Pine nut sheller

A technology of pine nuts and racks, applied in the field of nut processing equipment, can solve the problems of inconvenient use, low production efficiency, inconvenient feeding, etc., and achieve the effects of convenient collection, improved shell opening rate, and convenient shell opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

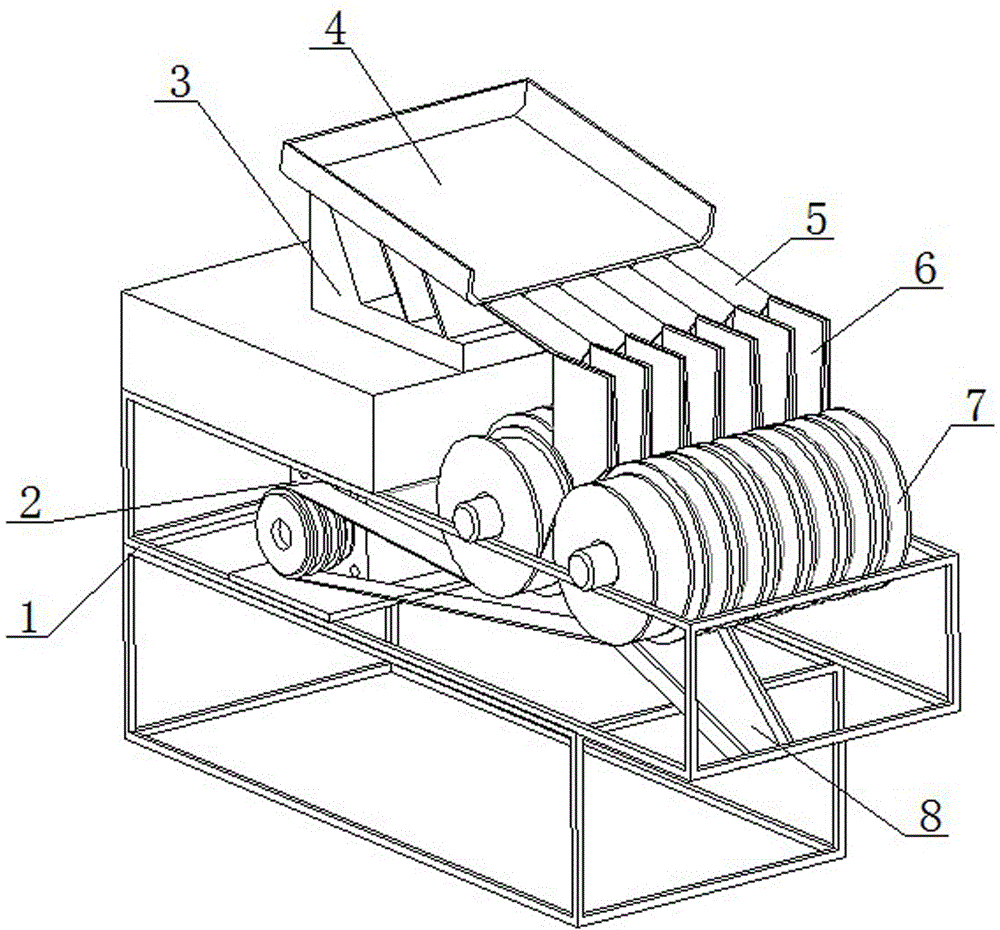

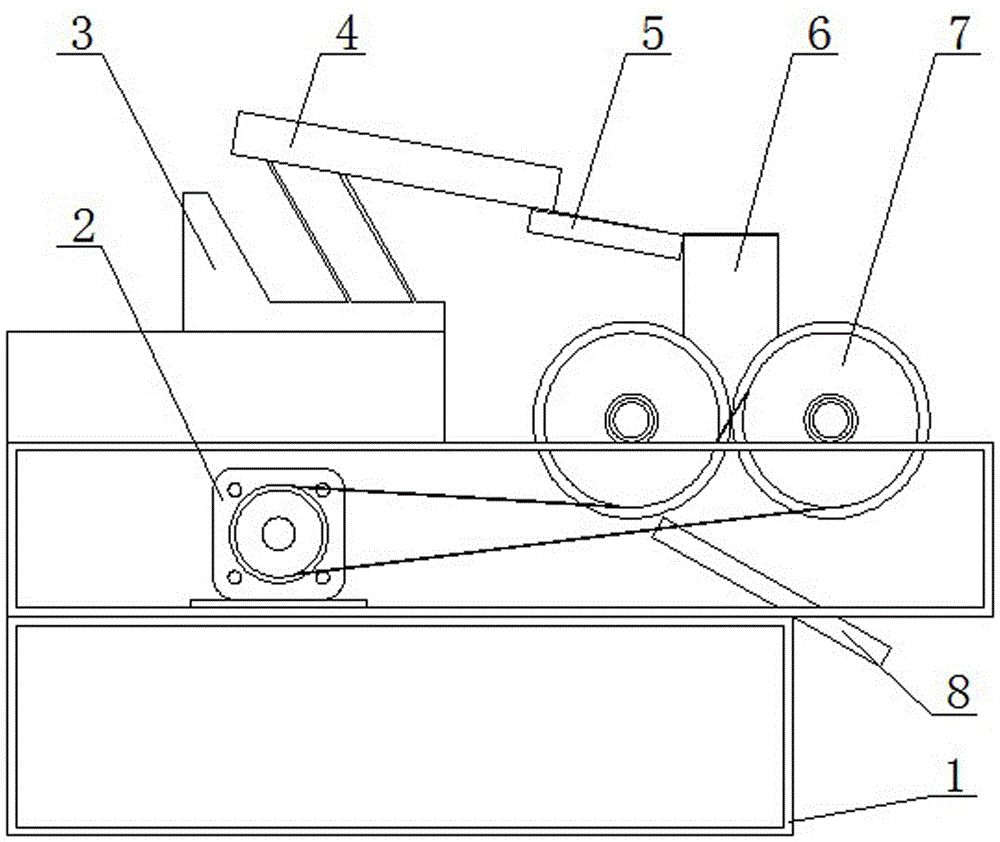

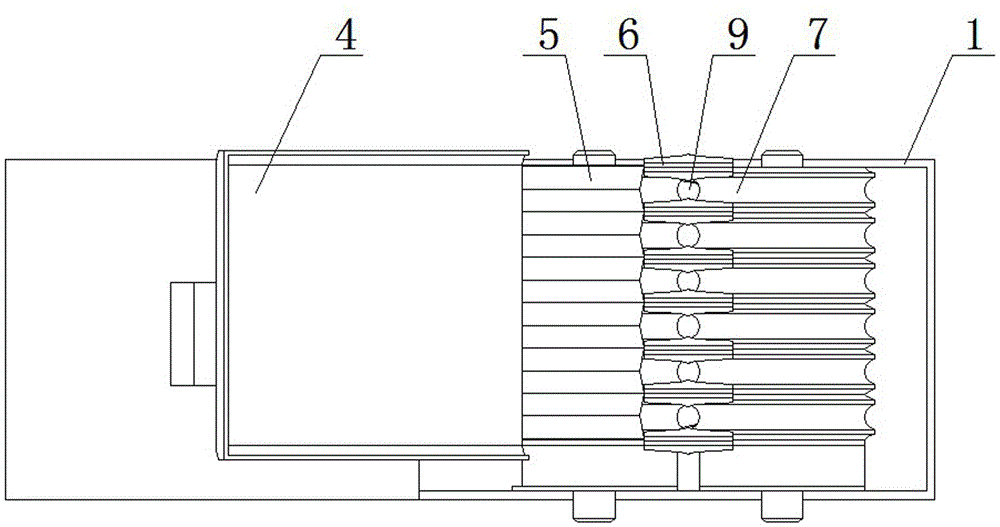

[0014] according to Figure 1~4 The specific structure of the present invention will be described in detail. The pine nut sheller includes a stainless steel frame 1 and a vibrating feeder 3 arranged on the frame 1 (such as the GZV series miniature electromagnetic vibrating feeder produced by Nantong Zhenqiang Machinery Manufacturing Co., Ltd.), a shell opening mechanism, a tilting Parts such as the discharge hopper 8 at a certain angle, the driving machine 2 (such as a miniature gear reduction motor). Wherein, the shell opening mechanism is a pair of relatively rotating steel pressing rollers 7 driven by the driving machine 2 . The driving machine 2 is connected with the pulleys on the same side of the two pressure rollers 7 through the pulley at the output end, as figure 1 In the connection mode, the two pressure rollers 7 can be driven to move relative to each other at the same time. Each pressure roller 7 is provided with some arc-shaped grooves arranged axially along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com