Drafting assembly of spinning machine

A drafting device and spinning machine technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve problems such as high pressure on the cradle, increased drafting force, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

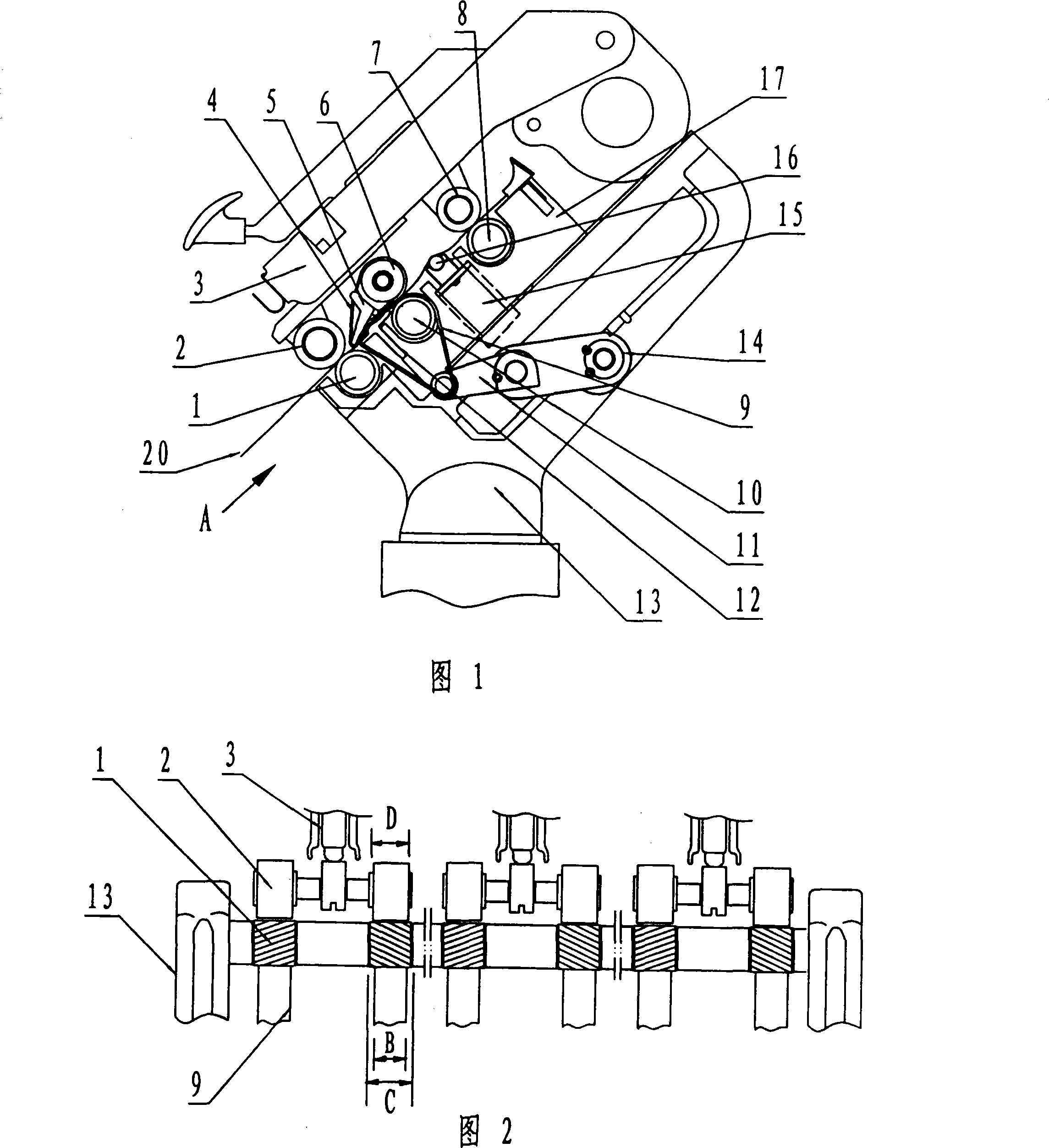

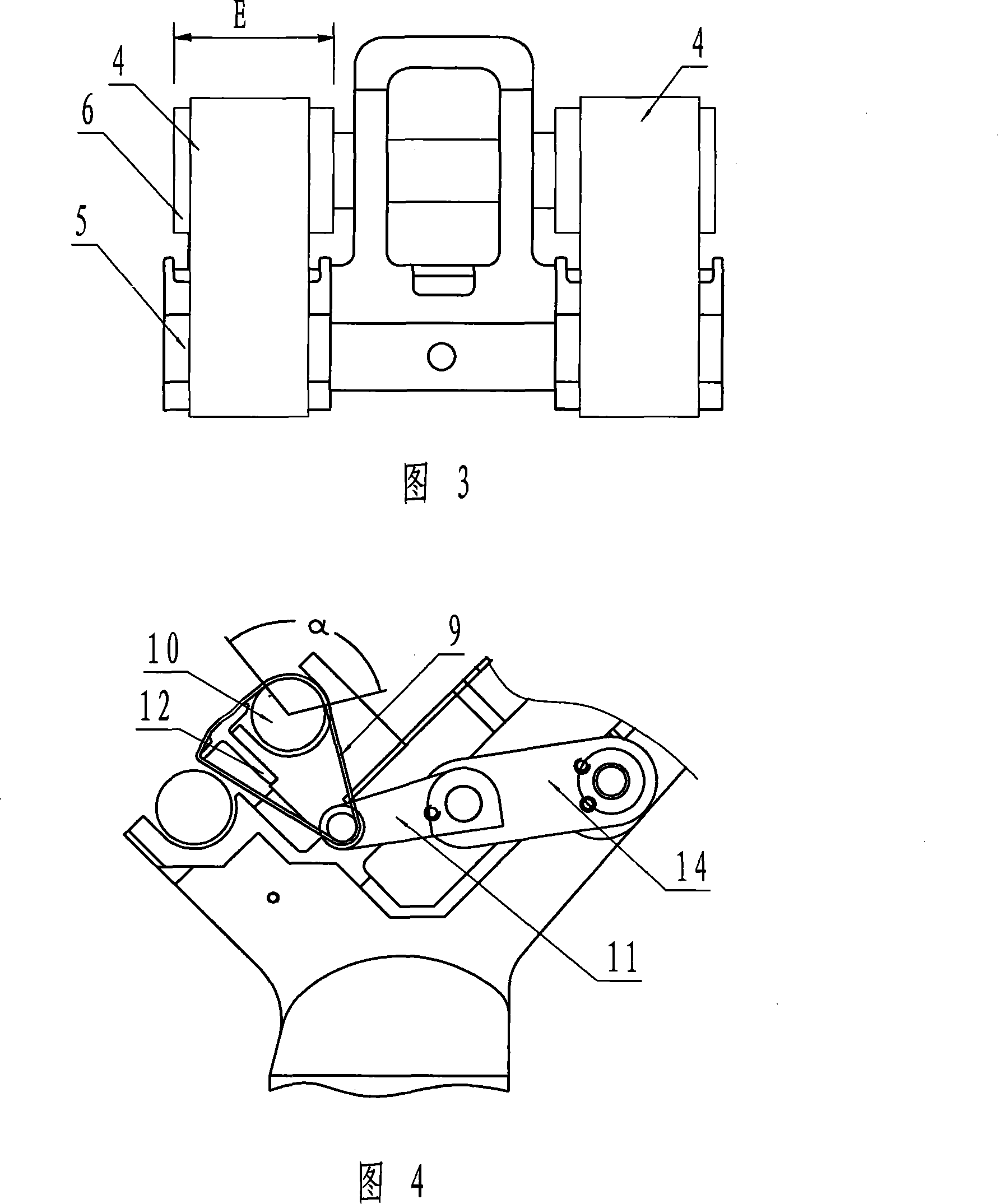

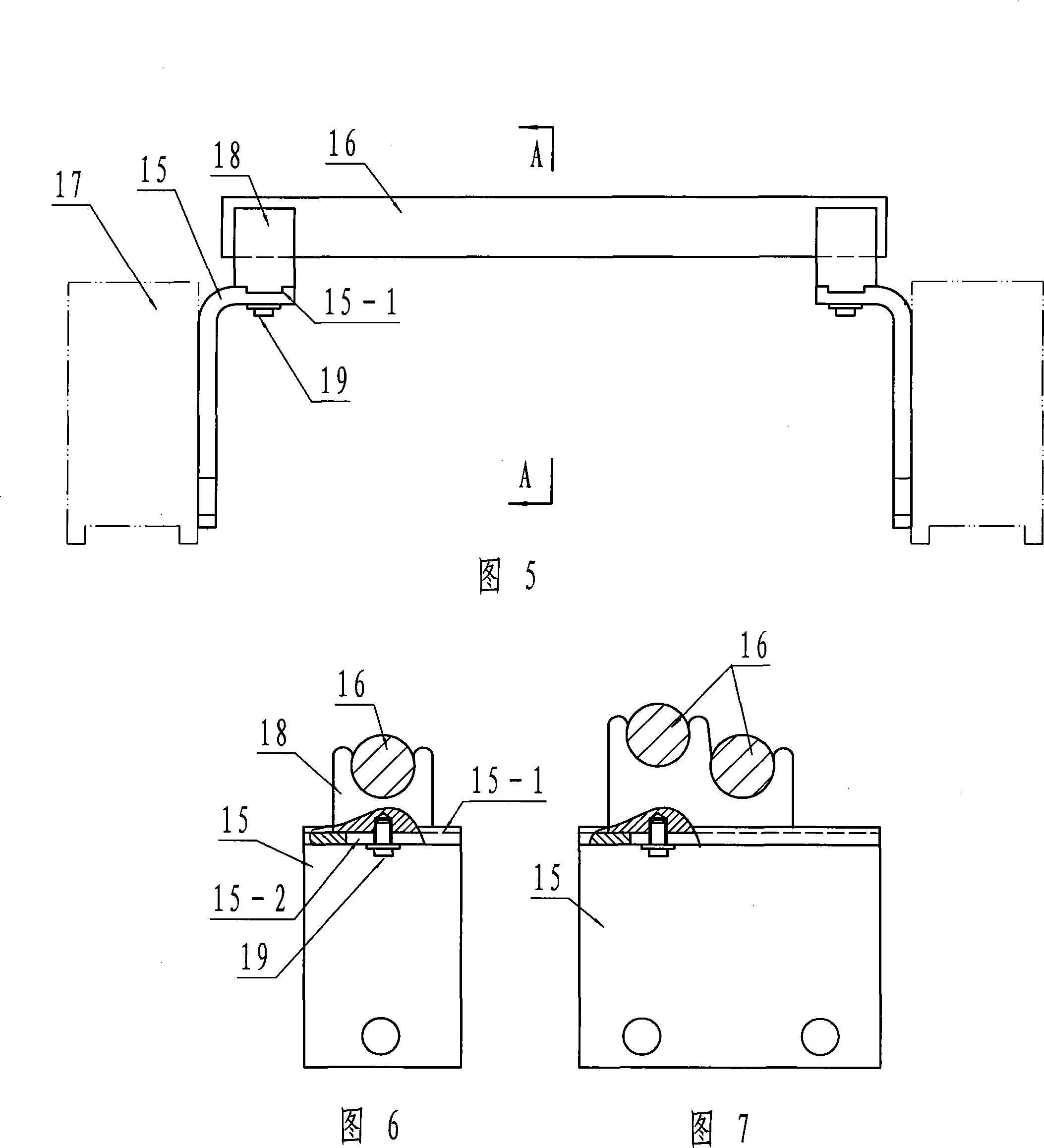

[0022] Referring to Fig. 1~Fig. 3, in the composition of the present invention, comprise the front top roller 2, front bottom roller 1 that are positioned at the front portion of the drafting zone; The main drafting assembly in the middle, the main drafting assembly is made up of middle upper roller 6, upper pin 5, upper apron 4 surrounding the above two, middle and lower roller 10, lower pin 12, and lower apron 9 surrounding the above two. The front top roller, the rear top roller and the upper pin assembly are all positioned on the cradle 3; the front bottom roller, the rear bottom roller and the middle bottom roller are all positioned on the roller stool 13. In order to reduce the friction loss, the present invention optimizes the size of the relevant drafting device as follows: the working gear size D of the front top roller and the rear top roller is 15-28 mm, and the front bottom roller, the middle bottom roller and the rear bottom roller work gear The dimension C is 15-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com