Method for preparing high-purity lithium carbonate

A technology of high-purity lithium carbonate and lithium carbonate, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of dependence on dispersants and the influence of dispersant stability, and achieve small distribution range, uniform particle size, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

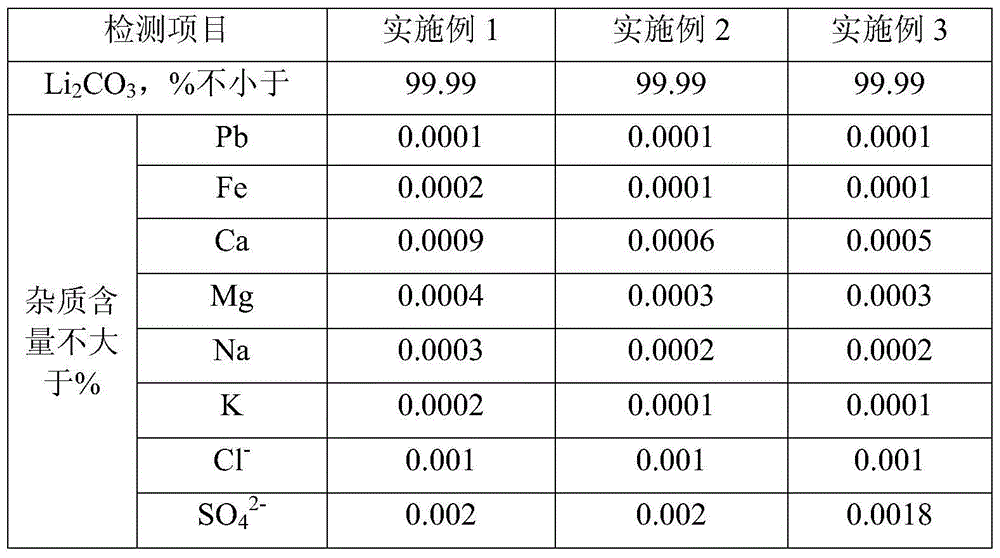

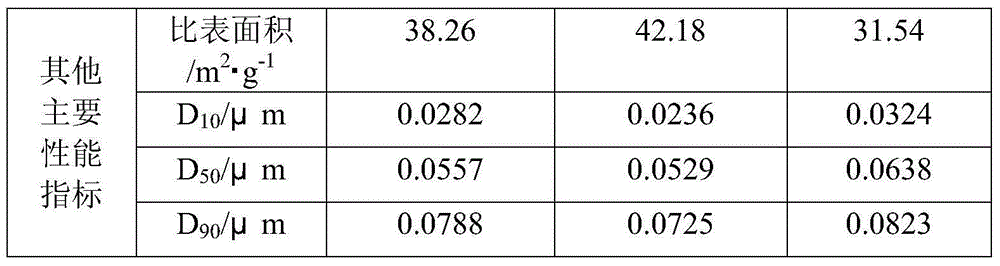

Embodiment 1

[0020] A preparation method of nanoscale high-purity lithium carbonate, the steps are as follows:

[0021] 1) After heating 75.6g of pure water to 60°C, mix it with 37.8g of lithium hydroxide monohydrate, add 1.1g of sodium dodecylbenzenesulfonate and fully stir for 20min, as a lithium source;

[0022] 2) Mix 30.0g carbonamide (urea) with 30.0g pure water as a carbonic acid source;

[0023] 3) Add the reaction precursor lithium source and carbonic acid source into a 250mL stainless steel hydrothermal synthesis reaction kettle in sequence, seal the kettle after fully stirring, put the hydrothermal synthesis reaction kettle into an oven, and raise the temperature to 100°C at a rate of 3°C / min. Insulated for 10 hours and taken out, quenched with cooling water, opened the kettle, filtered the lithium carbonate slurry in the reaction kettle to obtain a lithium carbonate filter cake, and washed 2 times while hot with boiled pure water to obtain a lithium carbonate wet material;

[...

Embodiment 2

[0026] A preparation method of nanoscale high-purity lithium carbonate, the steps are as follows:

[0027] 1) Slowly add 8.9g of anionic polyacrylamide (molecular weight 3 million to 22 million) into a plastic container filled with 89.0g of pure water (pH≈7), and mechanically stir at 100r / min until the solid is completely dissolved, and then 60 Mesh filtration makes dispersant solution;

[0028] 2) After heating 59.8g of pure water to 70°C, mix it with 29.9g of lithium hydroxide monohydrate, and add 5.4g of the dispersant solution obtained in step 1), and fully stir for 15min, as a lithium source;

[0029] 3) Mix 22.5g carbonamide (urea) with 22.5g pure water as a carbonic acid source;

[0030] 4) Add the reaction precursor lithium source and carbonic acid source into a 250mL stainless steel hydrothermal synthesis reaction kettle in sequence, seal the kettle after fully stirring, put the hydrothermal synthesis reaction kettle into an oven, and raise the temperature to 110°C a...

Embodiment 3

[0033] A preparation method of nanoscale high-purity lithium carbonate, the steps are as follows:

[0034] 1) After heating 41.3g of pure water to 80°C, mix it with 20.5g of lithium hydroxide monohydrate, and dropwise add 0.06g of anionic sodium polyacrylate (molecular weight: 1000-5000), stir well for 10min, as a lithium source;

[0035] 2) Mix 15.0g carbonamide (urea) with 15.0g pure water as a carbonic acid source;

[0036] 3) Add the reaction precursor lithium source and carbonic acid source into a 250mL stainless steel hydrothermal synthesis reaction kettle in sequence, seal the kettle after fully stirring, put the hydrothermal synthesis reaction kettle into an oven, and raise the temperature to 120°C at a rate of 3°C / min. Take out after being kept warm for 5h, open the kettle after quenching with cooling water, filter the lithium carbonate slurry in the reaction kettle to obtain lithium carbonate filter cake, and wash 4 times while hot with boiled pure water to obtain li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com