Automatic pyrotechnic composition mixing system

A pyrotechnic powder and mixing technology, which is used in mixers, fluid mixers, transportation and packaging, etc., can solve the problems of easy local high temperature, high explosion risk, severe friction, etc., so as to reduce the risk and reduce the friction area. , Improve the effect of mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

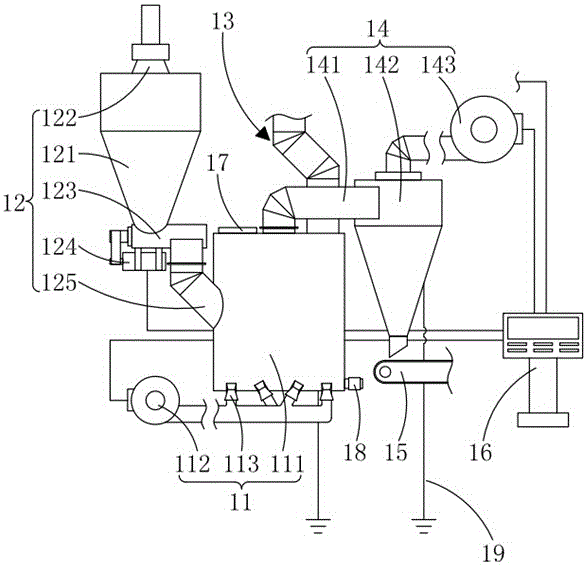

[0024] see figure 1 , is a structural schematic diagram of the pyrotechnic powder automatic mixing system provided by the present invention.

[0025] The pyrotechnic powder automatic mixing system 1 includes a mixing unit 11, an oxidant feeding unit 12, a reducing agent feeding unit 13, a collection unit 14, a packaging line 15, a control box 16, a manhole 17, a sewage pipe 18 and a grounding wire 19.

[0026] The mixing unit 11 includes a mixing chamber 111 , a blower 112 and a nozzle 113 . One end of the four nozzles 113 runs through the bottom of the mixing chamber 111 , and the other end is connected to the air blower 112 by pipes. The four nozzles 113 are eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com