Patents

Literature

54results about How to "No carbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

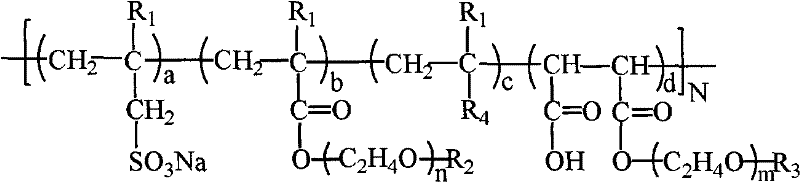

Preparation method for polycarboxylic acid series comb-shaped surface active agent

InactiveCN102199298AEnergy savingShort preparation timeTransportation and packagingMixingSolventSurface-active agents

The invention discloses a preparation method for a polycarboxylic acid series comb-shaped surface active agent, which comprises the following steps of: mixing two comonomers, an initiator, a chain transfer agent and a solvent under the protection of nitrogen, heating to a reacting temperature for polymerization to obtain an intermediate polymer; adding a graft compound, a catalytic agent and a dissolvant into the intermediate polymer, carrying out graft reaction at graft temperature, decompressing and removing part of solvent in a reaction system after reaction, and then precipitating the product with a precipitator; dissolving filter cakes with the solvent; precipitating the dissolved solution with the precipitator again, dissolving repeatedly, precipitating again and then refining, and finally decompressing and drying the product to the constant weight. The preparation method has the advantages of reasonable technology, simple operation, low preparation cost, mild reacting conditions and good product quality.

Owner:CHINA RES INST OF DAILY CHEM IND

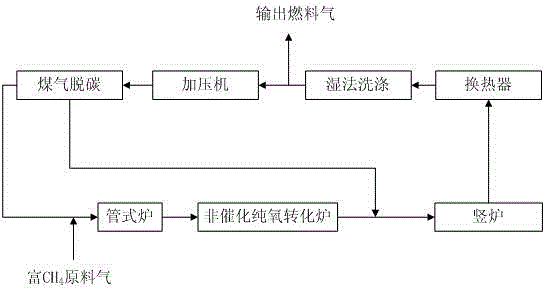

Bamboo fiber/polylactic acid composite material and preparation method thereof

The invention discloses a bamboo fiber / polylactic acid composite material and a preparation method thereof. The bamboo fiber / polylactic acid composite material specifically comprises the following rawmaterials in parts by weight: 60-80 parts of polylactic acid, 10-30 parts of talcum powder, 3-15 parts of modified bamboo fibers, 2-15 parts of a flexibilizer, 0.1-0.3 part of a coupling agent, 0.1-0.3 part of an antioxidant, 0.2-0.6 part of an auxiliary antioxidant, 0.2-0.5 part of a lubricating agent, 0.2-1 part of a nucleating agent, 0.1-0.3 part of an anti-floating fiber agent and 0.5-3 partsof a hydrolysis resistance agent. According to the composite material disclosed by the invention, the bamboo fibers are modified and thermally treated, the bamboo fibers and talcum powder are treatedby using the coupling agent, and according to a certain mixing sequence and suitable extrusion process parameters, the problems that the bamboo fiber / polylactic acid composite material is rough in surface and has silver filaments and local black spots and the compatibility between the polylactic acid and the bamboo fibers is poor are solved.

Owner:浙江明江新材料科技股份有限公司

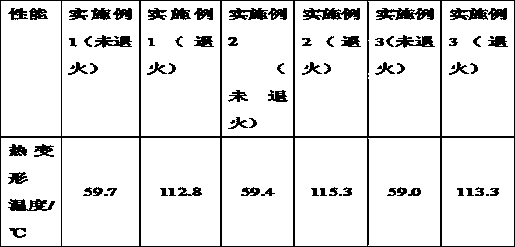

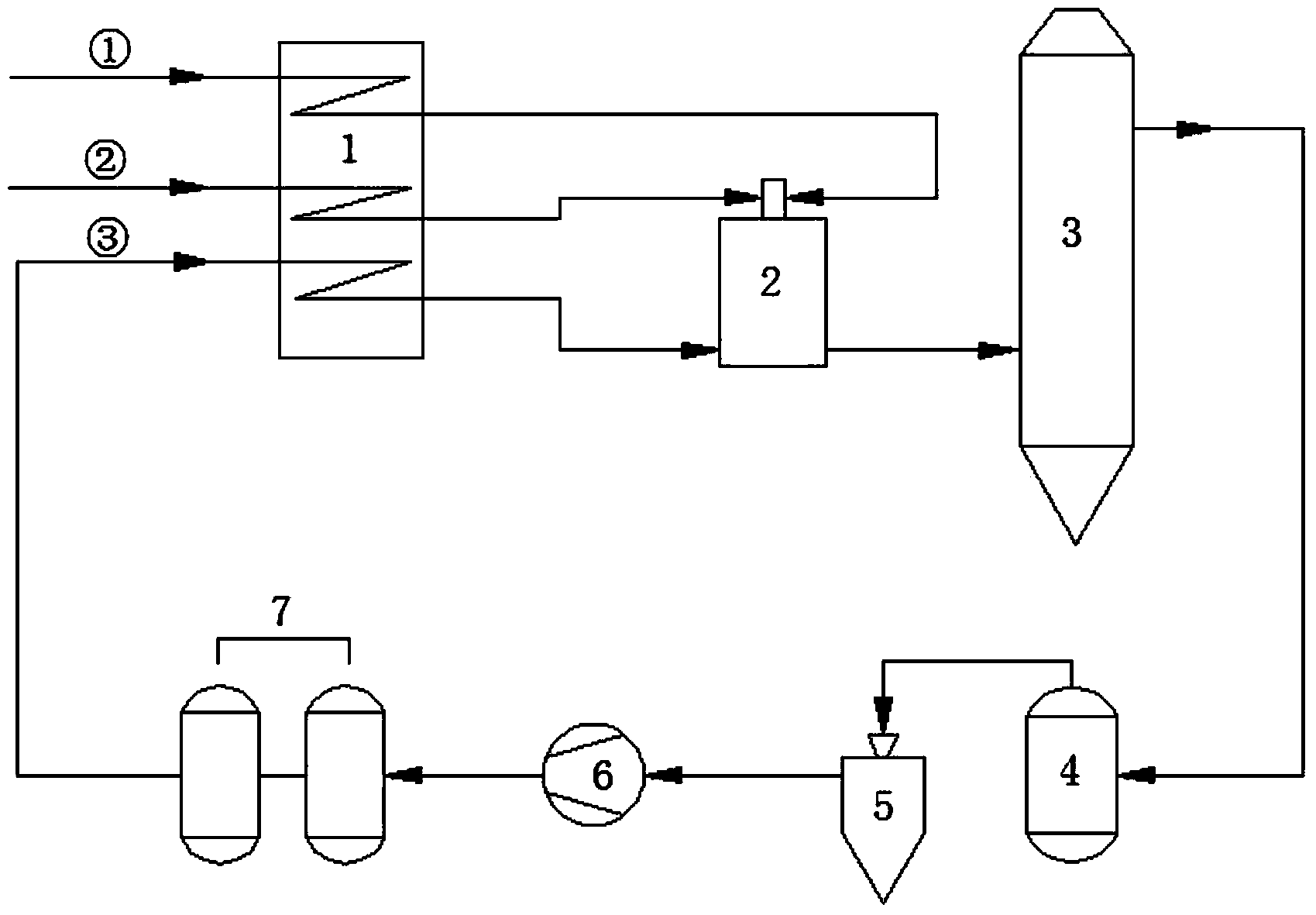

Direct reduction process for sponge iron production implemented by using non-catalytic conversion of CH4

ActiveCN103146866ALower the preheat temperatureLess investmentShaft furnaceGas emission reductionDust controlShaft furnace

The invention discloses a direct reduction process for sponge iron production implemented by using the non-catalytic conversion of CH4, and the direct reduction process comprises the following steps: feeding a feed gas rich in CH4 and subjected to purification and pressure regulation and a stock gas output by a shaft furnace and subjected to cooling, dust removal, pressurization and decarburization into a tube furnace together and preheating; feeding the preheated coal gas into a non-catalytic pure oxygen reforming furnace, performing combustion reaction and heating on the preheated coal gas and oxygen in the non-catalytic pure oxygen reforming furnace, and performing non-catalytic conversion on the CH4 so as to generate CO+H2; after the high-temperature coal gas discharged from the non-catalytic pure oxygen reforming furnace and the stock gas discharged at the front end and subjected to cooling, dust removal, pressurization and decarburization are mixed and cooled, feeding the mixed gas into the shaft furnace and reducing iron ores, thereby producing sponge irons; and after the stock gas discharged from the shaft furnace is subjected to cooling, dust removal, pressurization and decarburization, feeding part of the stock gas and the supplementary feed gas rich in CH4 into the tube furnace and the non-catalytic pure oxygen reforming furnace together, wherein the other part of the stock gas is used as the cold-doped coal gas of the high-temperature coal gas discharged from the non-catalytic pure oxygen reforming furnace. Because the preheating temperature is low, no carbon precipitation occurs, and no strict limitation on the H2S content of the feed gas rich in CH4 exits, so that the bonding of the sponge irons can be prevented.

Owner:CISDI ENG CO LTD

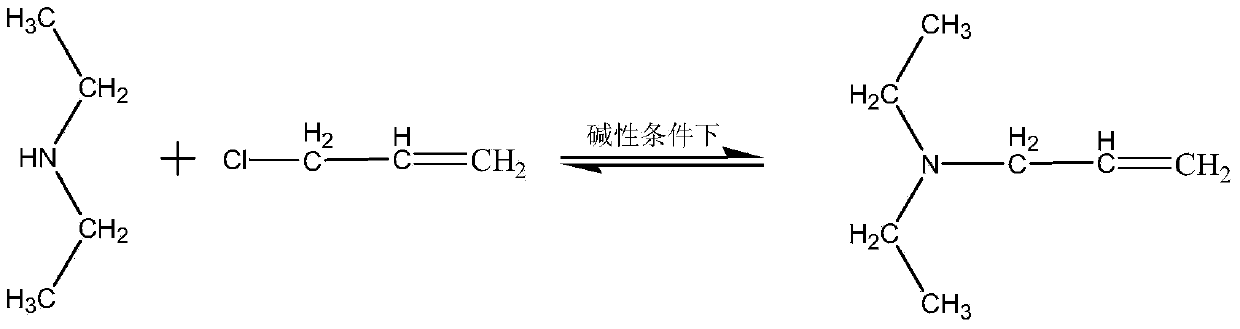

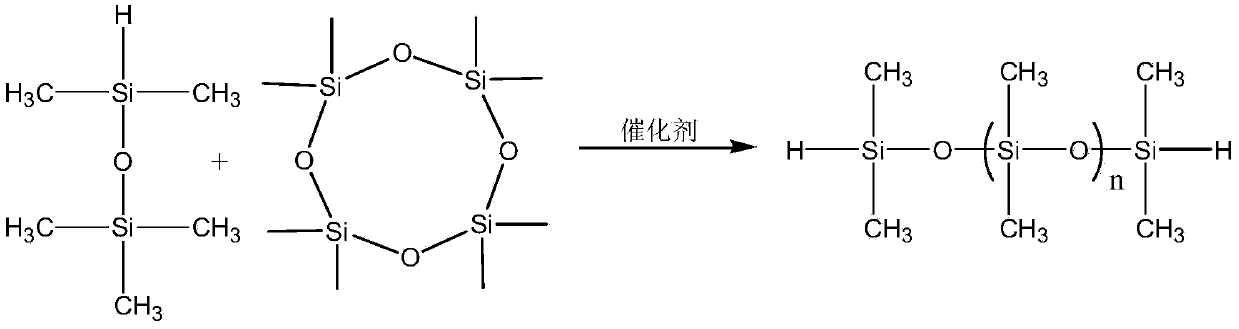

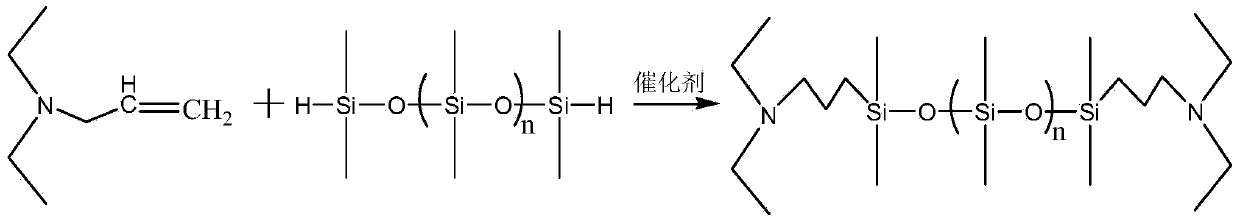

Preparation method for organosilicone positive ion waterborne polyurethane

ActiveCN104327238AEasy to separateSimple and fast operationPolyurea/polyurethane coatingsCarbonizationHydrosilylation

The invention relates to a preparation method for organosilicone positive ion waterborne polyurethane. The preparation method comprises the following steps: (1) reacting diethylamine with allyl chloride in the presence of an alkaline to generate diethyl allylamine; (2) carrying ring opening on D4 under the effect of a catalyst and blocking by using HMM (hexamethylmelamine) to generate dihydro-blocked polysiloxane; (3) carrying out hydrosilylation reaction on dihydro-blocked polysiloxane and diethyl allylamine; (4) carrying out quaternization reaction on the production of the addition reaction and chloropropanol; and (5) generating a prepolymer through reaction between HMDI and PTMEG1000 and extending chains in water by using the quaternization product to generate the organosilicone positive ion waterborne polyurethane. The preparation method provided by the invention is simple and convenient to operate, mild in reaction condition, free of carbonization and products are easily separated and recycled. Firstly, polysiloxane with amido at two terminals is salified and then chains are extended, and the conventional step of salifying positive ions with an acid and then neutralizing is cancelled, so that use of a nitrogen-containing chain extender is reduced, the cost is saved and the problem that positive ion polyurethane gets yellow is prevented.

Owner:QILU UNIV OF TECH

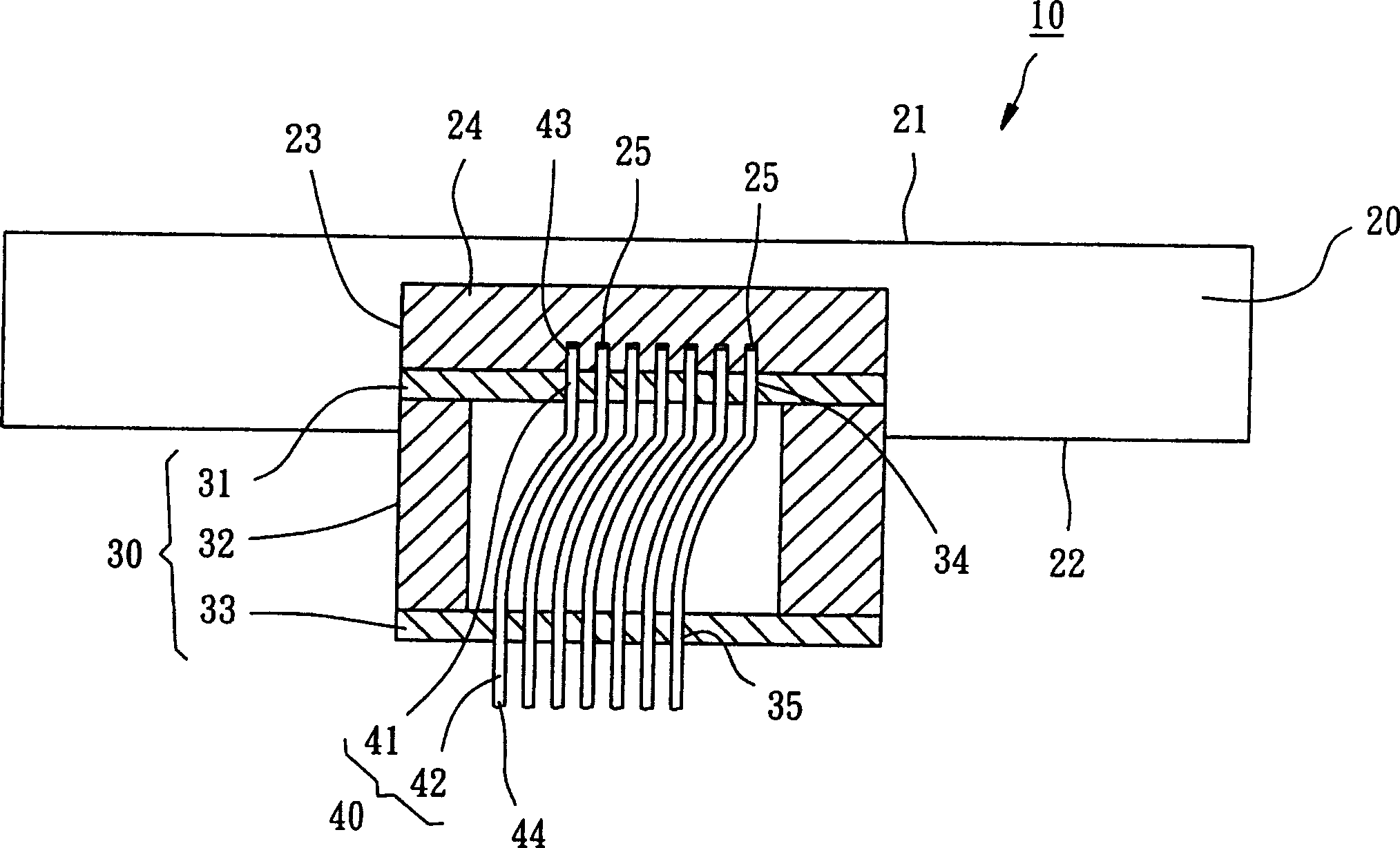

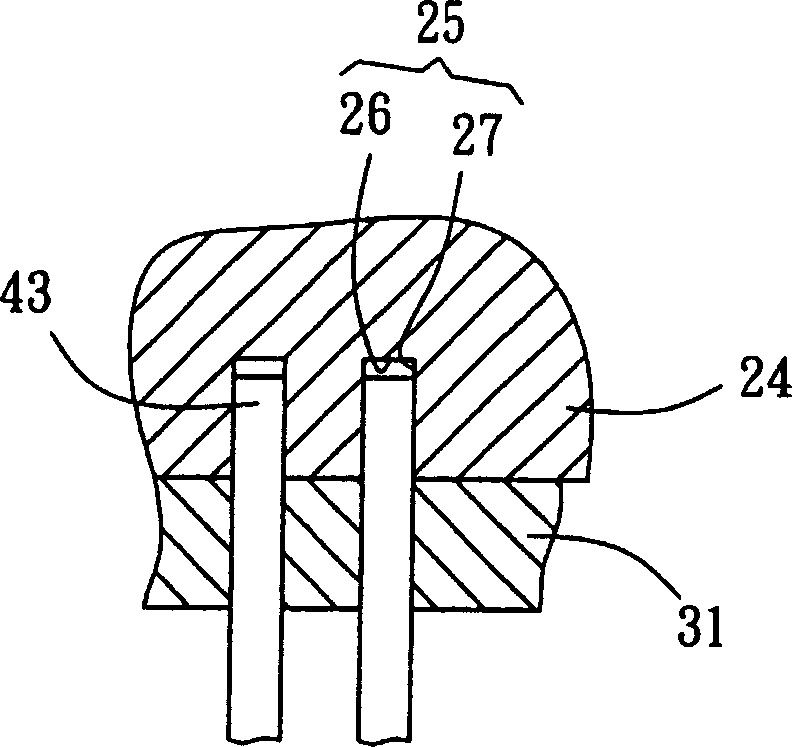

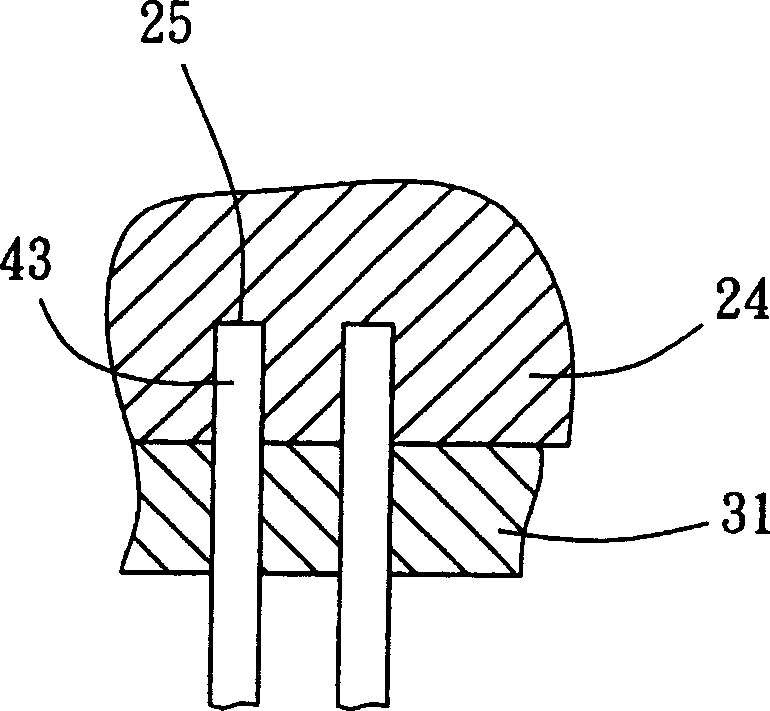

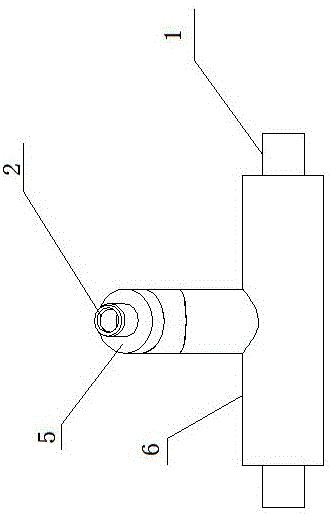

Vertical probe card

ActiveCN1912634AExtended service lifeNo carbonizationElectronic circuit testingElectrical measurement instrument detailsProbe cardEngineering

A vertical probe card is prepared as setting multiple concave conductive groove on surface of circuit board as each said groove being set with a ring wall, setting multiple through hole on guide mechanism being set at circuit board surface with conductive groove, setting the first end of probe in said conductive groove to make probe be connected against with ring wall and be electrically connected to circuit board and passing the second end of probe through said through hole set on guide mechanism.

Owner:VISERA TECH CO LTD

Antifatigue basic magnesium sulfate cement and preparation method thereof

The invention discloses an antifatigue basic magnesium sulfate cement which is composed of the following components in percentage by mass: 42-58% of magnesium oxide, 18-25% of magnesium sulfate heptahydrate, 10-15% of industrial waste residue powder, 5-13% of white slag, 3-5% of mineral admixture, 4-6% of straw, 2-4% of desulfurized gypsum, 3-5% of fly ash and 1-2% of thickening time control agent. The appropriate additives are added into the magnesium oxysulfate cement to form a new basic magnesium sulfate phase and generate the antifatigue basic magnesium sulfate cement which has completely different properties and characteristics from the traditional magnesium oxysulfate cement. The main hydration product is high-strength 517 whisker. The antifatigue basic magnesium sulfate cement belongs to novel special cement which has the advantages of whisker self-formation, high strength, high toughness, high folding ration, carbonization resistance, salt resistance, hydrothermal resistance, seawater resistance, impact resistance, fatigue resistance, reinforcing steel rust resistance, high durability and long service life.

Owner:周末

Vegetable protein aerogel and preparation method thereof

InactiveCN105582864ALower conditionsAccelerateAerogel preparationColloidal chemistry detailsSolventChemistry

The invention discloses vegetable protein aerogel and a preparation method thereof, belonging to the field of aerogel. According to the invention, the aerogel can be prepared depending on vegetable protein purely through vacuum freezing drying. The preparation method comprises the following specific steps: performing hydro-thermal treatment with lye on vegetable protein powder to obtain a protein adhesive liquid; adding a cross-linking agent and standing to obtain gel; and replacing the gel with a replacement solvent, freezing, and drying in vacuum to obtain the vegetable protein aerogel. The aerogel has the features that the apparent density is 0.15-0.2g / cm<3> and the specific surface area is 110-130m<2> / g, is rich in mesopore, and can be taken as an adsorbent. During the preparation process, the raw materials are readily available, the cost is low, and the operation is environmentally friendly. The preparation technique is simple, the period is short, and the safety is high.

Owner:FUJIAN AGRI & FORESTRY UNIV

Carbonation-resistant basic magnesium sulfate cement and preparation method thereof

The invention discloses carbonation-resistant basic magnesium sulfate cement. The carbonation-resistant basic magnesium sulfate cement is prepared from the following components in percentage by mass: 40 to 55% of magnesium oxide, 20 to 25% of magnesium sulfate heptahydrate, 10 to 20% of industrial waste residue powder, 5 to 9% of white slag, 3 to 8% of mineral admixtures, 2 to 4% of desulfurization gypsum, 6 to 8% of mineral slag, 2 to 4% of straws, 1 to 3% of silica fume and 1 to 3% of adjustable solidification agent. Proper additives are added in magnesium oxysulfate cement to form a novel basic magnesium oxysulfate phase; the carbonation-resistant basic magnesium sulfate cement with totally different property and performance from traditional magnesium oxysulfate cement is produced; the main hydration product of the basic magnesium sulfate cement is 517 crystal whisker; the carbonation-resistant basic magnesium sulfate cement is novel special cement with features of self-formed crystal whisker, high intensity, high toughness, high ratio of compressive strength, carbonation resistance, brine resistance, hydrothermal resistance, seawater corrosion resistance, shock resistance, antifatigue, corrosion of steel bar resistance, high durability and long service life.

Owner:周末

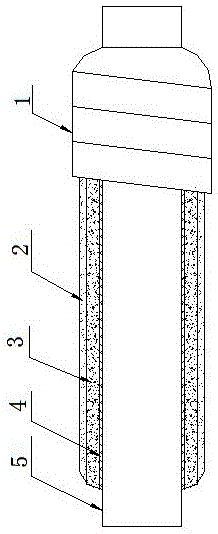

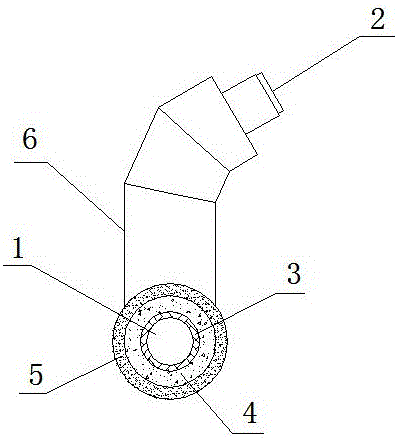

Ultrahigh-temperature prefabricated direct burial heat preservation pipe and heat preservation method

PendingCN106523856AEfficient use ofLow thermal conductivityThermal insulationPipe protection by thermal insulationPetrochemicalEngineering

The invention discloses an ultrahigh-temperature prefabricated direct burial heat preservation pipe and a heat preservation method. According to the current original heat preservation technology, the technology adopting polyurethane, rock wool, silicate and other heat preservation materials is adopted for conducting heat preservation on ultrahigh-temperature pipelines, although the above structure can play a certain heat preservation role, the energy dissipation rate is high, and the service life of a heat preservation layer is short. The ultrahigh-temperature prefabricated direct burial heat preservation pipe comprises a steel pipe (1), an aerogel heat preservation layer (2) and a polyurethane heat preservation layer (3). The outer wall of the steel pipe is annularly wrapped through the rock wool in a closed manner, and a rock wool heat preservation layer is formed. The outer side of the rock wool heat preservation layer is annularly wrapped by aerogel felt in a closed manner, and the aerogel heat preservation layer is formed. The outer side of the aerogel heat preservation layer is evenly wrapped by a heat reflection layer. Polyurethane is sprayed to the outer sides of the aerogel heat preservation layer and the reflection layer, rigid polyurethane spray expanding foam is formed, and the polyurethane heat preservation layer is formed. The ultrahigh-temperature prefabricated direct burial heat preservation pipe and the heat preservation method are applied to 2,000 DEG C ultrahigh-temperature prefabricated heat isolation and heat preservation pipelines used in the fields of heat supply, cold supply, petroleum and petrochemicals and ships.

Owner:哈尔滨朗格思特供热装备科技有限公司

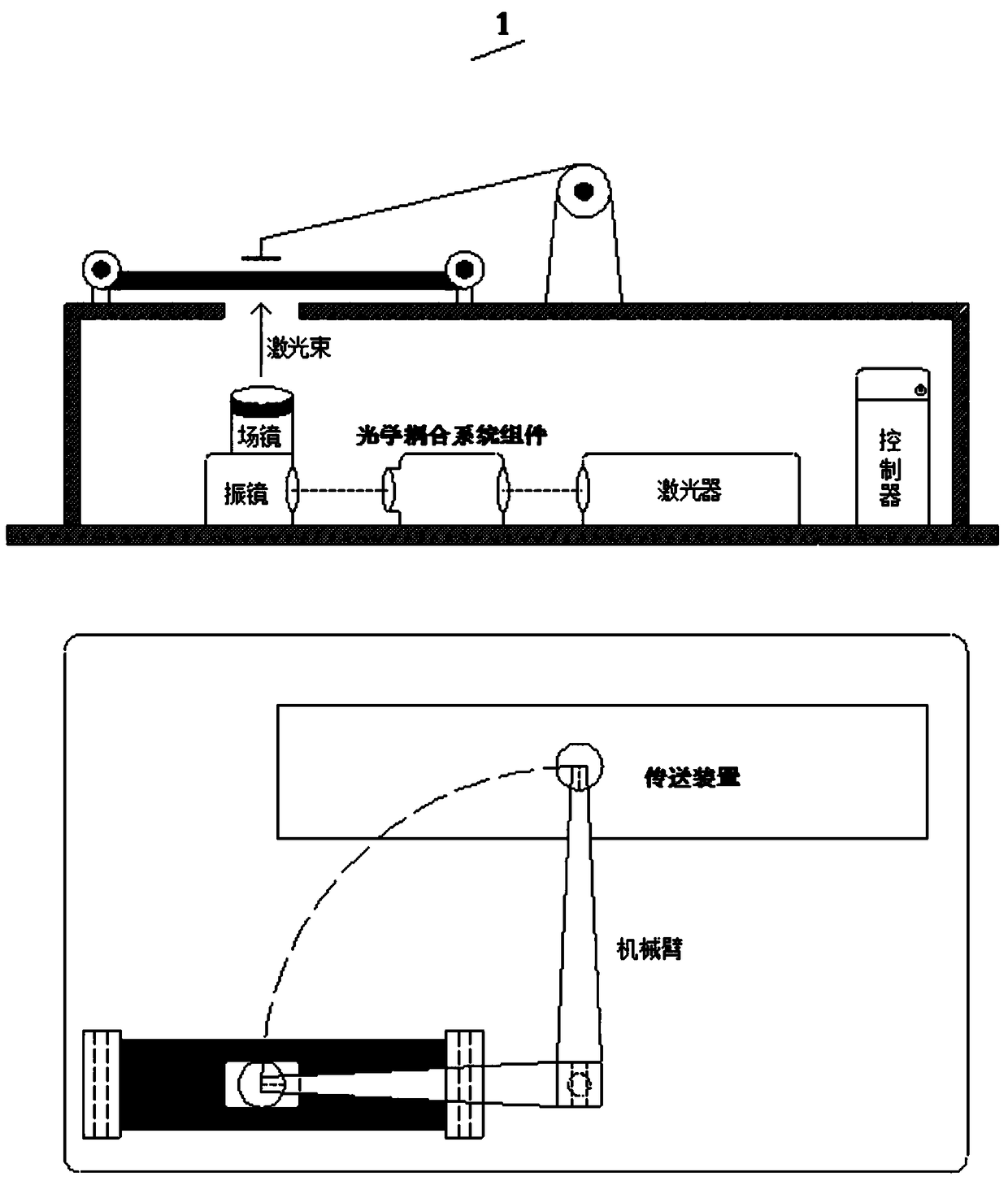

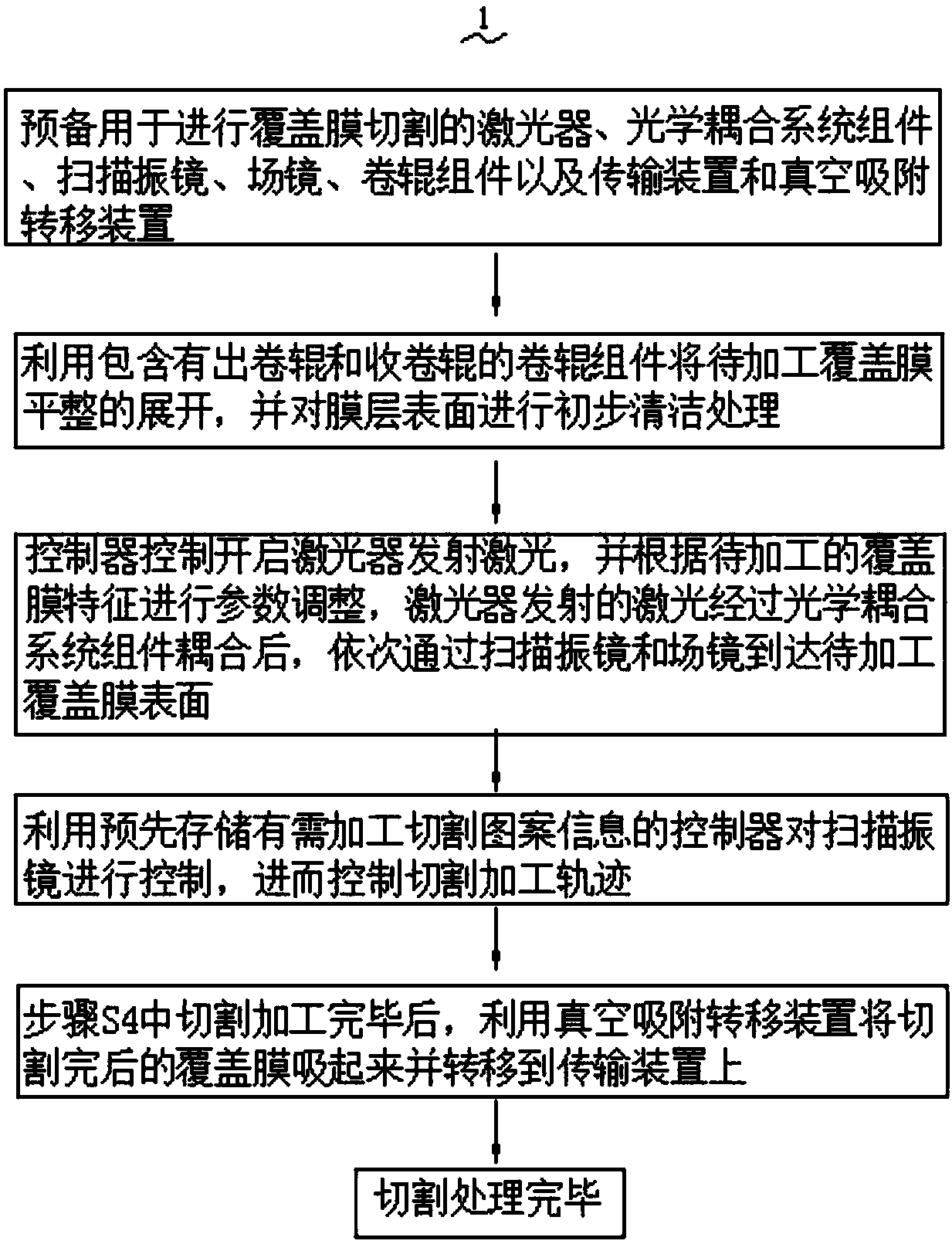

Roll-to-roll covering film laser cutting system and cutting method

InactiveCN108067752AImprove work efficiencyContour edges are neat and smoothLaser beam welding apparatusIdeal machineGalvanometer

The invention provides a roll-to-roll covering film laser cutting system and cutting method. The system comprises a controller, a laser device used for emitting a laser beam, an optical coupling system assembly arranged on the front portion of the laser device and used for coupling the laser beam, a scanning galvanometer used for controlling the moving track of the laser beam, a field lens arranged on the output end of the scanning galvanometer, a rolling roller assembly used for unfolding and folding a covering film, a transmission device used for conveying the machined film material and a vacuum absorption transfer device. The optical coupling system assembly is located between the laser device and the scanning galvanometer; the vacuum absorption transfer device comprises a mechanical arm used for transferring the covering film to the transmission device from the rolling roller assembly. According to design, production cost is greatly reduced, product quality is improved, due to thefact that the laser focusing spot is only tens of microns, high-density circuit and micro hole machining can be achieved, due to the advantages, circuit design development space is achieved, and the system is an ideal machining tool of PI covering film windowing.

Owner:深圳光韵达激光应用技术有限公司

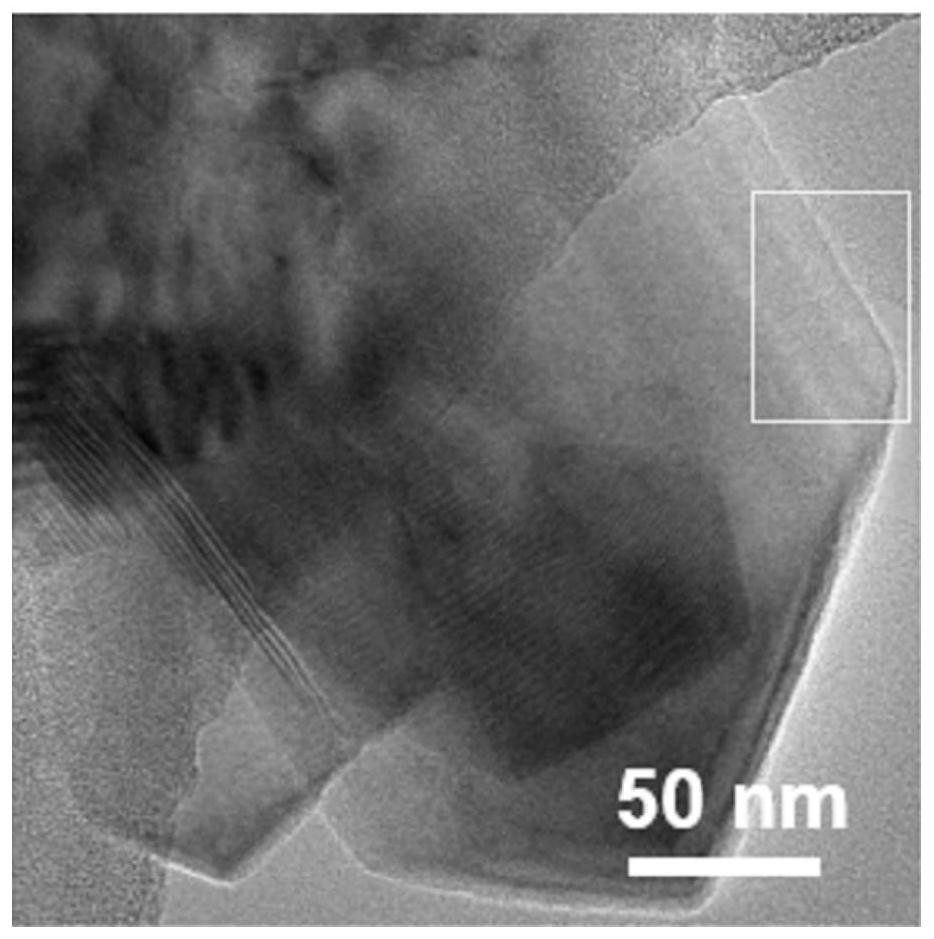

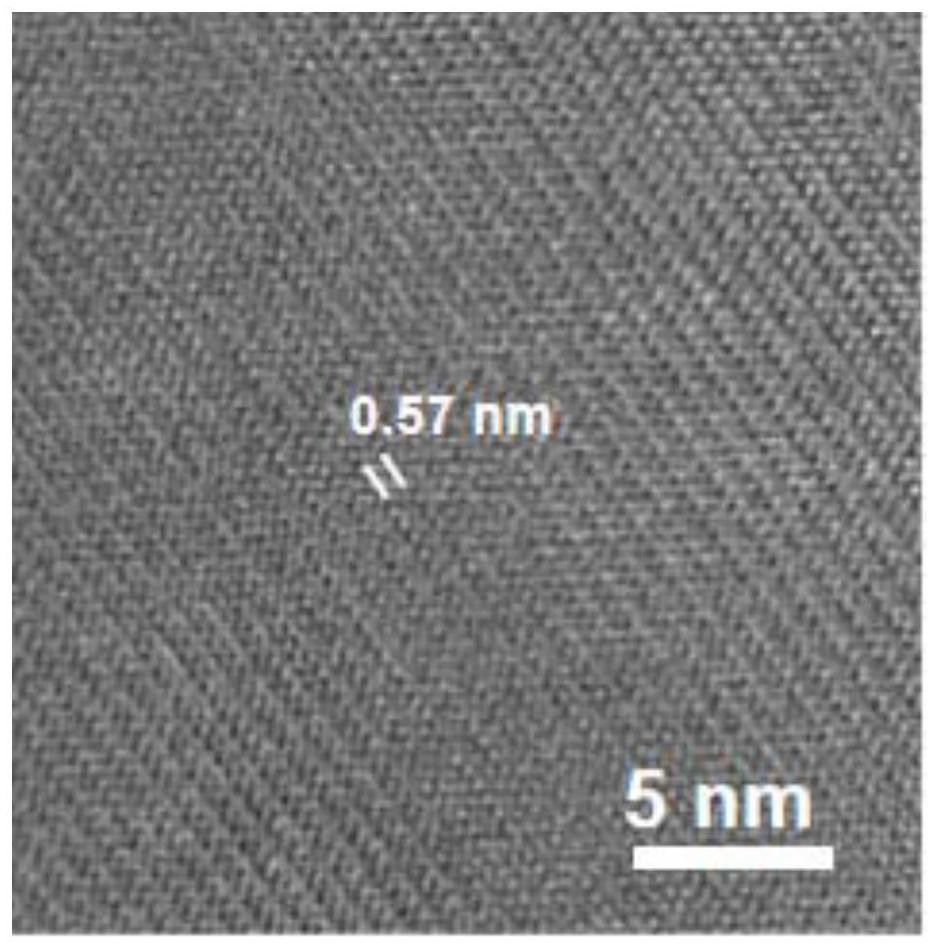

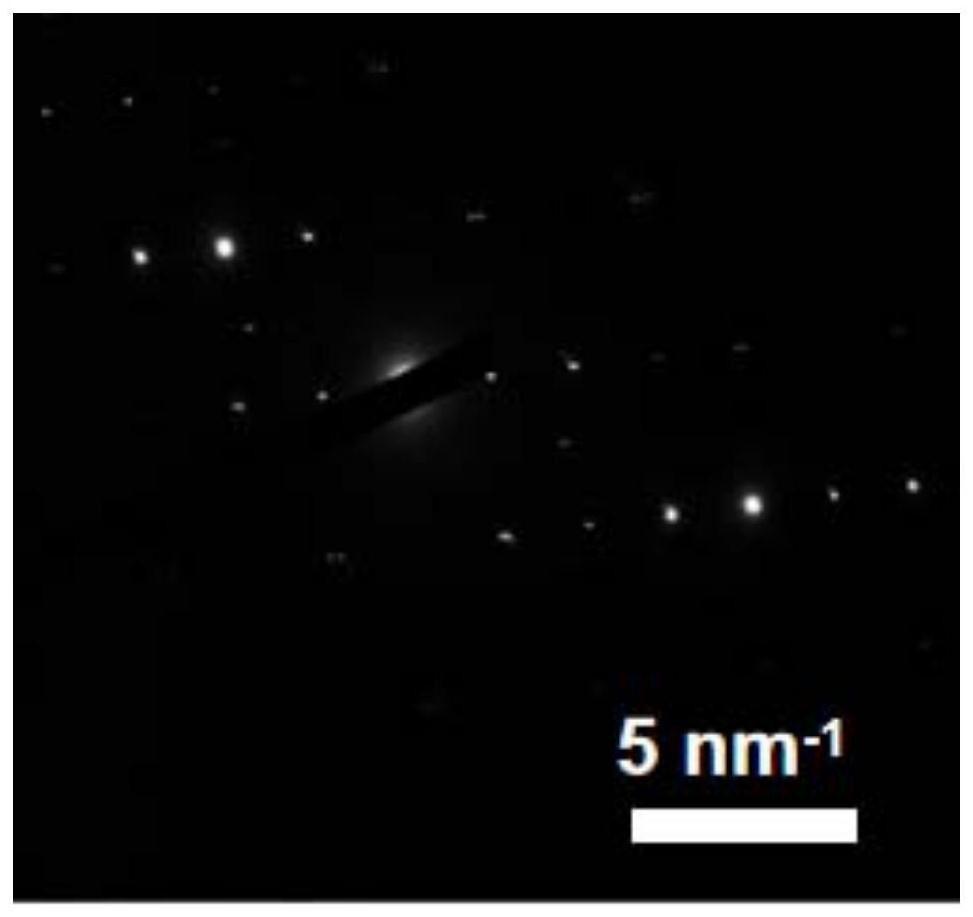

Covalent triazine organic framework material as well as preparation method and application thereof

ActiveCN112023981APull down forceHigh crystallinityCatalyst carriersOther chemical processesPtru catalystReaction rate

The invention provides a covalent triazine organic framework material as well as a preparation method and application thereof. The preparation method comprises the following steps of: mixing raw materials including a covalent triazine organic framework material precursor, a first solvent and a catalyst, and performing a reaction on the mixture; and carrying out solid-liquid separation on the reacted mixture. According to the preparation method disclosed by the invention, by introducing the first solvent, the reaction rate and the viscosity of a reaction system are properly reduced, and the strong acting force between a triazine intermediate product and the catalyst is reduced, so that the triazine intermediate product can fully perform molecular motion nucleation through a conjugation effect, and a crystalline CTF material is easy to obtain; The preparation method is safe and convenient to operate, has low requirements on reaction devices and reaction conditions, and is easy for batchsynthesis; and the prepared CTF material has the advantages of high crystallinity and good thermal stability.

Owner:THE CHINESE UNIV OF HONG KONG SHENZHEN

Direct reduction process for producing sponge iron by using CH4 non-catalytic oxygen-enriched transformation

ActiveCN104313228ALower the preheat temperatureLess exhaust smokeShaft furnaceGas emission reductionOxygen enrichmentCaking

The invention relates to a direct reduction process for producing sponge iron by using CH4 non-catalytic oxygen-enriched transformation. A process route comprises the following steps: preheating a CH4-enriched raw gas and oxygen-enriched air which are subjected to purification and pressure regulation, then introducing the CH4-enriched raw gas and the oxygen-enriched air into a non-catalytic oxygen-enriched transformation furnace for a combustion reaction in the non-catalytic oxygen-enriched transformation furnace, and raising the temperature to transform CH4 therein into CO and H2 to form a high-temperature transformation gas; in the meantime, cooling, dedusting and pressurizing a top gas of a shaft furnace, then introducing the top gas into a hydrogen purification device to prepare purified hydrogen, preheating the purified hydrogen, and then introducing the preheated purified hydrogen into the lower part of the catalyst oxygen-enriched transformation furnace to be mixed with the high-temperature transformation gas generated through the combustion reaction to form a reduced coal gas; and introducing the reduced coal gas into the shaft furnace to reduce iron ores into the sponge iron. The direction reduction process disclosed by the invention not only has the advantages of short process flow, availability for energy saving and emission reduction, long service life of a nozzle and low investment cost, and can be used to prevent the sponge iron from caking and avoid carbon formation.

Owner:CISDI ENG CO LTD

Method for processing yak horn comb blank

The invention discloses a method for processing an yak horn comb blank, which comprises the following steps: (1) preparing the primary yak horn comb blank: choosing an yak horn with the shape and thickness suitable for making a comb, cutting off leftover materials, making the yak horn into the primary yak horn comb blank by cutting the yak horn from the middle part along the direction extending towards the ox-head from the tip of the yak horn, and storing for later use; (2) heating and softening: putting the made primary yak horn comb blank into a paraffin liquid which is melted and is at 120-150 DEG C, and heating and softening for 2-3 minutes; and (3) preparing the yak horn comb blank: putting the softened primary yak horn comb blank into a pressing machine for flattening and straightening the primary yak horn comb blank, and obtaining the yak horn comb blank after cooling the flattened and straightened primary yak horn comb blank. By using the method provided by the invention, the phenomenon that a large amount of water is sucked in the process of preparing the yak horn comb blank is completely eradicated, the original organic matters of the raw materials are protected well, the yak horn comb blank cannot be easily carbonized in the preparation process, the prepared product is difficult to deform and is not brittle, the yak horn comb blank can be produced in batch, and the quality and the service life of the yak horn comb blank are promoted.

Owner:雅安市长益生物科技有限公司

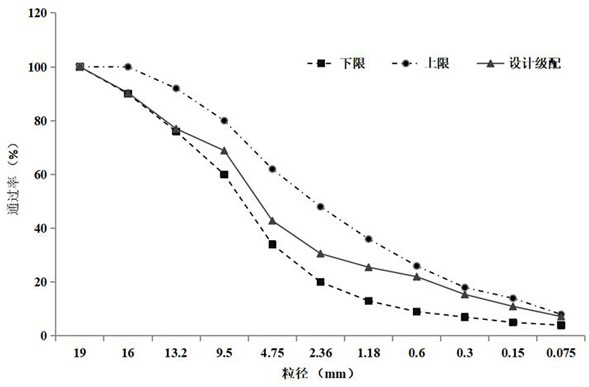

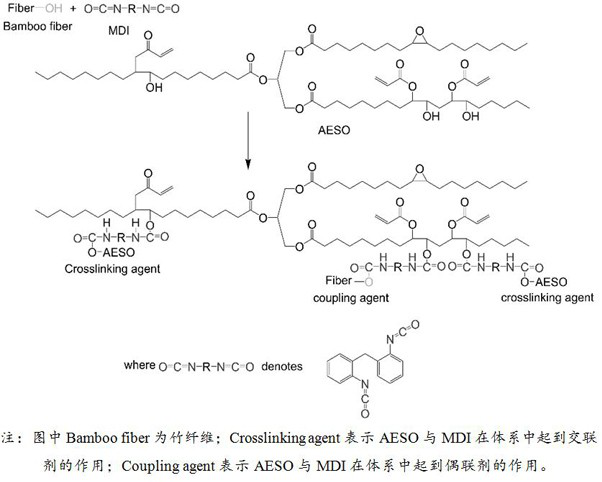

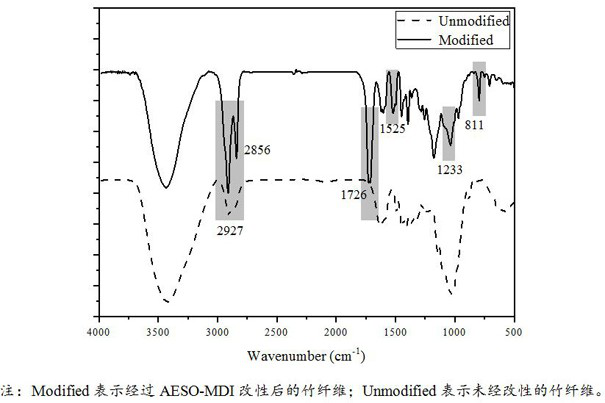

Modified bamboo fiber reinforced asphalt mixture and preparation method thereof

ActiveCN113185191AImproved interfacial adhesionEfficient couplingSolid waste managementPolymer chemistrySoybean oil

The invention belongs to the technical field of fiber reinforced asphalt mixtures, and particularly relates to a modified bamboo fiber reinforced asphalt mixture and a preparation method thereof, epoxidized soybean oil acrylate (AESO) and diphenylmethane diisocyanate (MDI) are adopted to modify bamboo fibers, and then the modified bamboo fibers are added in the preparation process of the asphalt mixture for reinforcement. The modified bamboo fiber reinforced asphalt mixture prepared by the invention is environment-friendly, and has good mechanical properties, high-temperature stability, low-temperature crack resistance and water stability.

Owner:FUJIAN AGRI & FORESTRY UNIV

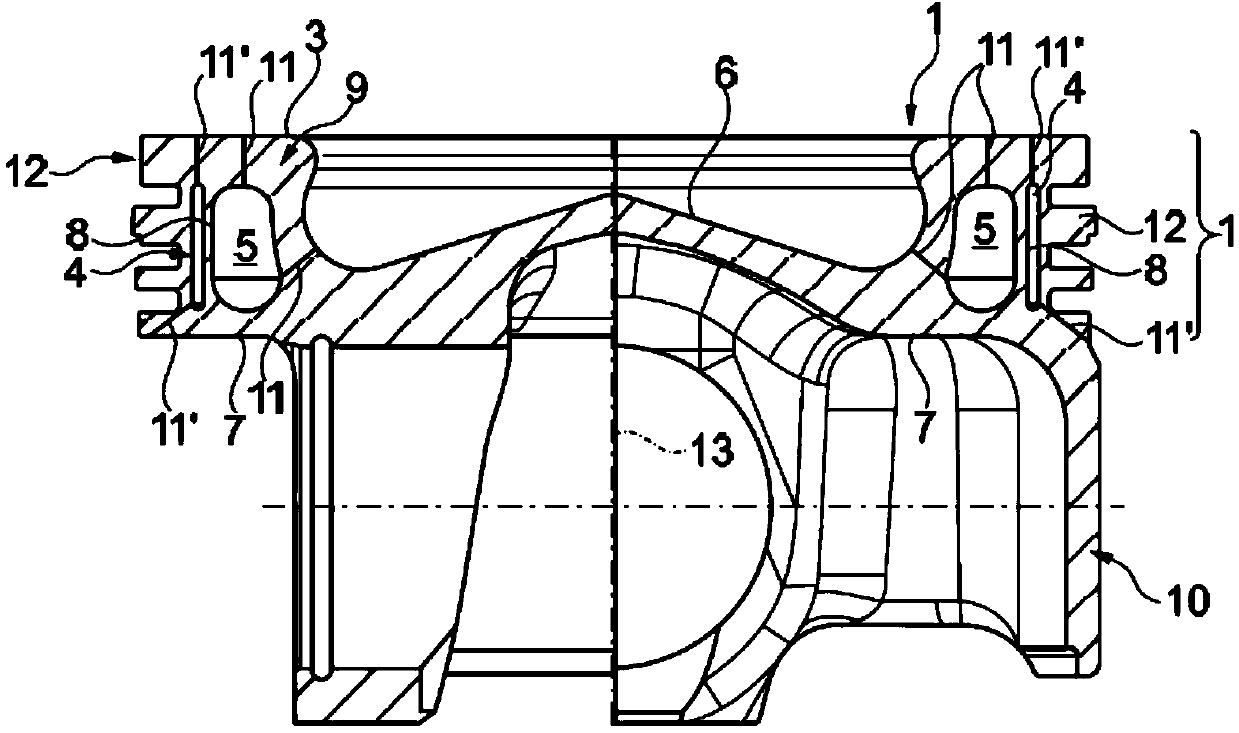

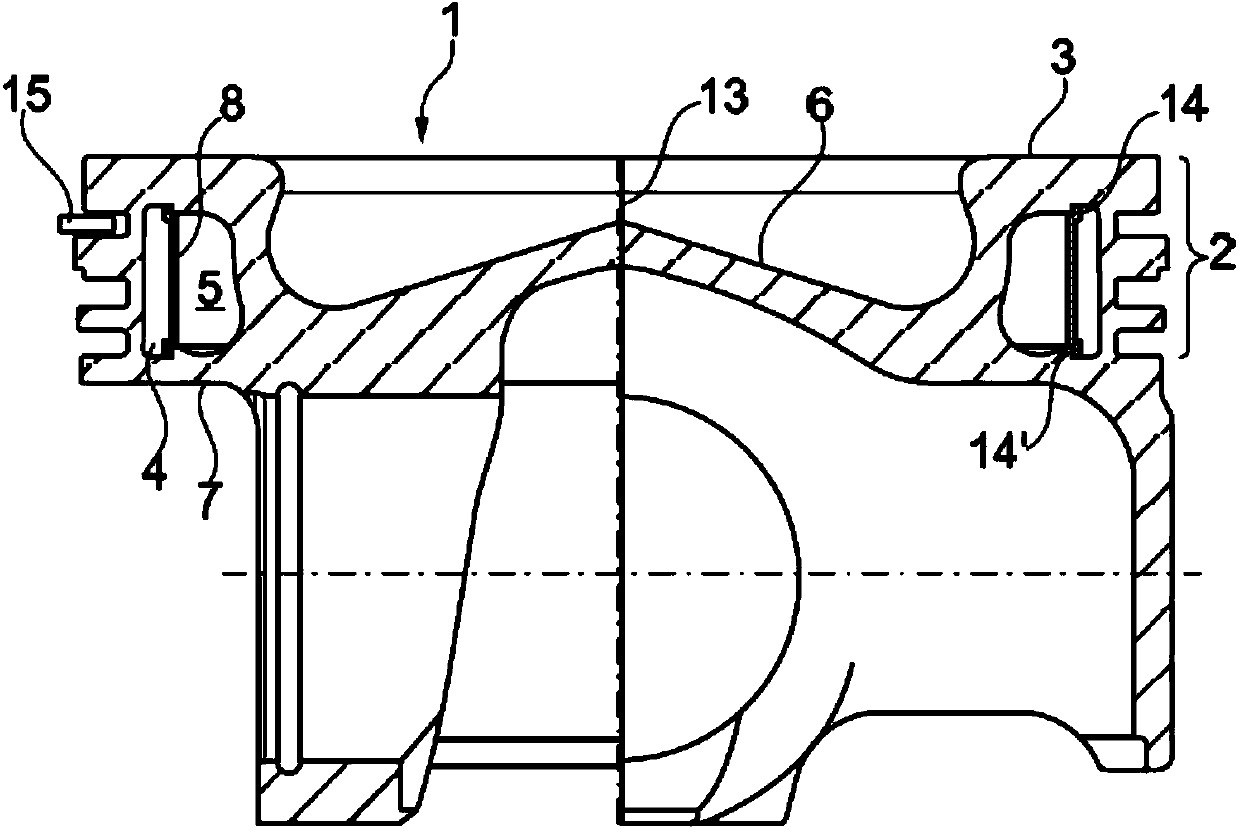

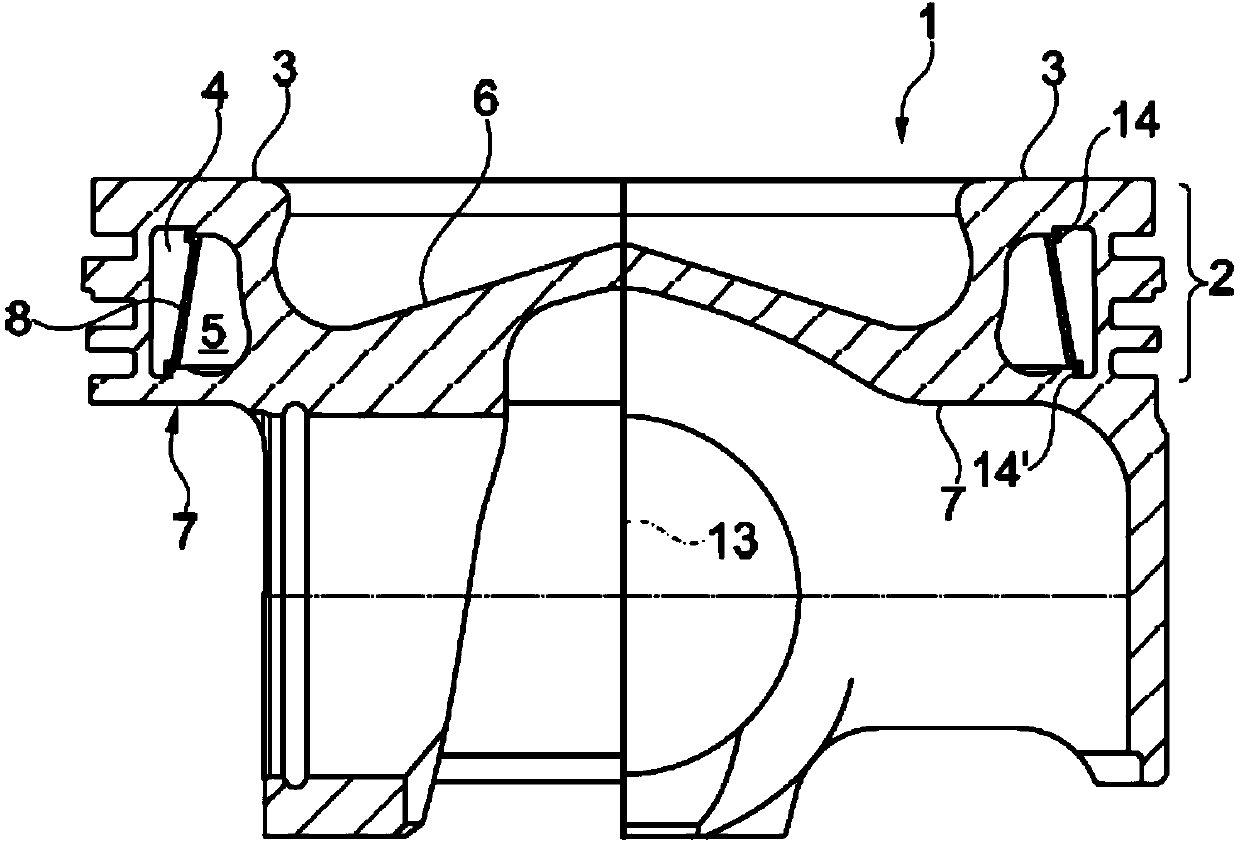

Piston for an internal combustion engine

InactiveCN104220736AAvoid high temperatureReduce heat transferMachines/enginesPistonsHeat flowExternal combustion engine

The present invention relates to a piston (1) for an internal combustion engine, having an encircling ring section (2) in the region of a piston crown (3), having a convection region with a cavity containing a cooling fluid, for example an encircling inner duct (5), and having a heat insulation region arranged between the ring section (2) and the convection region, the heat insulation region being for example an encircling outer duct (4) arranged coaxially with respect to said ring section and convection region. Here, it is essential to the invention that the outer duct (4) is in the form of a heat insulator which reduces a heat flow substantially radially outward and which thermally insulates the ring section (2) with respect to the high temperatures at the piston crown and the inner duct (5), whereas the inner duct (5) is in the form of a cooling duct and contains a heat transfer medium for the improved dissipation of heat from a piston crown to the underside (7) of the piston (1) by convection.

Owner:MAHLE INT GMBH

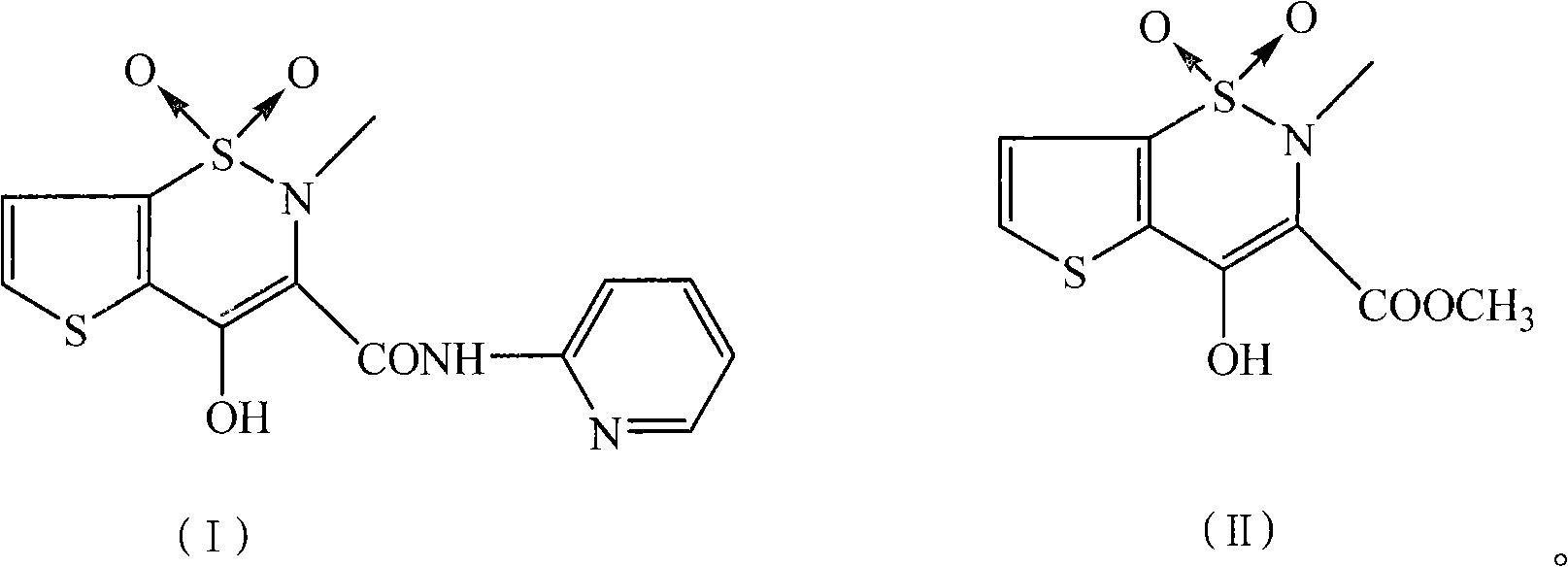

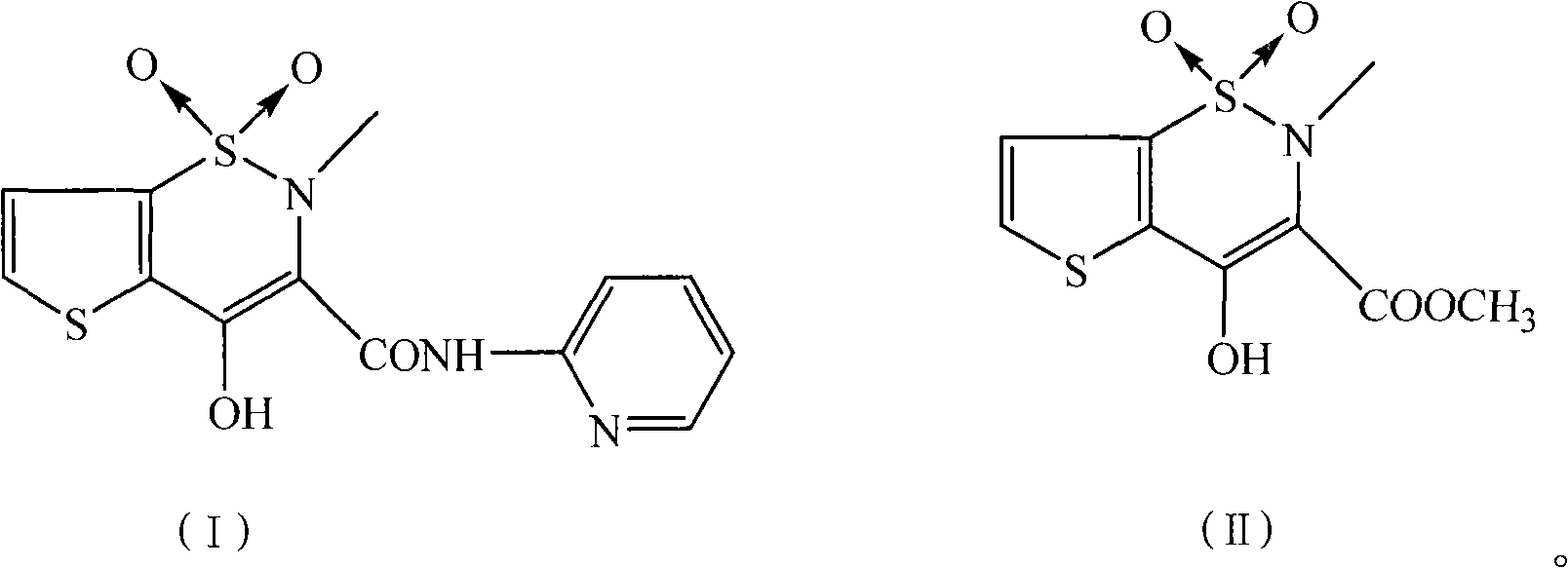

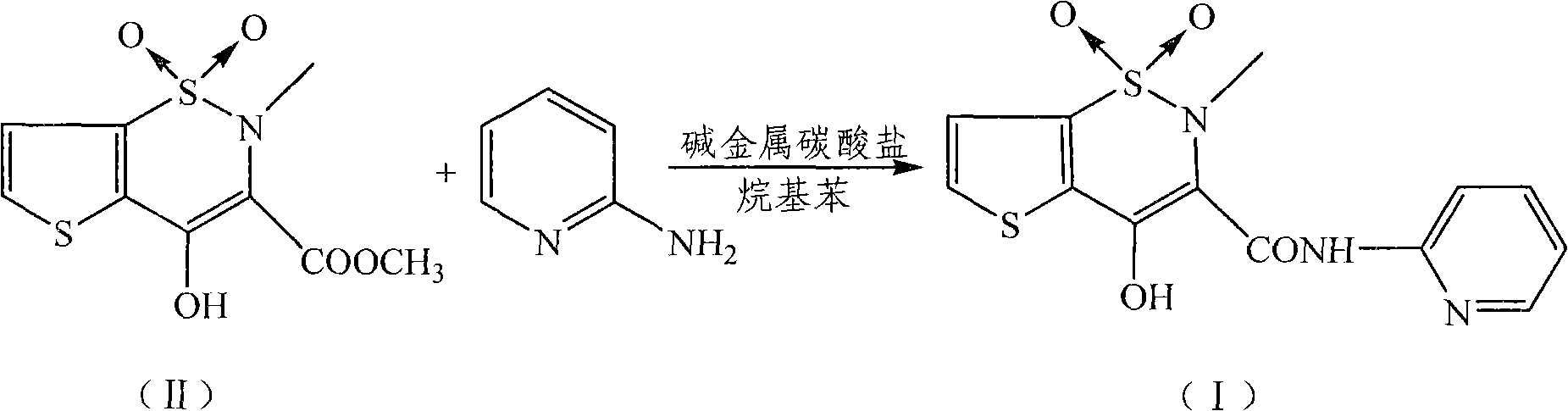

Preparation method of tenoxicam

The invention provides a preparation method of tenoxicam shown in a chemical formula (I), which is characterized in that: evenly mixing Methyl 2-Methyl-4-Hydroxy-2H-Thieno[2,3-e]-1,2-Thiazine-3-Carboxylate-1,1-Dioxide shown in a chemical formula (II) and 2-aminopyridine in alkylbenzene; then adding alkali carbonate dried and activated at the temperature of 150 DEG C to the mixture and reacting for 10-20 hours at reflux temperature; separating crystals out after reaction products are cooled to 0-15 DEG C; then filtering; drying the filter cakes to obtain crude products; and obtaining the tenoxicam after the crude products are purified. The molar ratio of Methyl 2-Methyl-4-Hydroxy-2H-Thieno[2,3-e]-1,2-Thiazine-3-Carboxylate-1,1-Dioxide to 2-aminopyridine to alkylbenzene is 1 to 1-1.4 to 1-3. The preparation method has the advantages of reduced reaction temperature, shortened reaction time, complete reaction and reduced secondary reaction. The yield is higher than or equal to 85 percent, the raw materials and the reaction products can not be carbonized and decomposed, and a product is easy to purify. The invention is a tenoxicam synthesis process capable of realizing industrialized production.

Owner:ZHEJIANG UNIV

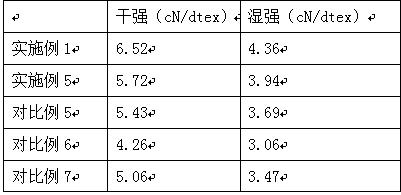

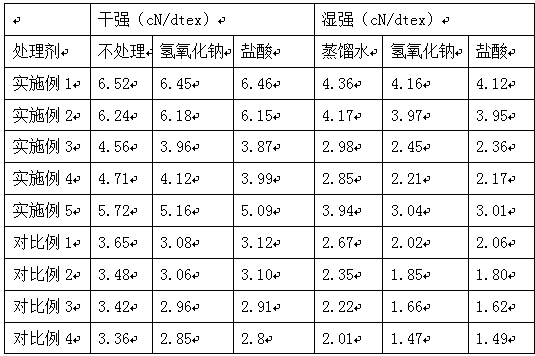

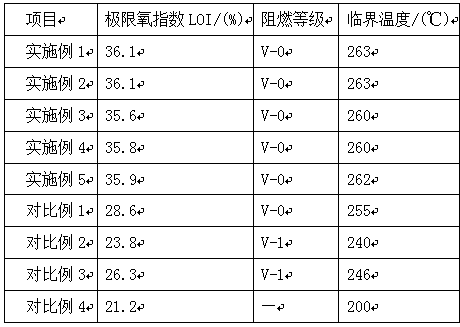

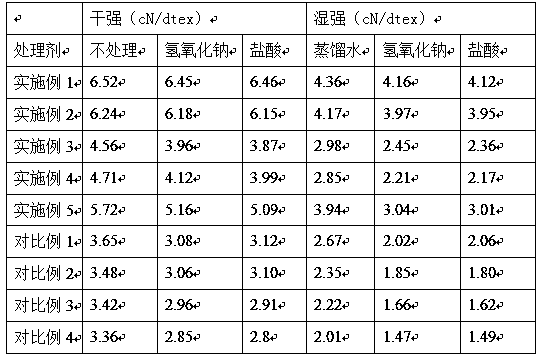

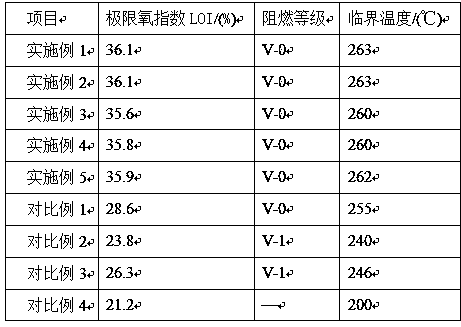

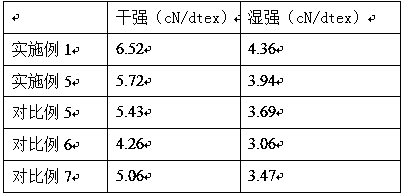

Preparation method for novel corrosion-resistant high-strength fiber

InactiveCN108998857AHigh strengthGuaranteed StrengthFlame-proof filament manufactureConjugated synthetic polymer artificial filamentsFiberEpoxy

The invention discloses a preparation method for a novel corrosion-resistant high-strength fiber, mainly belonging to the technical field of processing of novel fibers. The novel corrosion-resistant high-strength fiber is prepared from the following raw materials by weight: 10 to 15 parts of chitosan, 60 to 75 parts of glycidyl ester type epoxy resin, 2 to 3 parts of carbon nanotubes and 15 to 18parts of nanometer titanium dioxide. The fiber prepared in the invention has strong acid and alkali resistance, good dyeing stability and a wide application range.

Owner:马鞍山卓凡新材料科技有限公司

Method for preparing long-chain dicarboxylic dialkyl ester

InactiveCN1508117AEasy to separateLess side effectsOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The method for preparing long-chain dicarboxylic acid dialkyl ester uses dicarboxylic acid of C8-C18 and excess C6-C18 monobasic alcohol as raw material, adopts proper acidic resin as catalyst, and makes them implement esterification reaction at higher temp., at the same time of esterification the formed water content is evaporated out, the conversion rate of reaction can be raised, and the reaction liquid can be undergone the processes of distillation, etc. and can be purified. Said invention has the advantages of short process, high esterification rate, short operation period, and low energy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

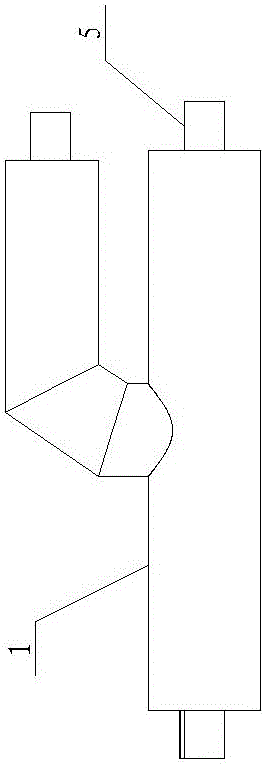

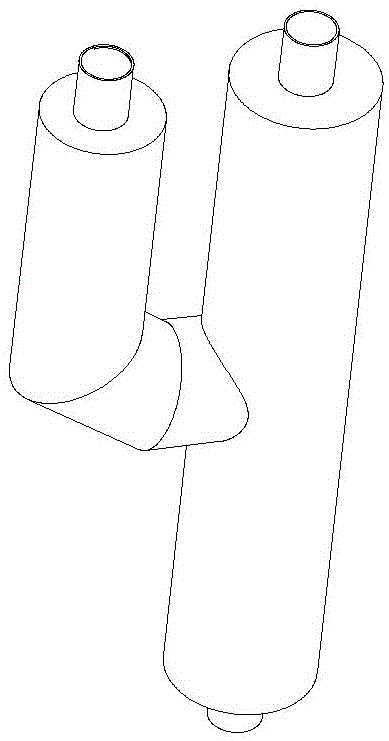

Super-high-temperature prefabricated directly-buried heat-preservation pipe fitting tee and production and usage method

PendingCN106764251ASolve the problem of longevityFix security issuesThermal insulationPipe protection by thermal insulationInsulation layerPipe fitting

The invention discloses a super-high-temperature prefabricated directly-buried heat-preservation pipe fitting tee and a production and usage method. At present, according to an original heat preservation technology, heat preservation materials, such as polyurethane, rock wool and silicate, are adopted to preserve heat for a super-high-temperature pipe fitting tee, but the heat conductivity coefficient is high, the dissipation rate of energy sources is high, and the service life of a heat preservation layer is short. The super-high-temperature prefabricated directly-buried heat-preservation pipe fitting tee comprises a steel pipe tee (5), wherein the steel pipe tee (5) is wrapped with a rock wool heat insulation layer (4); an aerogel layer (3) is applied and coated on the outer side of the rock wool heat insulation layer; a polyurethane heat preservation layer (2) is applied and coated on the outer side of the aerogel layer; and a metal outer protection pipe (1) is coated on the outer side of the polyurethane heat preservation layer. The invention relates to the field of energy source conveying pipelines, in particular to the super-high-temperature prefabricated directly-buried heat-preservation pipe fitting tee and the production and usage method.

Owner:哈尔滨朗格思特供热装备科技有限公司

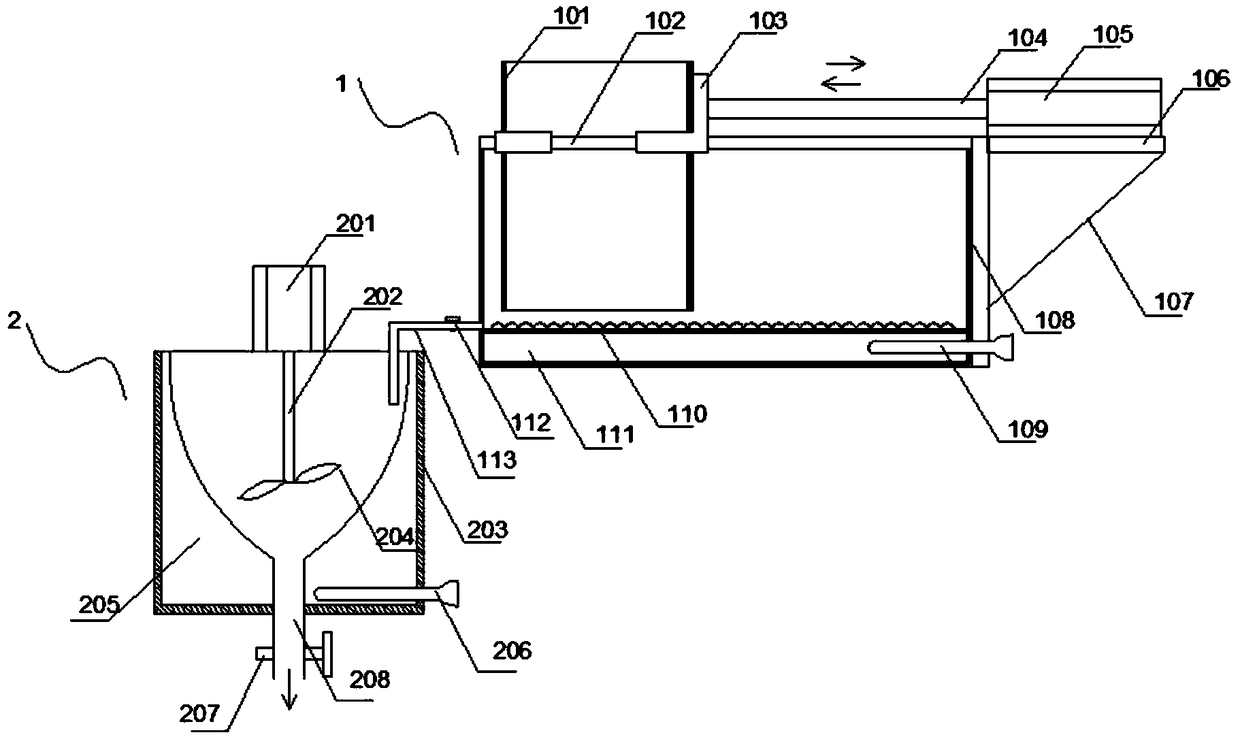

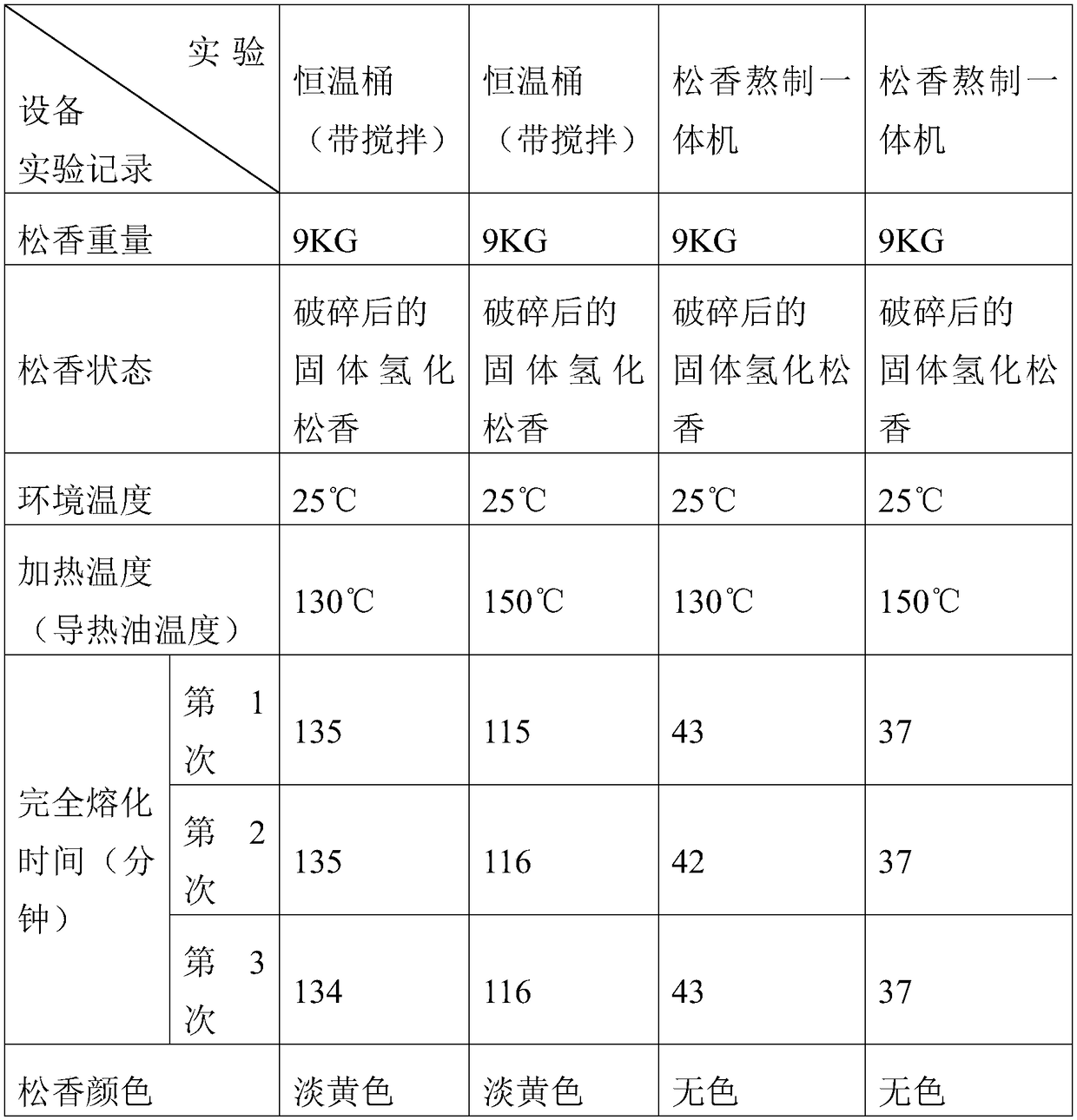

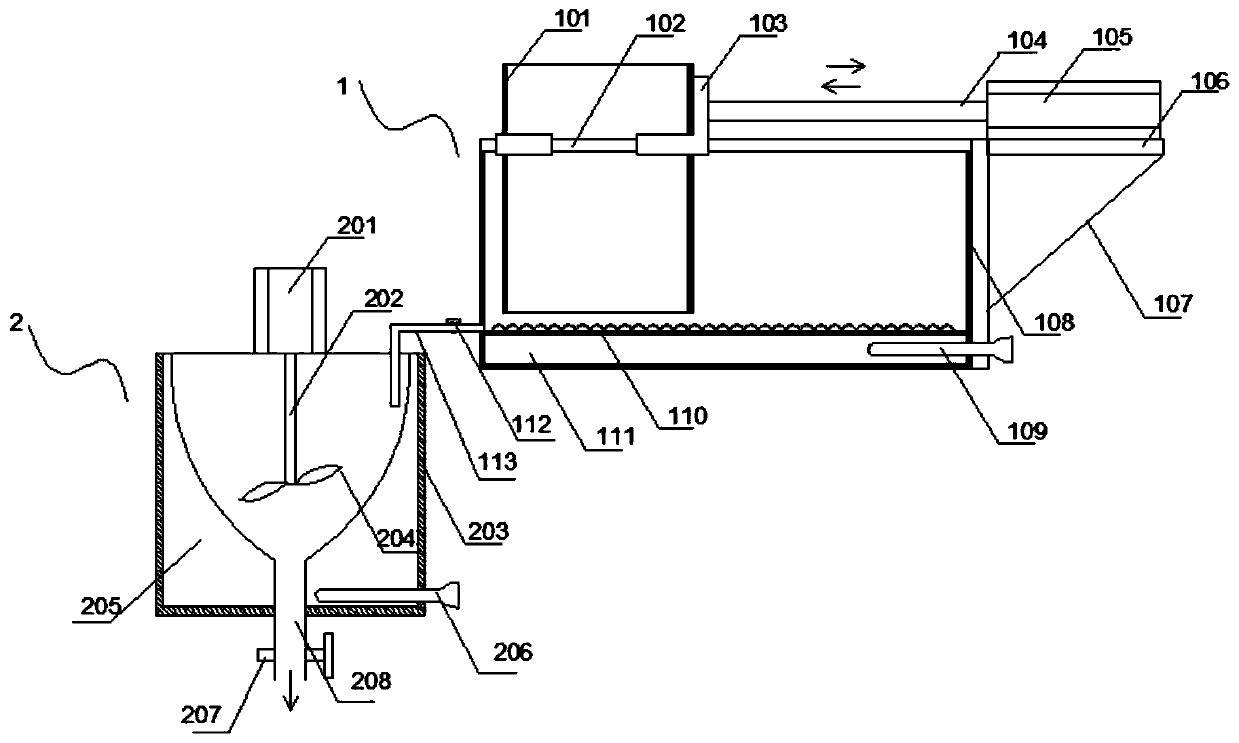

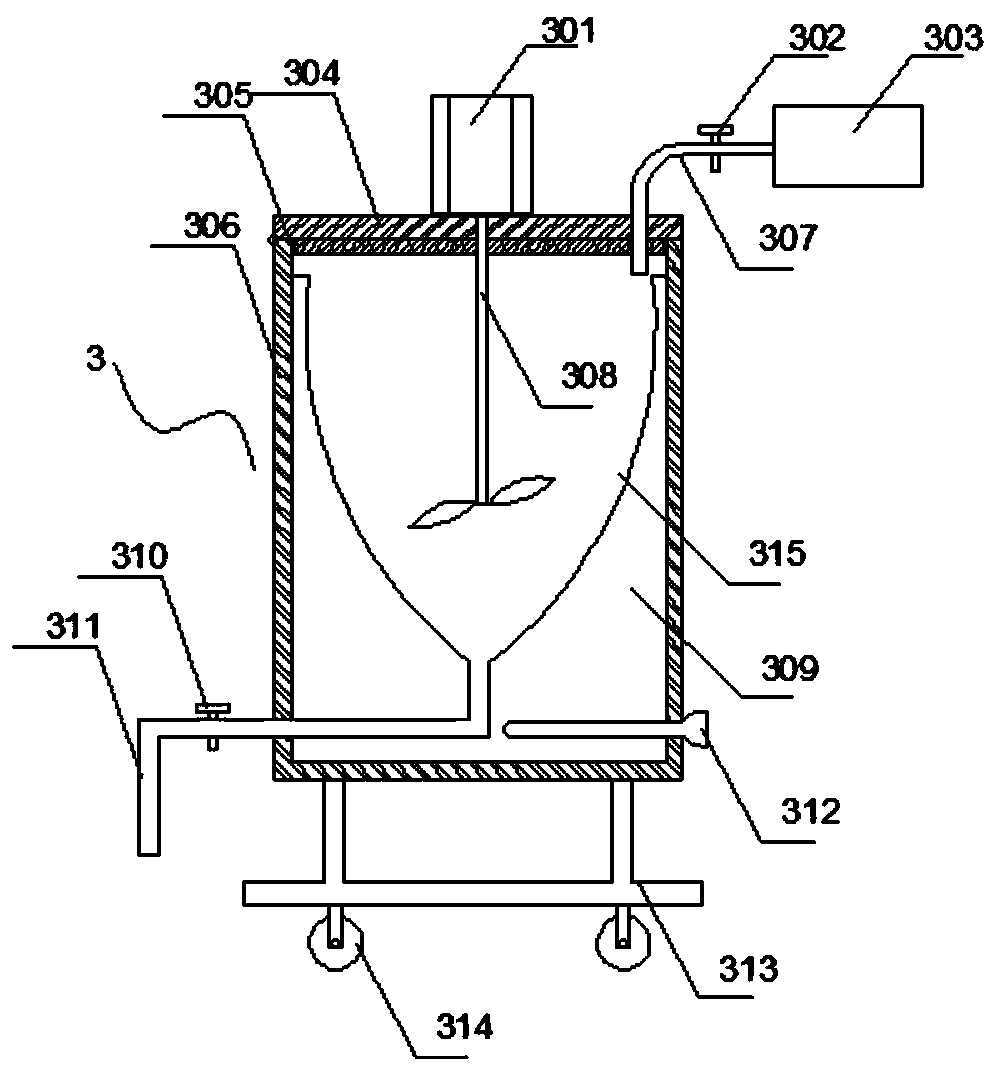

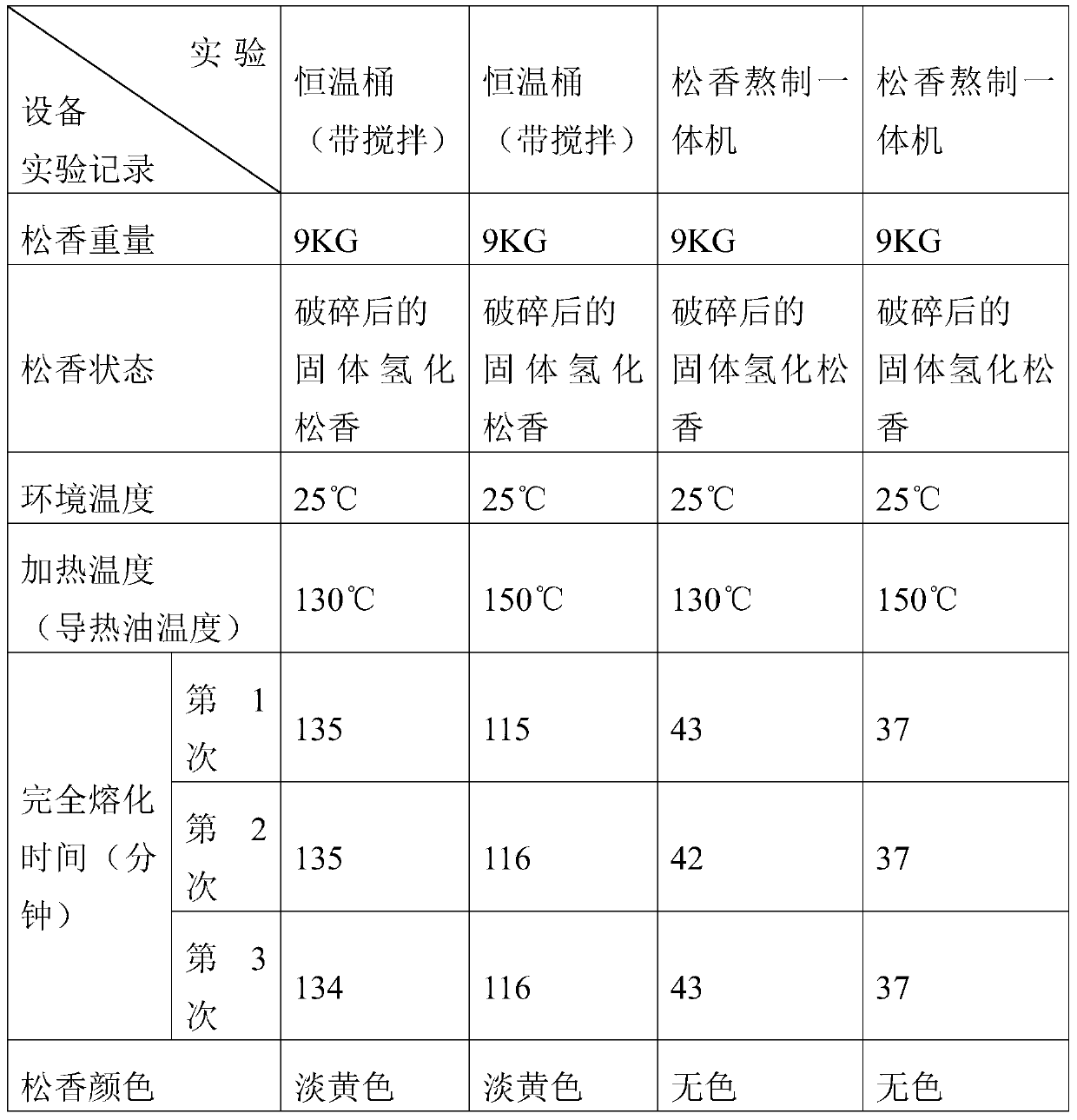

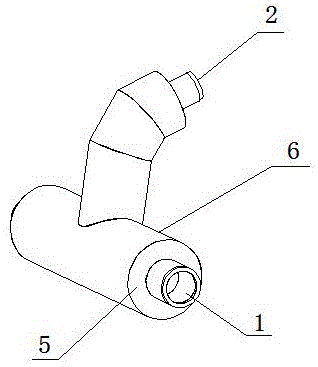

All-in-one rosin decoction machine

ActiveCN108907511AImprove qualityImprove continuityWelding/cutting media/materialsSoldering mediaHeat conductingHeater Rod

The invention discloses an all-in-one rosin decoction machine which comprises a rosin melting device and a temporary storage device. The rosin melting device comprises an air cylinder, a heating tankand a discharging basket, wherein a sliding rail is arranged above the heating tank, a sliding block is slidingly connected to the sliding rail and is fixedly connected with the outer wall of the discharging basket, the upper end and the lower end of the discharging basket are open, a placement block is fixed to the upper end of the heating tank, the air cylinder is fixed to the placement block and outputs power to the sliding block through a push rod, the inner bottom of the heating tank is provided with a heat conducting plate, a first sealed cavity is formed under the heat conducting plateand is filled with heat conducting oil, a first heating rod for heating and controlling temperature of heat conducting oil is arranged in the first sealed cavity and is communicated with the temporarystorage device through a first discharging pipe. By adopting the technical scheme, rosin is not in contact with the same heat source for a long time, no carbonizing phenomenon is produced, the rosinquality is improved, and the rosin melting efficiency is improved.

Owner:杭州友邦焊锡材料有限公司

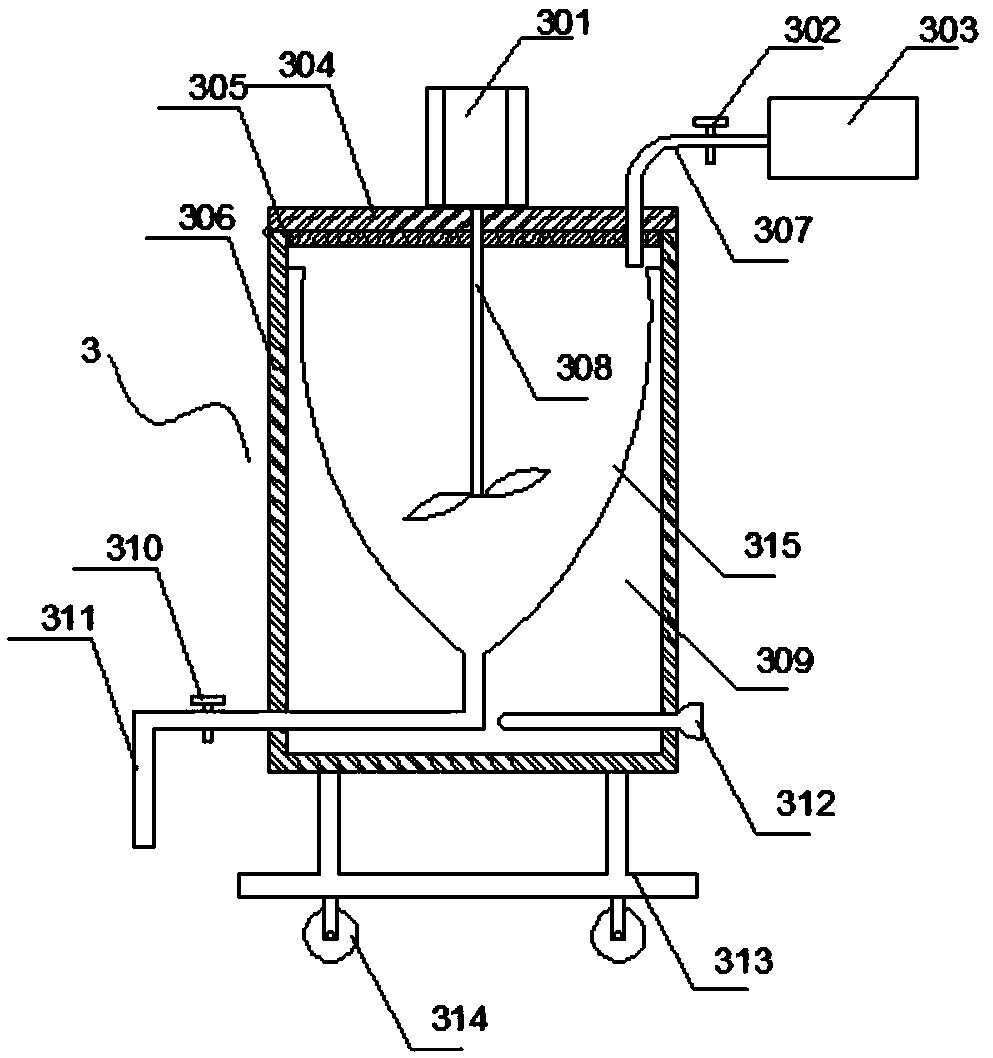

Rosin cooking machine

ActiveCN108907511BImprove qualityImprove continuityWelding/cutting media/materialsSoldering mediaThermodynamicsHeat conducting

The invention discloses an all-in-one rosin decoction machine which comprises a rosin melting device and a temporary storage device. The rosin melting device comprises an air cylinder, a heating tankand a discharging basket, wherein a sliding rail is arranged above the heating tank, a sliding block is slidingly connected to the sliding rail and is fixedly connected with the outer wall of the discharging basket, the upper end and the lower end of the discharging basket are open, a placement block is fixed to the upper end of the heating tank, the air cylinder is fixed to the placement block and outputs power to the sliding block through a push rod, the inner bottom of the heating tank is provided with a heat conducting plate, a first sealed cavity is formed under the heat conducting plateand is filled with heat conducting oil, a first heating rod for heating and controlling temperature of heat conducting oil is arranged in the first sealed cavity and is communicated with the temporarystorage device through a first discharging pipe. By adopting the technical scheme, rosin is not in contact with the same heat source for a long time, no carbonizing phenomenon is produced, the rosinquality is improved, and the rosin melting efficiency is improved.

Owner:杭州友邦焊锡材料有限公司

Lubricating agent for copper cladding aluminum enamelled wire

InactiveCN105969493ALow kinematic viscosityImprove the lubrication effectLubricant compositionCarbonizationDissolution

The invention provides a lubricating agent for a copper cladding aluminum enamelled wire. The lubricating agent is prepared from the following raw materials in parts by weight: 30 to 40 parts of beeswax, 15 to 18 parts of 42-percent chlorinated paraffin, 5 to 7 parts of epoxidized soybean oil, 5 to 7 parts of triglyceride, 25 to 32 parts of paraffin, 8 to 14 parts of linseed oil, 22 to 35 parts of No.93 gasoline, 50 to 60 parts of absolute ethyl alcohol and 20 to 27 parts of lubricating aids. The lubricating agent provided by the invention is very suitable for being used for copper cladding aluminum enamelled wire lubrication; the kinematic viscosity of the lubricating agent is low; the lubricating performance is good; the fracturing of the enamelled wire in the lubricating process can be prevented; in addition, the stability of the lubricating agent is very high; the oxygen dissolution content is low; the deterioration cannot occur after the long-time placement in the open air. The lubricating agent can meet the lubrication use requirements of the enamelled wire at the high temperature of 132 DEG C; the lubricating agent cannot generate carbonization phenomena at high temperature; the stability of the enamelled wire cannot be changed at high temperature.

Owner:ANHUI JIUHUA KIMRUN COPPER IND

Paint-free plate repairing paper and production method thereof

ActiveCN106087533AEnsure quality stabilityEasy to fillPaper coatingSynthetic cellulose/non-cellulose material pulp/paperFiberGlass fiber

The invention belongs to the technical field of domestic finishing carpentry plates, and relates to a paint-free plate repairing paper having wide application range and being simple to use, and a production method thereof. The paint-free plate repairing paper is used for repairing secondary defective paint-free plates in the production process. Raw materials for producing the repairing paper comprise, by weight, 20-40 parts of needle leaf wood-ground pulp fibers, 10-20 parts of broadleaf wood chemimechanical pulp fibers, 5-15 parts of glass fibers, and 30-65 parts of thermosetting resin; and the thermosetting resin comprises epoxy resin-modified acrylic resin. The production method of the paint-free plate repairing paper comprises pulping, pasting molding, thermosetting resin coating, primary drying, secondary drying and packaging. The paint-free plate repairing paper has the advantages of good filling property and repairability, simplification of the repairing treatment technology of the defective paint-free plates, realization of repairing only through one-shot sanding and one-shot hot pressing, avoiding of the carbonization and bottom exposure problems of finished plates, simple repairing step, wide adaptability, good repairing effect, and environmental protection and healthiness, and the production method is simple and reliable.

Owner:SHANDONG LUNAN NEW MATERIALS

A kind of method that moso bamboo material prepares ecological board

The invention relates to a method for preparing an ecological board from a moso bamboo material, and belongs to the technical field of building material production. The present invention firstly collects the bamboo leaves and trunks on moso bamboo, beats the trunks into shavings, and then exposes them to the sun and dries them for later use. The dried bamboo leaves are crushed into bamboo leaf powder, stirred and mixed evenly with polyvinyl chloride resin, and Put it in an internal mixer and put it on a flat vulcanizer for hot pressing, take it out and cold press it to get the bamboo leaf resin layer, then crush the particle board into bamboo chips, mix with polyethylene resin, limestone powder and other substances, impregnate, Filtrate, wash with ethanol, dry, banbury, plasticize, cold press to obtain the middle layer of micro-foamed bamboo chips, and finally make the bamboo leaf resin layer into the upper and lower layers, and the middle layer is the middle layer of micro-foamed bamboo chips, and carry out hot pressing and cold press. Finally, the beneficial effects of the present invention are: no bubbling, pollution resistance, no carbonization phenomenon, mass production is possible, production efficiency is improved; production steps are simple, and cost is saved.

Owner:班尔奇(上海)家居科技有限公司

High-intensity durable heat insulation building material as well as preparation method and application thereof

InactiveCN107555935AImprove fire and flame retardant performanceAddresses flammable defectsCoatingsWater vaporWater vapor permeability

The invention discloses a high-intensity durable heat insulation building material as well as a preparation method and application thereof. An inorganic heat insulation building material is prepared from the following ingredients including magnesium oxide, magnesium sulfate, magnesium chloride, talcum powder and ultrafine building material efficient additives. After being smeared onto the surfaceof a polystyrene heat insulation plate, the heat insulation building material tightly covers the polystyrene heat insulation plate, and can comprehensively seep into the inside of the polystyrene heatinsulation plate; the mutual seepage is realized under the high-pressure effect; after the forming, a compact water-tight and air-tight hard framework is formed; the polystyrene heat insulation platecovered at the inside is protected; the water absorption rate of the polystyrene heat insulation plate is reduced; the transmission rate of air and water vapor is effectively prevented; the anti-aging performance of the polystyrene heat insulation plate is improved.

Owner:四川方壹特建筑工程有限公司

Novel high-strength, acid-resisting and alkali-resisting fibers

InactiveCN108977930AHigh strengthGuaranteed StrengthConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberEpoxy

The invention mainly relates to the technical field of processing of novel fibers and discloses novel high-strength, acid-resisting and alkali-resisting fibers. The novel high-strength, acid-resistingand alkali-resisting fibers are prepared from the following raw materials in parts by weight: 10 to 15 parts of chitosan, 60 to 75 parts of glycidyl ester type epoxy resin, 2 to 3 parts of carbon nanotube and 15 to 18 parts of nano titanium dioxide. The fibers prepared by the invention have strong acid-resisting and alkali-resisting performance, good dyeing stability and a wide application range.

Owner:马鞍山卓凡新材料科技有限公司

Cooling process for green pole plate of lead-acid storage battery after curing

ActiveCN107068984AIncrease difficulty of formationReduce capacityLead-acid accumulator electrodesRoom temperatureEngineering

The invention discloses a cooling process for a green pole plate of a lead-acid storage battery after curing, and aims to overcome the defects that the cooling time is long after the pole plate of the storage battery is cured and a lattice structure between an active substance on a surface of the pole plate and a grid is not stable so as to improve defective rate of the pole plate, and the surface of the pole plate is easy to carbonize so as to improve the formation difficulty of the pole plate and reduce the capacity and the cycle lifetime of the battery. The cooling process comprises the following steps of (a) placing the green pole plate which is cured just now in a curing chamber under a normal-temperature environment for normal-temperature cooling for 0.5-1.5 hours; (b) performing temperature reduction on the curing chamber placed with the green pole plate, adjusting a temperature to 5-10 DEG C, simultaneously blowing air by a fan, and controlling time for 2-3 hours; and (c) placing the green pole plate in the curing chamber under a room-temperature ventilation environment for 0.5-1 hour, wherein pole separation and brush can be performed.

Owner:CHAOWEI POWER CO LTD

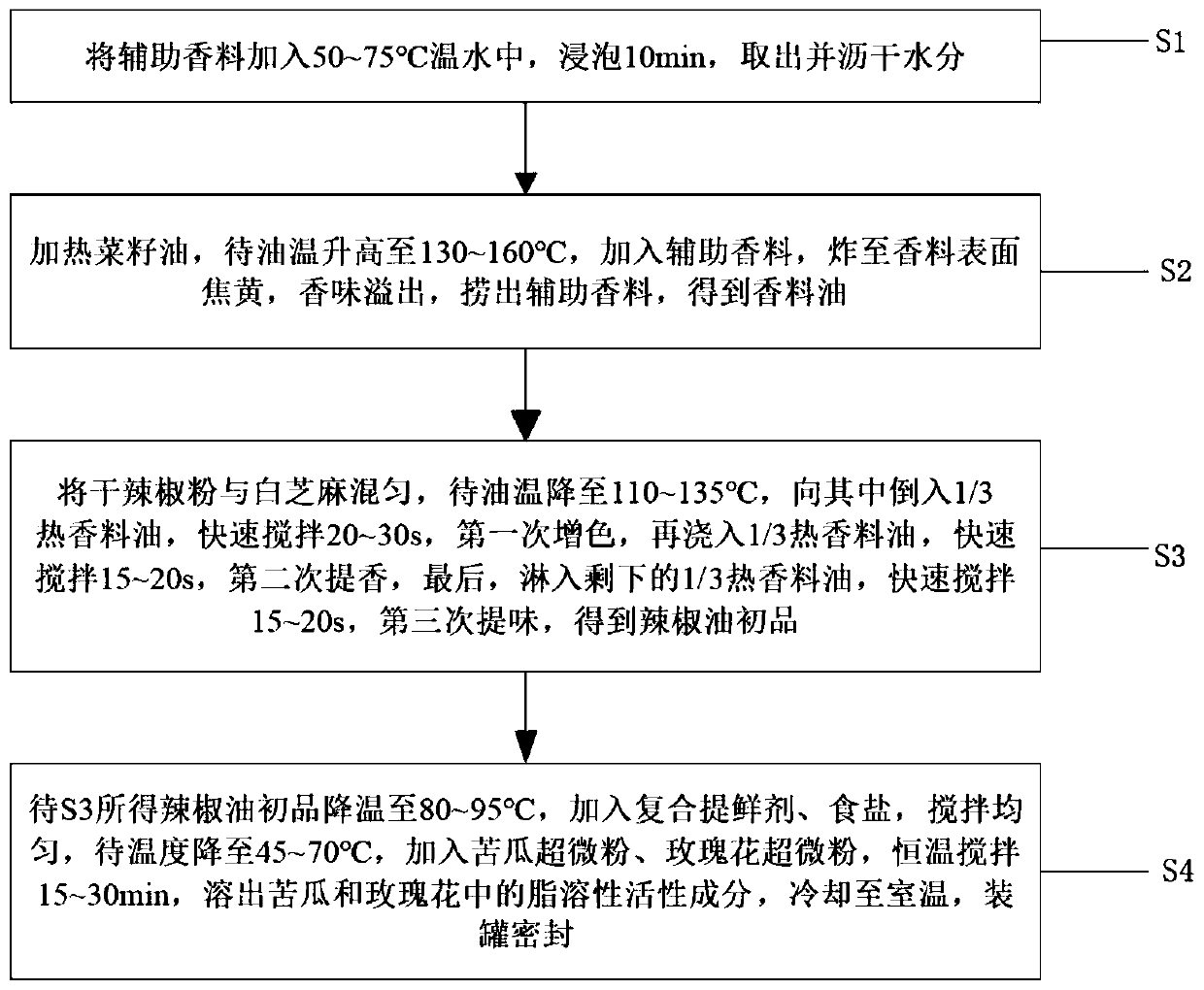

Chili oil and preparation process thereof

The invention discloses chili oil and a preparation process thereof. The chili oil is prepared from, by mass, 100 parts of rapeseed oil, 20-25 parts of dried chili powder, 5-6 parts of auxiliary spices, 1.5-2 parts of white sesame seeds, 0.1-0.5 part of ultrafine bitter gourd powder, 0.5-1.5 parts of ultrafine rose flower powder, 0.1-0.5 part of a composite freshness-enhancing agent and 0.4-0.5 part of edible salt; the auxiliary spices are prepared from, by mass, 10 parts of Sichuan peppers, 3-6 parts of ginger, 3-6 parts of garlic, 3-5 parts of star anise, 0.2-0.8 part of myrcia, 0.1-0.5 partof lemon grass, 0.5-2 parts of dried mint, 1-2 parts of rhizoma kaempferiae, 2-3 parts of fructus foeniculi, 1-2 parts of fructus amomi rotundus, 0.5-2 parts of cortex cinnamomi, 0.5-5 parts of peppers, 0.5-2 parts of tsaoko amomum fruits, 3-5 parts of red cape jasmine fruits and 4-6 parts of licorice root. The chili oil is bright red in color and luster and is not blackened or burnt, integratescolor, fragrance, pungency, freshness and spiciness and can be stored for a long time; since bitter gourds and rose flowers can effectively neutralize the spicy taste of the chili oil, a person does not easily suffer from inner heat when eating the chili oil.

Owner:安徽省益丰生态农业科技有限公司

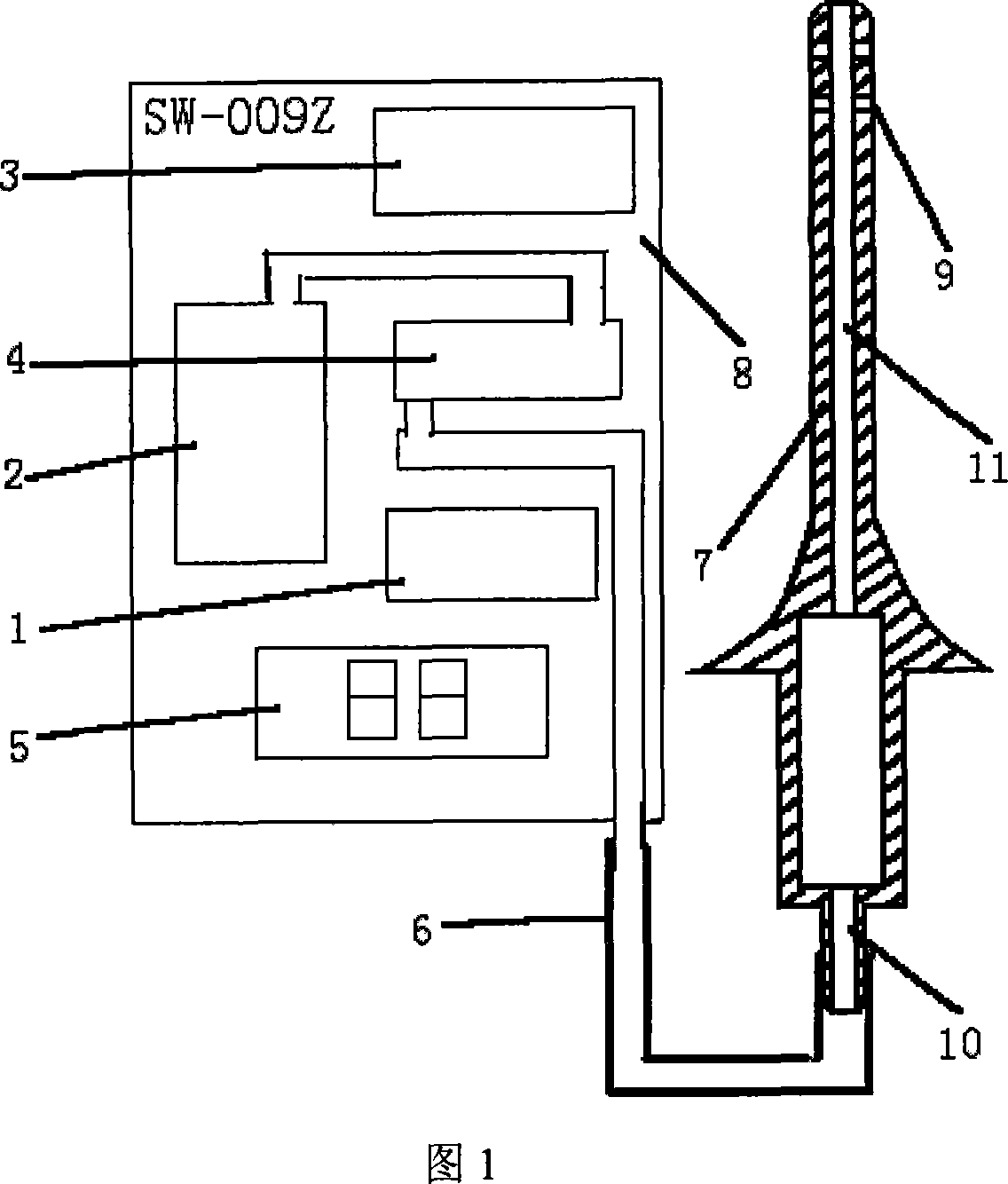

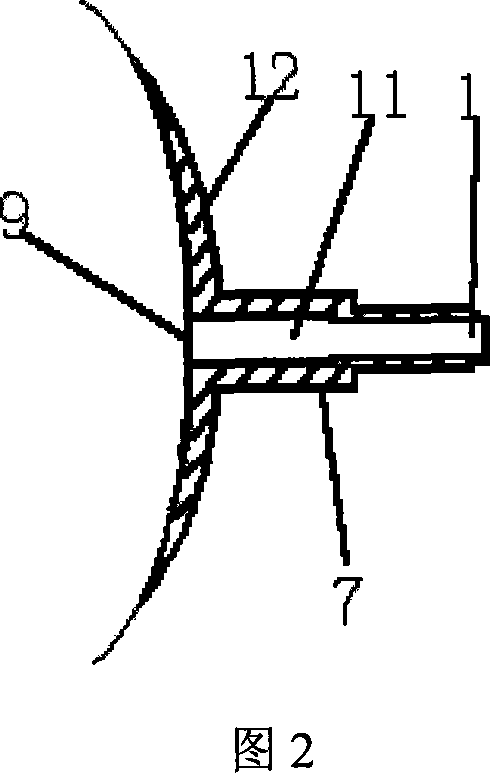

Ozone ion instrument for treating haemorrhoids

InactiveCN101045031AAvoid the hassle of being able to operateSolve operational troublesBathing devicesAnal canalAnal fistula

A medical ozone ion instrument for treating piles, rectal polyp, pointed condyloma, fissure in ano, anal fistula and perianal itching is composed of an ozone generator with shell and ozone tube, a therapeutic head with central ozone channel and front ozone outlet, and an ozone guide tube connected between said ozone generator and therapeutic head.

Owner:方华

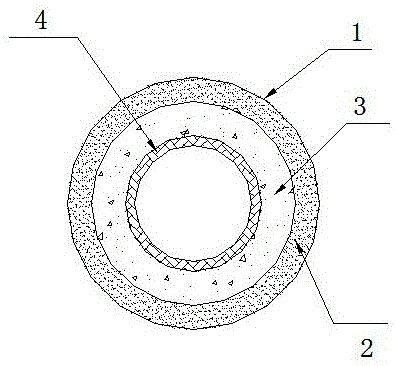

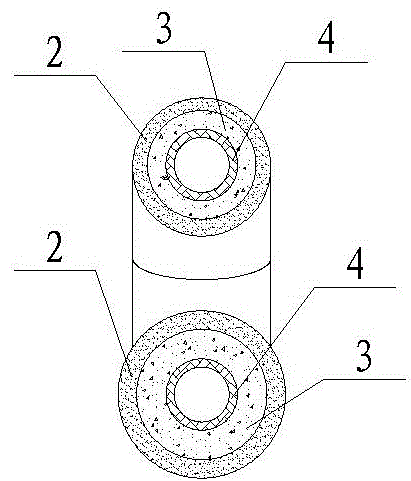

Ultrahigh-temperature prefabricated direct burial heat preservation pipe fitting spanning tee joint and heat preservation method

PendingCN106523857AEfficient use ofLow thermal conductivityThermal insulationPipe protection by thermal insulationPipe fittingPetrochemical

The invention discloses an ultrahigh-temperature prefabricated direct burial heat preservation pipe fitting spanning tee joint and a heat preservation method. According to the current original heat preservation technology, the technology adopting polyurethane, rock wool, silicate and other heat preservation materials is adopted for conducting heat preservation on ultrahigh-temperature pipelines, although the above structure can play a certain heat preservation role, the heat conduction coefficient is high, the energy dissipation rate is high and the service life of a heat preservation layer is short. The ultrahigh-temperature prefabricated direct burial heat preservation pipe fitting spanning tee joint comprises a steel pipe A (1), a steel pipe B (2), a rock wool heat preservation layer (3), an aerogel heat preservation layer (4) and a polyurethane heat preservation layer (5). The outer wall of the steel pipe A and the outer wall of the steel pipe B are annularly wrapped by rock wool in a closed manner, and a rock wool wrapping layer is formed. The outer side of the rock wool wrapping layer is annularly wrapped by aerogel felt in a closed manner, and the aerogel heat preservation layer is formed. The outer side of the aerogel heat preservation layer is evenly wrapped by a heat reflection layer. The ultrahigh-temperature prefabricated direct burial heat preservation pipe fitting spanning tee joint and the heat preservation method are applied to 2,000 DEG C ultrahigh-temperature prefabricated heat isolation and heat preservation pipelines used in the fields of heat supply, cold supply, petroleum and petrochemicals and ships.

Owner:哈尔滨朗格思特供热装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com