Drum tile telescoping mechanism of tyre building machine

A telescoping mechanism and molding machine technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of heavy maintenance workload, increased production cost, and large contact area, so as to reduce maintenance workload, reduce production cost, The effect of small friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

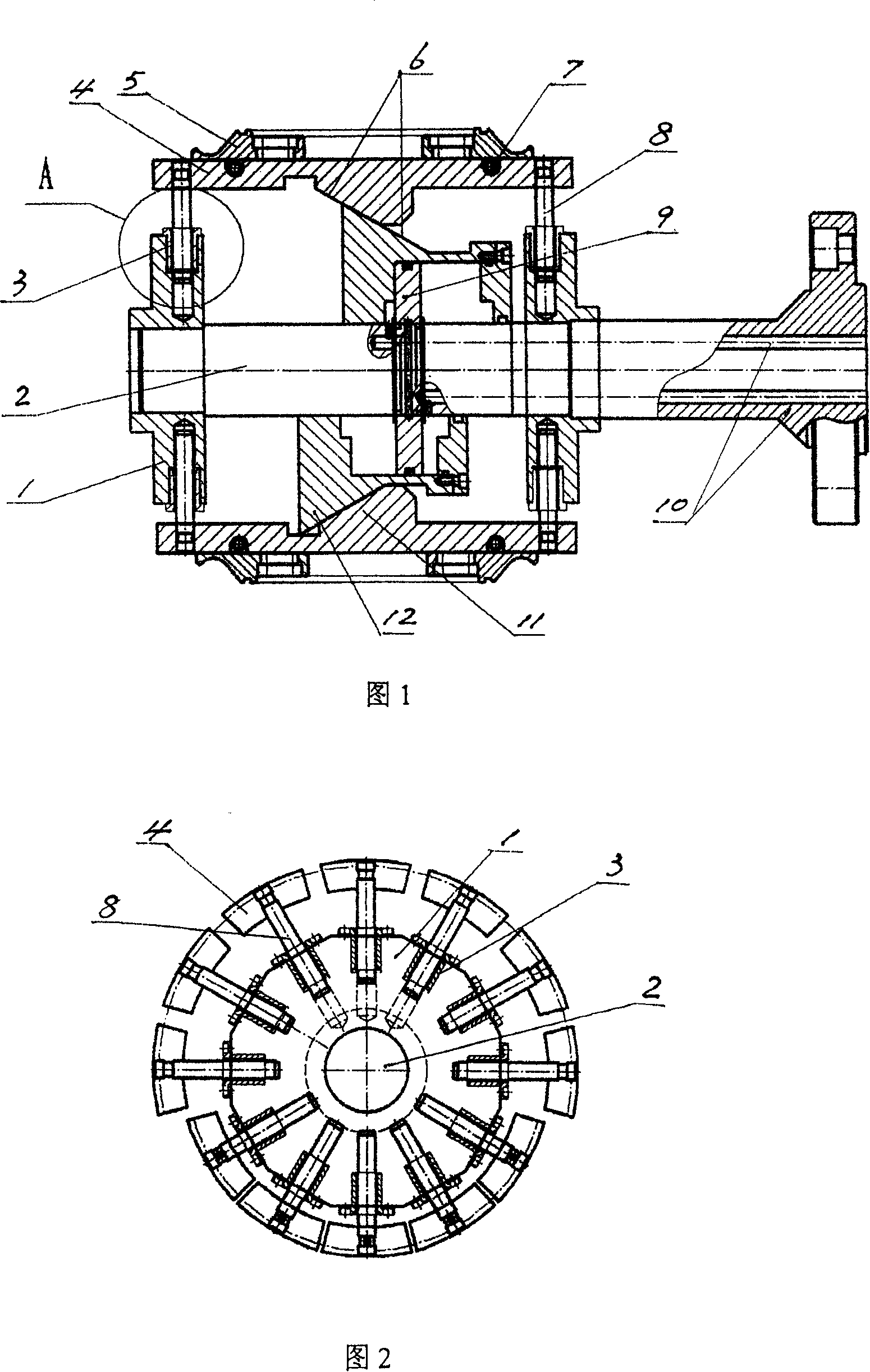

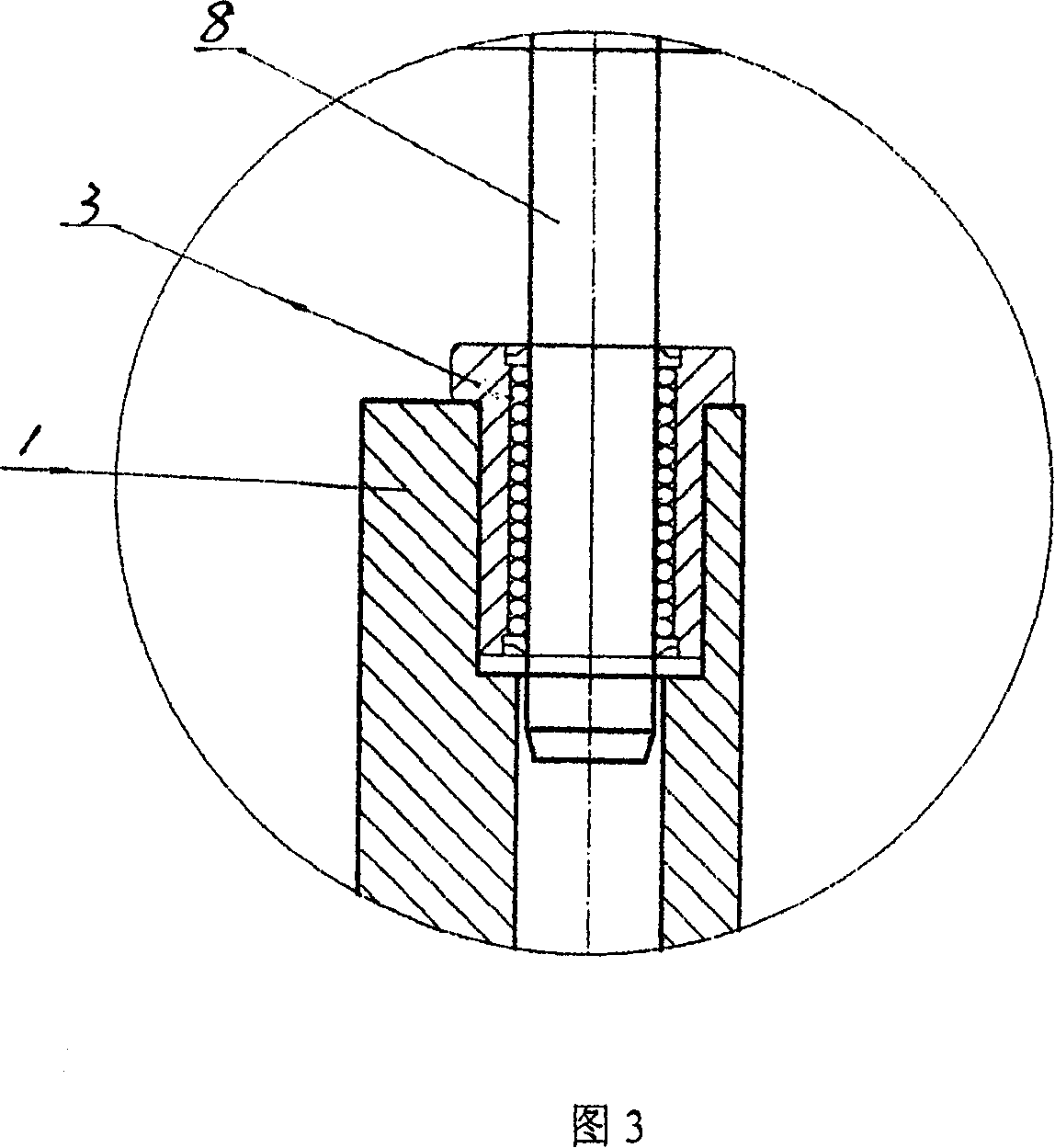

[0011] As shown in Fig. 1, Fig. 2 and Fig. 3, the drum tile telescoping mechanism of the tire building machine of the present invention contains a main shaft 2, two fixed discs 1 and some strip tiles 4 and forming drum tiles 5. Wherein, the diameters of the two fixed discs 1 are the same, they are all fixed on the main shaft 2, and there is a space between them, which corresponds to the center distance of the strip tiles 4 . There are 12 radial holes evenly distributed on the outer circumference of the two fixed disks 1 , and there are 12 guide rods 8 between both ends of each strip tile 4 and the corresponding fixed disk 1 . The formed drum tiles 5 are fixed on the outside of the strip tiles 4 one by one. Screw holes are processed at both ends of the strip tiles 4. One end of the guide rod 8 is processed with external threads. Screw into the screw holes at both ends of the strip tile 4, so that the guide rod 8 is arranged radially along the strip tile 4. Linear motion ball b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com