Chili oil and preparation process thereof

A preparation process, technology of chili oil, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of aggravating dampness and heat in the body, carbonization and blackening of chili pepper, affecting the flavor of chili oil, etc., to promote metabolism and bright red color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

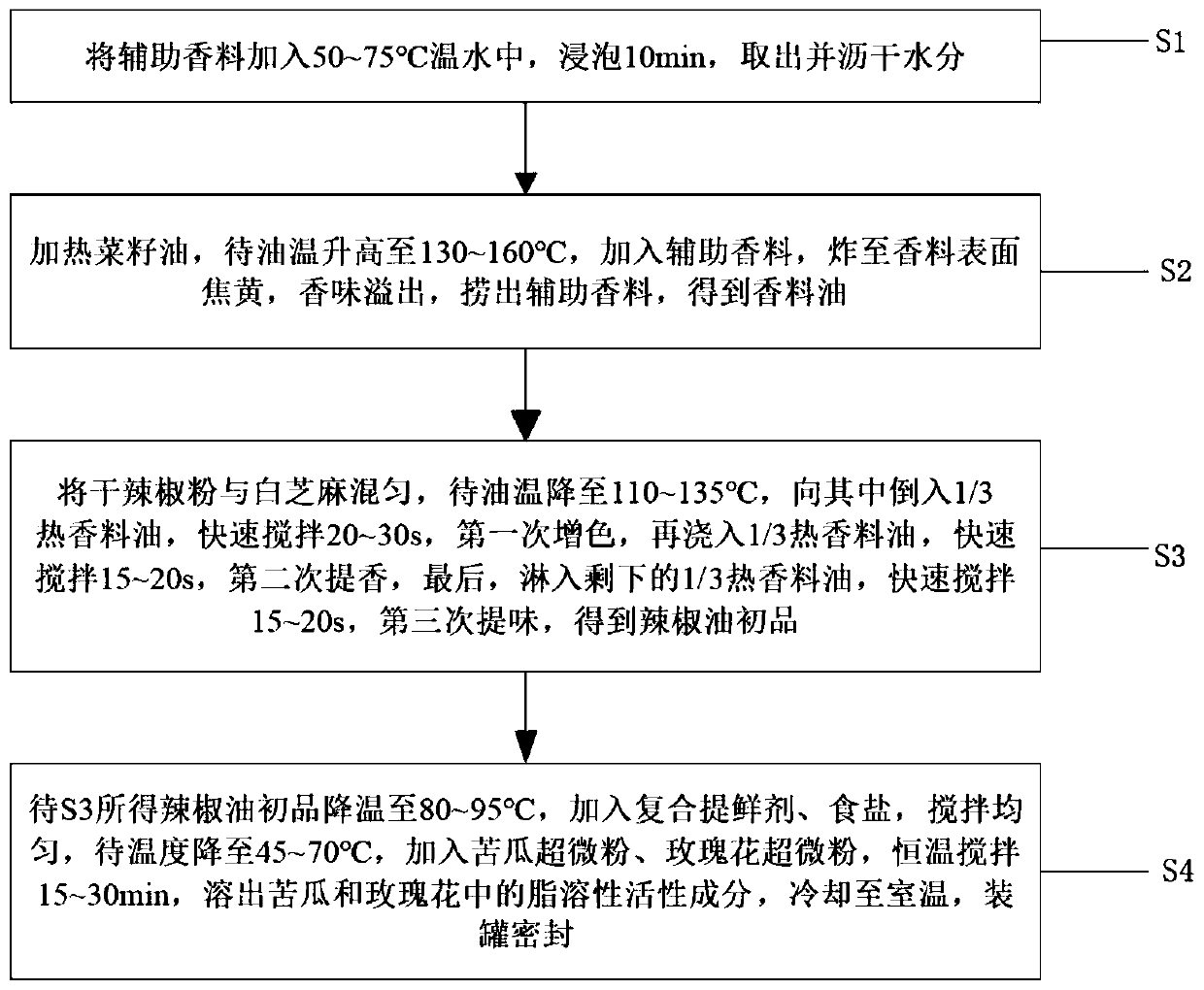

Method used

Image

Examples

Embodiment 1

[0025] A chili oil, the chili oil is prepared from the following raw materials in parts by mass: 100 parts of rapeseed oil, 20 parts of dried chili powder, 5 parts of auxiliary spices, 1.5 parts of white sesame, 0.1 part of 500-mesh bitter gourd superfine powder, 350-mesh 0.5 parts of rose superfine powder, 0.1 parts of compound freshening agent, 0.4 parts of table salt;

[0026] The auxiliary spice components and parts by mass are: 10 parts of Chinese prickly ash, 3 parts of ginger, 3 parts of garlic, 3 parts of star anise, 0.2 parts of bay leaf, 0.1 part of lemongrass, 0.5 parts of dried mint, 1 part of kaempferen, and 2 parts of cumin , 1 part of white cardamom, 0.5 part of cinnamon, 0.5 part of pepper, 0.5 part of grass fruit, 3 parts of red gardenia, 4 parts of licorice;

[0027] The compound freshness enhancing agent is composed of ethyl maltol, 5'-taste nucleotide disodium and yeast flavor in a mass ratio of 1:0.8:1.5.

[0028] A kind of preparation technology of chili...

Embodiment 2

[0034] A chili oil, the chili oil is prepared from the following raw materials in parts by mass: 100 parts of rapeseed oil, 22.5 parts of dried chili powder, 5.5 parts of auxiliary spices, 1.8 parts of white sesame, 0.3 parts of 600-mesh bitter gourd superfine powder, 450-mesh 1 part of rose superfine powder, 0.3 part of compound freshening agent, 0.4 part of table salt;

[0035] The auxiliary spice components and parts by mass are: 10 parts of Chinese prickly ash, 4.5 parts of ginger, 4.5 parts of garlic, 4 parts of star anise, 0.5 parts of bay leaves, 0.3 parts of lemongrass, 1 part of dried mint, 1.5 parts of kaempferen, and 2.5 parts of fennel , 1.5 parts of white cardamom, 1 part of cinnamon, 1 part of pepper, 1 part of grass fruit, 4 parts of red gardenia, 5 parts of licorice;

[0036] The compound freshness enhancer is composed of ethyl maltol, disodium 5'-taste nucleotide and yeast flavor in a mass ratio of 1:1.5:2.

[0037] A kind of preparation technology of chili o...

Embodiment 3

[0043] A chili oil, the chili oil is prepared from the following raw materials in parts by mass: 100 parts of rapeseed oil, 25 parts of dried chili powder, 6 parts of auxiliary spices, 2 parts of white sesame, 0.5 part of 800-mesh bitter gourd superfine powder, 600-mesh 1.5 parts of rose superfine powder, 0.5 parts of compound freshening agent, and 0.5 parts of table salt;

[0044] The components and mass parts of the auxiliary spices are: 10 parts of Chinese prickly ash, 6 parts of ginger, 6 parts of garlic, 5 parts of star anise, 0.8 parts of bay leaves, 0.5 parts of lemongrass, 2 parts of dried mint, 1-2 parts of kaempferia, fennel 3 parts, 2 parts white cardamom, 2 parts cinnamon, 2 parts pepper, 2 parts grass fruit, 5 parts red gardenia, 6 parts licorice;

[0045] The compound freshness enhancing agent is composed of ethyl maltol, disodium 5'-taste nucleotide and yeast flavor in a mass ratio of 1:2:3.

[0046] A kind of preparation technology of chili oil, comprises the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com