Thin straight-piece product stacking machine

A stacking machine and straight sheet technology, applied in the field of thin straight sheet product stacking machine, can solve the problems of sheet-arranging accuracy, speed that cannot meet the requirements, large blade spacing of sheet-arranging mechanism, and large height-to-size ratio difference, etc., to achieve the working state Stable and reliable, reducing friction area and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

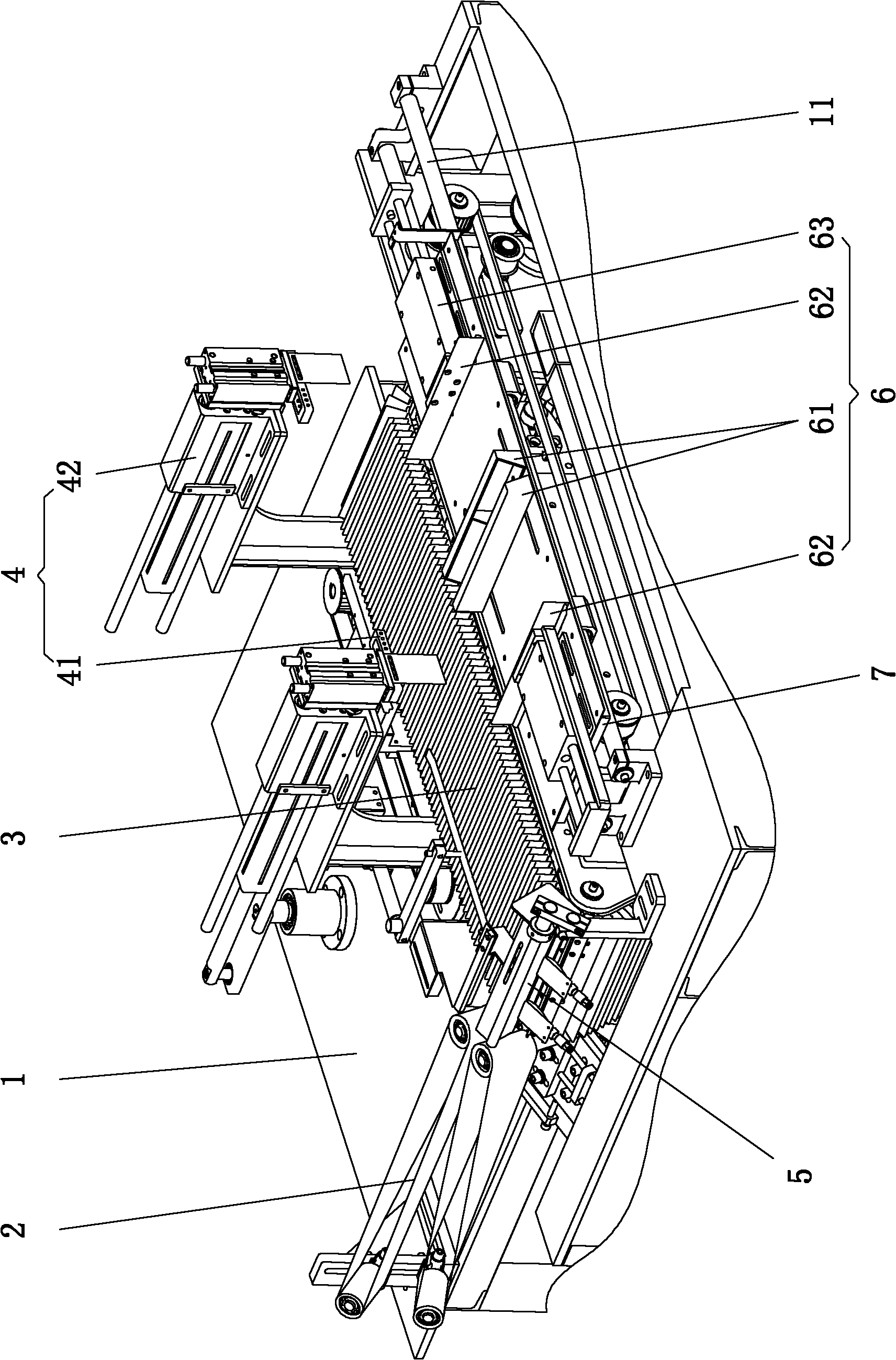

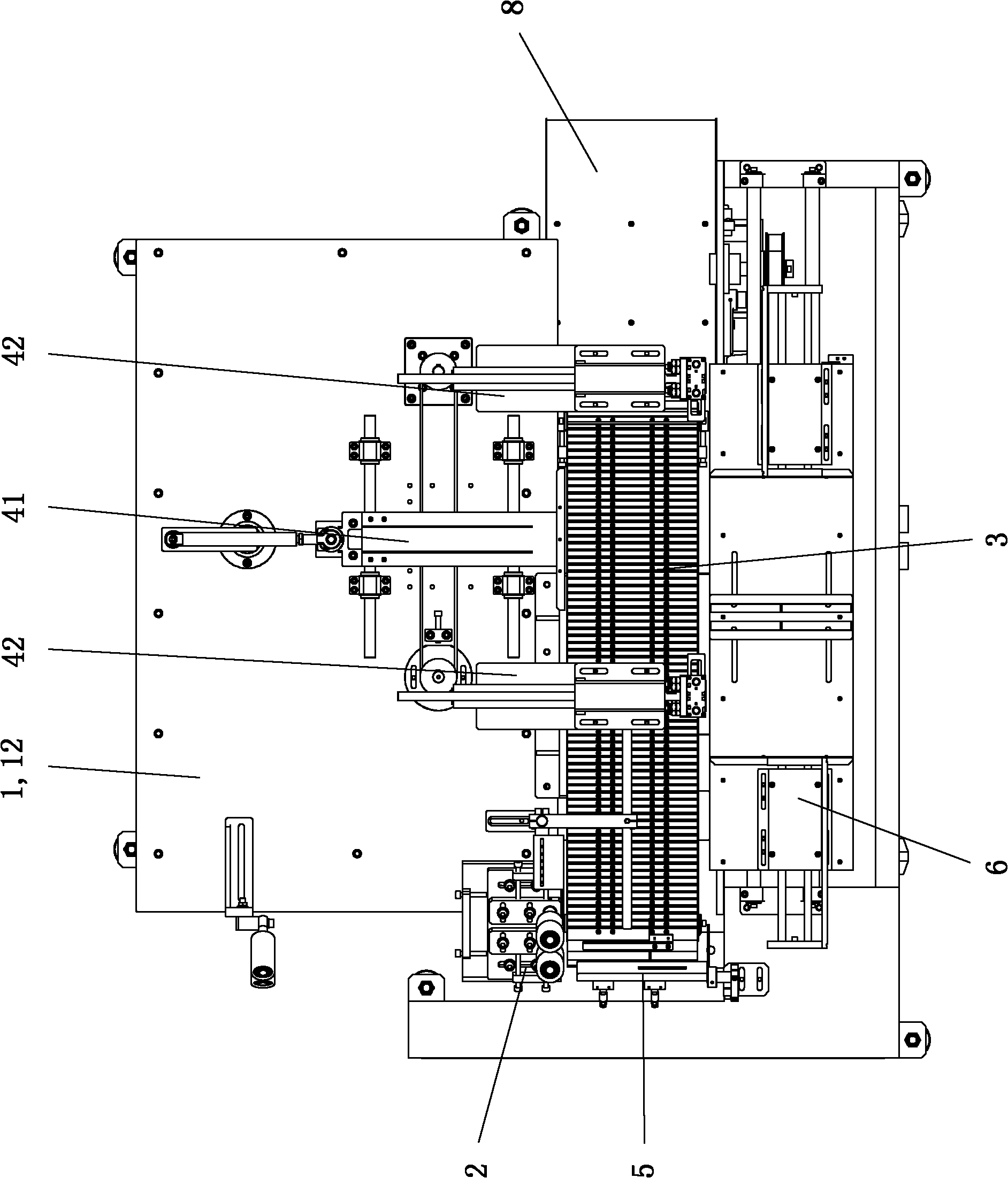

[0034] See Figure 1 to Figure 7 , the present invention has a frame 1, a feeding mechanism 2, a sheet arrangement mechanism 3, a push handle mechanism 4, a limit mechanism 5, a compacting mechanism 6, a sliding seat 7 and a waste slide plate 8;

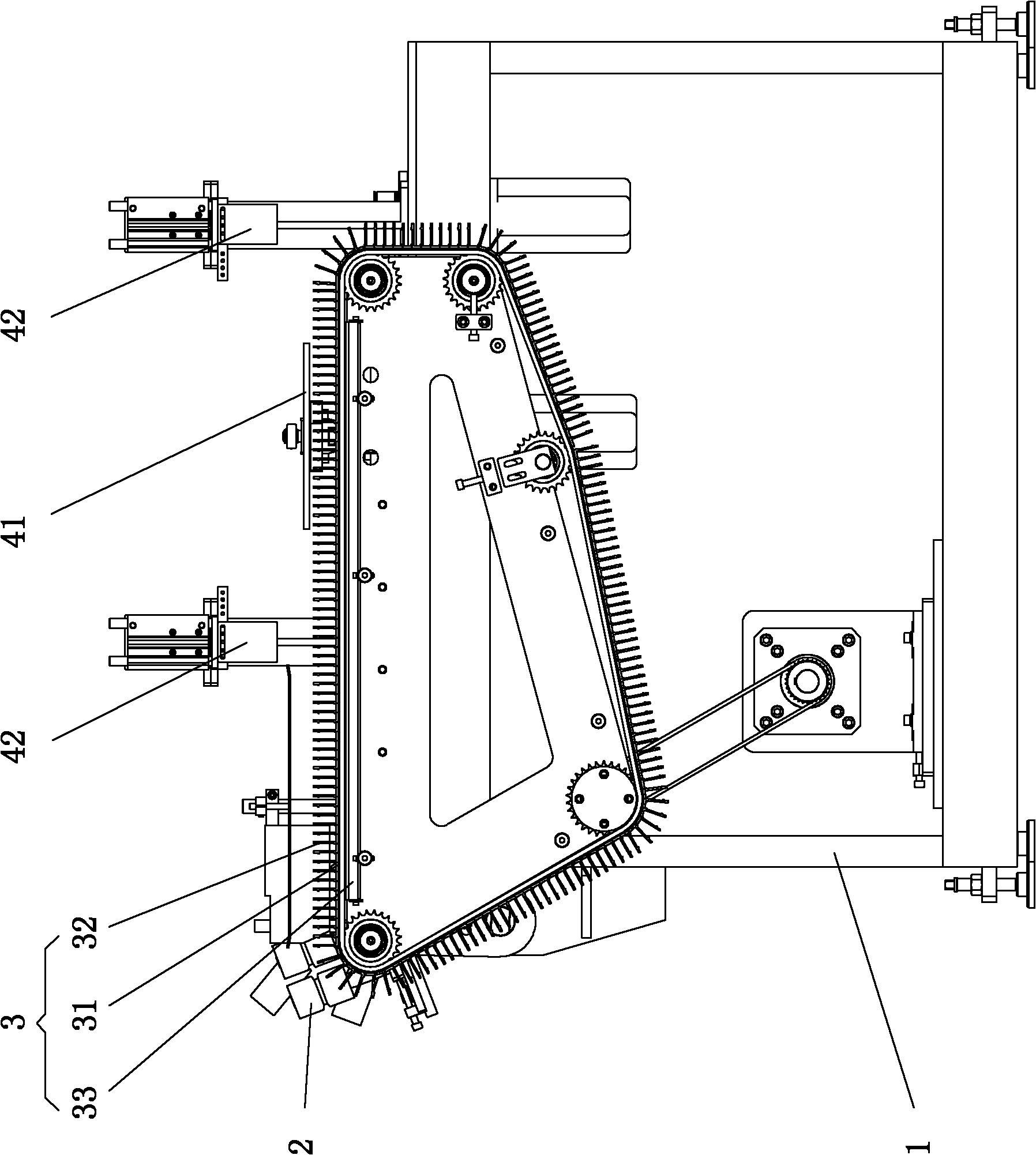

[0035] Wherein the sheet arranging mechanism 3 is a loop-closed conveying chain driven by a sprocket, and has at least two inflection points. The blade belt 31 is connected on the chain, and the blades 32 are evenly arranged on the blade belt 31 through fasteners. The driving mechanism drives the chain and the blade belt 31 to circulate. transmission, so that the evenly arranged blades 32 move forward, and the part of the sheet arranging mechanism 3 located on the working table 12 of the frame 1 between the two inflection points is a working section, and a chain chute 33 is provided under the chain of the working section, and the chain slides The effect of the groove 33 is to play a supporting role to the chain and the blade belt 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com