All-cutting-edge knife flywheel

A cutter wheel and cutting edge technology, applied in the field of full-edge cutter wheel, can solve the problems of poor rotation of cutter wheel and large impact force of cutter wheel, so as to reduce the rate of defective cutting quality, improve impact resistance, and reduce friction area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

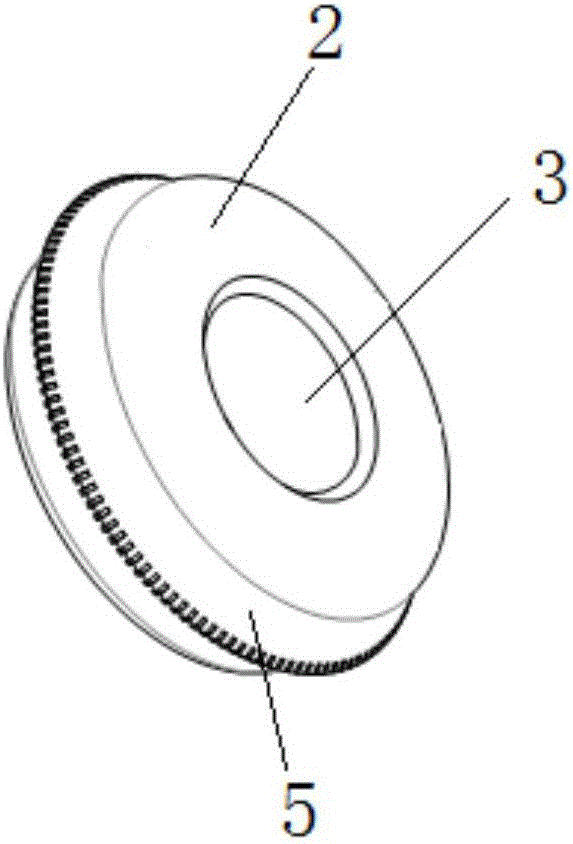

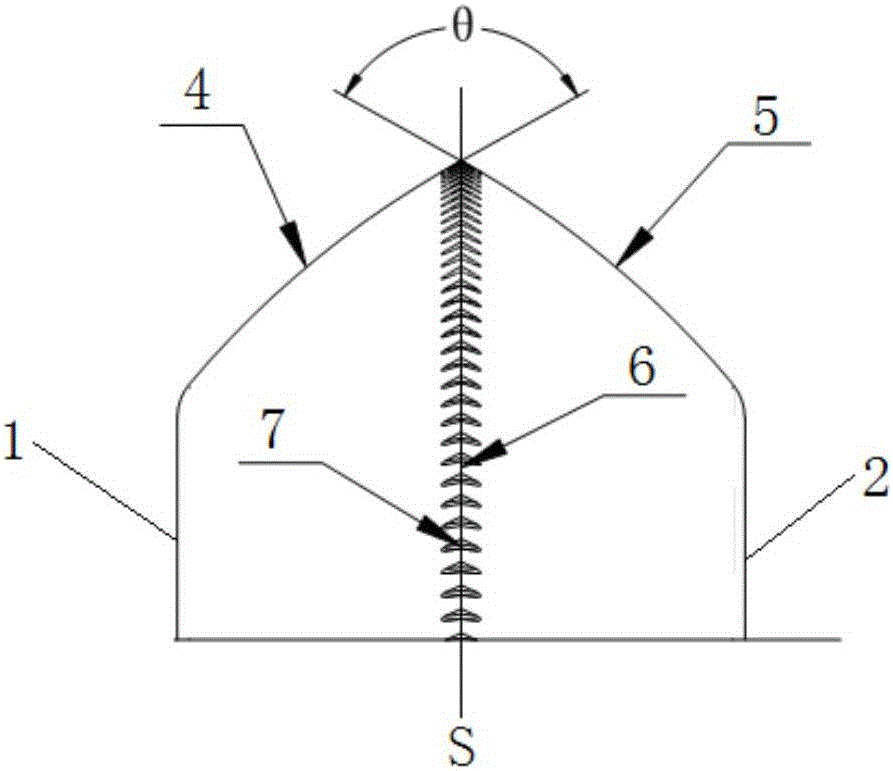

[0061] The structures of the first curved surface and the second curved surface in this embodiment are as follows figure 1 shown. The first curved surface 4 and the second curved surface 5 are symmetrical about the longitudinal center section of the cutter wheel. Wherein, the first curved surface 4 and the second curved surface 5 are both first convex arc surfaces. Wherein, the radius of the first convex arc surface is 0.75-0.9 mm. The central angle of the arc cut by the convex arc surface by the first central section is 20-70 degrees. The angle between the tangent line at the intersection of the first curved surface 4 and the circumferential cutting edge 6 and the tangent line at the intersection of the second curved surface 5 and the circumferential cutting edge 6 is 90-160 degrees.

[0062] It should be noted that the first central section mentioned in this application is a plane that can simultaneously cut the first curved surface, the second curved surface, the first c...

Embodiment 2

[0065] Figure 4 It is a schematic structural view of a full-blade cutter wheel according to a preferred embodiment. Such as Figure 4 As shown, the first curved surface 4 and the second curved surface 5 are symmetrical about the longitudinal center section of the cutter wheel. Wherein, both the first curved surface 4 and the second curved surface 5 include a second convex arc surface 40 and a first inclined surface 41 .

[0066] On the first curved surface 4 , one edge of the second convex arc surface 40 is connected to the first cutter wheel disc surface 1 ; the other edge of the first convex arc surface is connected to the first inclined surface 41 . On the second curved surface 5 , one edge of the second convex arc surface 40 is connected to the second cutter wheel disc surface 2 ; the other edge of the first convex arc surface is connected to the first inclined surface 41 . The other edge of the first inclined surface 41 on the first curved surface 4 intersects with th...

Embodiment 3

[0070] Figure 5 It is a partial structural schematic diagram of a full edge cutter wheel shown according to a preferred embodiment. Such as Figure 5 As shown, the first curved surface 4 and the second curved surface 5 are symmetrical about the longitudinal center section of the cutter wheel. Wherein, both the first curved surface 4 and the second curved surface 5 include a third convex arc surface 42 and a first concave arc surface 43 .

[0071] On the first curved surface 4 , one edge of the third convex arc surface 42 is connected to the first cutter wheel disk 1 , and the other edge of the third convex arc surface 42 is connected to an edge of the first concave arc surface 43 . On the second curved surface 5 , one edge of the third convex arc surface 42 is connected to the second cutter wheel disc surface 2 , and the other edge of the third convex arc surface 42 is connected to an edge of the first concave arc surface 43 . The other edge of the first concave arc surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com