Novel flexible conductive composite film and preparation method thereof

A composite film, a new type of technology, applied in the field of electrochemistry, can solve the problems of low conductivity and small capacitance value, and achieve the effect of high conductivity, large capacitance value and stable material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

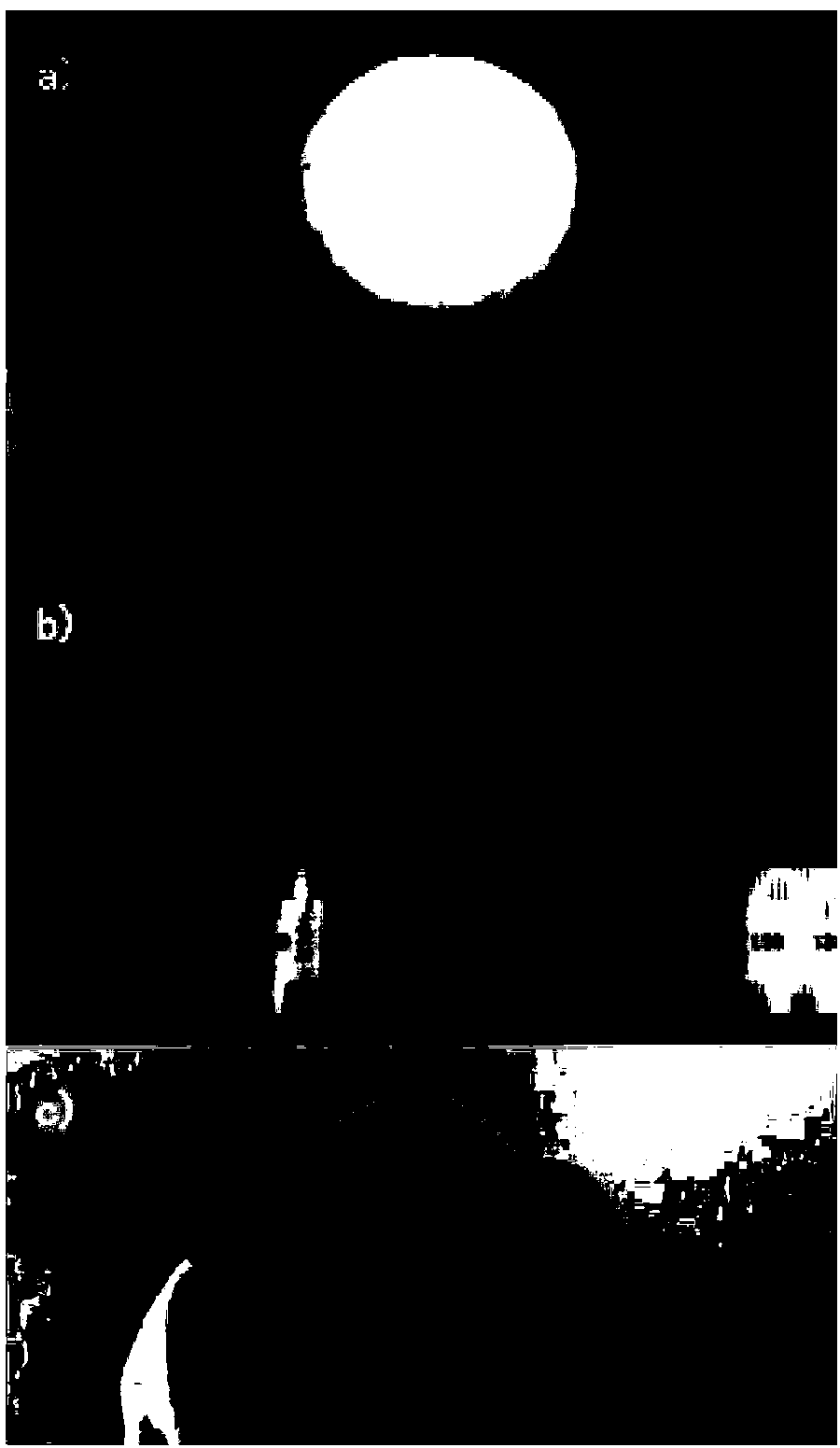

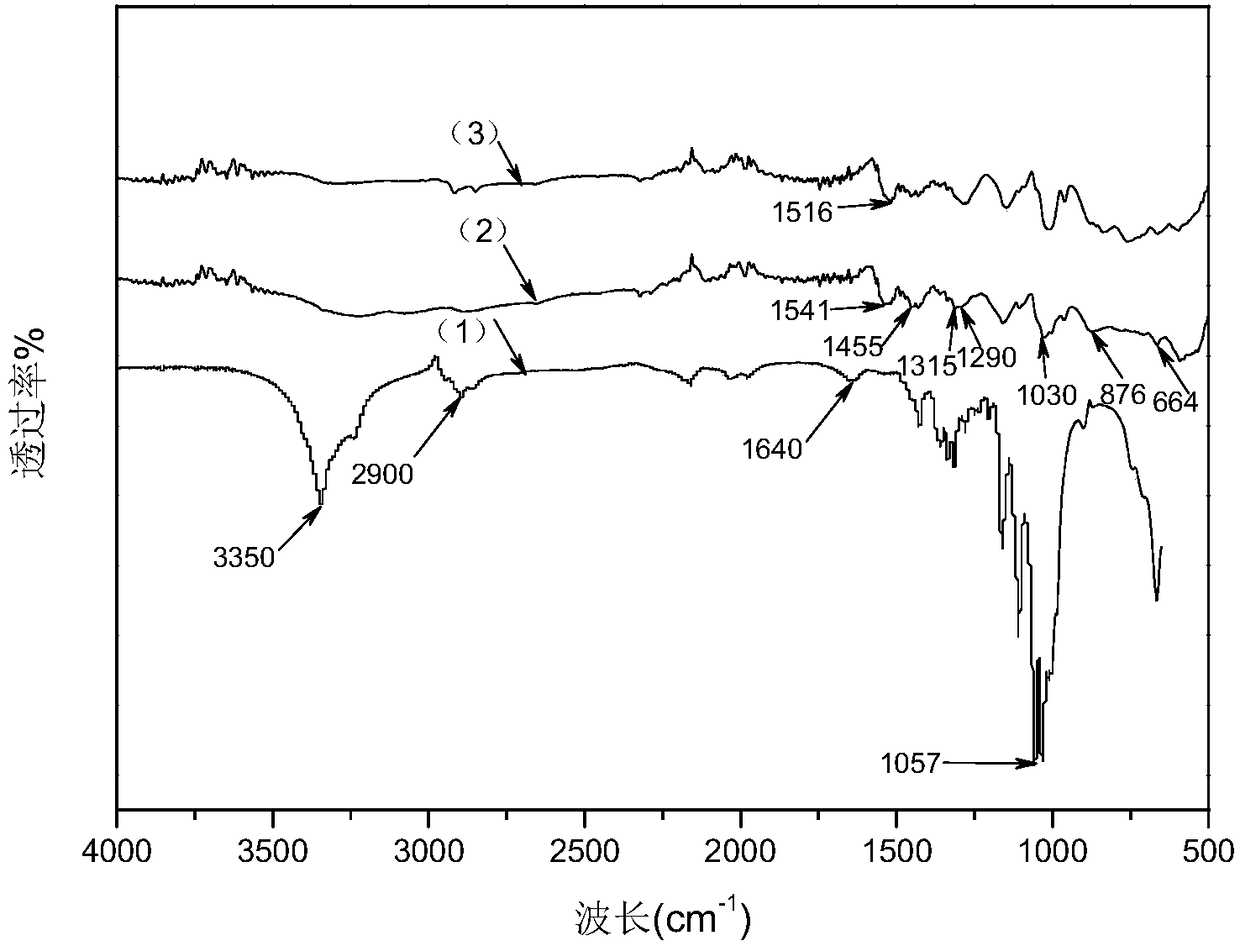

Image

Examples

Embodiment 1B

[0037] The preparation of embodiment 1BC / PPy / SWCNTs composite film

[0038] (1) First cut the BC film into small cubes, then use a soymilk machine to beat for 5 minutes, and then disperse at 7000rpm for 10 minutes by a high-speed disperser to make a BC nanofiber suspension with a concentration of 1 mg / mL;

[0039] (2) Add the BC nanofiber suspension to the mixed solution A mixed with hydrochloric acid and ferric chloride, ultrasonically treat it for 15 minutes, and cool to 1°C after stirring for 15 minutes to obtain the mixed solution B; the BC nanofiber suspension The volume ratio with the mixture A is 1:1;

[0040] Wherein, in the mixed solution A, the hydrochloric acid concentration is 1.0mol / L, and the ferric chloride concentration is 8mmol / L.

[0041] (3) Add the Py monomer into the mixed liquid B according to the volume ratio of 0.3:100, and react for 30 minutes at a low temperature of 1-10°C to obtain BC / PPy composite pulp, and pass the composite pulp through a dialysi...

Embodiment 2B

[0045] The preparation of embodiment 2BC / PPy / SWCNTs composite film

[0046] (1) First cut the BC film into small cubes, then use a soybean milk machine to beat for 10 minutes, and then disperse it at 10,000 rpm for 15 minutes by a high-speed disperser to make a BC nanofiber suspension with a concentration of 3 mg / mL;

[0047] (2) Add the BC nanofiber suspension to the mixed solution A mixed with hydrochloric acid and ferric chloride, ultrasonically treat it for 20min, and cool to 4°C after stirring for 20min to obtain the mixed solution B; the BC nanofiber suspension The volume ratio with the mixture A is 1:4;

[0048] Wherein, in the mixed solution A, the hydrochloric acid concentration is 3.0mol / L, and the ferric chloride concentration is 12mmol / L.

[0049] (3) Add the Py monomer into the mixed liquid B according to the volume ratio of 0.5:100, and react for 300 minutes at a low temperature of 1-10°C to obtain a BC / PPy composite slurry, and pass the composite slurry through...

Embodiment 3B

[0053] The preparation of embodiment 3BC / PPy / SWCNTs composite film

[0054] (1) First cut the BC film into pieces, then mechanically beat for 7 minutes, and then disperse for 12 minutes at 8500 rpm by a high-speed disperser to make a BC nanofiber suspension with a concentration of 2 mg / mL;

[0055] (2) Add the BC nanofiber suspension to the mixed solution A mixed with hydrochloric acid and ferric chloride, ultrasonically treat it for 16 minutes, and cool to 2.5°C after stirring for 16 minutes to obtain the mixed solution B; the BC nanofiber suspension The volume ratio with the mixture A is 1:1.5;

[0056] Wherein, in the mixed solution A, the concentration of hydrochloric acid is 2.0mol / L, and the concentration of ferric chloride is 10mmol / L.

[0057](3) Add the Py monomer into the mixed solution B according to the volume ratio of 0.4:100, and react at a low temperature of 4°C for 180 minutes to obtain BC / PPy composite pulp, which is removed by dialysis through a dialysis bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com