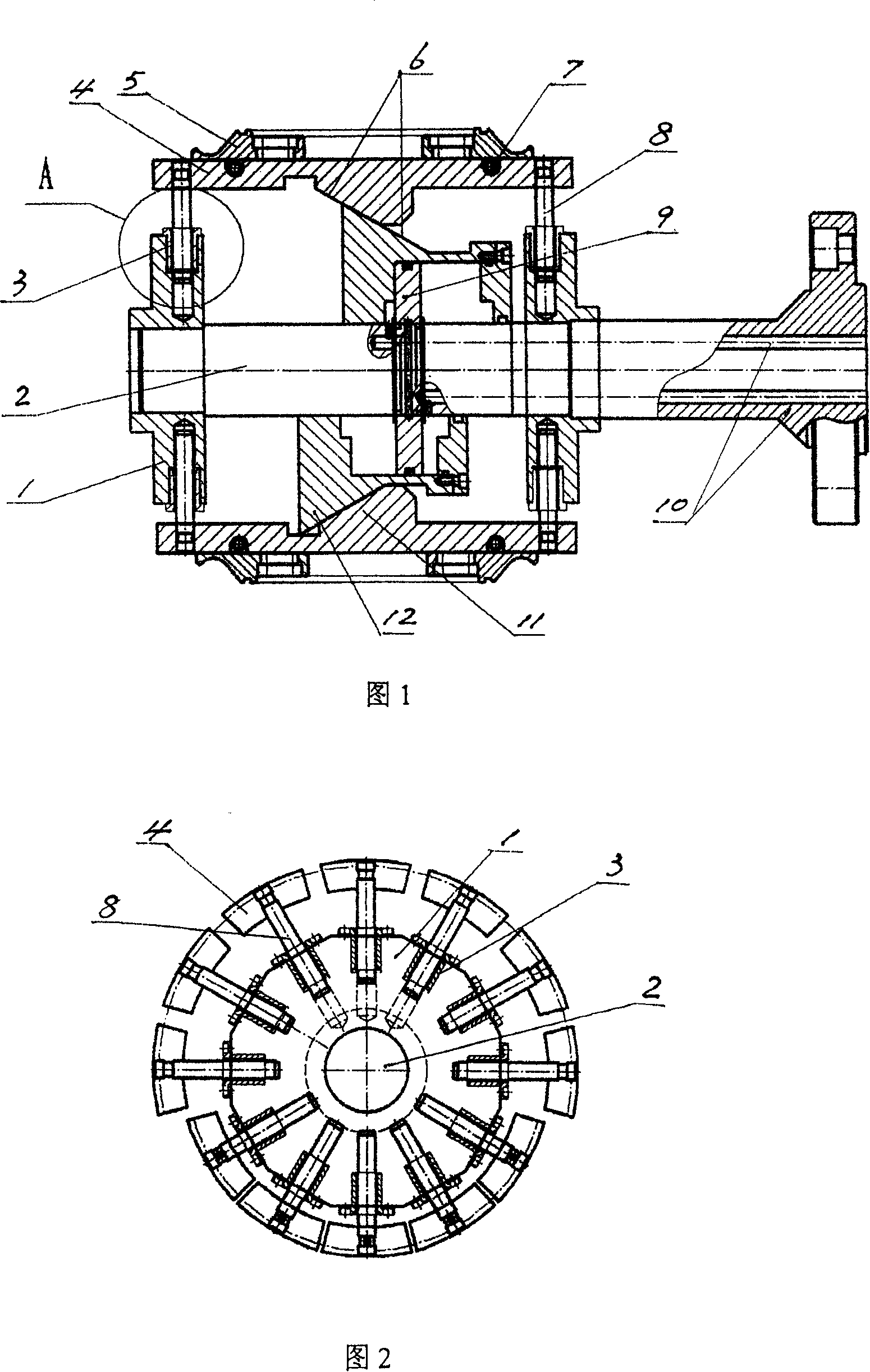

Clutch

The invention relates to a clutch. The clutch comprises a first rotor, a second rotor, a clutch mechanism, an air cylinder mechanism and an elastic assembly; the second rotor fixedly sleeves the firstrotor through a first bearing assembly; the clutch mechanism is provided with a first gear piece which is arranged on the first rotor and can rotate along with the first rotor and a second gear piecewhich is arranged on the second rotor and can rotate along with the second rotor. The air cylinder mechanism comprises a shell and a piston piece cooperating with the shell to form with an air cavity. The elastic assembly is provided with an elastic piece, and the elastic piece can push the first gear piece to get away from the second gear piece during resetting. The first gear piece is meshed with the second gear piece when a piston axially moves for a first predetermined distance. The clutch further comprises a stroke limiting piece for limiting the piston piece to axially move for a distance exceeding a second predetermined distance. The stroke of the piston piece is limited by the stroke limiting piece, the acting force borne by the elastic piece can be limited and stabilized, the counter-acting force borne by bearings connected with the elastic piece and other parts is limited and stabilized, and the service life of the other parts and the bearings is prolonged.

Owner:XIAMEN SOUTH SUPER MACHINERY CO LTD

Reciprocating compressor

ActiveUS8109199B2Easy to assembleGuaranteed uptimePositive displacement pump componentsPlungersFriction lossEngineering

A reciprocating compressor comprises: a cylinder having an oil pocket on an inner circumferential surface of a piston insertion hole for inserting a piston with a predetermined width and depth; and a piston having a bearing portion protruding so as to slidably contact an inner circumferential surface of the piston insertion hole, and inserted into the piston insertion hole of the cylinder, wherein the bearing portion is formed to have a length shorter than that of the oil pocket of the cylinder. Accordingly, a frictional loss between the cylinder and the piston is reduced.

Owner:LG ELECTRONICS INC

All-cutting-edge knife flywheel

ActiveCN105669016AImprove impact resistanceReduce resistanceGlass severing apparatusStone-like material working toolsSharp angleEngineering

The embodiment of the invention discloses an all-cutting-edge knife flywheel which comprises a first knife flywheel disk surface, a second knife flywheel disk surface and a shaft hole, wherein the shaft hole is positioned at the center of the knife flywheel and extends along the transverse direction. The all-cutting-edge knife flywheel comprises a first curved surface and a second curved surface, wherein the first curved surface extends to the longitudinal center cross section of the knife flywheel along the outer edge of the first knife flywheel disk surface and forms smooth transition with the outer edge of the first knife flywheel disk surface; and the second curved surface extends to the longitudinal center cross section of the knife flywheel along the outer edge of the second knife flywheel disk surface, and forms smooth transition with the intersection line of the outer edge of the first knife flywheel disk surface. The intersection line of the first curved surface and the second curved surface at the longitudinal center cross section of the knife flywheel forms the circumferential cutting edge. The circumferential cutting edge is uniformly distributed with a groove. A groove inner cutting edge is arranged in the groove. According to the all-cutting-edge knife flywheel, the two side disk surfaces and the two curved surfaces for forming the circumferential cutting edge do not form sharp angles, thereby enhancing the impact resistance of the knife flywheel, lowering the friction area between the two side disk surfaces of the knife flywheel and the knife rest inner wall, and reducing the resistance in the knife flywheel rotation process.

Owner:BEIJING WORLDIA DIAMOND TOOLS

Rotary excavating pile foundation double-steel-casing construction method

InactiveCN112227357AIncrease sinking depthReduce friction areaBulkheads/pilesArchitectural engineeringEngineering

The invention discloses a rotary excavating pile foundation double-steel-casing construction method. The rotary excavating pile foundation double-steel-casing construction method comprises the following steps that step 1, positioning and setting-out are constructed on site according to a construction drawing, a measuring grid is established, and points are measured and set out; step 2, after the position is adjusted, a guide hole is excavated; step 3, whether the pile position is consistent with the center of an outer steel casing or not is checked, the periphery of the outer steel casing is filled with soil and tamped after correction, and the outer steel casing is sunken to the height H1 through a crawler-type vibratory hammer; step 4, a positioning hoop is installed at an orifice of theouter steel casing, and then the crawler-type vibratory hammer is adopted to enable an inner steel casing to sink from the interior of the positioning hoop and penetrate through the outer steel casing to reach a dense soil layer or a strong weathered layer; step 5, a hole is formed through drilling, the hole is cleaned, and a reinforcement cage is installed; and step 6, concrete is poured, and the inner steel casing and the outer steel casing are pulled out. Compared with the prior art, the construction efficiency of the rotary excavating pile in the high backfill area is improved, and the processing quality and economic benefits of a pile foundation are improved.

Owner:CHONGQING CONSTR NINTH ENG

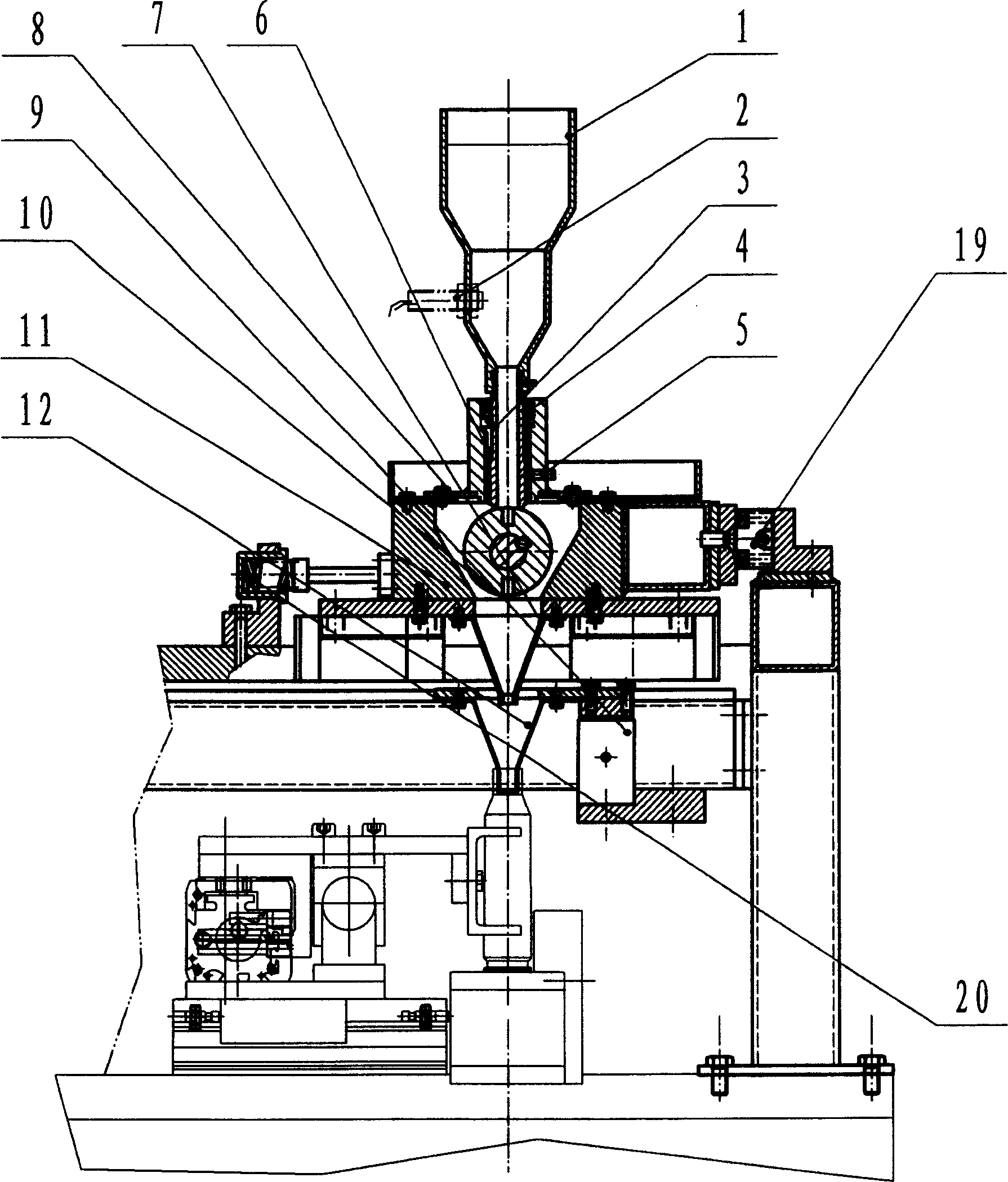

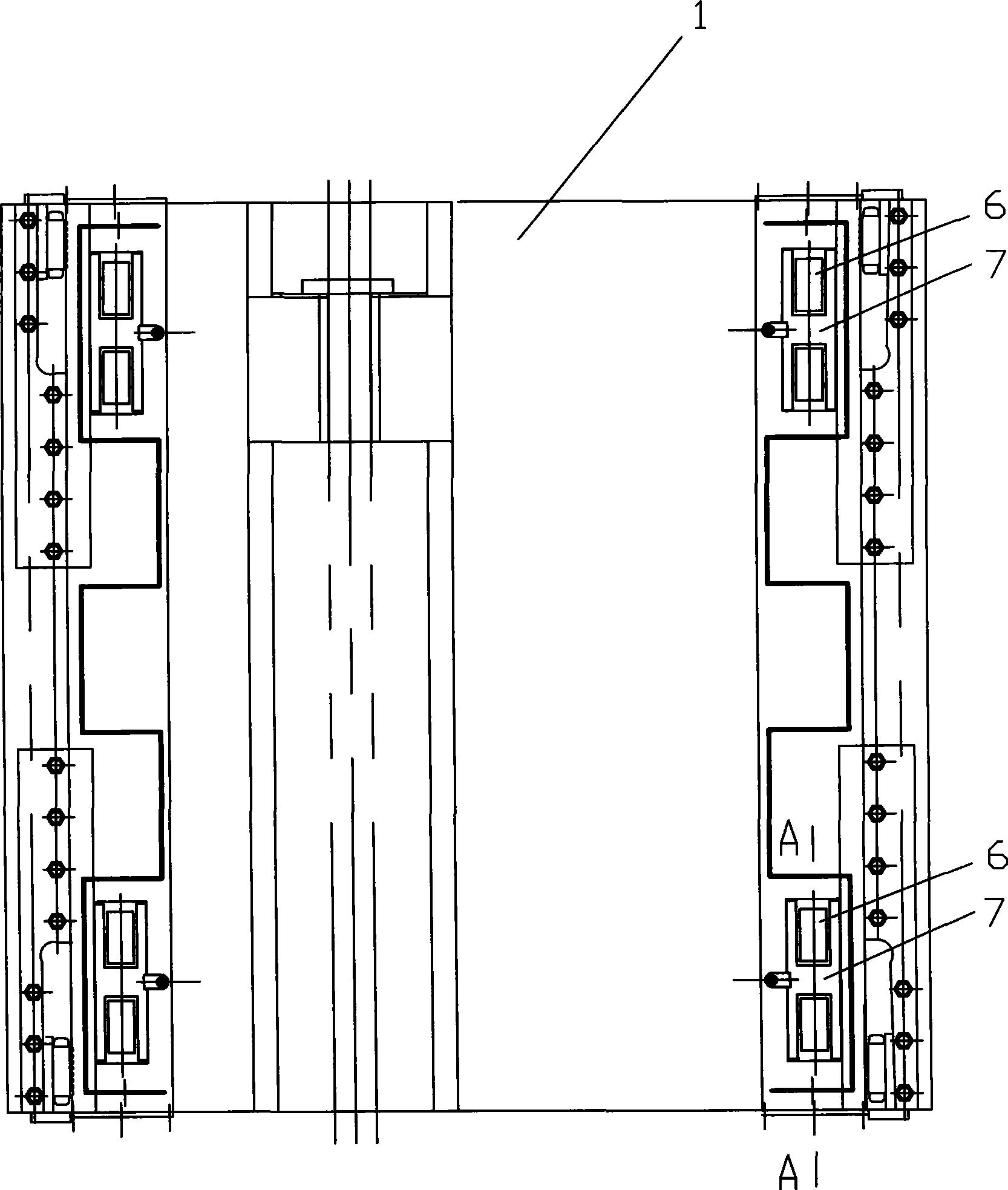

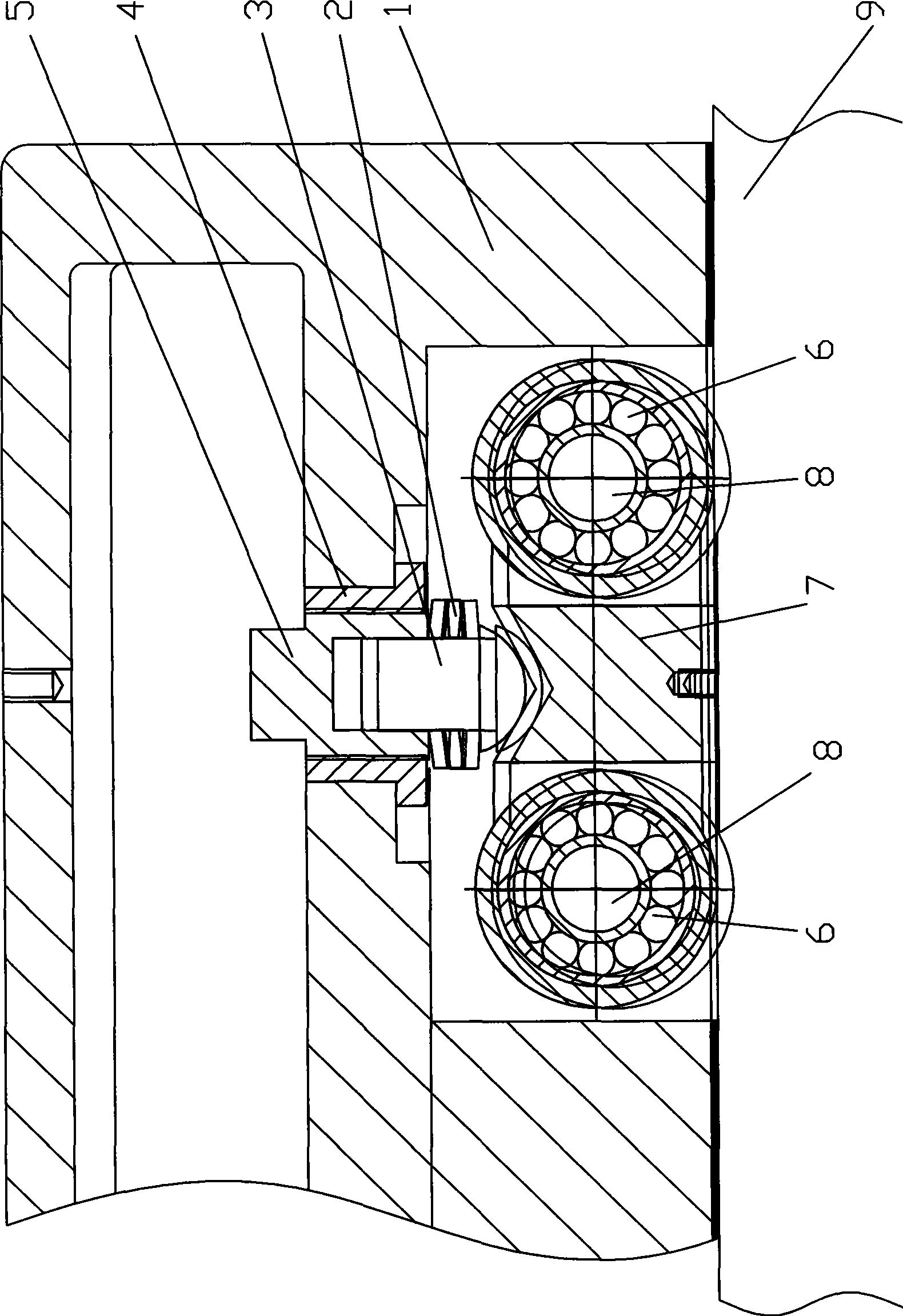

Sliding guide rolling unloading device

InactiveCN101508076AImprove contact stiffnessReduce friction areaLarge fixed membersEngineeringLubrication

The invention discloses a sliding device, in particular a slide guide rail rolling and unloading device for machine tool equipment. The device comprises a guide rail and a slide seat (1) which is positioned on the guide rail and can slide relative to the guide rail, and is characterized in that: at least three positions matched with the guide rail on the bottom surface of the slide seat (1) are provided with roller wheels (6), and the circumferential lateral surfaces of the roller wheels (6) are contacted with the upper surface of the guide rail positioned under the slide seat (1). In the device, as the slide seat and the guide rail do not directly contact, are supported by the roller wheel, and slide, the device realizes line contact of the roller wheel and the guide rail, greatly reduces the mutual friction area, reduces moving resistance, saves energy and lowers the requirement on lubrication compared with a sliding mode of surface contact.

Owner:DALIAN MACHINE TOOL GROUP CO LTD

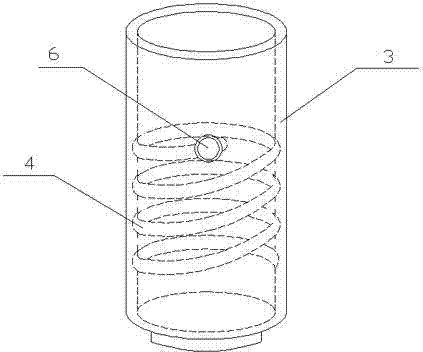

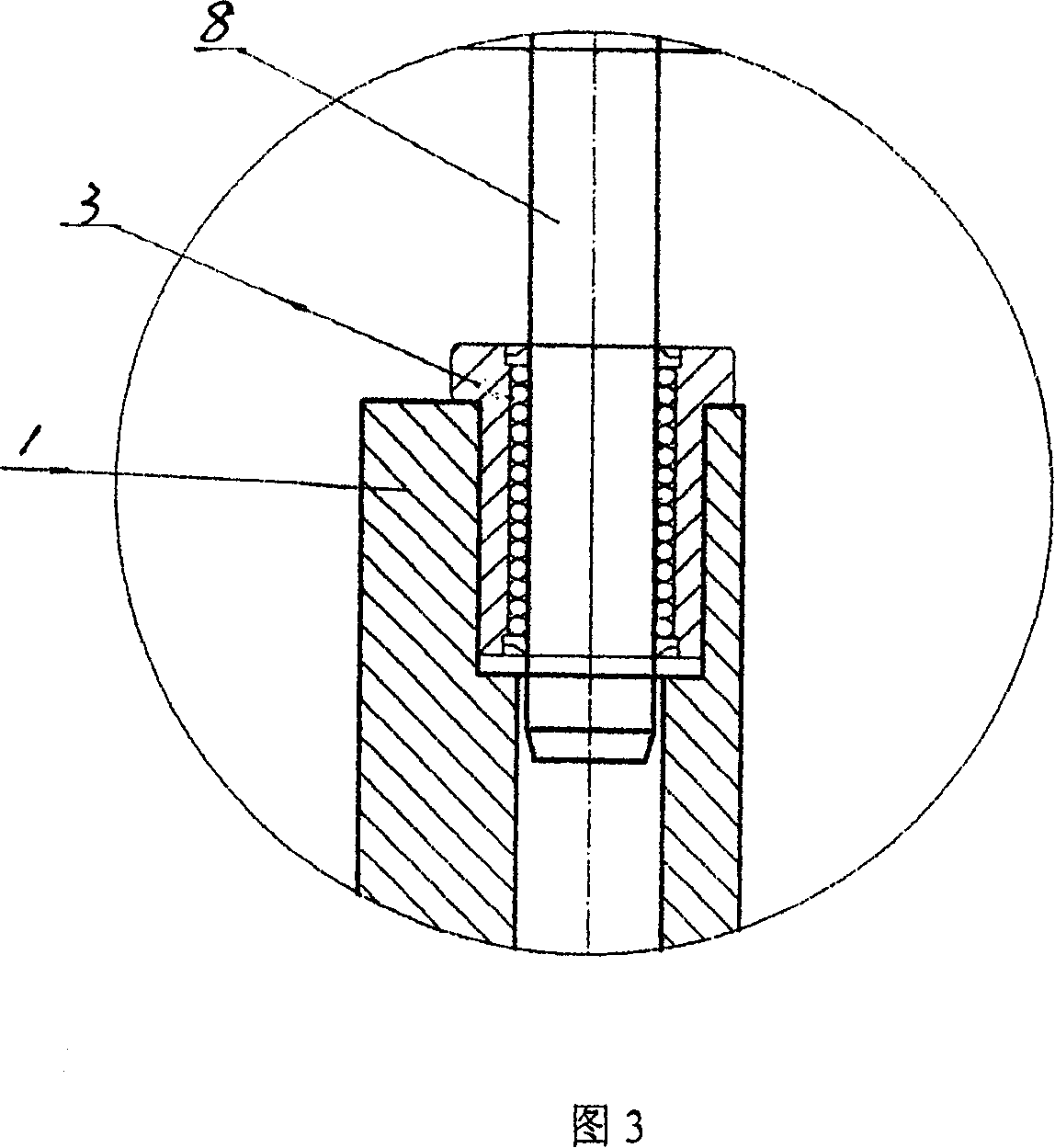

Lubricating device for needle bar of sewing machine

InactiveCN102337647ASimple structureReduce friction areaLubrication/cooling devicesBiomedical engineeringSewing machine

The invention relates to a lubricating device for a needle bar of a sewing machine, which comprises a vertical cylindrical needle bar arranged on the lower end of a handpiece shell and a cylindrical needle bar sleeve; the needle bar sleeve is connected to the handpiece shell and is sleeved at the outer side of the needle bar; an oil storage groove is arranged on the inner wall of the needle bar sleeve, and an oil injection hole is arranged in the upper part of the side face of a cylinder of the needle bar sleeve. The lubricating device is characterized in that the oil storage groove on the inner wall of the needle bar sleeve is helical with the axial line of the cylinder as a middle axle. The helical oil storage groove is used for reducing the friction area of the needle bar and the needle bar sleeve so as to reduce heat. Meanwhile, the helical groove is used as a flow channel for liquid lubricating grease to ensure that the grease is uniformly distributed within 360 degrees in the vertical and sectional directions of the axial line of the needle bar sleeve. The helical oil storage groove has a simple structure, and the upper end of the helical oil storage groove is arranged at the oil injection hole of the needle bar sleeve to conveniently inject oil.

Owner:吴江丰榖布艺整理厂

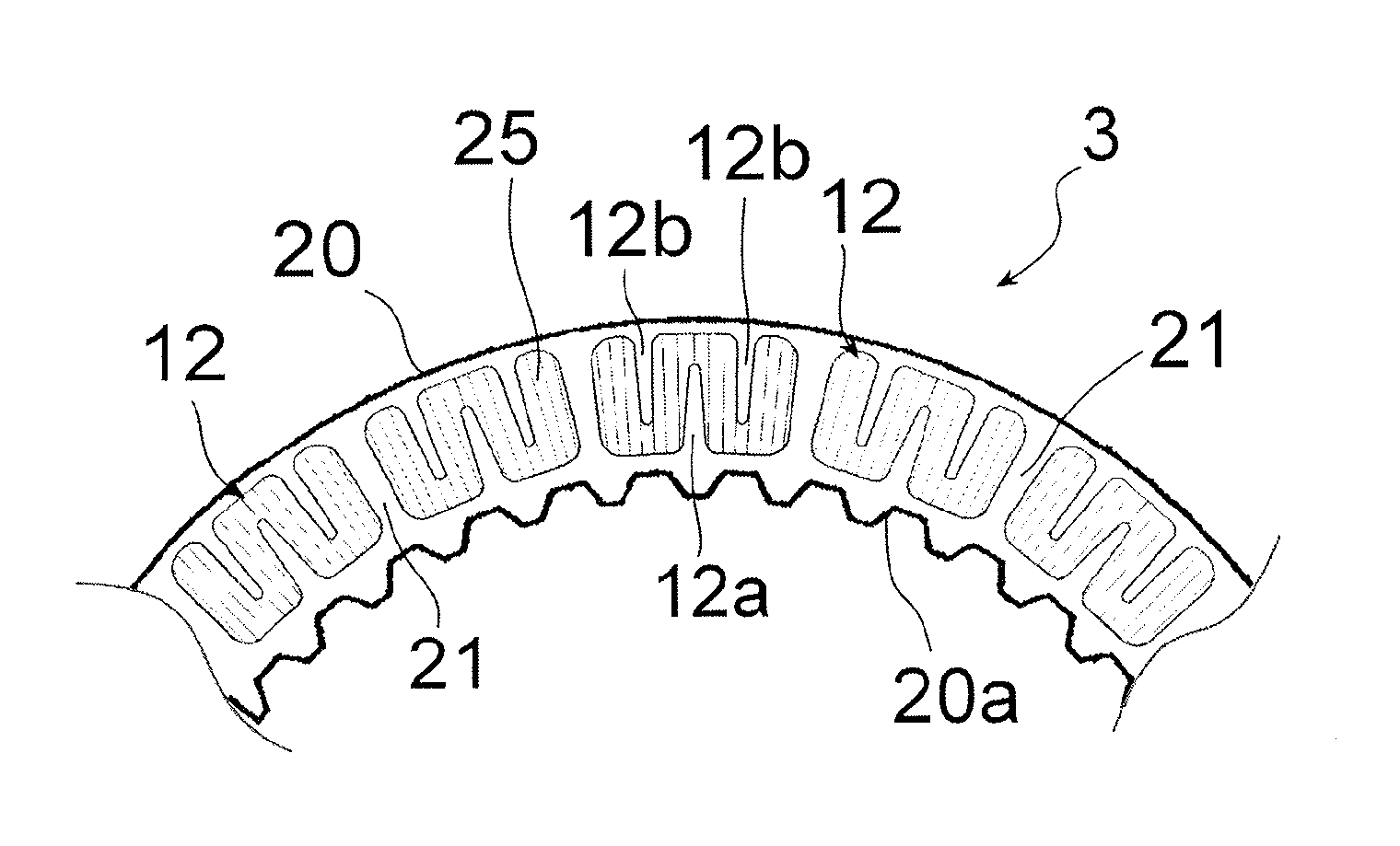

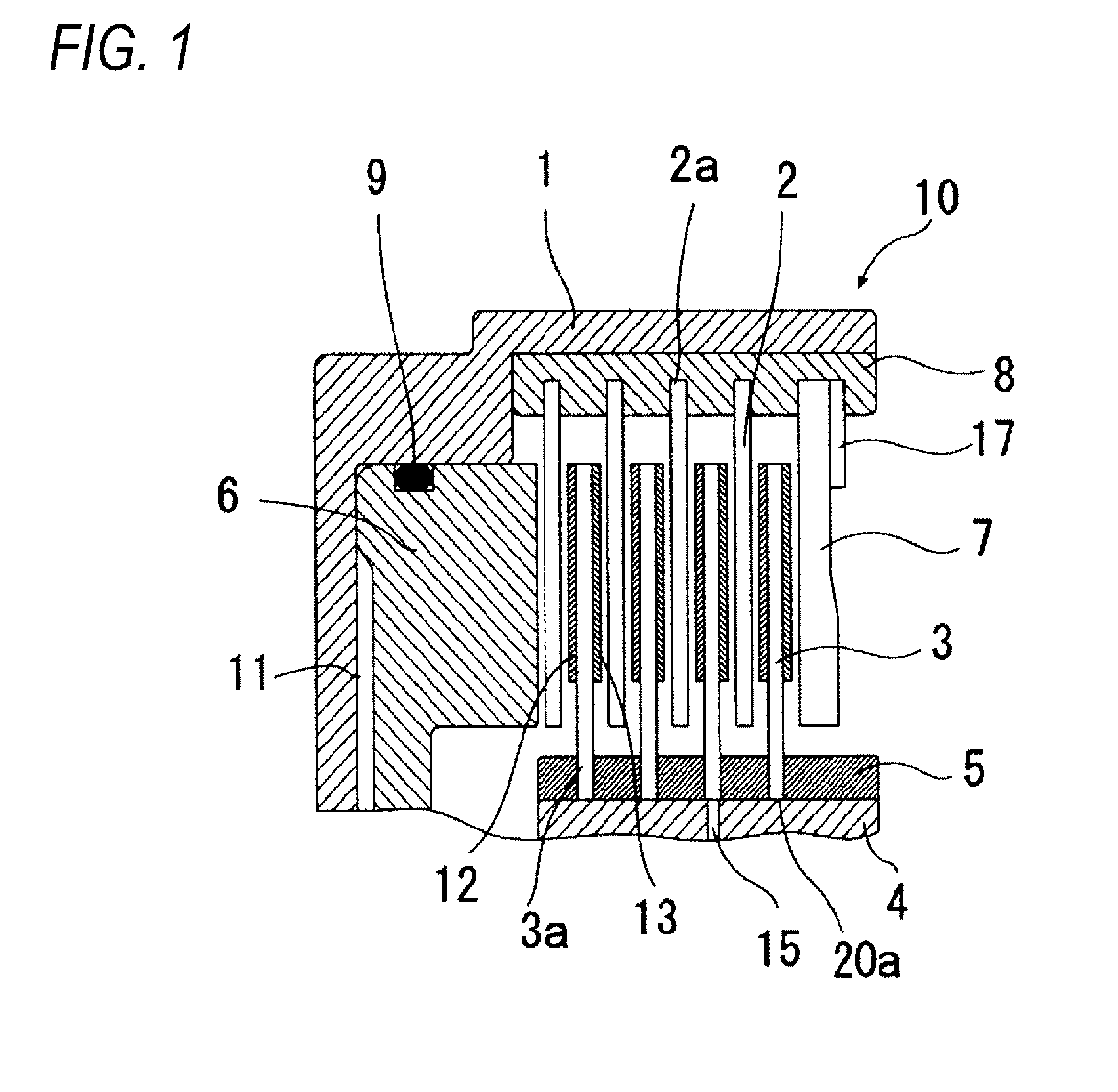

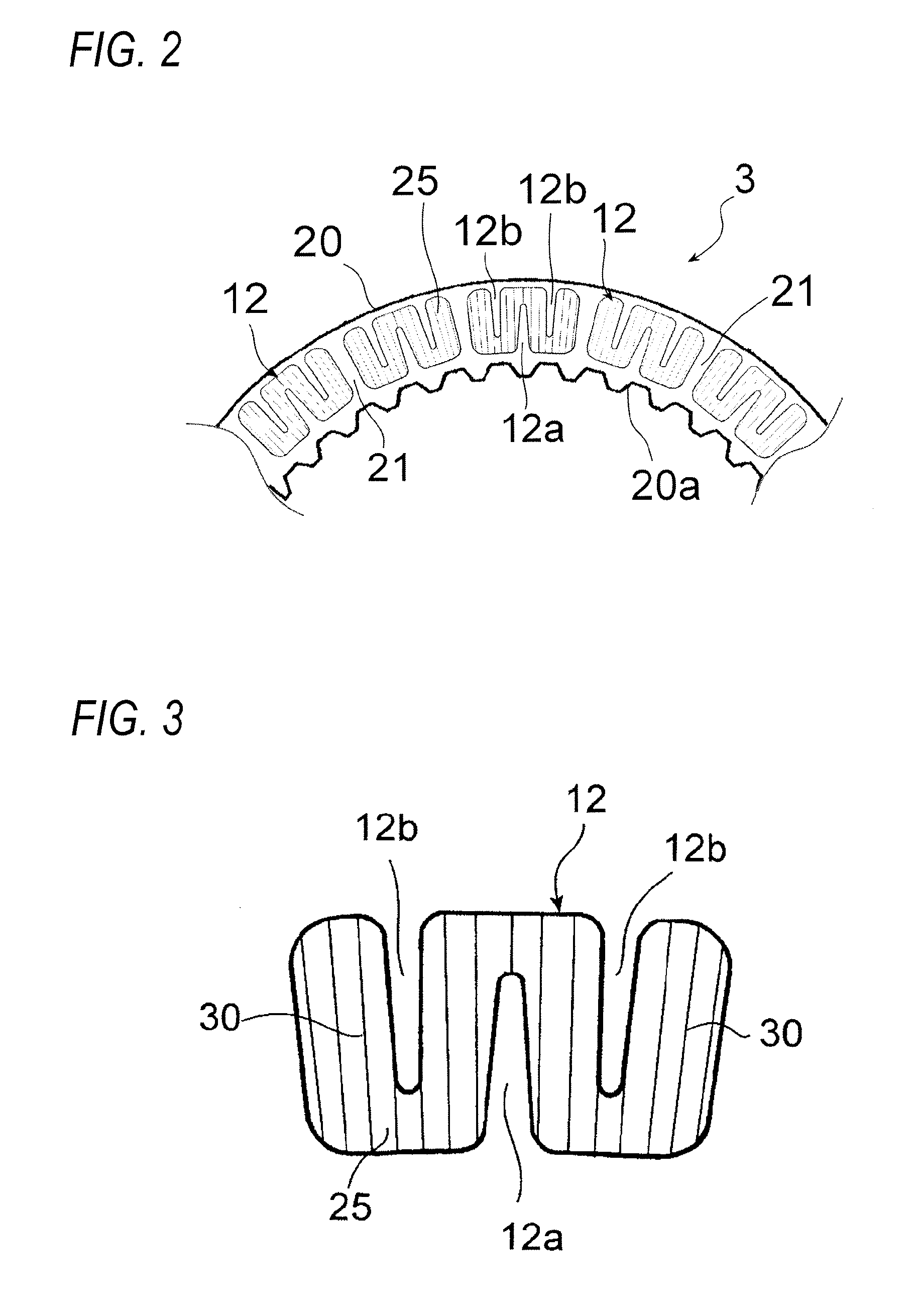

Friction plate and wet-type multiple-disc clutch with friction plate

ActiveUS20160025158A1Increased durabilityDegradation of heat resistanceFluid actuated clutchesFriction clutchesClutch

Owner:NSK WARNER

Wearing-resistant double-component graphene anti-corrosion coating

PendingCN110183934AReduce dead timeImprove bindingAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention discloses a wearing-resistant double-component graphene anti-corrosion coating and belongs to the technical field of macromolecule anti-corrosion materials. The method comprises the following steps: sequentially weighing the following components in parts by weight: 25-40 parts of an epoxy resin, 15-22 parts of a solvent, 3-5 parts of a leveling agent, 2-4 parts of a defoaming agent,3-5 parts of a dispersant, 12-16 parts of zinc powder, 10-15 parts of coarse whiting and 20-28 parts of modified graphene; mixing the epoxy resin with the solvent, adding the leveling agent, the defoaming agent, the dispersant, the zinc powder, the coarse whiting and the modified graphene, and conducting stirring and mixing so as to obtain a component A; sequentially weighing the following components in parts by weight: 10-15 parts of a curing agent and 5-6 parts of a solvent, mixing the curing agent with the solvent, and conducting stirring and mixing so as to obtain a component B; separatelypackaging the component A and the component B, so as to obtain the wearing-resistant double-component graphene anti-corrosion coating. The wearing-resistant double-component graphene anti-corrosion coating disclosed by the invention is excellent in wearing resistance and corrosion resistance.

Owner:陈理抗

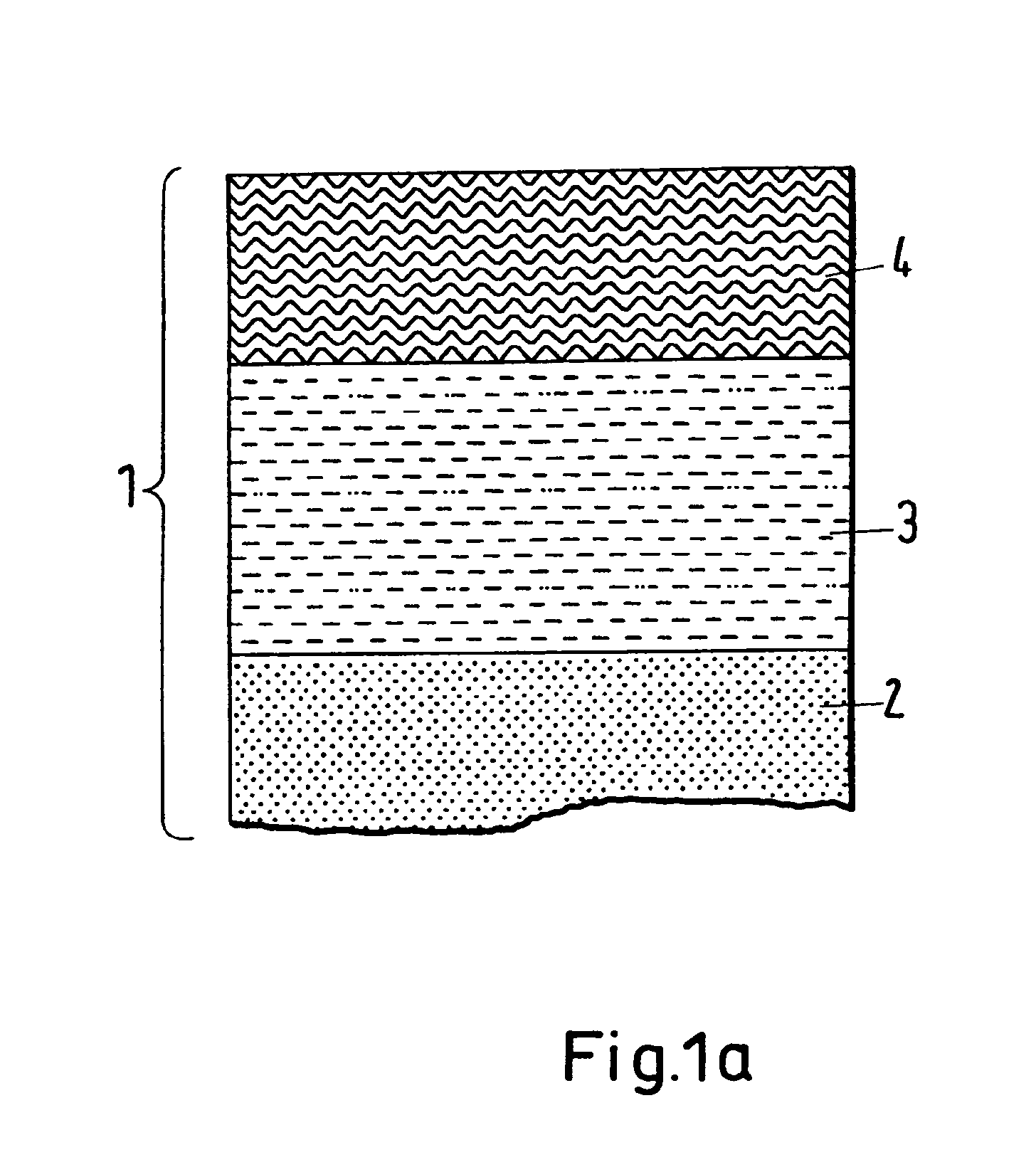

Protective coating, a coated member having a protective coating as well as method for producing a protective coating

ActiveUS20120196137A1Emission reductionReduce friction loss in and transmissionFibre treatmentVacuum evaporation coatingChemical compositionMetal

The invention relates to a protective coating, having the chemical composition CaSibBdNeOgHlMem, wherein Me is at least one metal of the group consisting of {Al, Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W, Y, Sc, La, Ce, Nd, Pm, Sm, Pr, Mg, Ni, Co, Fe, Mn}, with a+b+d+e+g+l+m=1. According to the invention, the following conditions are satisfied: 0.45≦a≦0.98, 0.01≦b≦0.40, 0.01≦d≦0.30, 0≦e≦0.35, 0≦g≦0.20, 0≦1≦0.35, 0≦m≦0.20. The invention relates also to a coated member having a protective coating, as well as to a method for producing a protective coating, in particular a multilayer film for a member.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

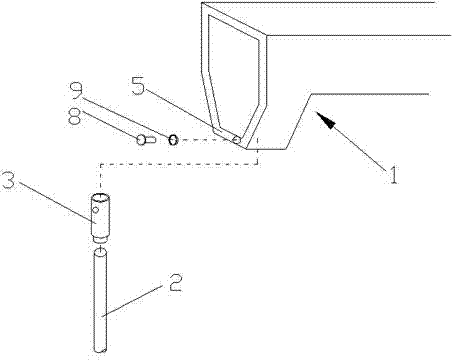

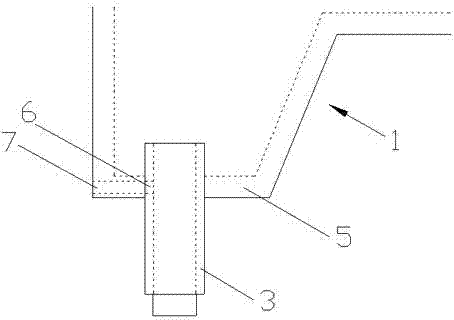

Lamp post billboard supporting device

InactiveCN101923807AReduce friction areaAvoid damageSignsPedestrianElectrical and Electronics engineering

The invention aims to provide a billboard supporting device arranged on a lamp post. The device comprises a billboard body, a fixing strip, a spring, a bag-type billboard and the like, wherein a connection device of a foldable billboard structure of the billboard body is connected with a shedding device of a ]-shaped clamp so as to rotate by using a shaft pin; the fixing strip is used for fixing the ]-shaped clamp to the lamp post; the spring is used for connecting the connection device of the billboard body and the fixing strip; and the bag-type billboard is sleeved on the billboard structure. The billboard body is safely supported by the ]-shaped clamp; and because the friction area among various materials is small, the generated noise is low. The spring which is used for connecting the billboard body and the fixing strip can properly absorb an air pressure borne by the bag-type billboard sleeved on the billboard structure so as to prevent the billboard body or the lamp post from being damaged. Simultaneously an inside component of the billboard structure is connected with an upside component, an outside component and a downside component through hinges in turn; and when the billboard is not used, the upside component, the outside component and the downside component can be closed on the inside component, which not only prevents the appearance of a street lamp from being affected, but also ensures the safety of vehicles and pedestrians.

Owner:赵章济

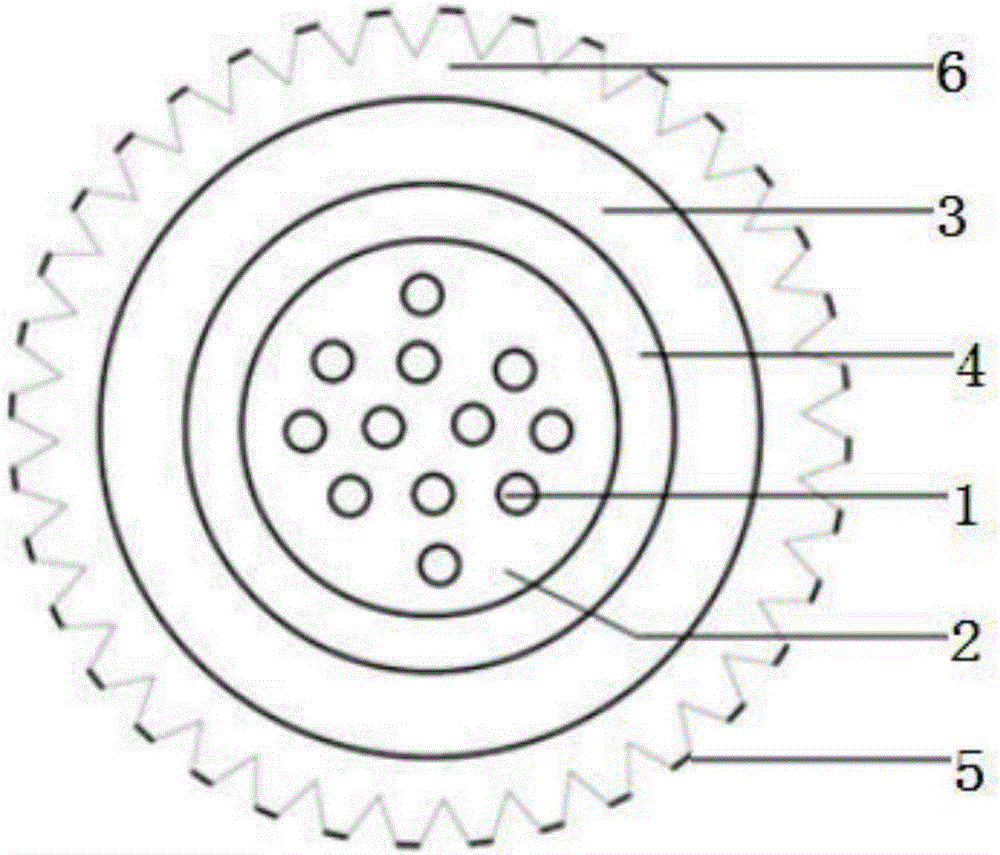

Ultra-microscopic air-blown cable and air-blowing cable process

ActiveCN106054334AHigh densityReduce additive attenuationOptical fibre/cable installationFibre mechanical structuresFiberHigh pressure

The invention relates to an ultra-microscopic air-blown cable and an air-blowing cable process. The cable comprises a loose tube which is wrapped with a plurality of optical fibers, and the loose tube is filled with fiber paste. An external protection sleeve is provided on the loose tube. A reinforced material layer is arranged between the loose tube and the external protection sleeve. The external side wall of the external protection sleeve is provided with a plurality of teethed gears in a circular manner. The end parts at the free ends of the teethed gears are provided with conductive layers which generate heat under the force of electromagnetic radiation. The cable blowing process is done as follows. A cable blowing machine and a silicon core pipe are located beneath the ground. And the cable blowing machine is communicated with one end of the silicon core pipe. The ground is further provided with a high-frequency electromagnetic heating device. The cable blowing machine sends optical fibers into the silicon core pipe through high-pressure air flows, and the high-frequency electromagnetic heating device moves in the extending direction of the silicon core pipe and conducts electromagnetic radiation towards the silicon core pipe. The inner wall of the silicon pipe is coated with lubricant.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Drum tile telescoping mechanism of tyre building machine

The present invention discloses a tire molding machine drum watt telescopic mechanism which comprises a spindle, two fixed disks and a plurality of banding tiles and a molding drum watt. A space is between the two fixed disks and the two fixed disks are both fixed on the spindle. A radial hole is arranged equally on the outer circle. The banding tile is provided with an oriented rod on the inside of two ends. One end of the oriented rod is fixed on and connected with two ends of the banding tile, and the other end of the oriented rod slides and extends into the corresponding radial hole which is arranged on the fixed disk. A cylinder is arranged between the two fixed disks. And the cylinder is shape of cone. An axial stomata is arranged on the spindle and is communicated with a cylinder body intracavity. A piston is arranged in the cylinder body. A inside boss club is arranged on the same position of the banding tile inside. An inclined plane is arranged on the inside boss club. The inclined plane sliding cooperates with the cone-shaped cylinder body. A pullback spring is also connected with the outside of the banding tile. The present invention is characterized in that a linear motion ball bearing is arranged in the radial hole of the fixed disk; the oriented rod sliding cooperates with the radial hole by the linear motion ball bearing. Using the present invention can reduce maintenance workload and production cost. The present invention is suitable for manufacturing tires of motorcycle and bicycle.

Owner:杨建忠

Positionable stainless steel tube inner wall polishing device

InactiveCN107639479AAvoid stickingAvoid damageRevolution surface grinding machinesDrive motorEngineering

The invention discloses a positionable stainless steel tube inner wall polishing device. The device comprises a rack, a pair of parallel conveying tracks are arranged at one end of the top of the rack, a polishing machine is arranged on the conveying tracks, a first roller set and a second roller set fixed to the rack are sequentially arranged on one sides of the conveying tracks, one roller in the first roller set and one roller in the second roller set are connected through a connecting shaft, a rotating gear is arranged at one end of the connecting shaft, the rotating gear is connected witha driving gear through a driving chain, one end of the driving gear is connected with a driving motor fixed to the rack, and a pushing device is arranged on the outer side of the second roller set. The axial position of a stainless steel tube can be effectively adjusted, the positioning precision is high, and the safety is good.

Owner:湖州南浔永涛不锈钢材料有限公司

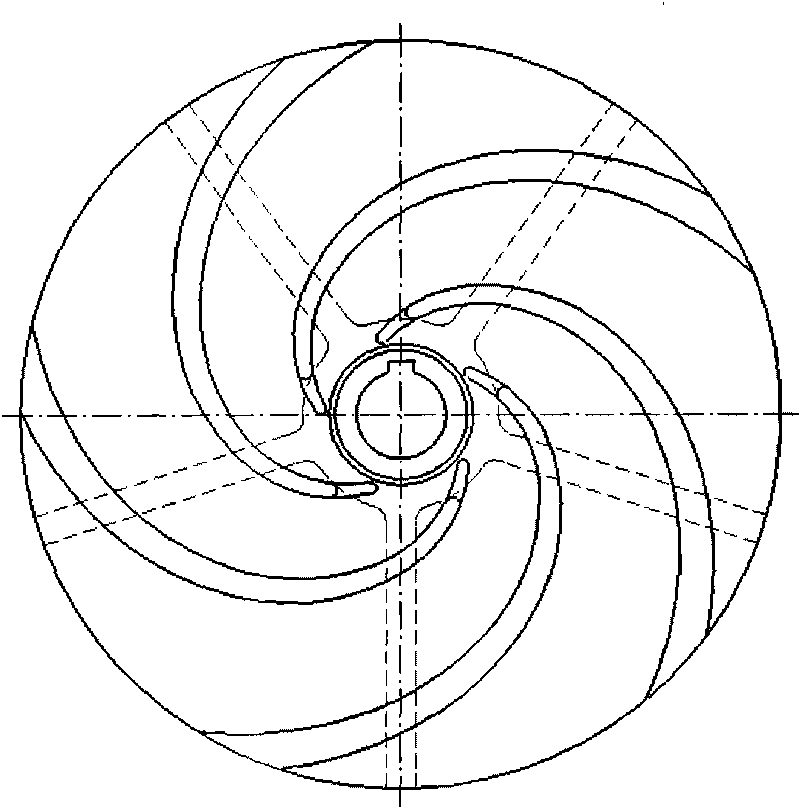

Impeller modified structure of chemical process pump

InactiveCN101691872AAffect efficiencyDoes not affect pump efficiencyPump componentsPumpsHelical lineImpeller

The invention relates to an impeller structure of a pump, in particular to an impeller structure of a chemical process pump, which belongs to the field of mechanical fluid. The impeller structure comprises blades, cover plates and a hub, wherein molded lines of the blades are drawn by using equal changeable angle logarithmic spiral lines, and the thickness of the blades gradually increases from an inlet end to an outlet end along the molded lines; the outline on the left side of the cover plates is in smooth and backward inclined extension, and the thickness of the cover plates gradually increases from the inlet end to the outlet end along the smooth and backward inclined extension; an outlet of the blades is uniformly distributed with hollow cover plates, and a part of the cover plates is retained; each cover plate is uniformly distributed with balance holes for balancing a part of axial force; and the hub is a ring body and is provided with a key slot in the junction with an axis. The components are connected in the following relation: the blades, the cover plates and the hub are cast into a whole body to form an impeller; the blades are uniformly distributed on the cover plates; and the hub is arranged on the back side of the cover plates. The impeller structure is to improve the efficiency of the chemical process pump and prevent fins from abrading a pump cover near the impeller so as to ensure the use efficiency and reduce the running maintenance cost of the chemical process pump.

Owner:XIANGYANG WU ER WU PUMP IND

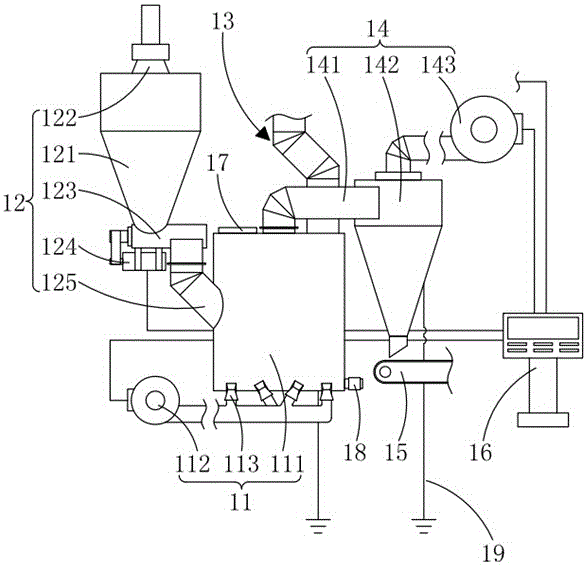

Automatic pyrotechnic composition mixing system

InactiveCN106139991AReduce friction areaReduce riskFlow mixersTransportation and packagingPyrotechnic compositionEngineering

The invention provides an automatic pyrotechnic composition mixing system. The automatic pyrotechnic composition mixing system comprises an oxidant feeding unit, a reducing agent feeding unit, a mixing unit and a collecting unit; the mixing unit comprises a mixing cavity, an air blower and nozzles; one end of each of the plurality of nozzles penetrates through the bottom of the mixing cavity and the other ends of the nozzles are connected with the air blower through pipelines; the oxidant feeding unit and the reducing agent feeding unit are arranged on the two sides of the mixing cavity respectively; and the collecting unit is arranged at the top of the mixing cavity. With the adoption of the automatic pyrotechnic composition mixing system provided by the invention, the technical problems of a pyrotechnic composition mixing manner in the prior art that dangers are relatively great and explosion is easy to occur are solved.

Owner:HUNAN WUJIANG INFORMATION SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com