Automatic-control continuous feeding device for intraocular lens growth

A feeding device and artificial crystal technology, applied in the direction of crystal growth, single crystal growth, self-melt pulling method, etc., can solve problems such as blockage, small particle size, and loss of meaning of automatic feeding device, and achieve good economic and social benefits. Simple structure, realize the effect of computer automatic program control management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, content of the present invention will be further described:

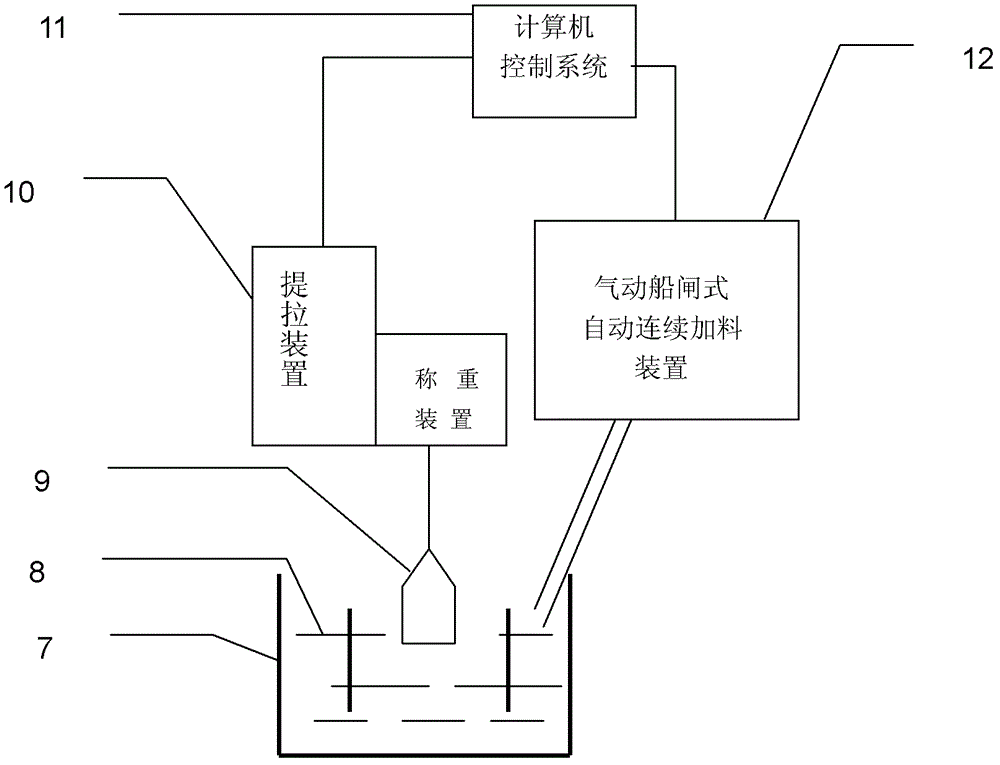

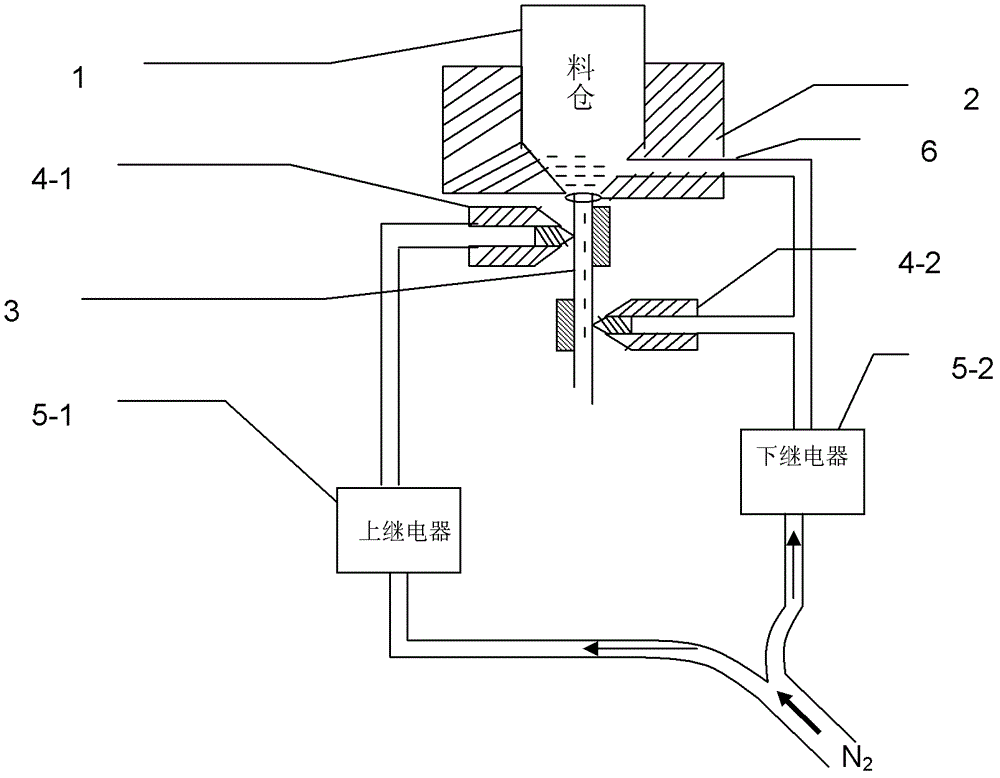

[0014] Such as figure 1 , artificial crystal automatic control growth continuous feeding device, including hanging crucible crystal growth furnace, computer control system 11 and pneumatic ship lock type automatic continuous feeding device 12. Wherein, the hanging crucible crystal growth furnace includes a hanging crucible system 7, an intermediate frequency coil, a crystal lifting and weighing system 10, a growth furnace body and a temperature control cabinet; figure 2 As shown, the pneumatic ship lock type automatic continuous feeding device of the present invention includes a silo 1, a feeding pipe 3, two pneumatic shut-off valves 4 and two relays 5; the crystal lifting and weighing system 10 and the temperature control cabinet pass through The data line is connected with the computer control system 11; the feed bin 1 is fixed on the base 2, the middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com