Efficient dry method sand making production line

A production line, high-efficiency technology, applied in the field of machinery, which can solve problems such as general dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

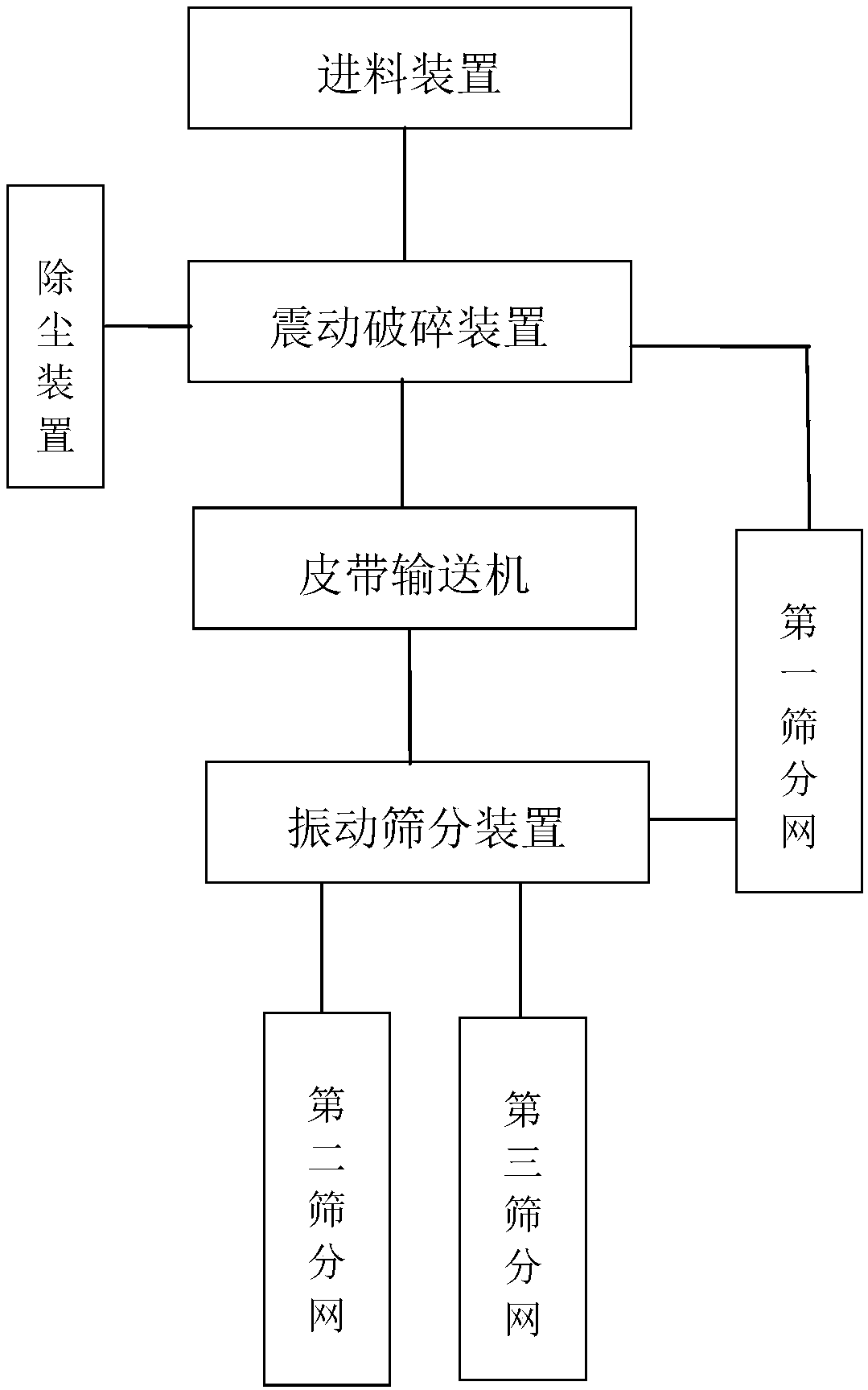

[0020] Such as figure 1 As shown, a high-efficiency dry sand production line includes a feeding device, a vibrating crushing device, a belt conveyor, a vibrating screening device, a high-efficiency powder separator, a dust removal device, a control center, and a hydraulic device. The feeding device is a circular Cylindrical structure, the feeding device includes a material hanging device, a material inlet, a material placement device, and a discharge outlet. The material placement device is equipped with an infrared detection device, and the infrared detection device detects the material in the material placement device. How much, the infrared detection device is connected with the control center, the material inlet is located above the material placement device, the material outlet is located on the lower right side of the material placement device, and the material outlet is Circular structure, the lifting device includes a mechanical arm, the lifting device is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com