Patents

Literature

63results about How to "Control feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

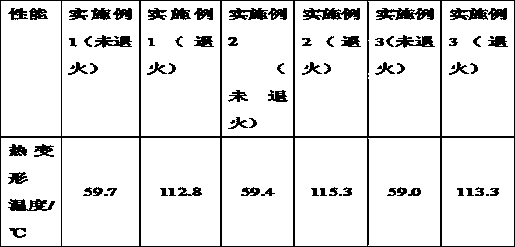

Bamboo fiber/polylactic acid composite material and preparation method thereof

The invention discloses a bamboo fiber / polylactic acid composite material and a preparation method thereof. The bamboo fiber / polylactic acid composite material specifically comprises the following rawmaterials in parts by weight: 60-80 parts of polylactic acid, 10-30 parts of talcum powder, 3-15 parts of modified bamboo fibers, 2-15 parts of a flexibilizer, 0.1-0.3 part of a coupling agent, 0.1-0.3 part of an antioxidant, 0.2-0.6 part of an auxiliary antioxidant, 0.2-0.5 part of a lubricating agent, 0.2-1 part of a nucleating agent, 0.1-0.3 part of an anti-floating fiber agent and 0.5-3 partsof a hydrolysis resistance agent. According to the composite material disclosed by the invention, the bamboo fibers are modified and thermally treated, the bamboo fibers and talcum powder are treatedby using the coupling agent, and according to a certain mixing sequence and suitable extrusion process parameters, the problems that the bamboo fiber / polylactic acid composite material is rough in surface and has silver filaments and local black spots and the compatibility between the polylactic acid and the bamboo fibers is poor are solved.

Owner:浙江明江新材料科技股份有限公司

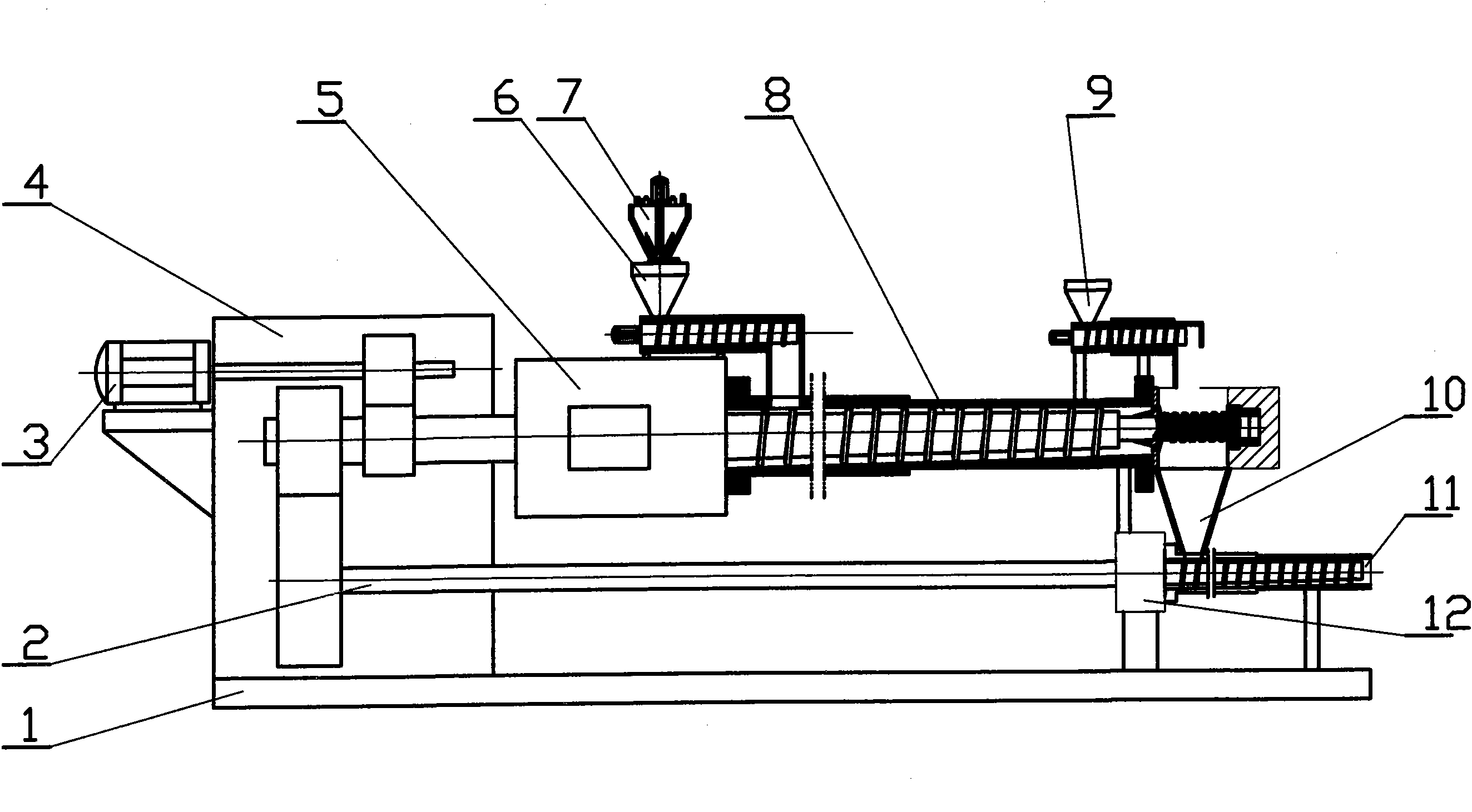

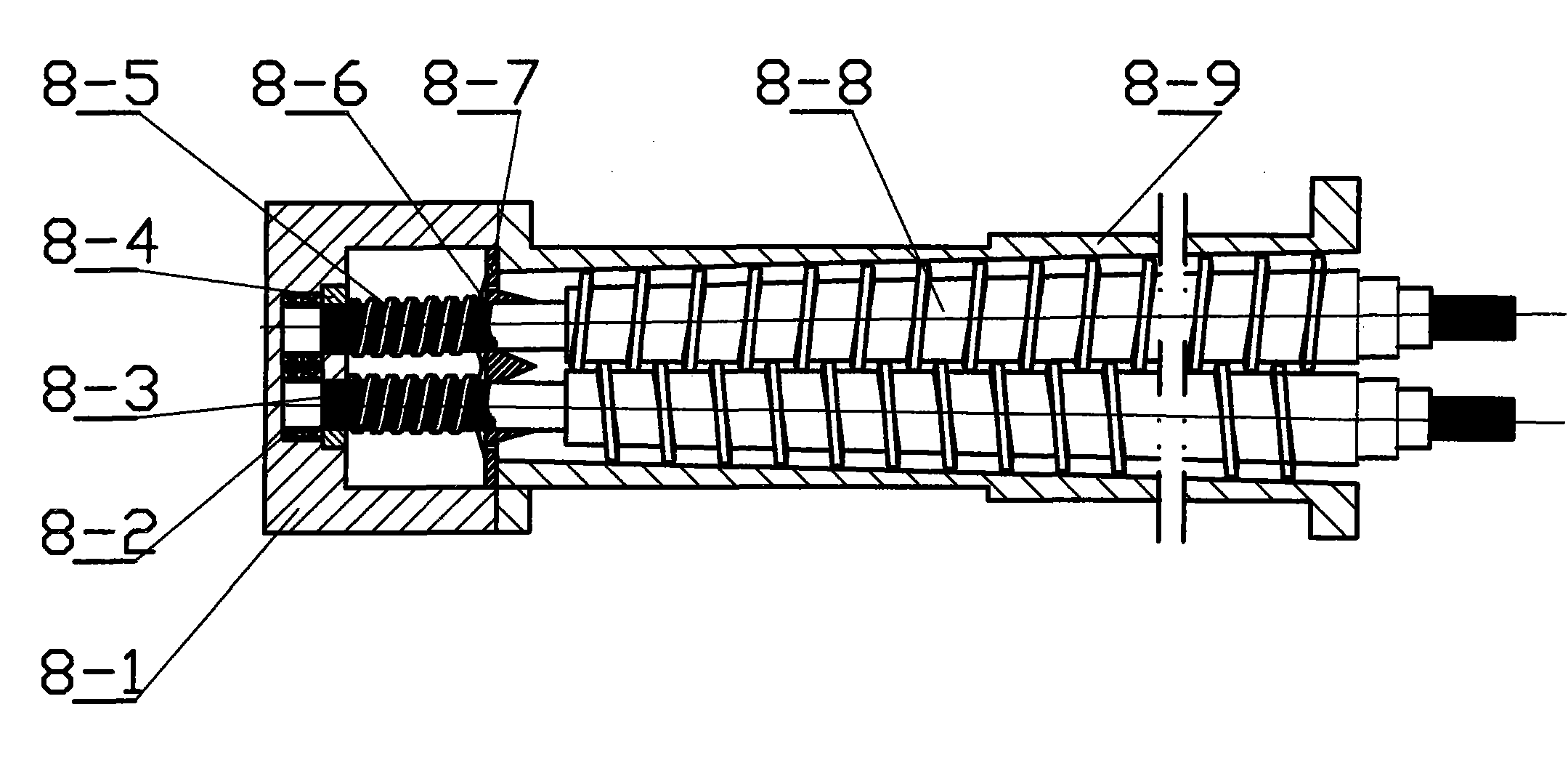

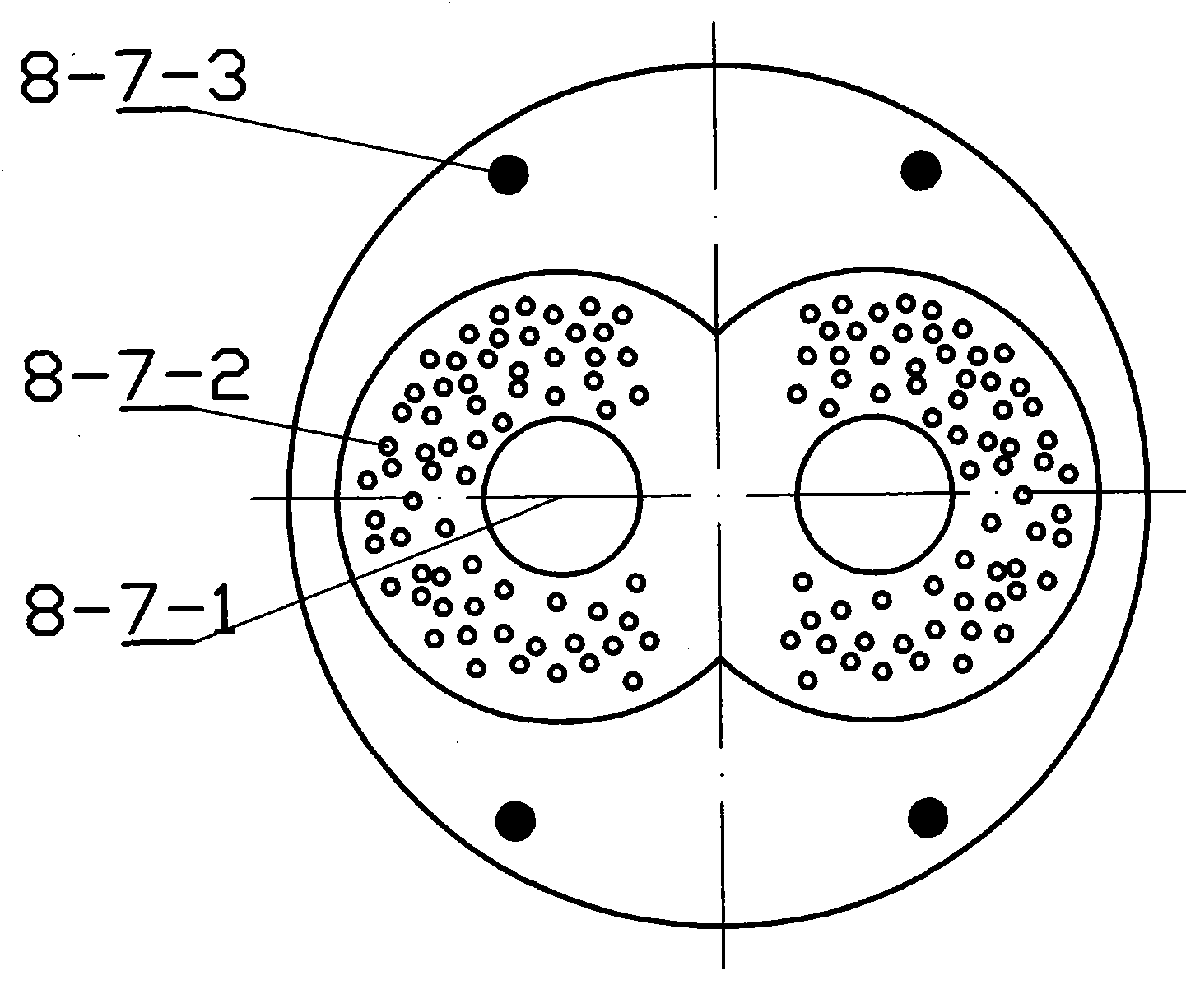

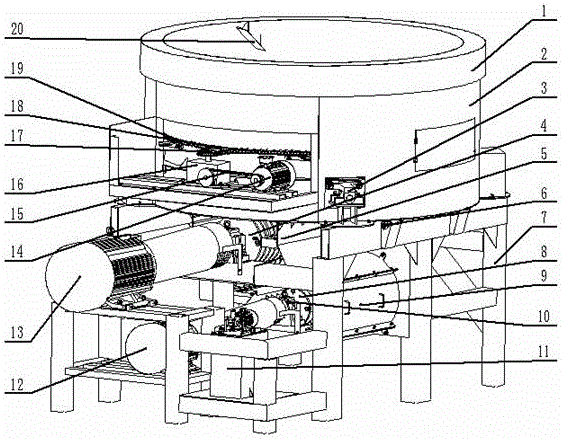

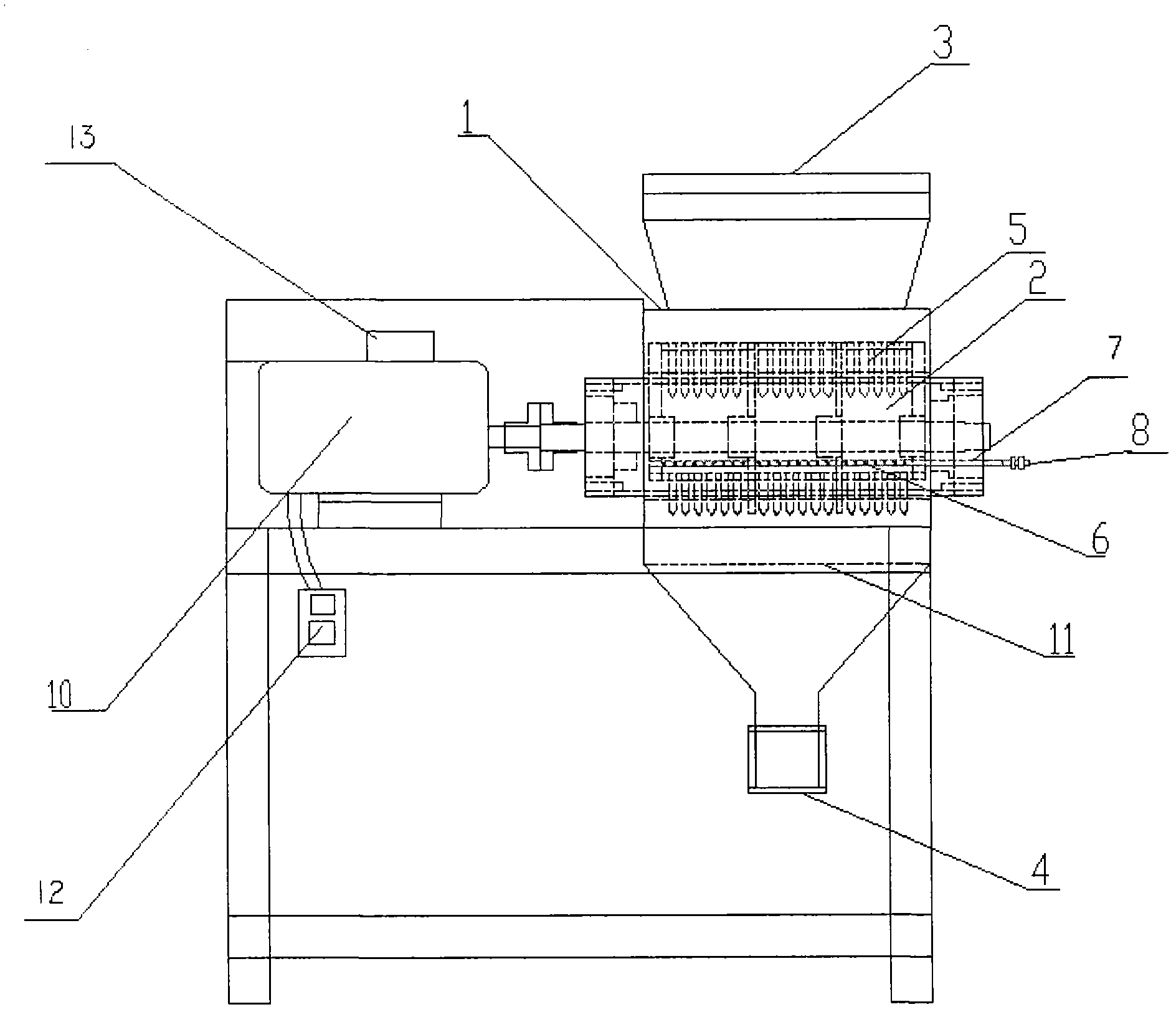

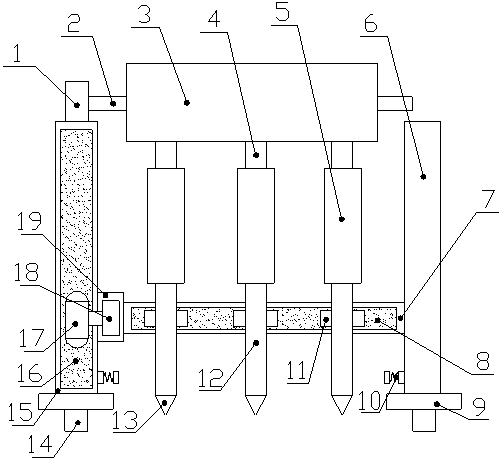

Multifunctional wood-plastic composite material one-step method extruder

A novel multifunctional wood-plastic composite material one-step method extruder is provided. A motor is connected with a twin-screw gear distribution box and a speed-adjusting speed-varying box respectively through a gear speed-varying box and an extending transmission shaft; the gear distribution box is connected with a twin-screw granulator; a material mixing device is connected with the twin-screw granulator through a twin-screw feeder; a master batch feeding device is connected with the twin-screw granulator; a connecting barrel is connected with the twin-screw granulator and a single-screw extruder; the single-screw extruder is connected with the speed-adjusting speed-varying box; all devices are connectedly arranged on a machine base. The extruder is mainly used for extrusion processing of a wood-plastic composite material and composite materials having similar properties, can also be used just for granulation, can complete production by the one-step method after raw materials are mixed, has high efficiency, and saves energy; the extruder completely avoids friction damage of screws and screw tubes, thereby improving the usage usefulness of equipment; the extruder allows extrusion processed products to have various wood imitation patterns; and the extruder can be applied to composite materials with various systems and much extrusion capacity.

Owner:江苏文嘉勄木塑装备制造有限公司

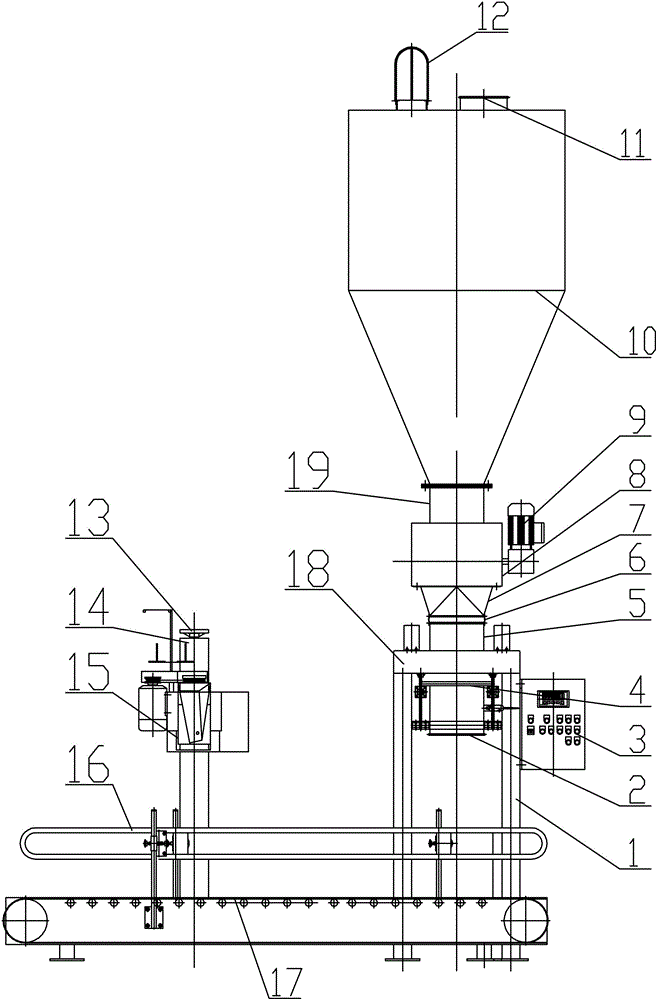

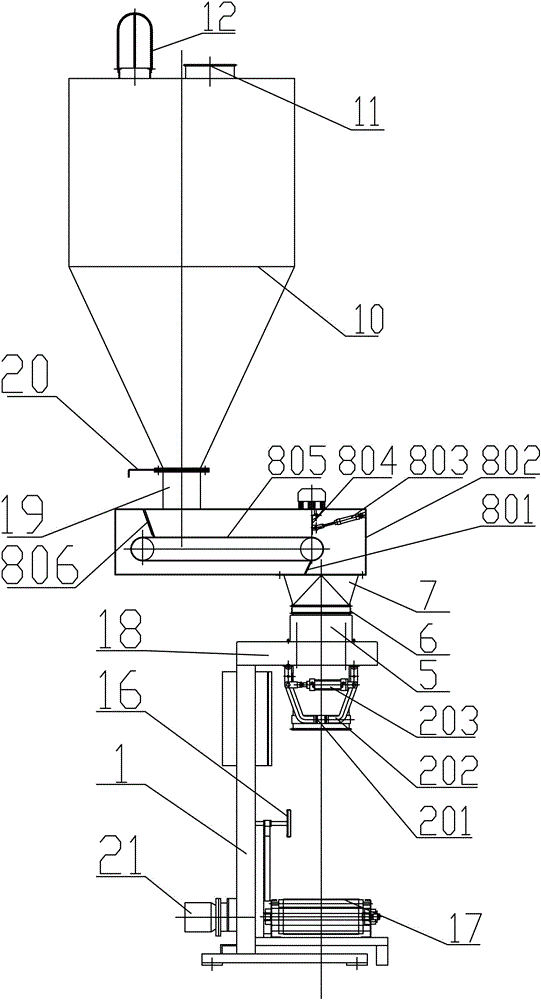

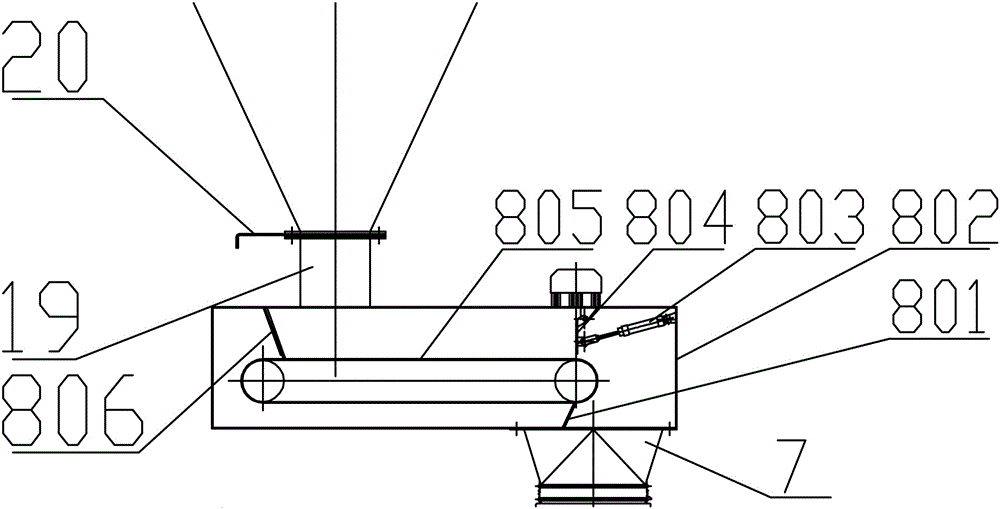

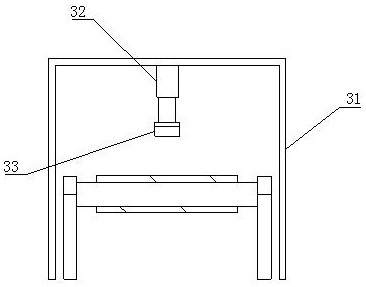

Quantitative packaging scale and quantitative packaging method capable of precisely controlling supply quantity

InactiveCN106240860AEasy maintenanceEasy unloading and loadingSolid materialConveyor partsEngineeringMechanical engineering

The invention relates to a quantitative packaging scale and quantitative packaging method capable of precisely controlling supply quantity. The scale comprises a rack, an automatic weighing device is mounted on the end face of the bottom of a top work platform of the rack and is provided with a pneumatic clamping device, and a receiving hopper is mounted on the end face of the top of the top work platform and is connected with a bottom discharging hopper through a flexible connecting cylinder; the bottom discharging hopper is arranged at the discharging end of a quantitative feeding device, the feeding end of the quantitative feeding device is connected with a top discharging hopper, the top discharging hopper is arranged at the bottom of a storage hopper, a bearing conveying belt is arranged at the bottom of the rack, a protection plate is mounted in the conveying direction of the bearing conveying belt, and an automatic package sewing device is arranged on the side face of the bearing conveying belt; the packaging scale can automatically complete material feeding, automatic discharging is achieved, automatic weighing is achieved, it is ensured that the weight in each-time discharging is kept consistent, and automatic packaging and conveying are carried out.

Owner:CHINA THREE GORGES UNIV

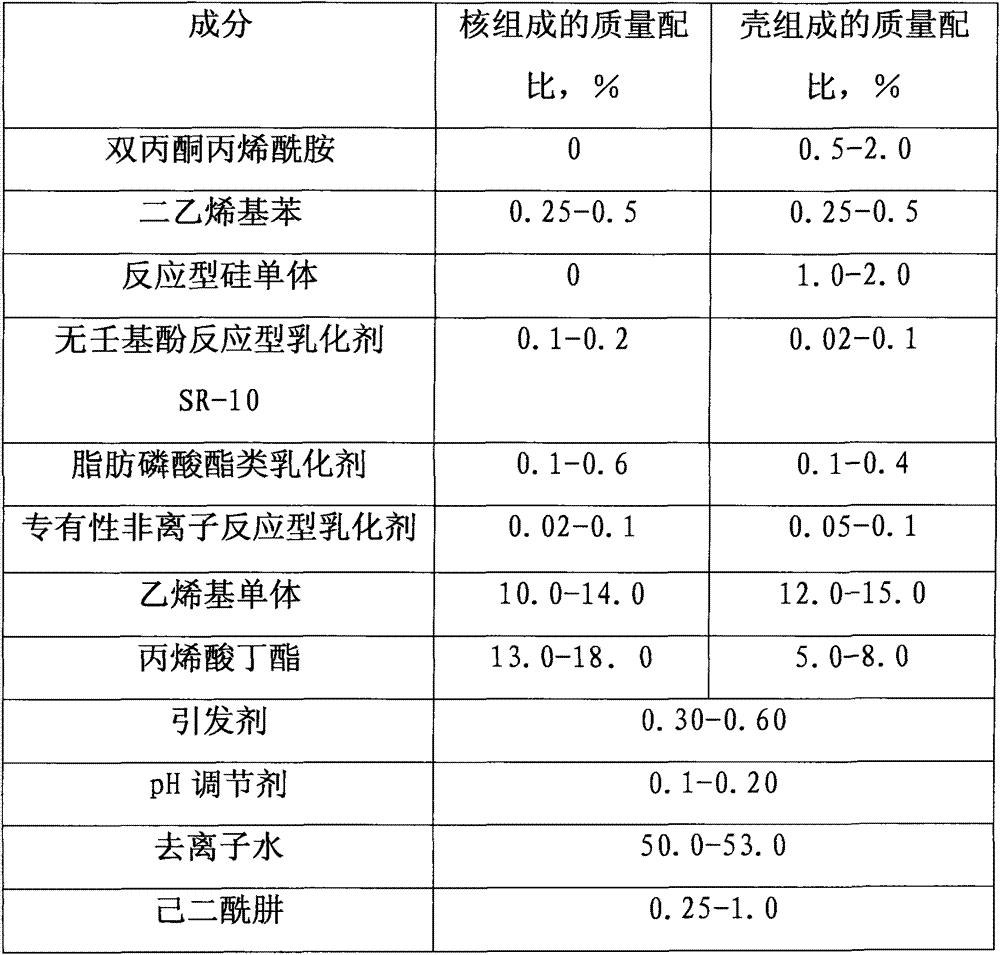

Interpenetrating polymer network core-shell emulsion and preparation method thereof

InactiveCN103936939AGood scrub resistanceIncrease the addition ratioPhosphoric Acid EstersSodium bicarbonate

The invention discloses an interpenetrating polymer network core-shell emulsion and a preparation method thereof. The core-shell emulsion is prepared from a monomer, emulsifiers, an initiator, a PH regulating agent and water. The core-shell emulsion is characterized in that the monomer consists of a functional monomer and a mixed monomer, wherein the mixed monomer consists of a vinyl monomer and butyl acrylate, and the functional monomer consists of diacetone acrylamide, adipic dihydrazide, divinyl benzene and a reactive type silicon monomer; the emulsifiers refer to a nonylphenol-free reactive type emulsifier SR-10, a fatty phosphoric acid ester emulsifier and an exclusive non-ion reactive type emulsifier; the initiator refers to sodium persulfate; the PH regulating agent refers to sodium hydrogen carbonate; water refers to deionized water. The preparation method comprises the following steps: (1) in a raw material ratio, preparing a monomer mixed liquid for later use, preparing deionized water and an initiator and stirring to form an initiator mixed liquid for later use; and (2) polymerizing the emulsion. The core-shell emulsion and the method have the beneficial effects of being environmental-friendly and safe, the technology is simple, the scrubbing-resisting capability and the pigment filler bearing capability are strong and the stability of electrolyte and freeze thawing is high.

Owner:HEBEI SUNRISING CHEM CORP

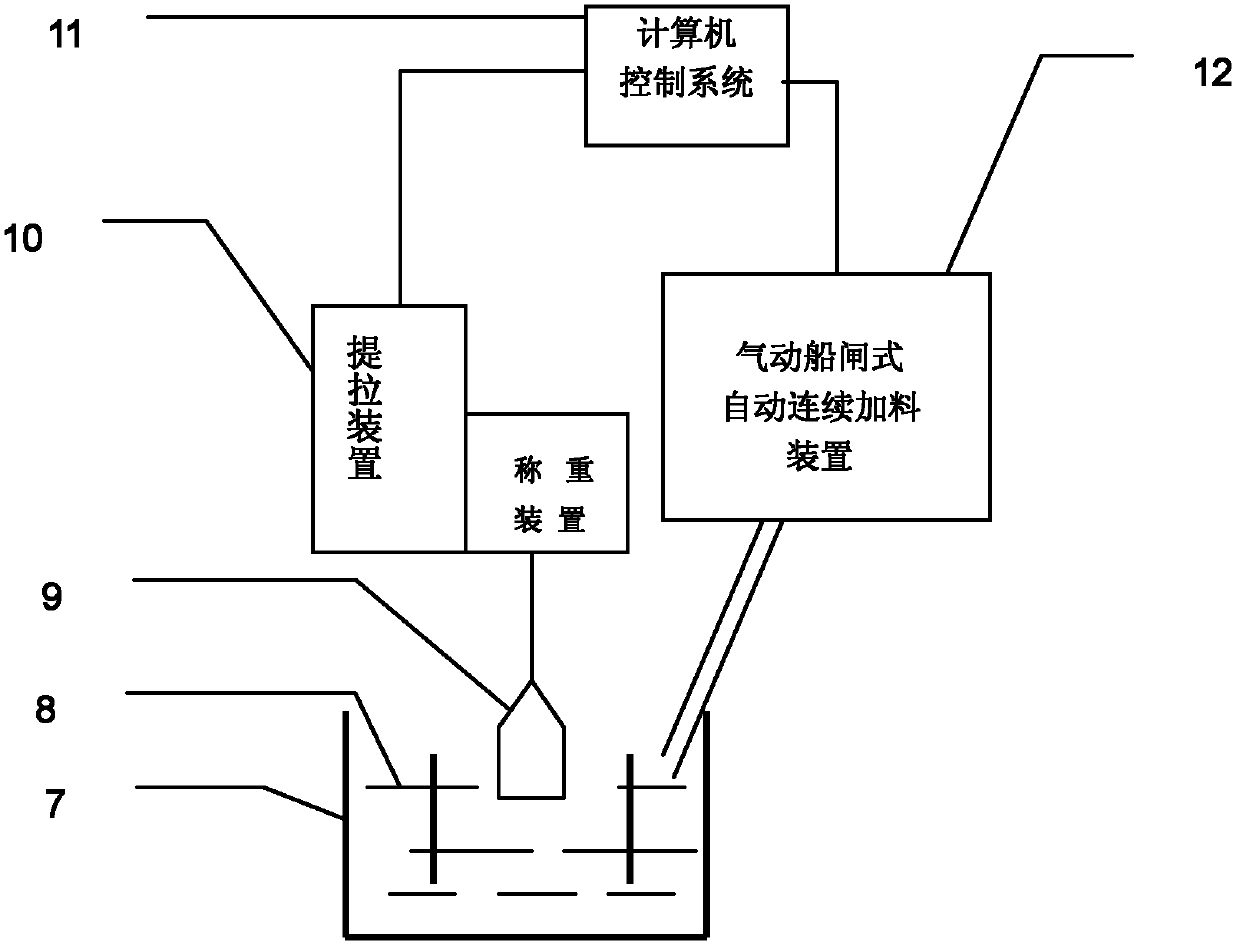

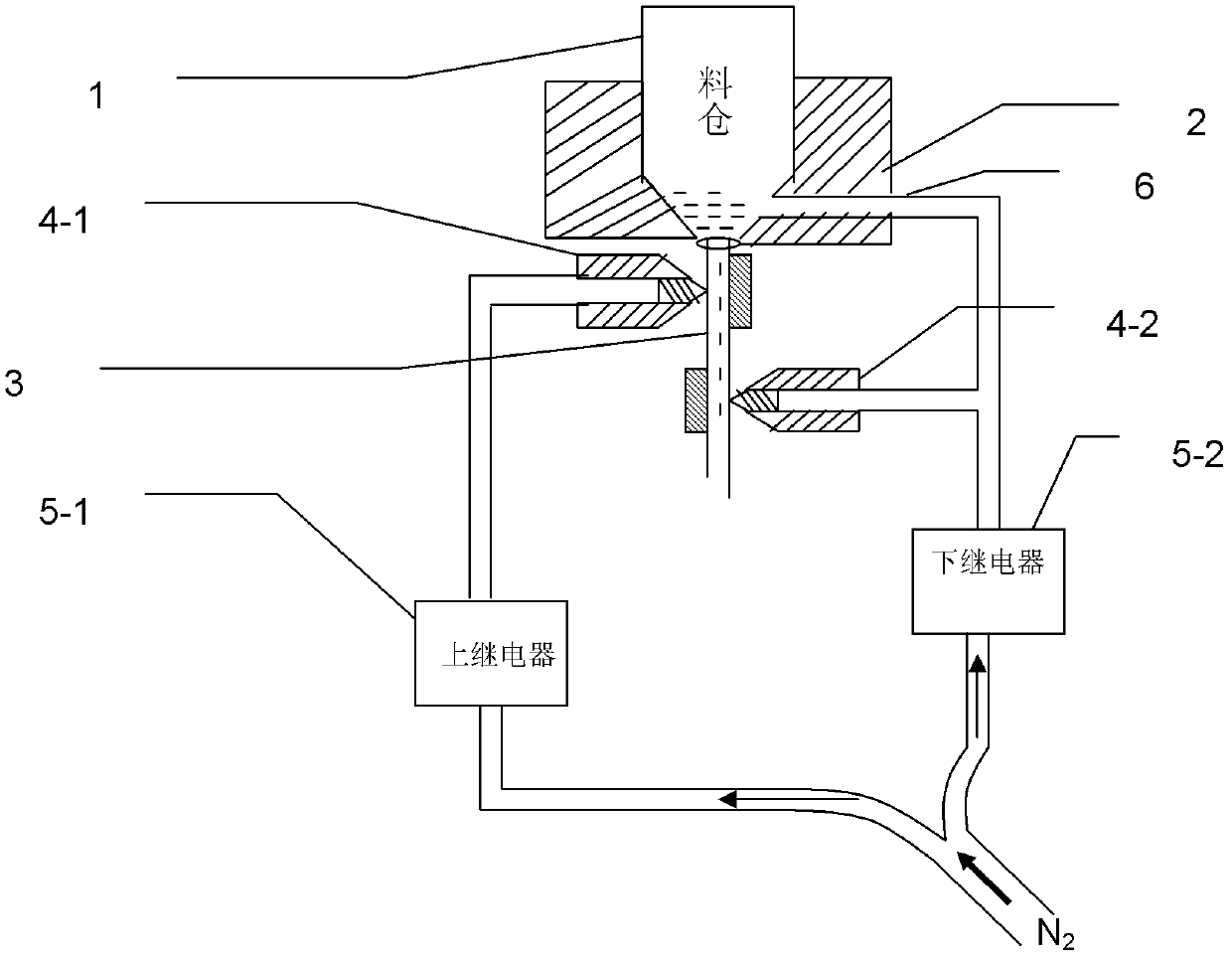

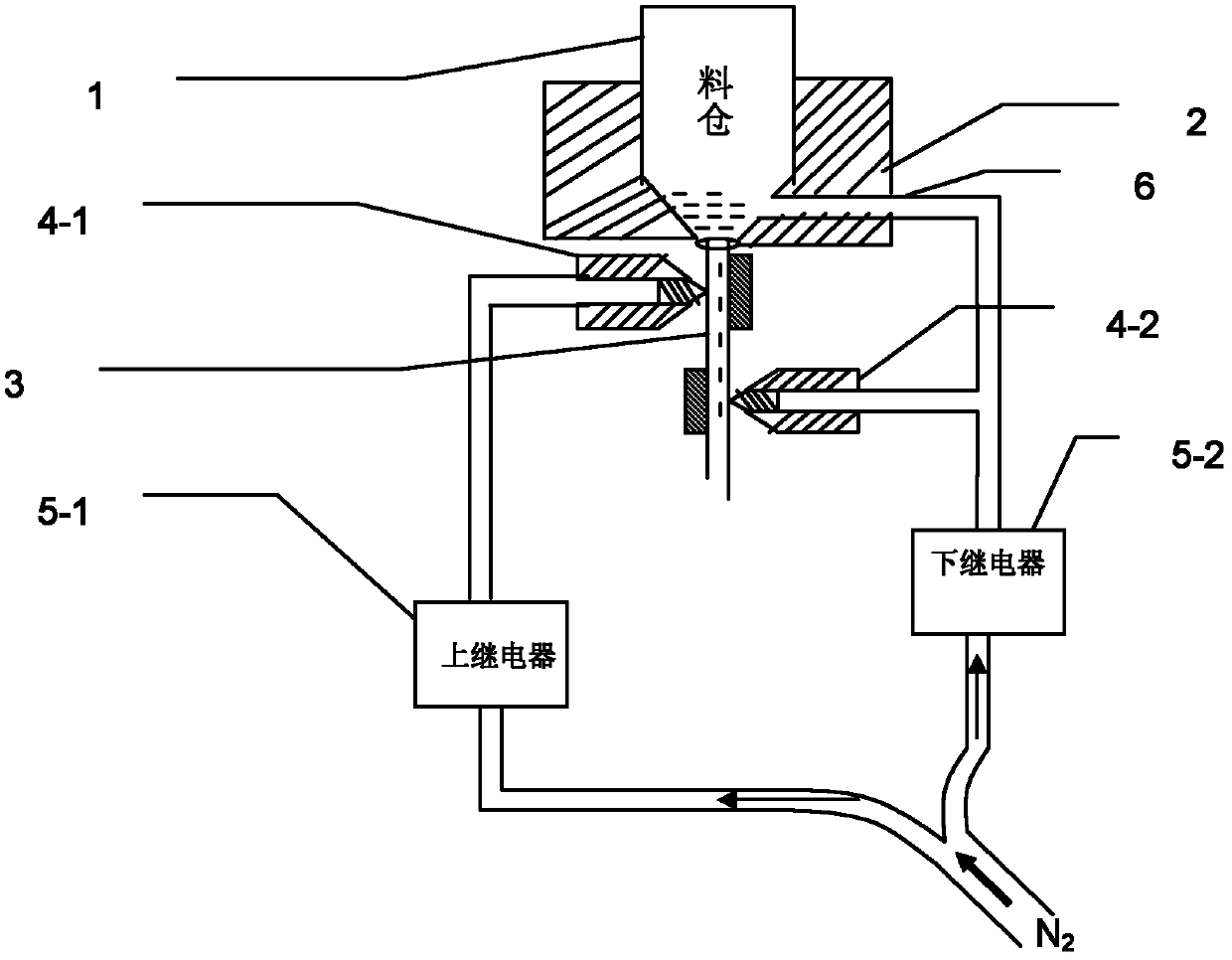

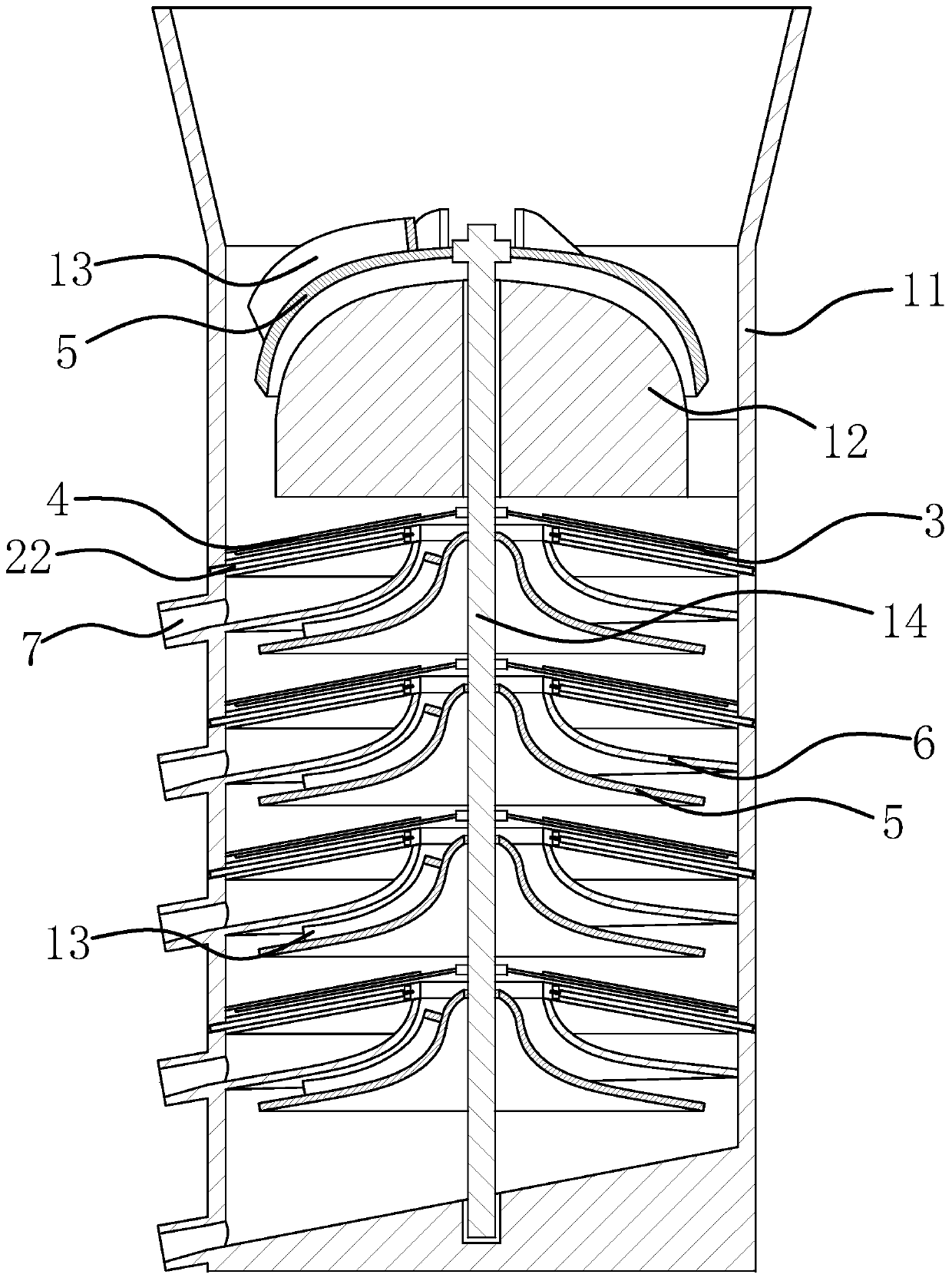

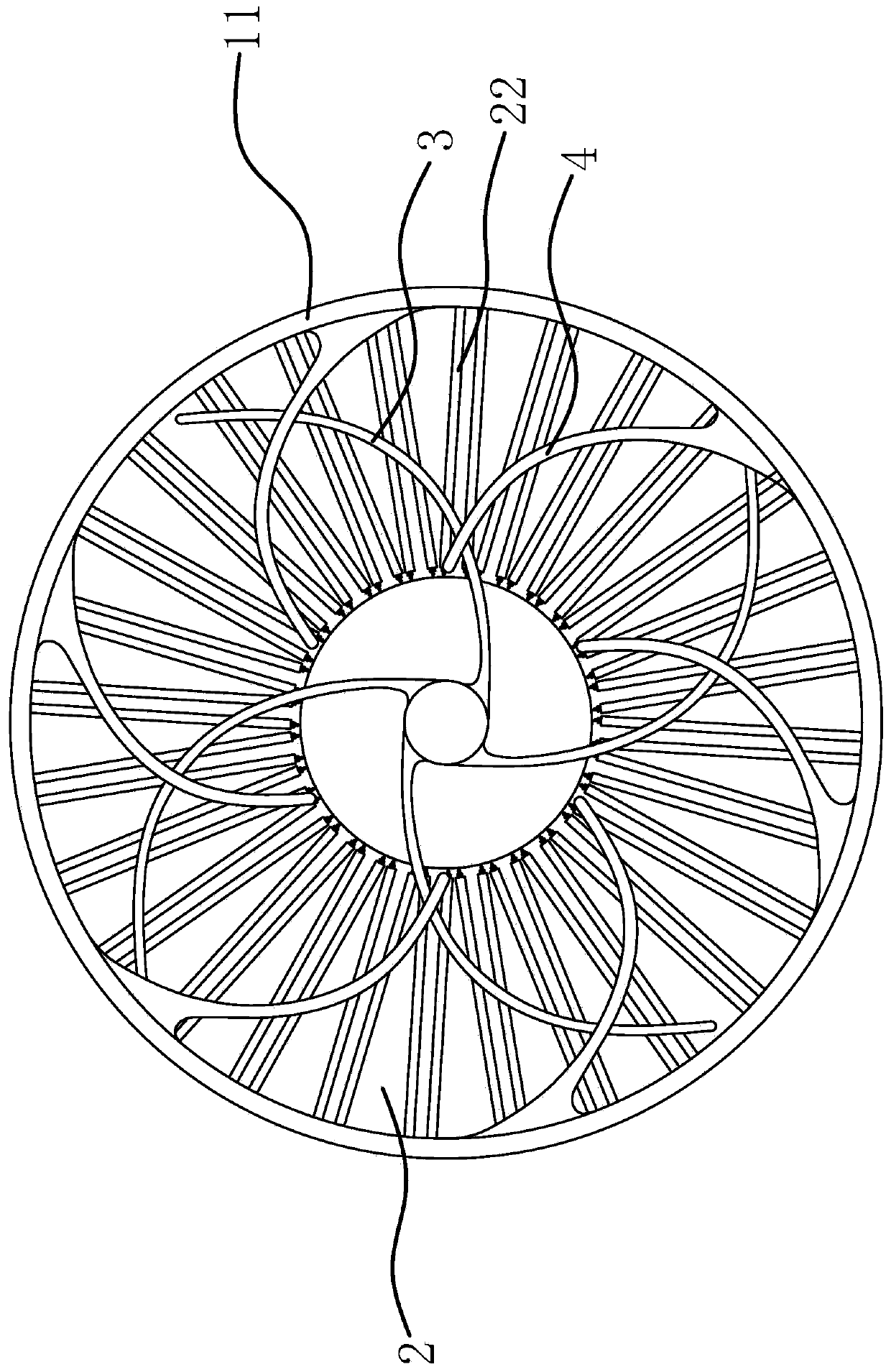

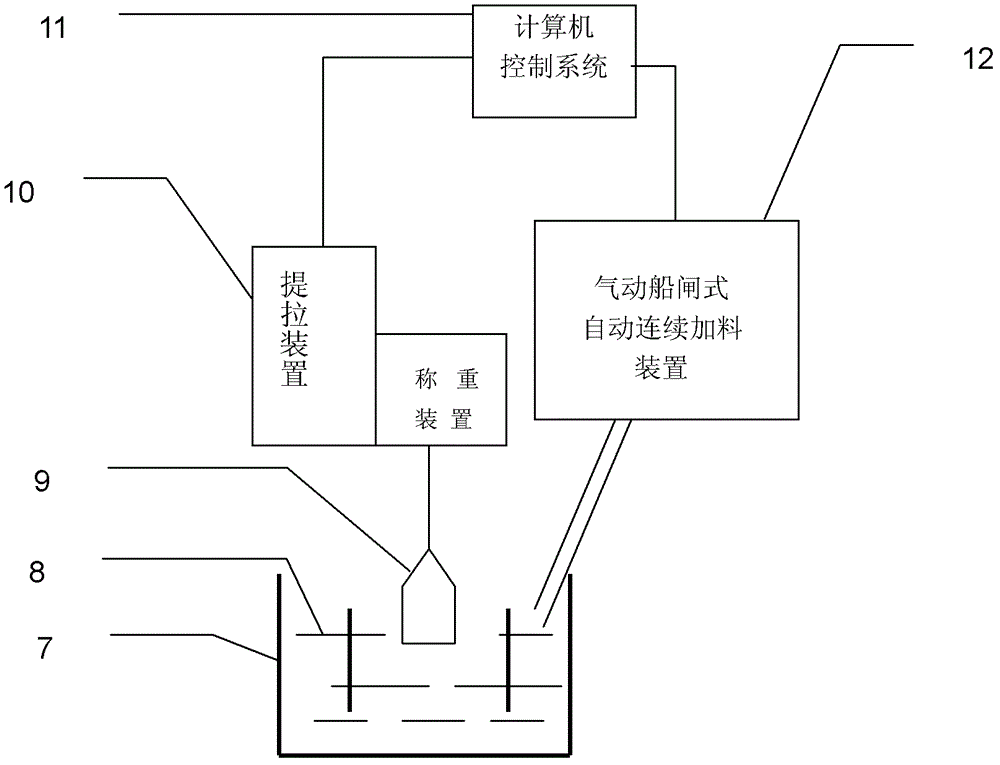

Automatic-control continuous feeding device for intraocular lens growth

ActiveCN102181917AGuaranteed growth quality requirementsSimple structureBy pulling from meltComputer control systemIntraocular lens

The invention discloses an automatic-control continuous feeding device for intraocular lens growth, which comprises a suspended crucible lens growing furnace, a computer control system and a pneumatic ship-lock automatic continuous feeding device. The device disclosed by the invention can be used for realizing non-blocking non-vibration continuous feeding and is very suitable for continuous feeding of intraocular lens growth. By the automatic-control continuous feeding device, automatic program control management of a computer can also be realized, an error caused by manual operation is avoided, and particularly the requirement on continuous feeding of lenses, such as lithium tantalate, lithium niobate and the like with nearly-stoichiometric ratio, which grow by a suspended crucible method, can be ensured.

Owner:SHANDONG UNIV +1

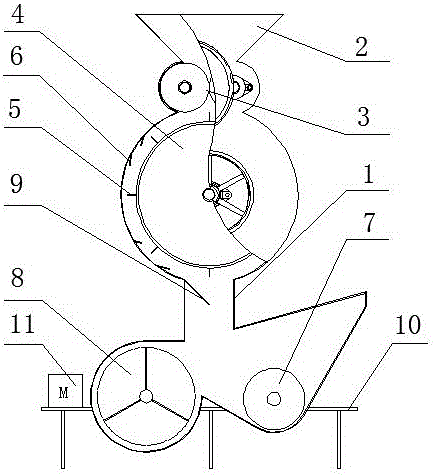

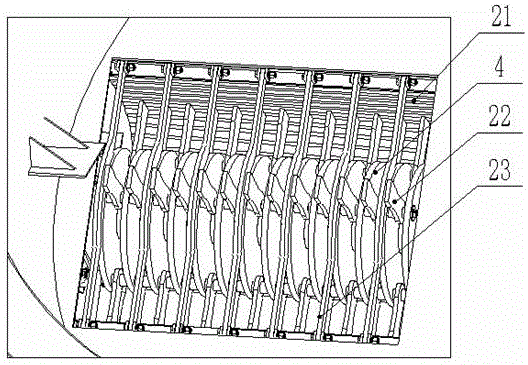

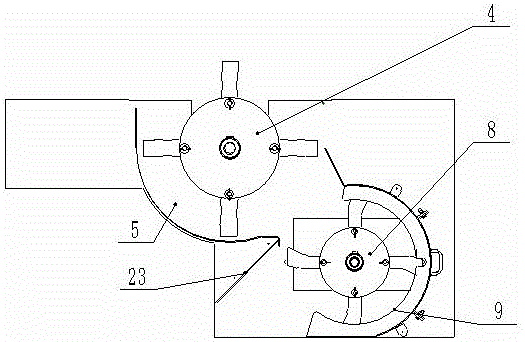

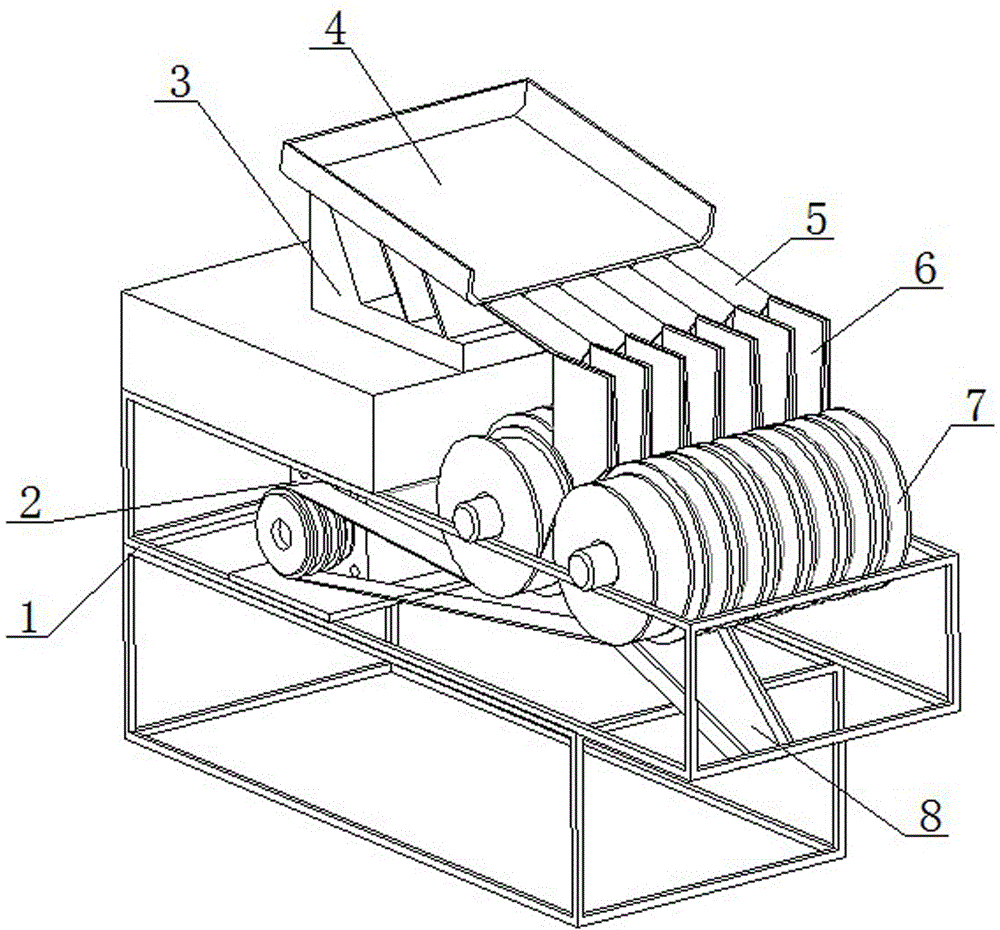

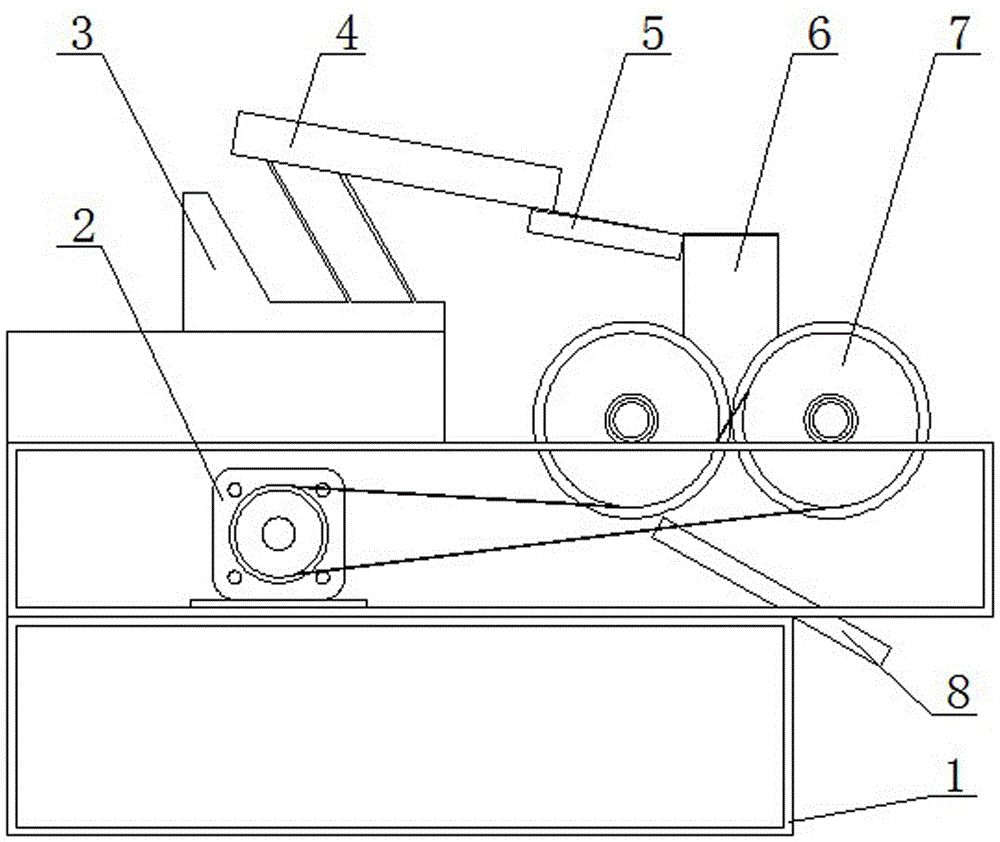

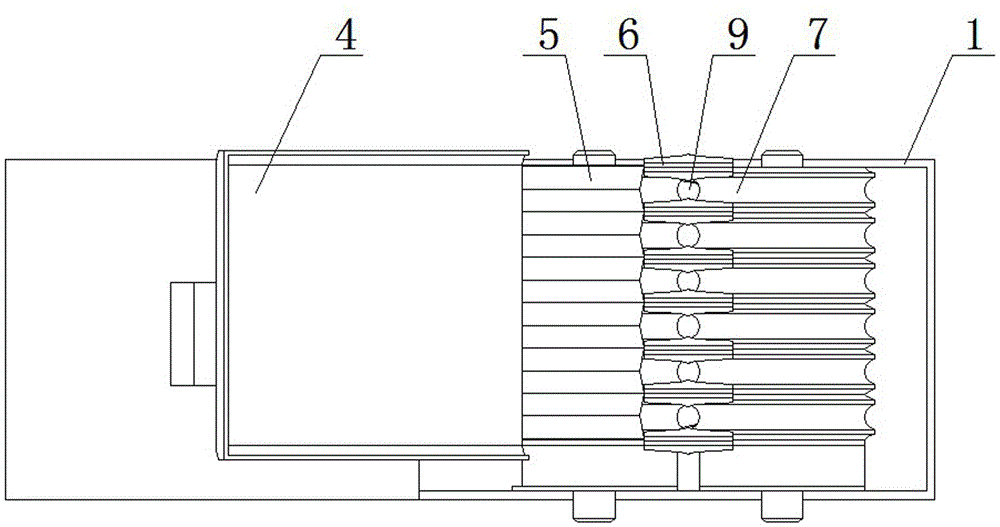

Differential pressing roller type peony seed unshelling and cleaning device

InactiveCN106723113ASmall footprintReduce power consumptionGas current separationFatty-oils/fats productionEngineeringSeparation system

The invention relates to the technical field of processing machinery of agricultural products and discloses a differential pressing roller type peony seed unshelling and cleaning device. The differential pressing roller type peony seed unshelling and cleaning device comprises an enclosure, wherein a feeding hopper is arranged above the enclosure; the enclosure is internally provided with a shell crushing system, a separation system and a winnowing system; the shell crushing system comprises two pressing rollers of which the roller surfaces have different linear speeds; the separation system comprises a rotary drum, a plurality of scraping plates which are arranged on the circumference of the rotary drum and are arranged along the axial direction of the rotary drum, and an impacting baffle which is arranged on an inner wall of the enclosure and is used for blocking materials and thrashing seeds and shells; the winnowing system comprises a packing auger which is arranged at one side below the rotary drum and a draught fan arranged at the other side below the rotary drum; the packing auger is parallel to the rotary drum; a discharging hole is formed in a part, located at a conveying terminal of the packing auger, on the enclosure; the direction of an air outlet of the draught fan is set to be inclined upwards and tangent to the upper part of the packing auger; an impurity discharging hole is formed in a position, opposite to the air outlet of the draught fan, on the enclosure. According to the differential pressing roller type peony seed unshelling and cleaning device, the peony seeds and shells are completely separated through a two-step method and a plurality of times of winnowing.

Owner:HENAN UNIV OF SCI & TECH

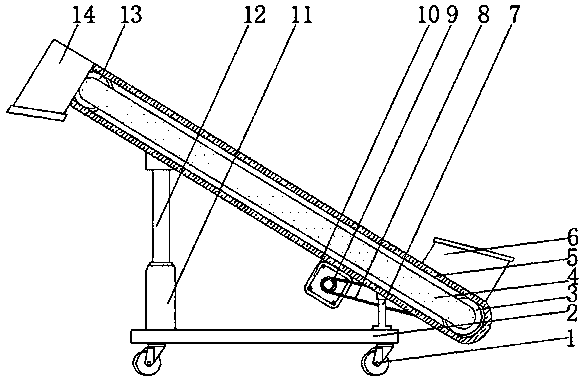

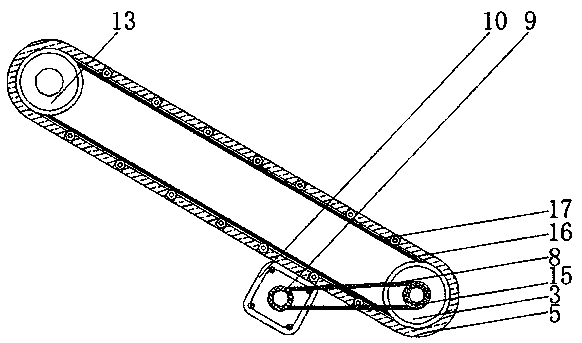

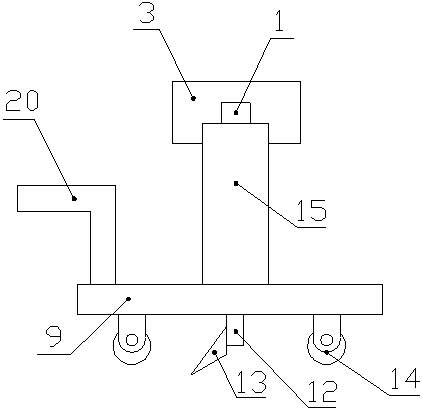

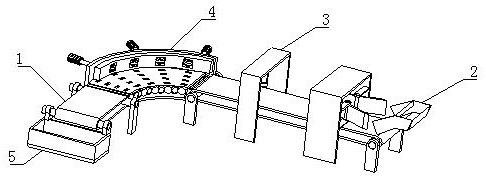

Feeding conveying belt capable of adjusting angle

InactiveCN108910448AEasy to transportControl feeding speedConveyorsSupporting framesHydraulic cylinderEngineering

The invention discloses a feeding conveying belt capable of adjusting the angle. The feeding conveying belt comprises a base. A supporting rod is arranged on the upper surface of the base, a hydrauliccylinder is arranged on one side of the supporting rod, the hydraulic cylinder is provided with a hydraulic telescopic rod, an outer shell is arranged above the hydraulic telescopic rod and the supporting rod, the lower surface of the outer shell is provided with first limiting blocks and second limiting blocks, the first limiting blocks are fixedly connected through a first rotating shaft, the two ends of the first rotating shaft penetrate through the first limiting blocks and extend to the outer sides of the first limiting blocks, the second limiting blocks are fixedly connected through a second rotating shaft, the two ends of the second rotating shaft penetrate through the second limiting blocks and extend to the outer sides of the second limiting blocks, the supporting rod is fixedlyconnected with the outer shell through the first limiting blocks, and the second rotating shaft penetrates through the top of the hydraulic telescopic rod. The arranged hydraulic telescopic rod can beused for adjusting the feeding angle during feeding of the conveying belt, the structure is simple, and operation is convenient.

Owner:NANJING HUANWU RESOURCES RECYCLING TECH

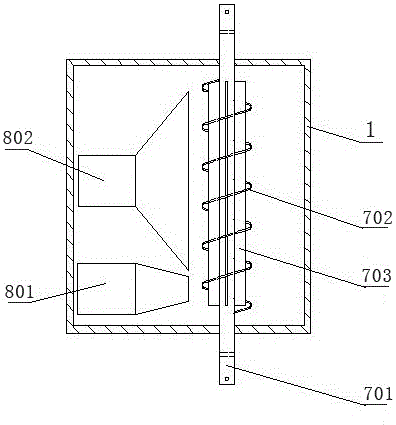

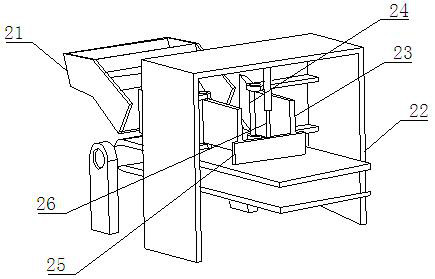

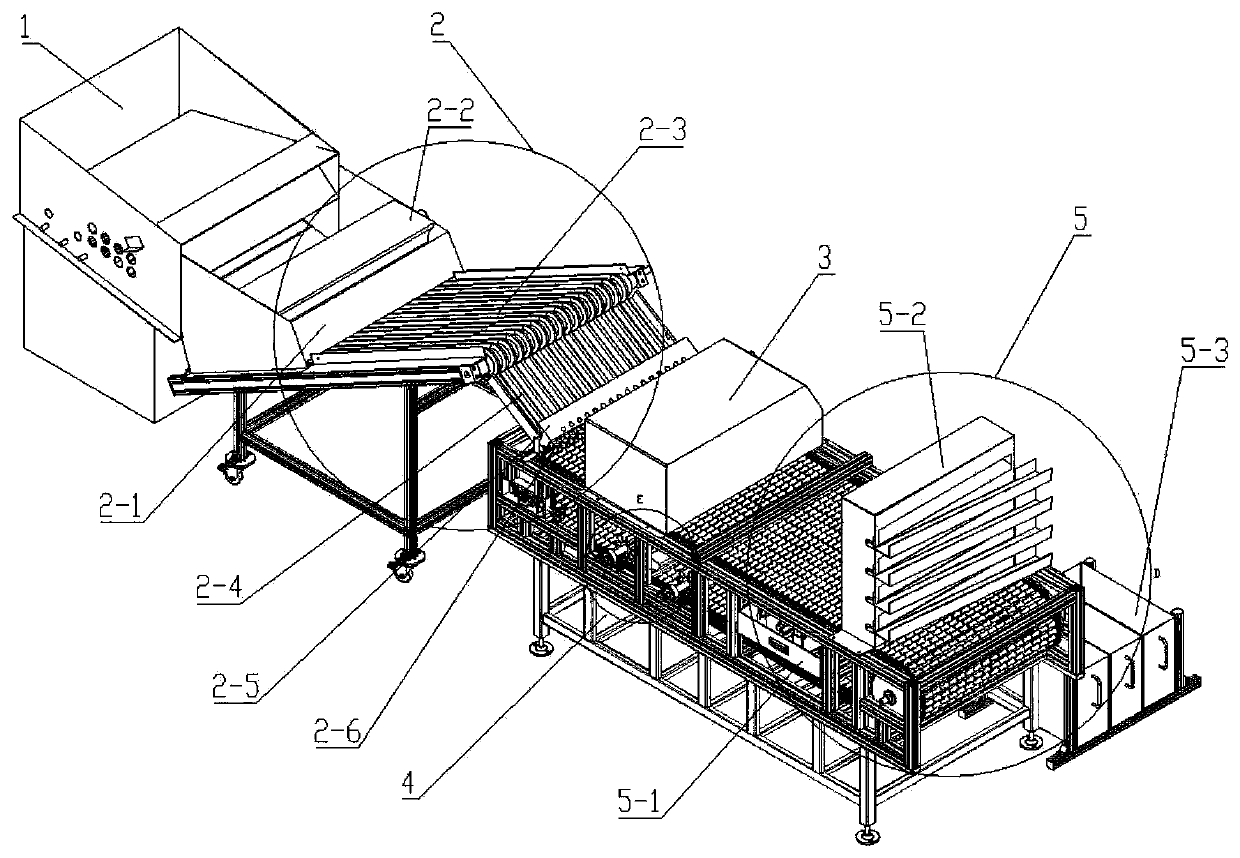

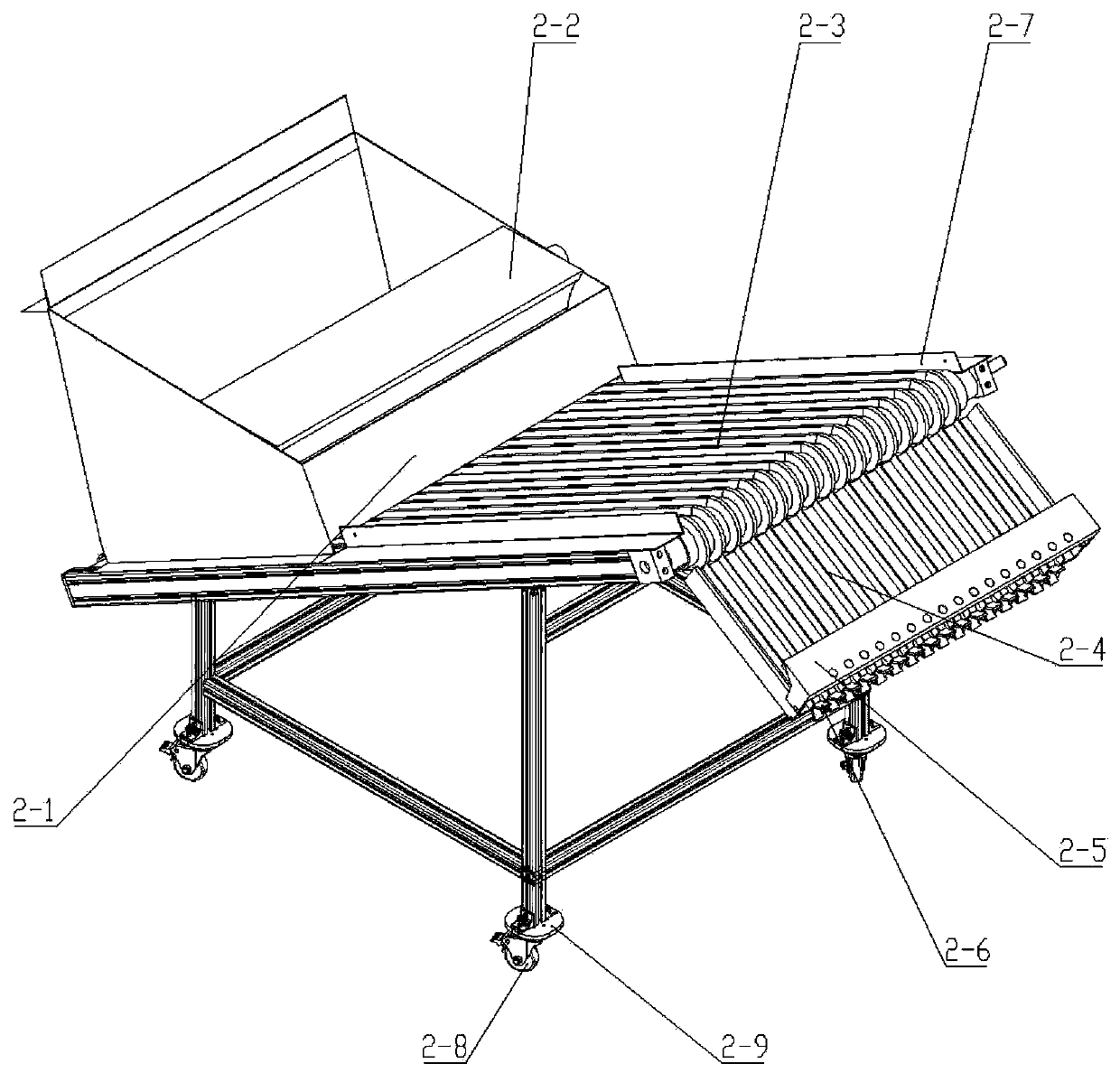

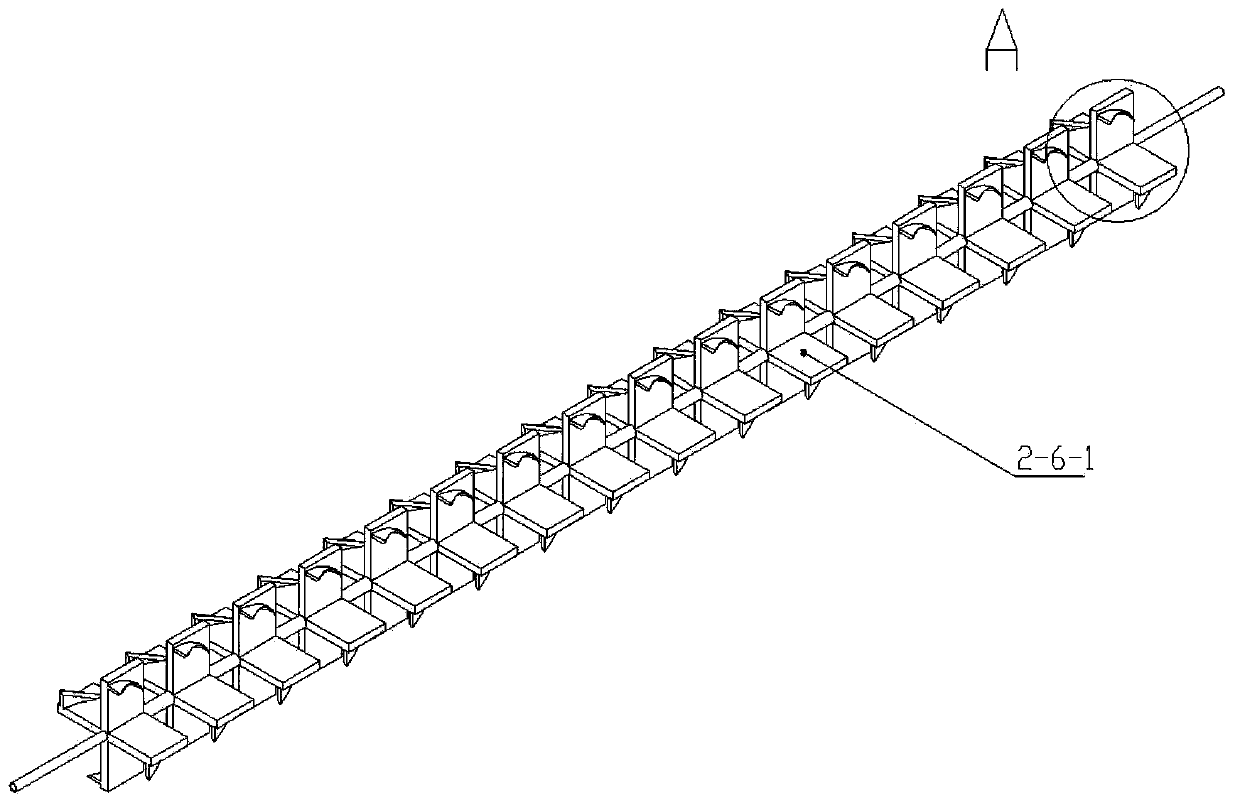

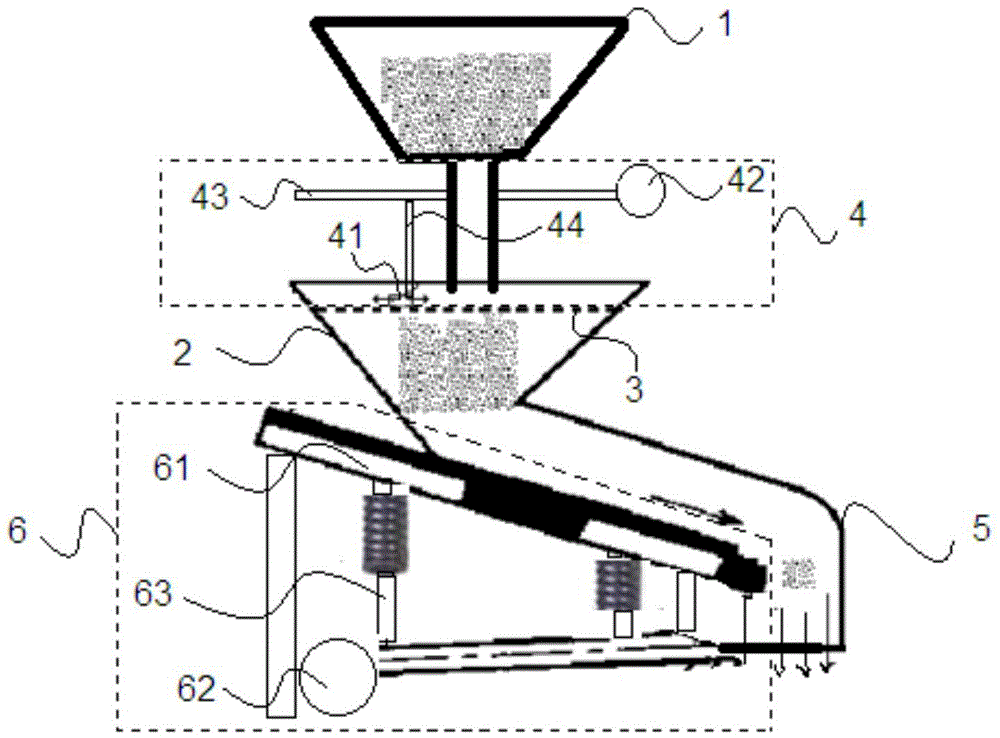

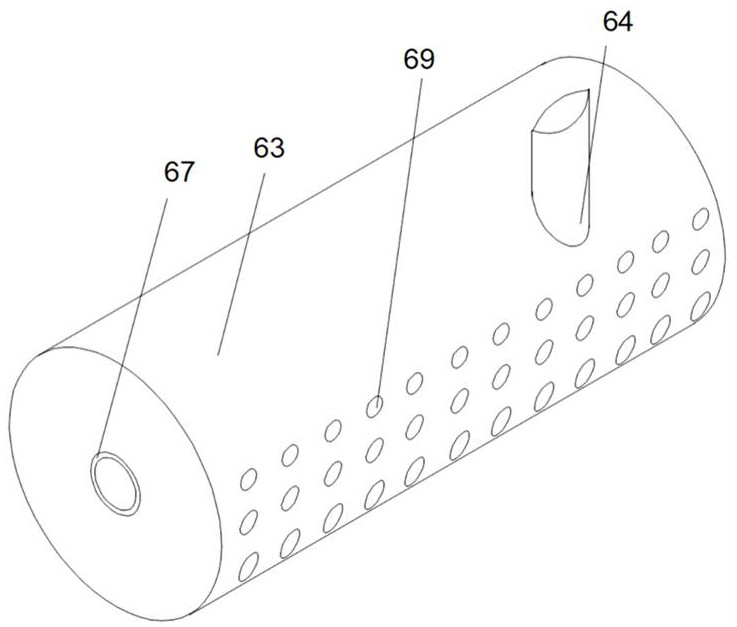

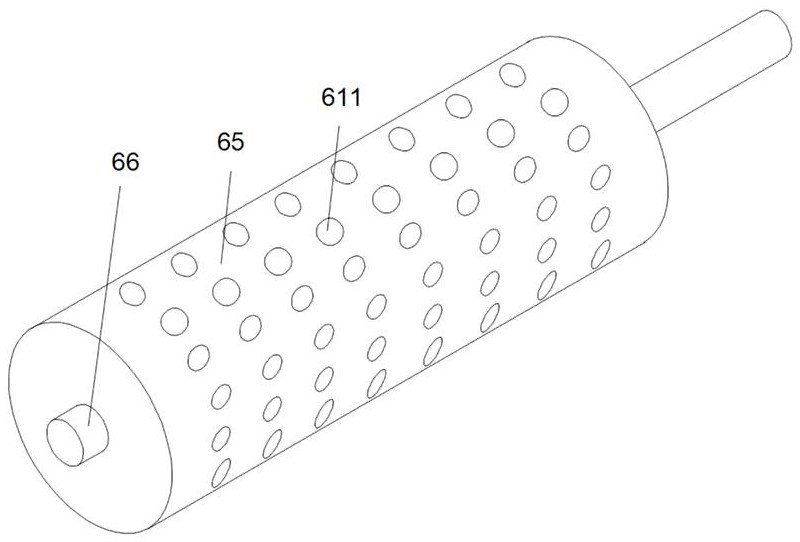

Automatic pyrotechnic composition mixing system

InactiveCN106139991AReduce friction areaReduce riskFlow mixersTransportation and packagingPyrotechnic compositionEngineering

The invention provides an automatic pyrotechnic composition mixing system. The automatic pyrotechnic composition mixing system comprises an oxidant feeding unit, a reducing agent feeding unit, a mixing unit and a collecting unit; the mixing unit comprises a mixing cavity, an air blower and nozzles; one end of each of the plurality of nozzles penetrates through the bottom of the mixing cavity and the other ends of the nozzles are connected with the air blower through pipelines; the oxidant feeding unit and the reducing agent feeding unit are arranged on the two sides of the mixing cavity respectively; and the collecting unit is arranged at the top of the mixing cavity. With the adoption of the automatic pyrotechnic composition mixing system provided by the invention, the technical problems of a pyrotechnic composition mixing manner in the prior art that dangers are relatively great and explosion is easy to occur are solved.

Owner:HUNAN WUJIANG INFORMATION SCI & TECH CO LTD

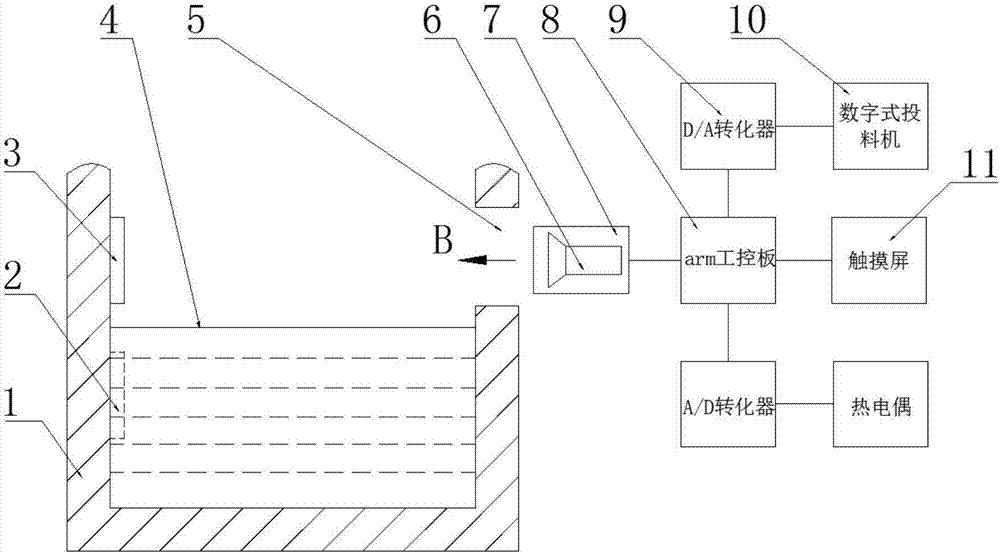

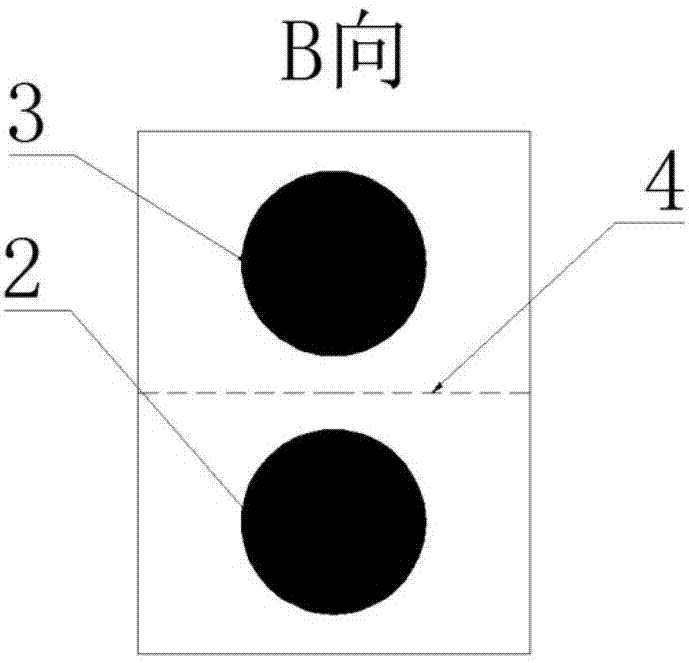

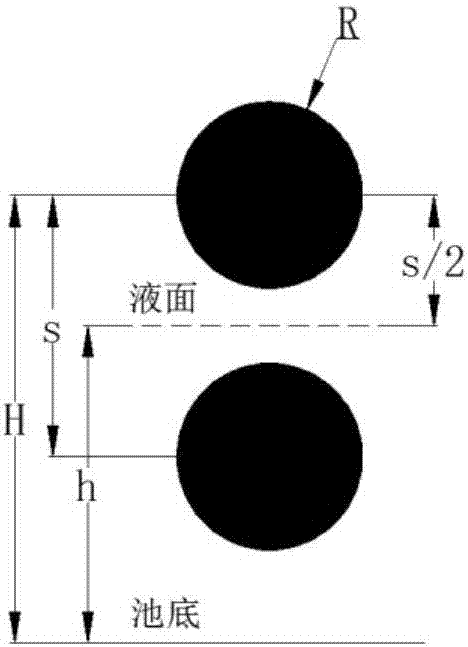

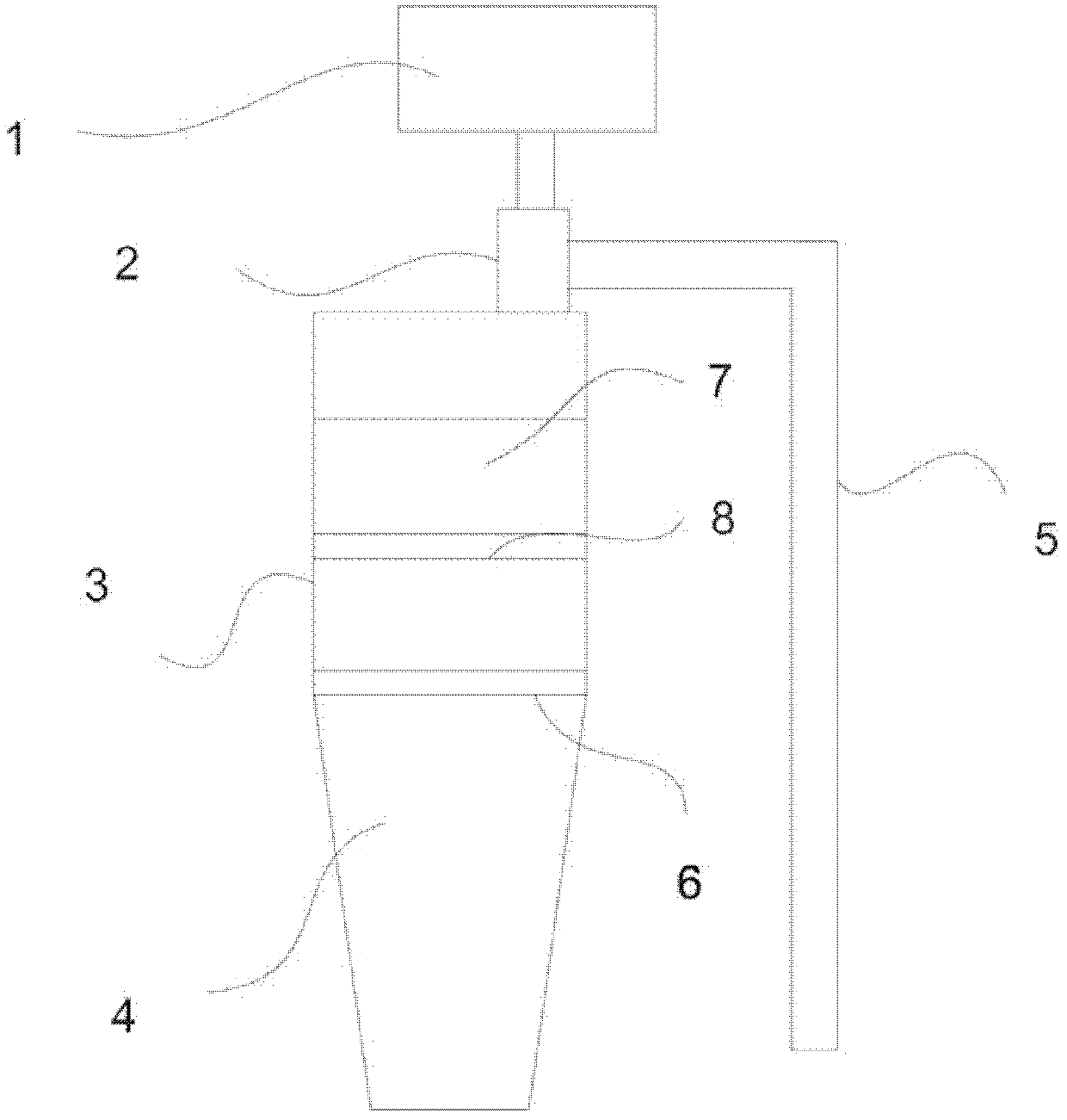

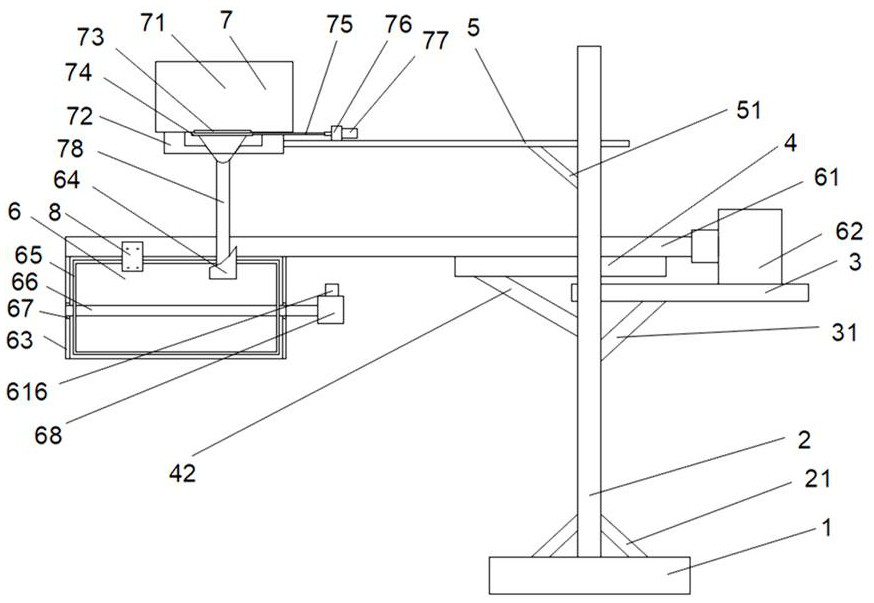

Glass melting furnace liquid level height measuring and controlling method based on machine vision

InactiveCN107367311AAccurate measurementEasy to controlImage enhancementImage analysisMachine visionControl signal

The invention provides a glass melting furnace liquid level height measuring and controlling method based on machine vision. A digital camera (6) collects images in a melting furnace through a peephole (5), the images are transmitted to an arm industrial control board (8) through a USB interface, the images are processed and the liquid level height is obtained in the arm industrial control board (8), the liquid level height and the images are displayed on a touch screen (11), the deviation e and the deviation change ec are calculated according to the designated liquid level height and the real-time liquid level height, a fuzzy PID algorithm is used for obtaining a suitable material feed speed, finally a speed control signal is sent to a digital material feeder (10) by the arm industrial control board (8) through a D / A converter (9), the feed speed is changed, and the control over the glass liquid level height is realized. The liquid level height in the glass melting furnace can be precisely measured and controlled, and high-quality glass liquid is provided for glass forming.

Owner:WUHAN UNIV OF TECH

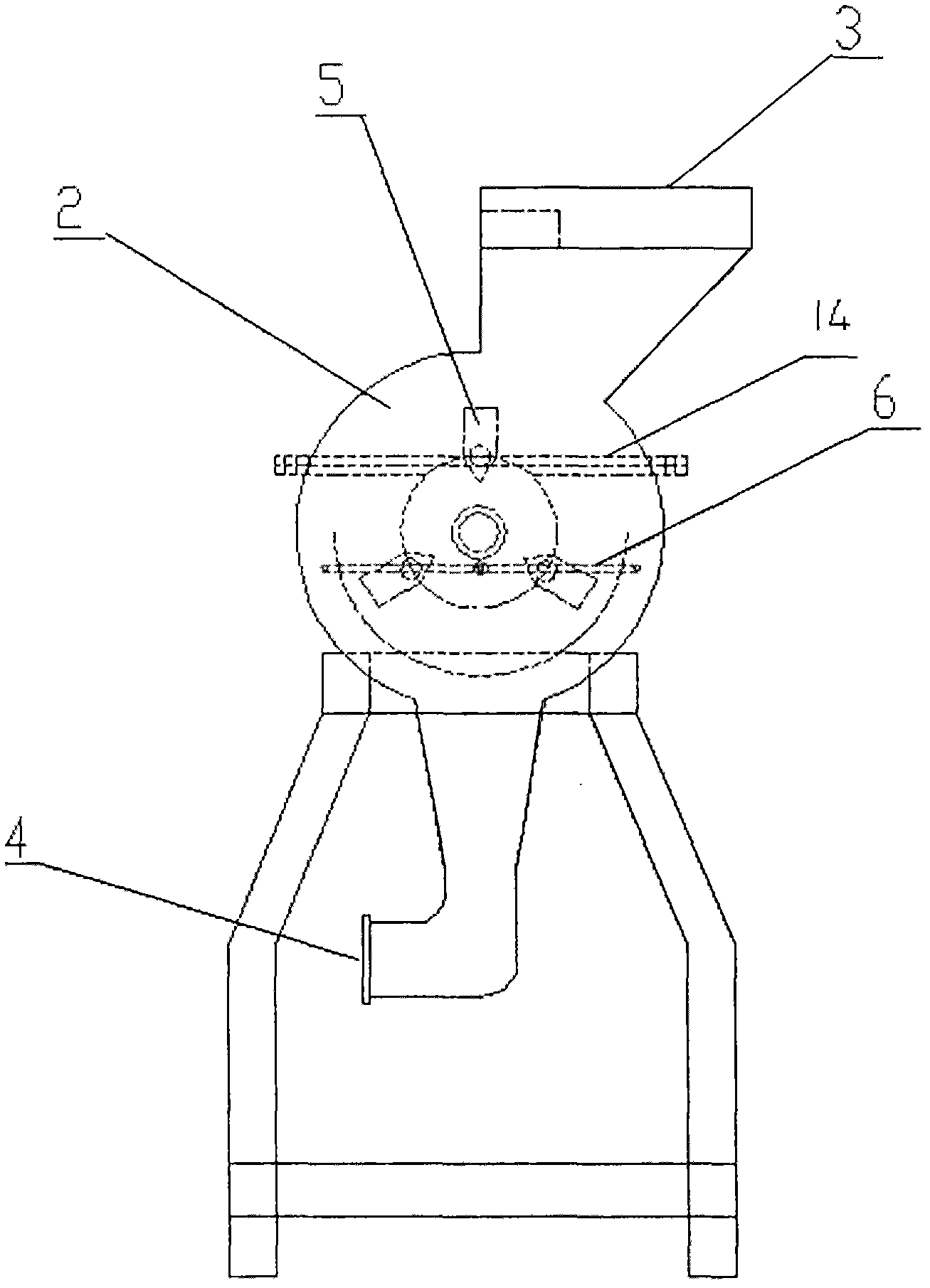

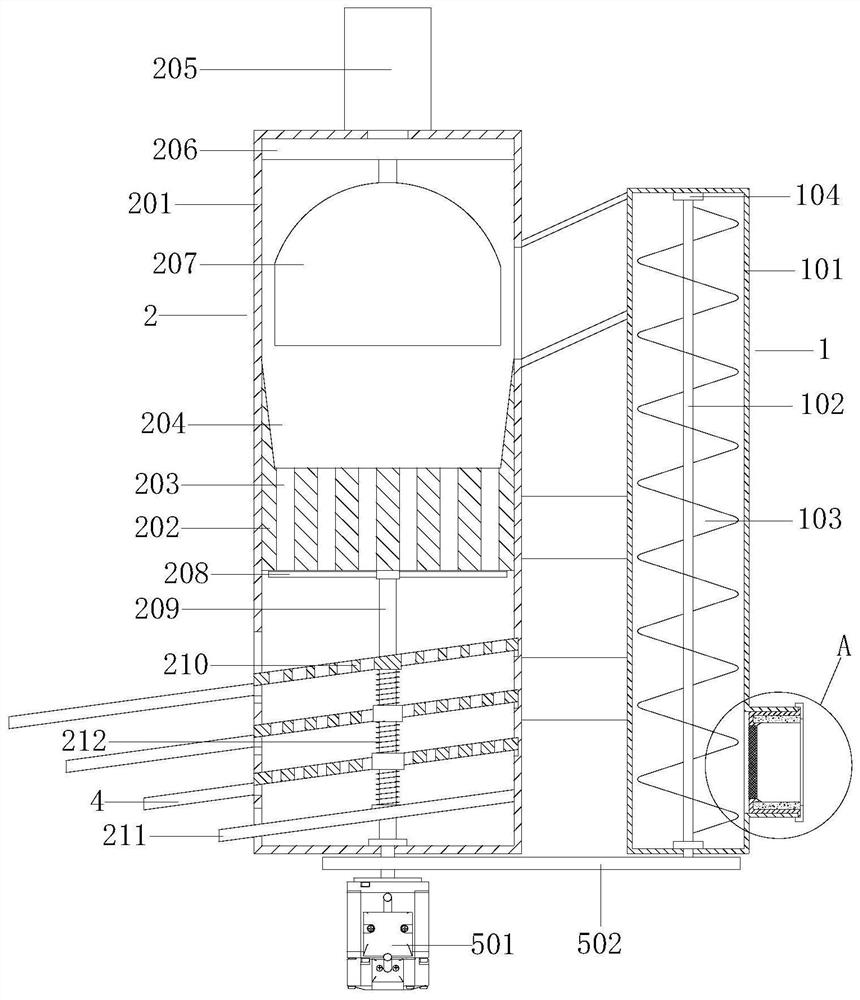

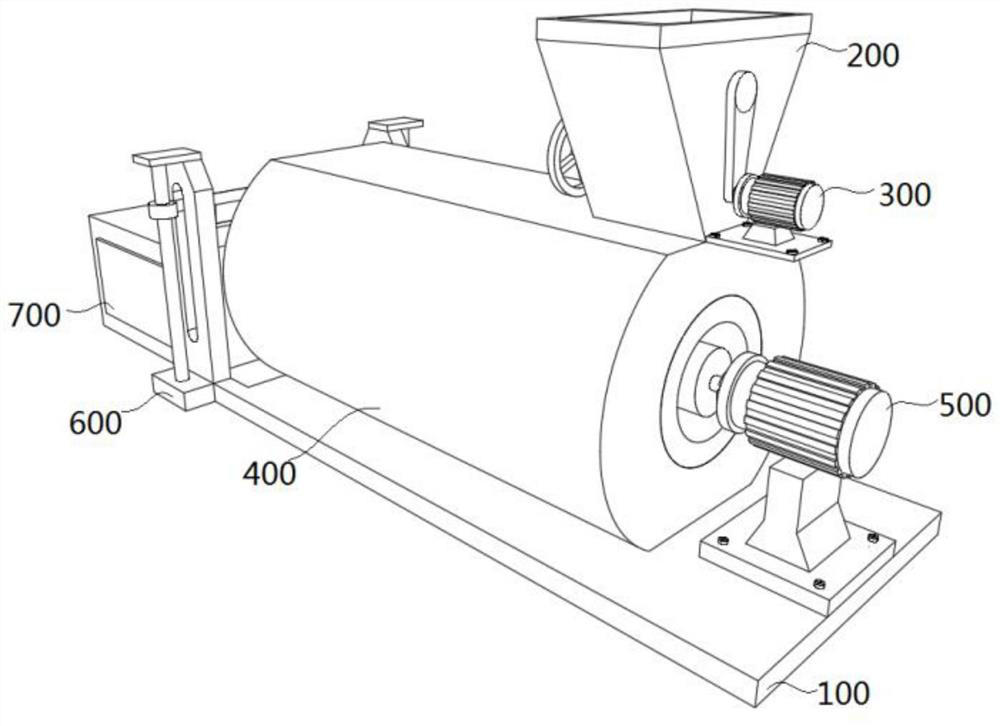

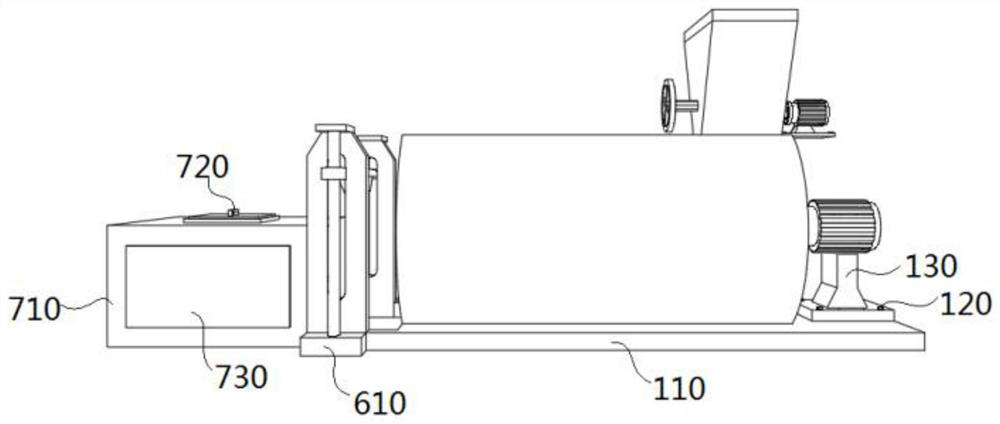

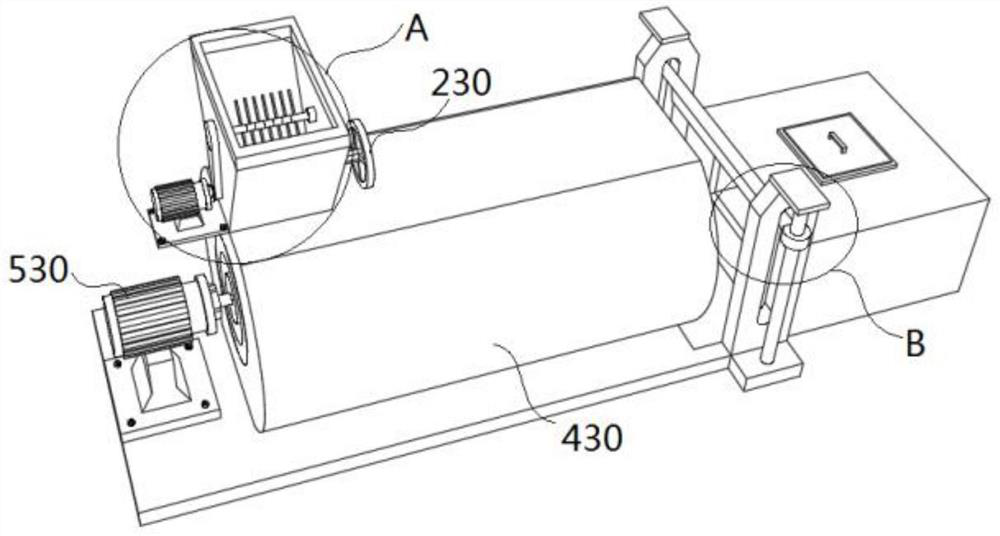

Large vertical straw pulverizer

The invention provides a large vertical straw pulverizer which is efficient and high in automation degree and can realize continuous production. The large vertical straw pulverizer comprises a base, a feeding device arranged above the base, a primary pulverizing device and a secondary pulverizing device, the feeding device comprises an outer barrel, an inner barrel arranged in the outer barrel and a power unit for driving the inner barrel to rotate; the primary pulverizing device comprises a primary pulverizing chamber provided with a feeding hole, a primary rotating shaft assembly arranged in the primary pulverizing chamber and a primary motor for driving the primary rotating shaft assembly to rotate; the secondary pulverizing device comprises a secondary pulverizing chamber, a secondary rotating shaft assembly arranged in the secondary pulverizing chamber and a secondary motor for driving the secondary rotating shaft assembly to rotate; and the primary pulverizing chamber and the second pulverizing chamber are connected in series and arranged in the base, and the primary rotating shaft assembly and the secondary rotating shaft assembly are opposite in rotation direction.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

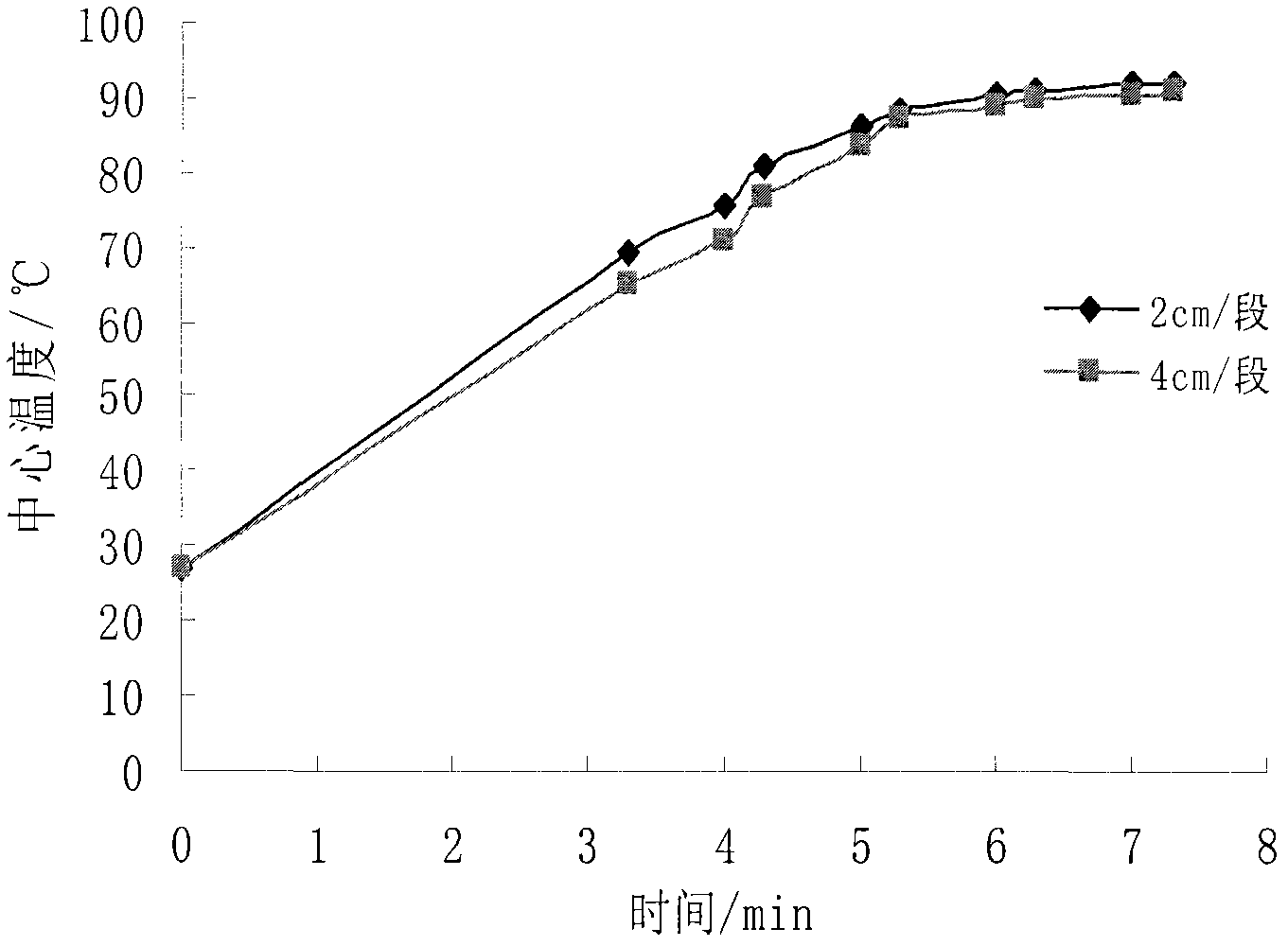

Method for processing fruit and vegetable beverage by efficiently carrying out enzyme-killing color protection

InactiveCN102578651AImprove crushing effectReasonable designFood scienceProcess equipmentCrop protection

The invention discloses a method for processing a fruit and vegetable beverage by efficiently carrying out enzyme-killing color protection. The method is characterized in that in the process of processing the fruit and vegetable beverage, when the pressure of steam in a steam tube of a fruit-vegetable enzyme killing and crushing plant reaches 0.15 to 0.18 MPa and the temperature of the steam reaches over 110 DEG C by regulation, cleaned fruit and vegetable raw materials are directly put into the inner cavity of the plant through a material feeding opening and a crushing tool is simultaneouslystarted; when the material temperature at a discharge port reaches over 85 DEG C, the discharge port is opened; and the materials discharged from the discharge port are blended, clarified, sterilizedand aseptically filled to obtain the fruit and vegetable beverage finished product. The method disclosed by the invention has a reasonable process equipment design; process parameters are properly selected; the method is very suitable for crushing and enzyme killing of fruits easy to brown and has excellent enzyme-killing color protection and fruit and vegetable crushing effects; the problem of great loss of the content of soluble solids in fruits, which is caused by blanching enzyme killing is solved; and the method has the advantages of short heat treatment time and low equipment investment. The method disclosed by the invention is very suitable to popularize and apply in the actual production.

Owner:JIANNING FUXIN LIANYE FOOD CO LTD

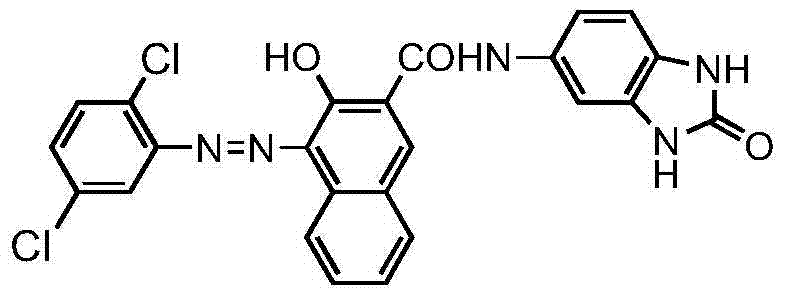

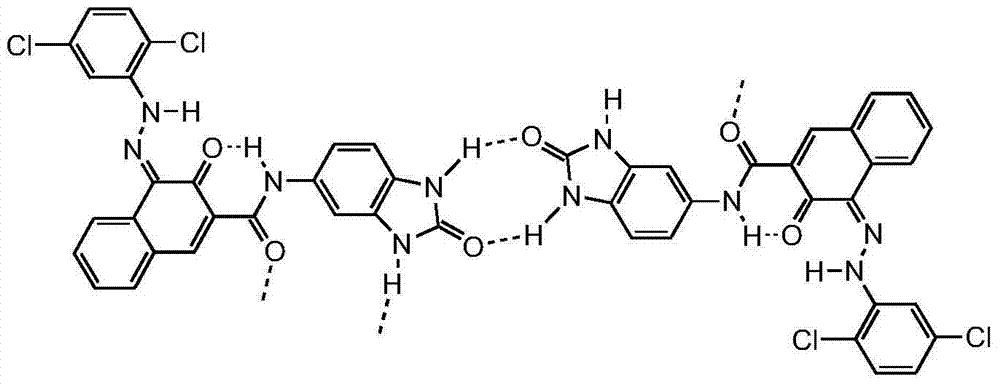

Preparation method of C.I. pigment brown 25

InactiveCN104497619AGuaranteed uniformityImproves color and tinting strengthMonoazo dyesBenzimidazoleAcid water

The invention discloses a preparation method of C.I. pigment brown 25. The preparation method comprises the following steps: (1) preparing a diazo salt liquid of 2,5-dichloroaniline; (2) dissolving 5-(2'-hydroxy-3'-naphthalene-carbamoyl)-2-benzimidazolone in an alkaline water liquid, and adding an acid water liquid to acidify, so as to prepare a suspended coupling liquid; (3) adding the diazo salt liquid into the coupling liquid to carry out a coupling reaction, controlling the pH value of the reacted mixed liquid at 5.5-6.5 by virtue of an alkaline additive in a coupling process, and processing after the coupling so as to obtain a rough pigment; and (4) carrying out pigmentation on the rough pigment to obtain the finished C.I. pigment brown 25. According to the preparation method, coupled components are separated out in a particle manner in an acidification process and are coupled with added diazo components, so that the uniformity of the coupling reaction is guaranteed, and the obtained C.I. pigment brown 25 has the beneficial effects that the particle sizes are uniform, particles are floppy, the dispersibility is excellent, the color is bright, and the coloring strength is high.

Owner:SHANGYU SHUNLIAN CHEM

Method for preparing ferroboron based on thermit self-propagating gradient reduction and slag-washing refining

ActiveCN107326254ASignificant progressSignificant advantagesProcess efficiency improvementChemical reactionThermal insulation

The invention relates to a method for preparing ferroboron based on a thermit self-propagating gradient reduction and slag-washing refining, and belongs to the technical field of ferroalloy. The method comprises the steps that after raw materials are preprocessed, by mass, 1.0 part of boric anhydride, 1.33-4.49 parts of Fe2O3 powder, 1.22-2.29 parts of aluminum power and 0.6-3.2 parts of CaO are weighed; then a thermit self-propagating reaction is conducted by adopting the mode of gradient feeding to obtain high temperature molten liquid, and gradient reduction smelting is conducted; after feeding is completed, thermal-insulation melt separation is conducted; and CaO-CaF2 base refining slag is added into the high temperature molten liquid, and the ferroboron is obtained after slag is removed. The gradient-feeding method achieves controlling over the reaction process and the temperature and thorough reducing of metallic oxides, and moreover, the smaller the gradients of the aluminum coefficients are, the fewer aluminum residues in the alloy molten liquid are; slag-washing refining achieves thorough chemical reaction of a slag-metal interface and slag-metal separation, and the recovery rate of boron is enhanced; and meanwhile, the temperature of the molten liquid is reduced, the system reaction heat is utilized, and energy consumption is reduced.

Owner:NORTHEASTERN UNIV

Fertilizer applicator with adjustable width for eucommia ulmoides fields

InactiveCN109479447AWith adjustable fertilization widthAvoid affecting the fertilization effectPlantingGravity flow based distributionAgricultural engineeringEucommia ulmoides

The invention discloses a fertilizer applicator with adjustable width for eucommia ulmoides fields. The fertilizer applicator comprises supporting seats and a fertilizer hopper, wherein the supportingseats comprise a left supporting seat and a right supporting seat; a vertical column A and a vertical column B are respectively connected to the upper ends of the left supporting seat and the right supporting seat; a rack is welded to the rear end surface of the vertical column A; the rack meshes with a gear; the gear is connected with an output shaft of a motor B; the motor B is mounted on a motor seat; a cross rod is connected to the right end of the motor seat; a sliding rail is connected to the rear end surface of the cross rod; sliding blocks are connected to the sliding rail in a sliding manner; material discharging pipes B are connected to the rear ends of the sliding blocks; a motor A is connected to the upper end of the vertical column A; a rotary shaft is connected to an outputshaft of the motor A; material discharging ports are formed in the lower part of the fertilizer hopper; material discharging pipes A are connected to the lower ends of the material discharging ports;plastic hoses are connected to the lower ends of the material discharging pipes A; the lower ends of the plastic hoses are connected with the material discharging pipes B; and plow heads are connectedto the front ends of the lower parts of the material discharging pipes B. The fertilizer applicator has the advantages of adjustable fertilizing depth and width, wide application range, adjustable blanking speed, high fertilizing efficiency, good fertilizing effect and good buffering effect.

Owner:禹州森茂迷迭香生物科技有限公司

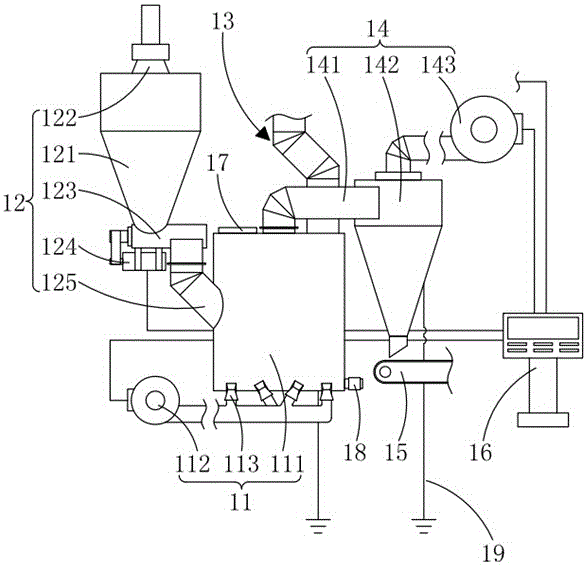

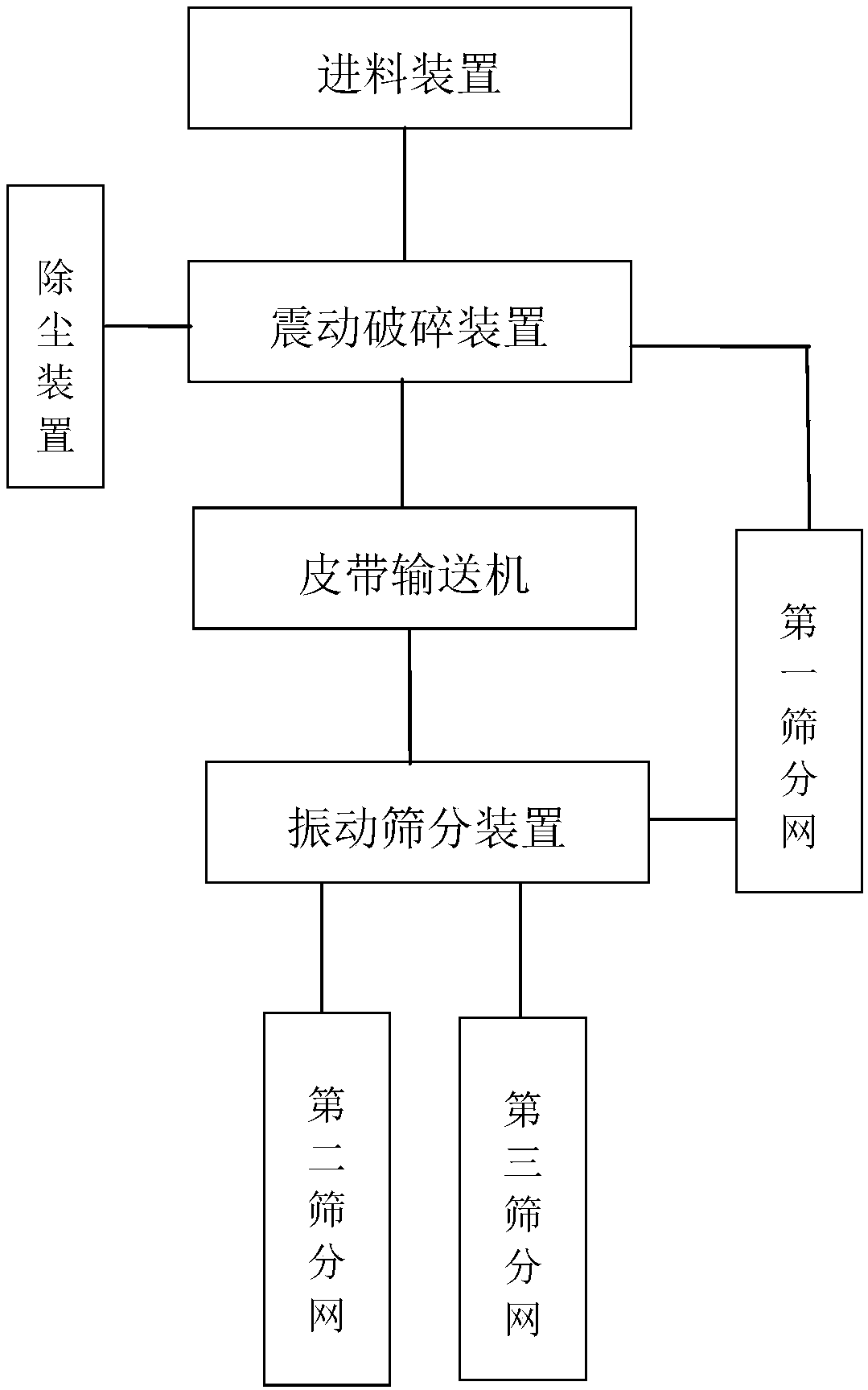

Efficient dry method sand making production line

The invention discloses an efficient dry method sand making production line. The efficient dry method sand making production line comprises a feeding device, a vibration crushing device, a belt conveyor, a vibration screening device, an efficient powder concentrator, a dust removal device, a control center and a hydraulic device. The feeding device is of a cylindrical structure. The feeding devicecomprises a material hanging device, a feeding port, a material containing device and a discharging port. The material containing device is provided with an infrared detection device. The infrared detection device detects the volume of materials in the material containing device and is connected with the control center. The feeding port is located above the material containing device, and the discharging port is located in the lower right side of the material containing device and is of a circular structure. The material hanging device comprises a mechanical arm and is connected with the hydraulic device. Power is provided through the hydraulic device, the material hanging device is connected with the control center, and the control center receives signals of the infrared detection deviceand controls the feeding speed of the material hanging device.

Owner:江苏赛日实业有限公司

Plastic particle loading machine capable of automatically weighing and discharging

The invention relates to a plastic particle loading machine and particularly relates to a plastic particle loading machine capable of automatically weighing and discharging. The plastic particle loading machine comprises a loading machine body and a material guiding device, wherein a drying machine is arranged on an outlet of the material guiding device, a material retention bin and a weighing retention bin are sequentially arranged in the loading machine body from top to bottom, a material discharging valve is arranged at the bottom of the material retention bin, and a weighing discharging valve is arranged at the bottom of the weighing retention bin. When the plastic particle loading machine works, the material discharging valve is switched on, so that materials can be retained in the weighing retention bin, and is discharged through the weighing discharging valve after being weighed, while the material discharging valve controls the height of the materials in the weighing retention bin, when the materials in the weighing retention bin is overhigh, the material discharging valve is switched off, so that the inaccurate weighing caused by redundant material accumulation in the weighing retention bin can be prevented; due to the control on the weight of loaded materials, the loading speed of the loading machine can be effectively controlled, so that production quality parameters can be accurately controlled.

Owner:天津市志强管业制造有限公司

High-speed turning belt conveyor line

PendingCN112645000AHigh speed turningAdjust the turning speedRollersVibration suppression adjustmentsTransmission beltConveyor belt

The invention discloses a high-speed turning belt conveyor line, and relates to the technical field of belt conveyor lines. The high-speed turning belt conveyor line comprises a conveyor belt, wherein a belt feeding device is fixedly arranged at the right end of the upper surface of the conveyor belt; a cover pressing device is fixedly arranged on the left side of the belt feeding device and above the conveyor belt; a high-speed turning device is fixedly arranged on the left side of the cover pressing device and between conveyor belts; and a collecting device is fixedly installed below the left end of the conveying belt. According to the high-speed turning belt conveyor line provided by the invention, by additionally arranging the turning device and adjusting the speed of a turning acceleration wheel, the purpose of adjusting the turning speed is achieved, so that high-speed turning of belt conveying is achieved; a buffering acceleration device and a position adjusting device are additionally arranged, so that through cooperation of the buffering acceleration device and the position adjusting device, materials are not damaged during turning acceleration and the smoothness in turning is realized, and meanwhile, the belt feeding position of the final material on the next conveying belt can be controlled; and the belt feeding device is additionally arranged, so that the feeding speed is increased, and meanwhile, the cost of the whole device is reduced.

Owner:南通利俊自动化设备有限公司

Method for synthesizing tributyl phosphate by sodium formate acid-binding method

The invention discloses a method for synthesizing tributyl phosphate by a sodium formate aid-binding method. The method comprises the following steps of: dissolving sodium formate into butanol; adding phosphorus oxychloride dropwise into the solution at the temperature of between 5 and 15 DEG C, and then preserving the heat and reacting with stirring for 15 to 30 minutes; and then performing distillation: performing atmospheric distillation, collecting fraction at the temperature of between 100 and 105 DEG C to obtain formic acid, and then reducing pressure to -0.96 to -0.98Mpa, and collecting the fraction at the temperature of between 160 and 180 DEG C to obtain the tributyl phosphate. In the method for synthesizing the tributyl phosphate by the sodium formate acid-binding method, the sodium formate is weak acid strong alkali salt and has a certain alkaline and is reacted with hydrogen chloride to form sodium chloride and the formic acid, and the formic acid subjected to separation can be reacted with sodium hydroxide to form the sodium formate for cycling; and compared with the conventional method, the method has the advantages that vacuumization is not needed, the using amount of the butanol is close to a theoretical amount, the yield of the tributyl phosphate is high (the yield is over 92.0 percent), and the like.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Automatic steel ball sorting device for bearing production

The invention provides an automatic steel ball sorting device for bearing production, and belongs to the technical field of bearing machining. The automatic steel ball sorting device comprises a vertical charging barrel, a feeding port is formed in the top of the charging barrel, a material guiding column located at the top of the charging barrel is fixedly arranged in the charging barrel, a gap allowing steel balls to pass through is formed between the outer wall of the material guiding column and the inner wall of the charging barrel, a rotating rod is rotationally connected in the materialguiding column, a plurality of sorting assemblies are sequentially arranged between the rotating rod and the inner wall of the charging barrel from top to bottom, and the width of a leaking groove ofeach sorting assembly is gradually increased from top to bottom; and a material guide disc fixed to the rotating rod is further arranged above the material guiding column. The automatic steel ball sorting device for bearing production has the advantage that steel balls of different sizes can be screened at a time.

Owner:HAINING QI SHENG BEARING

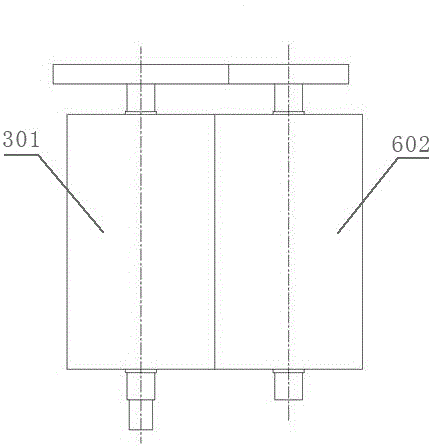

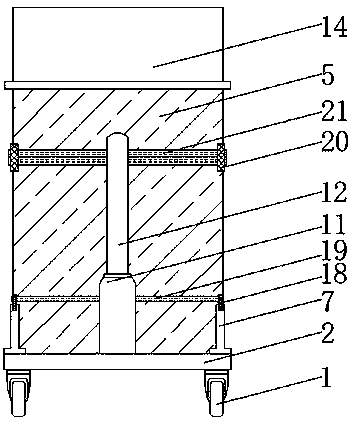

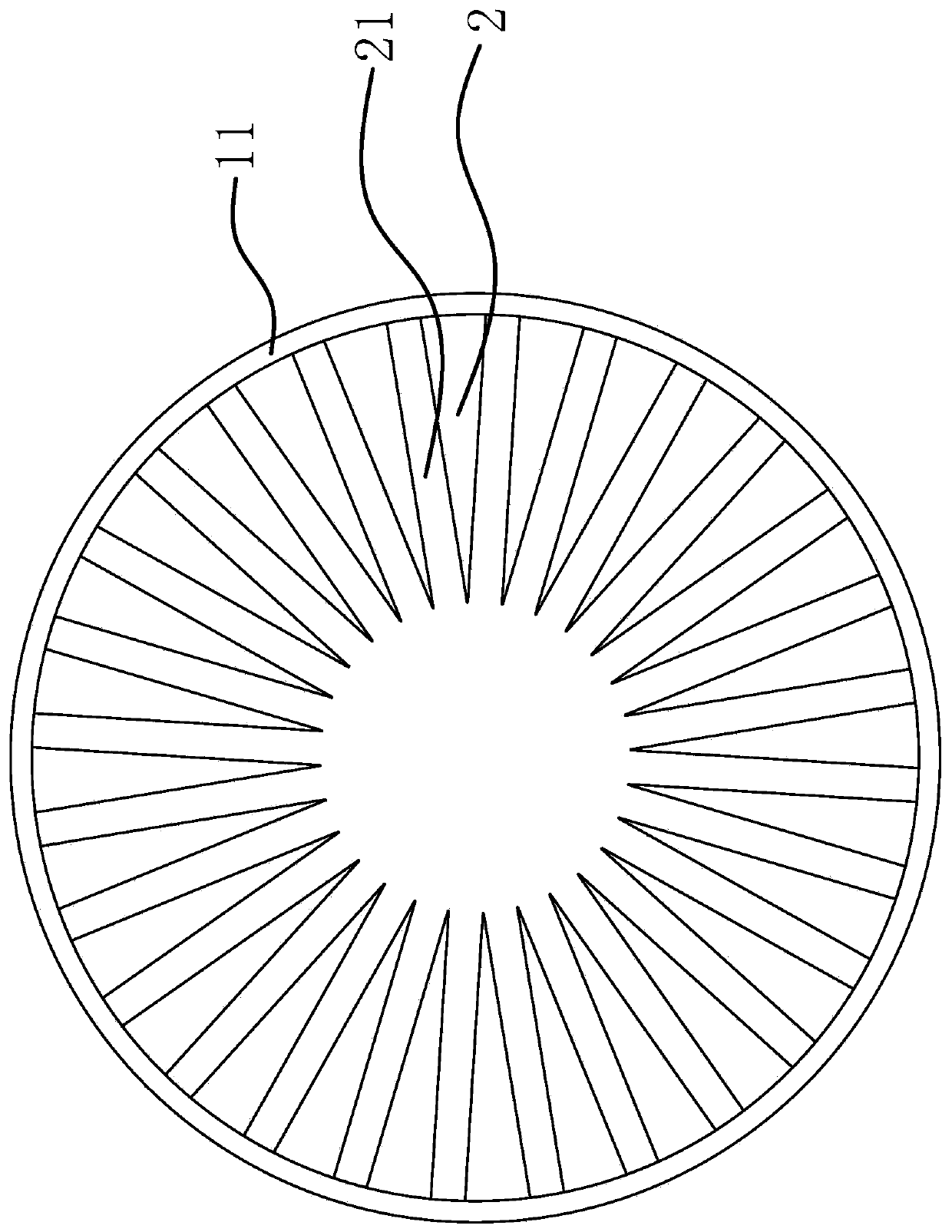

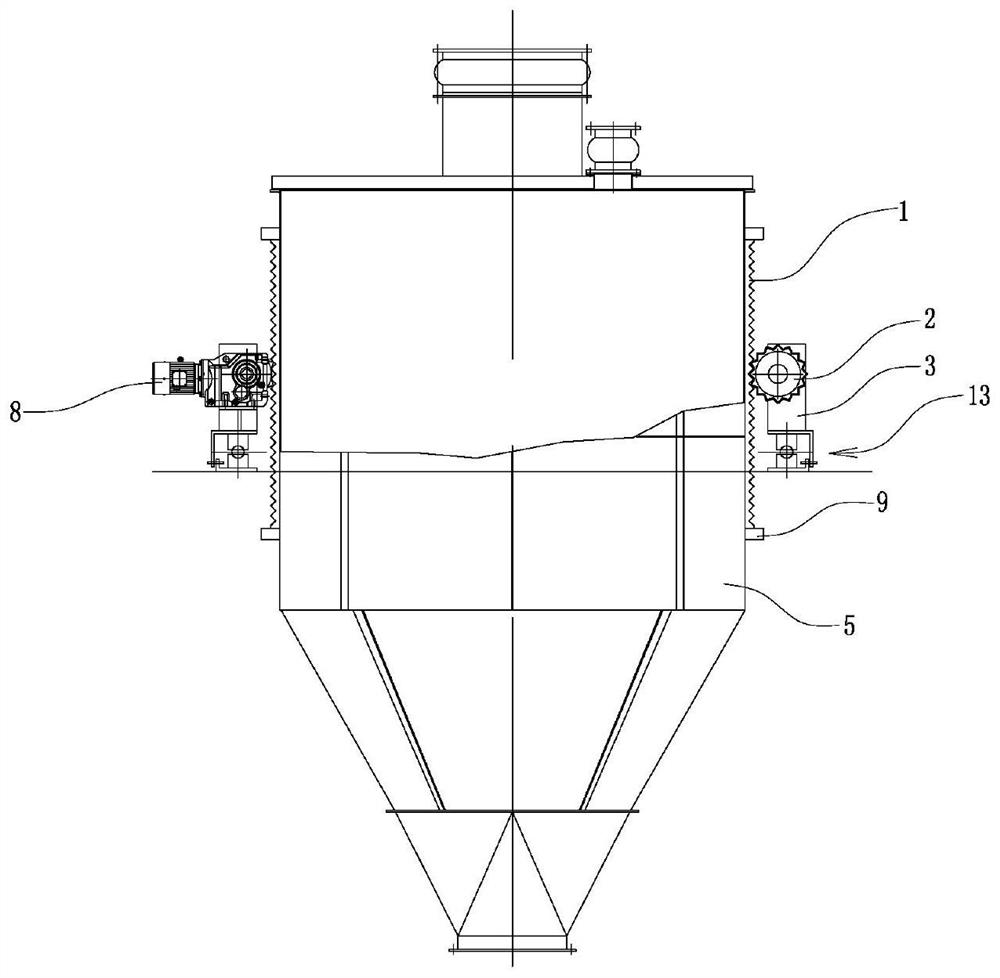

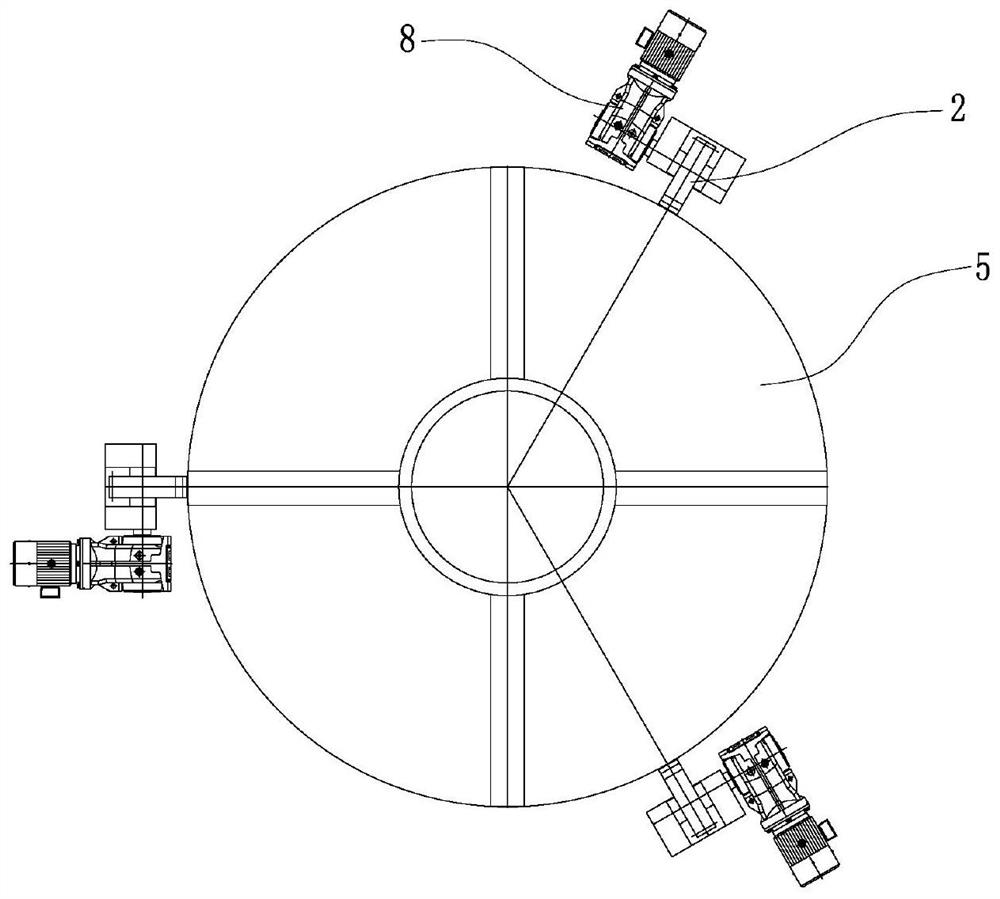

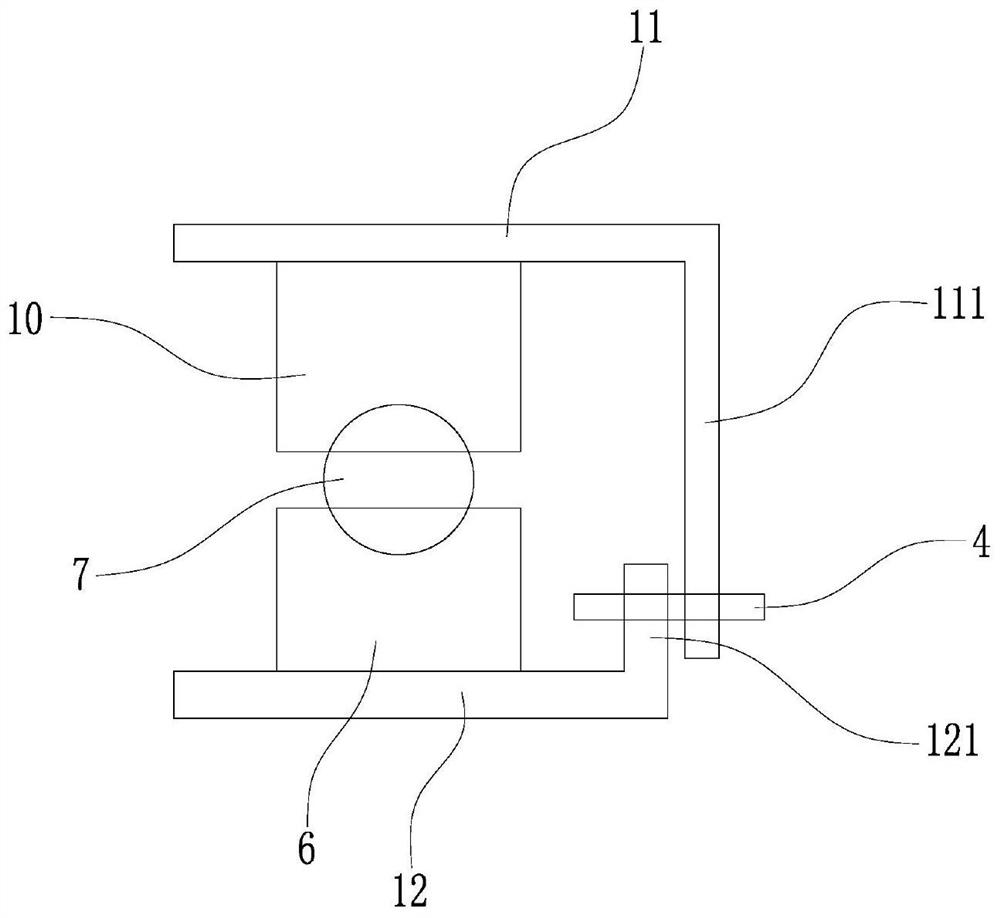

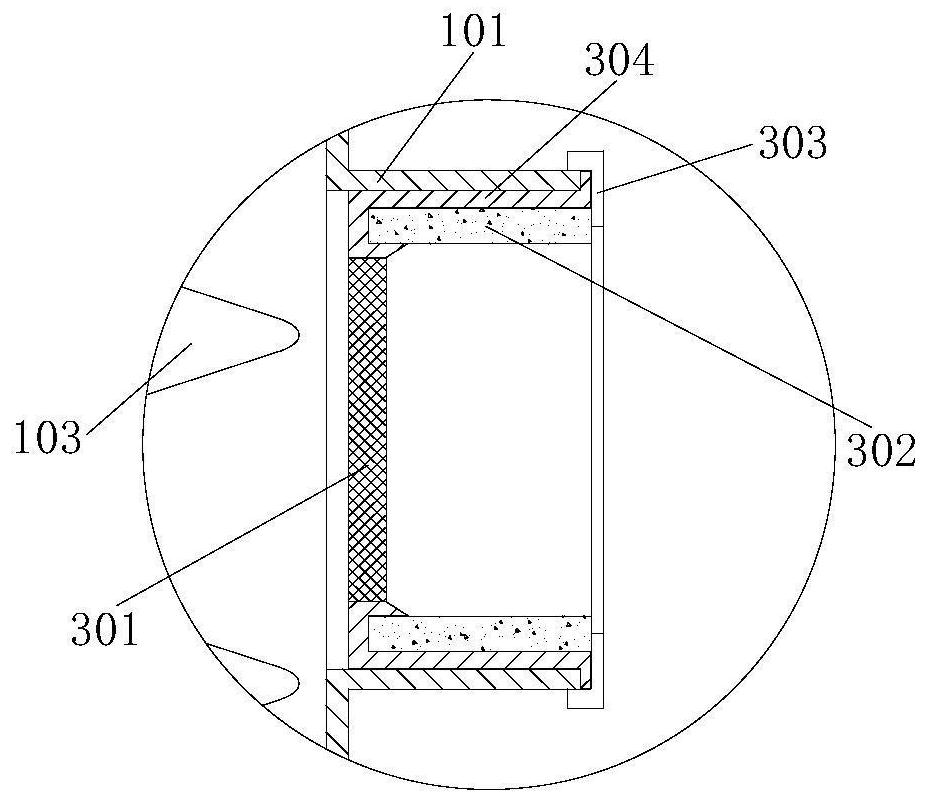

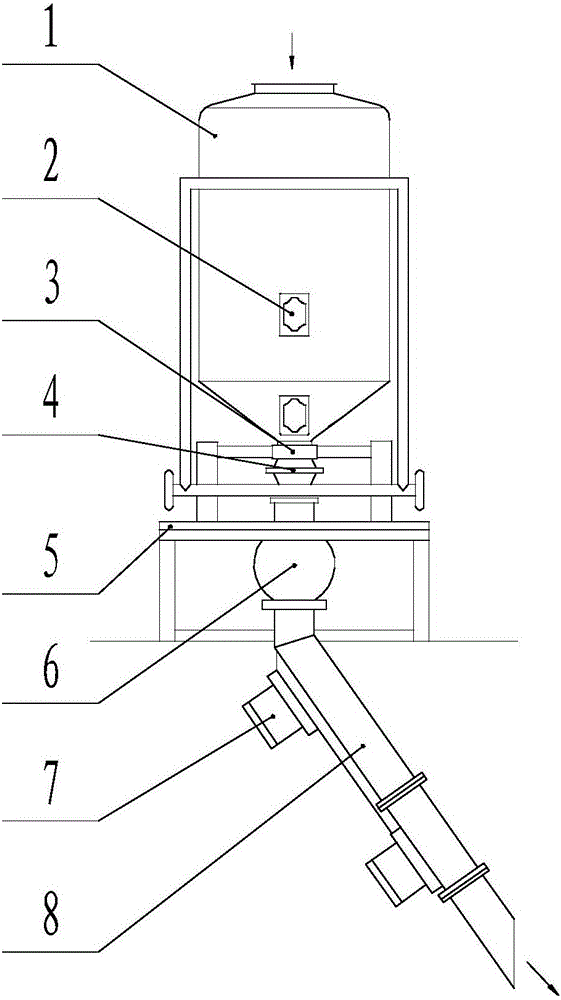

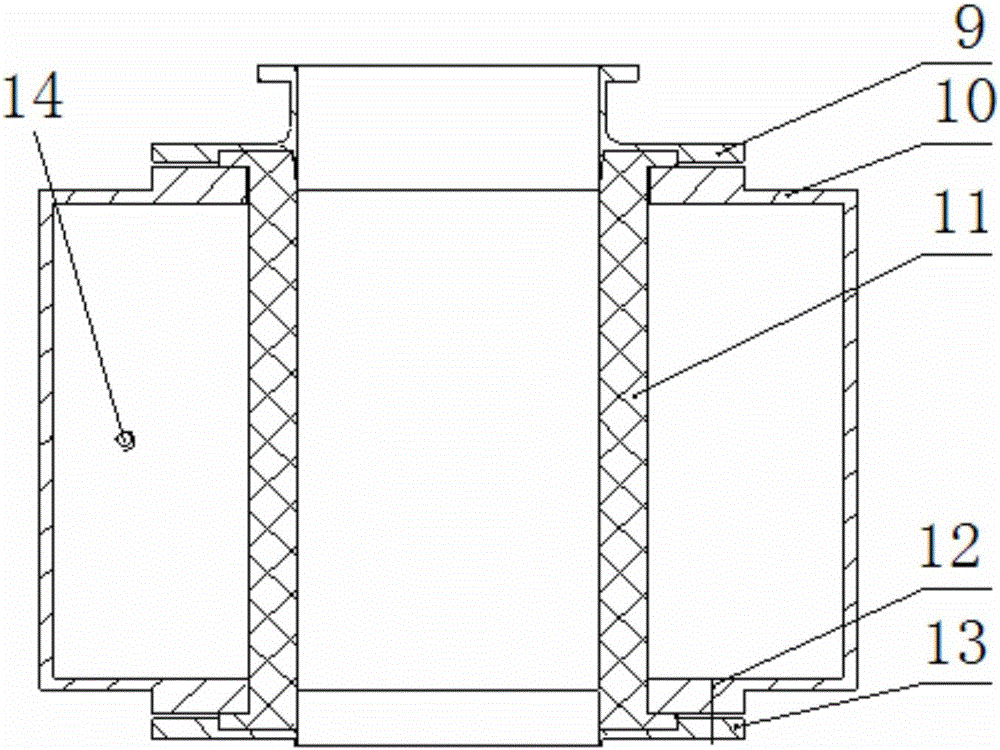

Feeding bin

InactiveCN111792399AControl feeding speedEasy to useConveyorsGrain treatmentsGear wheelElectric machinery

The invention relates to a feeding bin. The feeding bin comprises a bin body, racks, gears, supports and gear motors; the multiple supports which are distributed at equal angles in the circumferentialdirection are arranged on the outer side of the bin body; each gear motor is fixed to one side of the corresponding support, and each support is internally provided with the corresponding gear; the inner side of each gear is engaged with the corresponding rack, and all the racks are vertically fixed to the outer wall of the bin body; and rotating shafts of the gear motors transversely penetrate through one sides of the supports and are inserted and fixed into the gears, and the lower end of each support is further provided with a weighing assembly. The height of the bin body can be adjusted at any moment according to the need in the production process to adjust the discharging speed of the feeding bin, thus the feeding speed of a roller press is controlled, using is greatly facilitated, and stable operation of the feeding bin is ensured.

Owner:NANJING KISEN INT ENG

Fruit excellent selection device with material distributing box structure

PendingCN110732492AImprove recognition accuracyControl feeding speedSortingFood treatmentAgricultural engineeringMechanical engineering

Owner:ZHENGZHOU UNIV

Manufacturing device of fertilizer for soil remediation

InactiveCN111807913AEasy to recycleLower the altitudeSolid/semi-solid fertilisersFertilizer mixturesSoil remediationElectric machinery

The invention belongs to the technical field of ecological restoration, and discloses a manufacturing device of a fertilizer for soil restoration. The device comprises a feeding machine and a granulating machine, wherein a discharging hole of the feeding machine is communicated with a feeding hole of the granulating machine; a particle cutting mechanism is arranged in the granulating machine and connected with a driving mechanism, and the driving mechanism is in transmission connection with the feeding machine; an inlet pipeline of the feeding machine is connected with a feeding filtering mechanism. A multi-stage filter sieve is elastically connected in the granulating machine. Materials are filtered, impurities in the materials are removed, the feeding height is reduced, and the feeding labor force and cost are reduced; the particle cutting mechanism and the feeding machine are controlled to rotate, the number of used motors is reduced, the cost is reduced, the feeding speed and the rotating speed of the particle cutting mechanism can also be controlled, and the size of cut particles is controlled; the multi-stage filter sieve facilitates screening of finally prepared particles, screening can be conducted according to the sizes of the particles, selectivity is improved, and unqualified materials can be recycled and remanufactured conveniently.

Owner:四川省交通勘察设计研究院有限公司

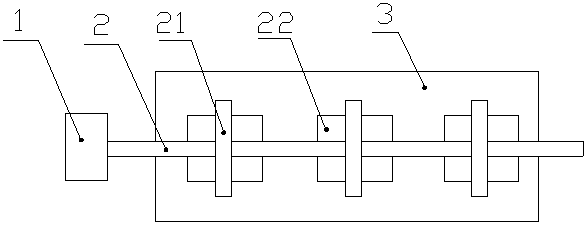

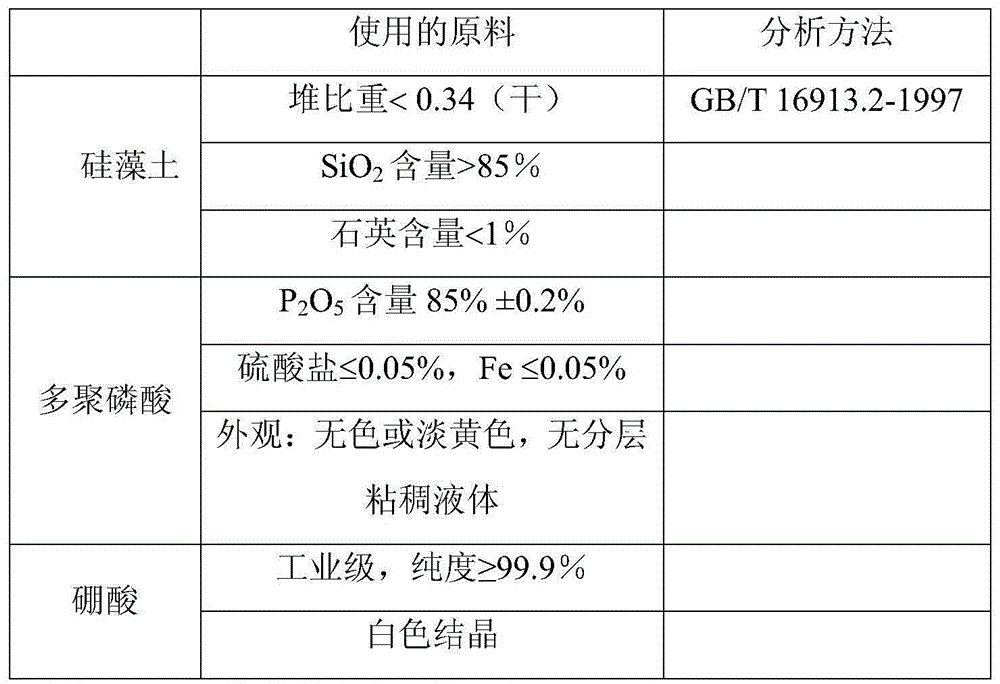

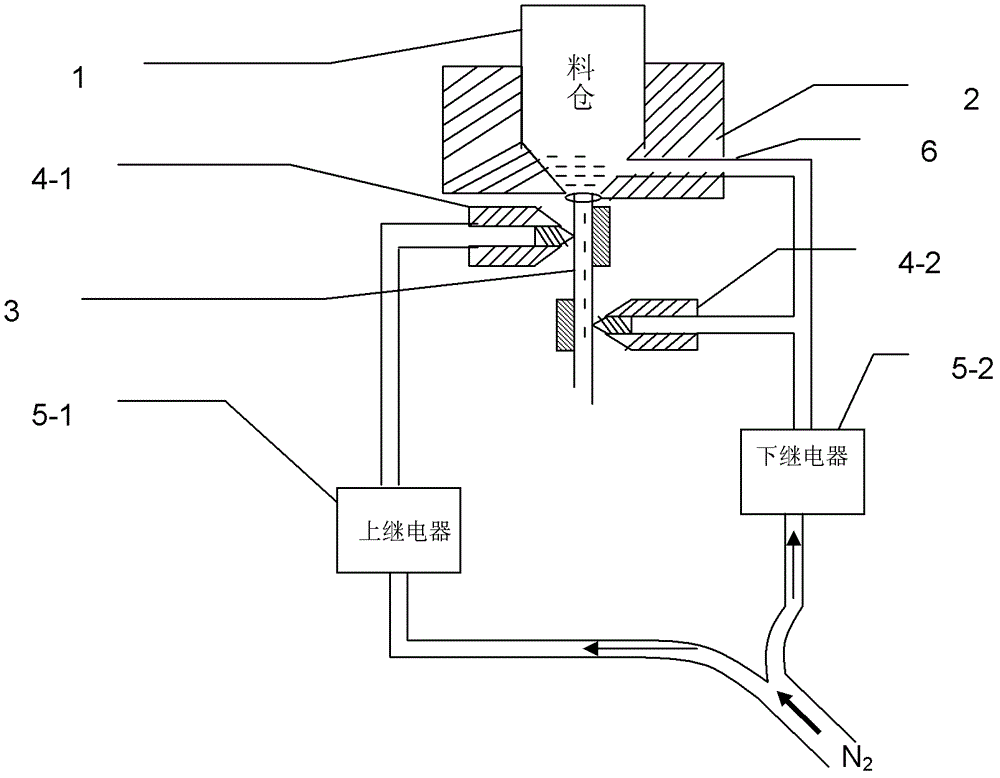

Preparation method of solid phosphoric acid catalyst, vibration type directional fine powder feeder applied to preparation method as well as application of feeder

ActiveCN105618092ANo entrainmentEnsure uniformity of dispersionPhysical/chemical process catalystsFeed devicesNiobiumPhosphoric acid

The invention relates to a preparation method of a solid phosphoric acid catalyst. The preparation method of the solid phosphoric acid catalyst comprises the steps of salt-forming reaction of niobium boron phosphate compound salt, forming of the solid phosphoric acid catalyst, and the like, so that the solid phosphoric acid catalyst is obtained. The invention further discloses a vibration type directional fine powder feeder and a feeding method of the feeder; the feeder and the feeding method are applied to the preparation method of the solid phosphoric acid catalyst. According to the preparation method of the solid phosphoric acid catalyst, the vibration type directional fine powder feeder applied to the preparation method as well as the application of the feeder, the production cost is reduced, and both the activity and the degradation in water of the solid phosphoric acid catalyst are improved, so that the solid phosphoric acid catalyst can be widely applied to large-scale industrial production.

Owner:RACHEM CHINA CO LTD

Extrusion tool for plastic tubular product

The invention discloses an extrusion tool for a plastic tubular product, and relates to the technical field of extrusion of plastic products. The extrusion tool disclosed by the invention comprises a supporting device, a feeding device, a stirring device, a heating device, an extruding device, a cutting device and a cooling device; the supporting device comprises a bearing plate and a supporting column; the upper surface of the bearing plate is connected with the lower surface of the supporting column; the feeding device comprises a feeding hopper; the stirring device comprises a transmission element and a stirring rod; the heating device comprises a shell; the lower surface of the shell and the upper surface of the bearing plate are welded together; the extruding device comprises a speed adjusting motor; the lower surface of the speed adjusting motor is connected with the upper surface of the supporting column; the cutting device comprises connecting plates; the cooling device comprises a cooling bin; and the outer surface of the cooling bin is connected with the inner surfaces of a plurality of connecting plates. According to the extrusion tool provided by the invention, under the rotation of an extrusion roller, an extruded plastic pipe is pushed out of an extrusion barrel through protruding threads on the surface, the plastic pipe is conveniently separated from the extrusion barrel, and the pushing speed of the extrusion roller can be adjusted through the speed adjusting motor, so convenience is provided for formation of plastic powder.

Owner:湖南承运机电有限公司

An energy-saving and environment-friendly aquaculture fish, shrimp and crab multifunctional feed feeder

ActiveCN110074034BTiming outputAvoid situations that cause differences in the amount of feedClimate change adaptationPisciculture and aquariaAnimal scienceZoology

Owner:湛江市润晖水产有限公司

A continuous powder feeding device and real-time control method

ActiveCN103754658BNo blocking phenomenonEliminate the influence of uncertain factorsLoading/unloadingEngineeringTime control

The invention relates to a continuous powder feeding device and a real-time control method. A hopper of the continuous powder feeding device is installed on a weighing platform of a scale located on a bracket, the upper end of a blanking valve is communicated with a discharge hole of the hopper, the lower end of the blanking valve is communicated with the upper end of a rubber tube valve, the lower end of the rubber tube valve is communicated with a blanking pipe, and two air hammers are installed on upper and lower portions of an outer wall of the blanking pipe respectively. During feeding, the initial feeding amount is weighed, the weight of the feeding device is weighed before and after connection with a mixture pot so as to control the feeding amount, and opening of the blanking valve and a switch of a vibrator are adjusted, so that feeding speed control is achieved. According to the continuous powder feeding device and the real-time control method, continuous and smooth feeding of large-weight and small particle size powder in large vertical mixers can be achieved, feeding speeds and feeding amount can be controlled, product qualities are improved, and safety of a feeding process is guaranteed.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

Pine nut sheller

A pine nut shell opening machine comprises a machine frame, a feeding mechanism, a shell opening mechanism, a discharging hopper and a driver. The feeding mechanism, the shell opening mechanism, the discharging hopper and the driver are arranged on the machine frame. The pine nut shell opening machine is characterized in that the feeding mechanism is a vibration feeding machine, the shell opening mechanism is a pair of pressing rollers, the pressing rollers rotate relatively and are driven by the driver, each pressing roller is provided with a plurality of arc grooves which are arrayed in the axial direction of the pressing roller, the arc grooves in the two pressing rollers are opposite, roller gaps are formed between arc grooves in the two pressing rollers, a discharging end of a feeding hopper is provided with a guiding groove which is provided with a plurality of feeding channels, discharging ends of the feeding channels are provided with a plurality of straightening devices which are used for enabling the tip portions of pine nuts to be downward to enter the pressing roller gaps, the two sides of each pressing roller gap are respectively provided with one straightening device, and the discharging hopper is arranged below the pressing rollers. The problems that feeding is not convenient, production efficiency is low, a production process can be easily stopped, occupied space is large, and using is not convenient are fundamentally solved, and the pine nut shell opening machine has the advantages of being high in automation degree and simple in operation method, energy is saved, environment is protected, noise is low, and shell opening efficiency is high.

Owner:张立新

Granulated feed feeding way for industrial aquaculture of fries

InactiveCN109673542AEasy feedingEvenly fedClimate change adaptationPisciculture and aquariaWater qualityWater flow

The invention discloses a granulated feed feeding way for industrial aquaculture of fries. The granulated feed feeding way comprises the following steps: (1) preparing for a bucket and a granulated feed required to be fed; (2) holding aquaculture water in the bucket; (3) siphoning the aquaculture water in the bucket into an aquaculture pond; (4) placing the granulated feed required to be fed intothe bucket in times, and carrying out stirring to make the granulated feed required to be fed siphoned into the aquaculture pond together with a water flow of the aquaculture water; and (5) adding theaquaculture water in time when the aquaculture water in the bucket is insufficient in a process that the aquaculture water in the bucket is siphoned into the aquaculture pond. The granulated feed feeding way is uniform in feeding, beneficial to the food intake of the fries, sufficient in utilization rate, low in settled feed quantity and loss and capable of indirectly keeping the water quality, also avoiding the fries from scrambling for food and effectively protecting the fries.

Owner:江苏省农业科学院泰州农科所

Automatic-control continuous feeding device for intraocular lens growth

ActiveCN102181917BControl feeding speedGuaranteed growth quality requirementsBy pulling from meltComputer control systemIntraocular lens

Owner:SHANDONG UNIV +1

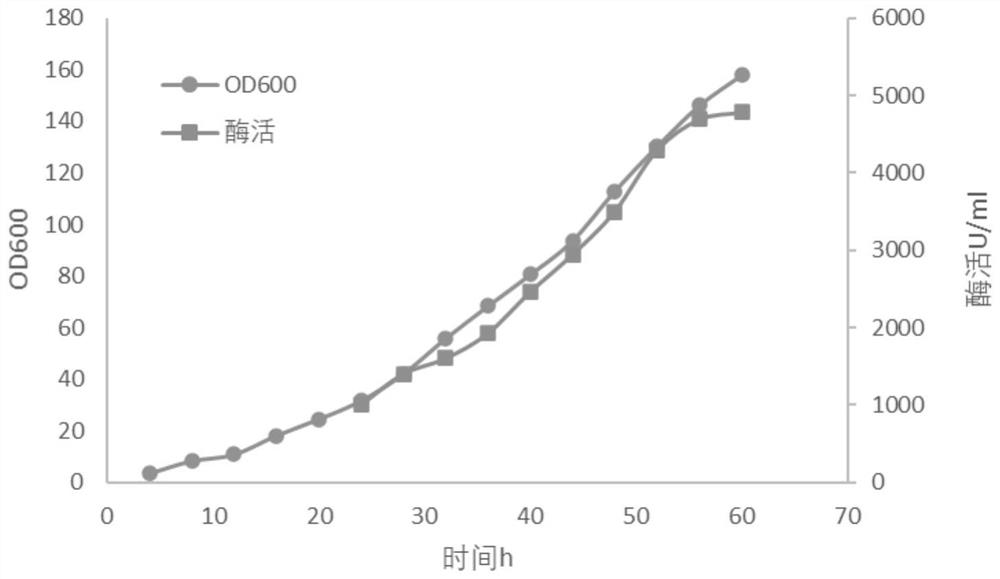

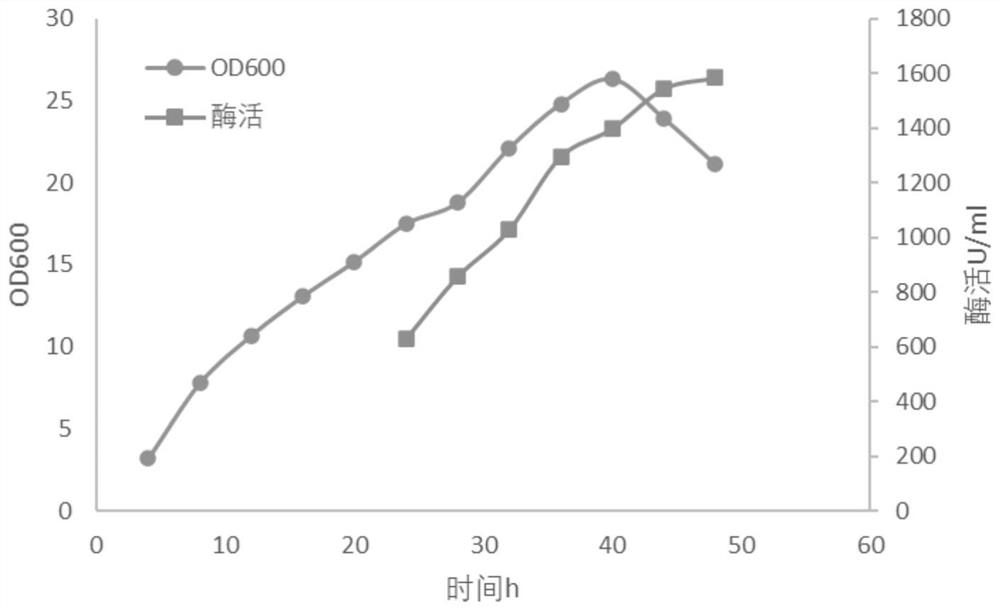

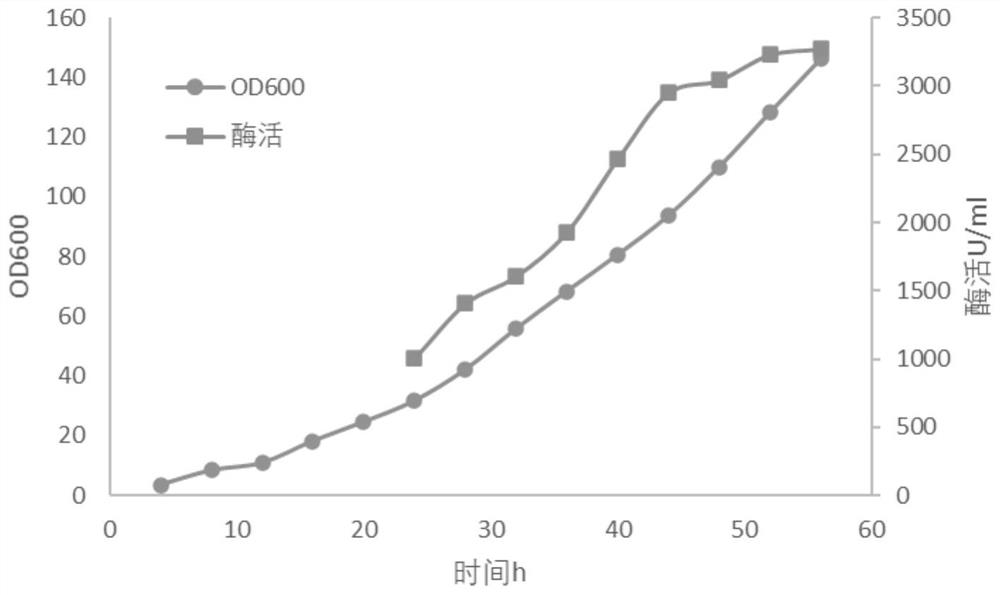

Method for producing psicose 3-epimerase through high-density fermentation

ActiveCN114480359AReduce the burden onHigh expressionBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention belongs to the technical field of microbial fermentation engineering, and particularly relates to a method for producing psicose 3-epimerase through high-density fermentation. Aiming at the problems of low expression quantity of psicose 3-epimerase in the current fermentation and the like, the fermentation OD value of the recombinant bacillus subtilis and the total enzyme activity of the psicose 3-epimerase in the fermentation liquor are remarkably improved by controlling the feeding speed in the fermentation process, increasing the culture temperature in the middle and later periods of the fermentation and the like; the expression quantity of the psicose 3-epimerase is remarkably increased, the production cost of psicose is reduced, and the psicose 3-epimerase has an extremely wide industrial application prospect.

Owner:HENAN ZHONGDA HENGYUAN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com