Patents

Literature

89results about How to "Small distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

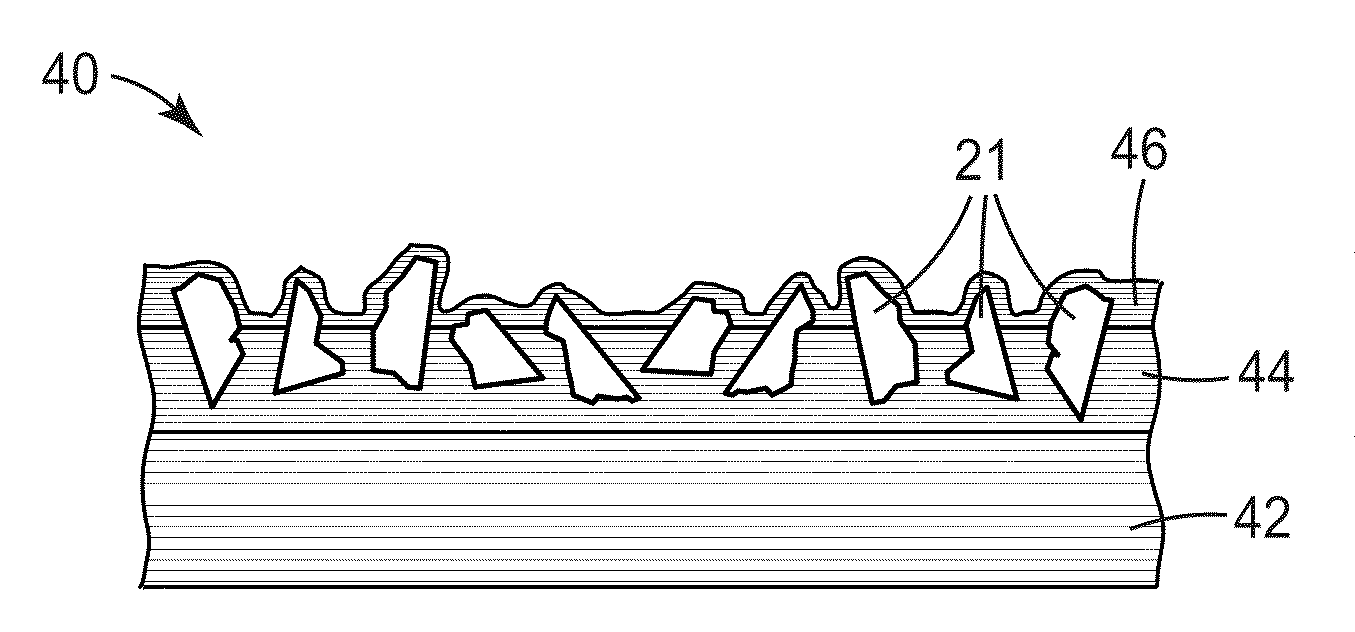

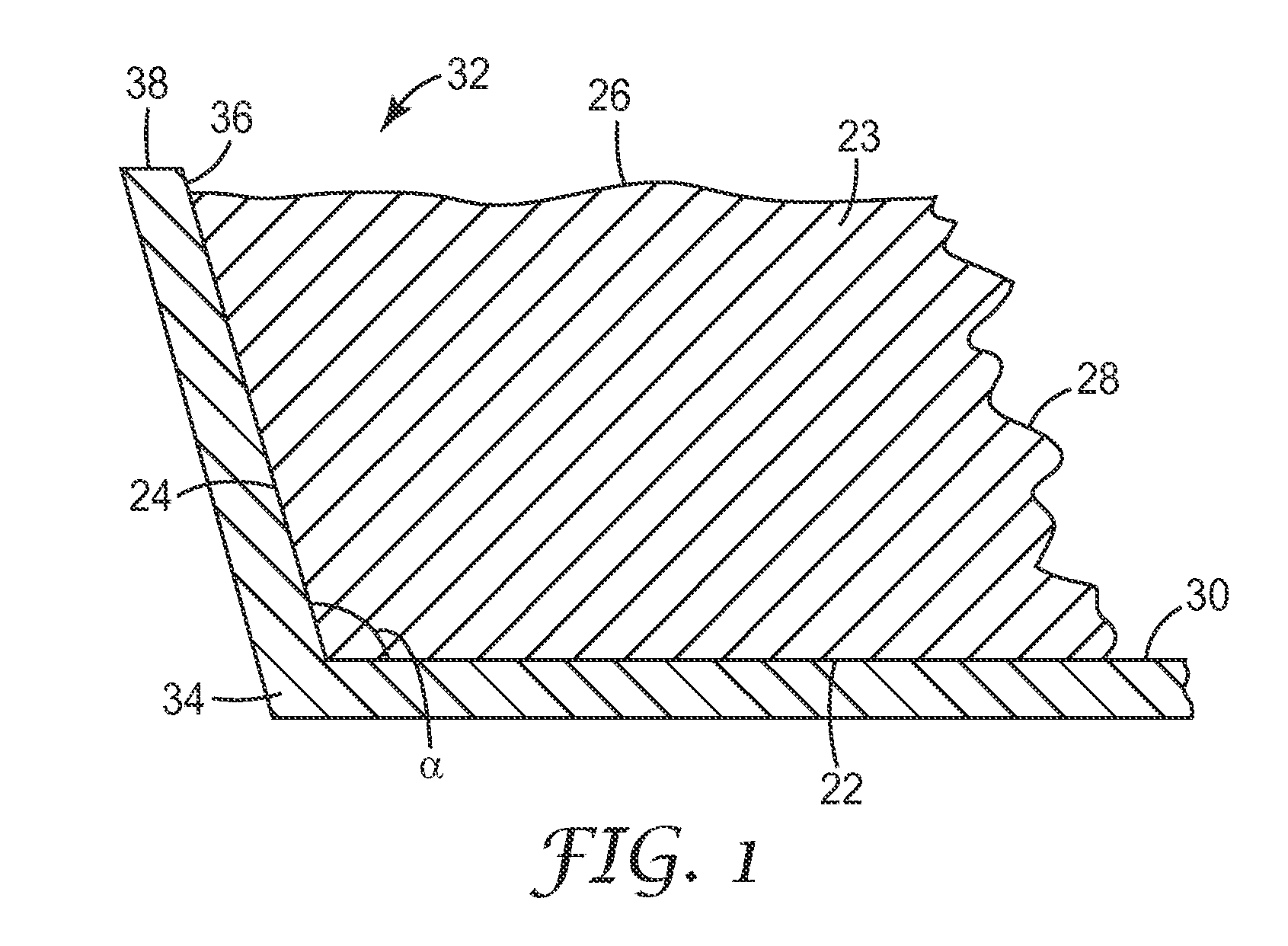

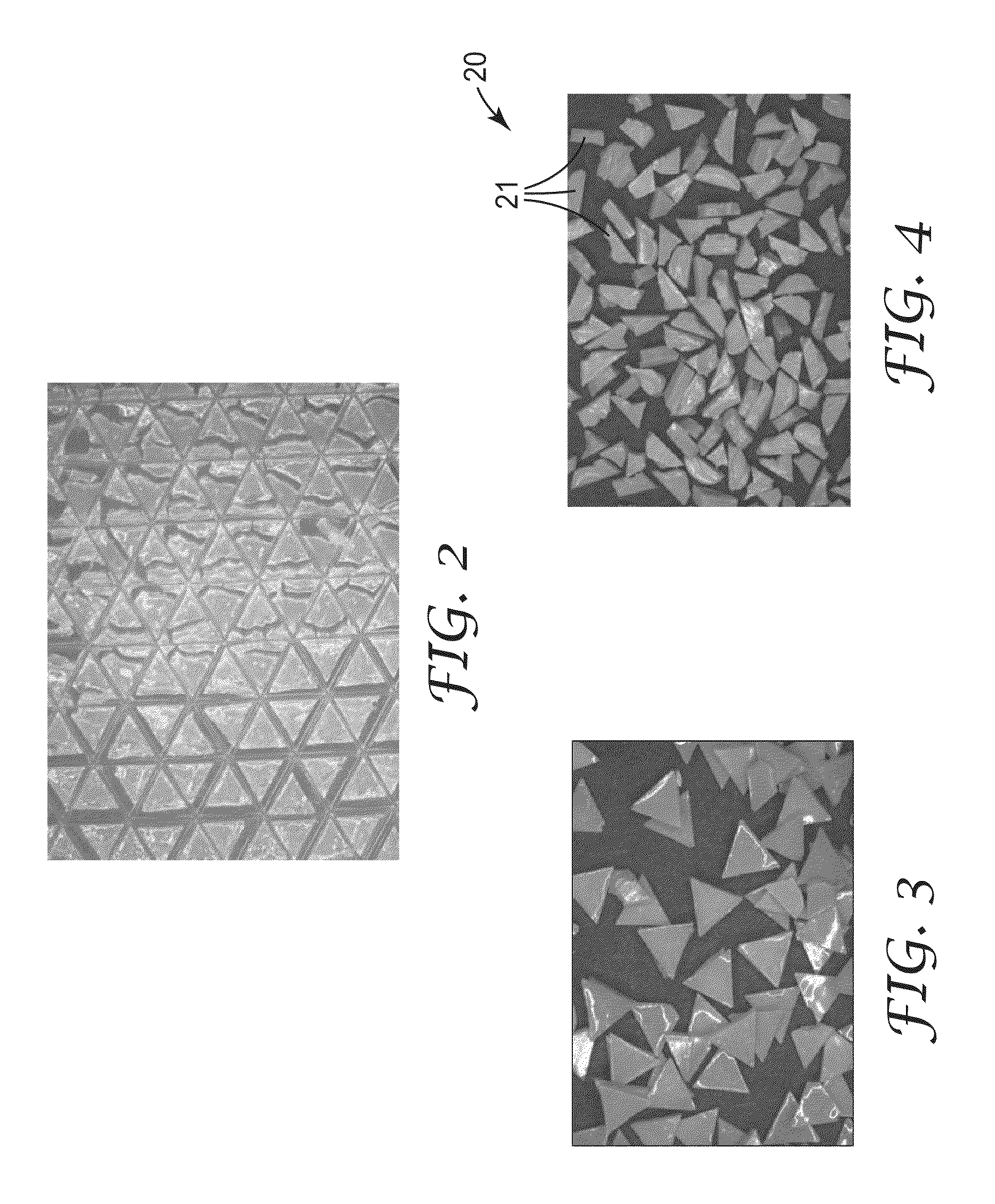

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

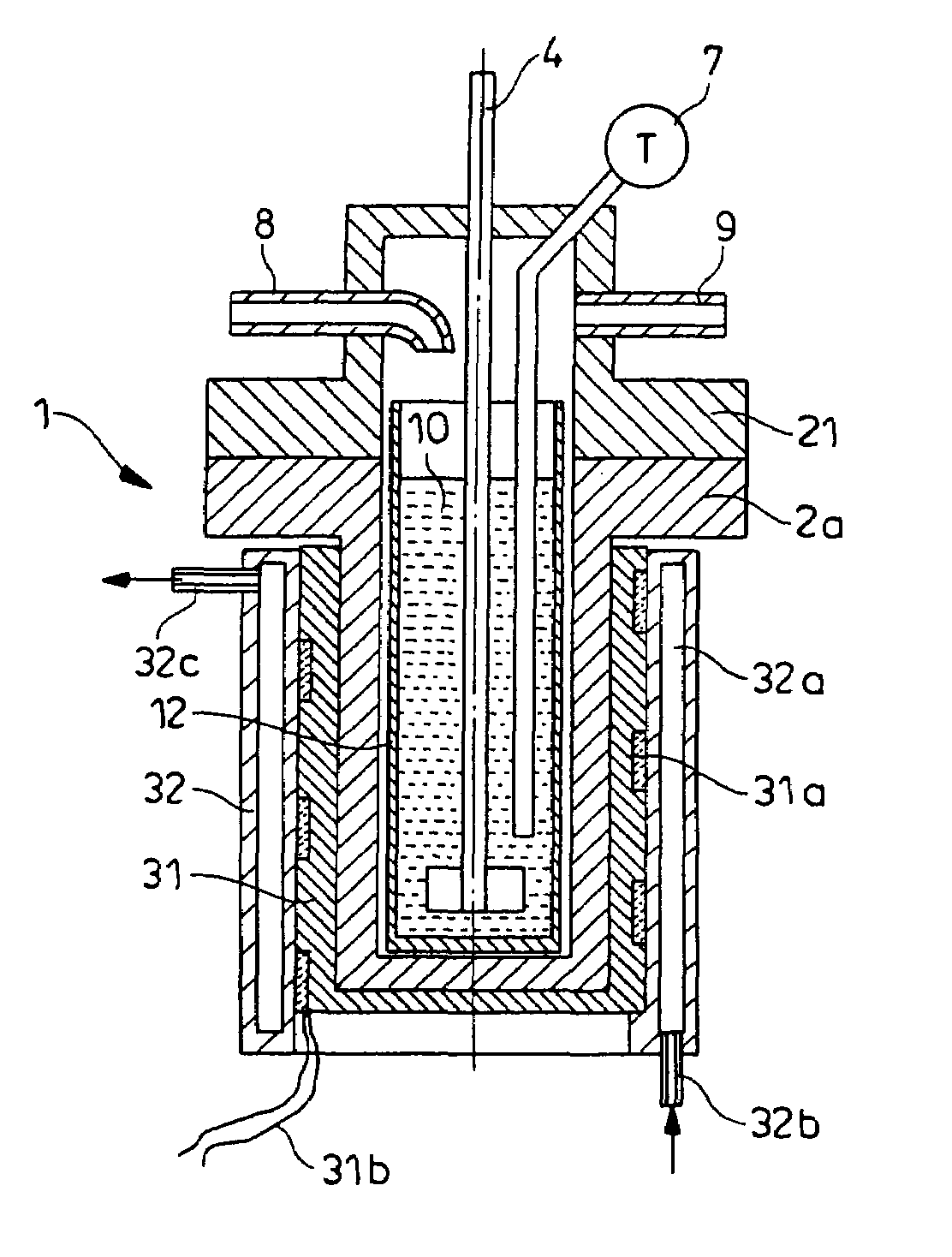

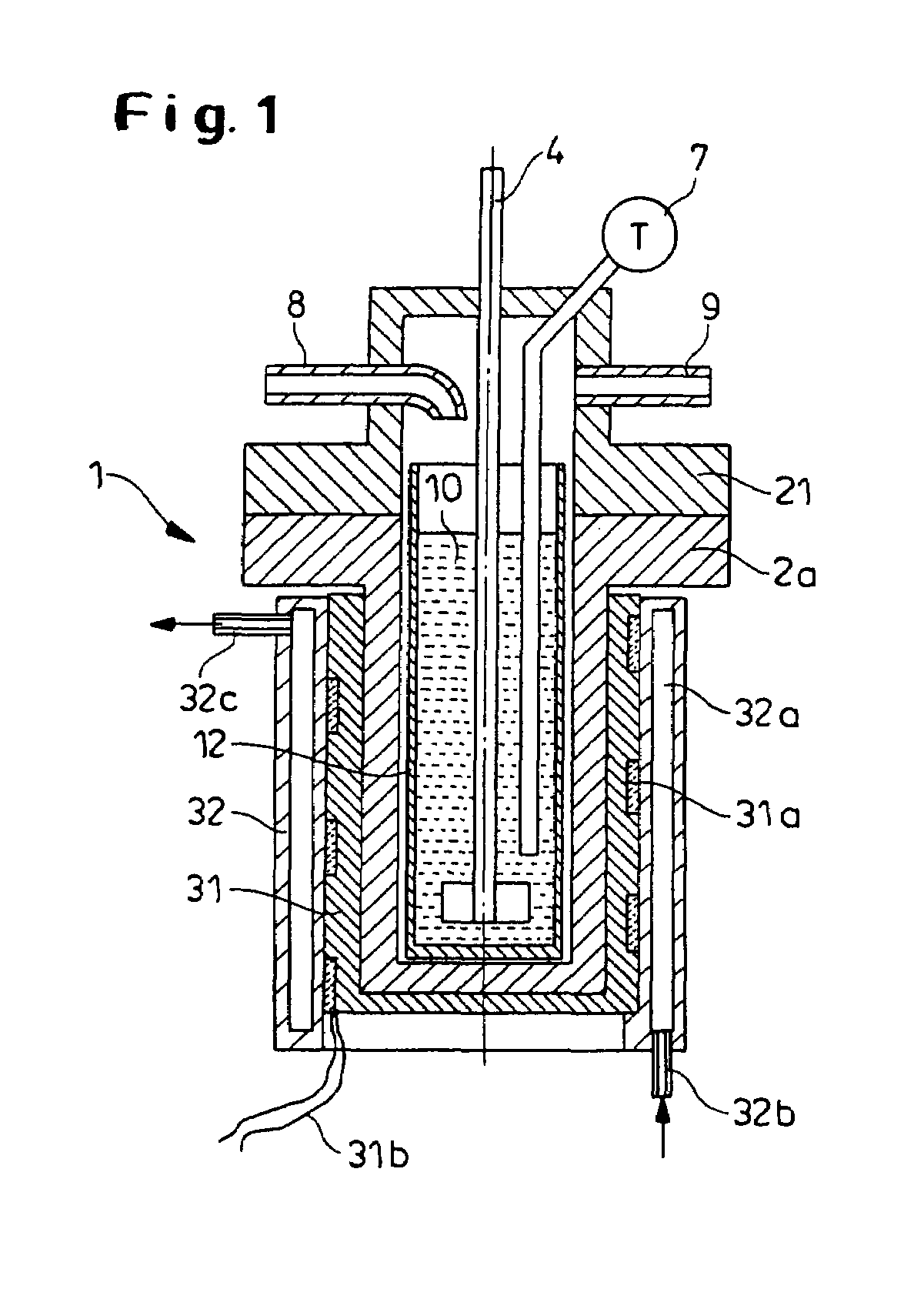

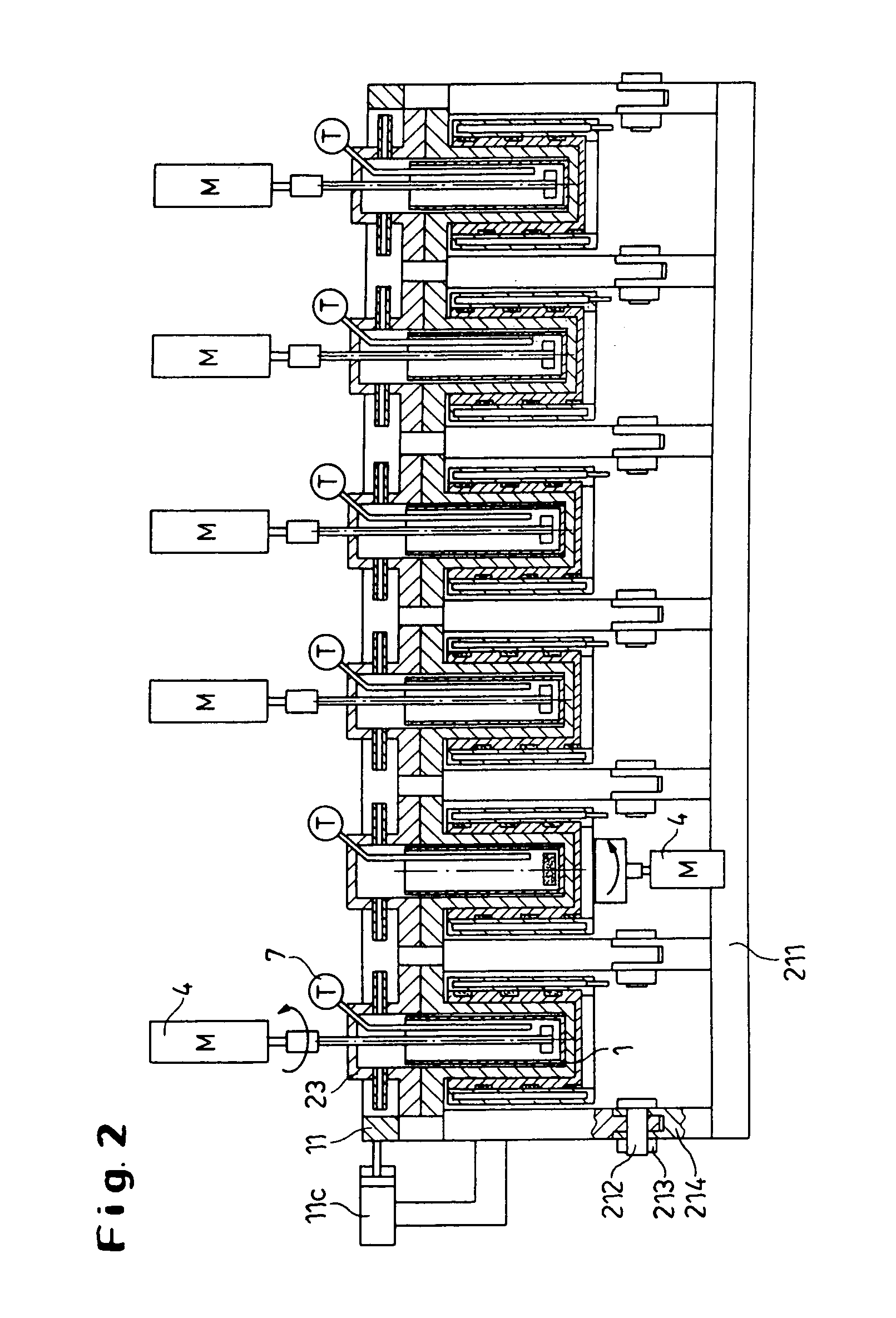

Device and method for carrying out experiments in parallel

InactiveUS7074364B2Better overviewOperational safety is highChemical analysis using catalysisSequential/parallel process reactionsEngineeringInstrumentation

Modular device and method for carrying out experiments in parallel on process substances to develop technical methods, comprising at least a multiplicity of individual reactors which are controllable independently of one another said reactors being comprised of pressure-tight chambers having separable sample vessels, and optionally, stirring devices, heating instruments, cooling instruments, or both, a monitoring unit for monitoring or controlling at least the pressure and the temperature in the individual reactors, pressure-tight lids having independent feed lines and optionally independent discharge lines for individual process substances; a plurality of the lids being simultaneously sealable upon the rectors by a common sealing means (11).

Owner:BAYER AG

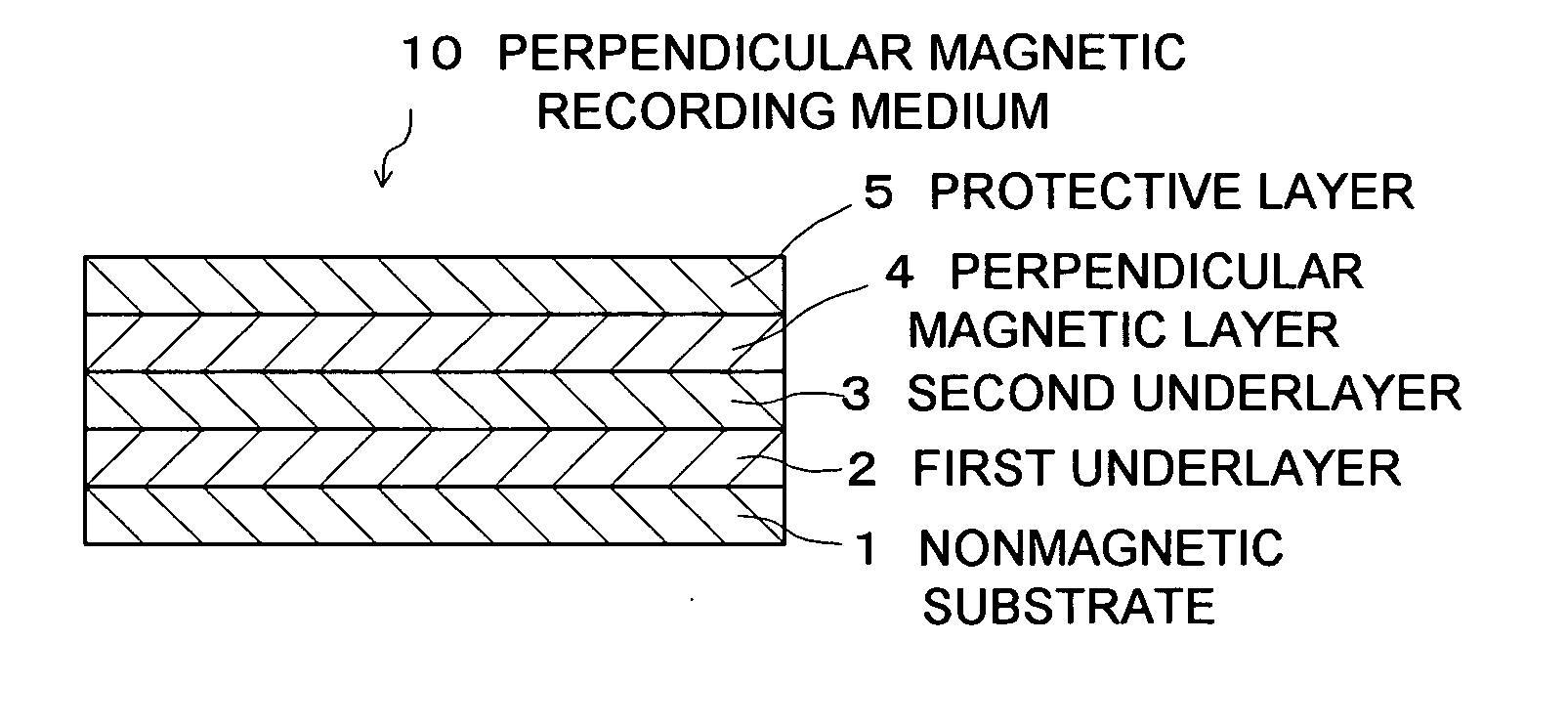

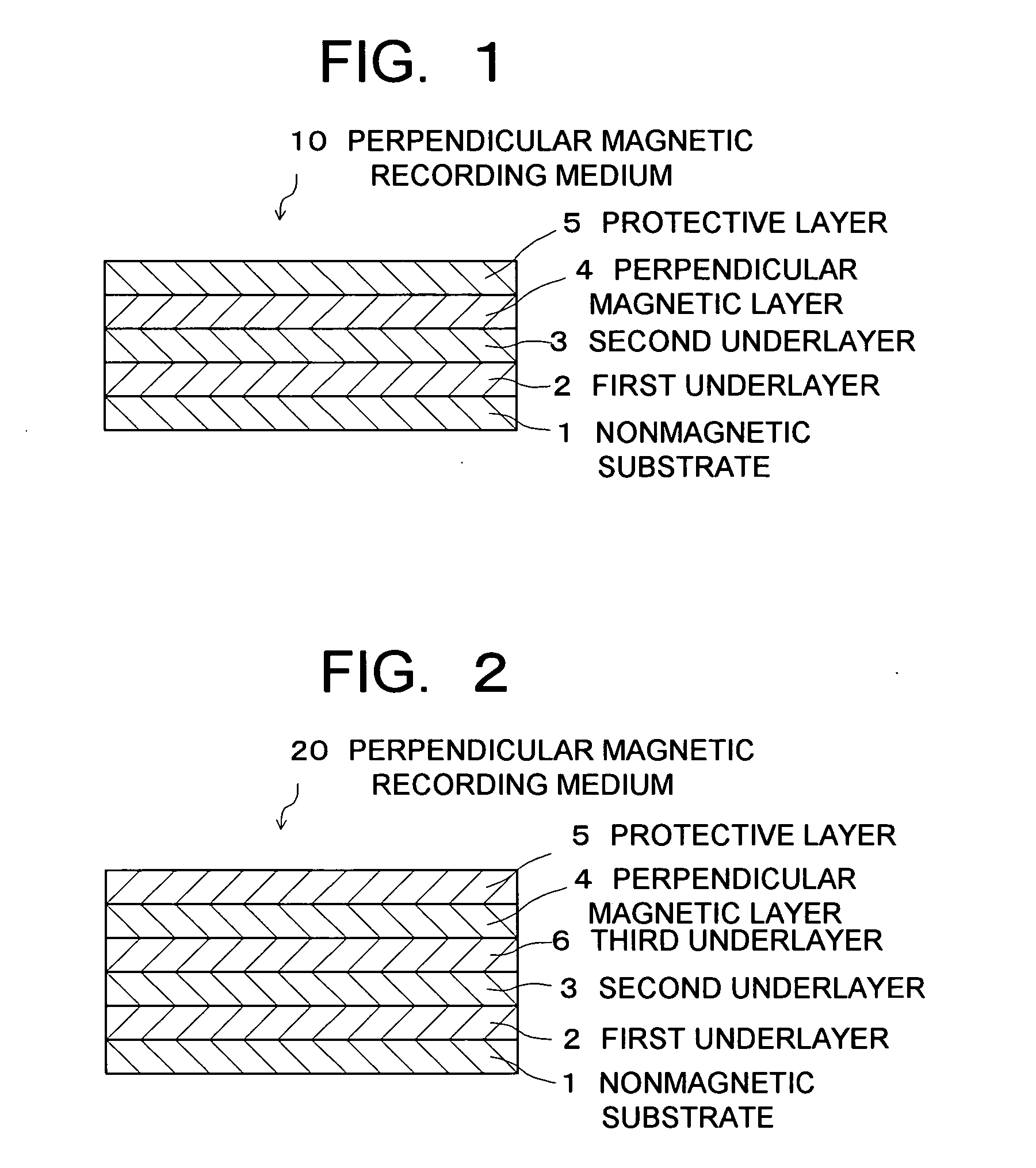

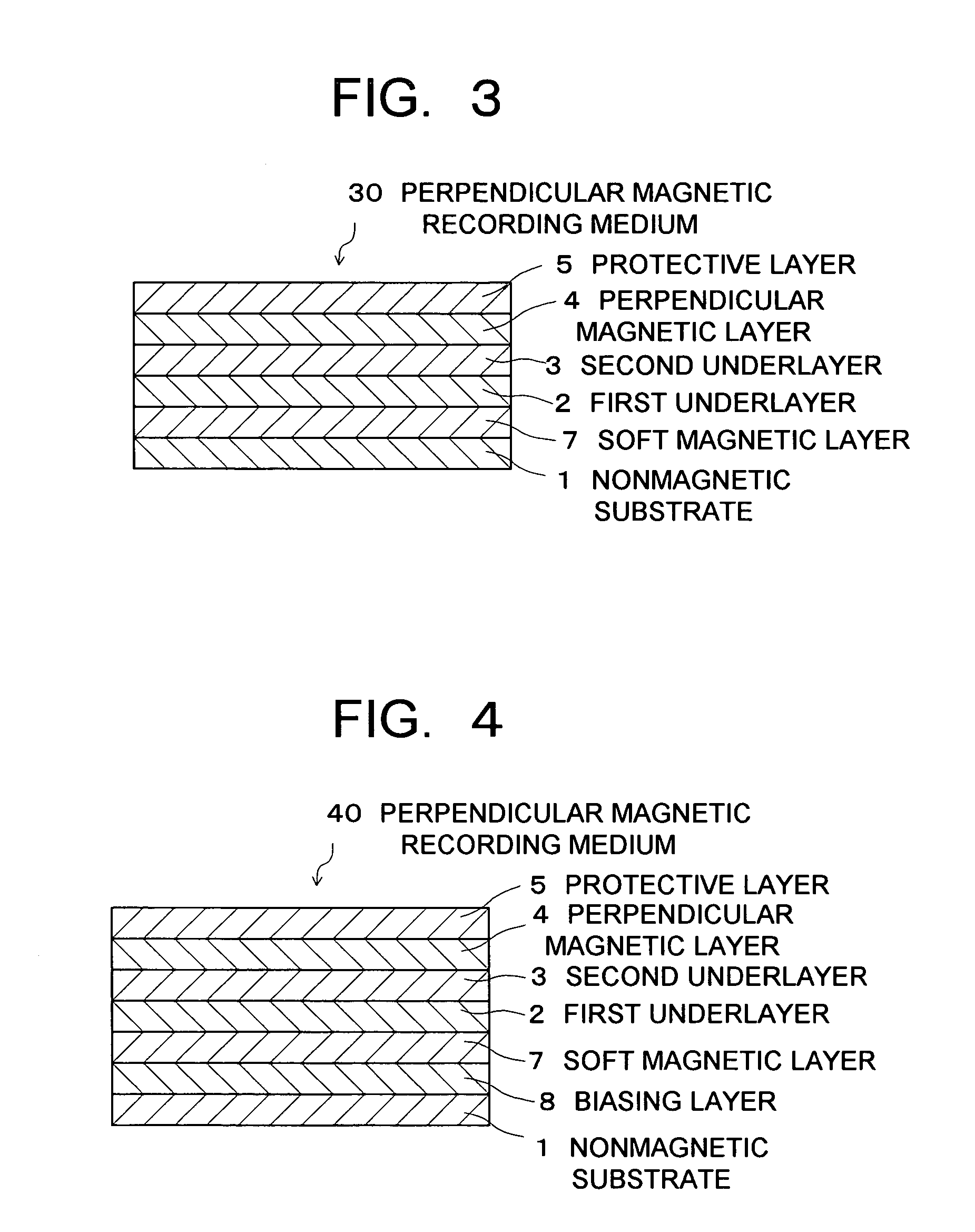

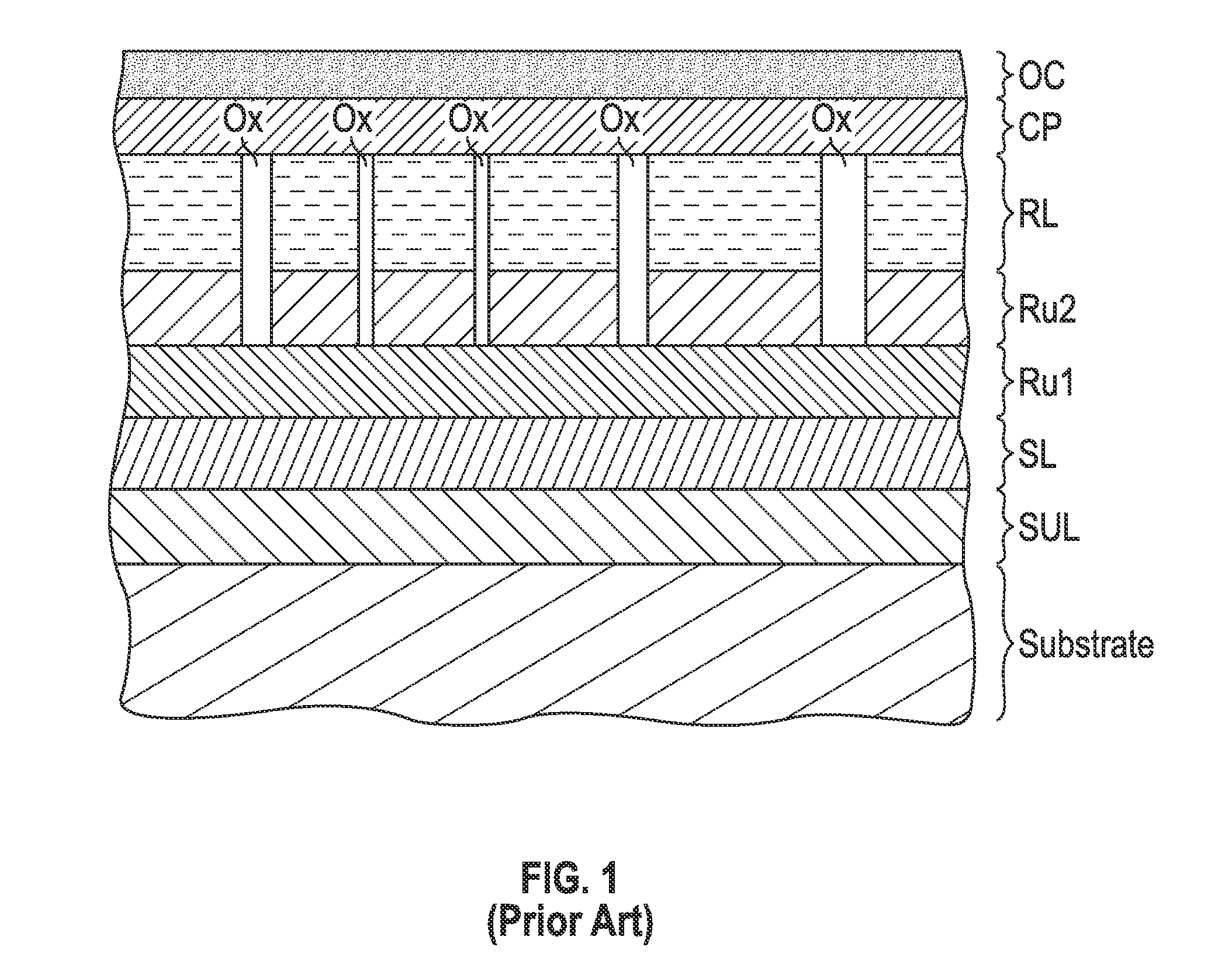

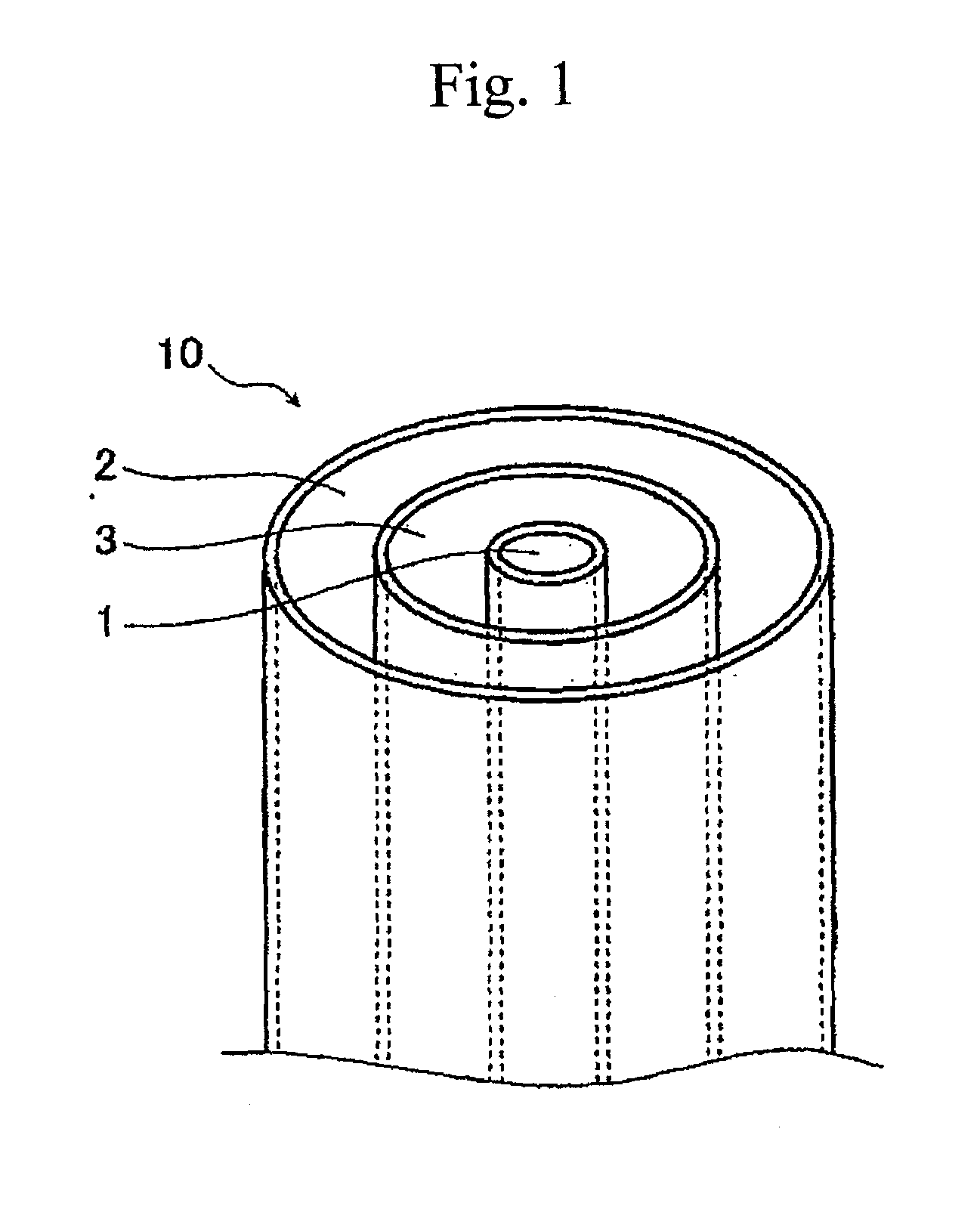

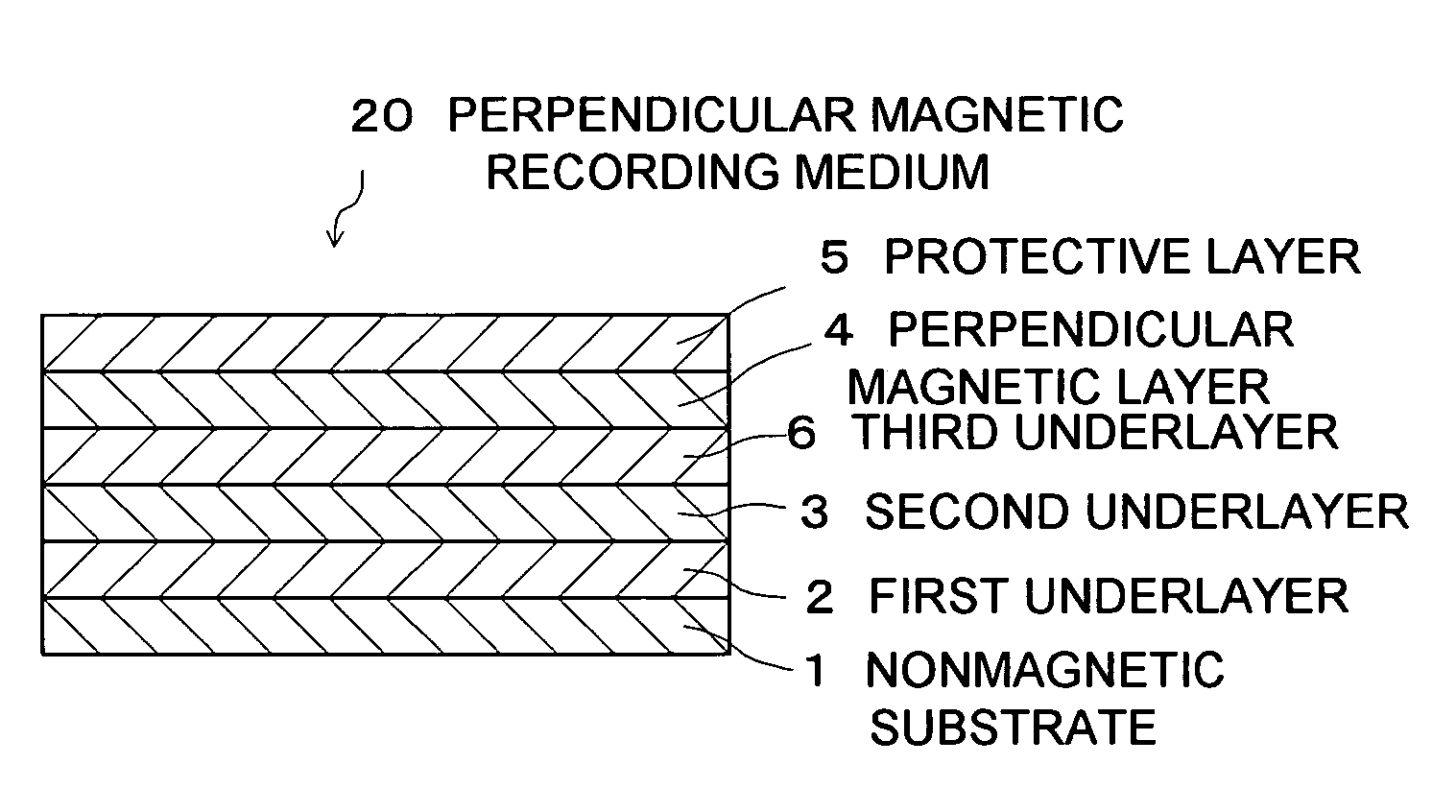

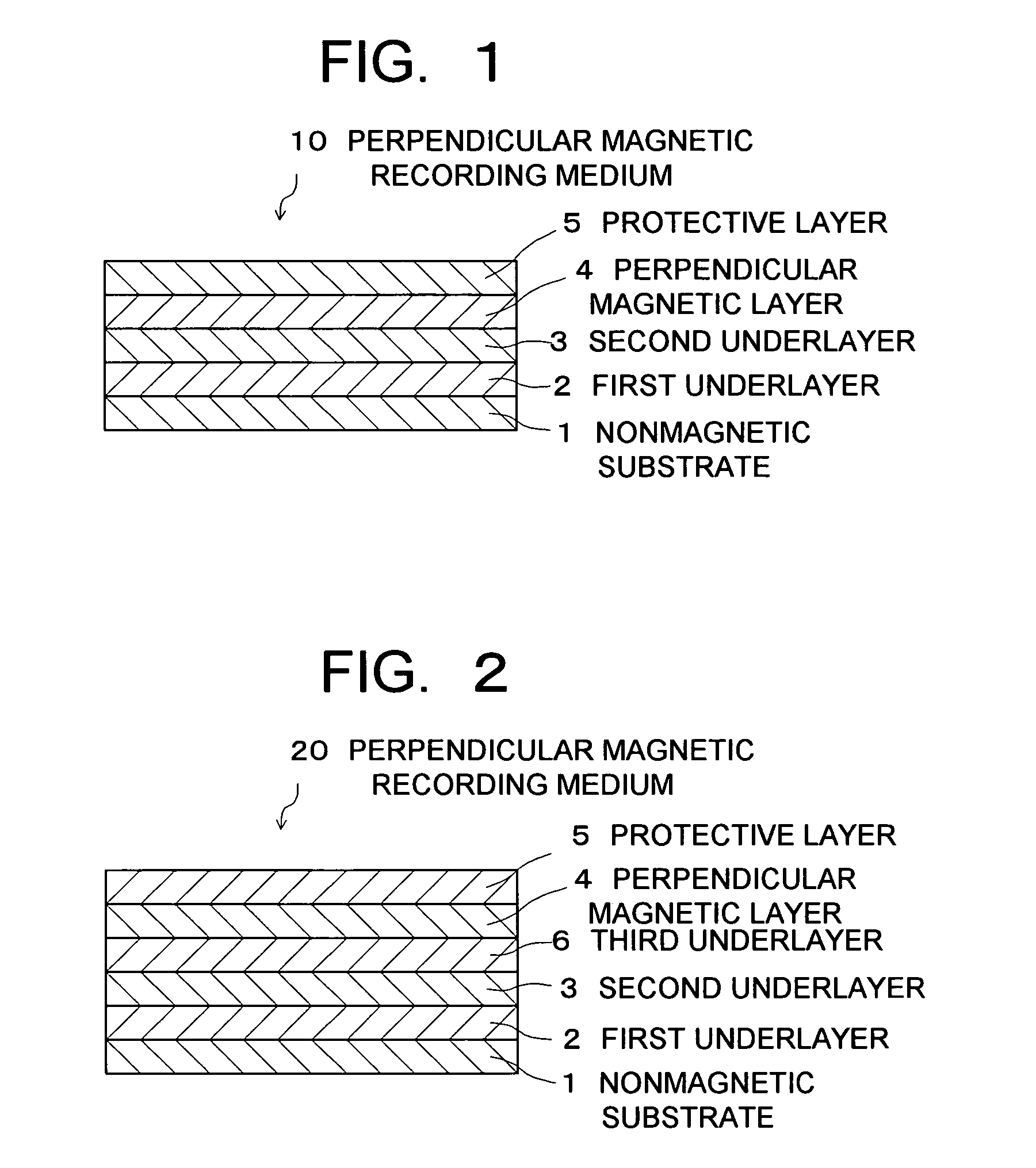

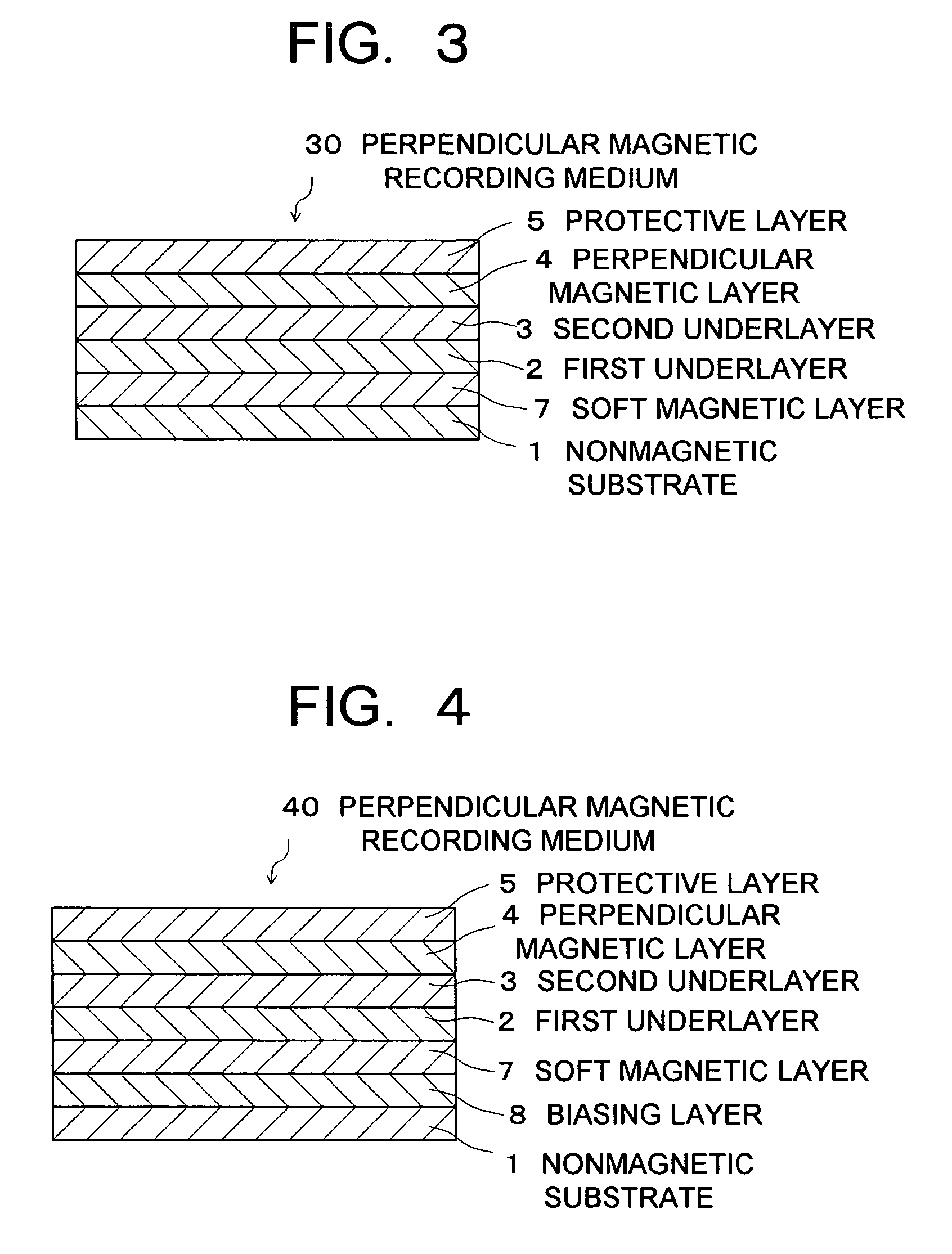

Perpendicular magnetic recording medium and magnetic recording/reproducing apparatus

InactiveUS20050214588A1Small grain distributionHigh crystallinityBase layers for recording layersRecord information storageGrain boundaryMaterials science

Disclosed is a perpendicular magnetic recording medium including: a nonmagnetic substrate; a first underlayer formed on the nonmagnetic substrate, mainly composed of at least two kinds selected from a group consisting of Fe2O3, CO3O4, MgO, MoO3, Mn3O4, SiO2, Al2O3, TiO2, and ZrO2, and having crystal grains growing in a columnar shape and crystal grain boundaries surrounding the crystal grains; a nonmagnetic second underlayer formed on the first underlayer and having crystal grains with one of a face-centered cubic structure and a hexagonal close-packed structure growing on the crystal grains of the first underlayer; a magnetic layer formed on the second underlayer; and a protective film formed on the magnetic layer.

Owner:KK TOSHIBA

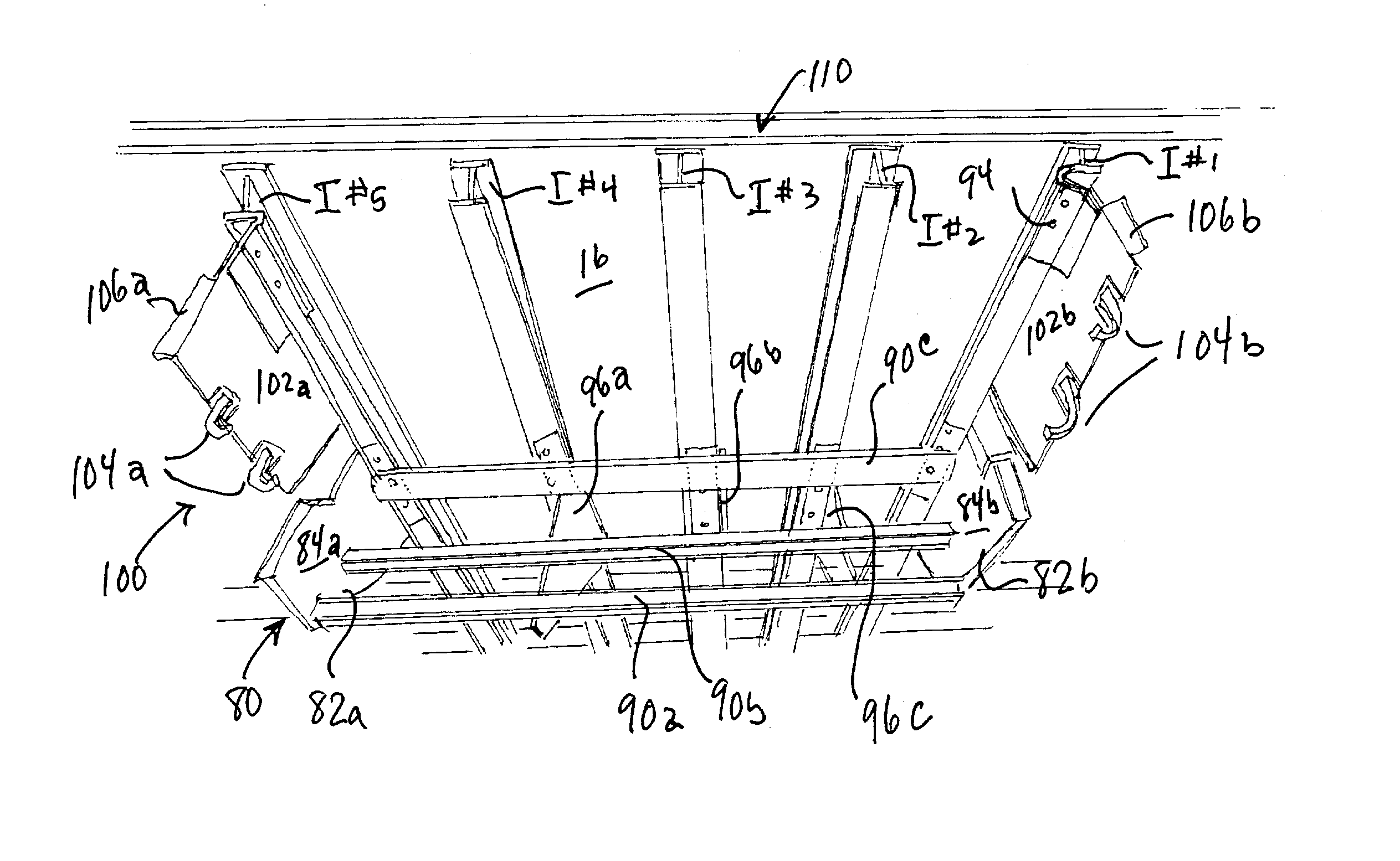

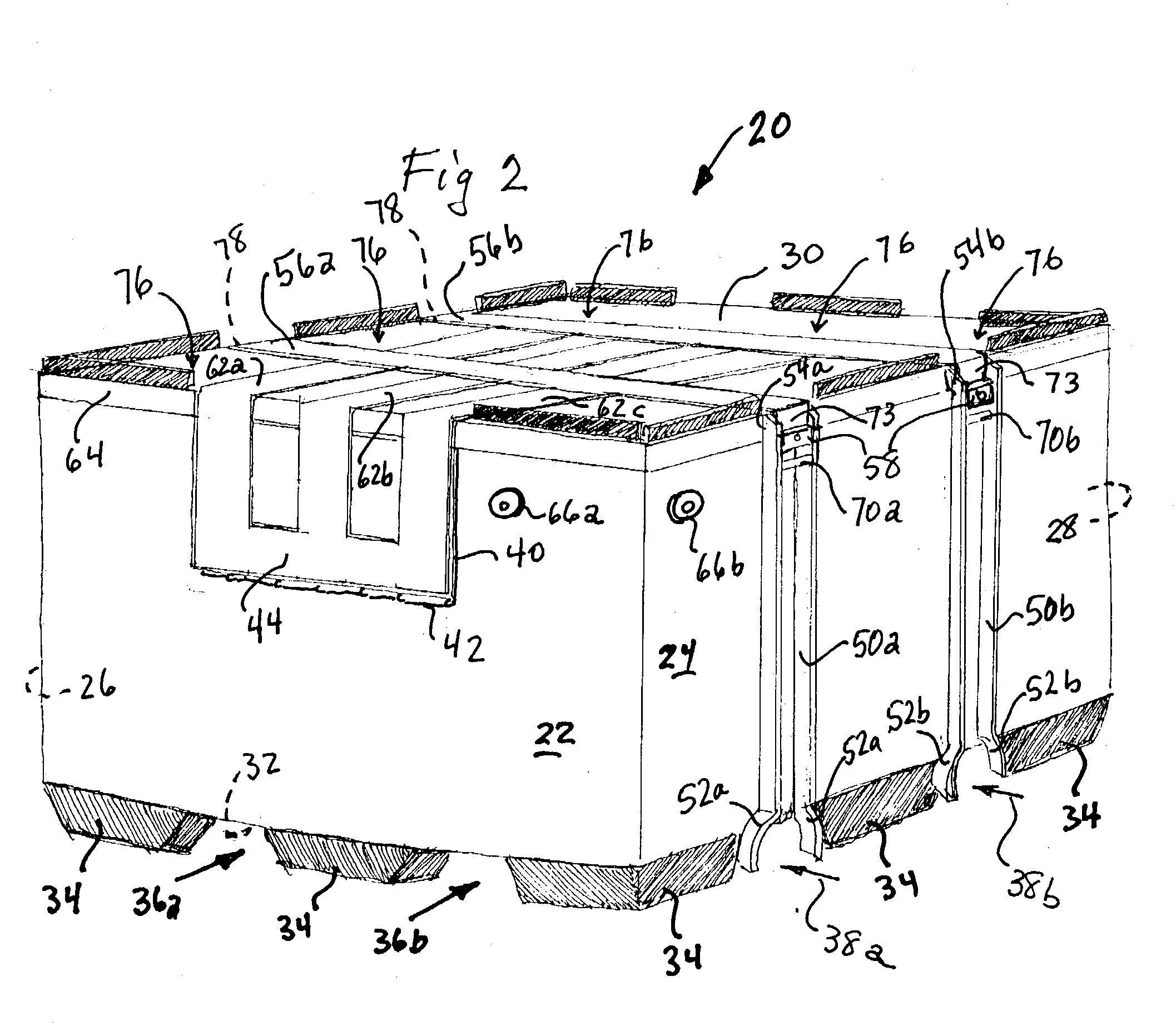

Private pallet-box cargo shipping system

InactiveUS20030123965A1Improve utilizationImprove stacking strengthTractor-trailer combinationsHand carts with one axisEngineeringSemi-trailer

A cargo transportation system comprising secure (fully closeable and lockable), sealable, stackable, trackable, universal, auto-latching "pallet boxes" that may be used in two main ways: 1) secured to the undercarriage transverse I-beams of over-the-road semi-trailers by means of loading alignment and hanger assemblies that provide positive locking-in-place; and 2) stackable, up to three or more high, inside the trailer bodies. The inventive pallet boxes are designed to be secured by auto-latching hanger assemblies that are retrofittable on individual types of semi-trailer undercarriages, both US and metric (European, Central and South American, and Asian) standard dimensions. The pallet boxes include vertical sidewall load-bearing channel members permitting stacking fully-loaded pallet boxes three or more high. The pallet boxes may be refrigerated, insulated, or atmospherically controlled, e.g., chargeable with preservative, security or disinfecting gases, during shipping.

Owner:VERDASEE SOLUTIONS +1

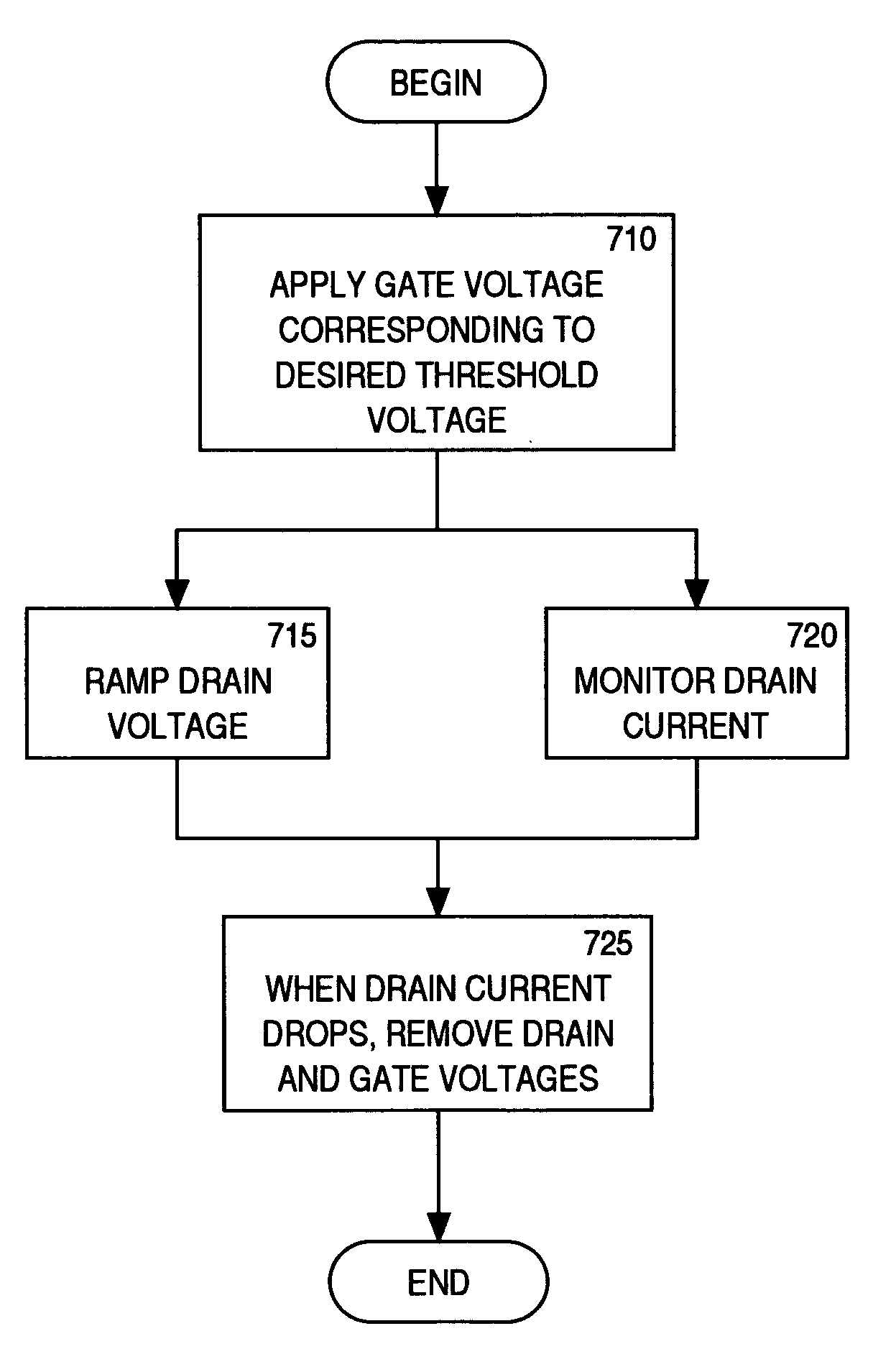

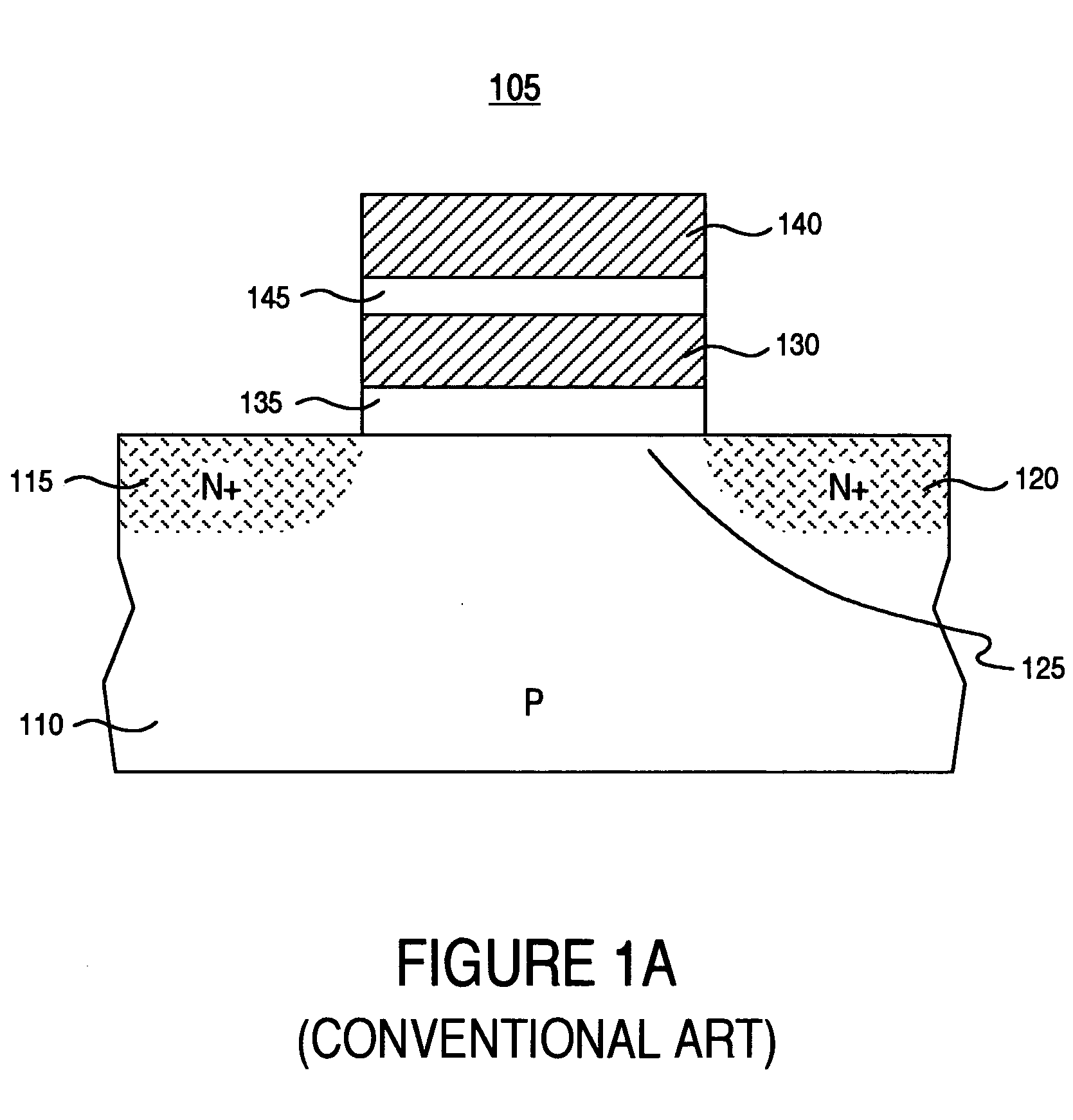

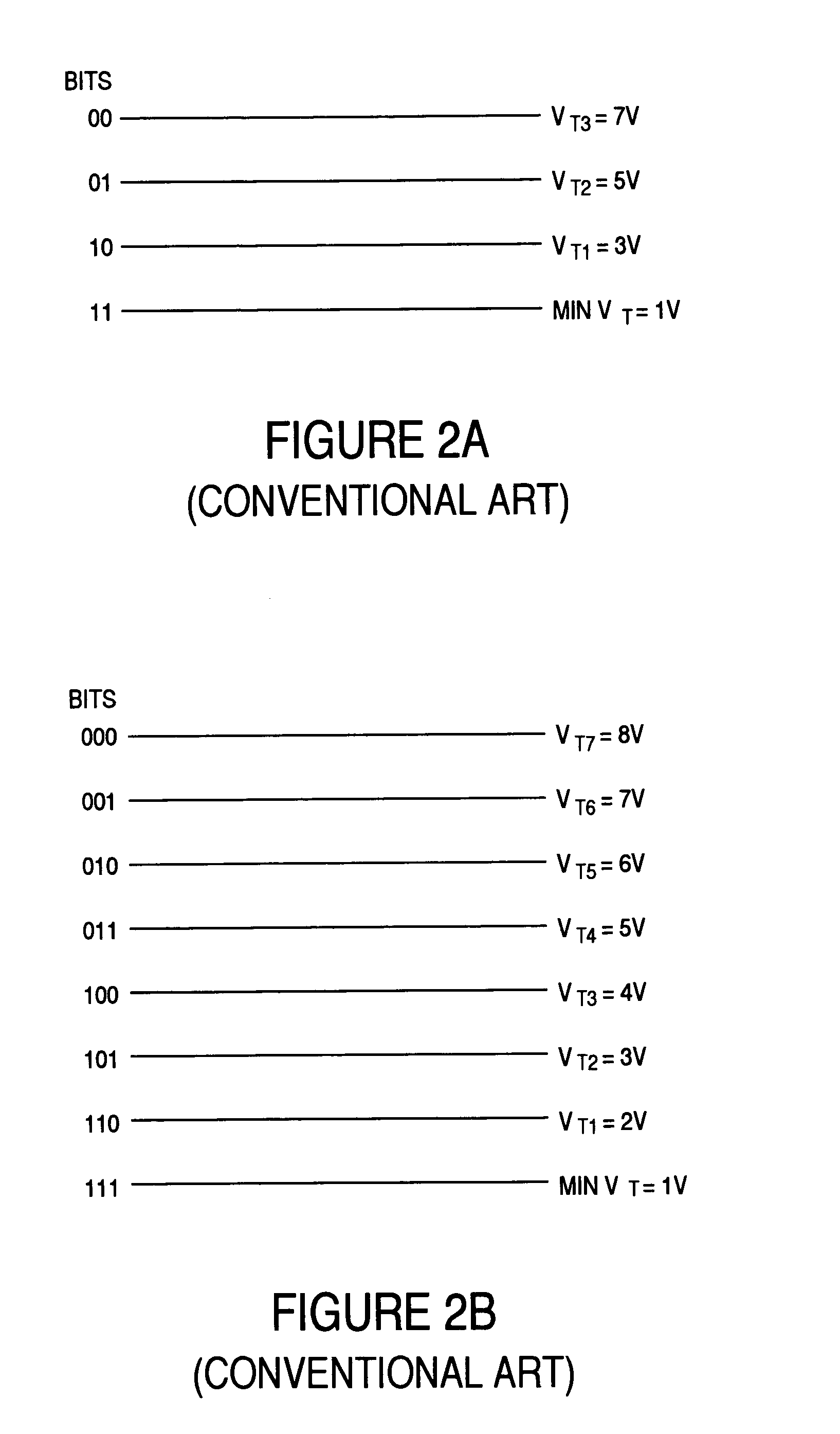

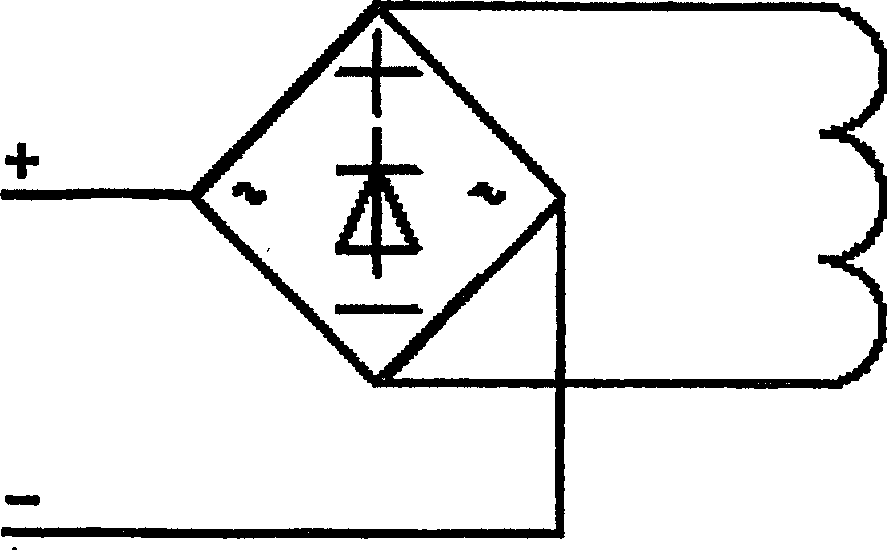

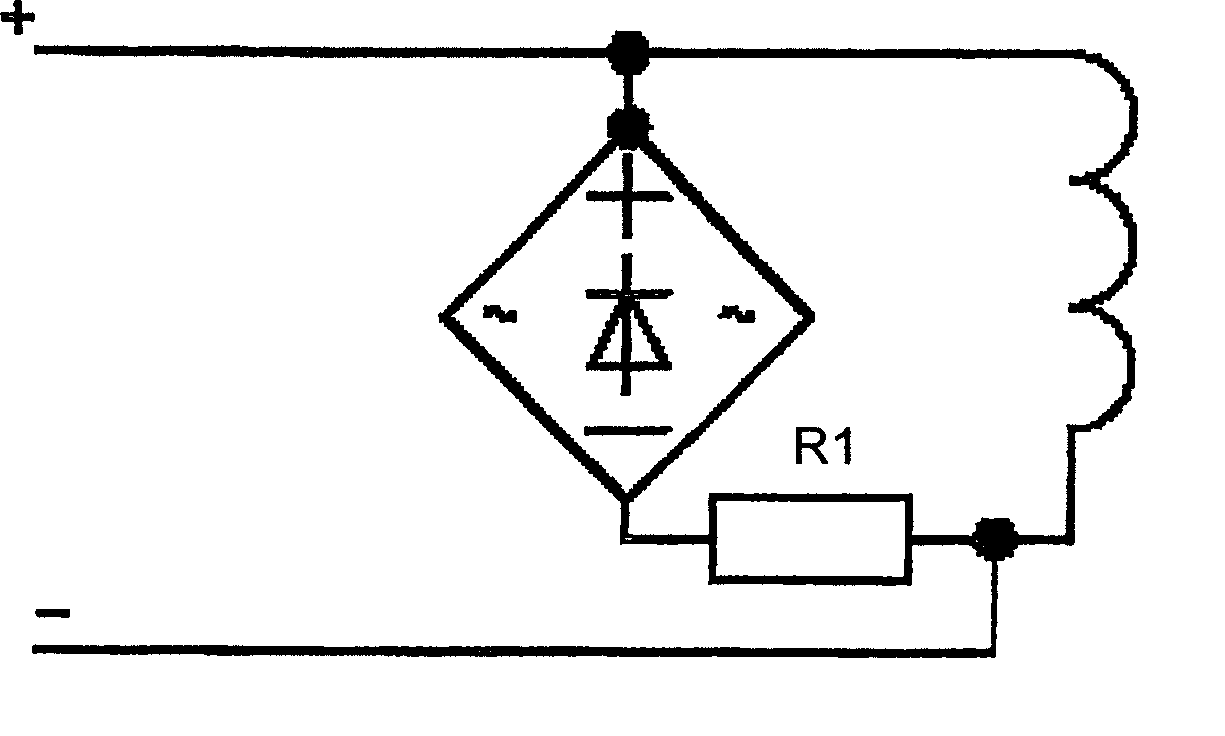

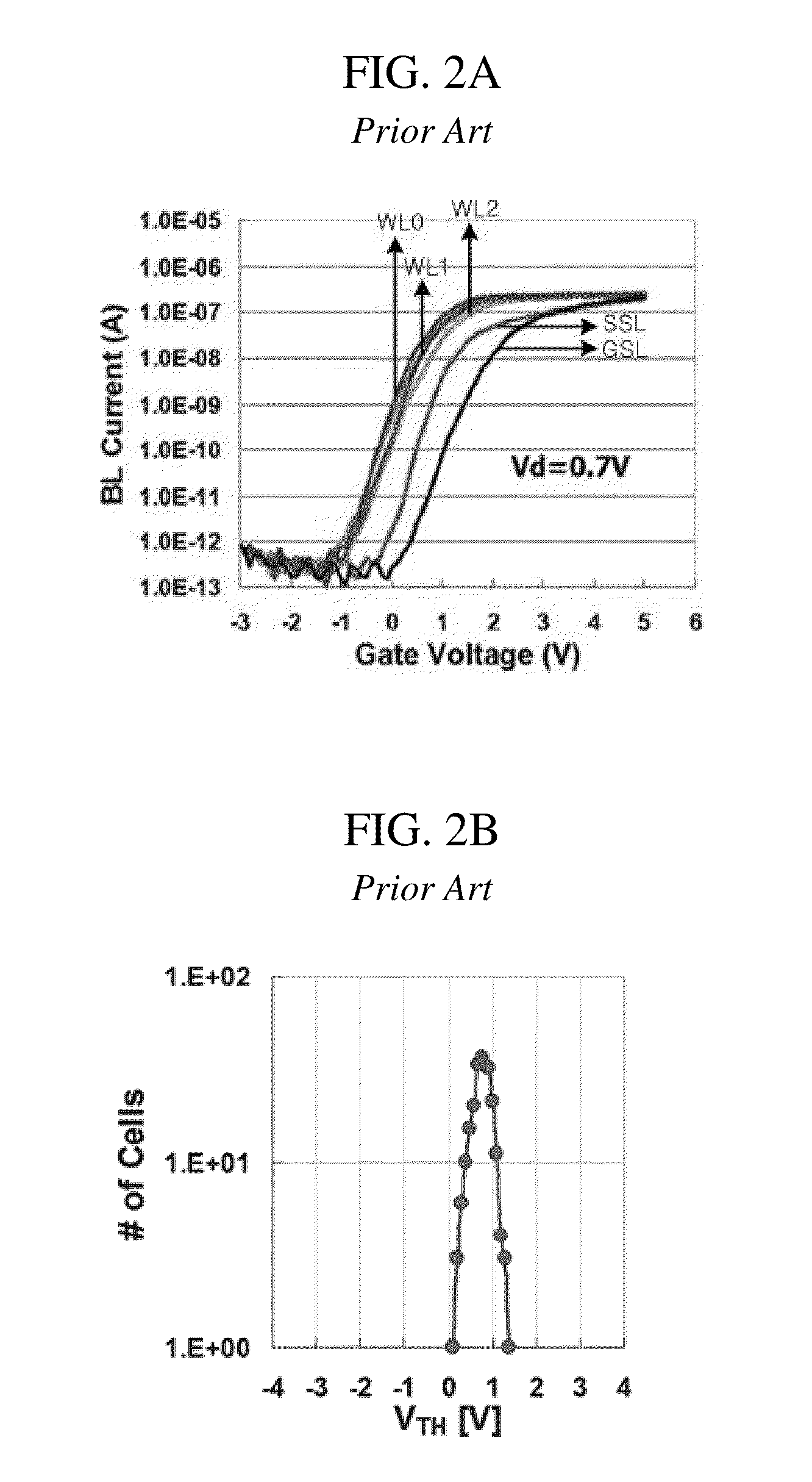

Programming of a flash memory cell

ActiveUS6937518B1Reduce programming timeIncrease reliabilityRead-only memoriesDigital storageVoltageEngineering

A method of programming a memory device comprises applying a first programming voltage to one of a plurality of wordlines, corresponding to a cell to be programmed. The first programming voltage is substantially equal to the desired threshold voltage. A second programming voltage is also applied to one of a plurality of bitlines, corresponding to the cell to be programmed. The second programming voltage gradually increases from a low level toward a high level. The first programming voltage and second programming voltage are removed when the corresponding bitline current begins to decrease.

Owner:MONTEREY RES LLC

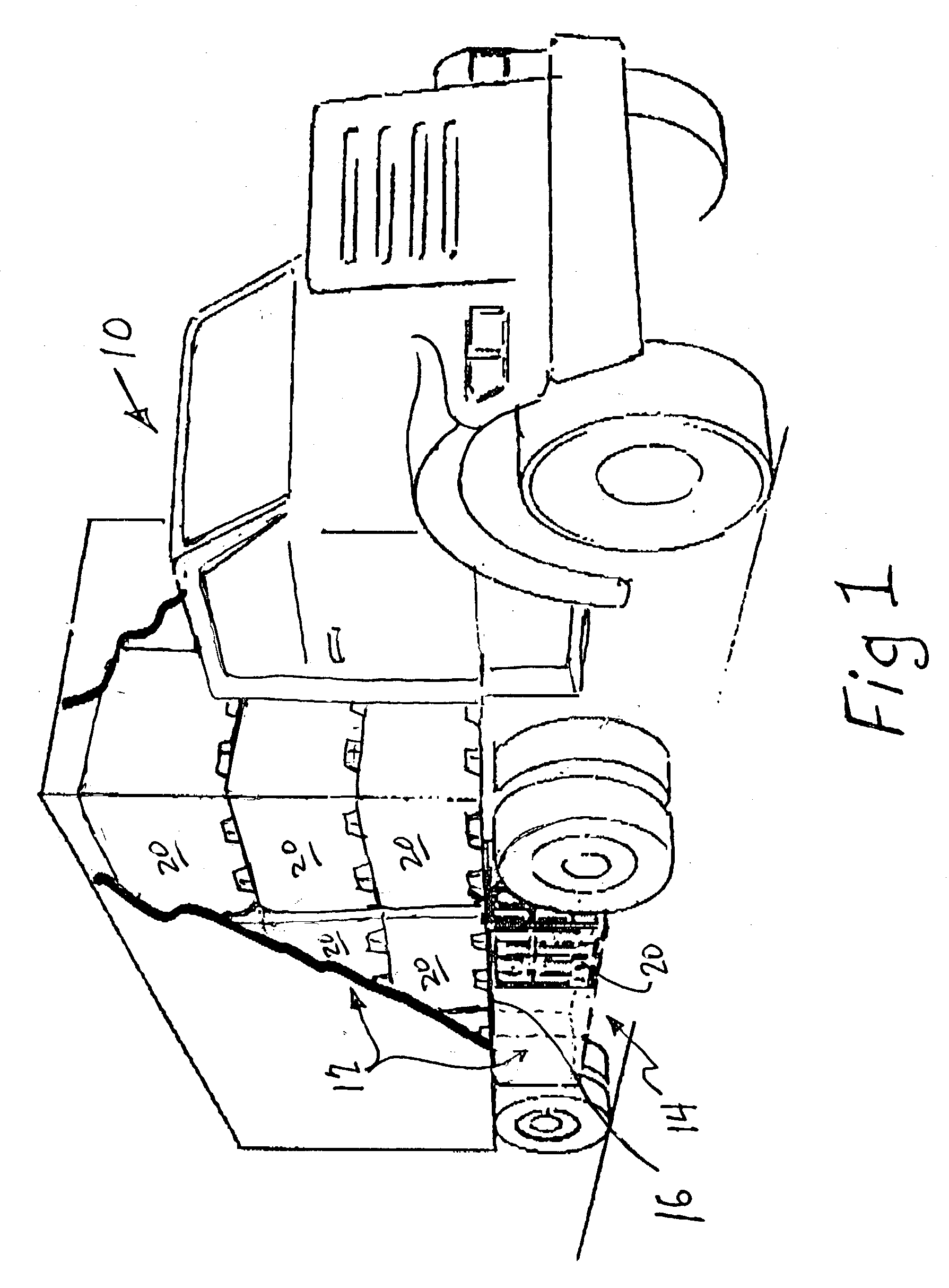

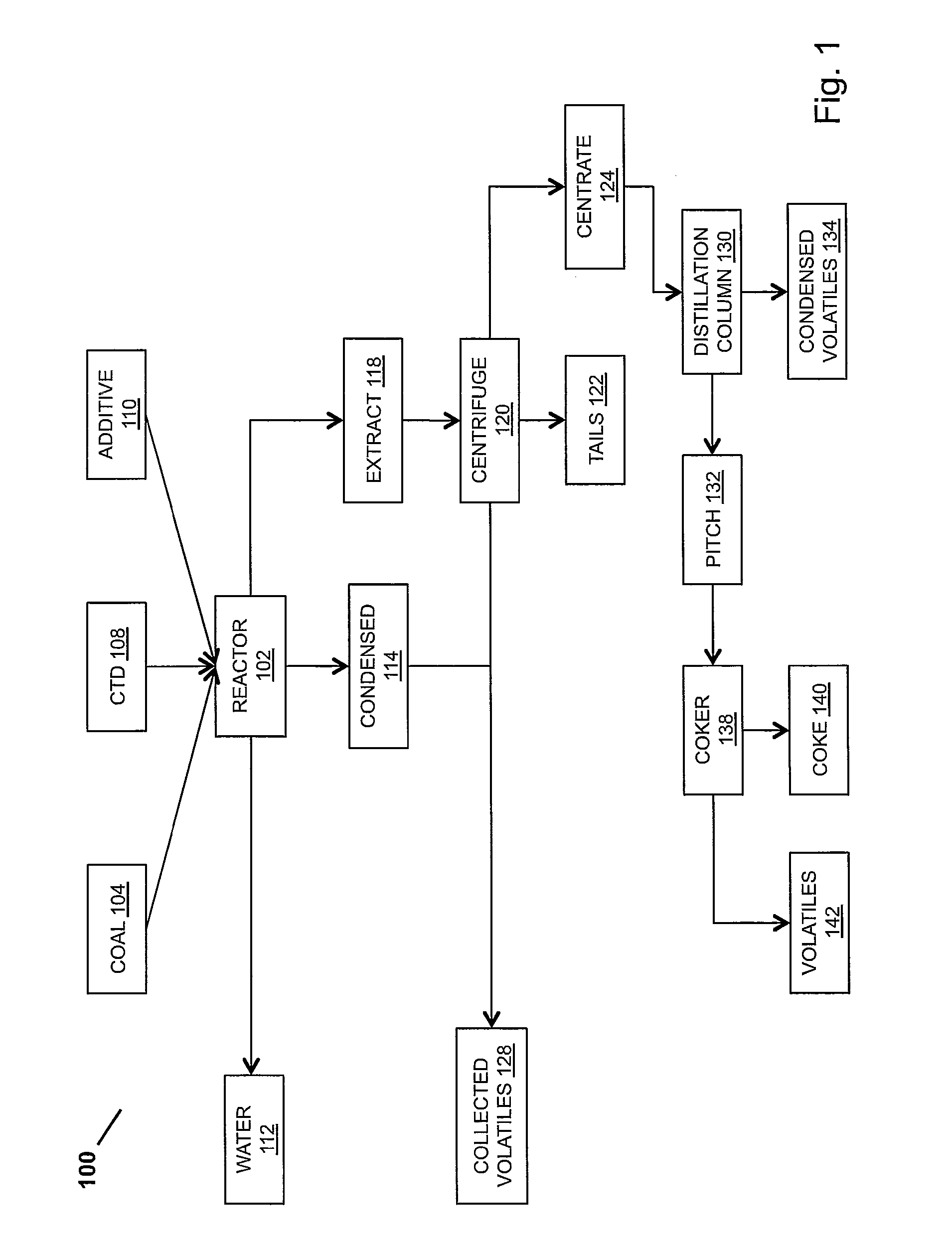

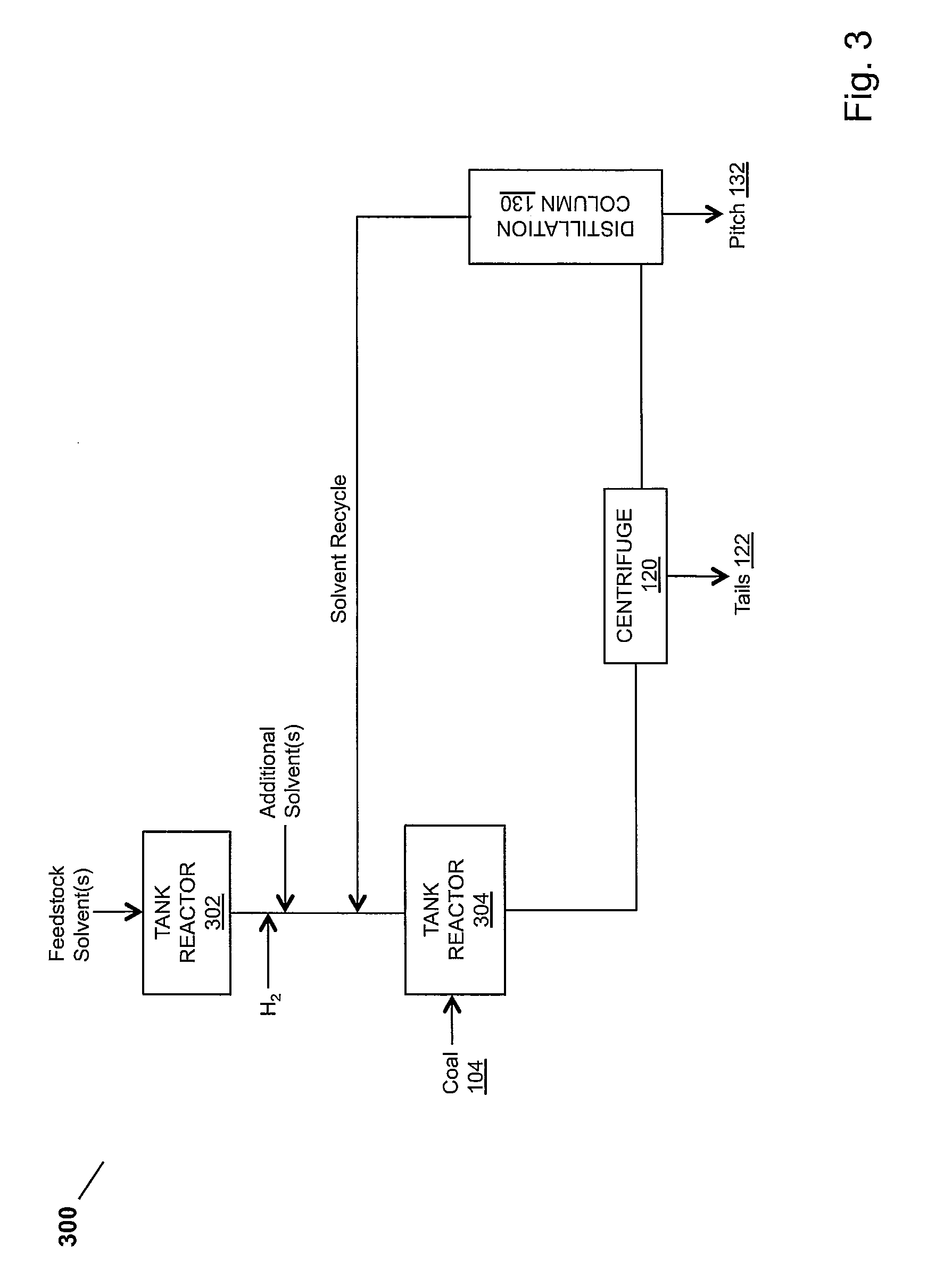

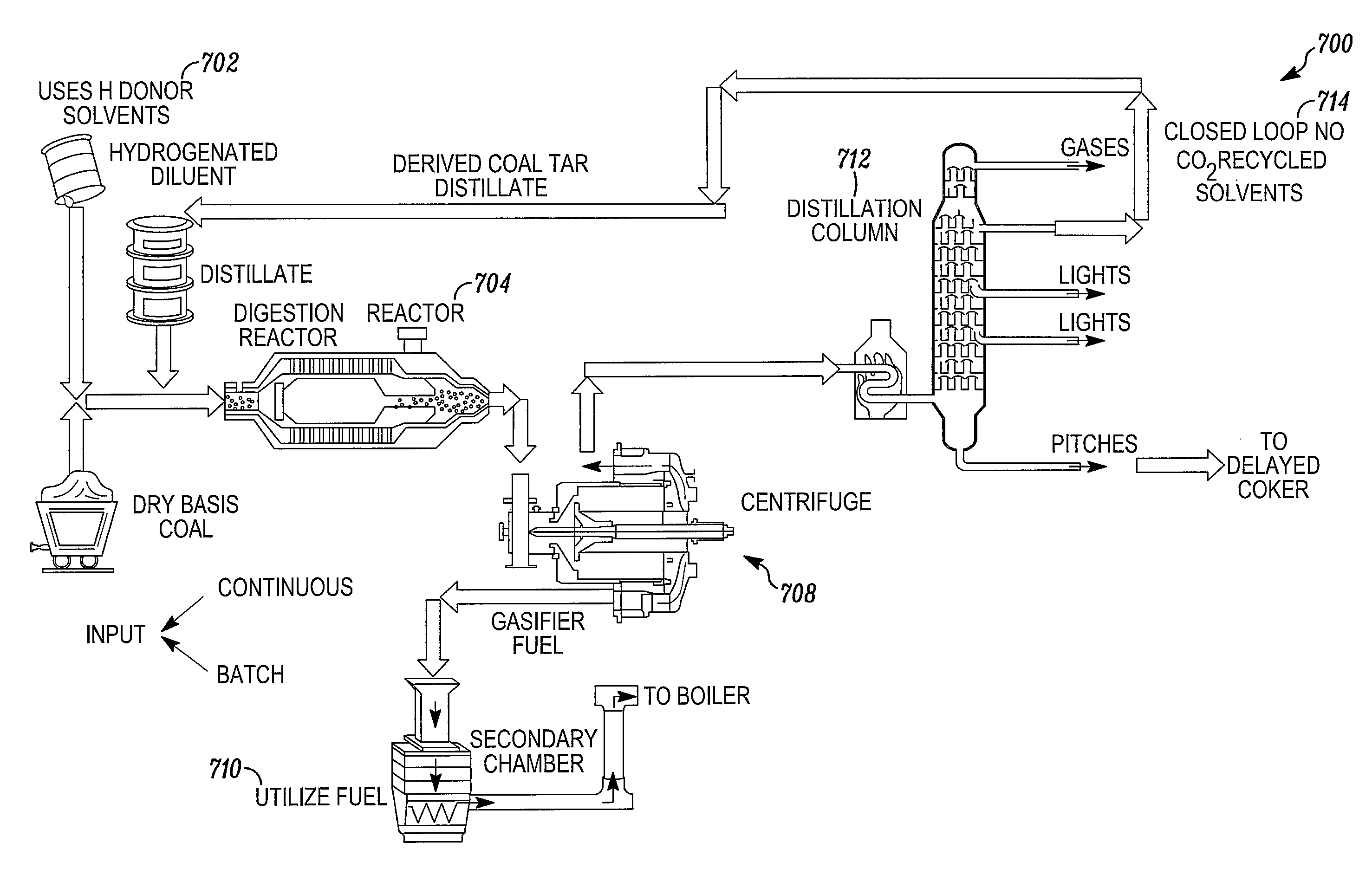

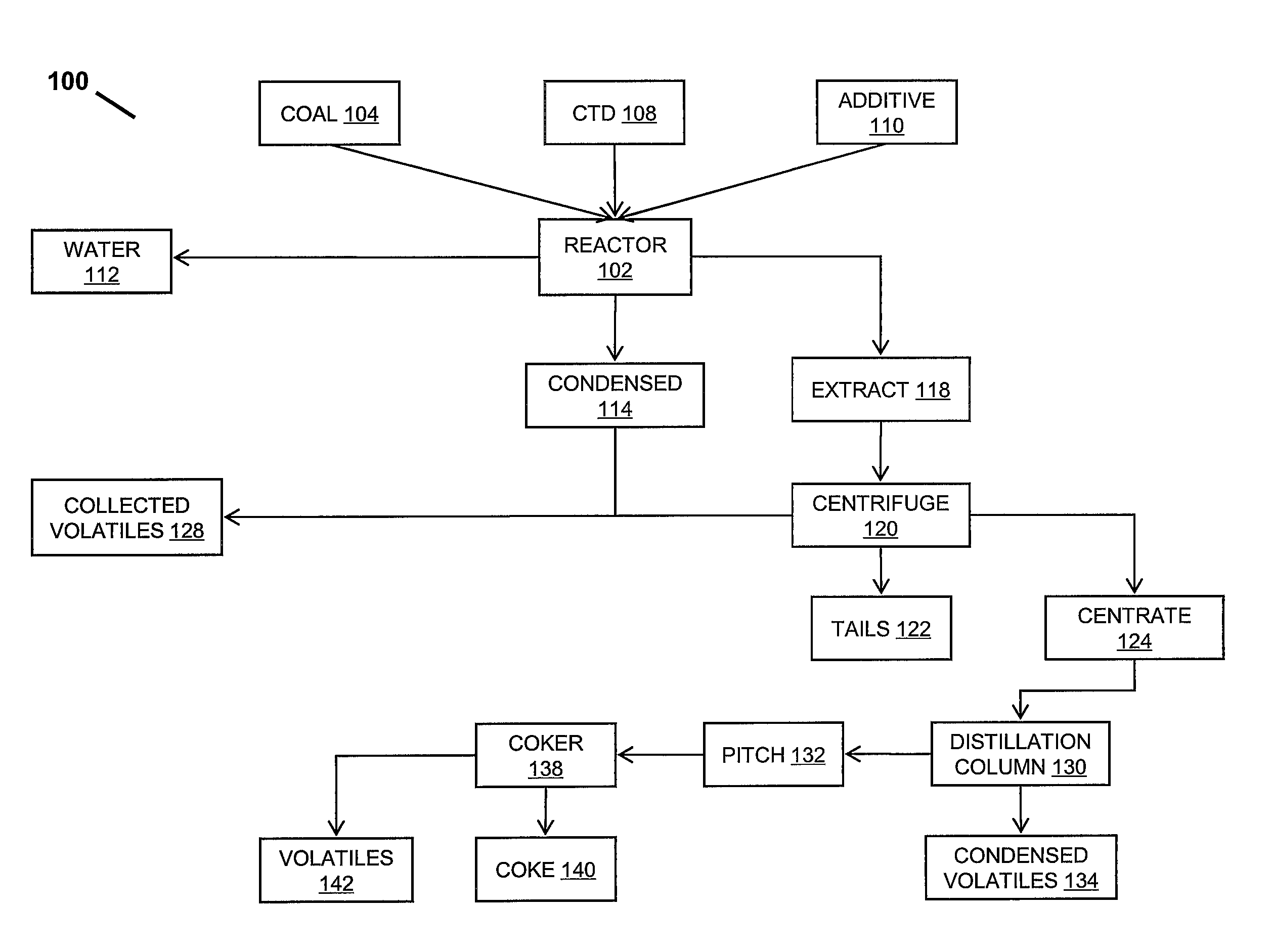

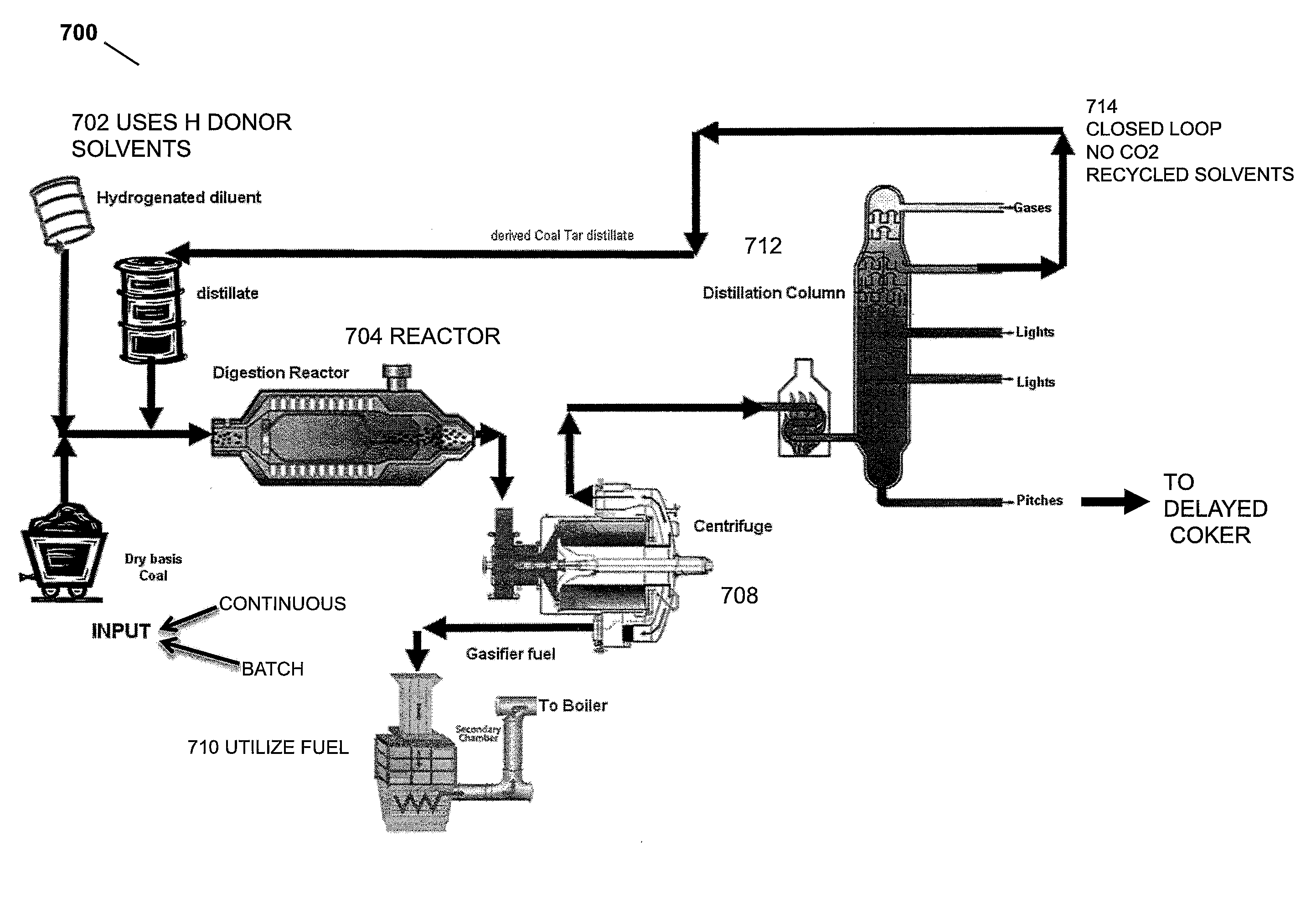

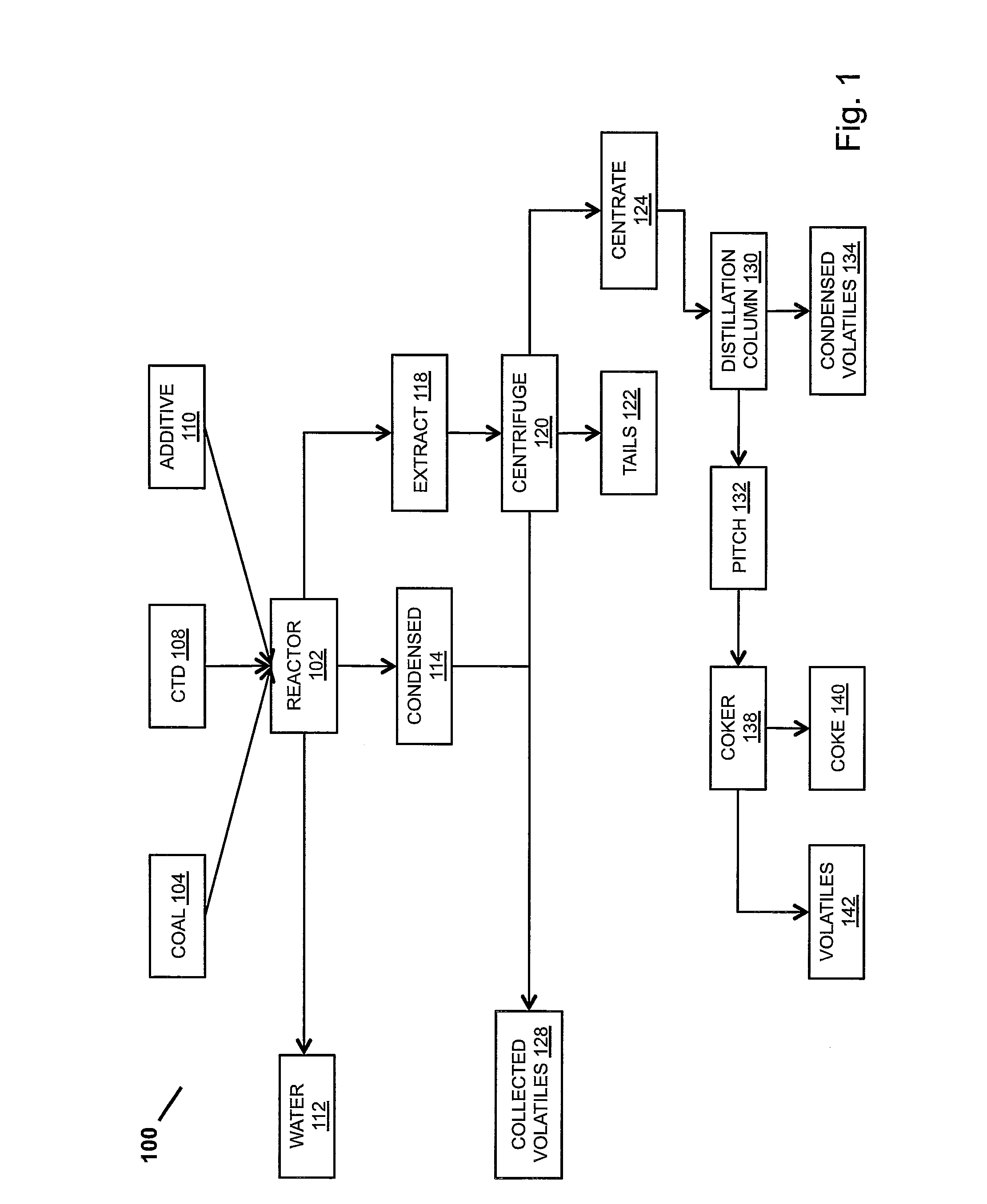

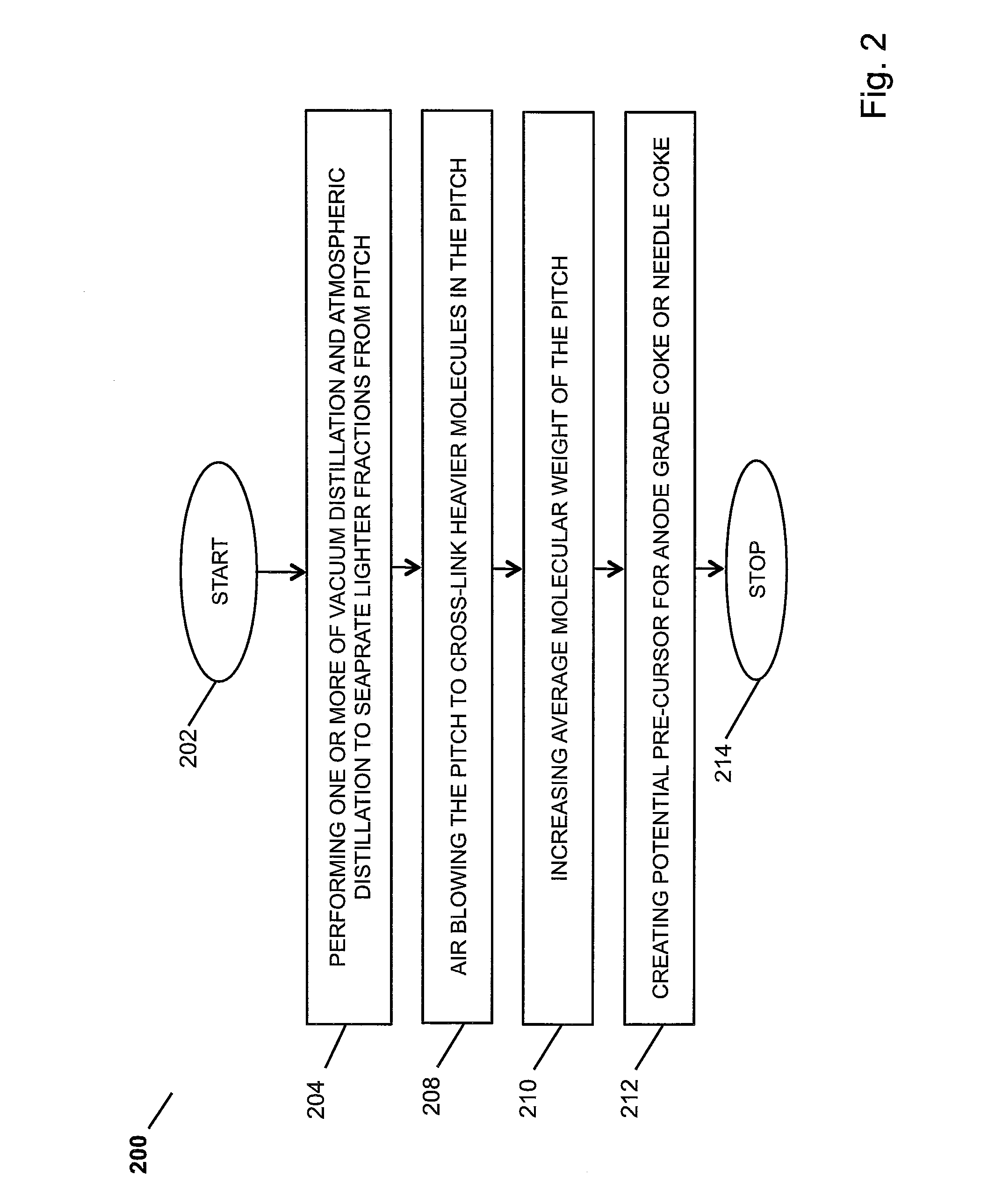

Modular Coal Liquefaction System

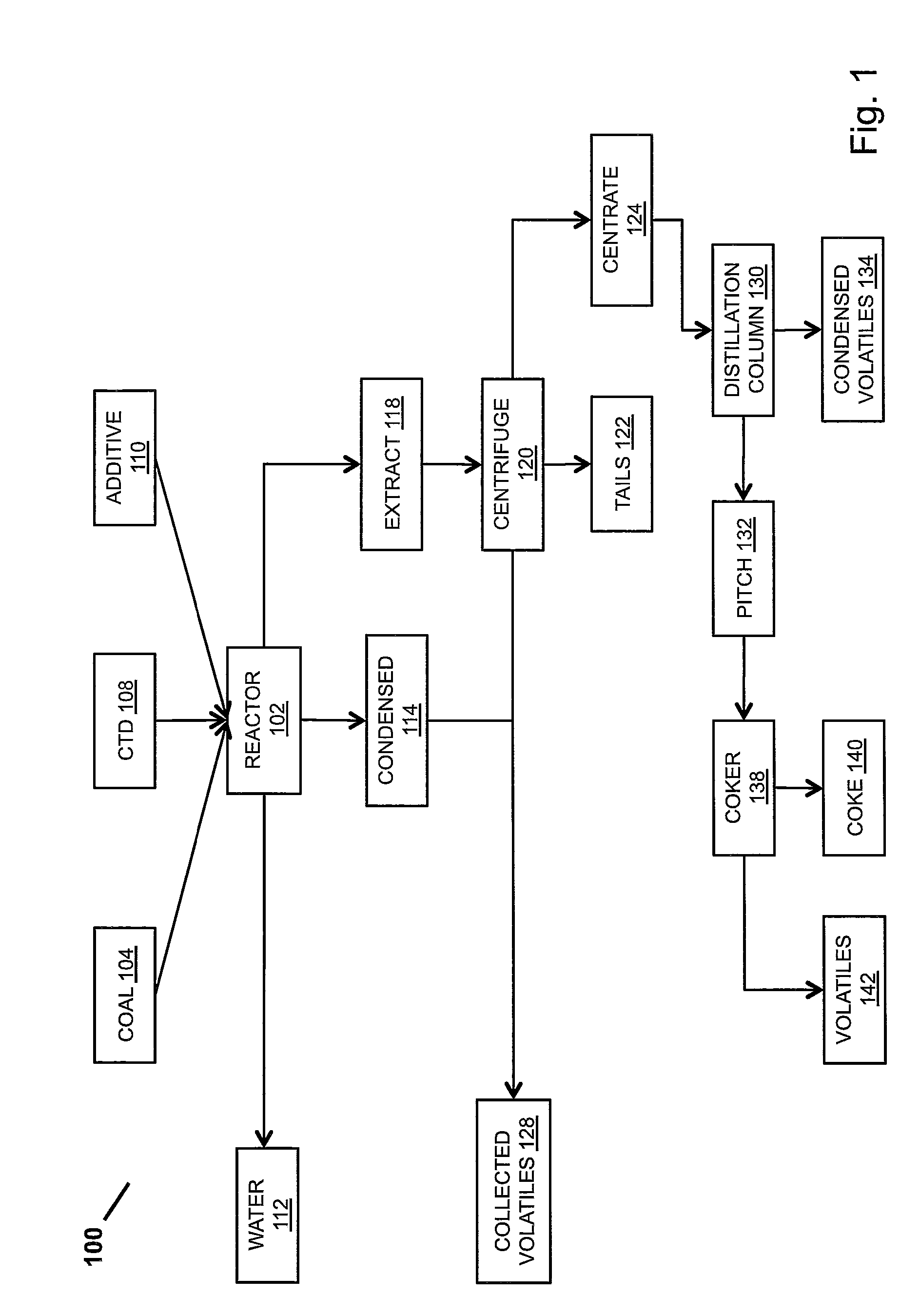

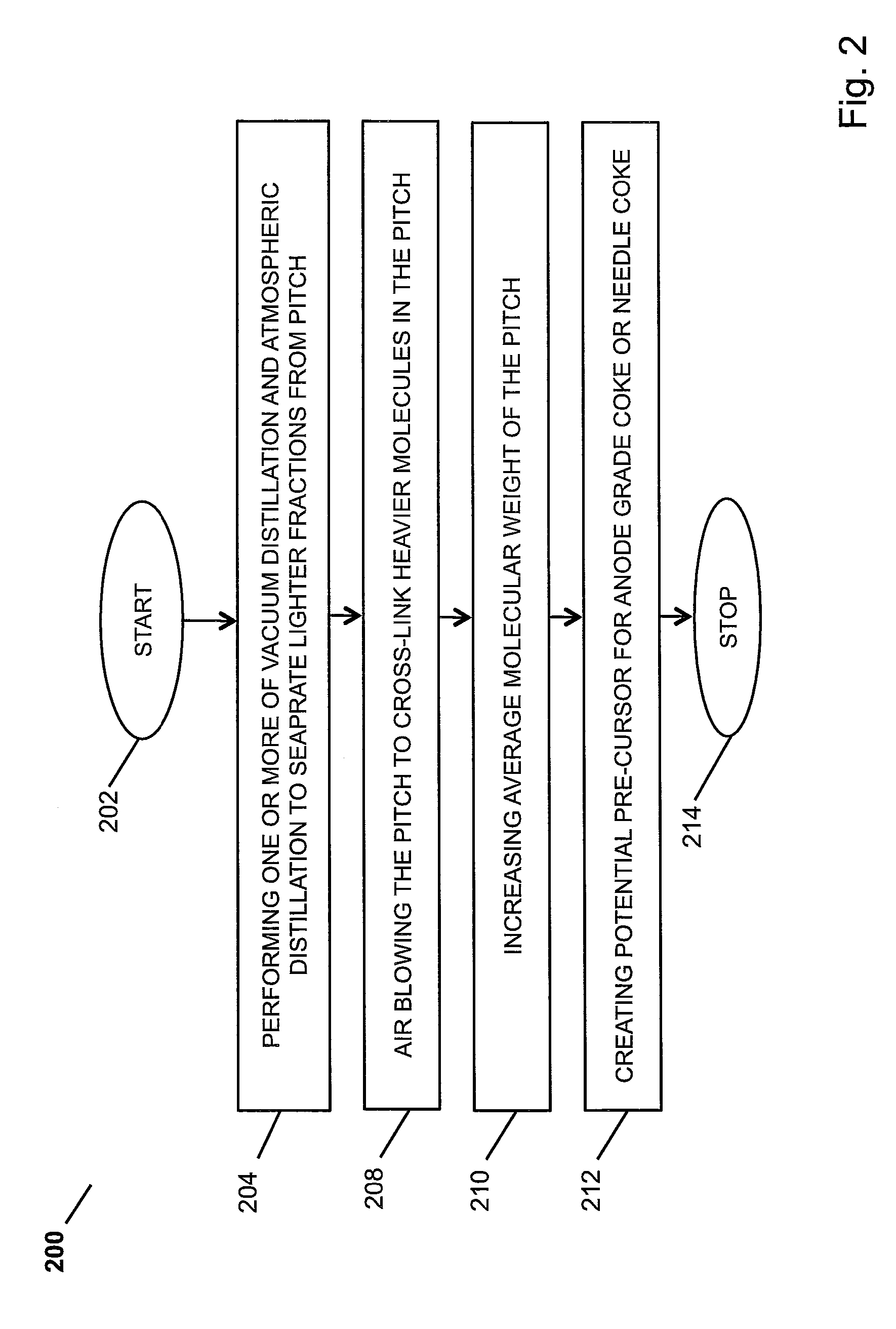

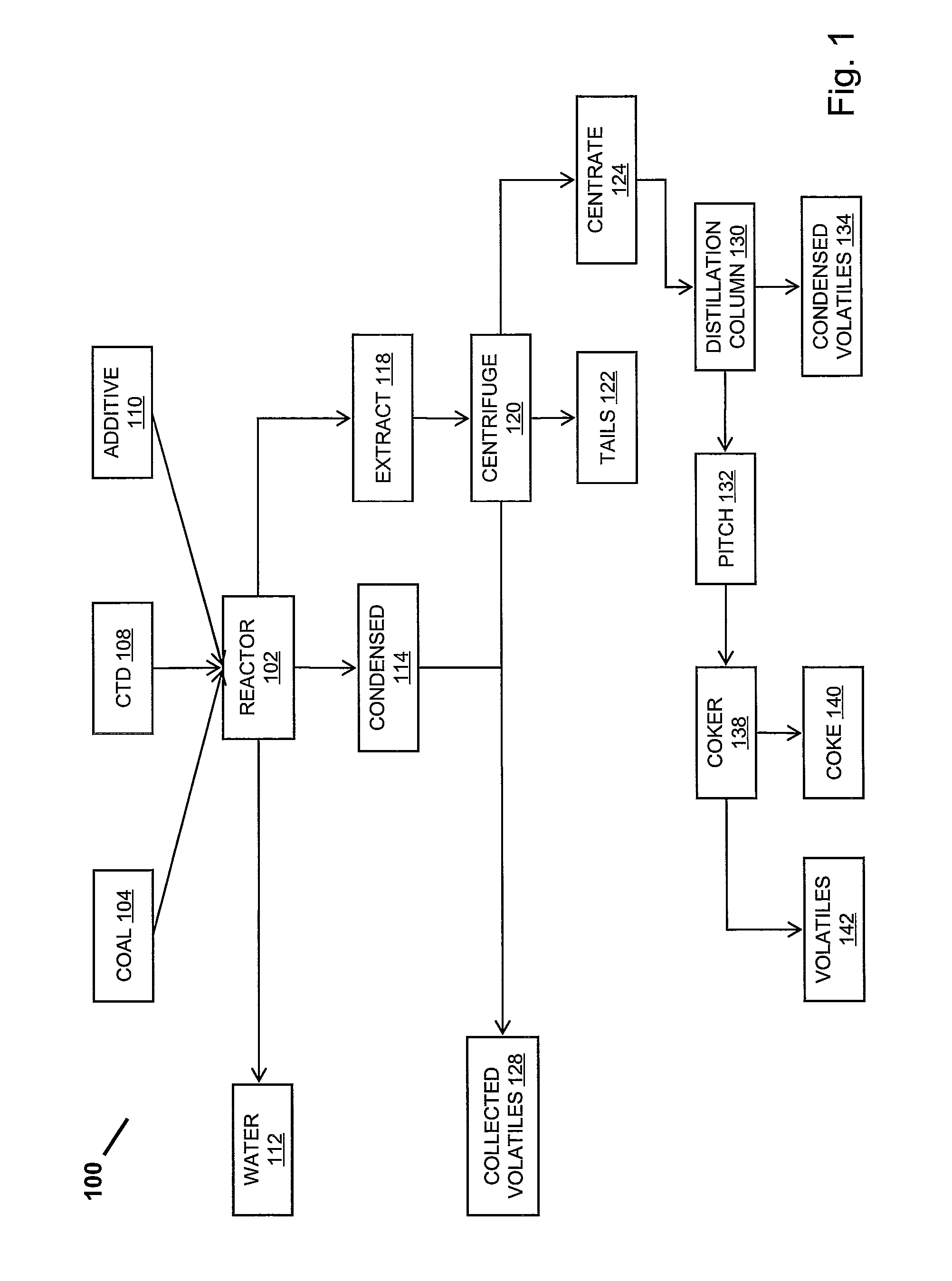

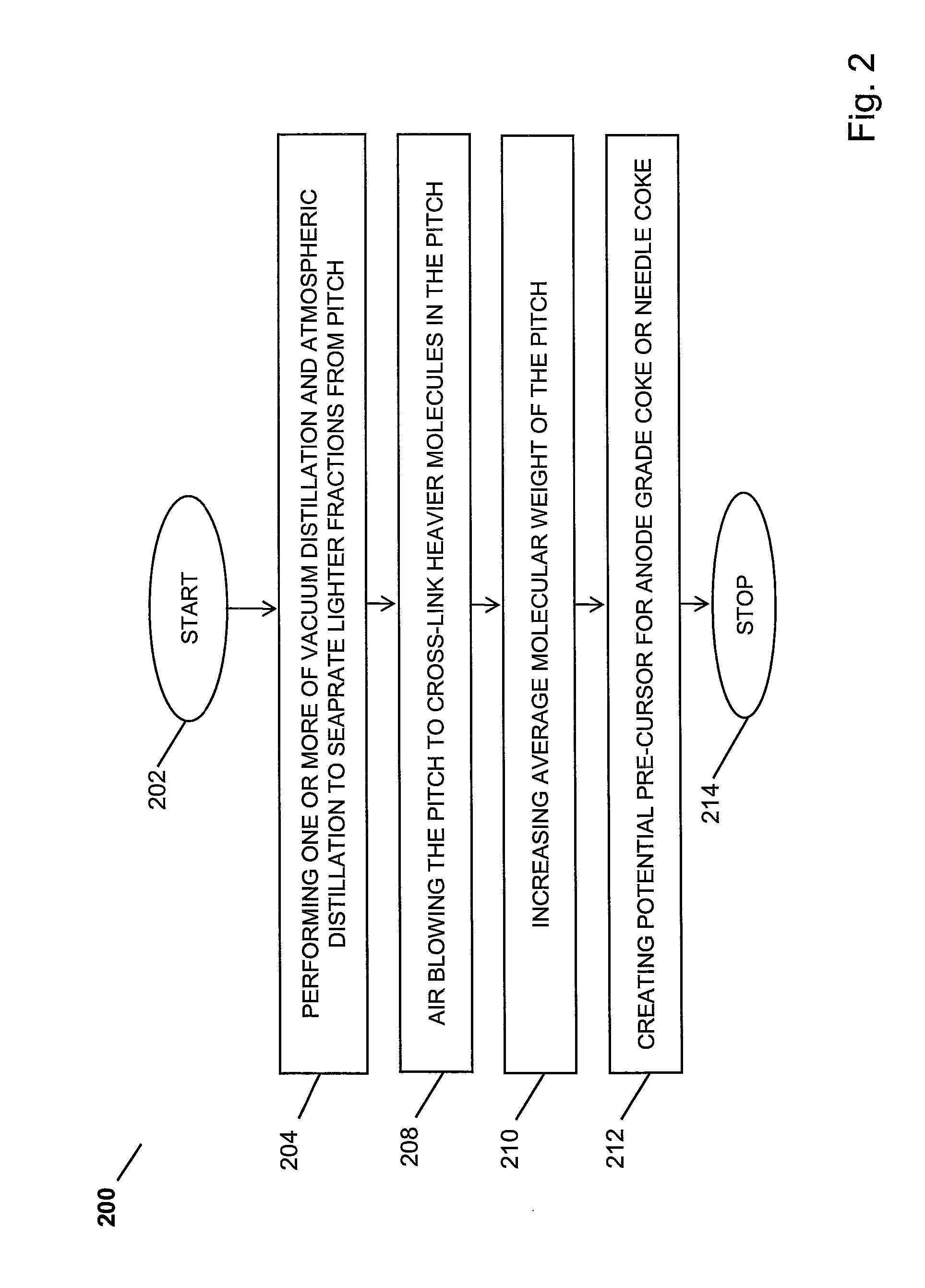

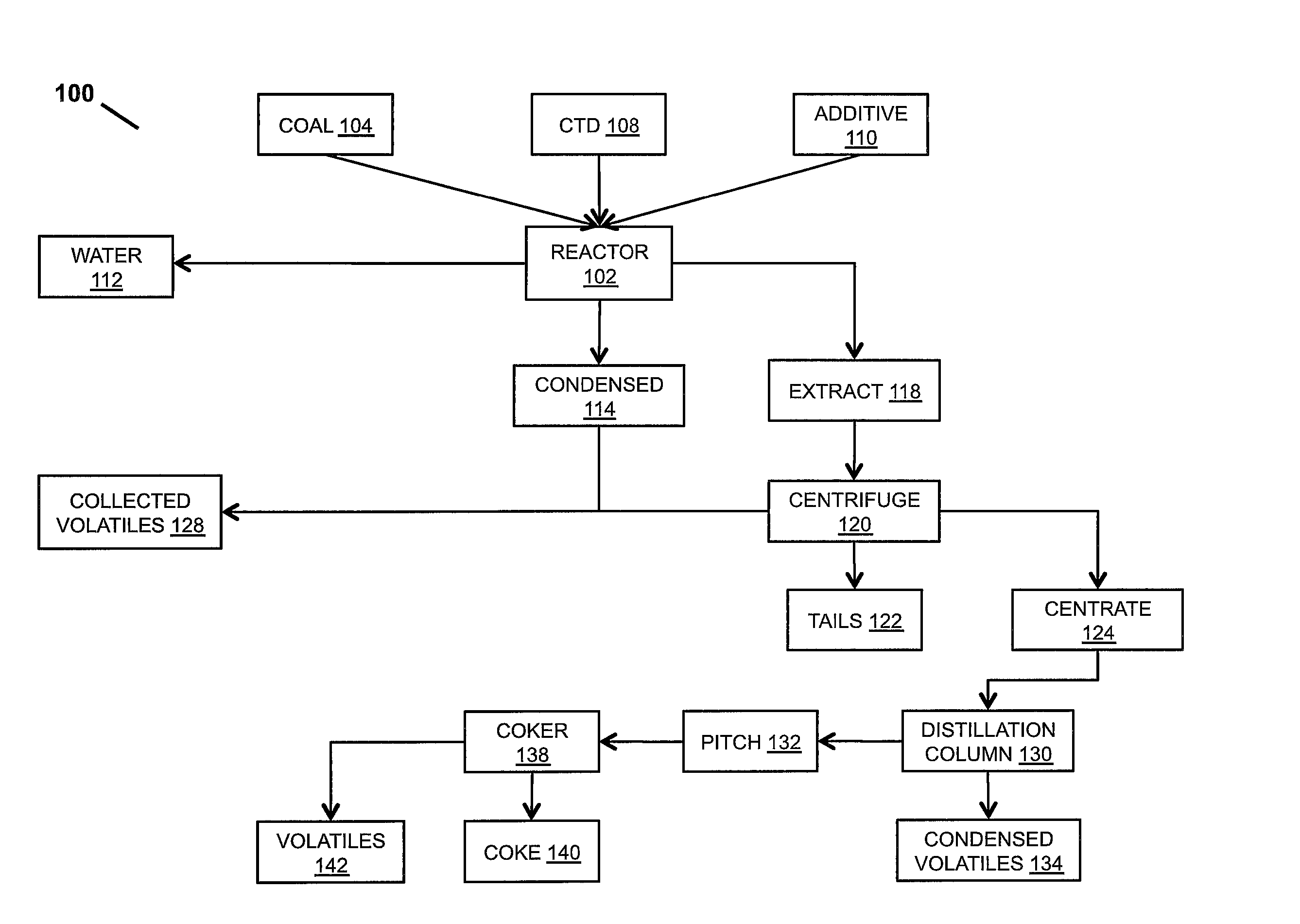

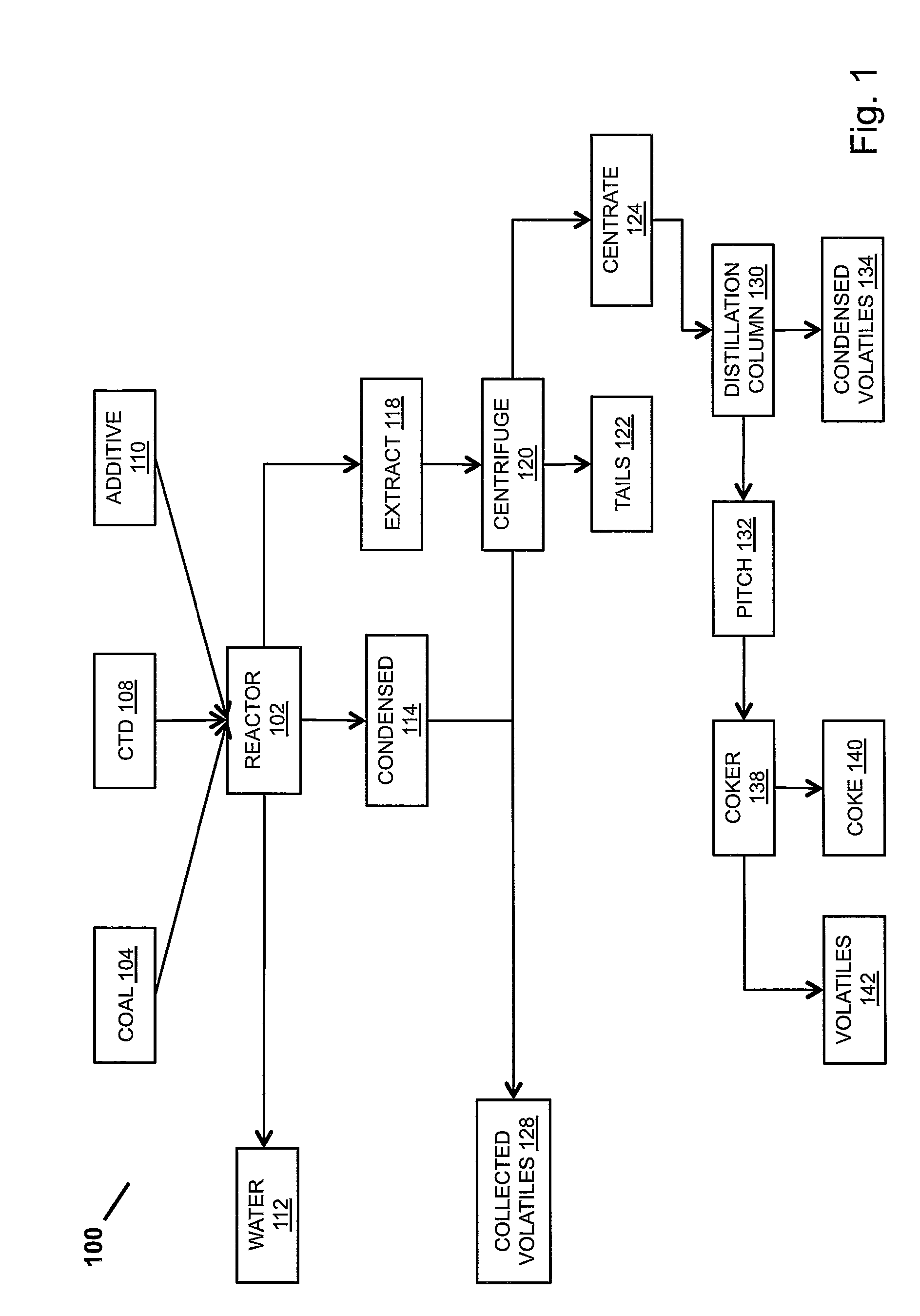

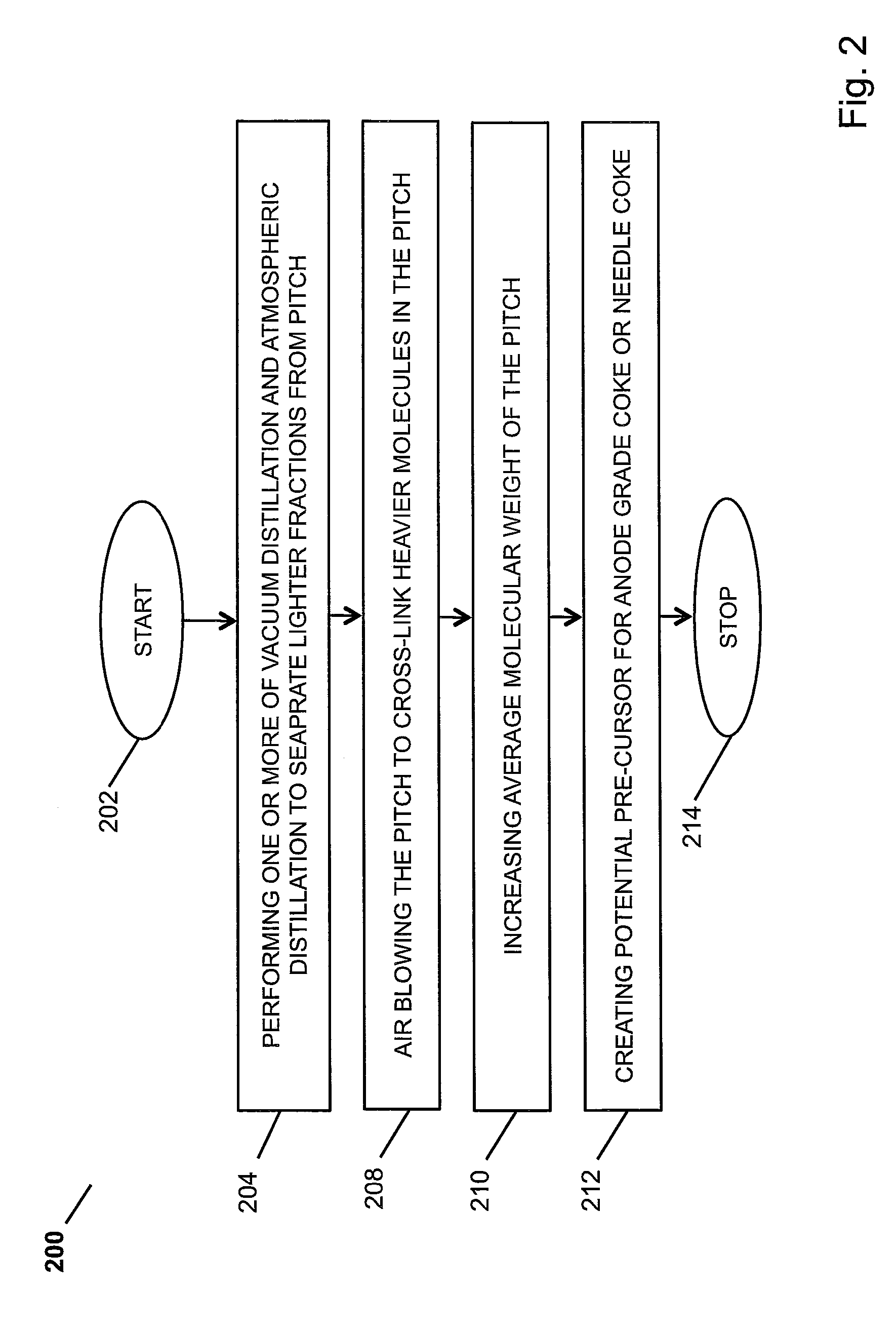

InactiveUS20120076703A1Low production costImprove solubilityOven incrustations prevention/removalLiquid hydrocarbon mixture productionTruck-trailerDownstream processing

The present disclosure provides methods and systems of a modular coal liquefaction system. A modular coal liquefaction system may include a reactor for exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, a heater that elevates the temperature of the slurry in the reactor to facilitate liquefying the coal and liberating a volatile matter, and a centrifuge that separates the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing, wherein the reactor, heater, and centrifuge are adapted to be modular. The system may further include a distillation column that distills the de-ashed coal extract to obtain a pitch. The system may further include a coker that cokes at least one of the de-ashed coal extract and the pitch to obtain a coke. The system may be adapted to be modularly disposed on a rail car. The system may be adapted to be modularly disposed on a semi-truck trailer.

Owner:WEST VIRGINIA UNIVERSITY

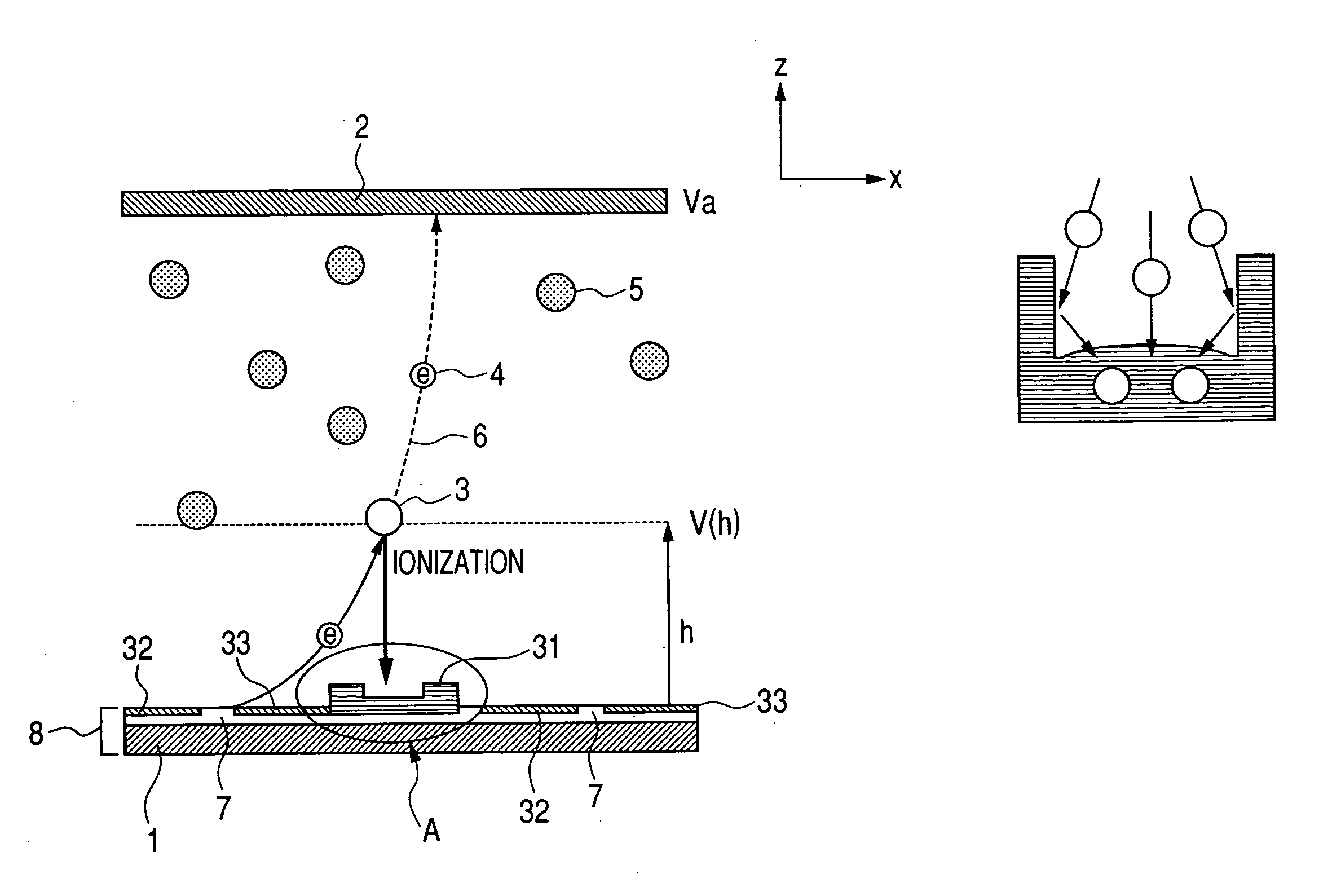

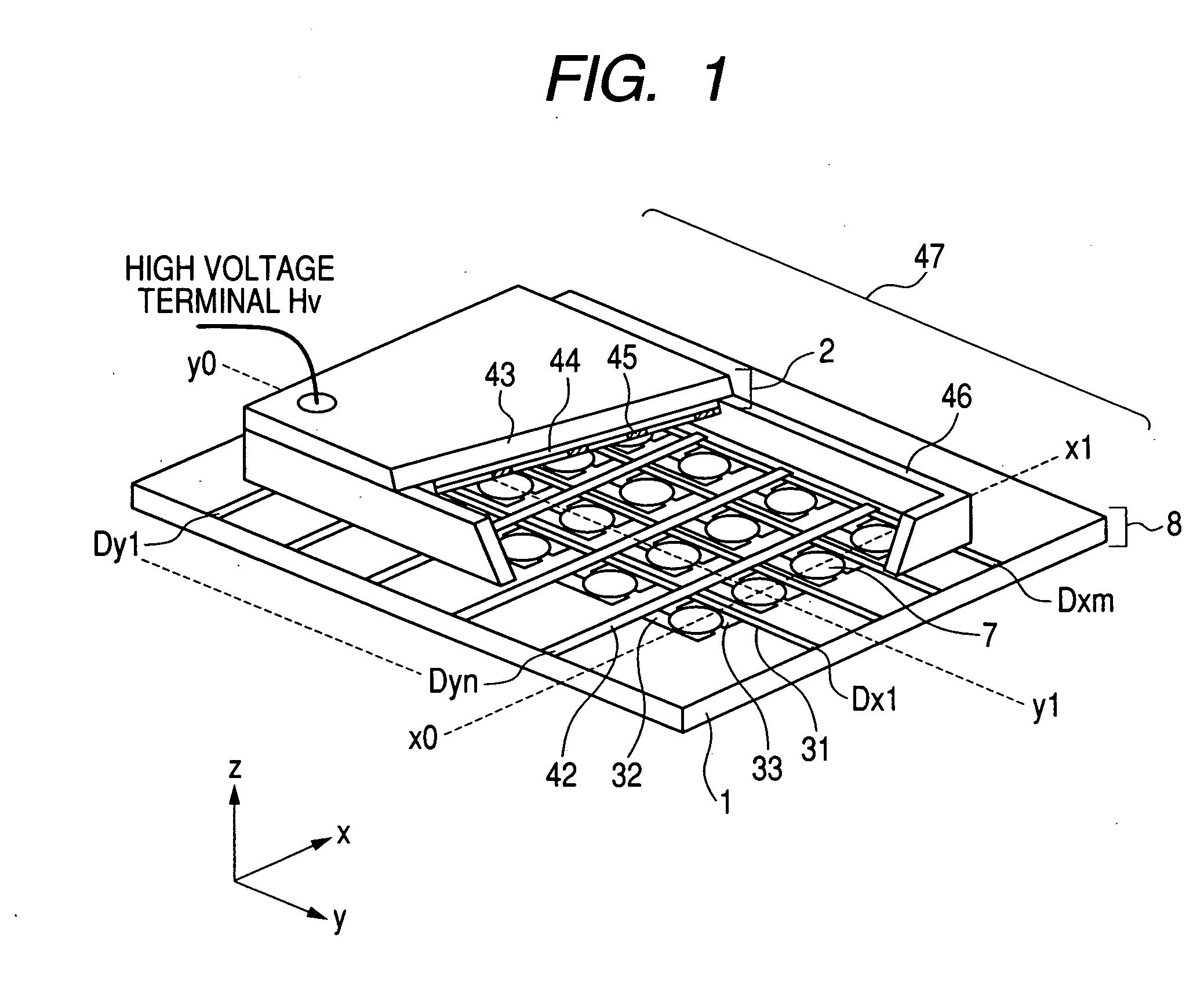

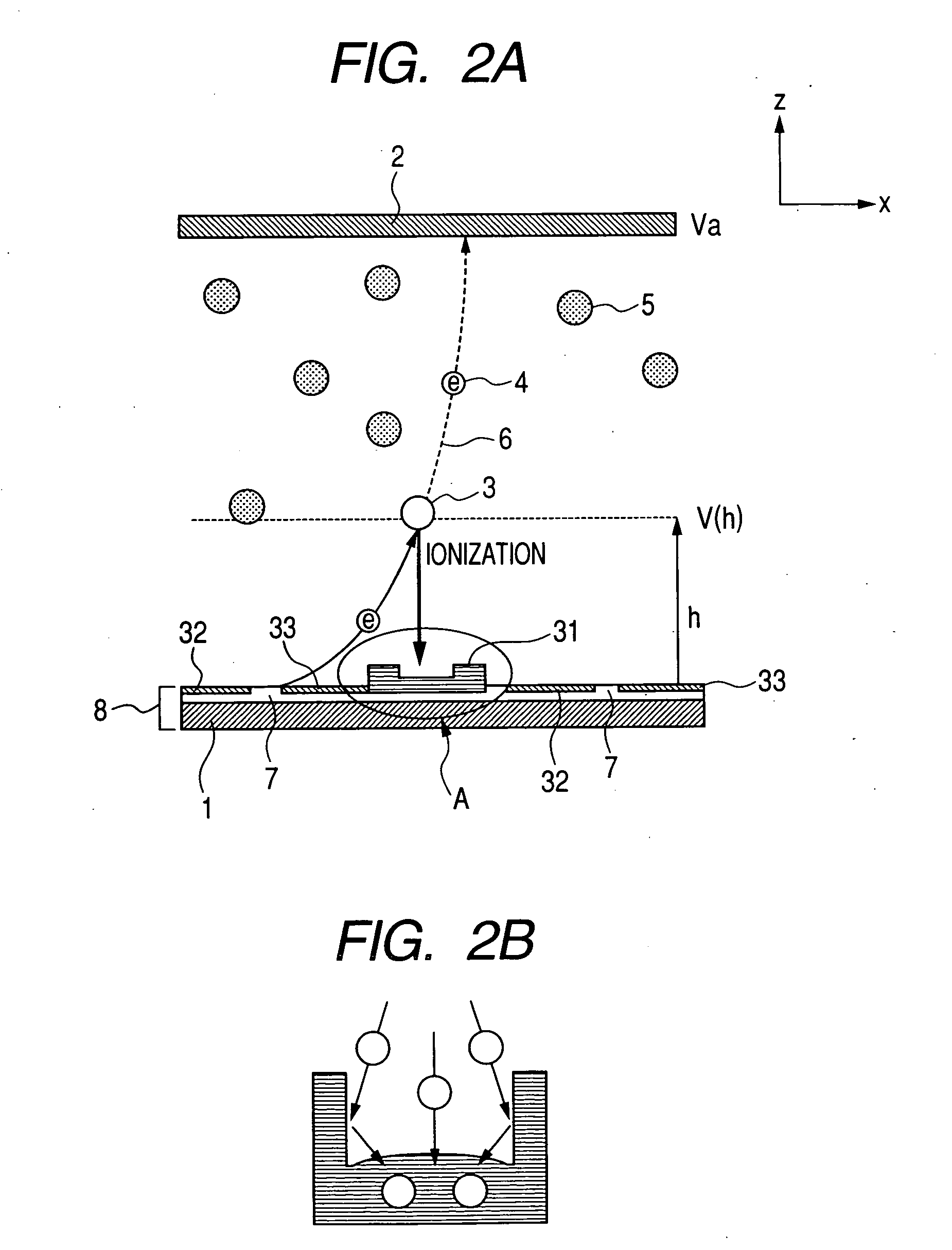

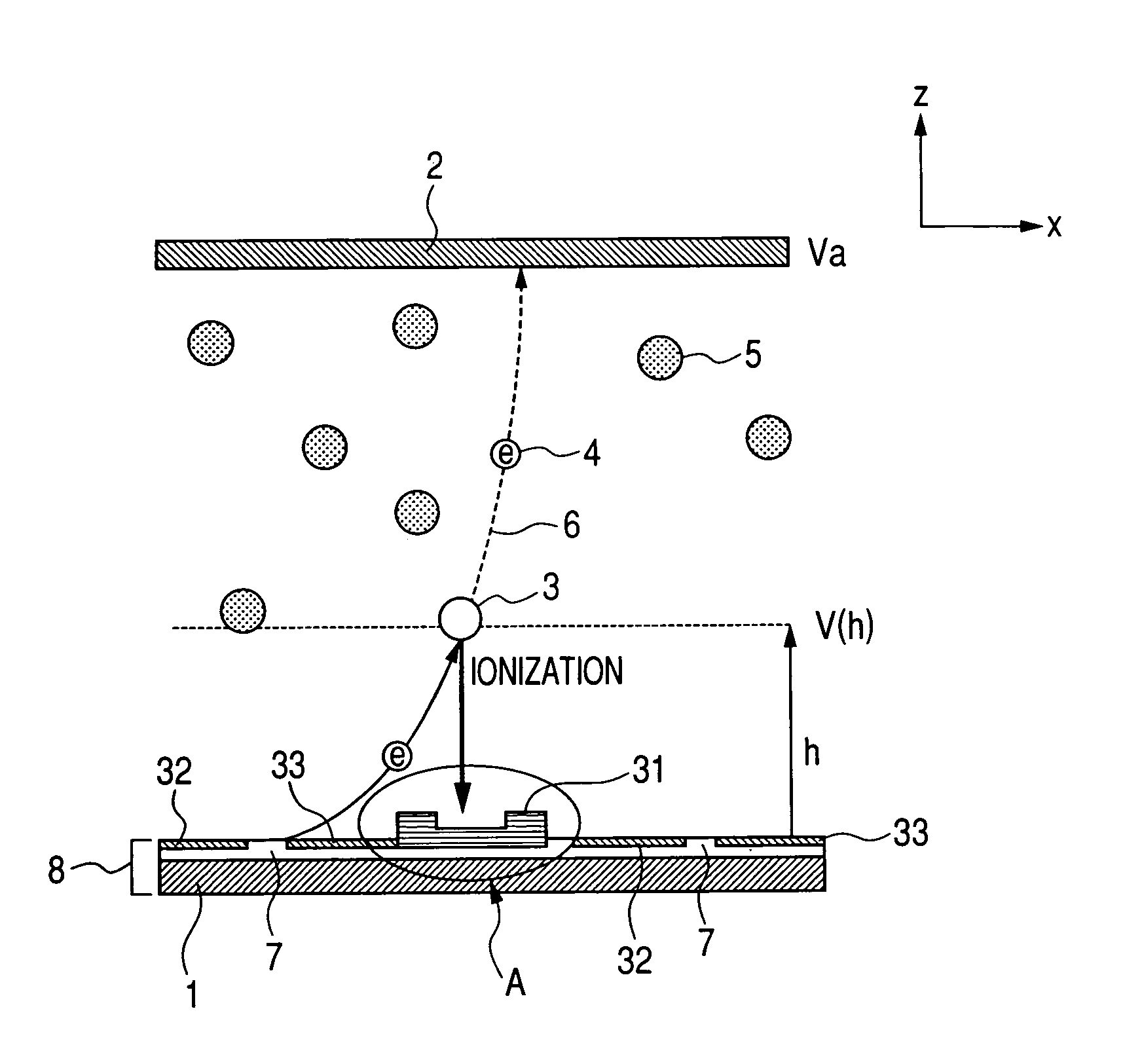

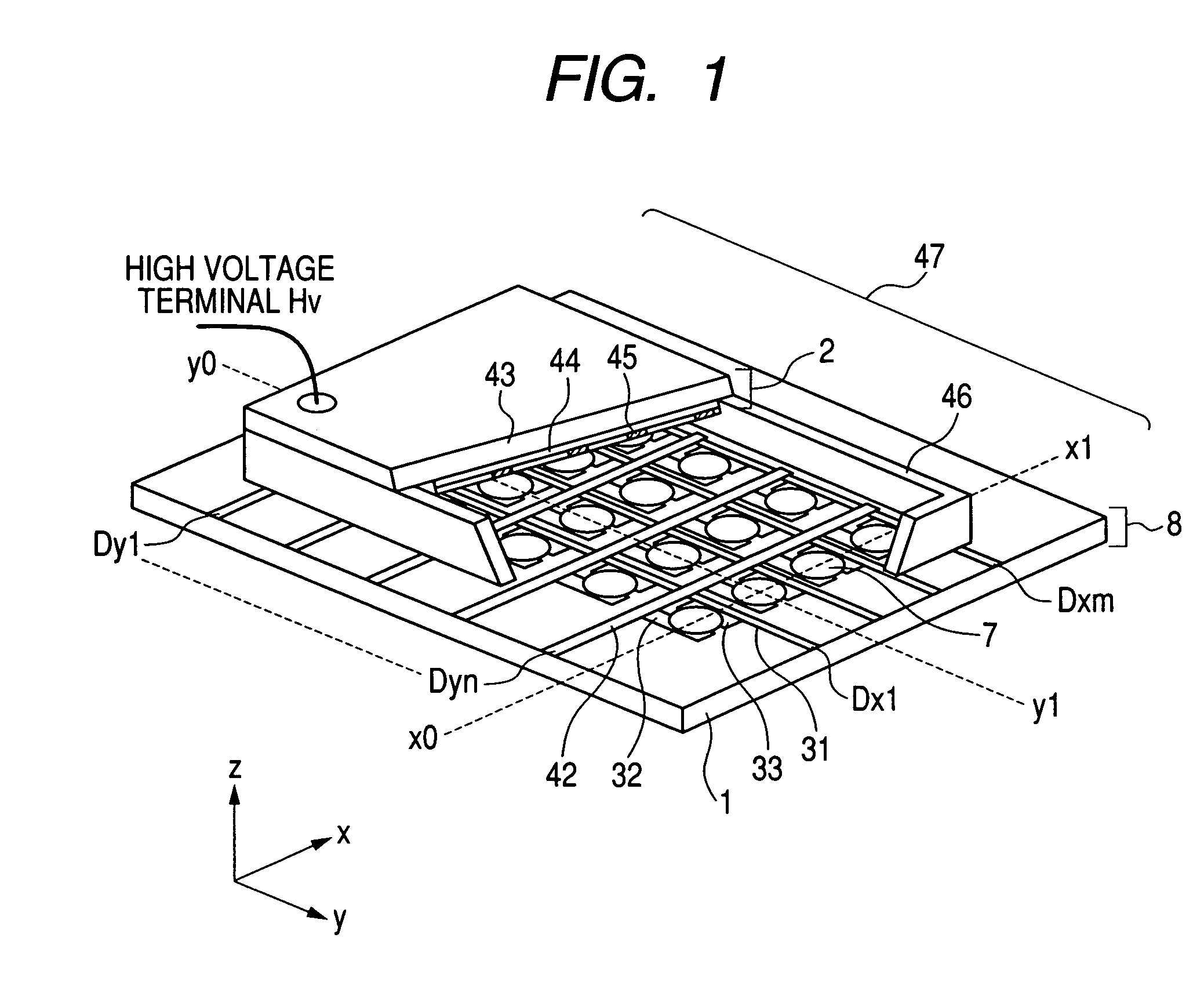

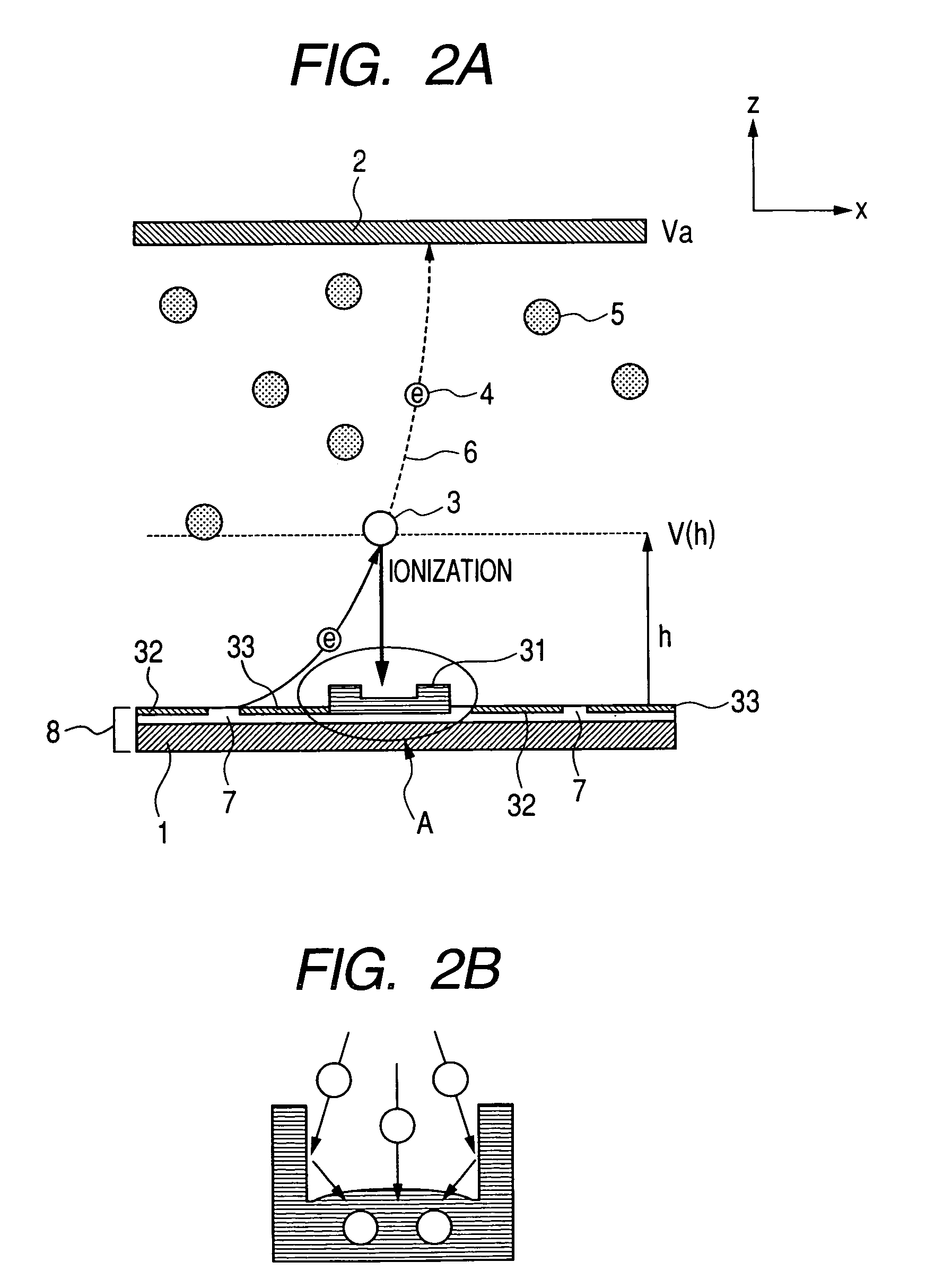

Image forming apparatus

InactiveUS20060087220A1Reduce lossesSmall distribution of luminanceGas filling substance selectionDischarge tube luminescnet screensImage formationImaging equipment

An image forming apparatus in which a first substrate provided with an electron-emitting device and an image displaying member which electrons emitted from the electron-emitting device irradiate are arranged to be opposed is provided with a deflecting means deflecting the electrons emitted from the electron-emitting device and a trapping unit trapping an inert gas ionized by the electrons. Thereby, the damages of the electron-emitting device by the inert gas are prevented, and the life of an image display apparatus is aimed to be elongated.

Owner:CANON KK

Reflective display based on liquid crystal materials

InactiveUS7387858B2Good lookingReduce eye fatigueLiquid crystal compositionsThin material handlingDisplay deviceLiquid crystal

The present invention relates to a high contrast reflective display comprising at least one substrate, at least one electrically conductive layer and at least one close-packed, ordered monolayer of domains of electrically modulated material in a fixed, preferably crosslinked, polymer matrix and a method of making the same.

Owner:IND TECH RES INST

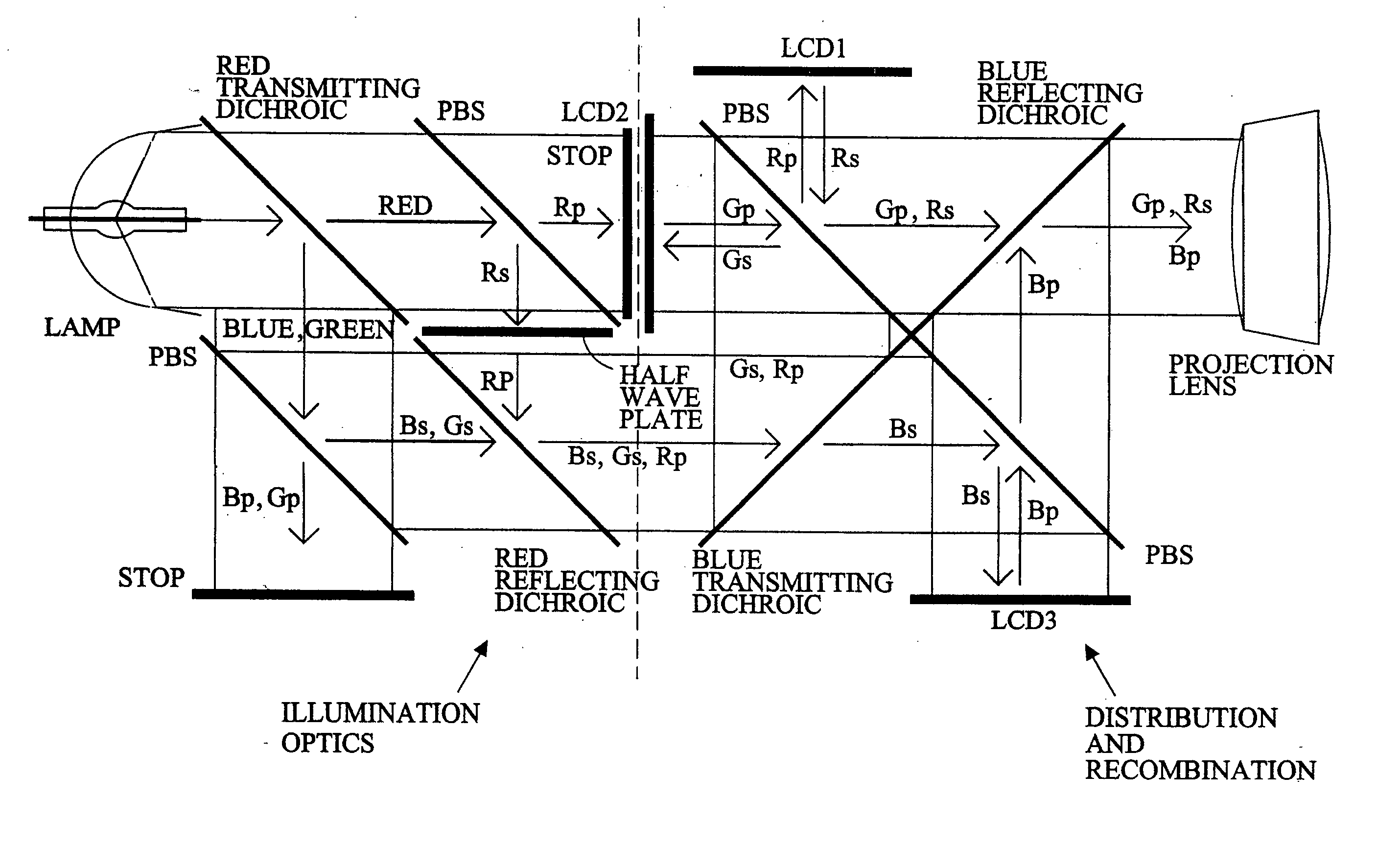

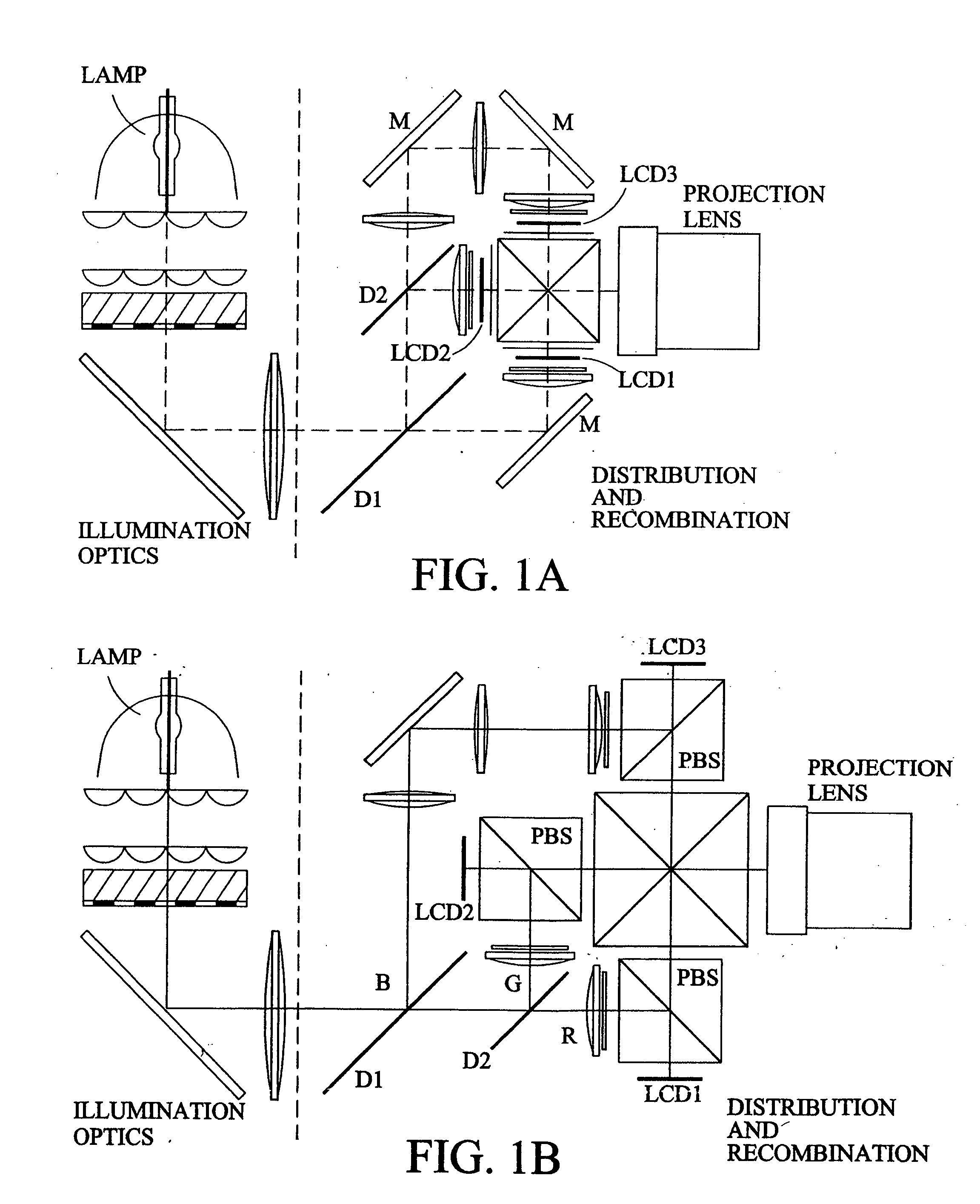

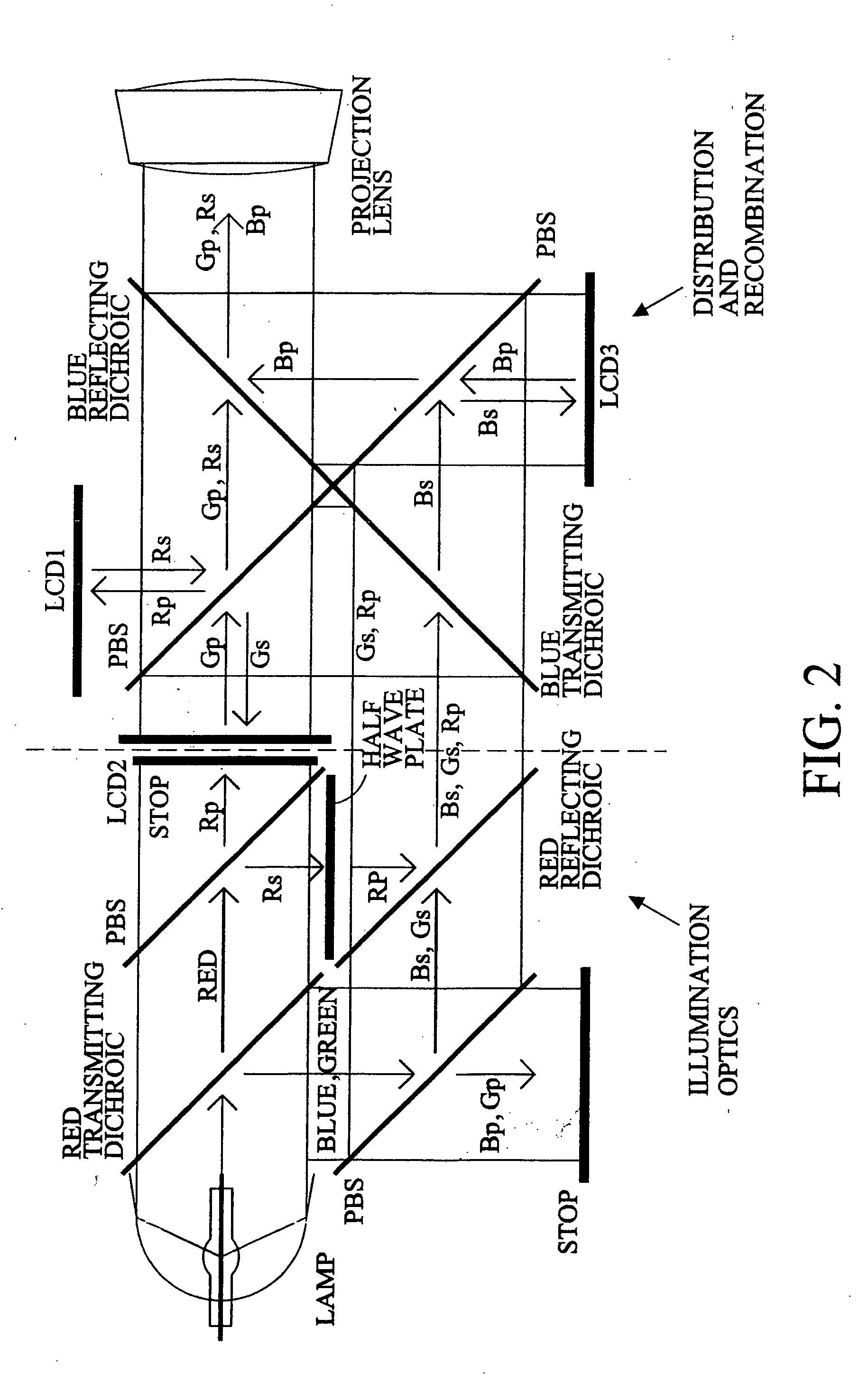

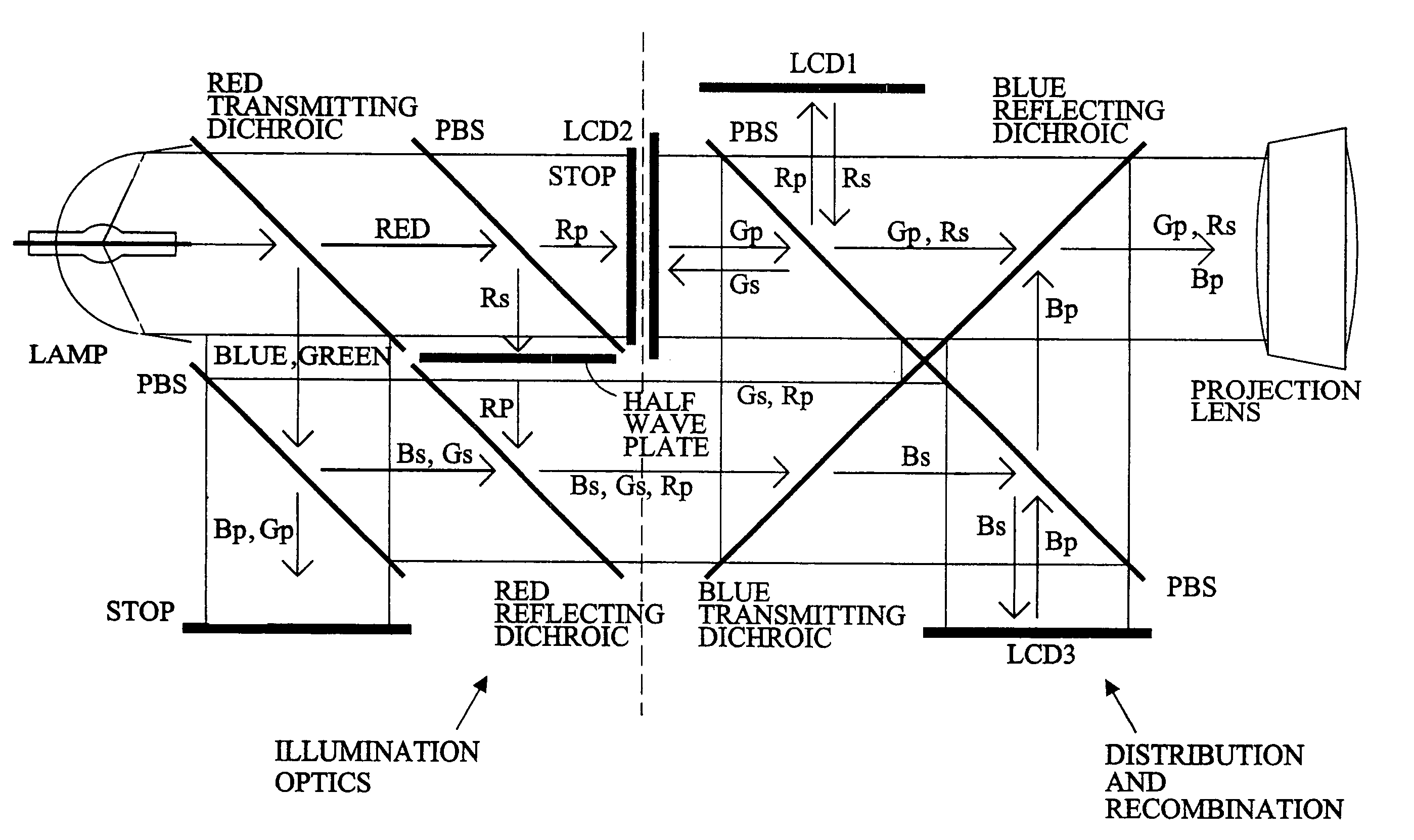

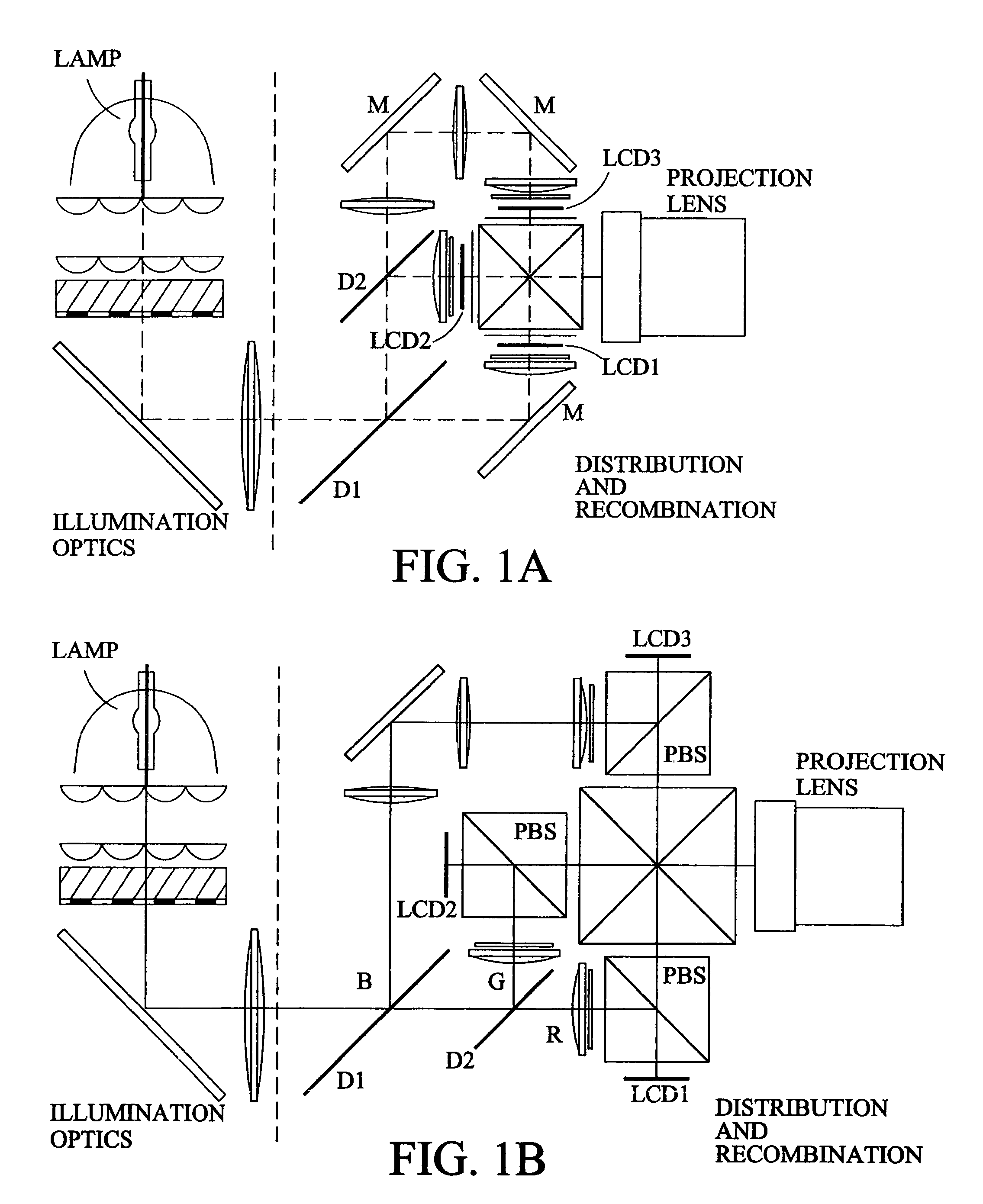

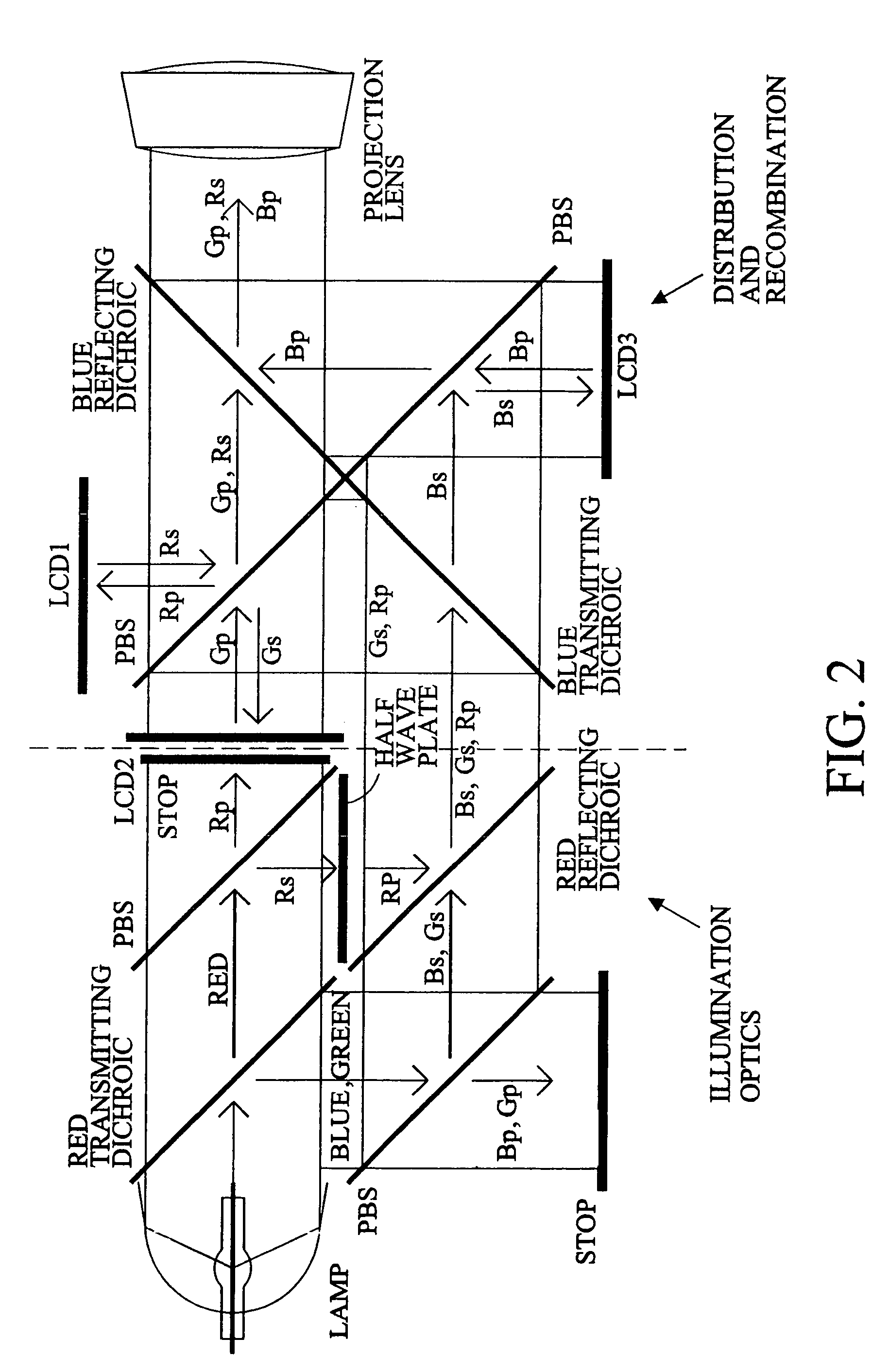

Projection display systems for light valves

InactiveUS20050157265A1SmallReduce projection display system sizeProjectorsColor photographyLiquid-crystal displayProjection display

Projection display systems for light valves such as liquid crystal display panels, and in particular to the use of color component rotators, such as retardation filters, to provide for improved projection display architectures.

Owner:SHARP KK

Hydrogenated Vegetable Oil in Coal Liquefaction

InactiveUS20120091042A1Low production costImprove solubilitySolid fuelsLiquid carbonaceous fuelsDownstream processingVegetable oil

The present disclosure provides methods and systems for coal liquefaction using a hydrogenated vegetable oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

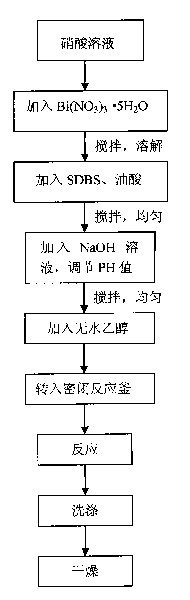

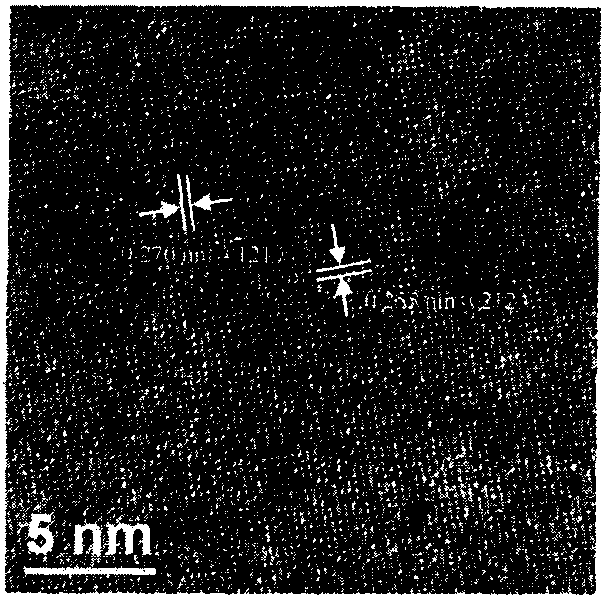

Method for solvent-thermally synthesizing nano bismuth oxide single-crystal chips

ActiveCN101748484AHigh yieldPreferential growthPolycrystalline material growthFrom normal temperature solutionsSingle crystalSolvent

The invention discloses a preparation method for nano bismuth oxide single-crystal chips. The method can controllably synthesize a large amount of high-purity monoclinic single-crystal chip-shaped nano bismuth oxide powder by adopting cheap, easily obtained materials and a solvent-thermal synthesization method assisted by the composite surfactant of oleic acid and sodium dodecyl benzene sulfonate. The specific steps are as follows: Bi(NO3)3.5H2O is firstly added into HNO3 solution, and is stirred until being dissolved; the surfactant is then added and uniformly stirred; in the process of continuing stirring, NaOH solution is dripped to regulate the pH value; absolute ethyl alcohol is then added and uniformly stirred; afterwards, the mixture is transferred into a closed container to carry out solvent-thermal reaction; and finally, the reaction product is washed by distilled water and absolute ethyl alcohol and dried, so that nano bismuth oxide single-crystal chips are obtained. The method for preparing nano bismuth oxide single-crystal chips has the advantages of short process flow, simple operation and excellent product properties.

Owner:NANJING UNIV OF SCI & TECH

Double metal cyanide complex catalyst, its production process and its utilization

InactiveUS7169956B2Improve filtering effectSmall distributionOrganic chemistryOrganic compound preparationAlcoholCyanide

Provided is a double metal cyanide complex catalyst with a high activity which is readily produced on an industrial scale. The double metal cyanide complex catalyst is of a fine particle form and contains t-butyl alcohol or, t-butyl alcohol and another organic compound as an organic ligand. The catalyst of the fine particle form has a volume-average particle size in a range of from 3 to 20 μm, based on measurement by a light scattering method for measuring fine particles having particle sizes of at least 0.15 μm. A particle content of the catalyst in a particle size range of at least 0.15 μm and at most 1 μm is less than 5% by volume, and a particle content of the catalyst over a particles size of 1 μm is in a range of more than 95% and at most 100% by volume.

Owner:AGC INC

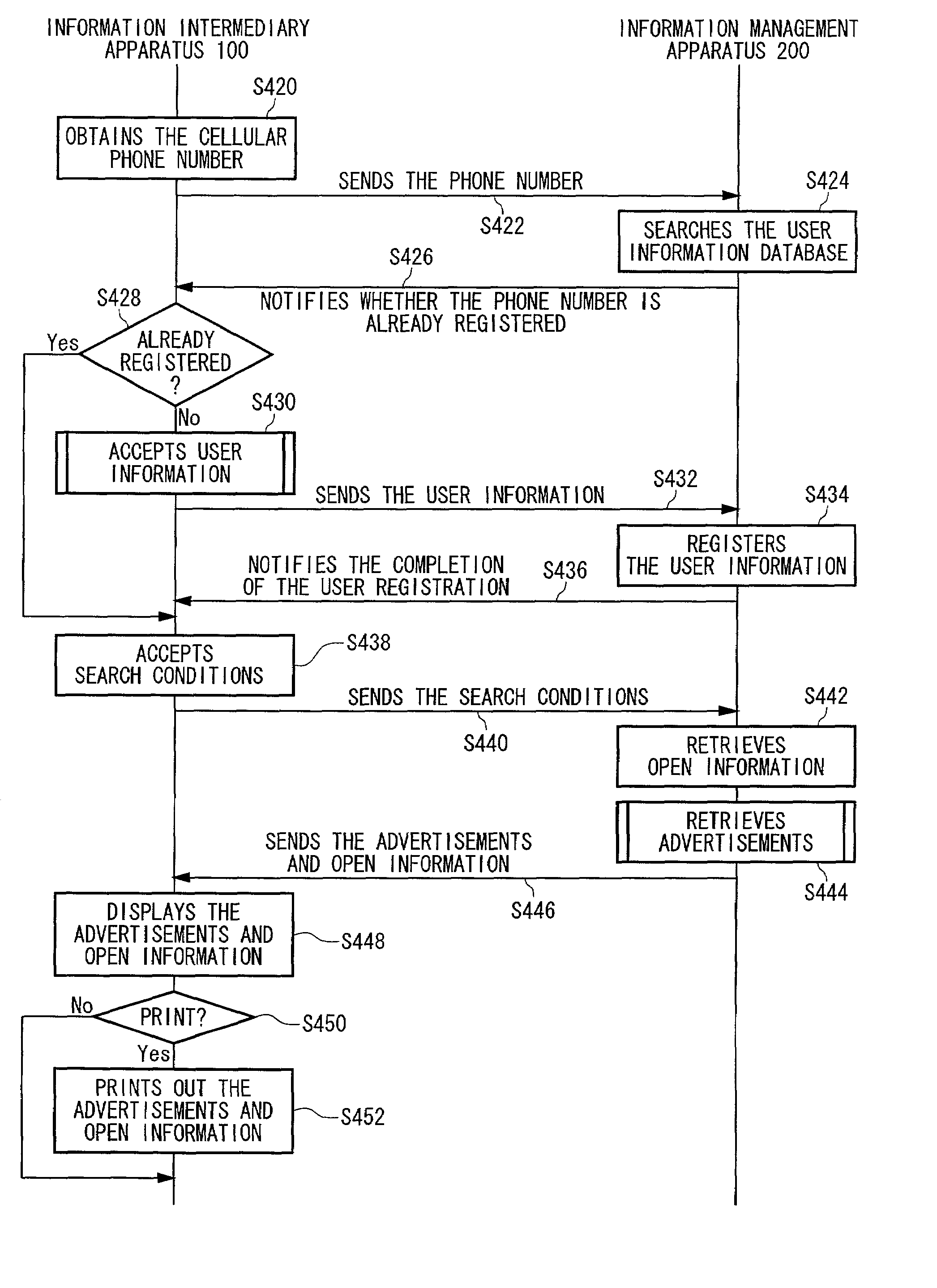

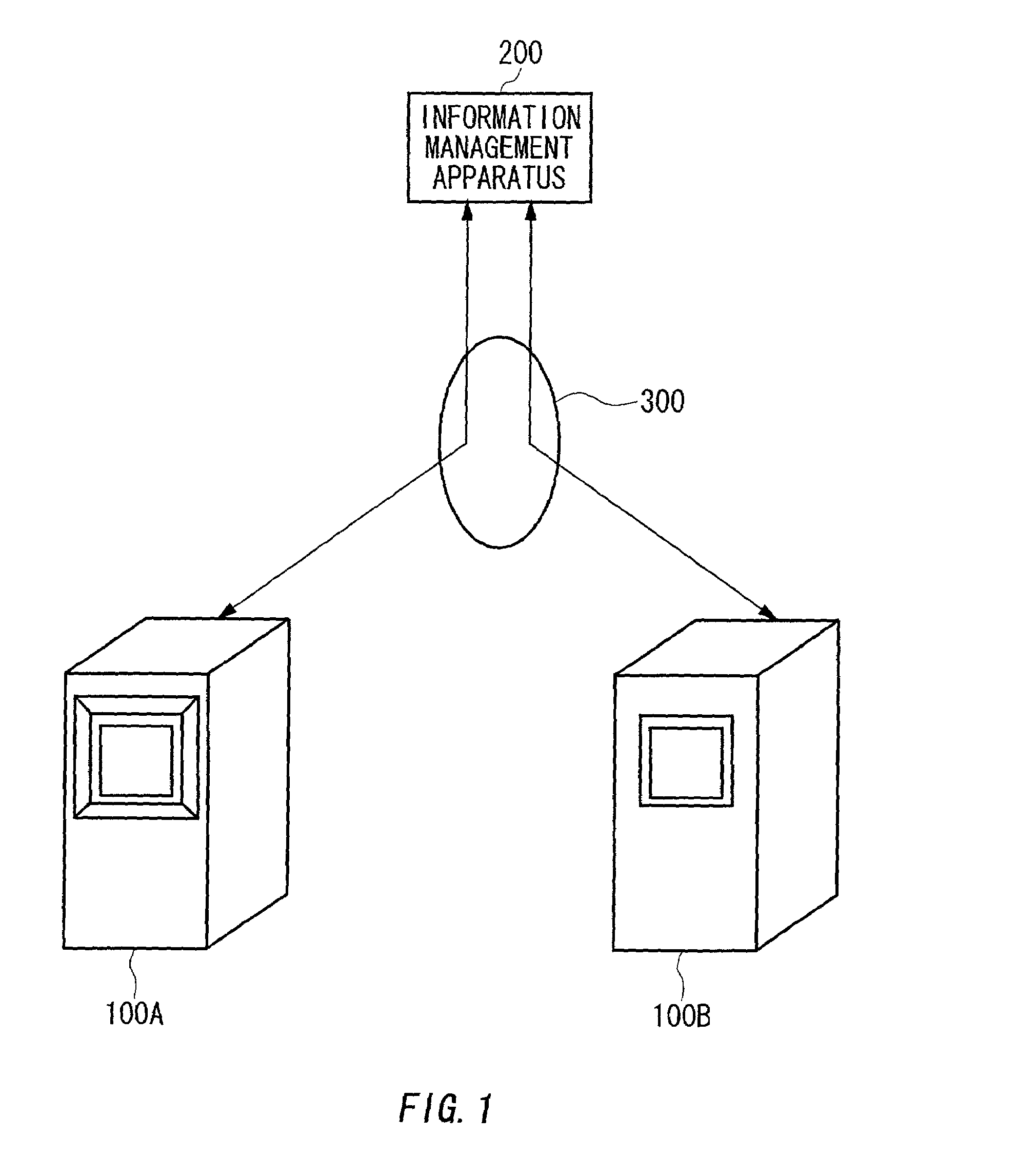

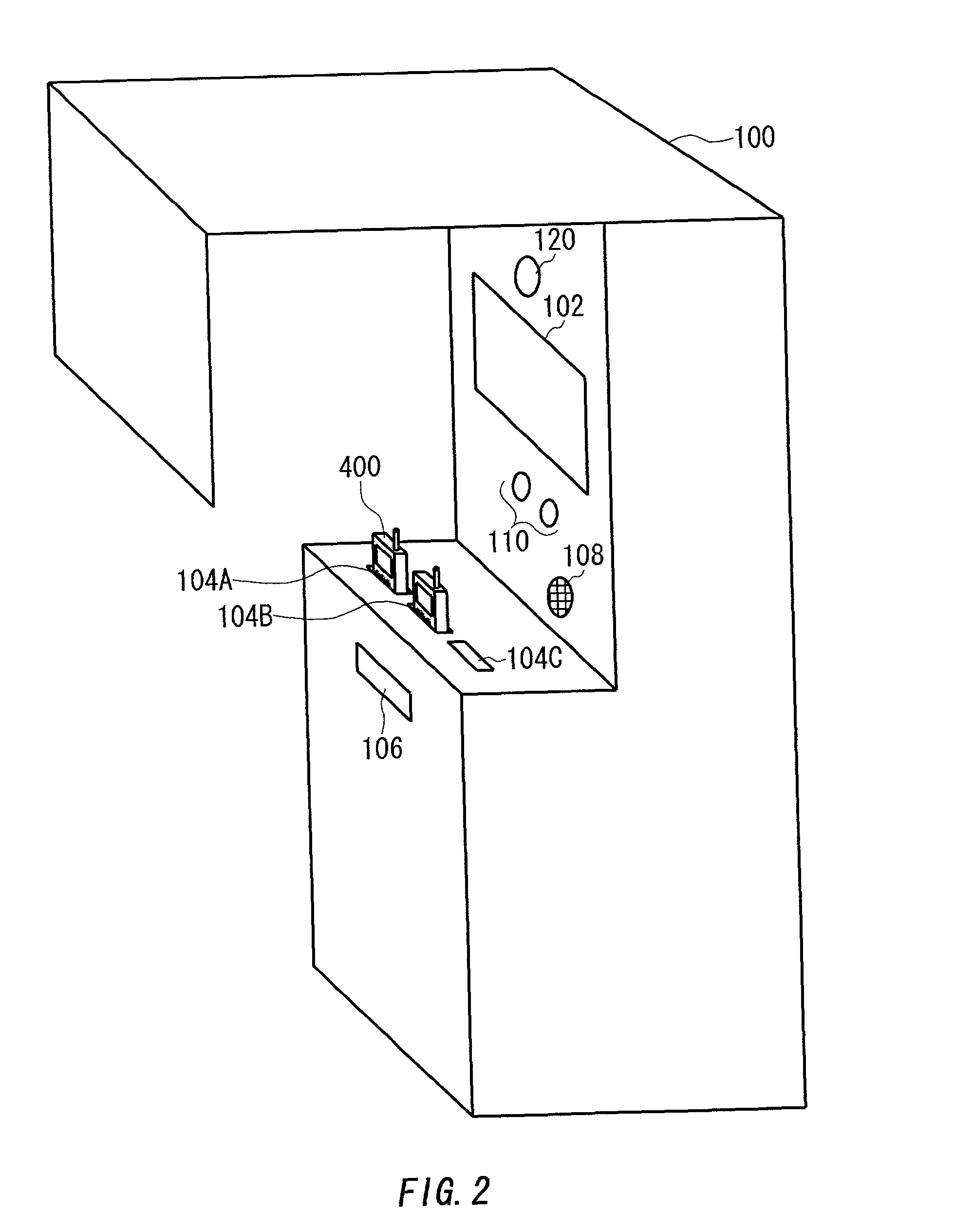

Information intermediary apparatus, information management apparatus, and information communication system

InactiveUS7051079B2Small distributionMultiple digital computer combinationsAutomatic exchangesCommunications systemUser input

An information intermediary apparatus for communicating through a communication network with an information management apparatus having user information stored therein, the information intermediary apparatus, which includes: a first communication section for establishing communication through the communication network with the information management apparatus; a second communication section for communicating with a portable communication apparatus having identification information for identifying a user; an identification information-obtaining section, connected with said second communication section, for obtaining said identification information from said portable communication apparatus through said second communication section; a user information input unit, connected with said first communication section, for inputting user information for the user of the portable communication apparatus; and a data-identifying section, connected with said identification information-obtaining section and said user information input unit, for associating said identification information with the user information.

Owner:FUJIFILM CORP +1

Alkali-free glass substrate and method for producing same

ActiveUS20160039710A1Well formedHigh light transmittanceGlass drawing apparatusGlass forming apparatusIn planeAlkali free

The present invention relates to an alkali-free glass substrate, having a strain point of 680° C. or higher, a Young's modulus of 78 GPa or greater, an UV transmittance at a wavelength of 300 nm of from 40% to 85% in terms of 0.5 mm thickness, an in-plane distribution of the UV transmittance at a wavelength of 300 nm in a G6-sized substrate of 1% or less in terms of 0.5 mm thickness, an average cooling rate around the glass transition point obtained according to a rate cooling method of 400° C. / min or lower, and an in-plane distribution of the average cooling rate of 40° C. / min or less.

Owner:ASAHI GLASS CO LTD

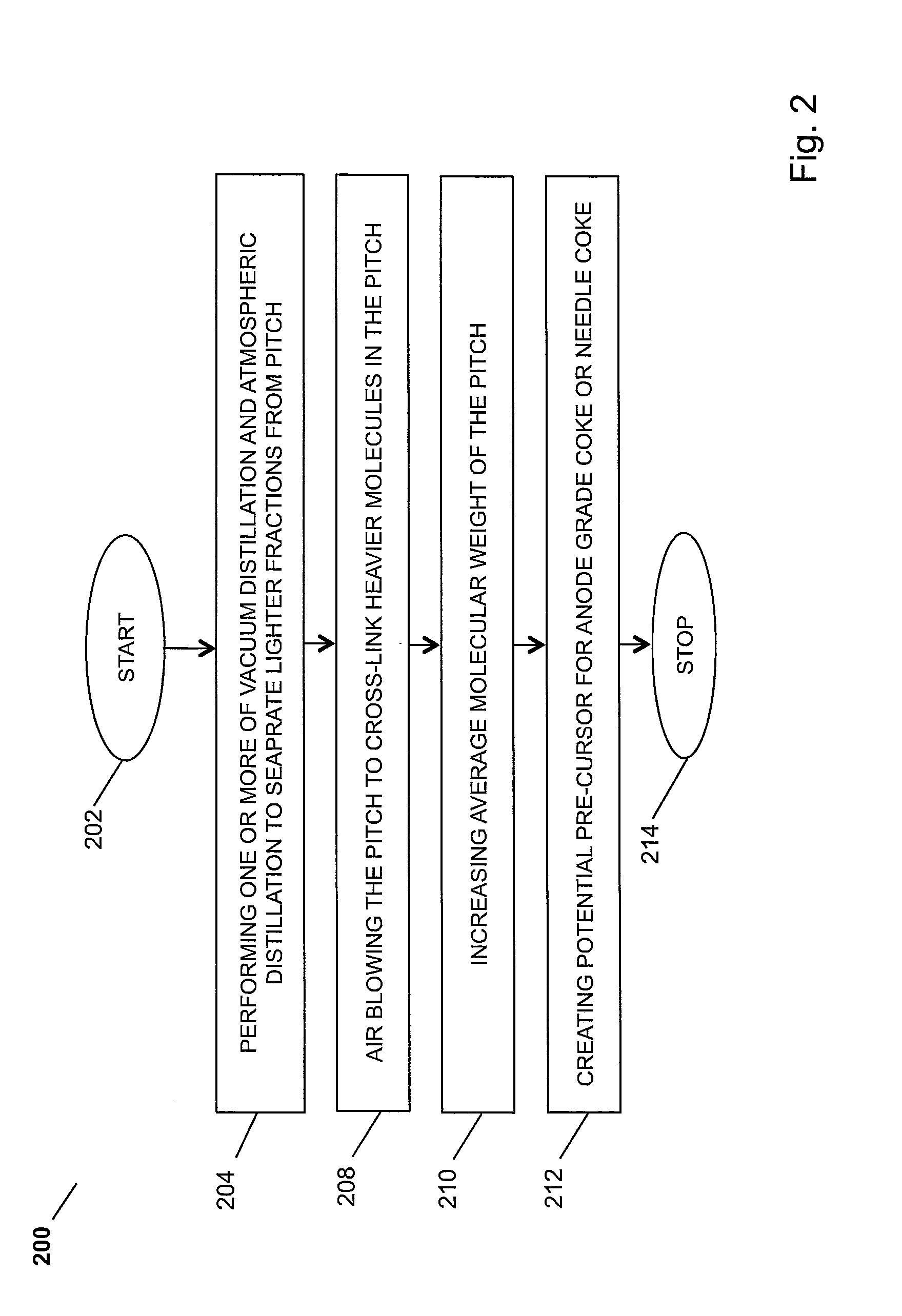

Coal Liquefaction System

ActiveUS20120082593A1Low production costImprove solubilityWorking-up pitch/asphalt/bitumen by distillationSolid fuelsVegetable oilDownstream processing

The present disclosure relates to a coal liquefaction system for utilizing a hydrogenated vegetable oil to liquefy coal. The system includes a reactor for exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, a heater that elevates the temperature of the slurry in the reactor to facilitate liquefying the coal and liberating a volatile matter, and a centrifuge that separates the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing. The system may also include a distillation column that distills the de-ashed coal extract to obtain a pitch. The system may also include a coker that cokes at least one of the de-ashed coal extract and the pitch to obtain a coke

Owner:WEST VIRGINIA UNIVERSITY

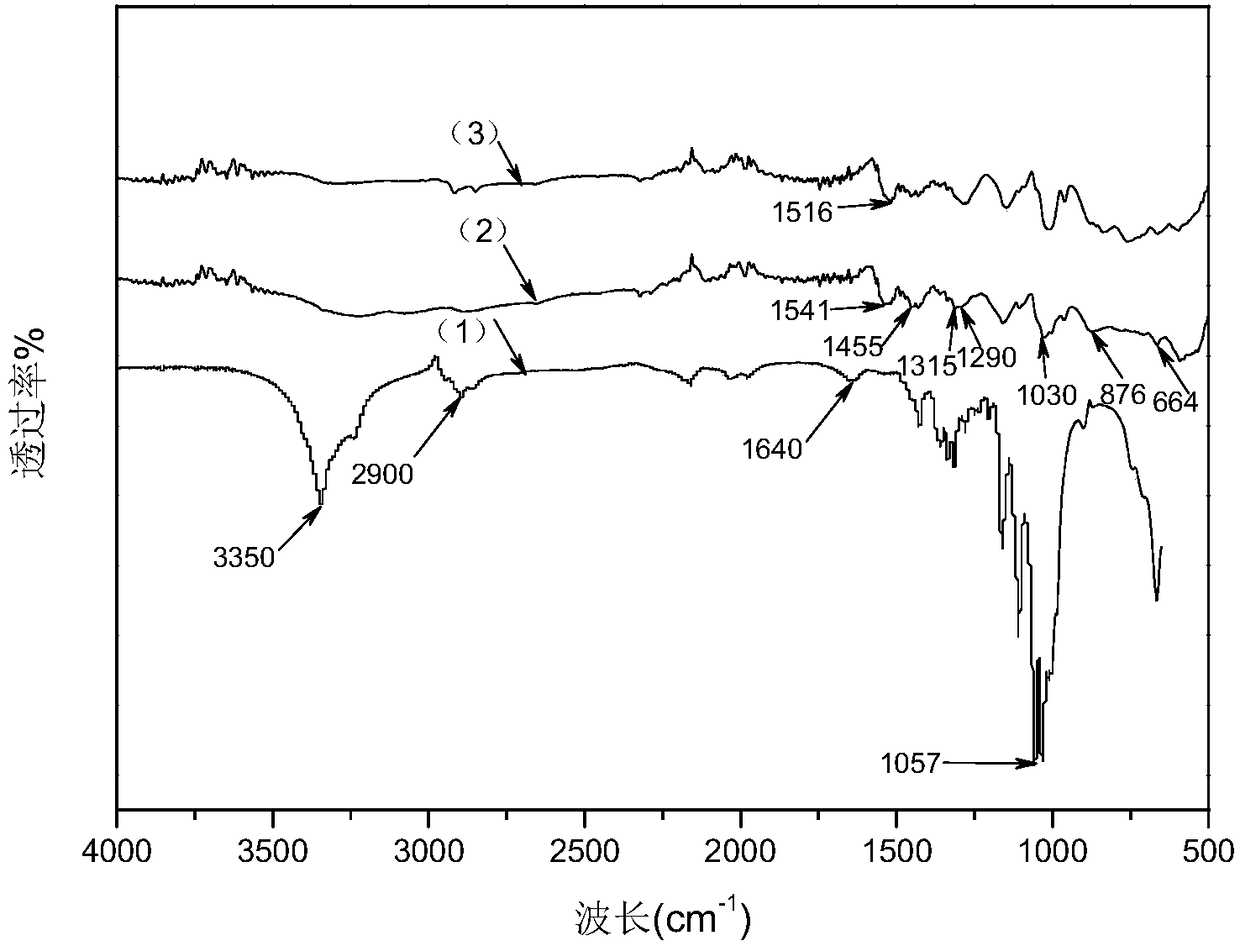

Novel flexible conductive composite film and preparation method thereof

The invention provides a novel flexible conductive composite film and a preparation method thereof. The novel flexible conductive composite film is mainly prepared by compounding bacterial cellulose,polypyrrole and a single-walled carbon nanotube material. The invention belongs to the field of electrochemistry. The preparation method disclosed by the invention mainly comprises the following steps: adding a BC nanofiber suspension into a mixed solution A mixed with hydrochloric acid and ferric chloride, performing ultrasonic treatment, adding a PPy monomer to be mixed so as to obtain BC / PPy composite slurry; dialyzing by a dialysis bag, adding single-walled carbon nanotubes and the like according to a certain volume ratio, stirring, performing suction filtration and film formation, so as to obtain the BC / PPy / SWCNTs composite film. The requirements of flexible electronic equipment on elastic stretching and bending properties of the material are met, and the material is stable in structure, high in conductivity and high in capacitance. Moreover, the preparation method is simple and feasible, and the composite film has great application prospects and high market value.

Owner:TIANJIN POLYTECHNIC UNIV

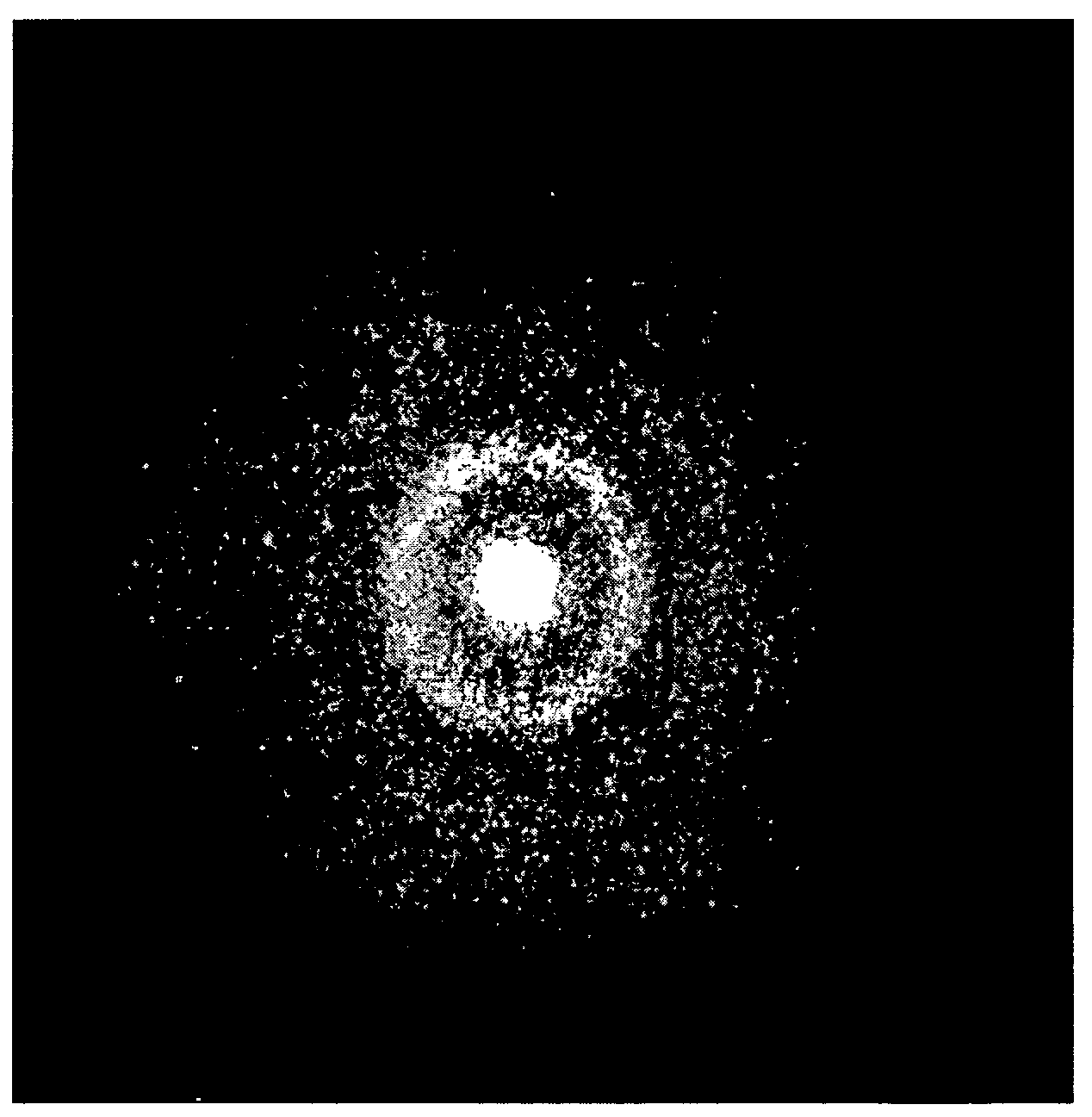

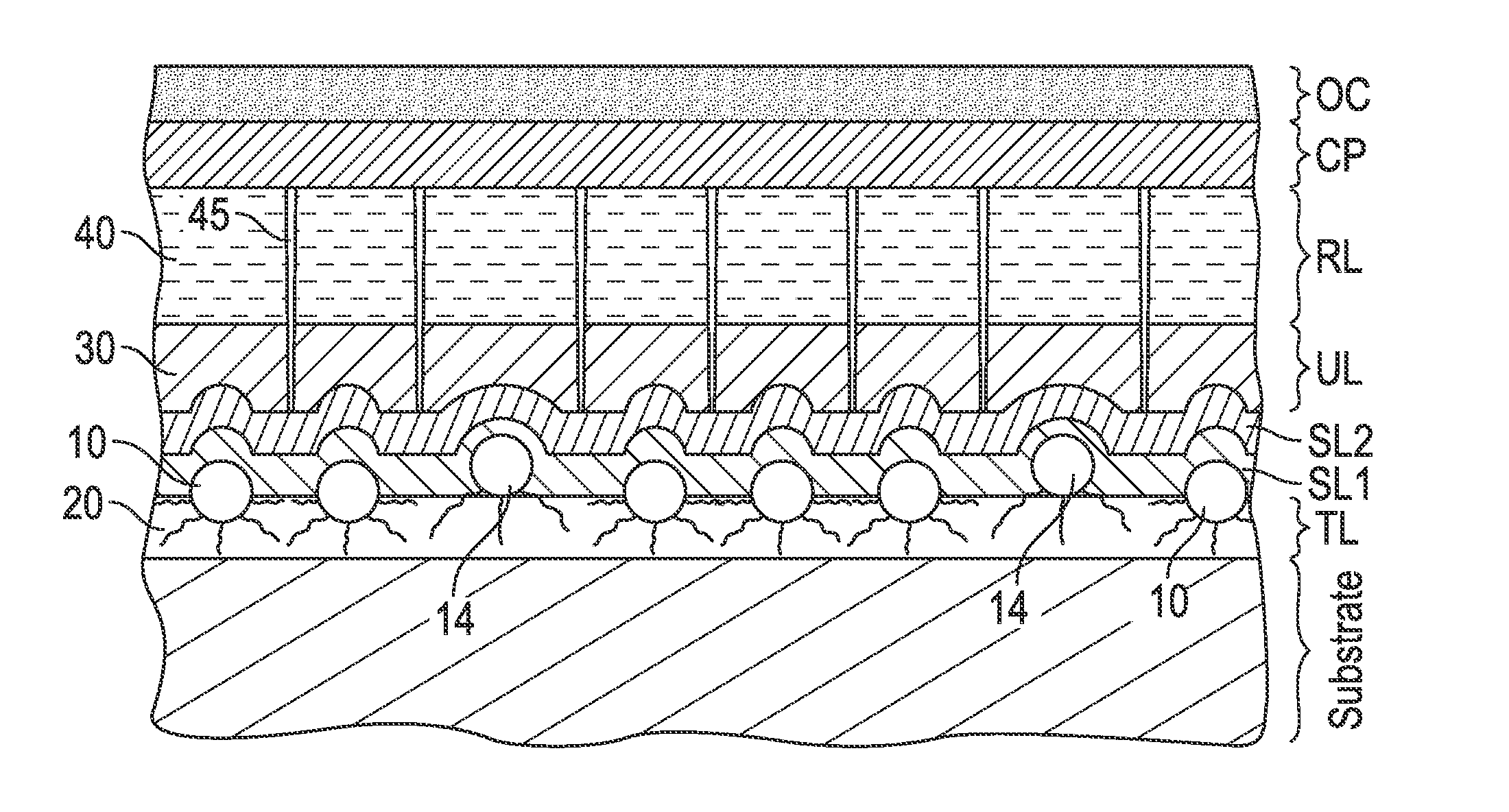

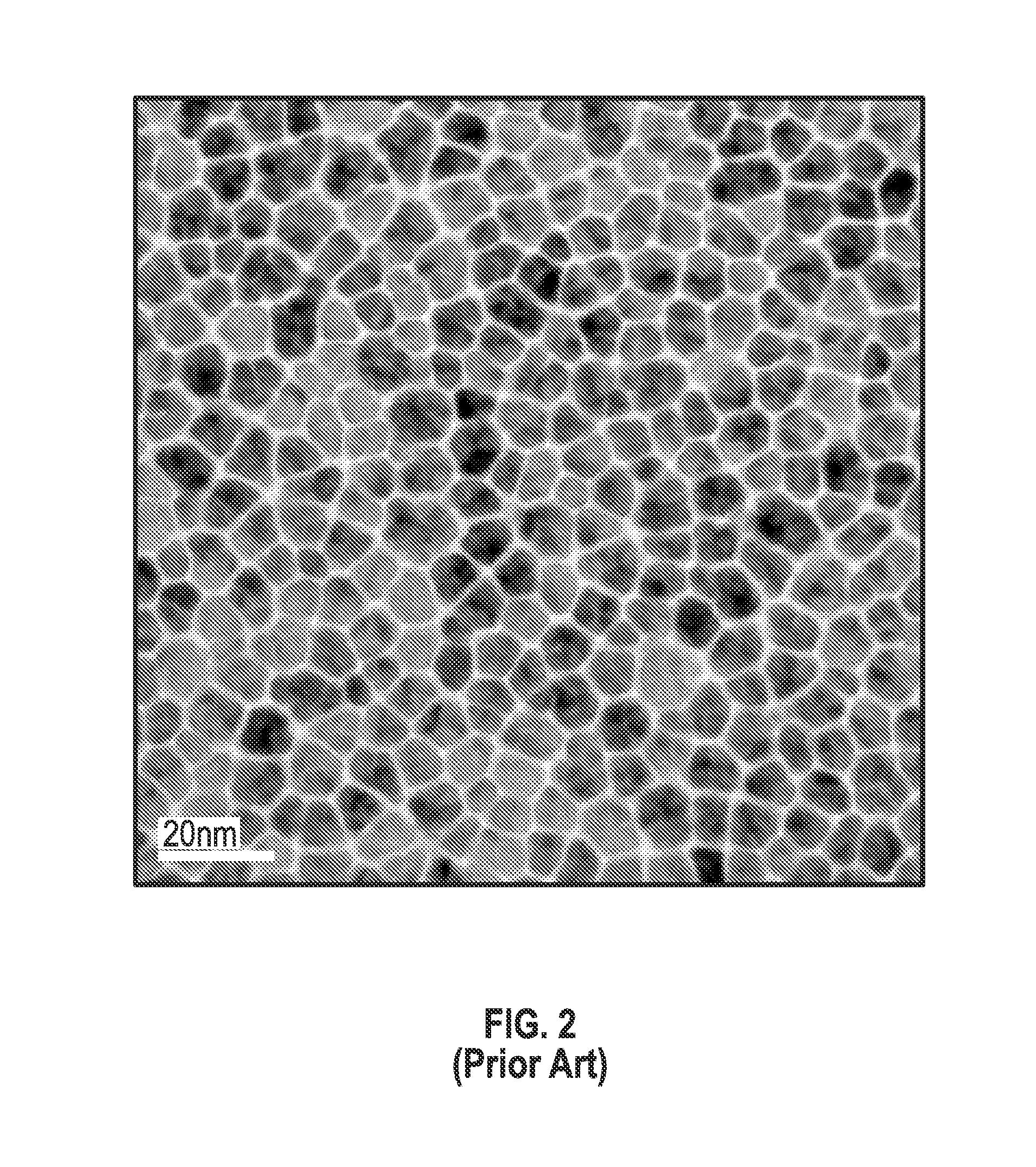

Perpendicular magnetic recording disk with template layer formed of a blend of nanoparticles

ActiveUS20150221330A1Reduce polydispersitySmall diameter distributionMagnetic materials for record carriersBase layers for recording layersNanoparticleRecording layer

A continuous-media perpendicular magnetic recording disk has a granular recording layer (RL) with controlled grain pitch distribution and controlled long range ordering of the grains. The disk includes a substrate with a template layer for the RL that comprises a blend of at least two different sized nanoparticles. The nanoparticles have a nanoparticle core with attached polymer ligands. The nanoparticle cores protrude above the surface of the template layer to provide a nonplanar surface topology. The blend of two sizes of nanoparticles causes the RL to have low grain pitch distribution and a disruption of long range ordering so that there are no large magnetic rafts. One of the nanoparticles types has a diameter greater than 105% of the diameter of the other nanoparticle type and is present in the total blend of nanoparticles of between about 5% and 35% or between about 55% and 90%.

Owner:WESTERN DIGITAL TECH INC

Pipeline Crude Oil in Coal Liquefaction

ActiveUS20120080358A1Low production costImprove solubilityWorking-up pitch/asphalt/bitumen by distillationSolid fuelsDownstream processingProcess engineering

The present disclosure provides methods and systems for coal liquefaction using a pipeline crude oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a pipeline crude oil to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

Double metal cyanide complex catalyst, its production process and its utilization

InactiveUS20060004233A1Improve filtering effectEasy to handleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSimple Organic CompoundsCyanide

Provided is a double metal cyanide complex catalyst with a high activity which is readily produced on an industrial scale. The double metal cyanide complex catalyst is of a fine particle form and contains t-butyl alcohol or, t-butyl alcohol and another organic compound as an organic ligand. The catalyst of the fine particle form has a volume-average particle size in a range of from 3 to 20 μm, based on measurement by a light scattering method for measuring fine particles having particle sizes of at least 0.15 μm. A particle content of the catalyst in a particle size range of at least 0.15 μm and at most 1 μm is less than 5% by volume, and a particle content of the catalyst over a particles size of 1 μm is in a range of more than 95% and at most 100% by volume.

Owner:ASAHI GLASS CO LTD

Seedling raising method for watermelons

InactiveCN108293677AIncrease productionOvercoming the disadvantages of difficulty in reproductionGraftingCultivating equipmentsContinuous croppingRootstock

The invention discloses a seedling raising method for watermelons. The method comprises the steps of rootstock preparation, seedling raising preparation, seedbed preparation, seedling raising, management in a sowing period, grafting and management of grafted seedlings. According to the method provided by the invention, watermelon grafting cultivation is performed on the continuous cropping ground,and above operation has the following advantages: 1, an occurrence of blight is effectively prevented; 2, the watermelons can be grown at lower temperature; and 3, a root system of pumpkin rootstockis stronger than that of a watermelon, the grafted seedlings have stronger water absorbing and fertilizer absorbing capacity, and the roots are widely distributed in soil, so that after the watermelons are grafted, fertilizers can be saved, and the yield of the watermelons can be improved; when tissue culture of triploid seedless watermelons is performed, root induction of vegetative propagation seedlings is more difficult, the vegetative propagation seedlings are used as scions to be grafted onto the pumpkin rootstock, so that a shortcoming that seedless watermelon seeds are difficult to reproduce is overcome; when industrialized seedling raising is performed, under the condition of small seeds, branches or buds are grafted onto the rootstock, so that a quantity of the grafted seedlings is greatly increased; and therefore, the method of using pumpkin and gourd as a rootstock and grafting watermelon seedlings is an effective way of development of watermelon planting.

Owner:钟宇民

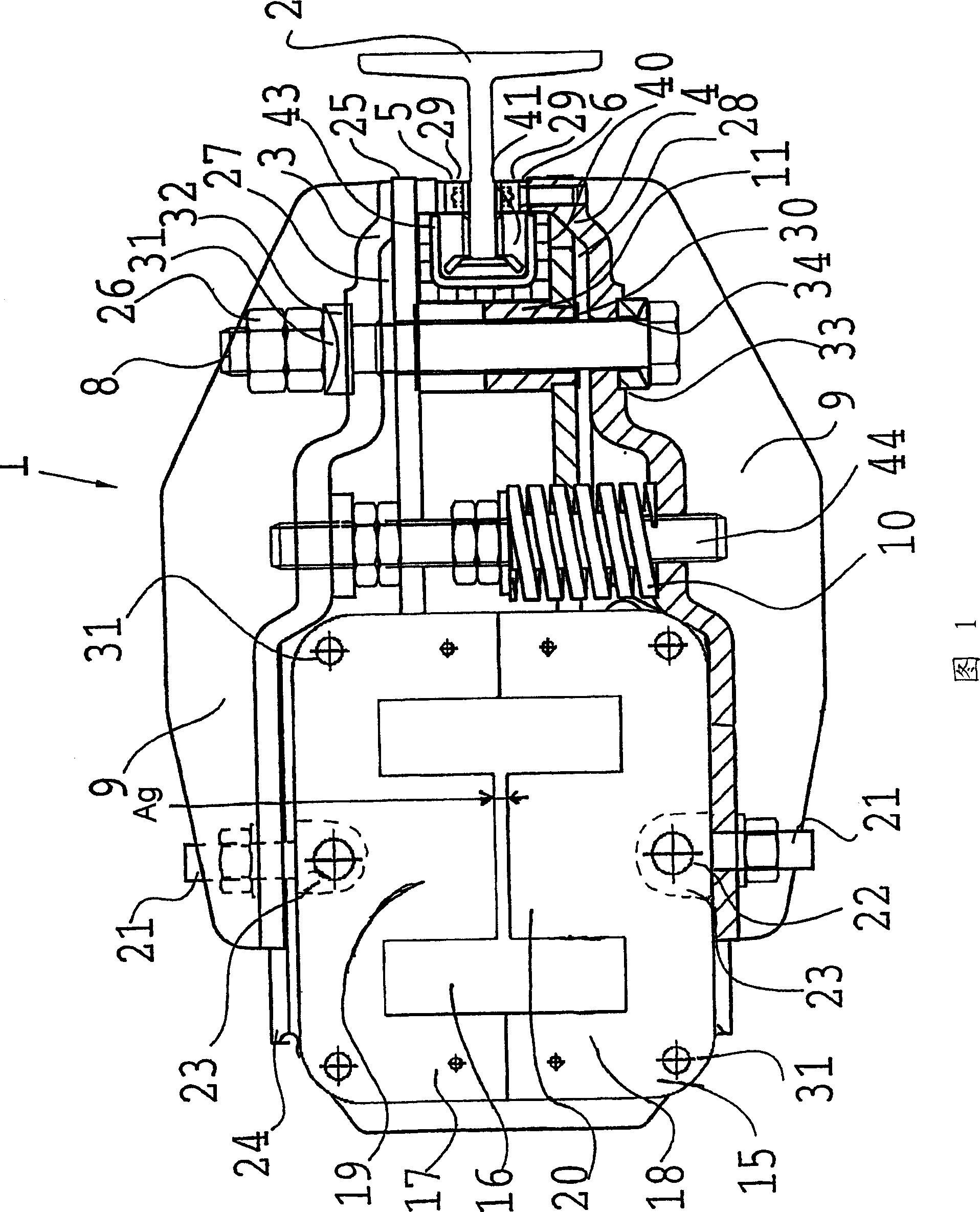

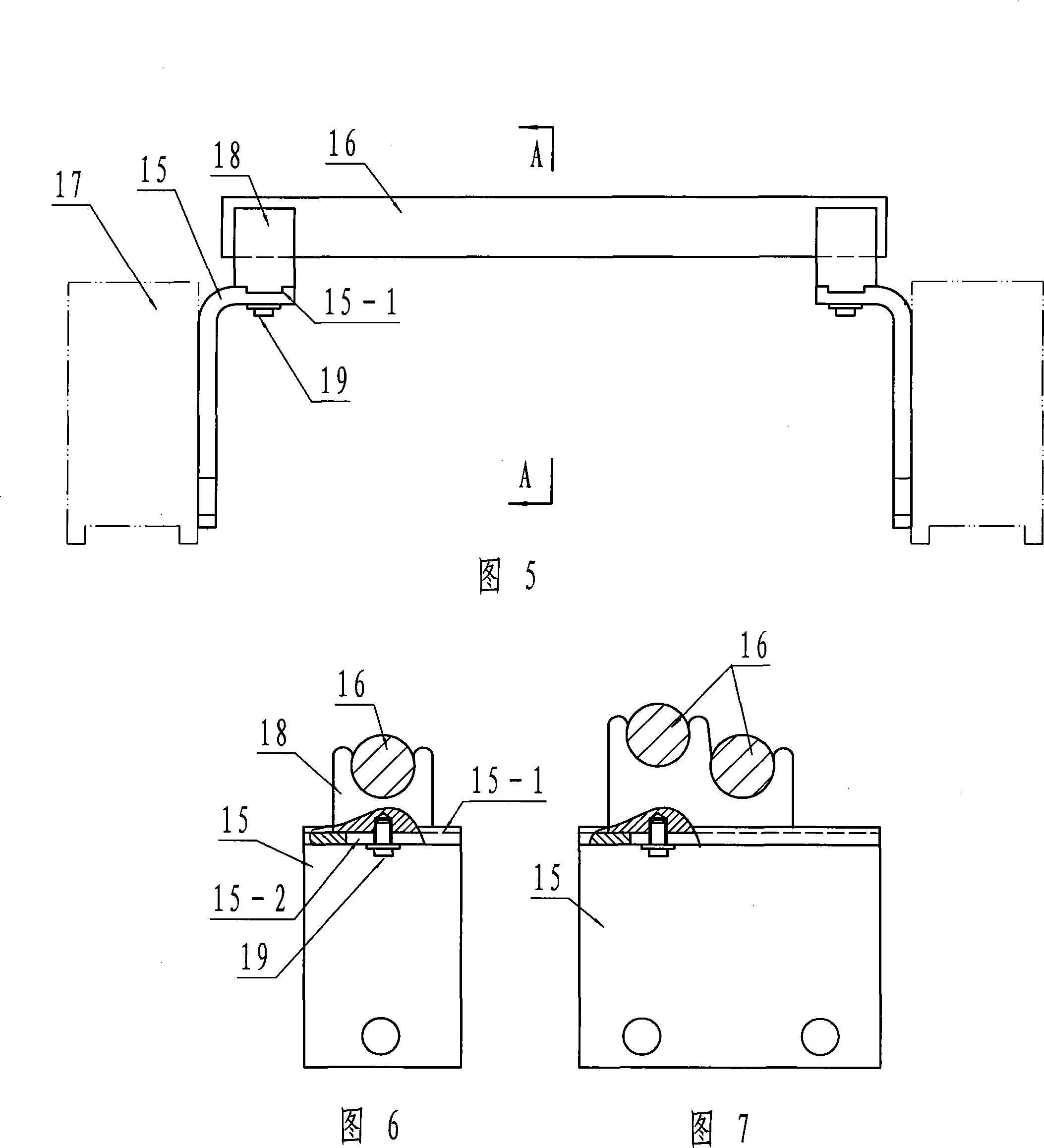

Guide-rail brake with electro-magnetic activation

A guide-rail brake (1) of an elevator and method for controlling the brake, which brake comprises a frame part fixed to the elevator car, and a prong part, which contains turning jaws (3,4) that correspond to the guide rail (2) via the braking surfaces when braking, a spring (10) loading the prong part to press the braking surfaces to the guide rail, a controllable mover, which is an electromagnet (15) , which electromagnet (15) contains two pulling core pieces (17,18) , the force effect of which electromagnet (15) on the prong part is opposed to the spring. In the guide-rail brake an air gap(ag) is structurally arranged between the center parts (19,20) of the pulling core pieces (17, 18) of the electromagnet of the guide-rail brake when the brake is fully energized, and a damping circuit is arranged in the coil (16) of the electromagnet (15) of the guide-rail brake to speed up operation of the guide-rail brake.

Owner:KONE CORP

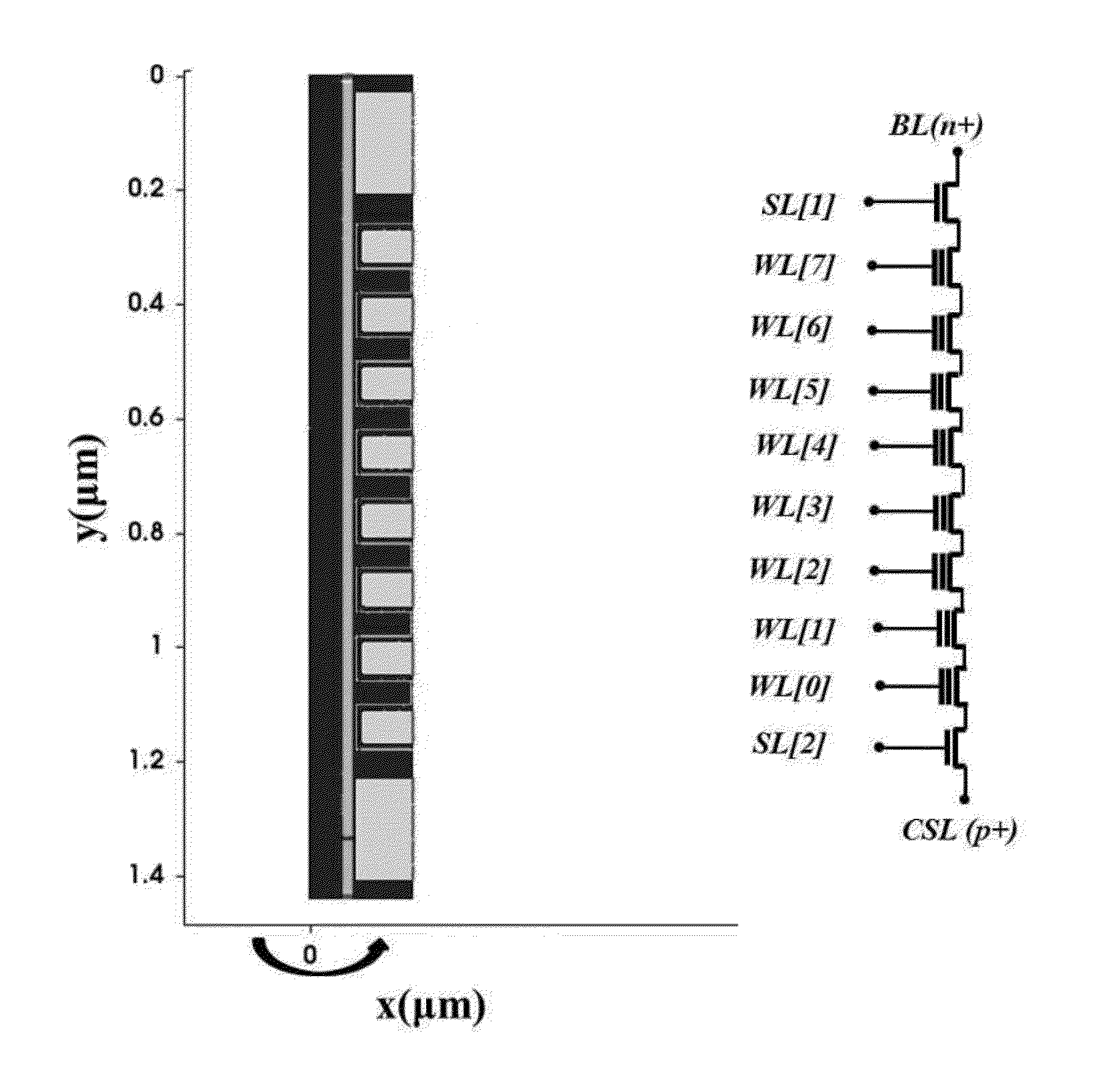

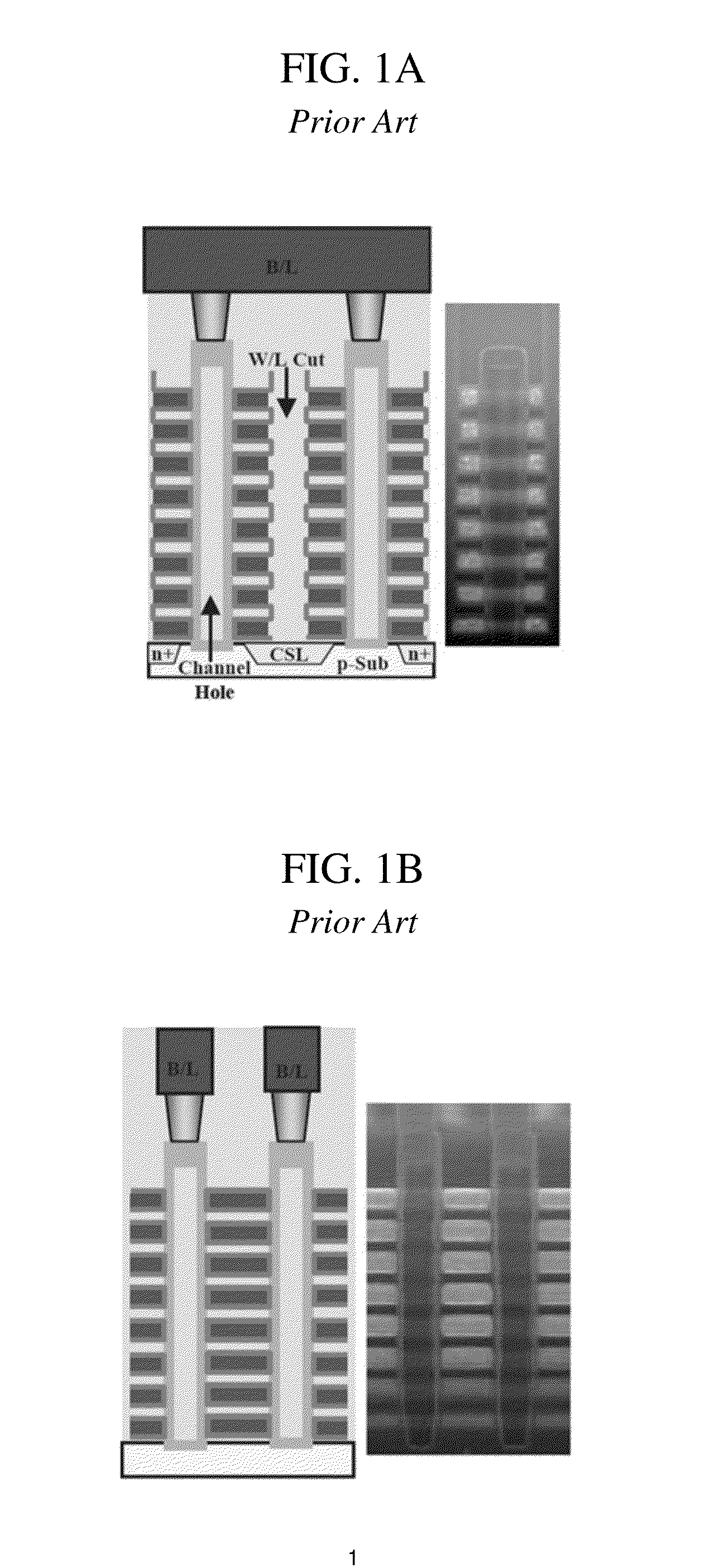

Cell string and reading method for the cell string

ActiveUS20150348639A1Small distribution of threshold voltageGood refresh marginSolid-state devicesRead-only memoriesMechanical engineeringMaterials science

Provided are a cell string and a reading method for the cell string. The cell string includes a semiconductor body formed on a surface of an insulating layer, first and second semiconductor regions formed at respective ends of the semiconductor body and are formed by being doped with different types of impurities, two or more control electrodes which are separated from each other to be electrically isolated, and a gate insulating film stack which is formed between the semiconductor body and the control electrodes, wherein the semiconductor body is configured to include at least two layers, and adjacent layers of the semiconductor body have different energy band gaps, wherein the semiconductor body is formed by an intrinsic semiconductor or a semiconductor being doped with impurities, and wherein the first and second semiconductor regions are doped with impurities of which concentration is higher than that of the semiconductor body.

Owner:SEOUL NAT UNIV R&DB FOUND

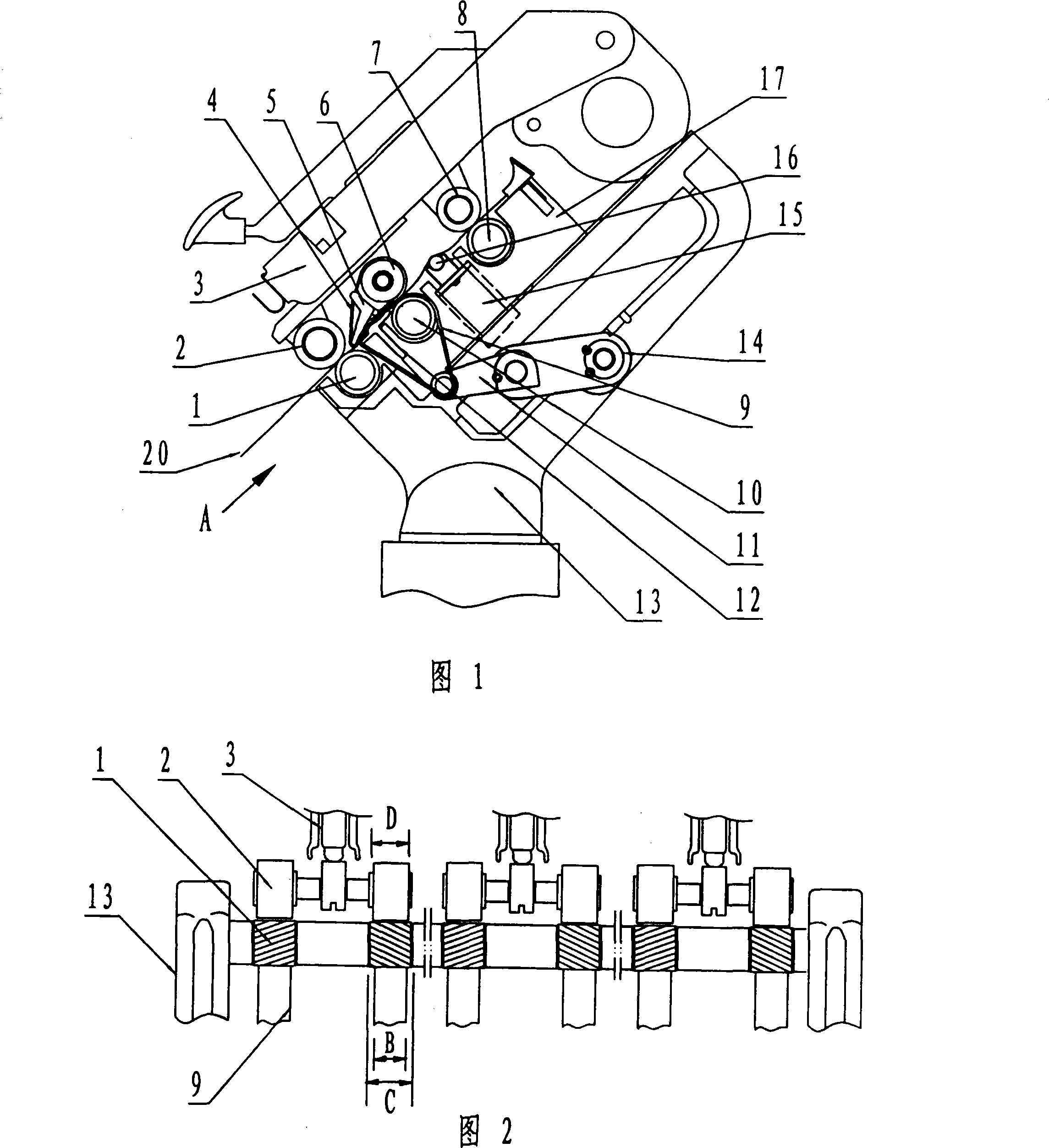

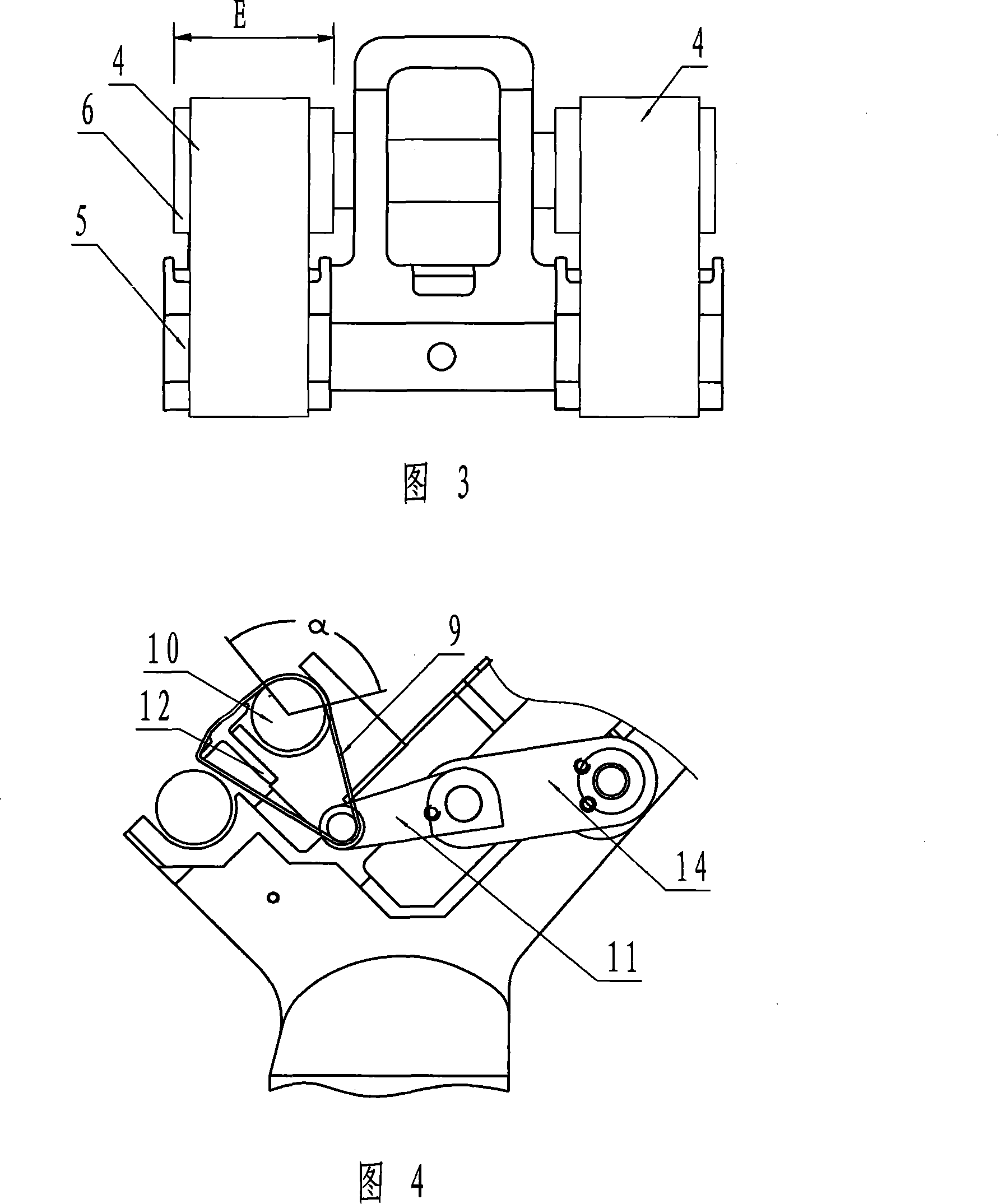

Drafting assembly of spinning machine

The invention relates to a drafting device of a spinning machine, belonging to the spinning technical field, comprising a cradle, a plurality of rollers, a front lower roller, a front upper rubber roller, a back upper rubber roller, a back lower roller and a main drafting component, wherein, the front lower roller and the front upper rubber roller are arranged at the front section of a drafting area, the back upper rubber roller and the back lower roller are arranged at the back area of the drafting area, and the main drafting component is arranged at the central section of the drafting area, the main drafting component comprises a middle upper roller, an upper pin, an upper leather collar, a middle lower roller, a lower pin and a lower leather collar. After improvement, the working position dimension D of the front upper rubber roller and the back upper rubber roller are 15 to 28 millimeters, the working position dimension C of the front lower roller and the middle lower roller and the back lower roller are 15 to 32 millimeters, the width dimension B of the upper leather collar and the lower leather collar are 14 to 27.5 millimeters, the width dimension E of the middle upper roller is 15 to 30 millimeters. The drafting device of the spinning machine has the advantages of reducing the friction area and the driving power, improving the operation stability of the drafting component, saving lots of consumable materials, effectively reducing the production cost and improving the quality of resultant yarn.

Owner:HEBEI TAIHANG TEXTILE MACHINERY CO LTD

Projection display systems for light valves

InactiveUS20060055891A1Reduce overall projection display system size and complexityWithout sacrificing brightnessProjectorsColor photographyLiquid-crystal displayProjection display

Projection display systems for light valves such as liquid crystal display panels, and in particular to the use of color component rotators, such as retardation filters, to provide for improved projection display architectures.

Owner:FLORENCE JAMES M +2

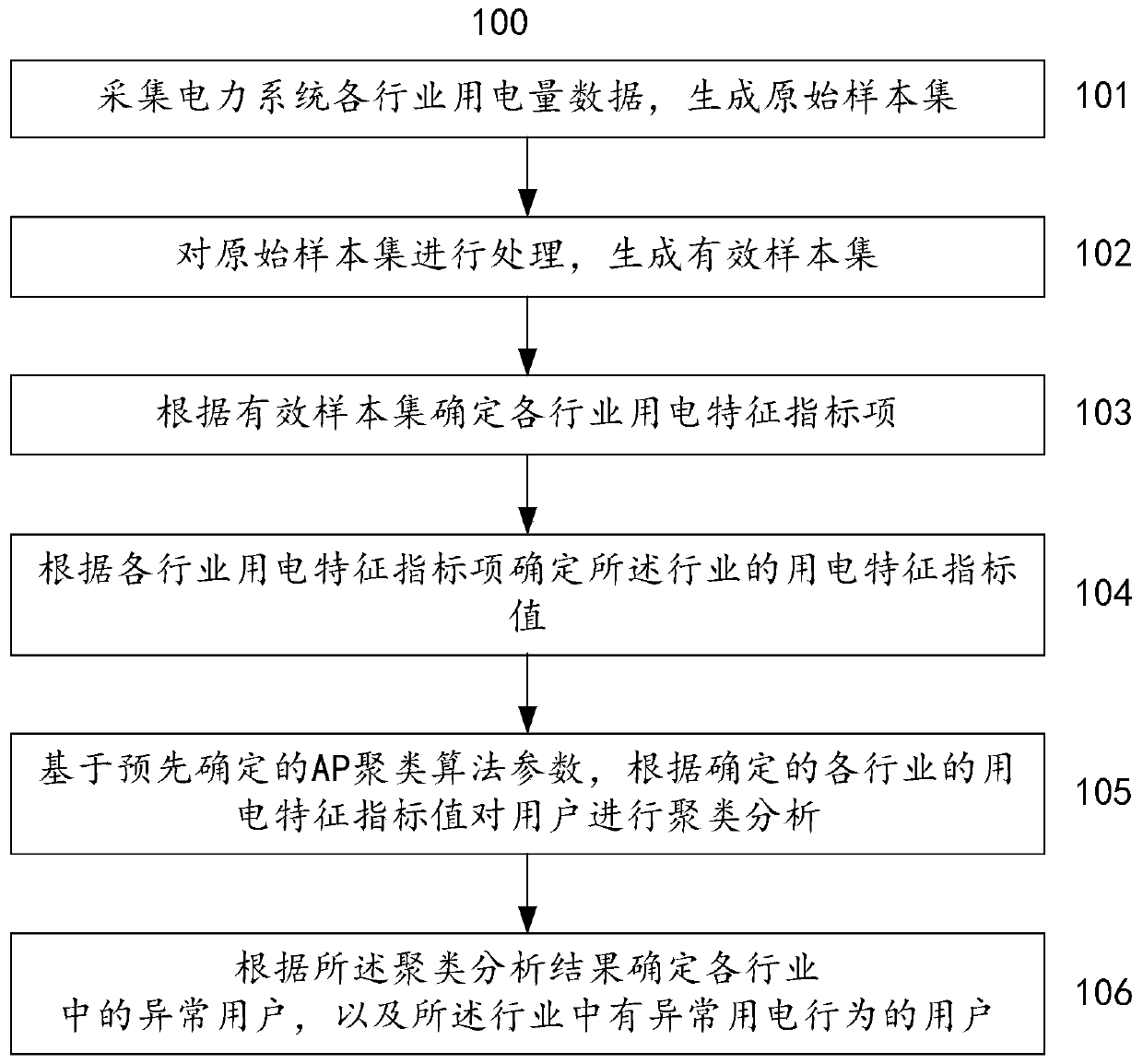

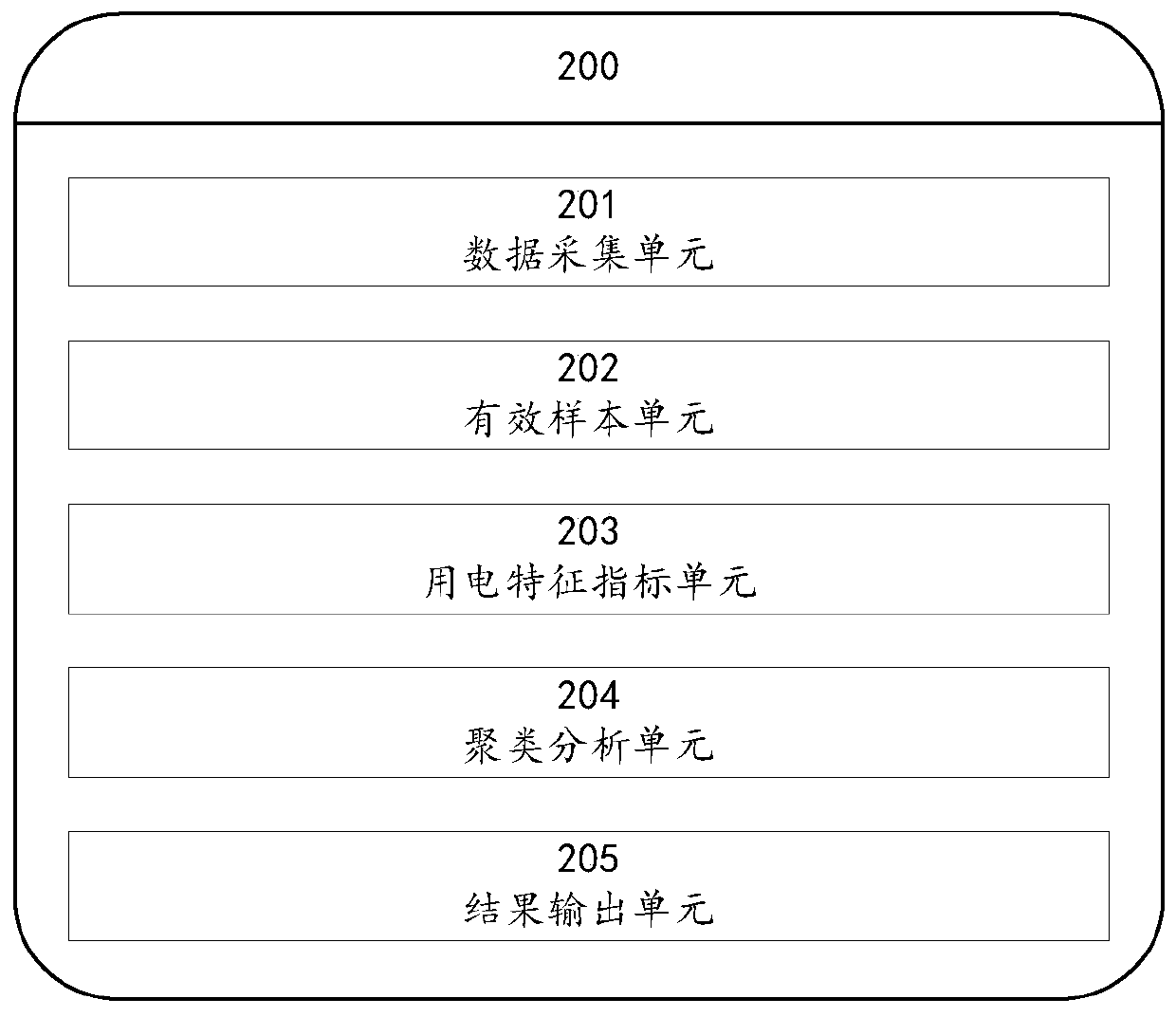

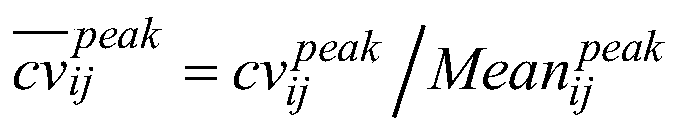

Method and system for identifying abnormal industry users and abnormal power utilization behaviors of power system

PendingCN110991477AReduce the number of clustersAvoid interferenceData processing applicationsCharacter and pattern recognitionCluster algorithmElectric power system

The invention provides a method and a system for identifying abnormal industry users and abnormal power utilization behaviors of a power system. The method comprises the following steps: acquiring power consumption data of each industry; establishing power utilization characteristic index items capable of accurately describing industry characteristics based on the industry characteristics; whereinthe power utilization characteristic index items comprise peak time periods, namely a valley period, valley period power consumption and peak period power consumption; determining user characteristicindex valley and peak load ratios through the power utilization characteristic index items; according to the method, on the basis of establishing power utilization characteristic index items, adopting an AP clustering algorithm to carry out clustering analysis on power utilization behaviors according to industries, and abnormal users with wrong power utilization industry attribute identificationand abnormal power utilization behavior users in the industries are identified through clustering results. According to the method and the system, the number of user clusters is remarkably reduced, the difficulty of electricity consumption abnormity detection and the false alarm rate of electricity stealing detection are correspondingly reduced, and the operation benefit of a power supply enterprise is effectively improved.

Owner:CHINA ELECTRIC POWER RES INST +6

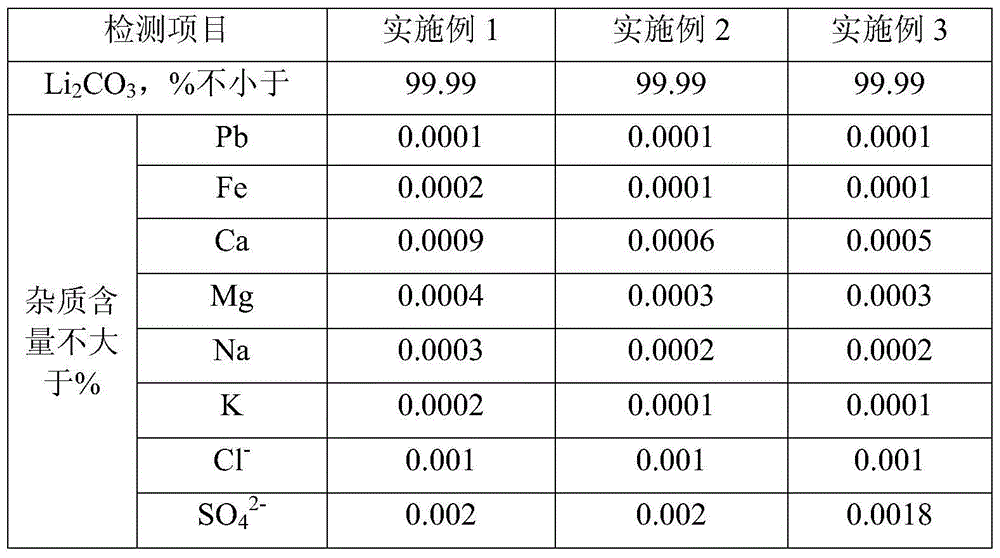

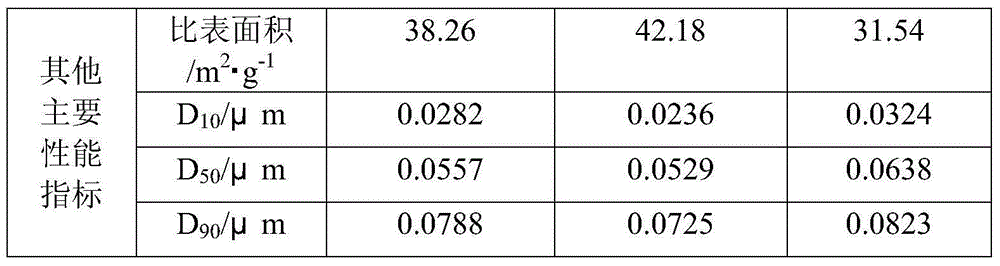

Method for preparing high-purity lithium carbonate

ActiveCN104701545AWell mixedStrong depolymerization abilityCell electrodesSecondary cellsMass ratioLithium carbonate

The invention belongs to the technical field of preparation of nanoscale lithium salt and particularly discloses a method for preparing high-purity lithium carbonate. The method includes the steps that firstly, pure water is heated to 60-80 DEG C, the pure water and lithium hydroxide monohydrate are mixed with the mass ratio being two to one, then, a small amount of water-soluble dispersant is added into the mixture and is sufficiently stirred, and the mixture serves as a lithium source; secondly, percarbamide and pure water are mixed in equal mass to serve as a carbonic acid source, and the molar ratio of the percarbamide to the lithium hydroxide monohydrate is 1:1.80-1.95; thirdly, the lithium source and the carbonic acid source are added into a hydro-thermal synthesis reaction still and are sufficiently stirred, then, the still is closed and placed in a drying oven, the still is heated to 100 DEG C-120 DEG C at the speed of 3 DEG C / min and is taken out after being contained for 5-10 h, lithium carbonate size in the still is filtered to obtain a filter cake, the hot filter cake is washed for 2-4 times through boiling pure, and then wet materials are obtained; fourthly, the wet materials are dried for 8-15 h at the temperature being 250 DEG C-350 DEG C, the pressure being -0.1 Mpa- -0.08 Mpa, and finally lithium carbonate powder with the particle diameter being 20-90 nm is obtained.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

Hydrogenated vegetable oil in coal liquefaction

InactiveUS8465561B2Low production costImprove solubilitySolid fuelsLiquid carbonaceous fuelsDownstream processingVegetable oil

The present disclosure provides methods and systems for coal liquefaction using a hydrogenated vegetable oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

Image forming apparatus with reduced loss of electron source caused by the inert gas

InactiveUS7733003B2Reduce lossesSmall aged deteriorationGas filling substance selectionDischarge tube luminescnet screensElectron sourceElectron ionization

An image forming apparatus in which a first substrate provided with an electron-emitting device and an image displaying member which electrons emitted from the electron-emitting device irradiate are arranged to be opposed is provided with a deflecting means deflecting the electrons emitted from the electron-emitting device and a trapping unit trapping an inert gas ionized by the electrons. Thereby, the damages of the electron-emitting device by the inert gas are prevented, and the life of an image display apparatus is aimed to be elongated.

Owner:CANON KK

Process for producing porous quartz glass object, and optical member for EUV lithography

InactiveUS20110301015A1Easy to controlSmall distributionGlass shaping apparatusGlass deposition burnersDopantHydrogen halide

The present invention relates to a process for producing a porous quarts glass body containing hydrolyzing a metal dopant precursor and an SiO2 precursor in a flame of a burner to form glass fine particles, and depositing and growing the formed glass fine particles on a base material, in which the burner has at least two nozzles, and in which a mixed gas containing (A) a metal dopant precursor gas, (B) an SiO2 precursor gas, (C) one gas of H2 and O2, and (D) one or more gases selected from the group consisting of a rare gas, N2, CO2, a hydrogen halide and H2O, with a proportion of the gas (D) being from 5 to 70 mol %; and (E) the other gas of H2 and O2 of (C), are fed into different nozzles of the burner from each other.

Owner:ASAHI GLASS CO LTD

Perpendicular magnetic recording medium and magnetic recording/reproducing apparatus

InactiveUS7431999B2Small distributionHigh crystallinityBase layers for recording layersRecord information storageGrain boundaryMaterials science

Disclosed is a perpendicular magnetic recording medium including: a nonmagnetic substrate; a first underlayer formed on the nonmagnetic substrate, mainly composed of at least two kinds selected from a group consisting of Fe2O3, Co3O4, MgO, MoO3, Mn3O4, SiO2, Al2O3, TiO2, and ZrO2, and having crystal grains growing in a columnar shape and crystal grain boundaries surrounding the crystal grains; a nonmagnetic second underlayer formed on the first underlayer and having crystal grains with one of a face-centered cubic structure and a hexagonal close-packed structure growing on the crystal grains of the first underlayer; a magnetic layer formed on the second underlayer; and a protective film formed on the magnetic layer.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com