A continuous powder feeding device and real-time control method

A feeding device and powder technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of inability to achieve speed control, friction sensitivity, large and fine oxidants, etc., and achieve the elimination of connection interference, short distance, and large inclination angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

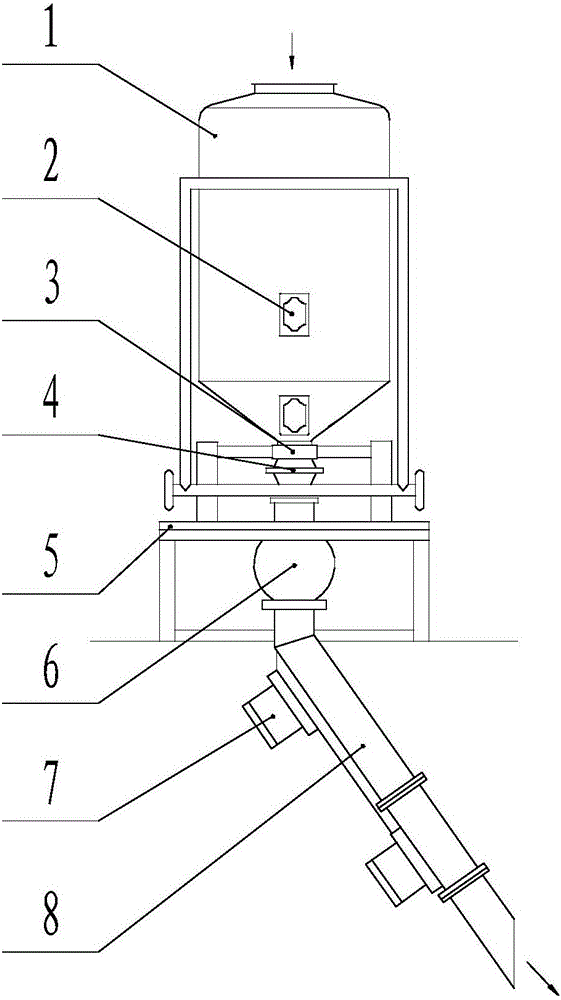

[0032]This embodiment is a continuous powder feeding device, including a hopper 1, a vibrator 2, a feeding valve 3, a scale 5, a hose valve 6, an air hammer 7 and a feeding pipe 8.

[0033] Hopper 1 is installed on the weighing platform of the scale 5 that is positioned at support. The upper end of the blanking valve 3 is communicated with the discharge port of the hopper 1, and the lower end of the blanking valve 3 is connected with the upper end of the rubber hose valve 6 through a flexible pipe 4; Two pneumatic hammers 7 are installed on the top and the bottom of the outer wall of the feeding pipe 8 respectively. Described hopper 1, scale 5 and support are all prior art. Air hammer 7 and vibrator 2 all adopt standard parts.

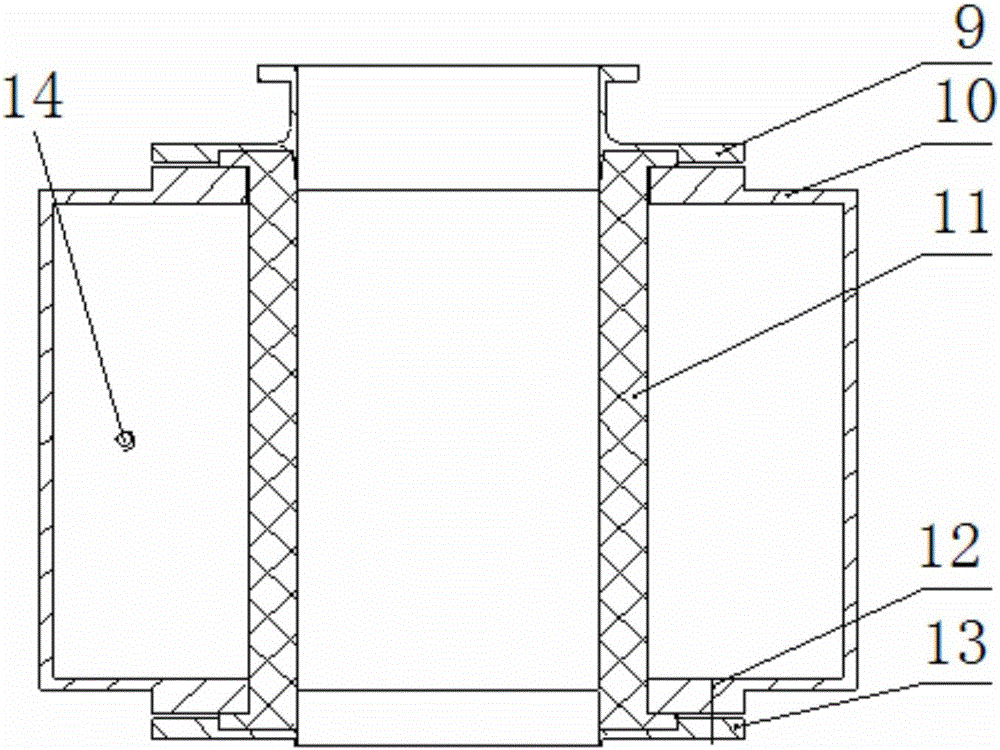

[0034] The hose valve 6 is a straight-through powder hose valve disclosed in the utility model patent application No. 201320659985.X by Xi'an Aerospace Chemical Power Plant, which is a non-standard processed part. The rubber hose valve 6 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com