Method for solvent-thermally synthesizing nano bismuth oxide single-crystal chips

A technology of nano-bismuth oxide and single wafer, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc. It can solve the problems of purity, low synthesis efficiency, difficult to control shape, and large one-time investment, etc., to achieve The effect of uniform product appearance, cheap raw materials, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

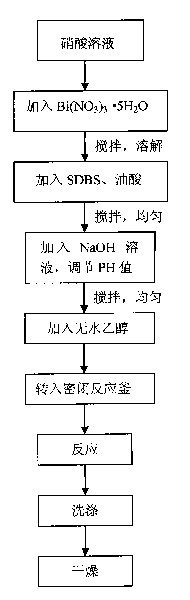

[0018] Take 10ml of 1mol / l. HNO 3 Placed in a beaker, add 1mmol of Bi(NO 3 ) 3 ·5H 2 O, stir, dissolve, then add 2mmol SDBS and 3ml oleic acid, stir evenly, continue to stir and drop NaOH solution to PH≈13, continue to add absolute ethanol to 80% of the closed container of the autoclave, after fully stirring, put The resulting mixture was transferred to an autoclave lined with polytetrafluoroethylene, the autoclave was sealed, and kept at 120°C for 8 hours of reaction. After the reaction, the final product was filtered, then washed several times with deionized water and absolute ethanol to completely remove the surfactant, and dried at 60° C. for 2 hours to obtain 0.224 g of nano-bismuth oxide single chip with a yield of 96 %.

Embodiment 2

[0020] Take 10ml of 0.5mol / l. HNO 3 Placed in a beaker, add 2mmol of Bi(NO 3 ) 3 ·5H 2 O, stir, dissolve, then add 1mmol SDBS and 4ml oleic acid, stir evenly, continue to stir and dropwise add NaOH solution to PH≈13, continue to add absolute ethanol to 80% of the closed container of the autoclave, after fully stirring, put The resulting mixture was transferred to an autoclave lined with polytetrafluoroethylene, the autoclave was sealed, and kept at 120°C for 8 hours of reaction. After the reaction, the final product was filtered, then washed several times with deionized water and absolute ethanol to completely remove the surfactant, and dried at 50° C. for 3 hours to obtain 0.416 g of nano-bismuth oxide single chip with a yield of 91.3 %.

Embodiment 3

[0022] Take 10ml of 1mol / l. HNO 3 Place in a beaker, add 5mmol of Bi(NO 3 ) 3 ·5H 2 O, stir, dissolve, then add 3mmol SDBS and 2ml oleic acid, stir evenly, continue to stir and dropwise add NaOH solution to PH≈10, continue to add absolute ethanol to 90% of the closed container of the autoclave, after fully stirring, put The resulting mixture was transferred to an autoclave lined with polytetrafluoroethylene, the autoclave was sealed, and kept at 120°C for 12 hours of reaction. After the reaction was finished, the final product was filtered, then washed several times with deionized water and absolute ethanol to completely remove the surfactant, and dried at 60°C for 2 hours to obtain a 1.06g (scale) nano-bismuth oxide single chip. The rate is 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com