Fruit excellent selection device with material distributing box structure

A technology of dividing box and fruit is applied to the equipment for collecting, screening, accurately controlling the number of feeding and the posture of the fruit through the dividing box, and the field of grading. To achieve the effect of precise control and improvement of recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

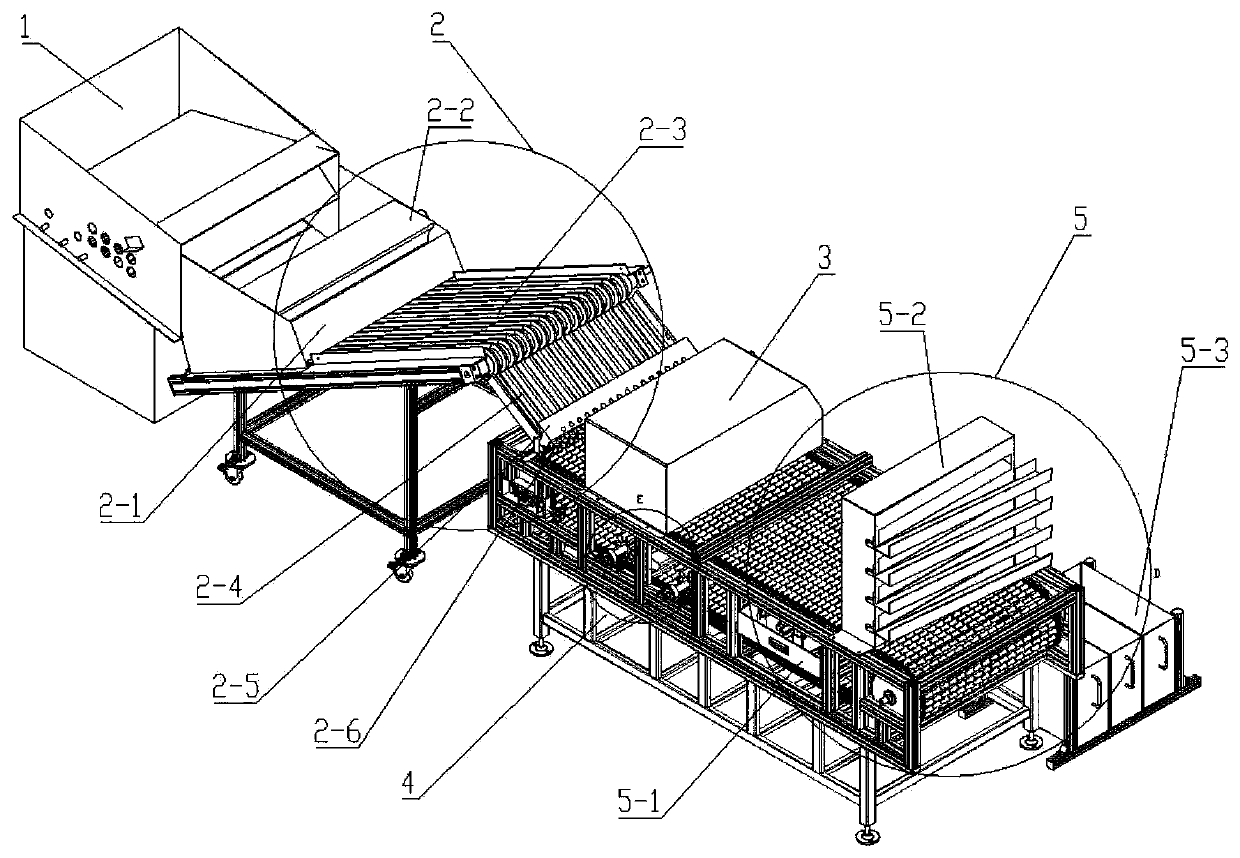

[0019] Implementation example 1, figure 1 It is a schematic diagram of the overall structure of the invention, the fruit cleaning-air-drying device (1) cleans and air-dries the fruit surface, thereby removing the attachments on the fruit surface, and can also realize the recovery of the cleaning liquid.

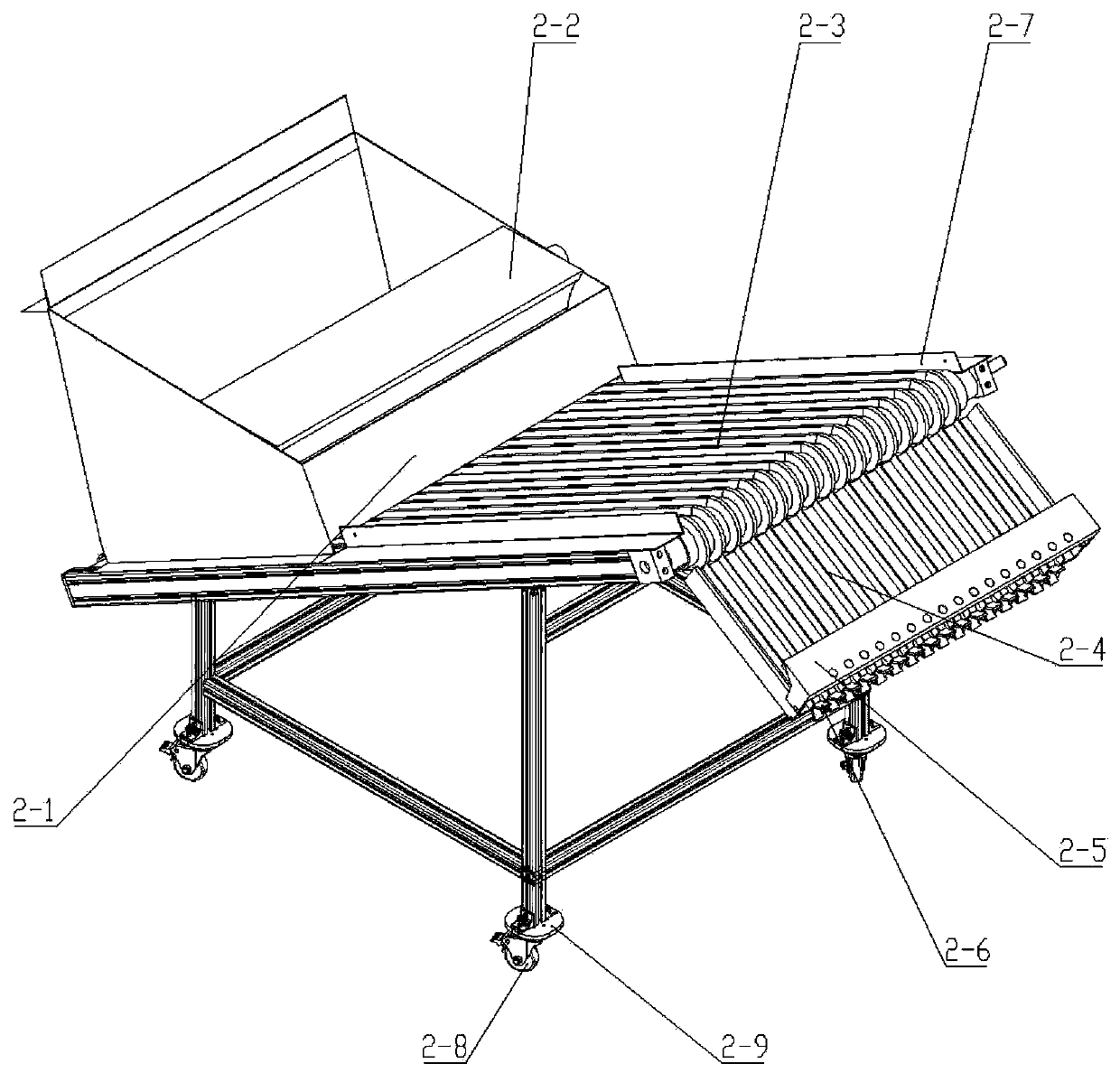

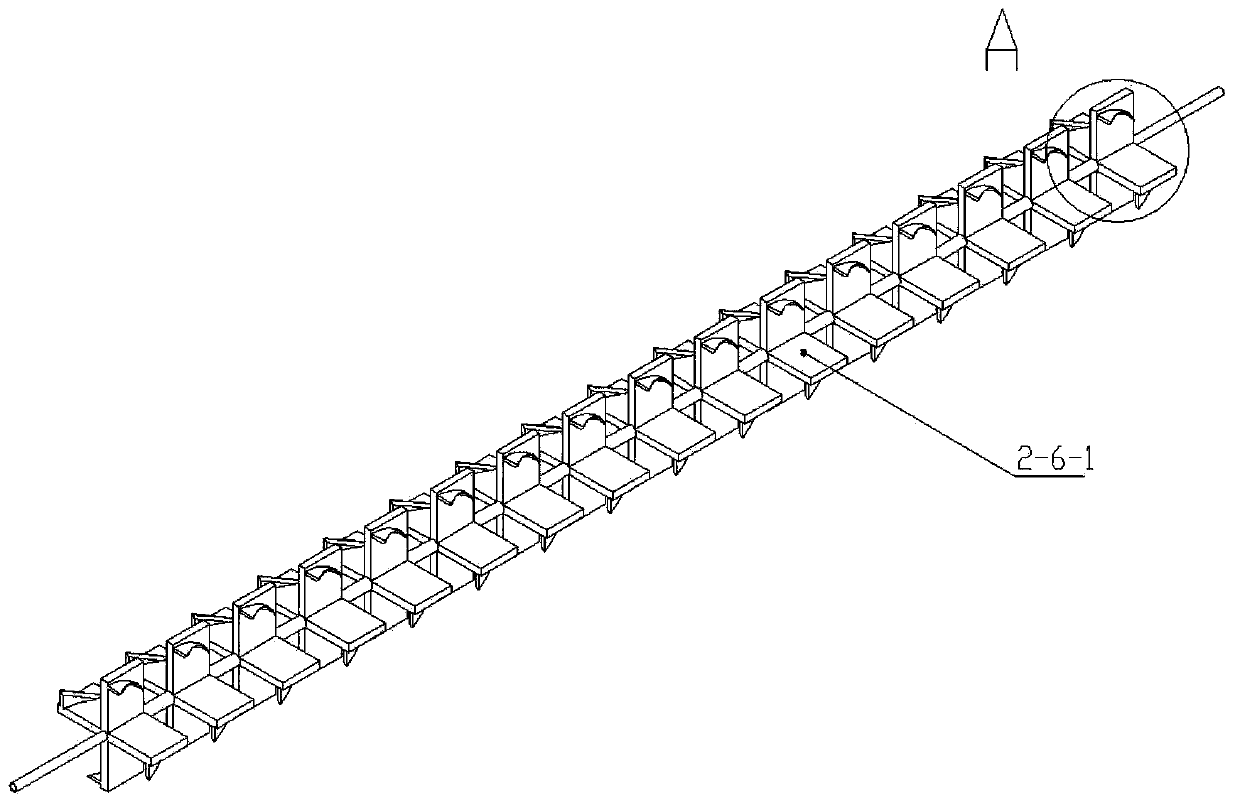

[0020] After fruit cleaning-the air-dried fruit enters in the feeding and distributing device (2), figure 2 It is a schematic diagram of the structure of the feeding and distributing device. The fruit entering the feeding box (2-1) is transported upwards under the drive of the conveyor belt (2-3). Air-dry for the second time to ensure that there are no water stains or other attachments on the surface of the fruit that will affect the identification accuracy of the fruit. The fruit after the second air-drying continues to be transported upwards. Under the action of the baffle plate in front of the distribution box (2-1), the fruit enters the corresponding groove of the conv...

Embodiment 2

[0023] Implementation example 2, when the distributed fruit is delivered to the bottom of the control box (3), the industrial camera inside the control box (3) recognizes excellent fruits of different qualities and divides them. When the fruit passes through the pneumatic mechanism (5-1), the pneumatic mechanism (5-1) blows the fruit into the different slides of the sorting box (5-2) in the form of a parabola according to the different qualities of the high-quality fruit, thereby completing the separation of the high-quality fruit. Quality rating. Other processes of this example are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com