Patents

Literature

45results about How to "Control oil temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

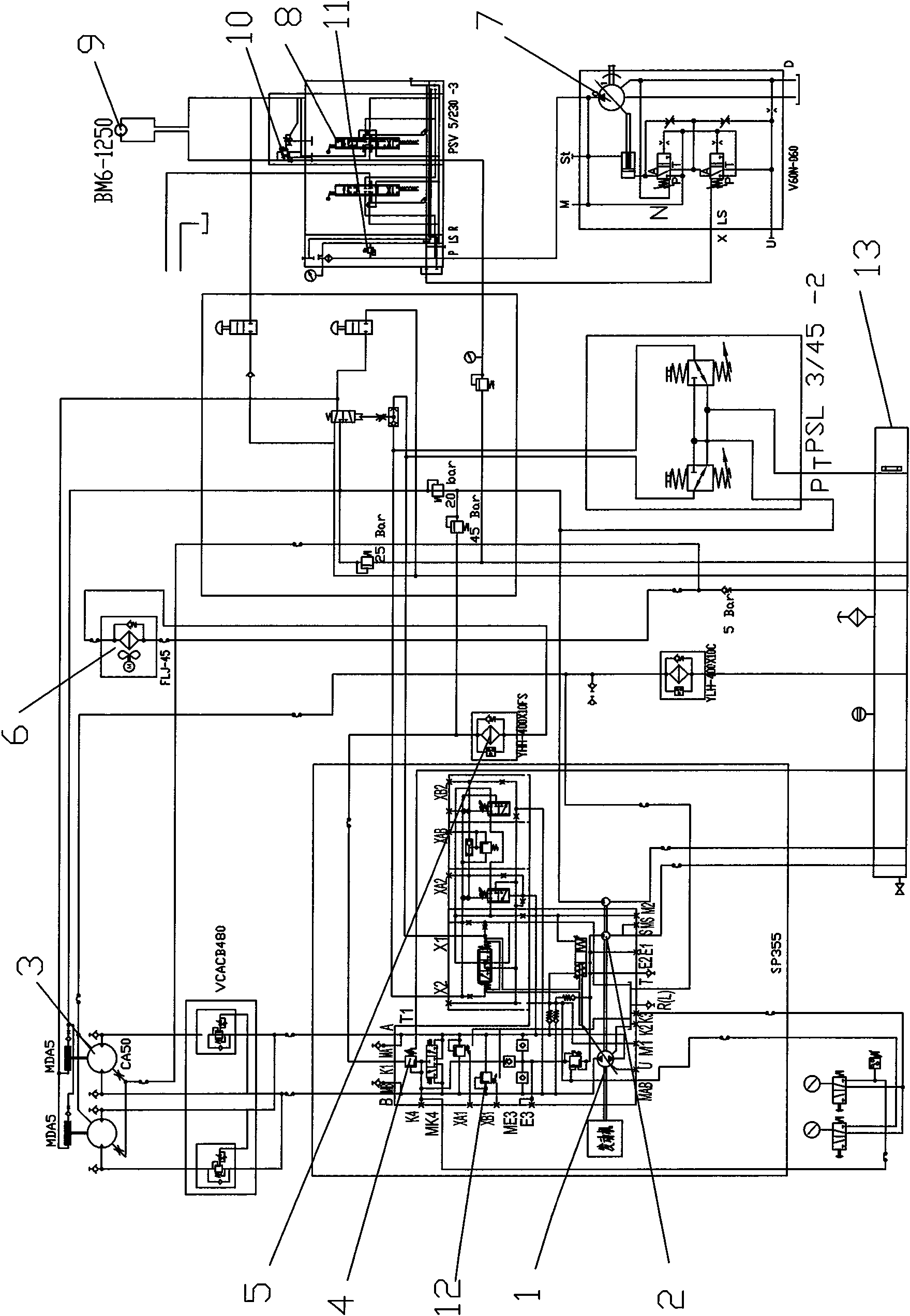

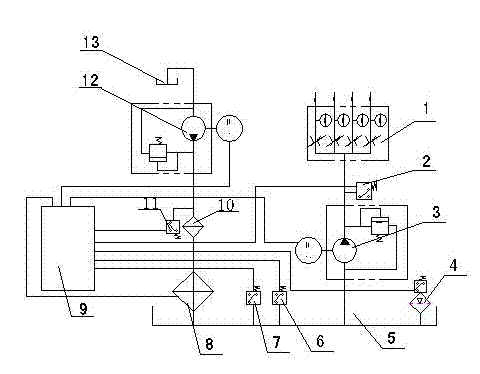

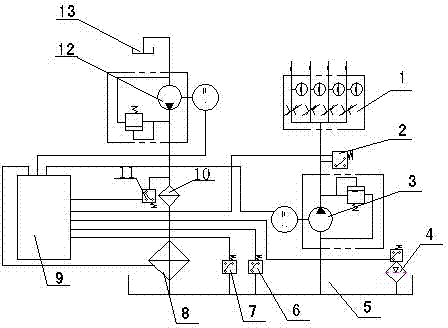

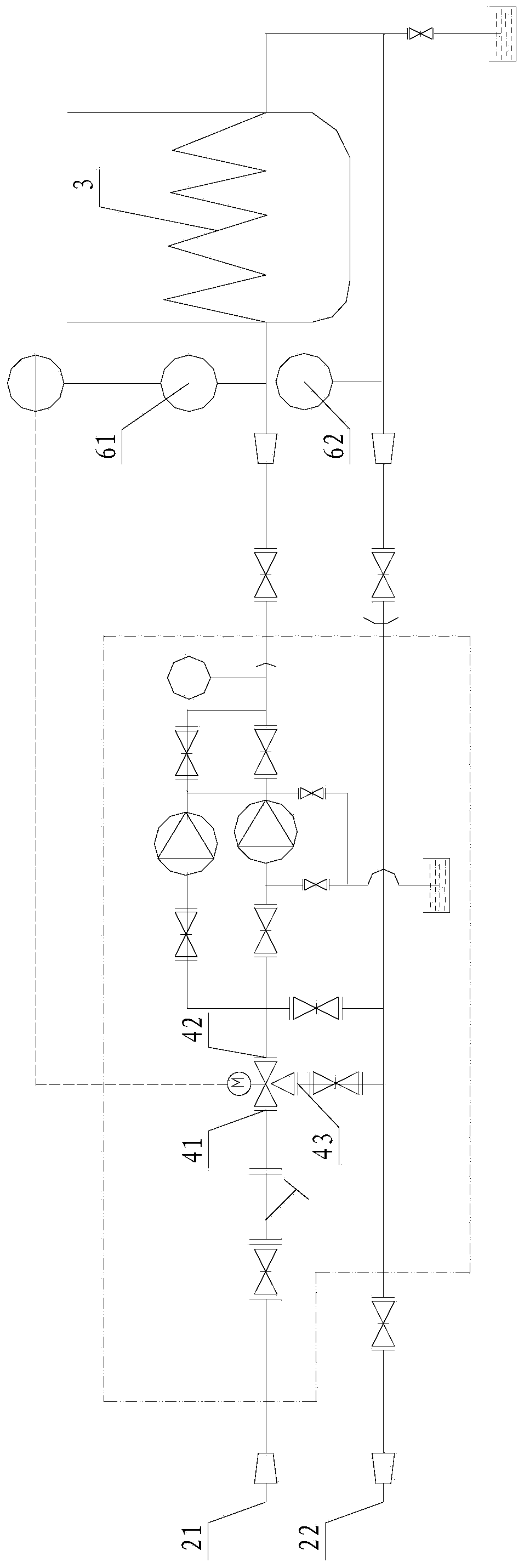

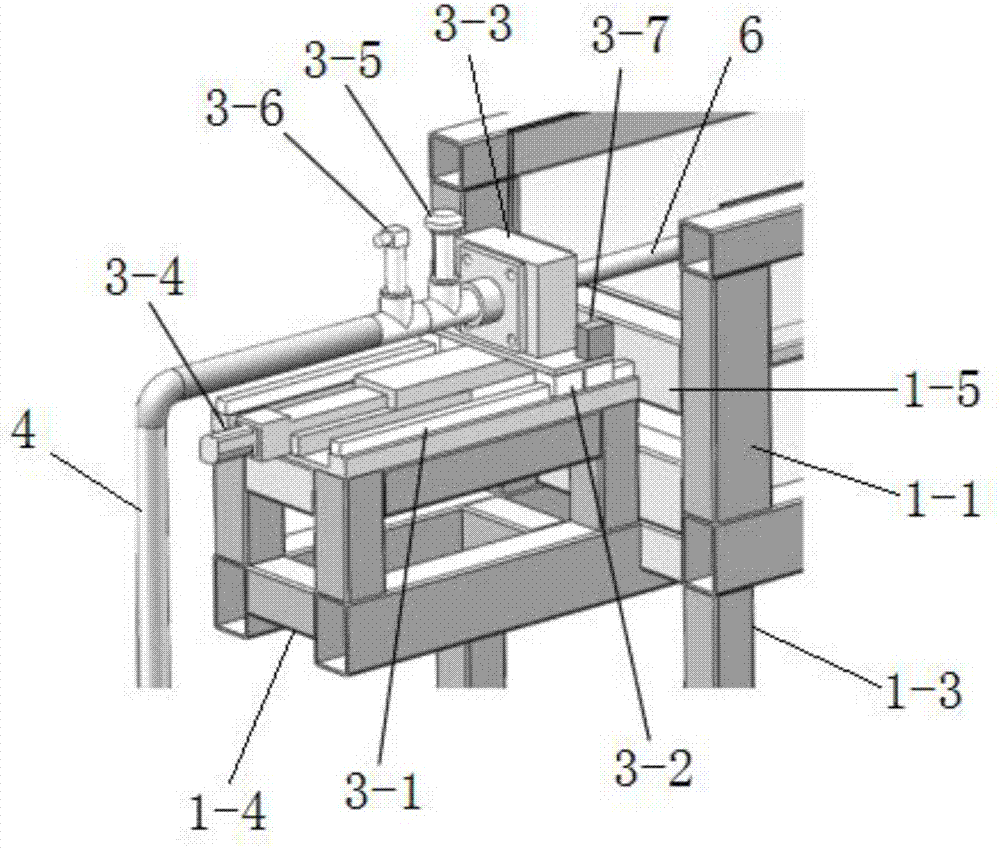

Hydraulic system of continuous string coiled tubing unit

InactiveCN101655005AReduce power lossLow calorific valueDrilling rodsFluid-pressure actuatorsCoiled tubingEngineering

The invention discloses a hydraulic system of a continuous string coiled tubing unit, consisting of an injection head hydraulic subsystem and a barrel hydraulic subsystem, wherein, the injection headhydraulic subsystem is a closed volume speed-modulating system and is composed of a two-way variable plunger pump, a quantitative radial plunger motor, a spillover valve, an oil filter, a cooler, an auxiliary slippagepump and a safety valve A; the barrel hydraulic subsystem is an open volume throttling speed-modulating subsystem and is composed of a load-sensitive pump, a manual proportional valve, a barrel motor, a variable back pressure valve and a safety valve B. As the injection head hydraulic subsystem in the invention uses the closed volume speed modulating, throttling power loss is zeroand spillover power of passing through the spillover valve has small loss; as the barrel hydraulic subsystem uses the open volume throttling speed modulating, the spillover power loss is zero and thethrottling power loss is small. Therefore, the whole system features high efficiency, small calorific power, small power loss and high precision of system transmission.

Owner:DALIAN JIAOTONG UNIVERSITY

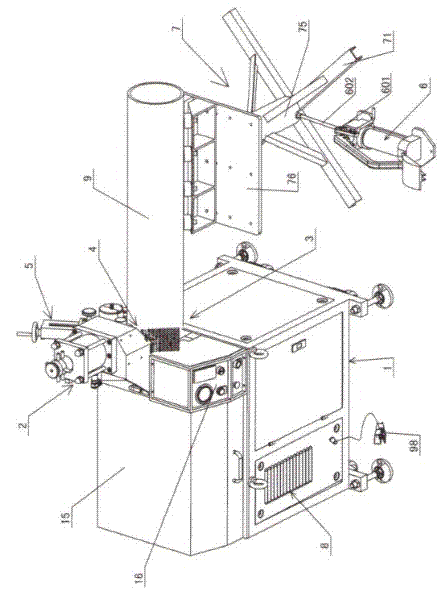

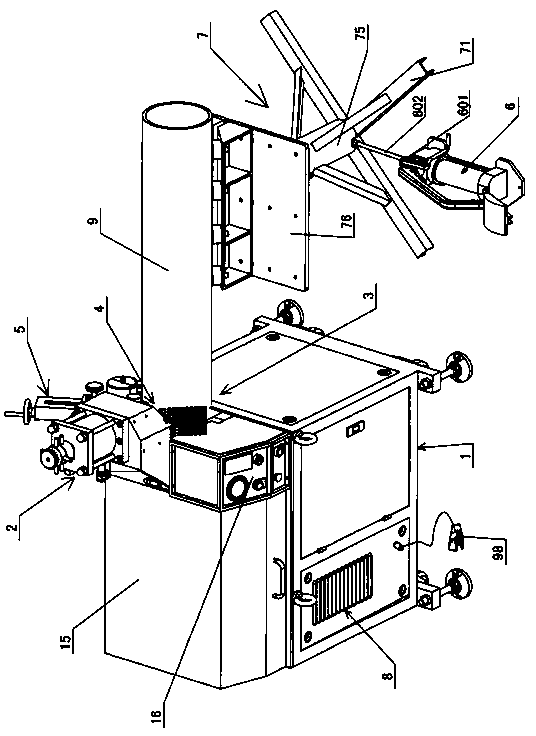

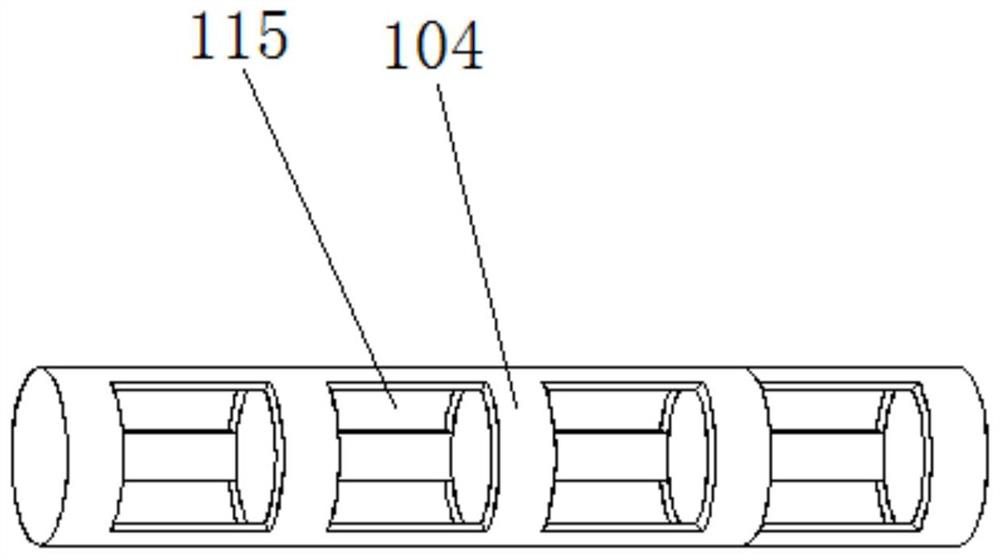

Automatic hydraulic channeling machine

The invention relates to an automatic hydraulic channeling machine. A frame part comprises a chassis, a sole plate, a universal wheel, machine legs, a shield and a panel; a hydraulic system comprises a cylinder base, a piston rod, a piston, a cylinder body, an adjusting nut, an adjusting rod and a ruler sleeve; a channeling mechanism comprises a main motor, a power head, a coupler, a spindle, a bearing, a knurl wheel, a pressing wheel guide shaft, a pressing wheel and a pressing wheel shaft; a guide wheel mechanism comprises a guide wheel shaft, a guide wheel, a sliding adjusting knob, an adjusting bolt, a guiding block, a hand wheel, a screw rod, a screw rod slide block and a guide wheel frame; an electric system comprises a pedal switch, an alternated current contactor, an intermediate relay, a breaker, a rectifier, a transformer, a time relay, a buzzer and an indicator lamp; a hydraulic control system comprises an oil tank, an oil pump motor, a gear pump, an oil-way block, a solenoid directional valve, a pressure relay, a flow control valve and an overflow valve; and a working bracket comprises a bracket base, a bracket cylinder sleeve, a bracket cylinder base, a bracket cylinder, a bracket piston rod, a bracket plate, a bracket lifting device, a quick connector and a high-pressure oil pipe.

Owner:浙江唯特利图伟管道设备有限公司

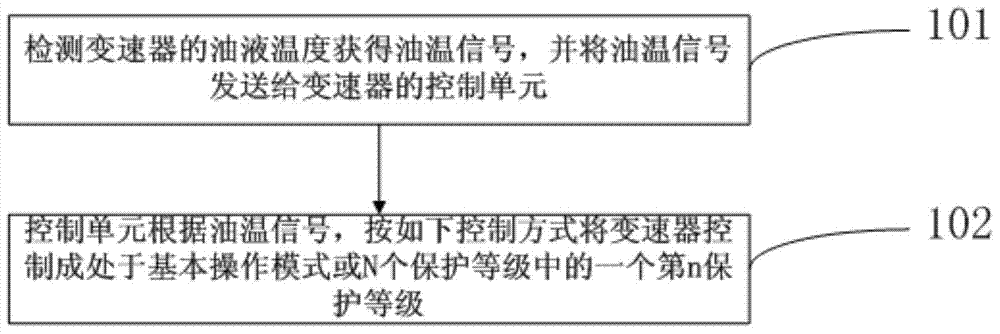

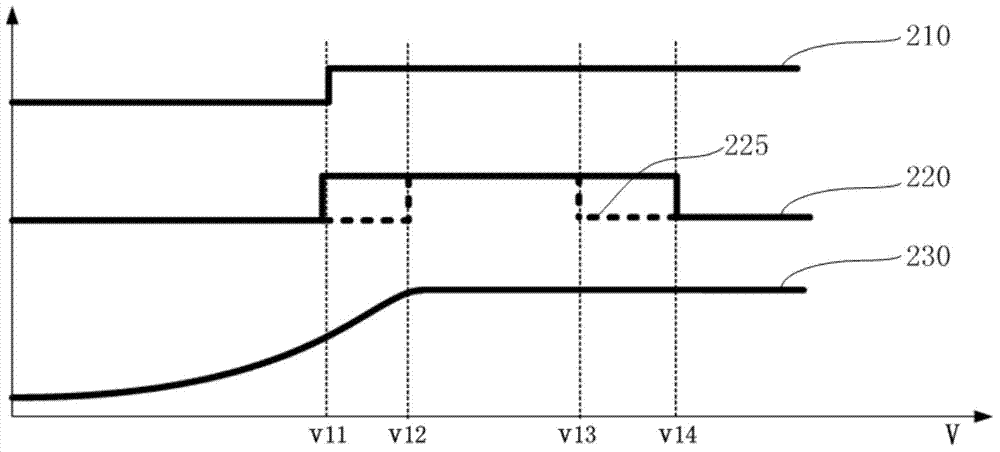

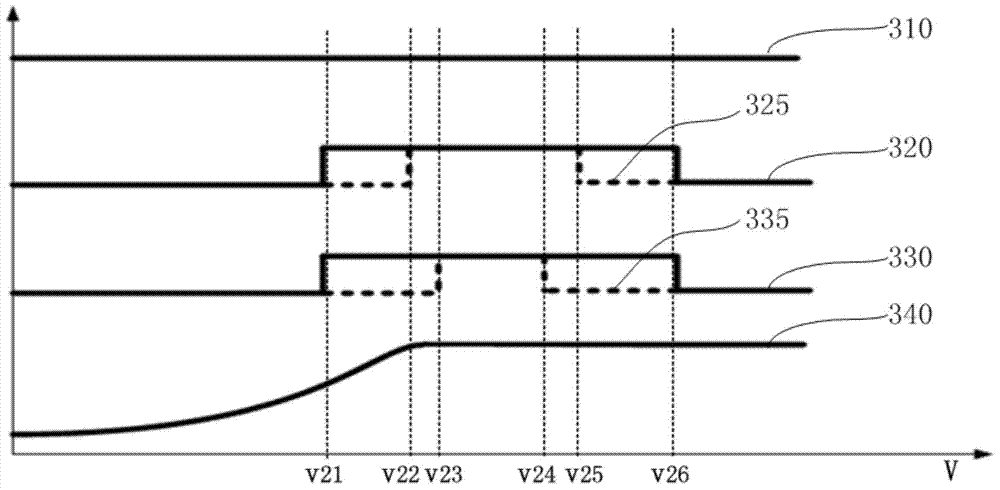

Classifying high-temperature protection method for speed changer

ActiveCN103697147AControl oil temperatureGuaranteed performanceGear lubrication/coolingGearing controlEngineeringProtected mode

The invention provides a classifying high-temperature protection method for a speed changer. The method comprises the steps of A, detecting the temperature of oil liquid of the speed changer to obtain an oil temperature signal and sending the oil temperature signal to a speed changer control unit; step B, controlling the speed changer to be at the basic operation mode or the nth protection class in N protection classes according to the oil temperature signal. Under the basic operation mode and each protection class, the speed changer is configured to respectively adopt the corresponding basic gear shifting mode, the partial protection gear shifting mode which is subjected to gear shifting earlier or later relative to the basic gear shifting mode and a full protection gear shifting mode or a disenabling mode. Furthermore, under each protection class, an engine, a torque converter of the speed changer and a fan are also specially controlled. Due to such design, different protection measures can be adopted by setting different protection classes according to different oil temperatures, so the oil temperature of the speed changer can be controlled under the premise of furthest ensuring vehicle performances, and safety accidents are prevented.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

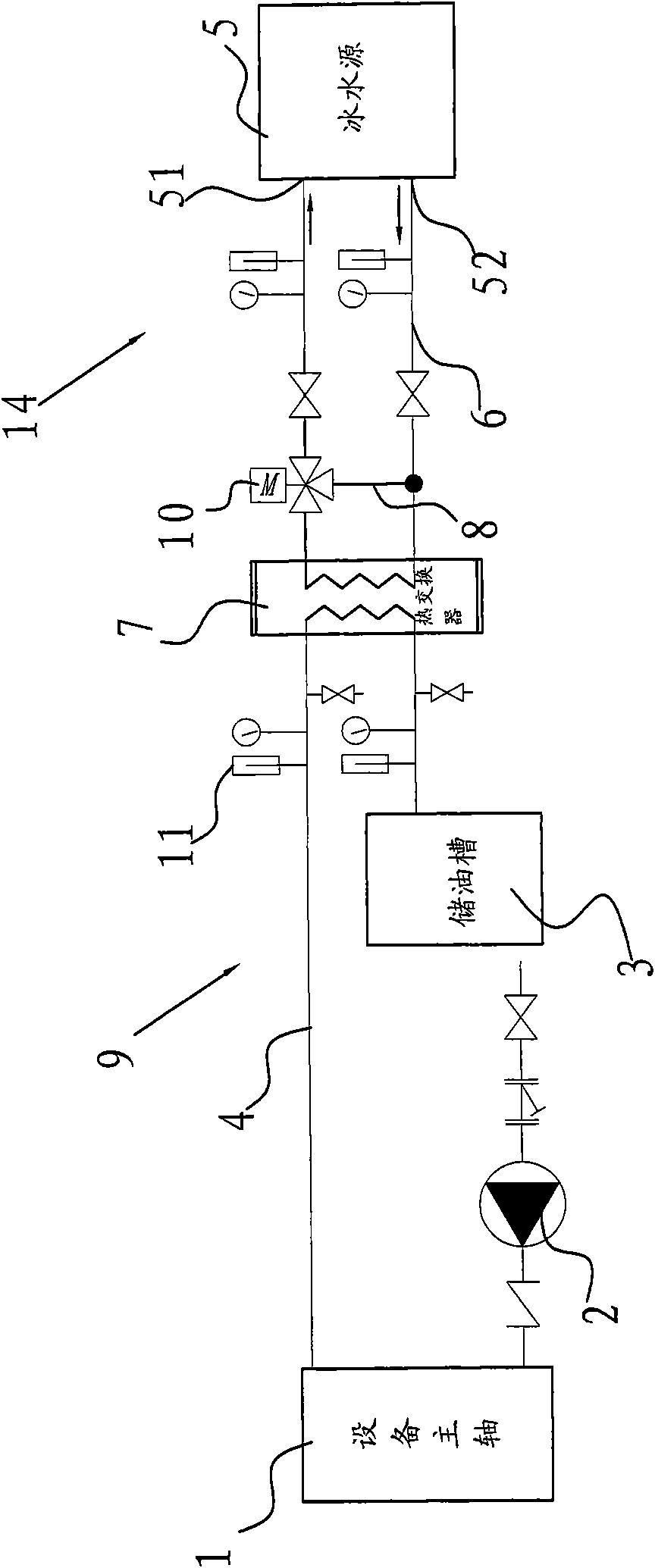

Liquid cooling system for device

The invention relates to a liquid cooling system for a device, which comprises a heat exchanger and two circulation loops including an oil circulation loop and an ice water circulation loop, wherein the oil circulation loop forms a closed loop by connecting an oil storage tank, a circulating pump, a main shaft of the device and the heat exchanger in turn through circulating oil pipes, and the ice water circulation loop forms a closed loop by connecting an ice water source and the heat exchanger in turn through circulating water pipes; and the cooling oil in the oil circulation loop and the ice water in the ice water circulation loop perform heat exchange in the heat exchanger so as to cool the oil temperature on the main shaft of the device. The liquid cooling system uses the circulation of a cooling medium ice water of the heat exchanger to take away the heat of oil cooling engine oil, and compared with the prior art, compressors and heat radiators for discharging the heat in a workshop out of the workshop are not needed. The liquid cooling system not only reduces the temperature of a working condition, but also removes a compressor radiator fan and prevents workers from being harmed by occupational diseases caused by dust and the like, and the working condition is comparatively comfortable.

Owner:KUNSHAN DINGXIN ELECTRONICS

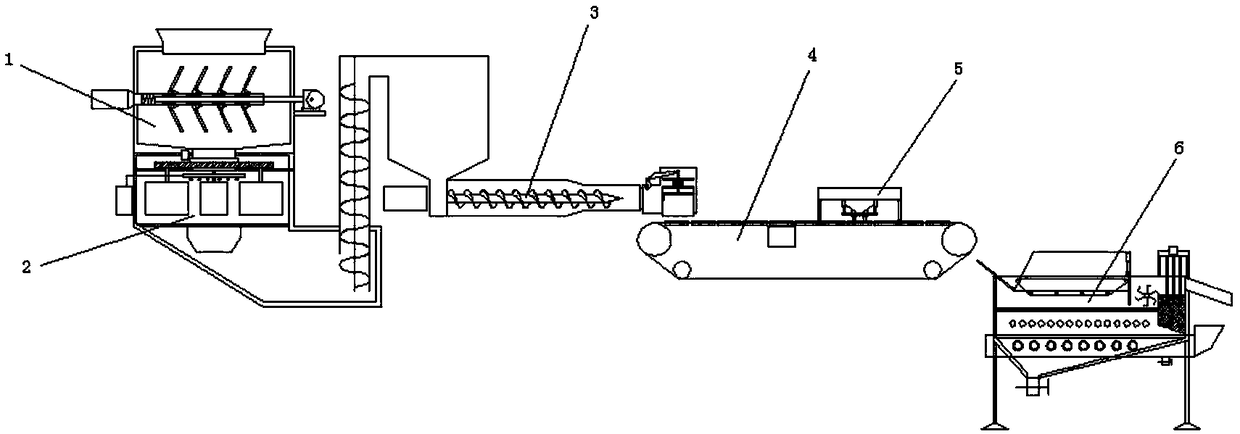

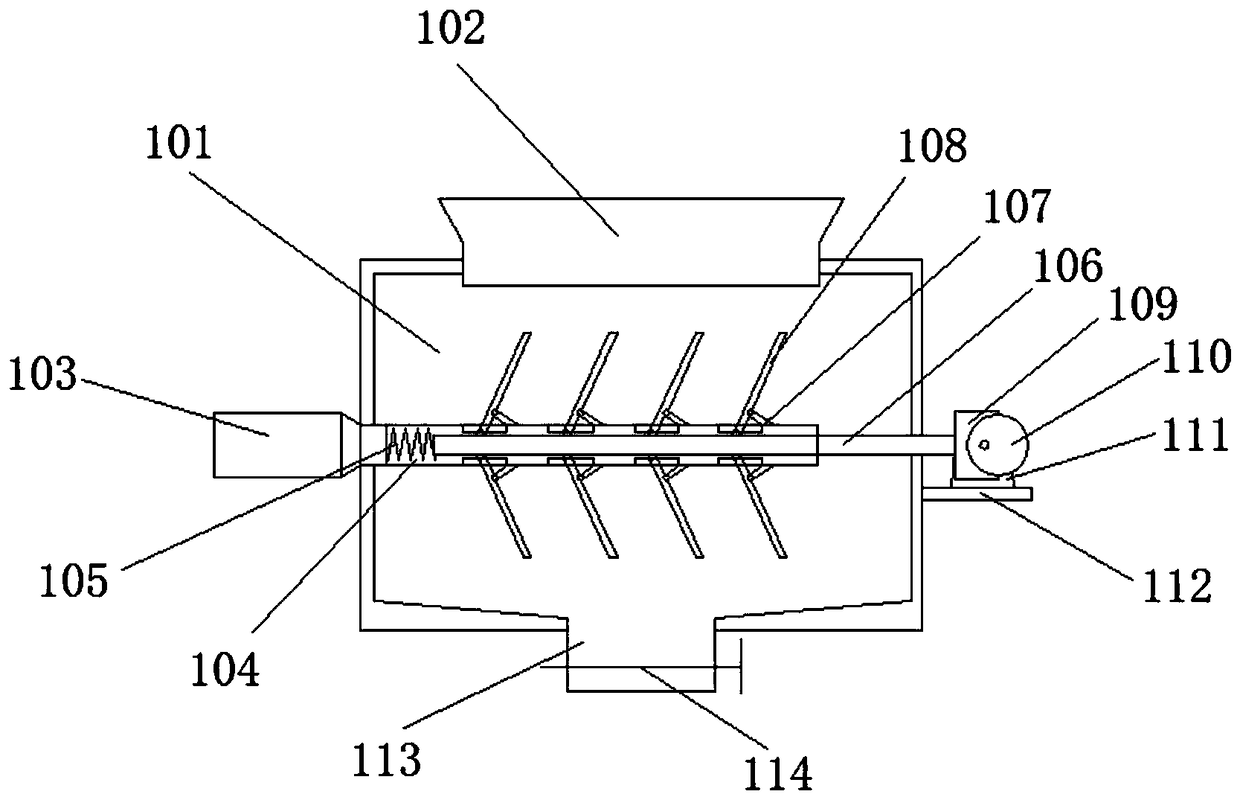

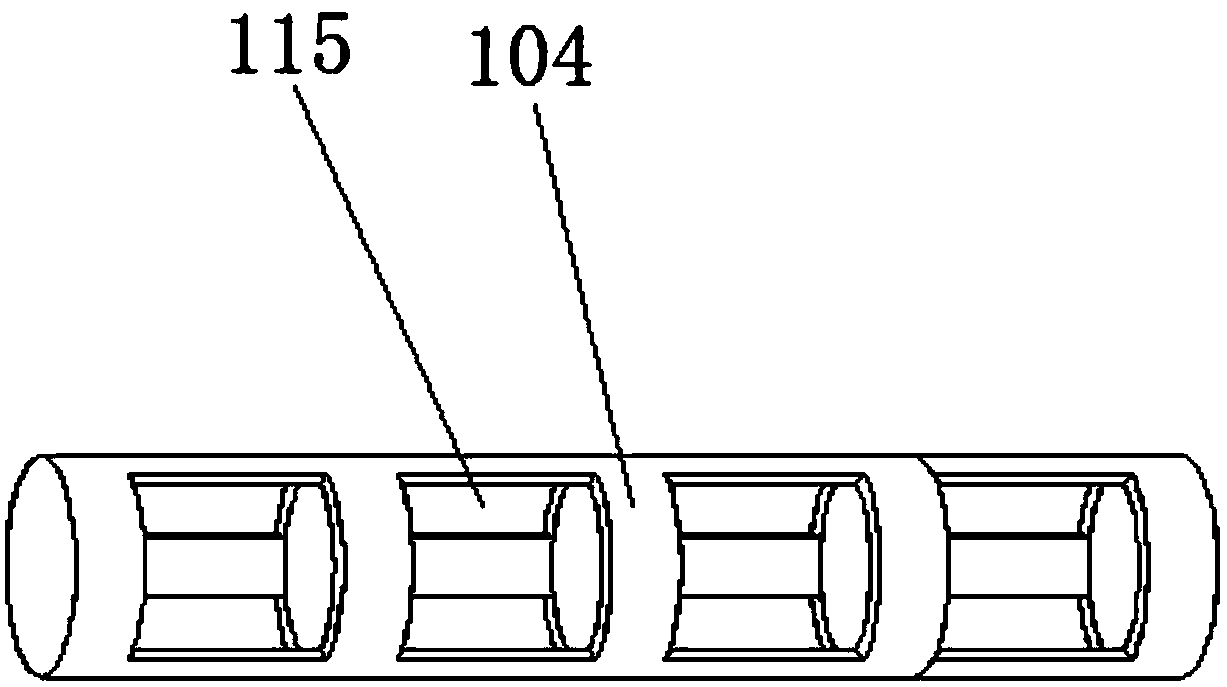

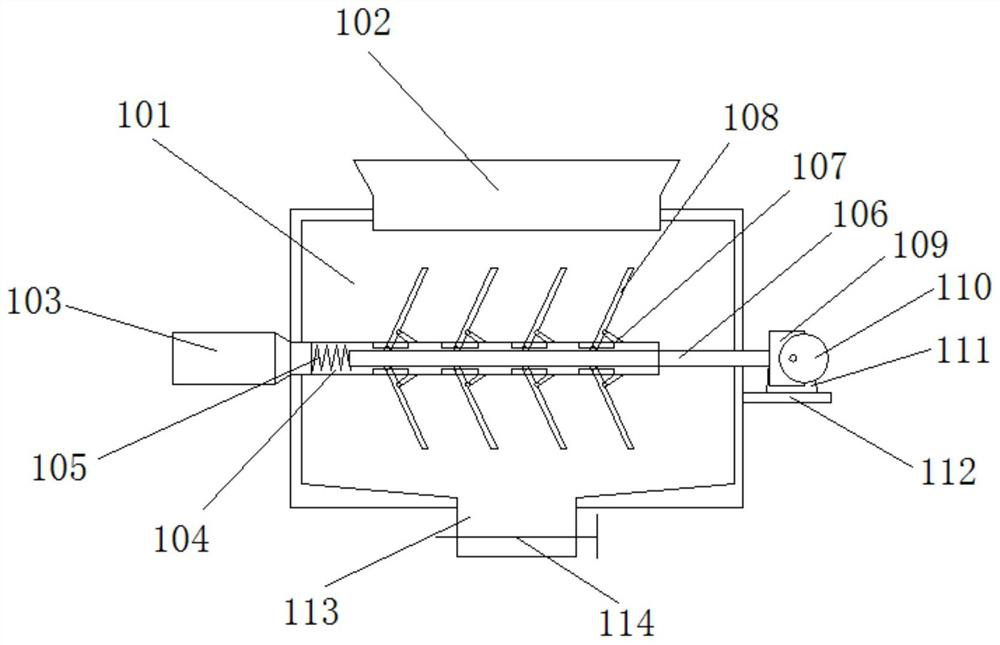

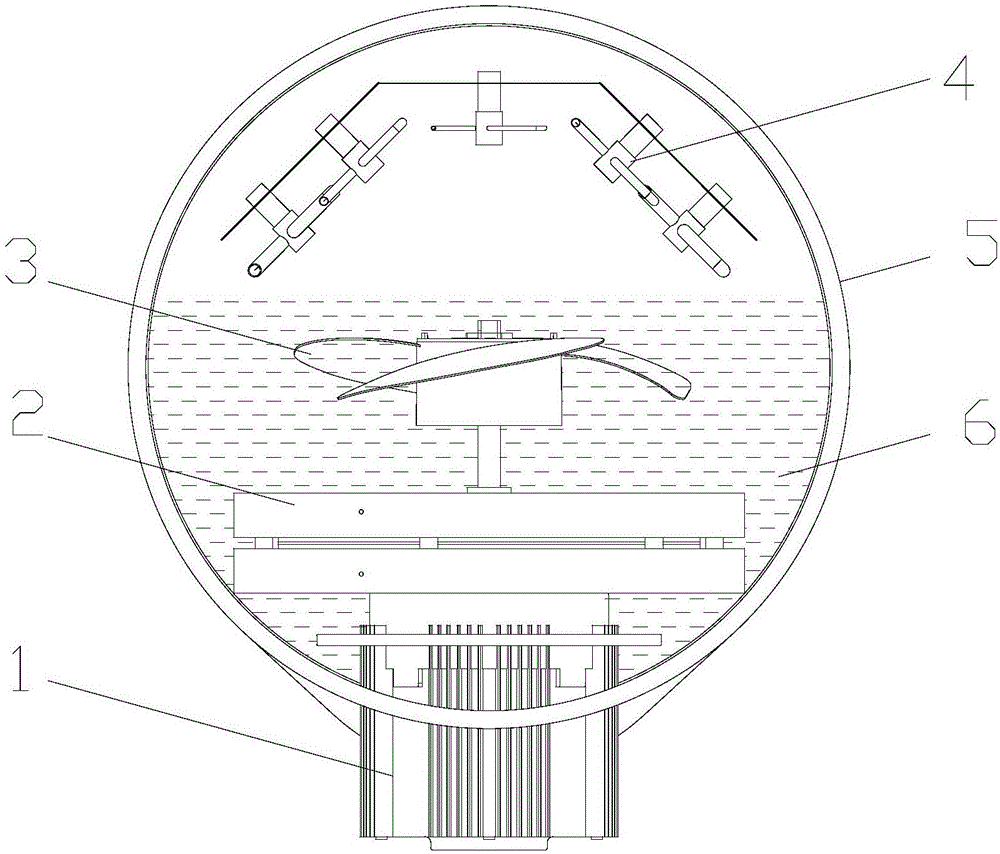

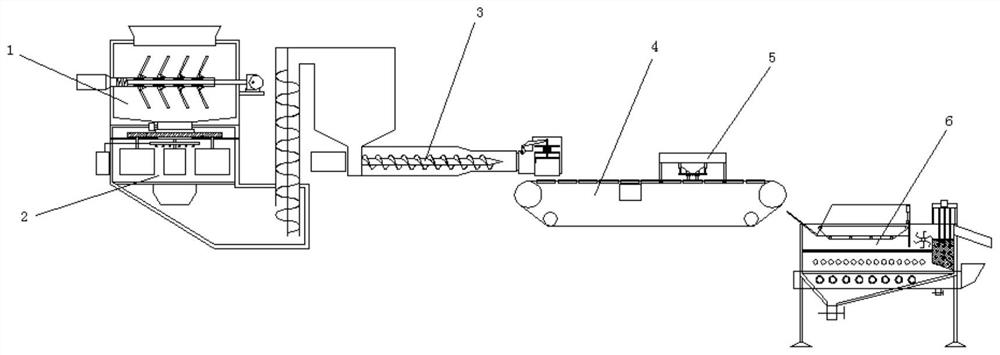

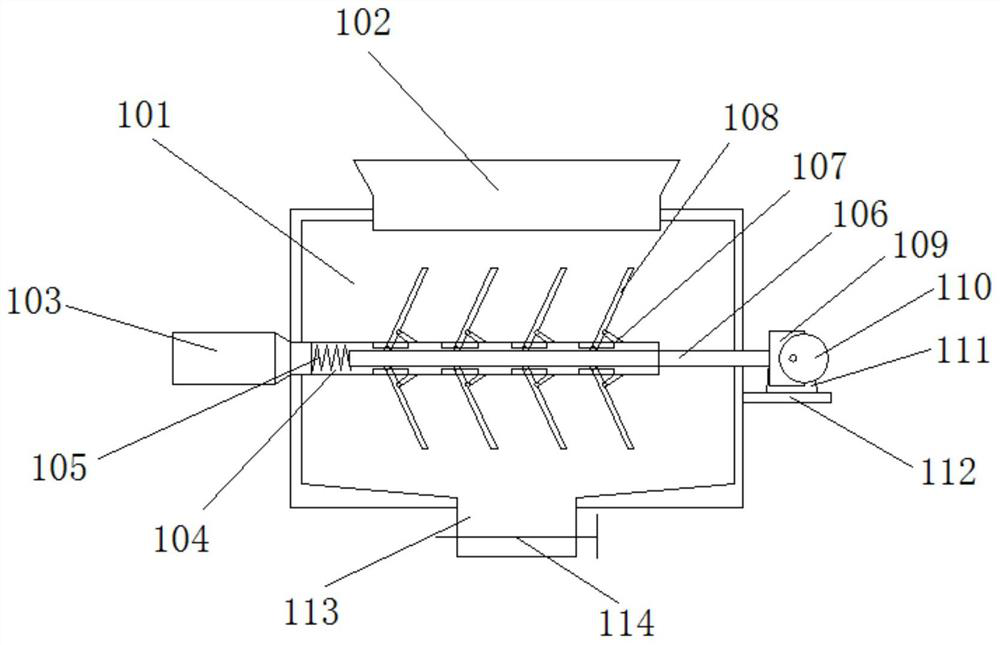

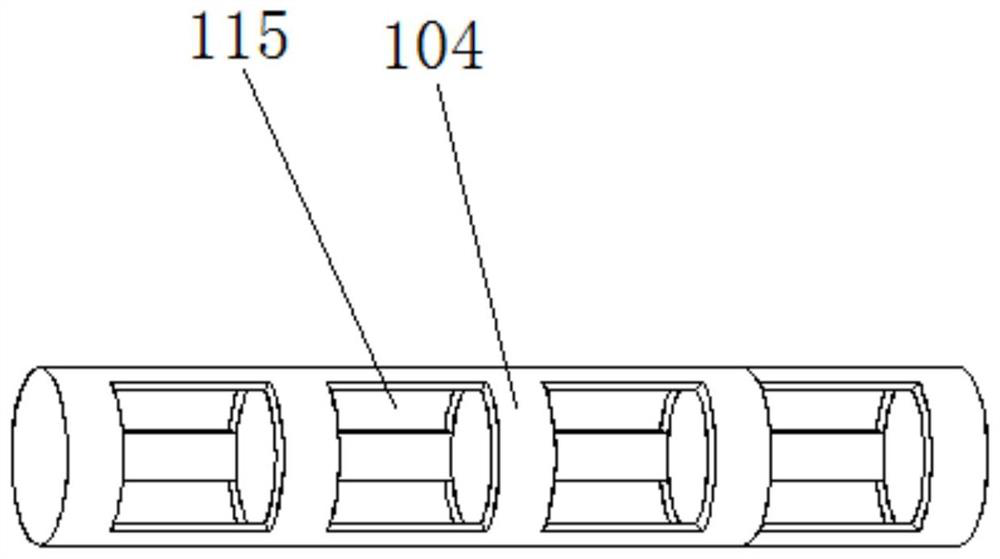

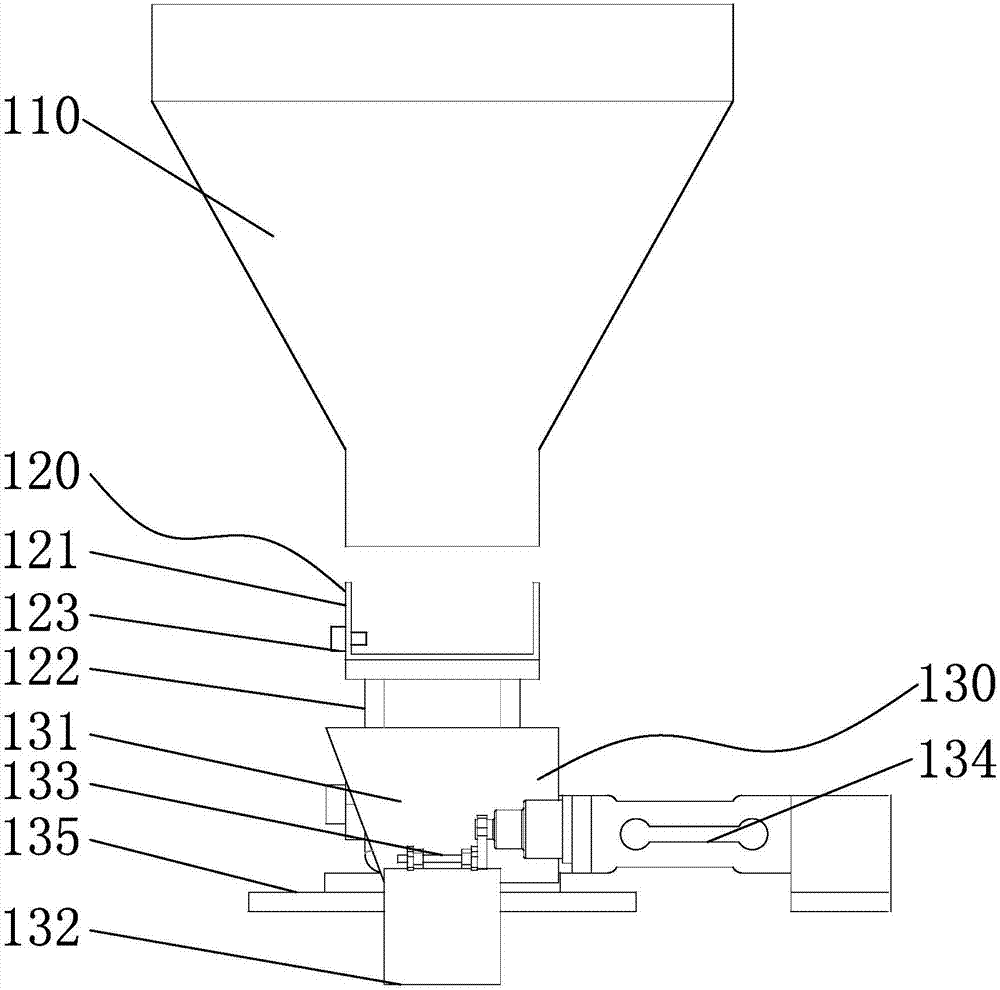

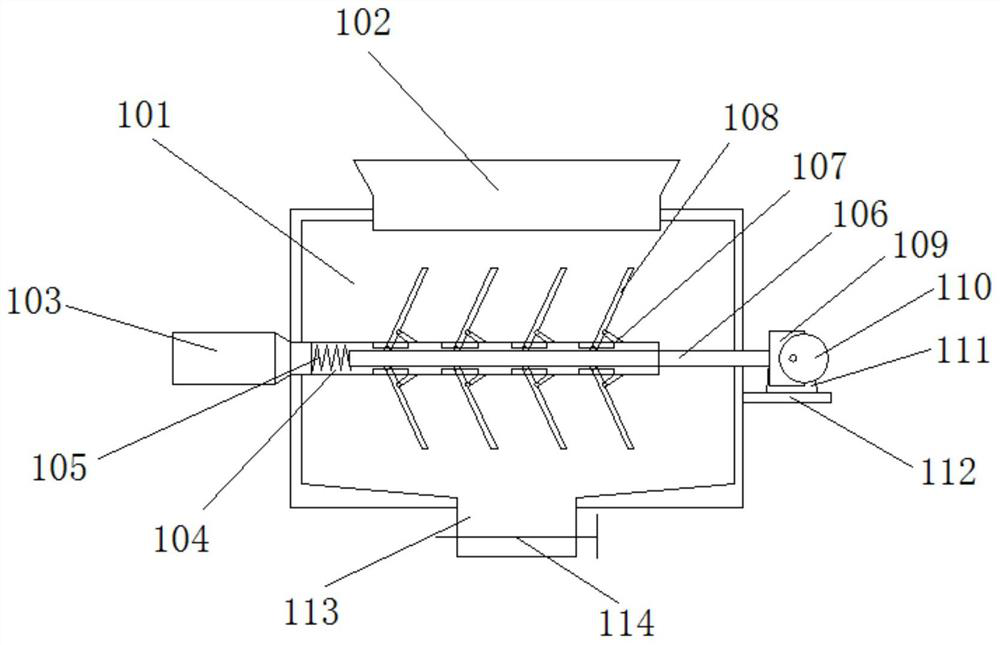

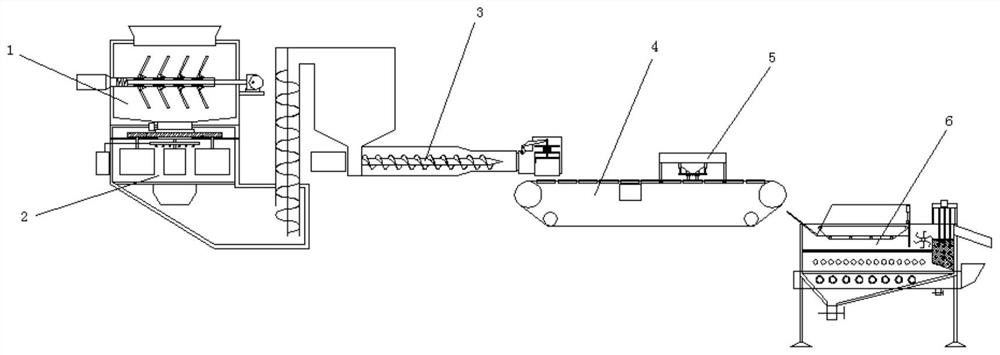

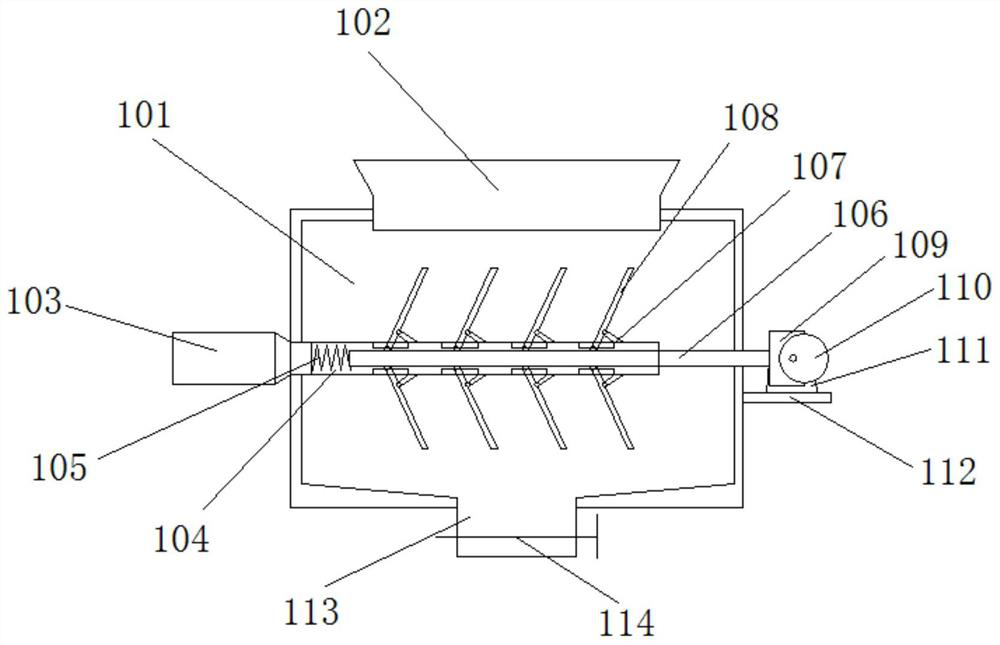

Flour mixing device of deep-fried dough stick machine

ActiveCN109006896AWell mixedImprove the mixing effectMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsDeep fryingAgricultural engineering

The invention discloses a flour mixing device of a deep-fried dough stick machine, and relates to the field of food processing. The flour mixing device includes a mixing mechanism, a dough kneading mechanism is arranged at the bottom of the mixing mechanism, a leavening cabin is connected to the right side of the dough kneading mechanism through a lifting machine, an extrusion machine is fixed tothe bottom of the leavening cabin, a discharging mechanism is arranged at the right end of the extrusion machine, a conveying machine is arranged below the discharging mechanism, a composite shaping mechanism is arranged at the middle of the conveying machine, a stretching detachment mechanism is arranged on the right portion of the conveying machine, and a deep-frying device is arranged at the bottom of the right end of the conveying machine. By adopting the flour mixing device of the deep-fried dough stick machine, a manual deep-fried dough stick making process can be stimulated, after wateris automatically added into flour and is mixed with the flour to make dough, the dough is kneaded, leavened, pressed, shaped and then stretched, finally, the dough is deeply fried, manual labor is greatly reduced, the mouthfeel of deep-fried dough sticks is ensured, the deep-fried dough sticks are efficiently and rapidly made, and the flour mixing device is suitable for being used in breakfast stores.

Owner:张乐

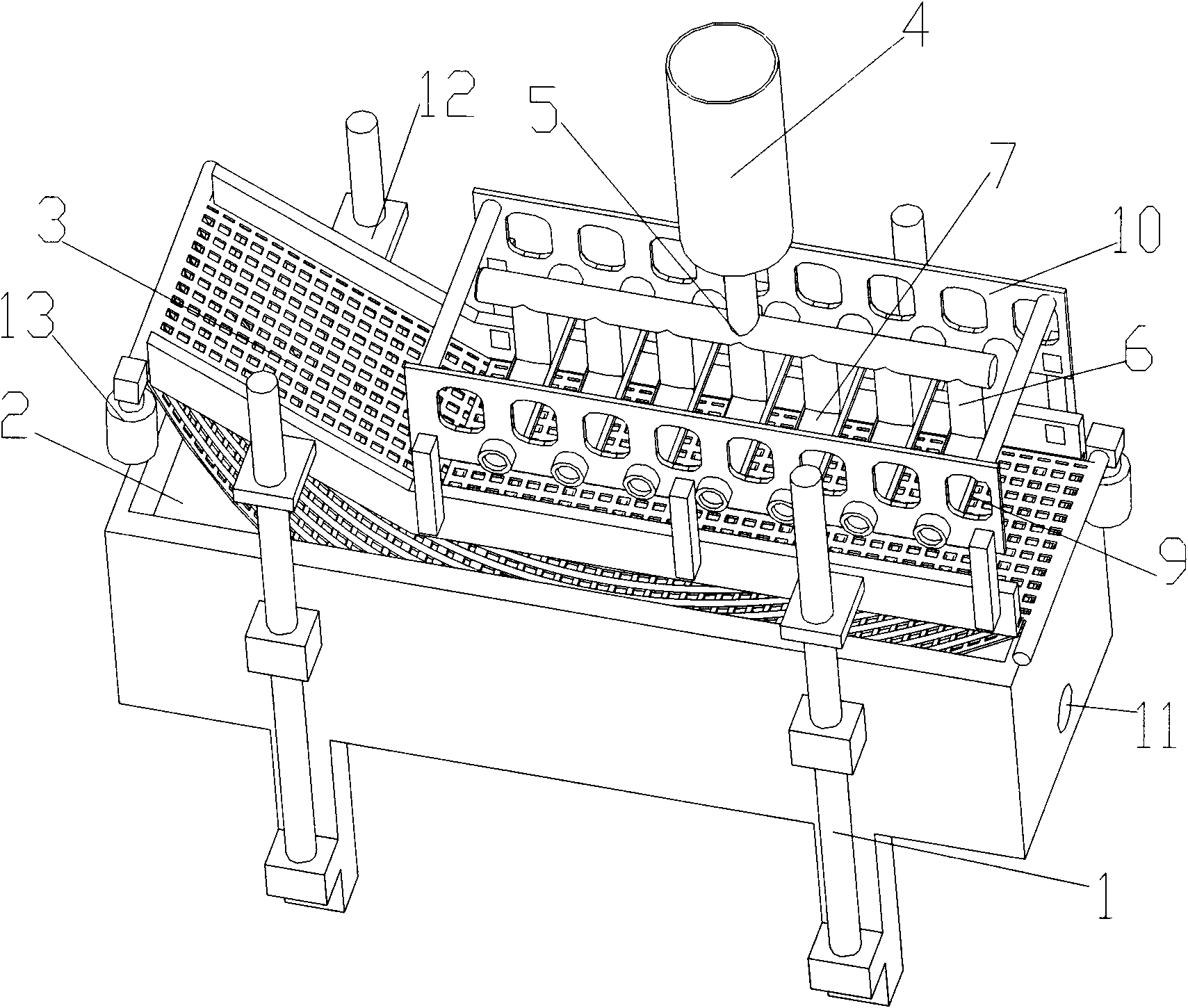

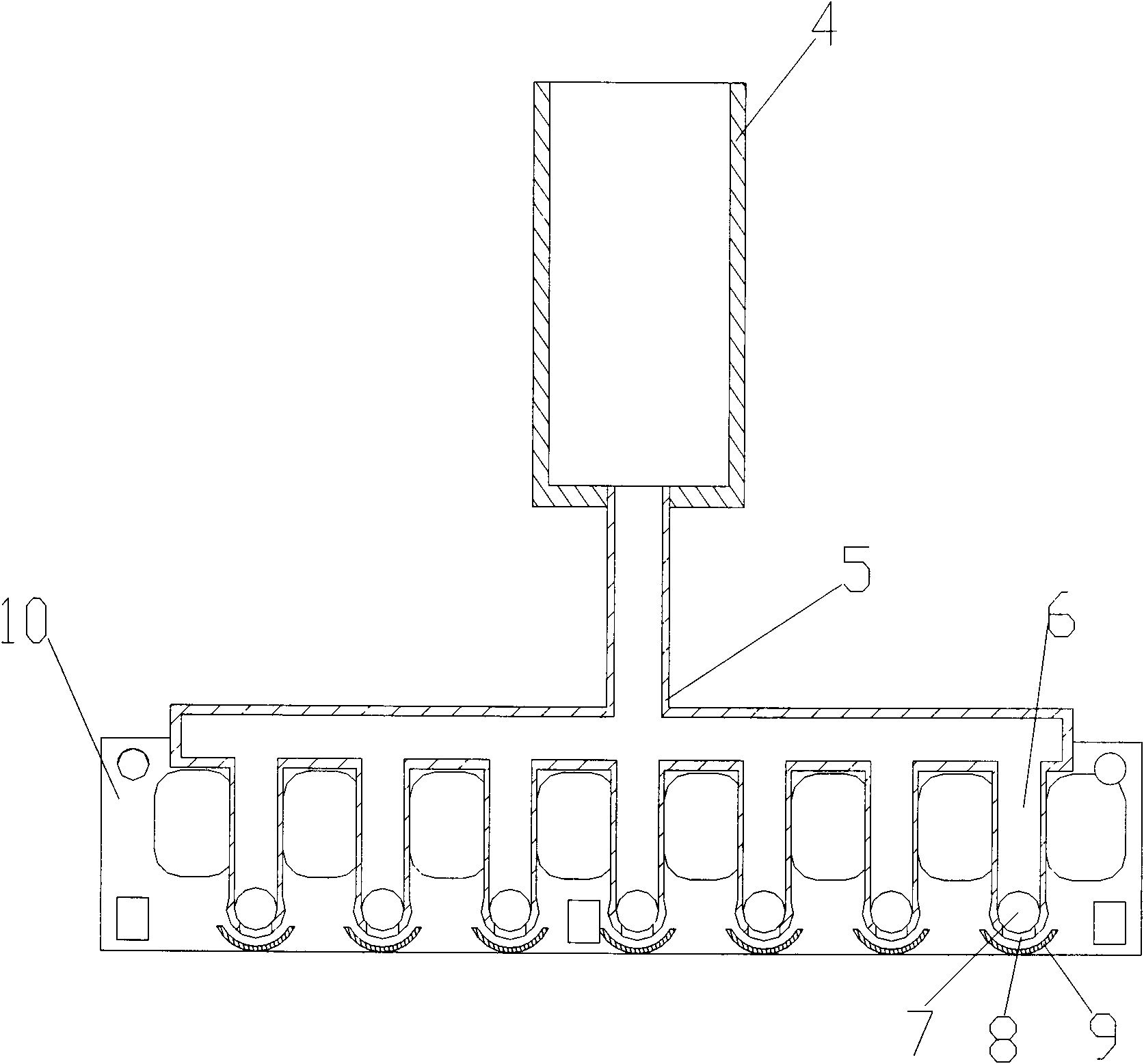

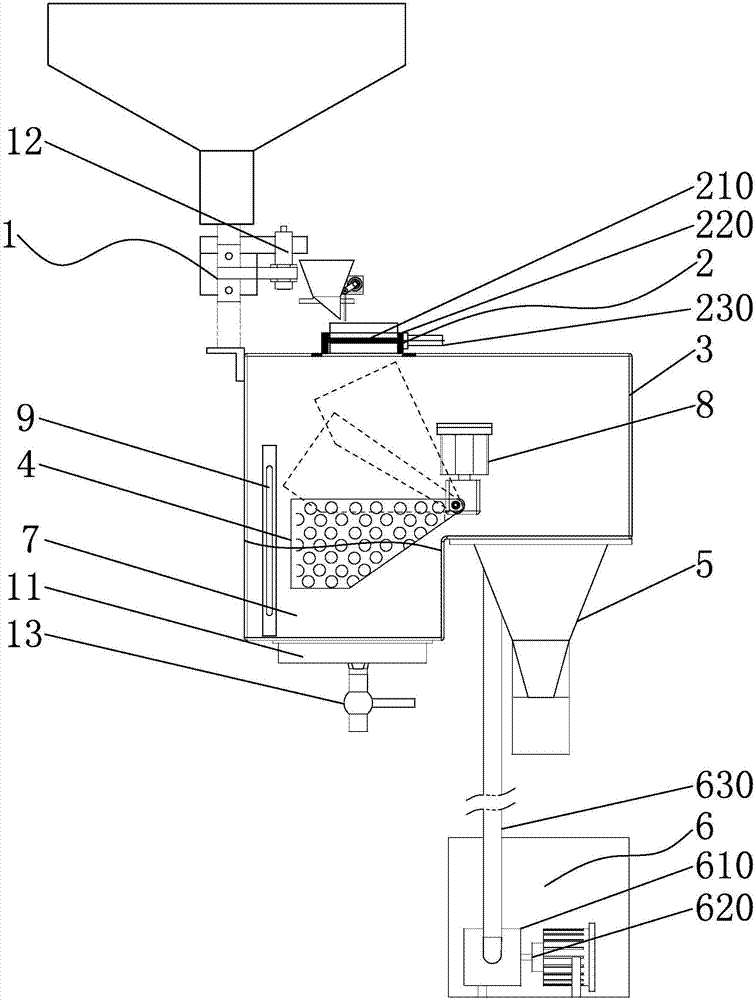

Oil-curtain-type frying machine

InactiveCN102986755AAchieve recyclingEffective control of oil temperatureOil/fat bakingRetention periodOil temperature

The invention discloses an oil-curtain-type frying machine which comprises an oil storage tank, a fixing device, a conveying device and an oil way device, wherein the fixing device comprises an underframe, a support plate fixed on the underframe and used for supporting the conveying device, and a supporting rack fixed on the support plate and used for supporting the oil way device; the oil storage tank is fixed on the underframe; the conveying device comprises a conveyer belt and a driving mechanism, wherein the oil way device comprises an oil tank and an oil pipe communicated with the oil tank; the oil pipe is provided with multiple branch pipes; the branch pipes are correspondingly communicated with oil ducts; arc-shaped grooves are correspondingly arranged below the oil ducts; and the peripheral surfaces of the oil ducts are provided with multiple oil leak holes. The oil-curtain-type frying machine is used for recycling oil and effectively controlling the oil temperature; and a warm oil curtain can be used for protecting the most frangible coating layer on the food, maintaining the original characteristics of products, improving the heat exchange efficiency, further improving the productive capacity, reducing the oil absorption rate of the products, keeping the tastes of the products fresh and ensuring the long retention periods of the products.

Owner:SUZHOU YOUI FOODS

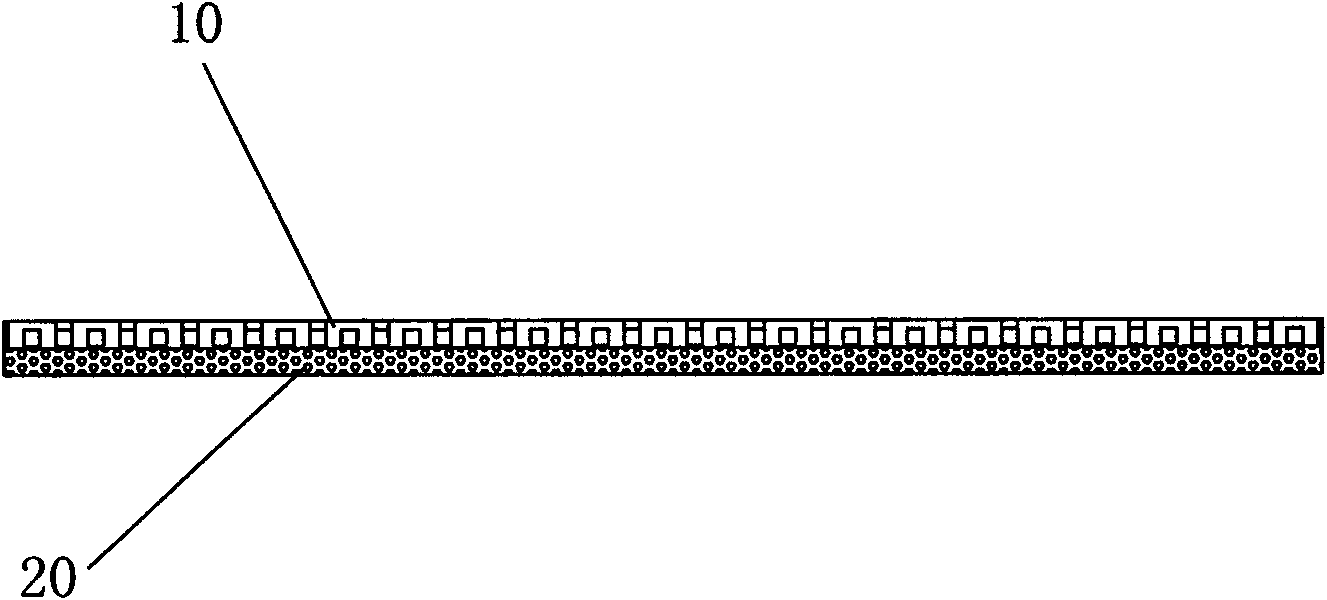

Composite packing material and manufacturing method thereof

InactiveCN101628646AGood lookingImprove buffering effectFlexible coversWrappersHeating oilEngineering

The invention relates to a packing material, in particular to a composite packing material compounding pearl wool with air bubble cloth and a manufacturing method thereof. The composite packing material comprises a substrate which is made of the pearl wool, wherein the outer side part of the pearl wool is pasted with the air bubble cloth, and the pearl wool and the air bubble cloth are extruded and pasted after the surfaces of the pearl wool and the air bubble cloth are melted at high temperature. The composite packing material has the advantages that the pearl wool and the air bubble cloth are compounded to generate a new packing material, thereby improving the properties of the pearl wool and the air bubble cloth and deficiencies; the interior of a film coating machine is filled with heating oil, and the temperature of the heating oil can be controlled by adjusting the amount of heating current so as to control the temperature of a roller; after the pearl wool and the air bubble cloth pass through the roller, and the roller melts the surfaces of the pearl wool and the air bubble cloth at high temperature and then pastes the pearl wool and the air bubble cloth together by extruding. The invention enhances the appearance and the buffering performance of a product singly made of the pearl wool or the air bubble cloth, and the air bubble cloth improves the buffering performance of the packing material, thereby guaranteeing the safety factor of the product of a client in the process of transport. Meanwhile, the pearl wool at the inner side has the effect of heat and warm preservation.

Owner:孙和永

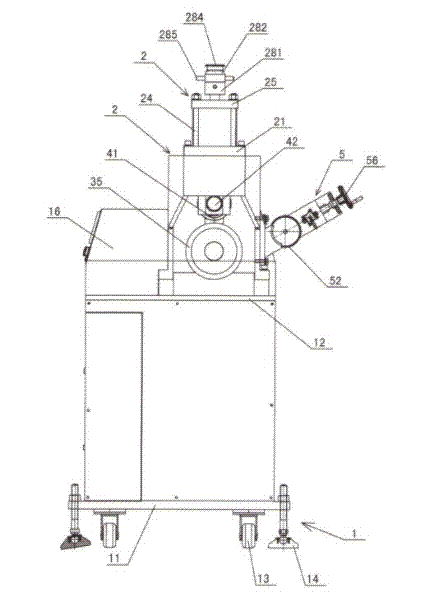

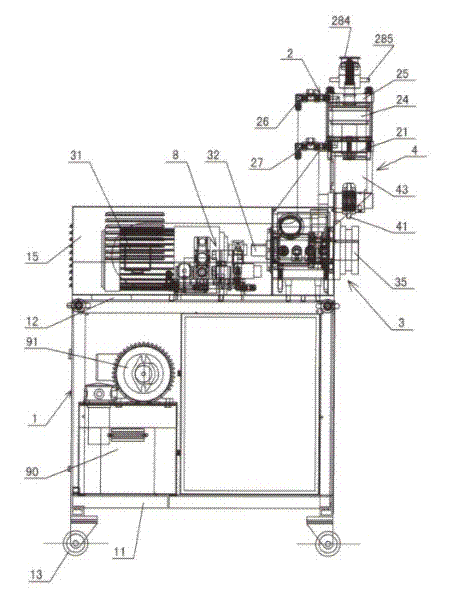

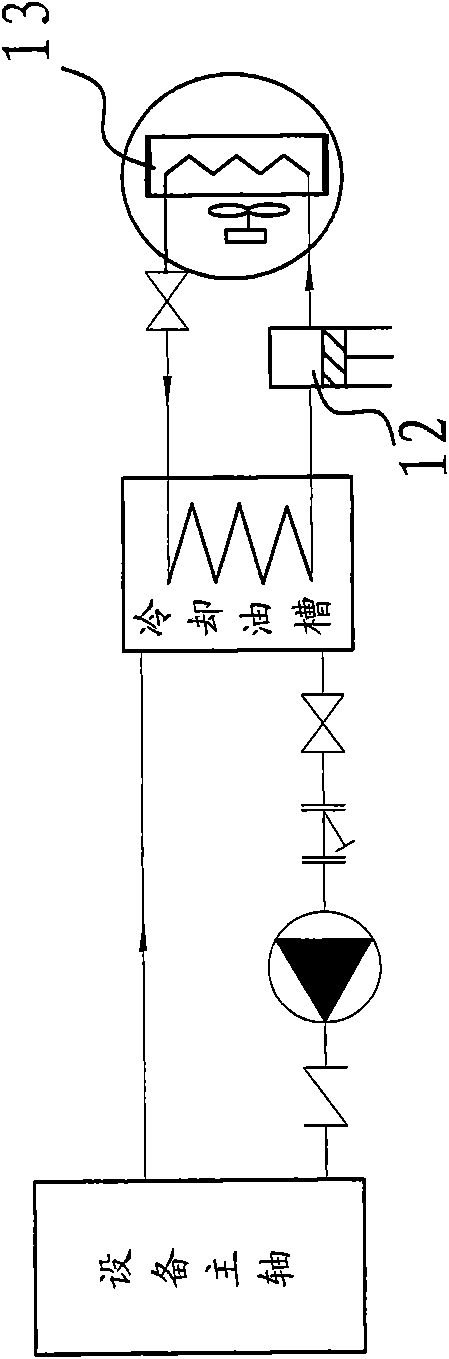

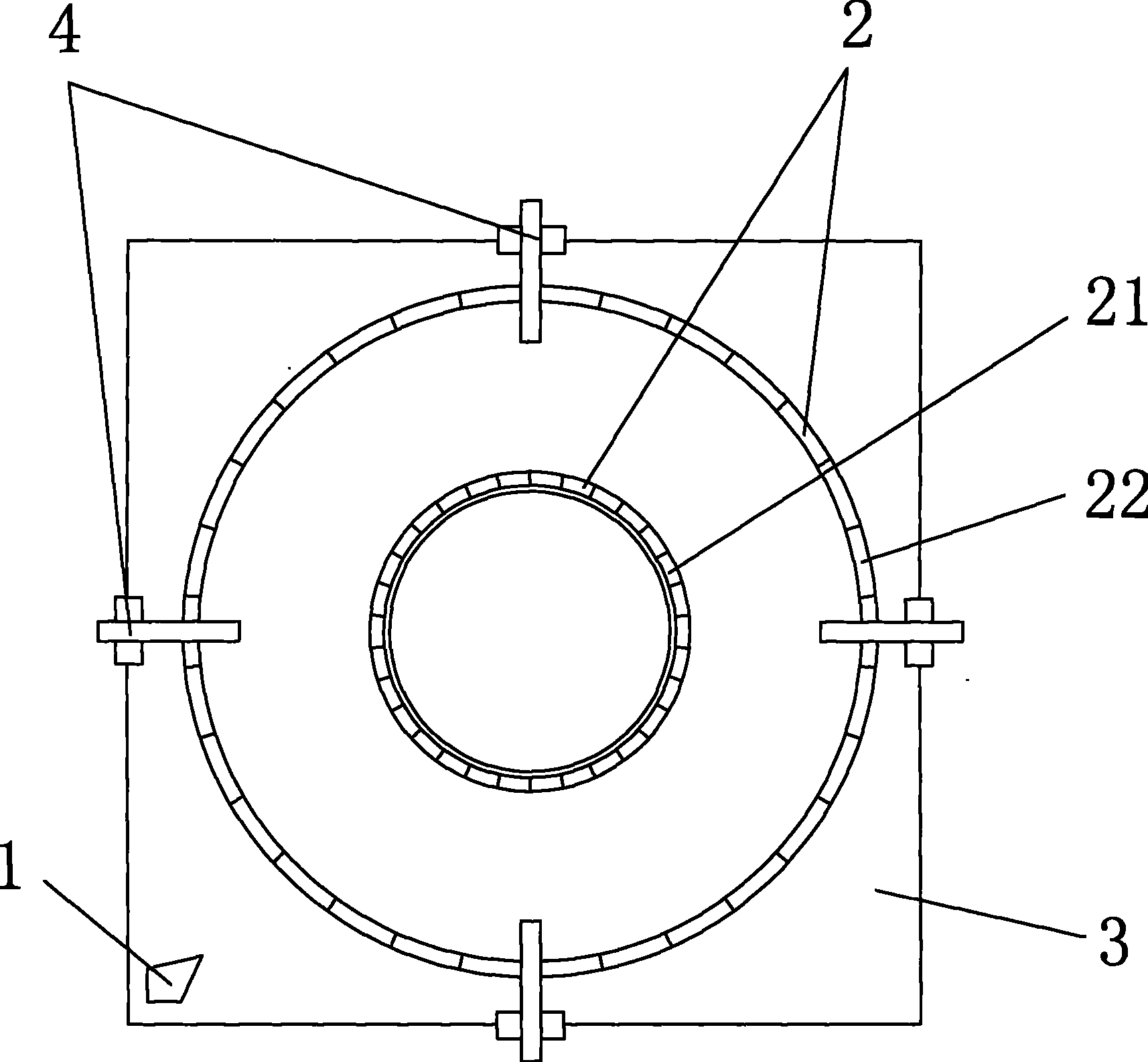

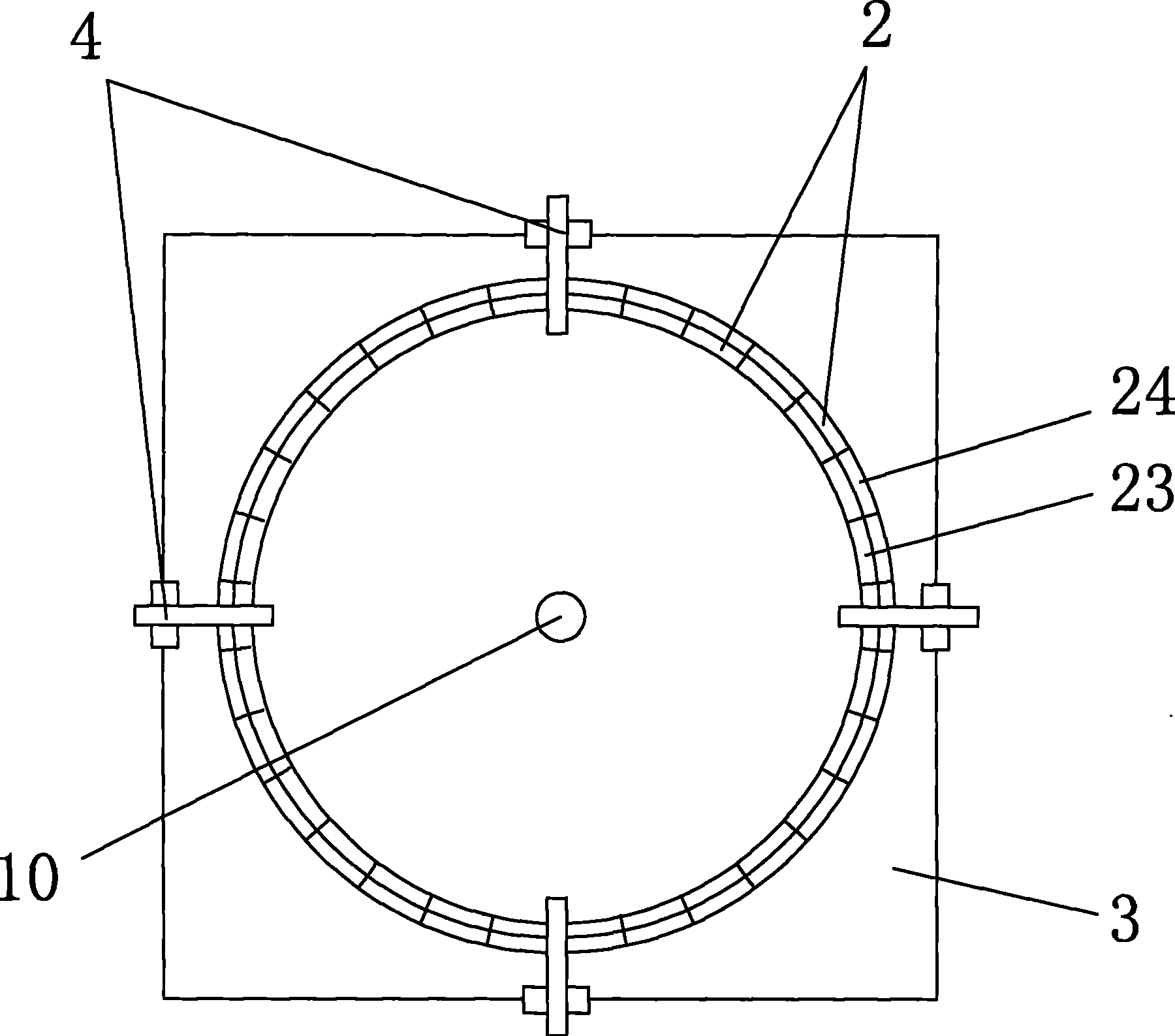

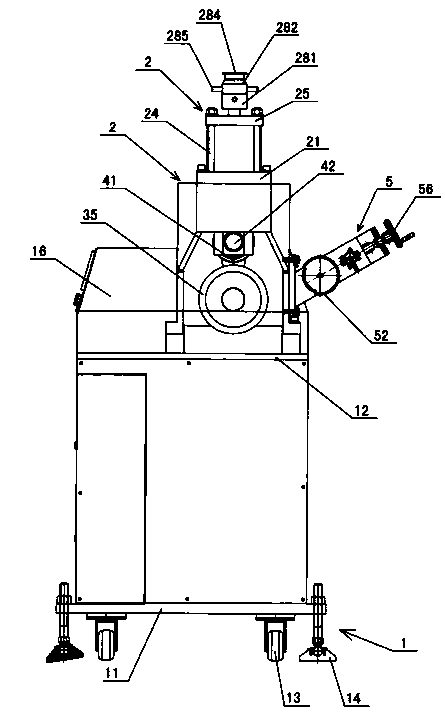

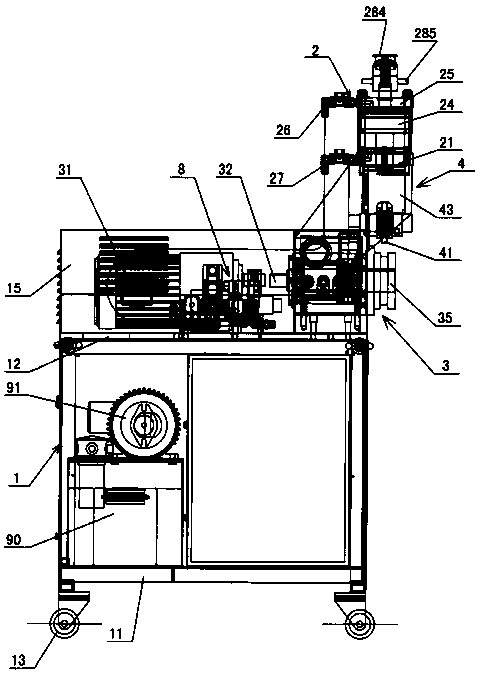

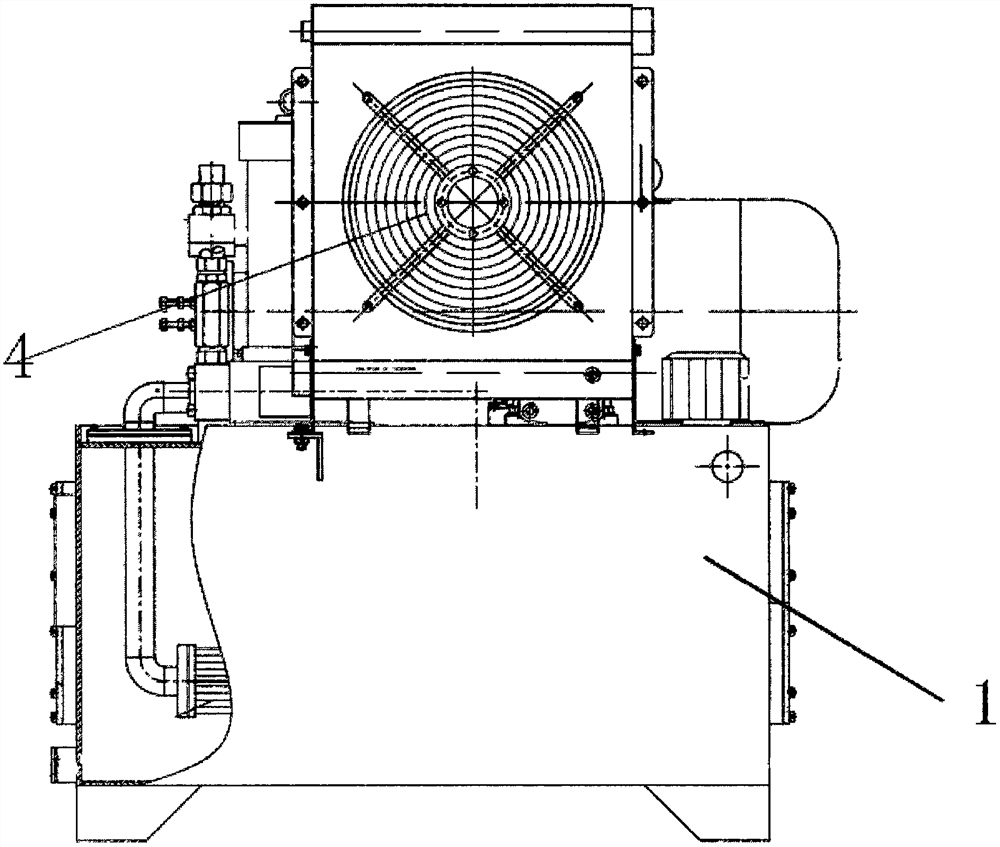

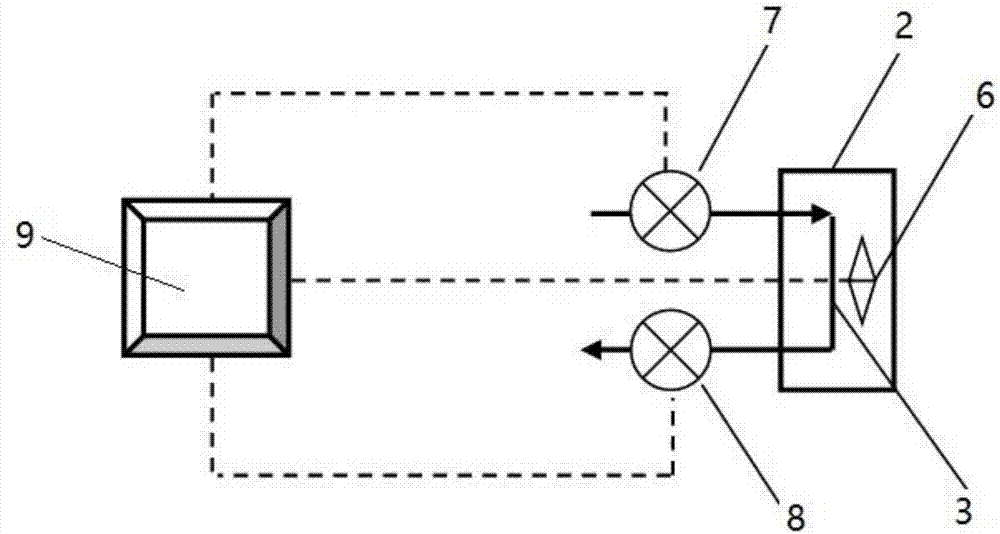

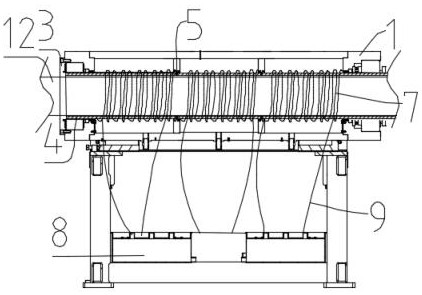

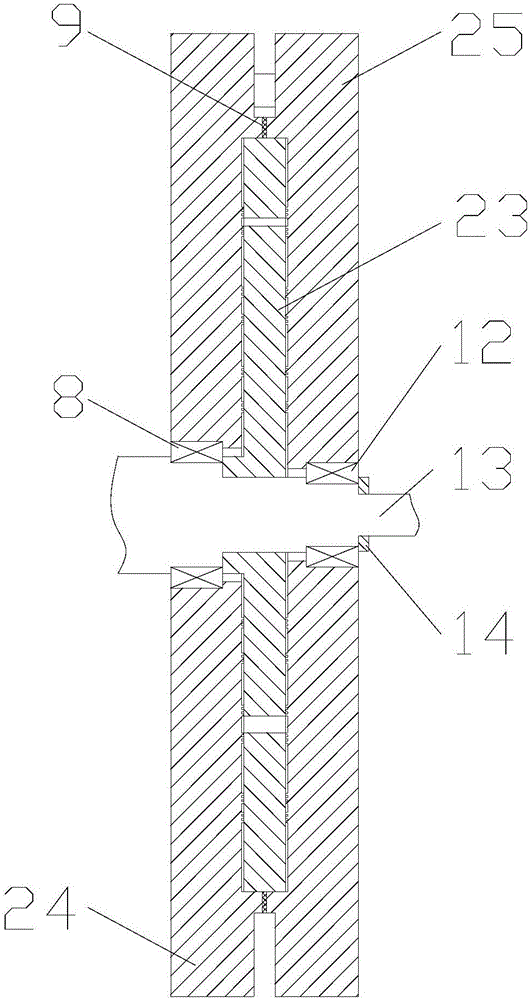

Automatically-controlled constant-temperature circulating and lubricating device

InactiveCN102229065AExtend your lifeControl oil temperatureMaintainance and safety accessoriesElectricityControl system

The invention discloses an automatically-controlled constant-temperature circulating and lubricating device which comprises a control system (9), an oil storage tank (5), an oil supply pump (3), a plurality of lubricating branches (1), an oil return pump (12), an oil filter (10) and a refrigerating system (8), wherein the oil supply pump (3) is controlled by the control system (9) and connected with the oil storage tank (5); the plurality of lubricating branches (1) are used for supplying oil for corresponding lubricating oil supply points and connected with the oil supply pump (3); the oil return pump (12) is controlled by the control system (9) and connected with a machine oil pool (3); the oil filter (10) is connected with the oil return pump (12); and the refrigerating system (8) is arranged between the oil return pump (12) and the oil storage tank (5) and connected with the control system (9). According to the automatically-controlled constant-temperature circulating and lubricating device, in the process of recycling the used lubricating oil, the oil temperature of the lubricating oil is set by the control system and can be well controlled through the refrigeration of a heat exchanger of the refrigerating system, therefore, the lubricating effect is more ideal, and the service life of the machine unit is favorably prolonged.

Owner:NINGBO JIUYUAN LUBRICATION EQUIP MFG

Anti-dried fire-controlling gas combustion range

ActiveCN101275754BControl supplyReduce or cut off supplyDomestic stoves or rangesLighting and heating apparatusCombustorFire control

The invention relates to a dry burning proof fire knockdown fuel gas oven, particularly a fuel gas oven which not only can intelligently control the size of the fuel gas oven but also can prevent the cookware dry burning for a long time to damage, including a burner, a fuel gas vent, a fuel gas valve, a power supply, a pressure switch, a temperature sensor, a control device, a fuel gas supply device and a control switch, wherein the fuel gas vent is equipped with the fuel gas valve and connected with the fuel gas supply device, the fuel gas valve, the power supply and the pressure switch constitute a close circuit, the temperature sensor, the control device, the power supply and the control switch constitute a control feedback loop, the temperature sensor and the pressure switch are arranged at the center of the fire ring of the burner. Hence the invention provides an oven which can control the size of the flame on the oven and intelligently control the size or cut the fuel gas supply, meanwhile control the temperature of the oil with high detecting precision, low cost, suitable for the large scale industrial production.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

Cooking pot

The invention discloses a cooking pot which comprises a combined pot body. The combined pot body comprises an inner pot and a material bag reaction pot which are sequentially sleeved from inside to outside, a specified gap is formed between the inner pot and the material bag reaction pot to form a reaction area, a reaction material bag is placed in the reaction area, and a closed ring connected with the upper end of the material bag reaction pot is arranged at the upper end of the inner pot. The cooking pot is characterized in that at least three pressure release valves are arranged on the closed ring and can adjust pressure release intensity. Heat is released by the aid of reaction of a heating bag and water, the water vapor temperature is increased by changing a pressure value in a reaction vessel, multiple cooking modes can be realized, the oil temperature can be controlled when the cooking pot is used for stir-frying, deep frying and frying, and oil smoke harming human body health is avoided.

Owner:武小娴

Method for processing chips with low temperature vacuum oil dehydration technology

The invention relates to a method for processing chips with a low temperature vacuum oil dehydration technology. The method comprises the following steps: selection of a potato raw material, peeling, cutting into strips, blanching, pre-cooling, freezing, vacuum oil dehydration and vacuum de-oiling. The chips processed with the method have the advantages that the original color and nutritional value of potatoes are greatly retained, characteristics of full shape and crisp taste are achieved, carcinogenic substances such as acrylamide in the frying process are effectively reduced, and the oil content of the chips is more effectively reduced; the chips are green and healthy fast food products.

Owner:内蒙古薯都凯达食品有限公司

Low-manganese cast grinding ball

ActiveCN104109796AImprove performanceReduce adverse effectsFurnace typesHeat treatment furnacesRoom temperatureManganese

The invention discloses a low-manganese cast grinding ball which is composed of the following components in percentage by mass: 2.1-2.8% of C, 0.3-0.8% of Si, 0.08-0.6% of Mn, 10-23% of Cr, 0-0.05% of P, 0-0.05% of S, 0.03-0.06% of Al and the balance of Fe. The grinding ball is prepared by the following steps: S1: weighing the raw materials according to percentage by mass, smelting, and carrying out casting molding to obtain a cast grinding ball semi-finished product; and S2: putting the grinding ball semi-finished product obtained in the step S1 into the furnace, heating to 510-530 DEG C, keeping the temperature for 140-160 minutes, heating to 740-760 DEG C, keeping the temperature for 140-160 minutes, heating to 880-960 DEG C, keeping the temperature for 140-160 minutes, heating to 970-1040 DEG C, keeping the temperature for 140-160 minutes, carrying out oil quenching in quenching oil with the temperature of 75-120 DEG C for 3-14 minutes, putting in a holding furnace, heating from room temperature to 300-380 DEG C at the heating rate of 20-100 DEG C / hour, keeping the temperature for 470-490 minutes, and slowly cooling to room temperature within 450-470 minutes to obtain the cast grinding ball. The cast grinding ball has favorable comprehensive properties.

Owner:宁国东方碾磨材料股份有限公司

Automatic hydraulic channeling machine

The invention relates to an automatic hydraulic channeling machine. A frame part comprises a chassis, a sole plate, a universal wheel, machine legs, a shield and a panel; a hydraulic system comprises a cylinder base, a piston rod, a piston, a cylinder body, an adjusting nut, an adjusting rod and a ruler sleeve; a channeling mechanism comprises a main motor, a power head, a coupler, a spindle, a bearing, a knurl wheel, a pressing wheel guide shaft, a pressing wheel and a pressing wheel shaft; a guide wheel mechanism comprises a guide wheel shaft, a guide wheel, a sliding adjusting knob, an adjusting bolt, a guiding block, a hand wheel, a screw rod, a screw rod slide block and a guide wheel frame; an electric system comprises a pedal switch, an alternated current contactor, an intermediate relay, a breaker, a rectifier, a transformer, a time relay, a buzzer and an indicator lamp; a hydraulic control system comprises an oil tank, an oil pump motor, a gear pump, an oil-way block, a solenoid directional valve, a pressure relay, a flow control valve and an overflow valve; and a working bracket comprises a bracket base, a bracket cylinder sleeve, a bracket cylinder base, a bracket cylinder, a bracket piston rod, a bracket plate, a bracket lifting device, a quick connector and a high-pressure oil pipe.

Owner:浙江唯特利图伟管道设备有限公司

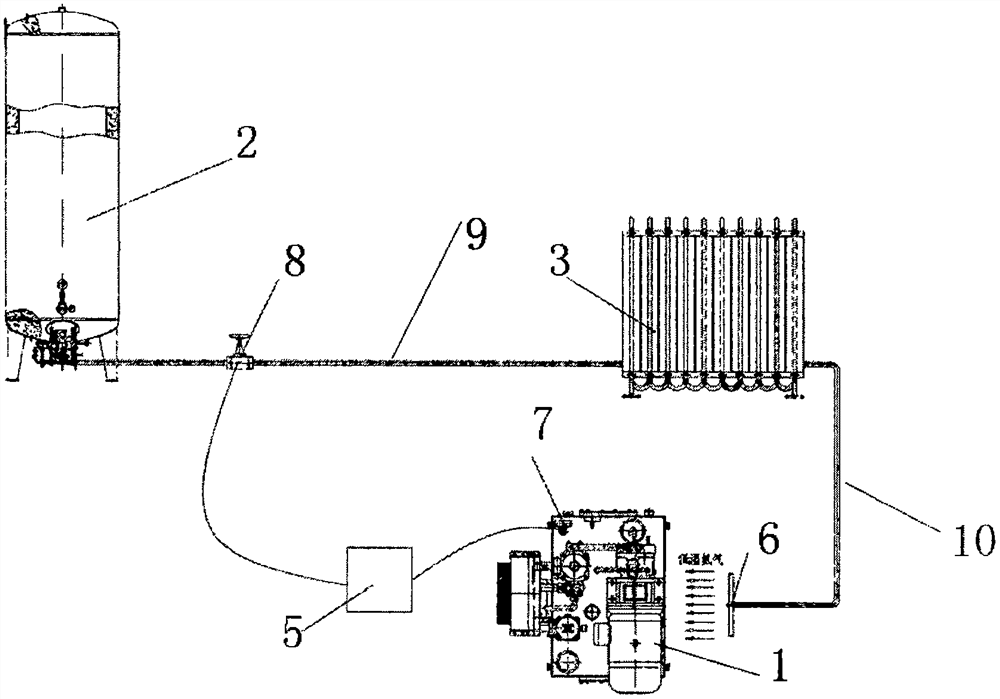

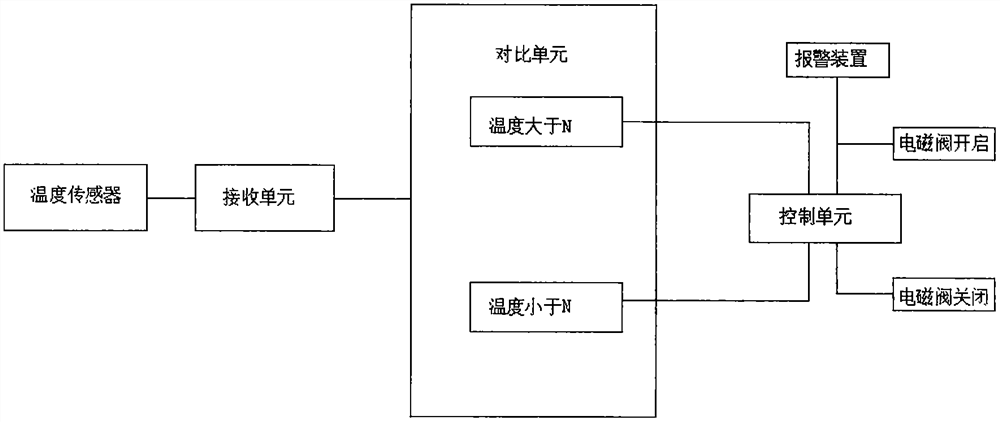

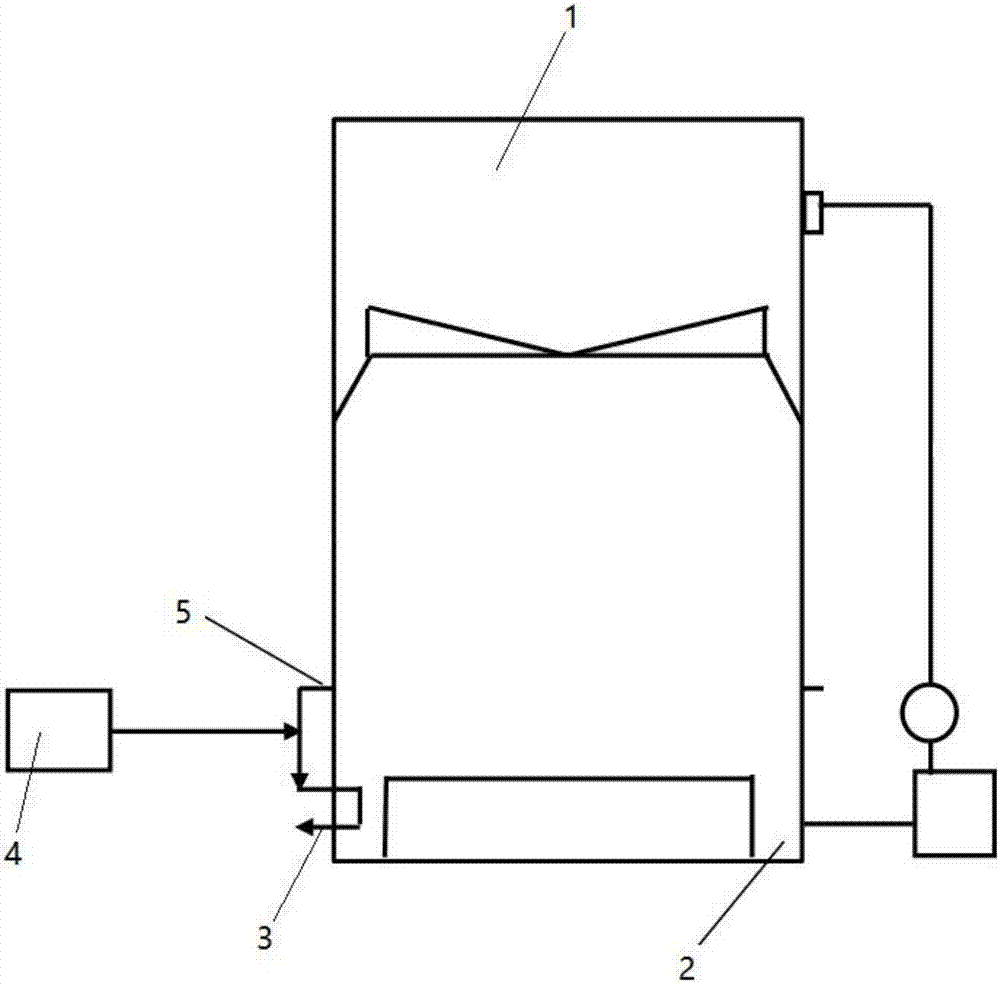

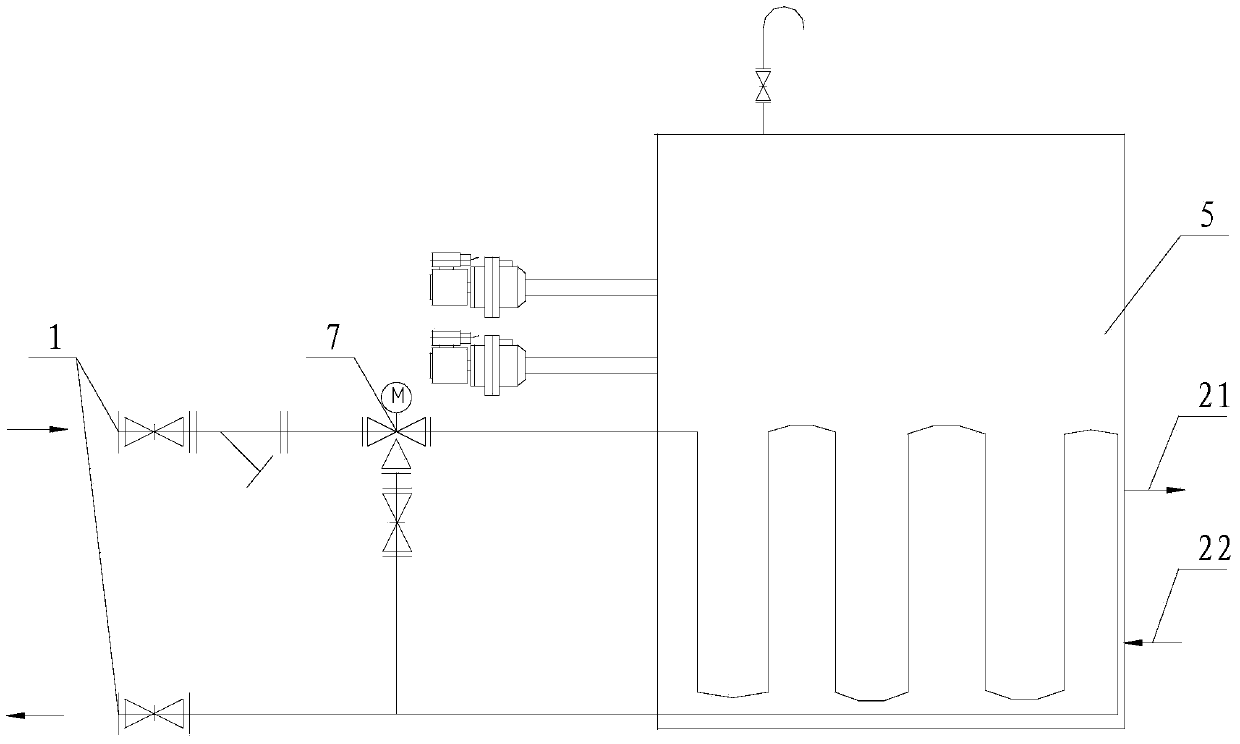

Hydraulic station novel closed control system

InactiveCN113374759AEffective control of oil temperatureControl oil temperatureFluid-pressure actuator testingServomotor componentsControl systemOil temperature

The invention discloses a hydraulic station novel closed control system. The system comprises a hydraulic station, a liquid nitrogen storage tank, a vaporizer and a central processing unit, the hydraulic station comprises an oil tank, an oil suction filter is arranged in the oil tank, and an air cooler is arranged at the top end of the oil tank; the hydraulic station is provided with a temperature sensor, and the temperature sensor is in signal connection with the central processing unit; and according to the system, the oil temperature of the hydraulic station can be effectively controlled within a reasonable temperature range, so that all parts (such as a hydraulic valve and various sealing elements) of the hydraulic station are protected, and the service life of the hydraulic station is prolonged.

Owner:HEZE BOILER FACTORY

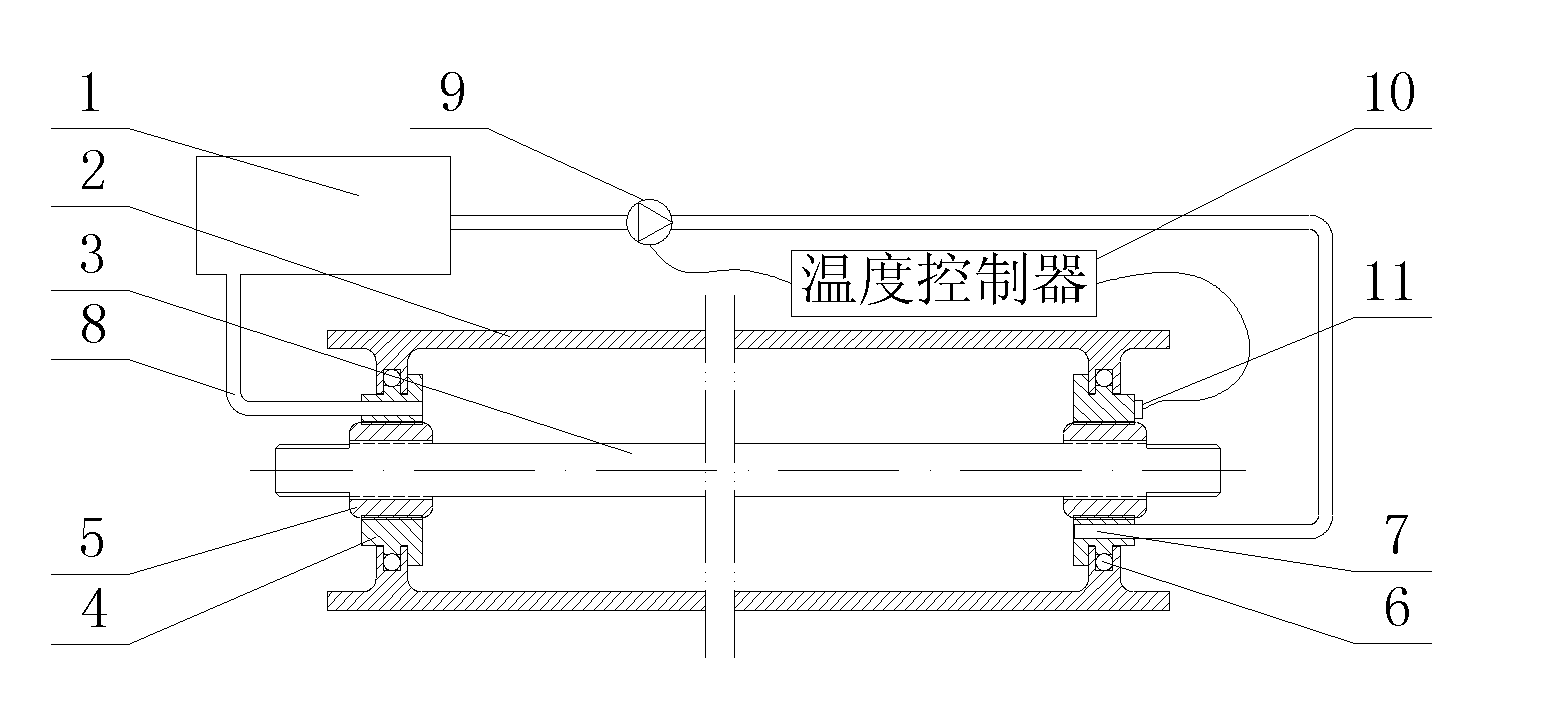

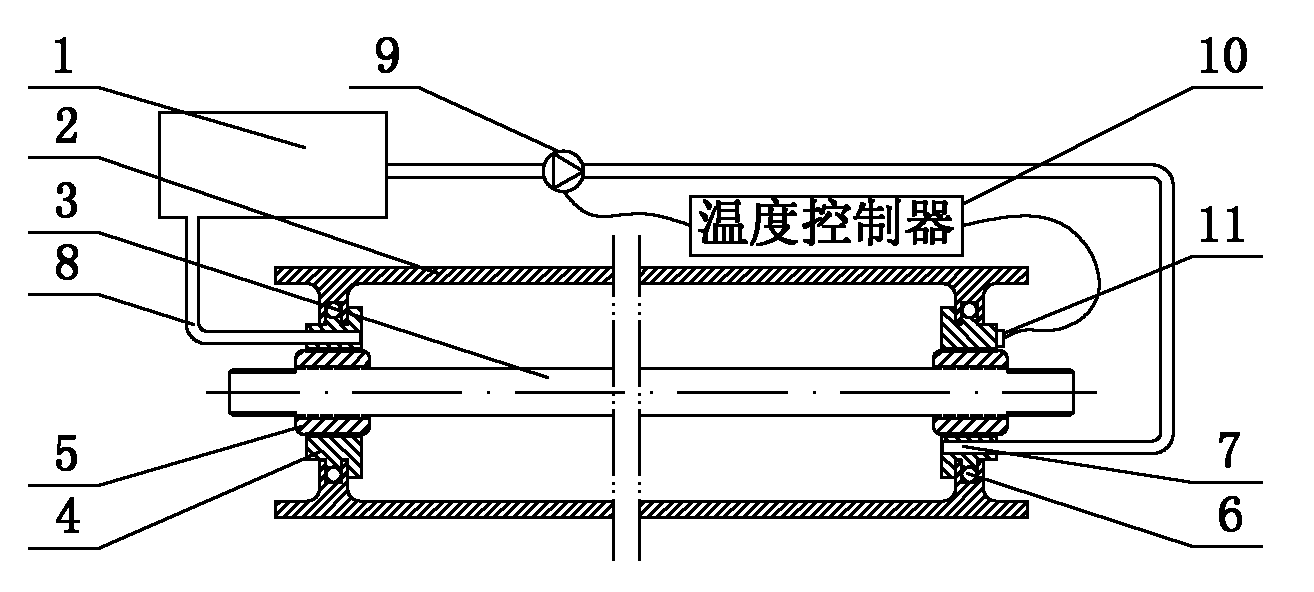

Oil heating system

InactiveCN102423742AControl oil temperaturePrecise control of hydraulic oil temperatureLiquid surface applicatorsCoatingsDrive shaftHydraulic pump

The invention provides an oil heating system, which comprises an oil tank, a roller casing and a driving shaft. Two ends of the roller casing are respectively connected with sealing blocks on the driving shaft through rotary joints, the sealing blocks are fixed on two ends of the driving shaft, the sealing block and the rotary joint are locked and hermetically connected, hydraulic oil apertures are respectively opened on two rotary joints, a hydraulic oil pipe is connected on each hydraulic oil aperture, two hydraulic oil pipes are respectively connected to the oil inlet and the oil outlet of the oil tank, a hydraulic pump is provided on the hydraulic oil pipe of the oil outlet of the oil tank; the hydraulic pump is connected with a temperature controller. The oil heating system has the beneficial effect that high temperature hydraulic oil in the oil tank can be continuously and circularly delivered in the roller casing by the hydraulic system, the temperature data can be detected through a temperature sensor and then sent to the temperature controller, the rotation speed of the hydraulic pump can be controlled by the temperature controller, so that the oil temperature of the hydraulic oil in the roller casing can be controlled and the effect of accurate control of the hydraulic oil temperature can be reached.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

Thin-oil-sealing gas holder

InactiveCN107883177AUniform heating of sealing oilGuaranteed uptimeVariable capacity gas holdersGas cabinetWater pipe

The invention discloses a thin-oil-sealing gas holder. The gas holder comprises a gas holder body, a holder bottom oil groove located in the lower end of the gas holder body, a bottom heating water pipe located in the holder bottom oil groove as well as a heat source communicating with the bottom heating water pipe; and the heat source inputs hot water, so that the bottom heating water pipe has the first predetermined temperature, and thin oil in the holder bottom oil groove has the second predetermined temperature. By the aid of the gas holder, the technical problem that a thin-oil-sealing gas holder cannot operate efficiently and stably due to the fact that sealing oil is not heated evenly and cannot be kept at the optimal performance temperature in the prior art is solved, and the technical effect that the thin-oil-sealing gas holder is ensured to operate efficiently and stably in winter due to the fact that the sealing oil is evenly heated and is kept at the optimal performance temperature is realized.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

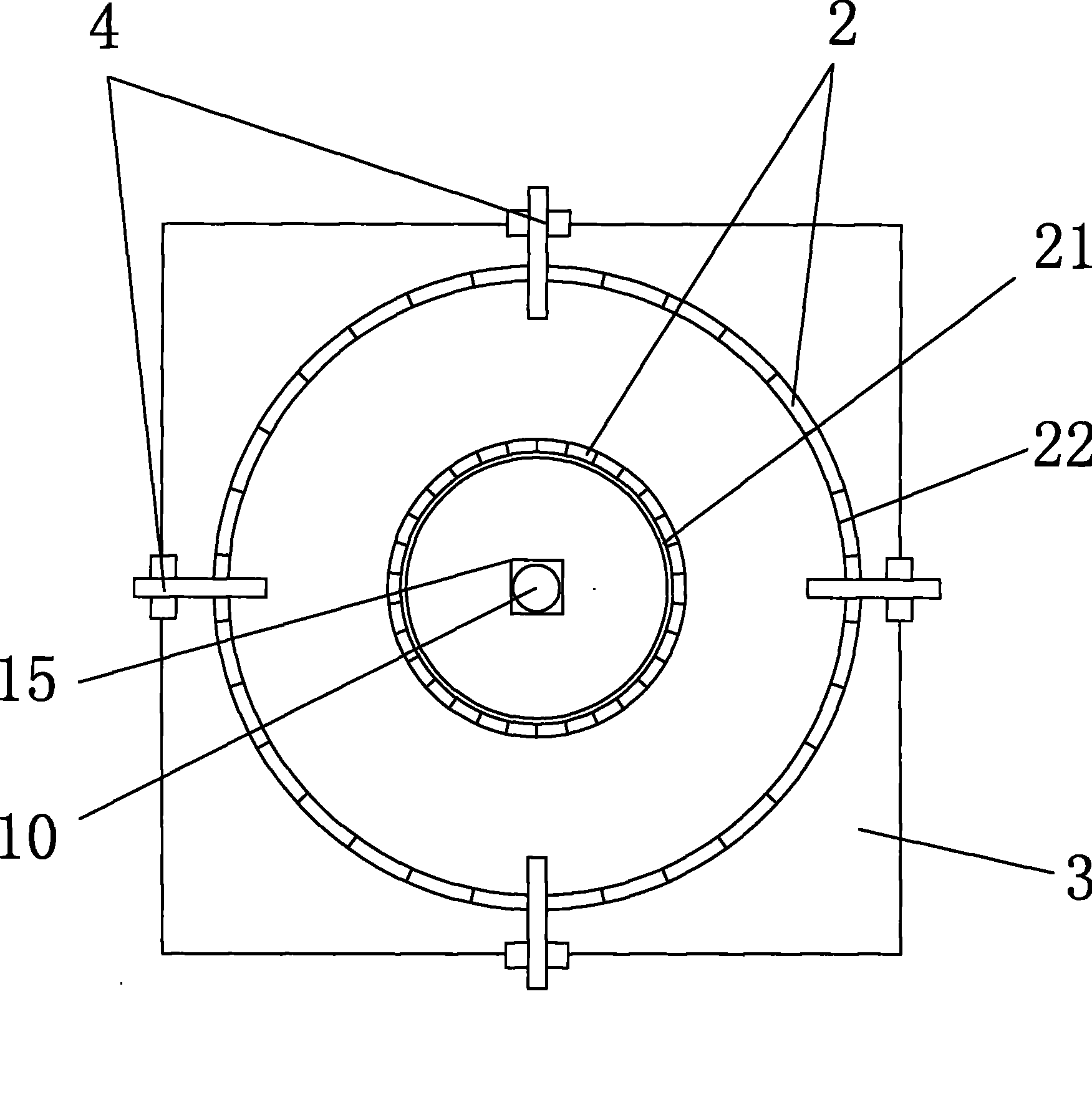

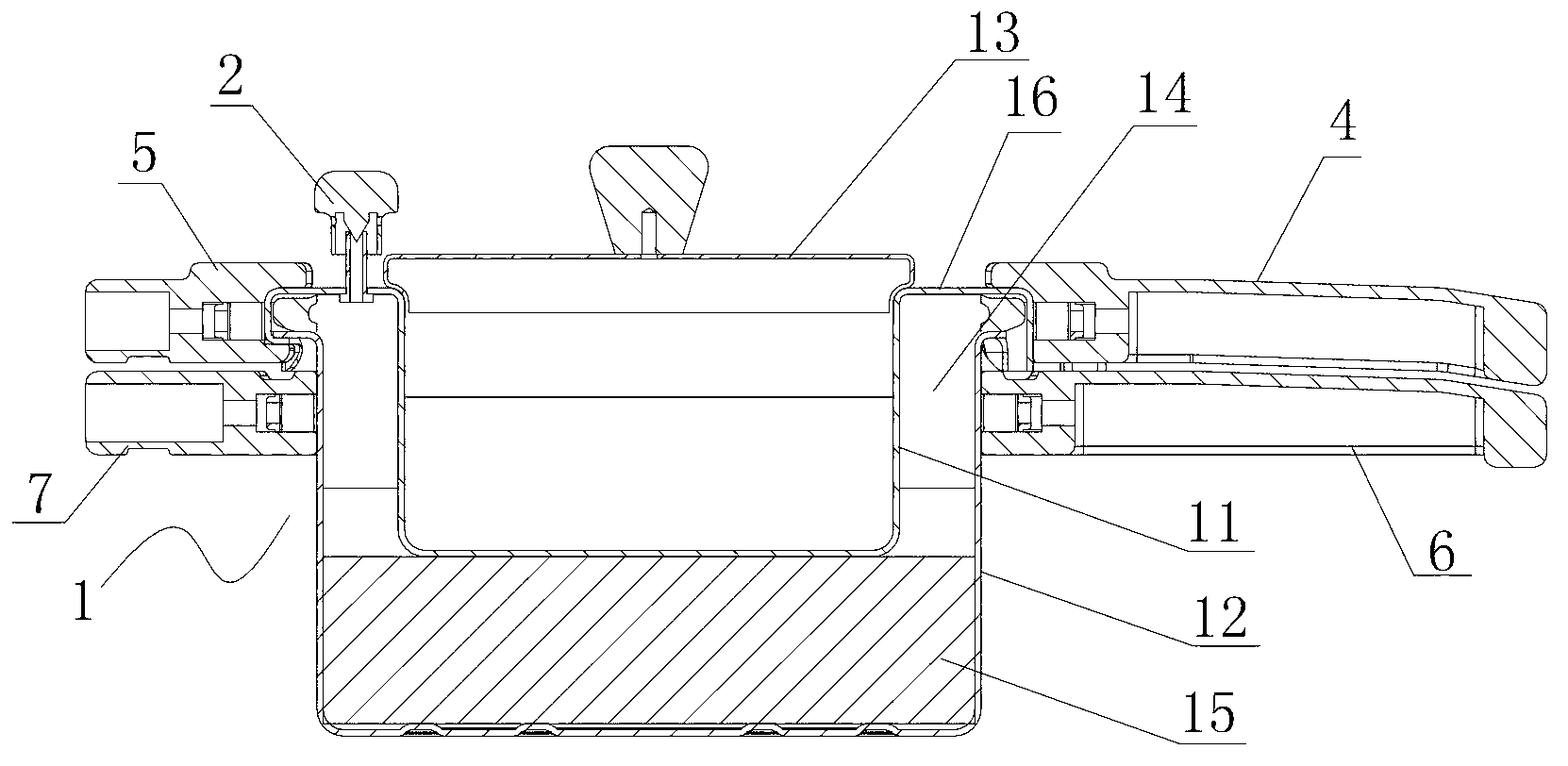

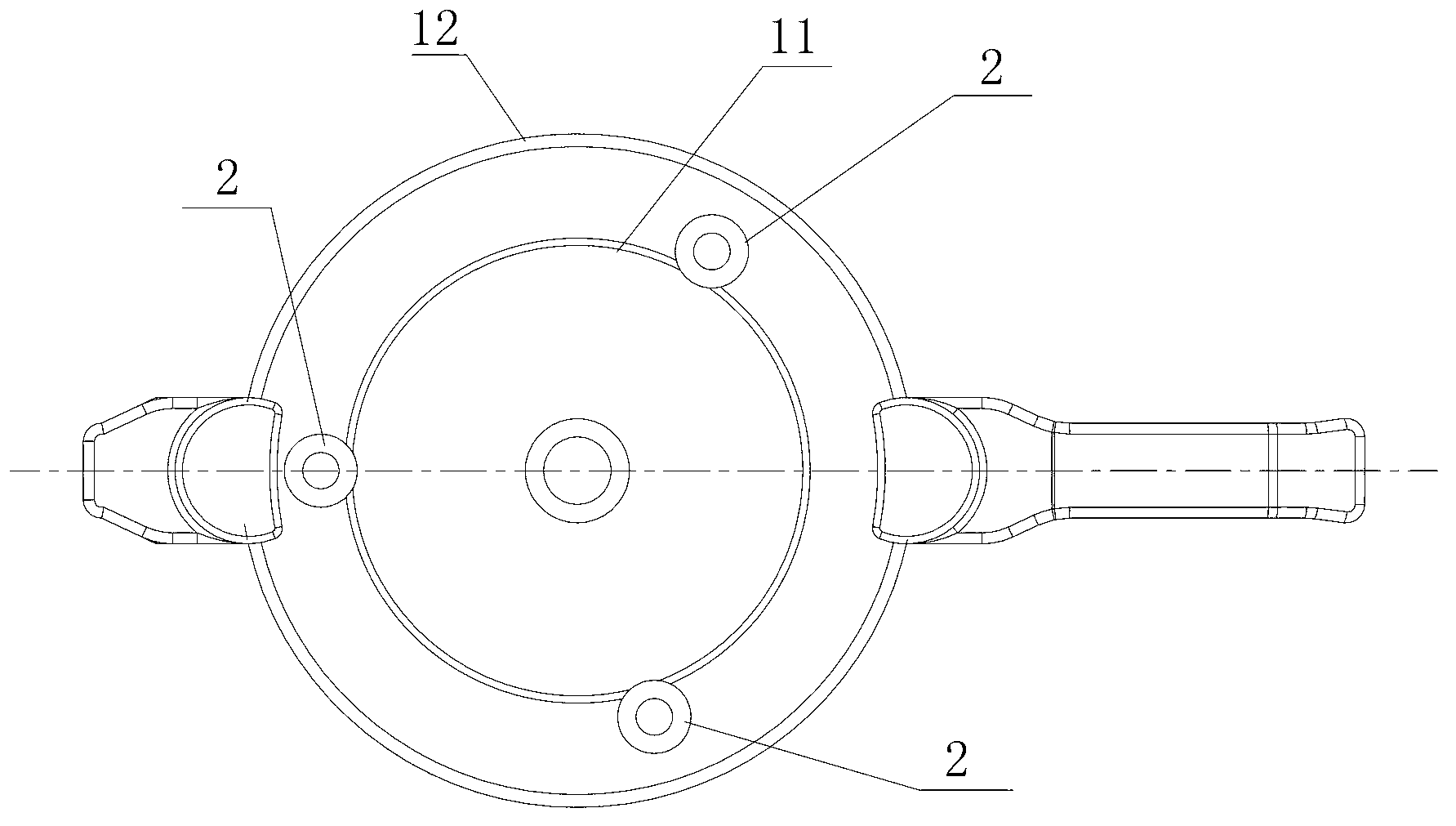

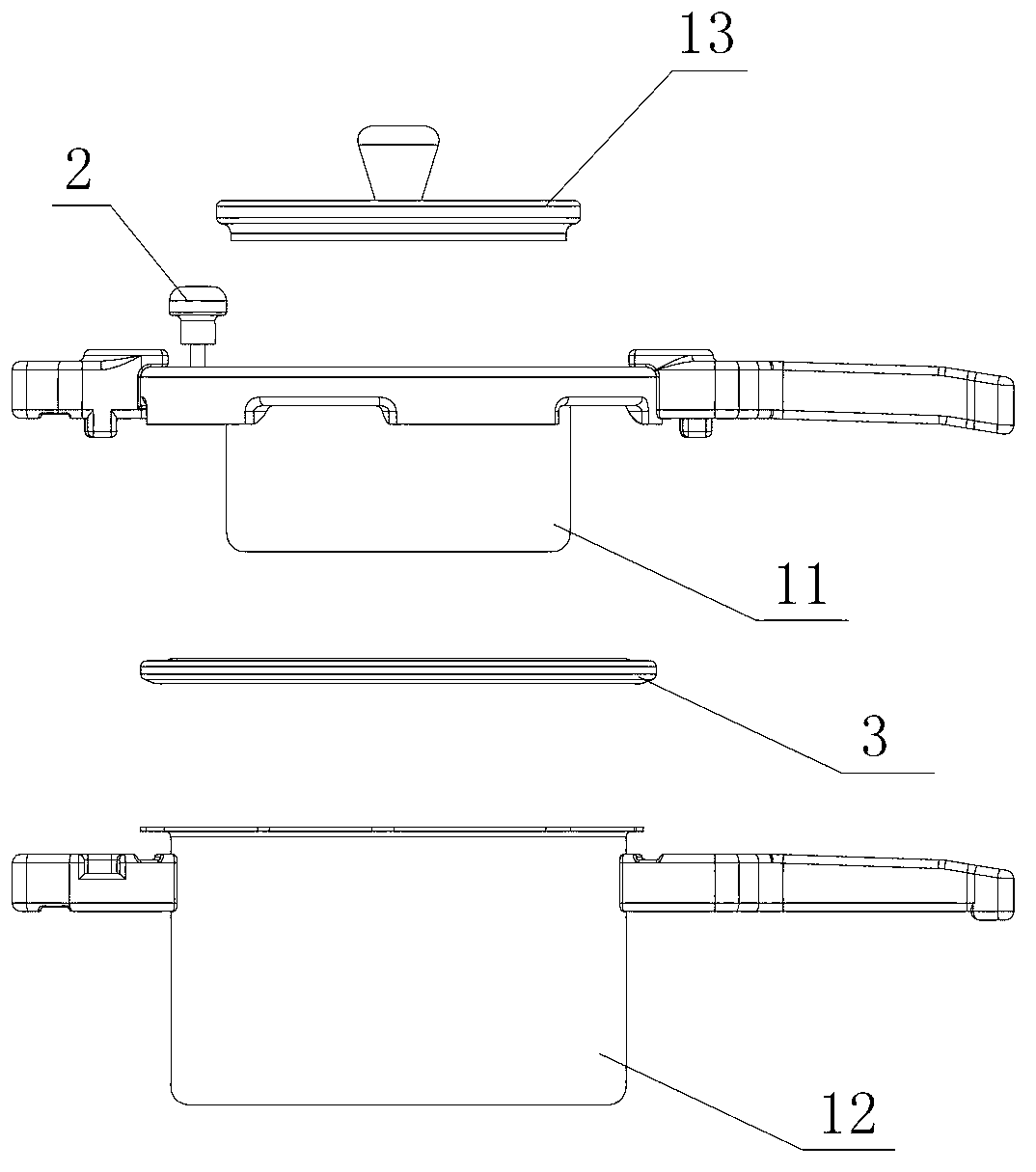

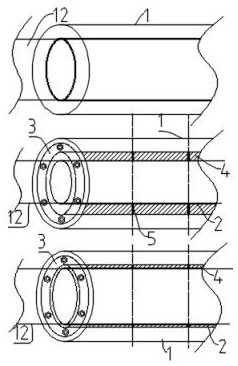

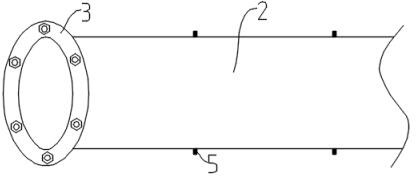

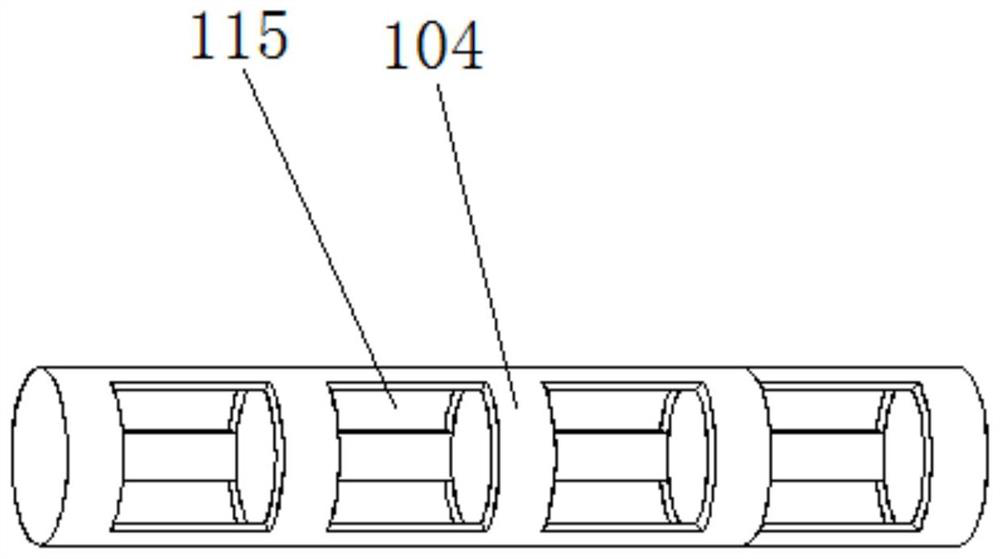

Forming furnace for multiple specifications of pipes

The invention discloses a forming furnace for multiple specifications of pipes. The forming furnace for multiple specifications of pipes comprises a furnace barrel and further comprises a sleeve with the outer diameter smaller than the inner diameter of the furnace barrel, wherein the end of the sleeve is in bolted connection with the furnace barrel through a flange plate, the space between the sleeve and the furnace barrel is filled with a heat conduction material, and multiple specifications of sleeves are provided. At least one annular heat insulation plate is arranged on the outer wall of the sleeve and divides the outer wall of the sleeve into at least two heating areas, and when the sleeve is installed in a furnace barrel, the heat insulation plate is in contact fit with the inner wall of the furnace barrel. By arranging the sleeve with the outer diameter smaller than the inner diameter of the furnace barrel, a furnace does not need to be additionally arranged when a pipeline with a small pipe diameter is machined; the heat conduction material fills the space between the sleeve and the inner wall of the furnace barrel, heat energy can be effectively conducted, and heat source loss can be reduced; and sleeves of other specifications can be conveniently disassembled and replaced through the flange plate bolt connection manner. The forming furnace is effectively suitable for machining of the pipes of multiple specifications, and the production cost is greatly reduced.

Owner:JINHU THREE WOOD MACHINERY IND

Heat transfer oil heating system with temperature accurate adjusting function

InactiveCN103727675AAccurate temperature regulationControl oil temperatureFluid heatersTemperature controlEngineering

The invention relates to a heat transfer oil heating system with the temperature accurate adjusting function. The heat transfer oil heating system comprises a main tube, at least one set of branches and an auxiliary heating system, wherein the main tube is used for allowing heat transfer oil to flow, the branches are led from the main tube, and the auxiliary heating system is used for conducting heating under the condition that no heat exists in the main tube; the set of branches comprise the oil inlet branch and the return oil branch, and an adjusting valve for adjusting the flow of the heat transfer oil is arranged between the oil inlet branch and heat equipment; an electric valve is arranged between the main tube and the auxiliary heating system; temperature sensors are arranged at the positions, close to a branch pipeline of the heat equipment, of the oil inlet branch and the return oil branch respectively, and the opening and closing state of the electric valve is controlled by the temperature sensors. According to the heat transfer oil heating system with the temperature accurate adjusting function, the temperature accurate control goal can be achieved by adjusting the flow, inlet oil of the main tube is controlled according to temperature measured by the temperature sensors close to the heat equipment, and oil temperature is further controlled; the auxiliary heating system is arranged, and therefore the temperature accurate control effect can still be achieved when no heat exists in the main tube.

Owner:CHANGZHOU OLYMSPAN THERMAL ENERGY EQUIP

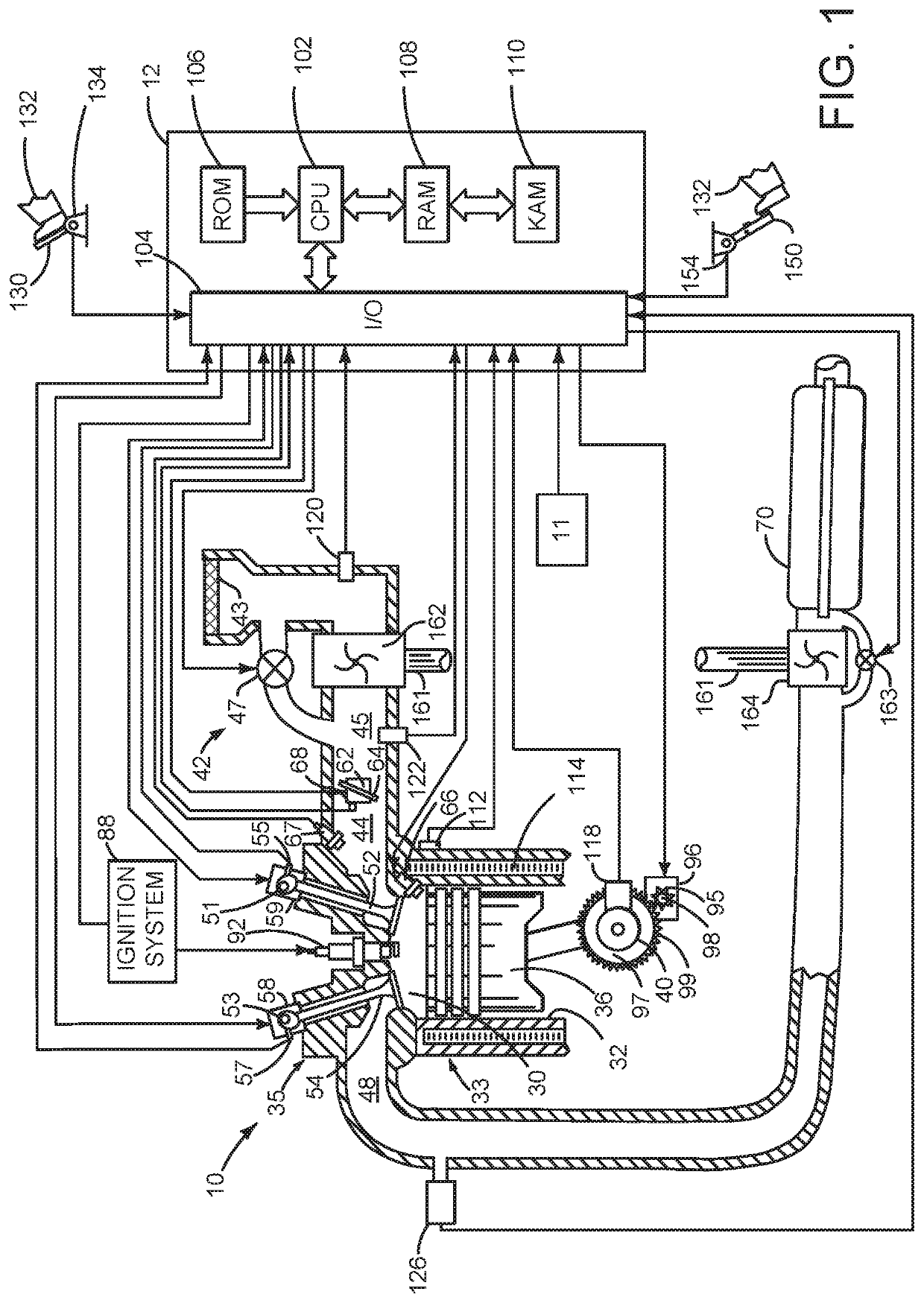

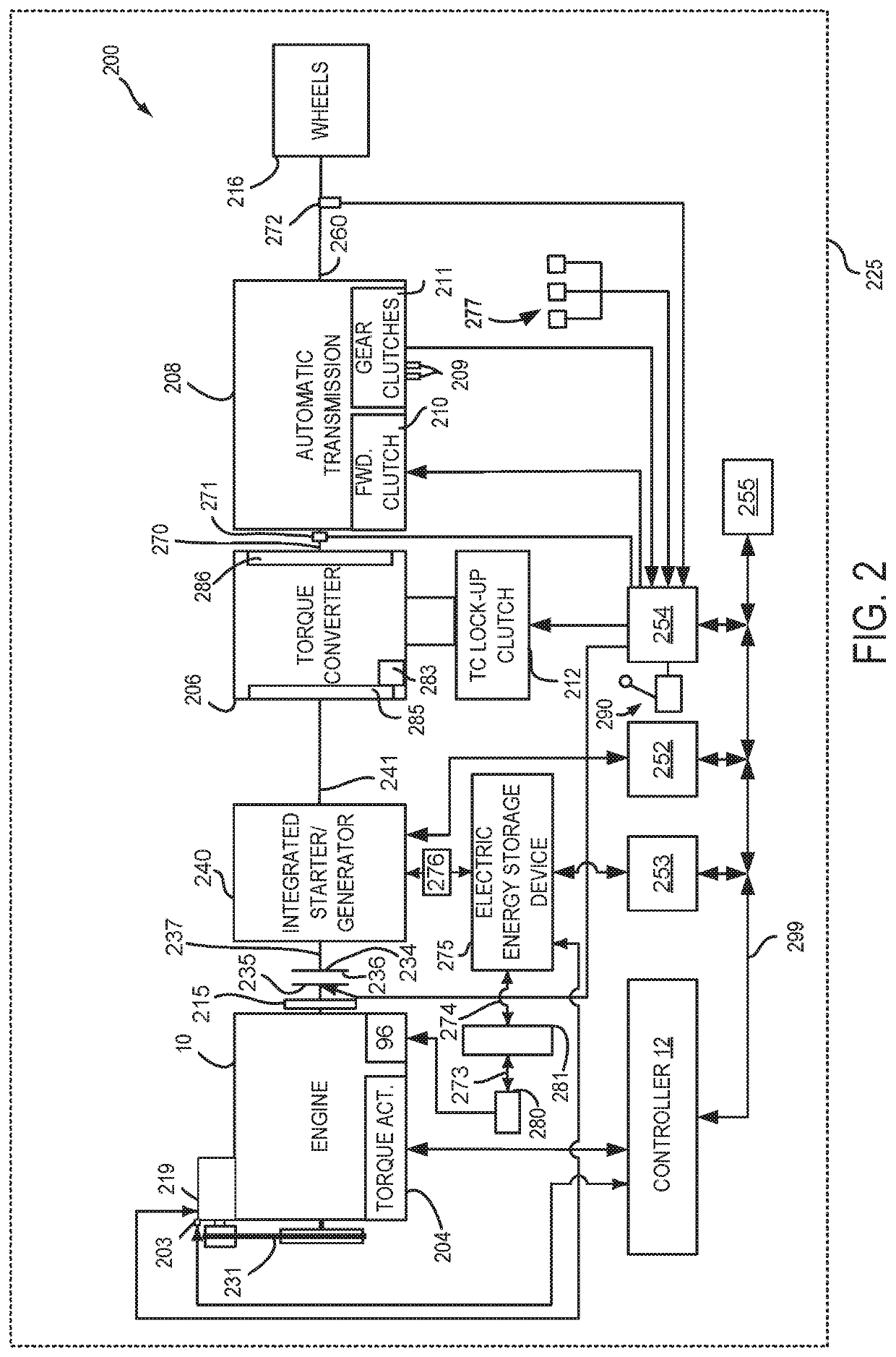

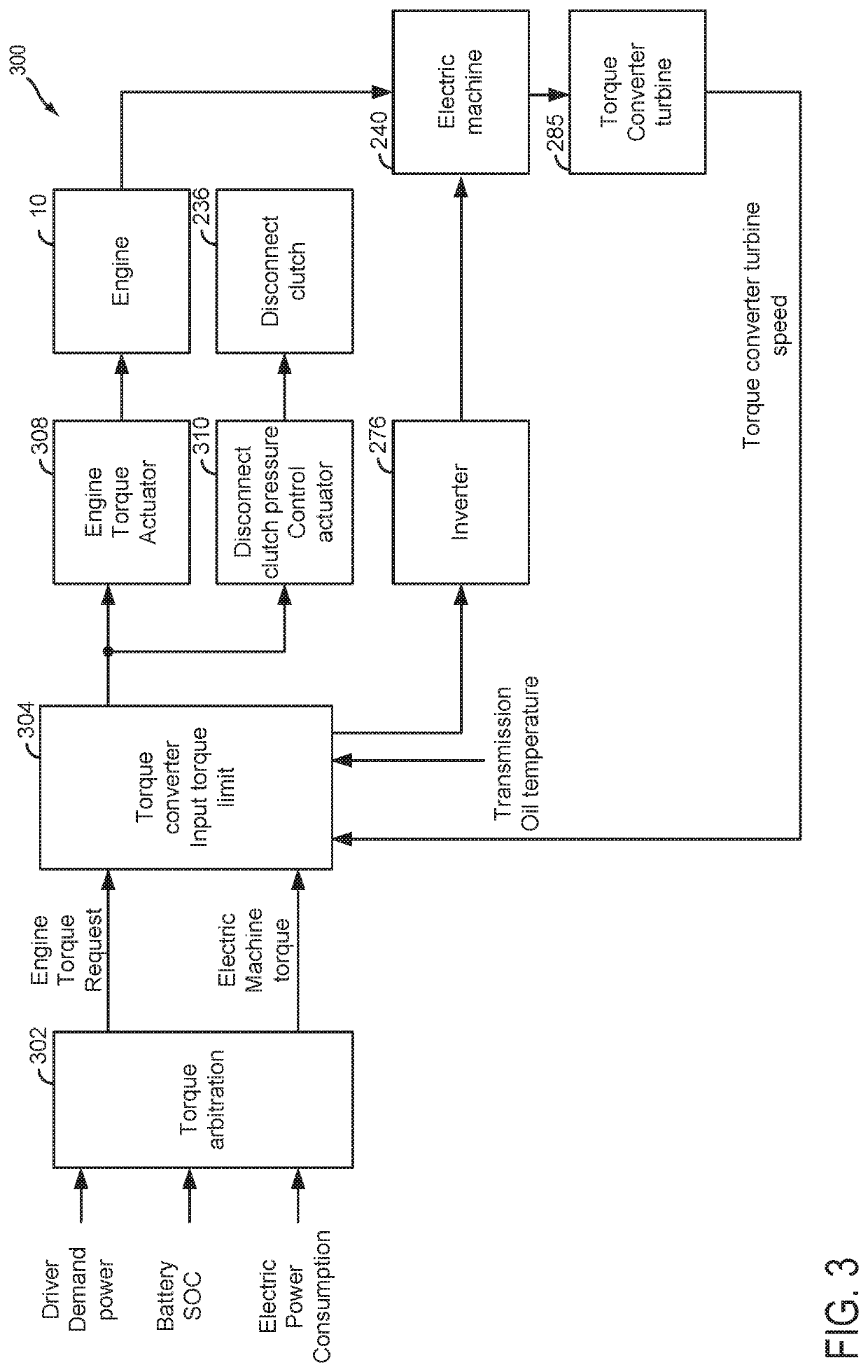

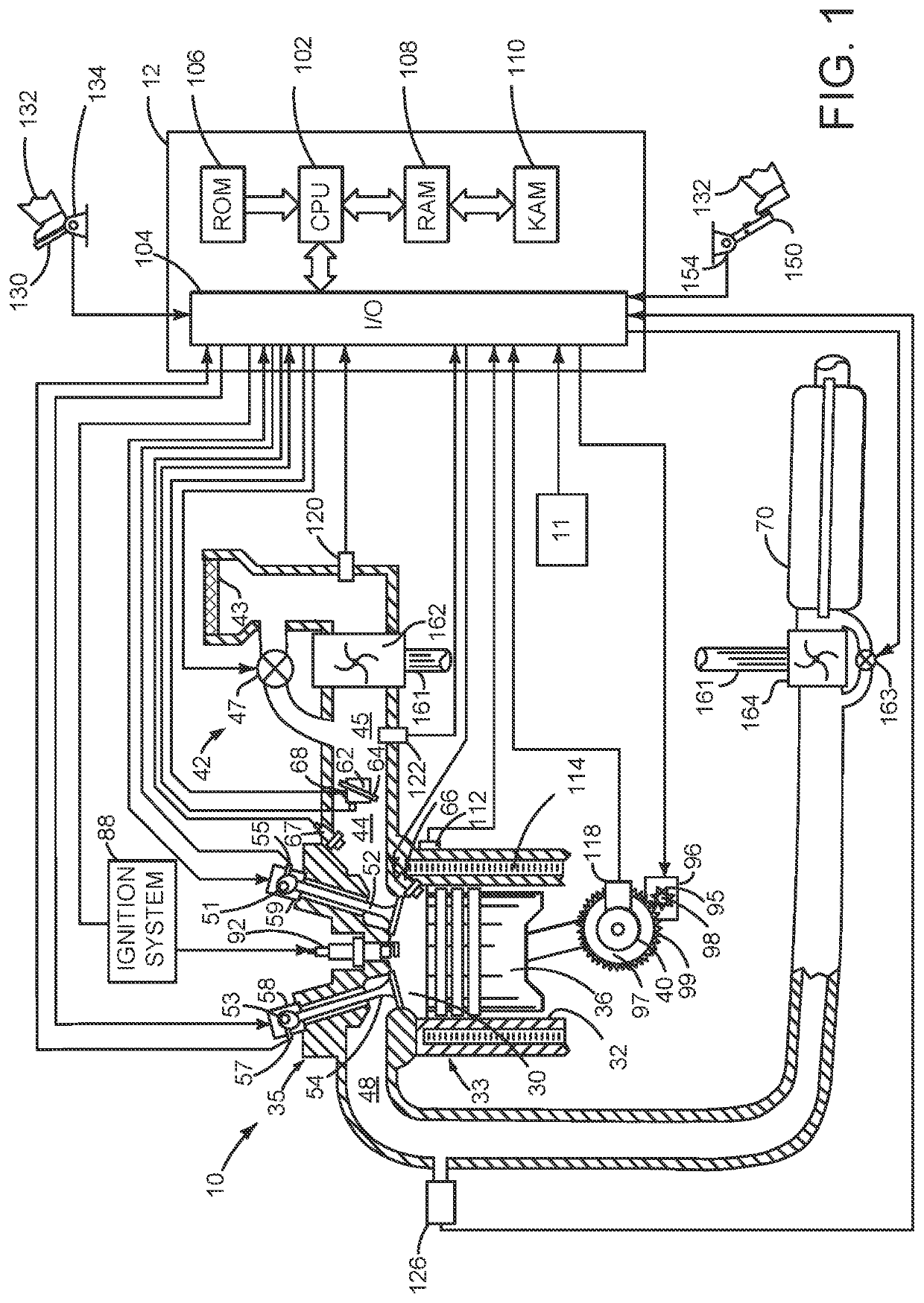

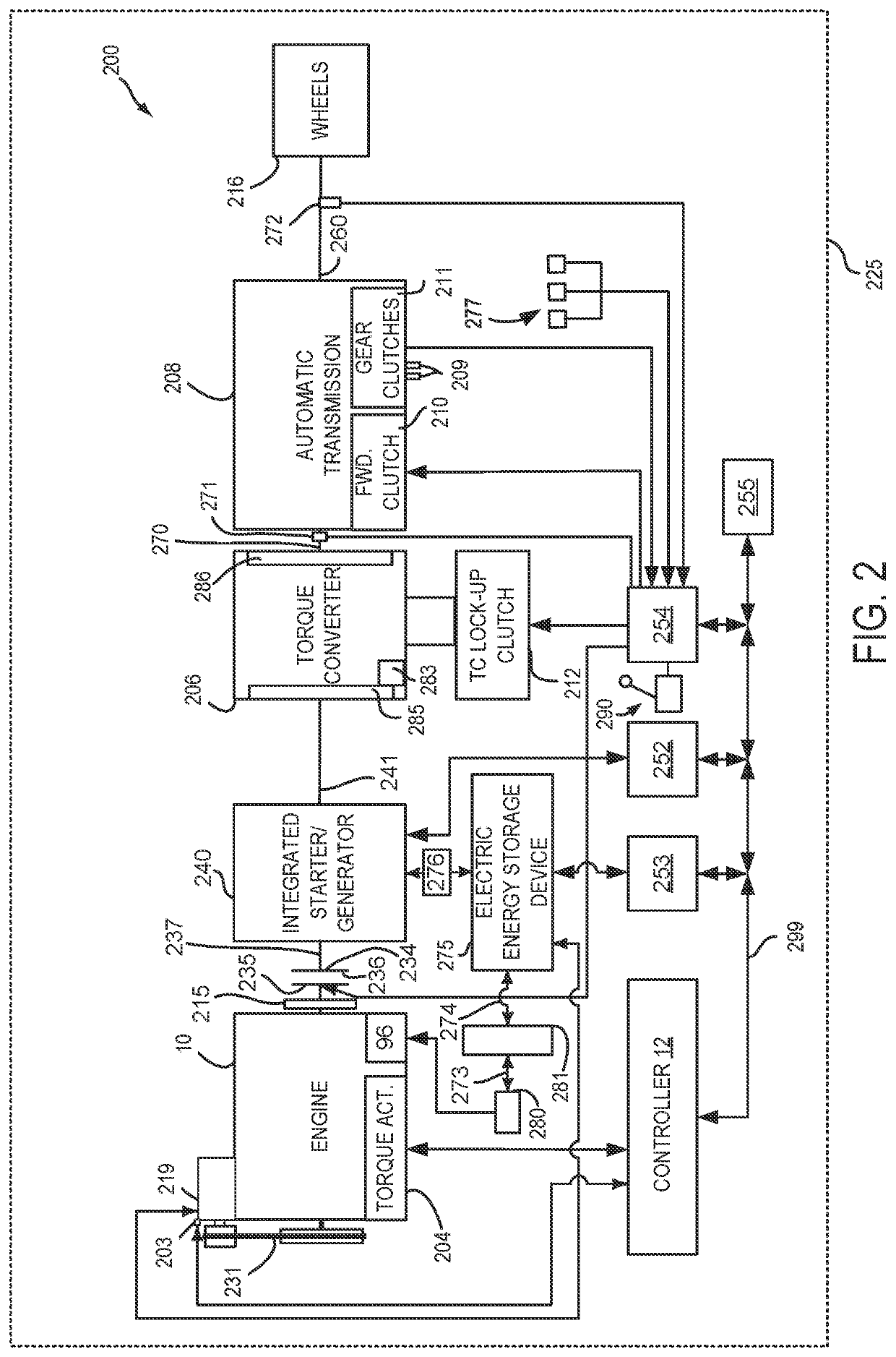

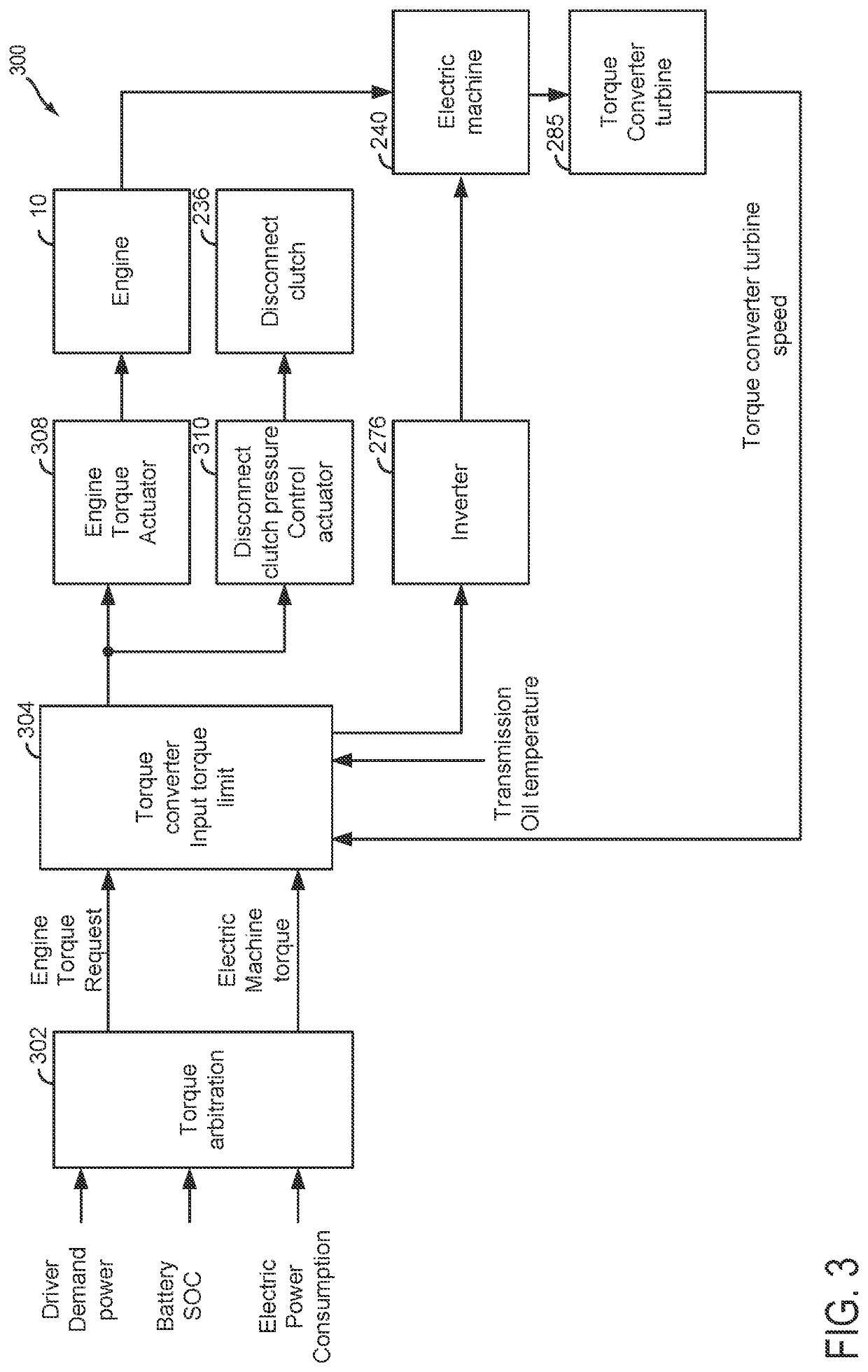

Methods and system for operating a driveline

ActiveUS20200216057A1Provide propulsive effortSave fuelHybrid vehiclesPlural diverse prime-mover propulsion mountingControl theoryHybrid vehicle

Systems and methods for operating a driveline of a hybrid vehicle are described. In one example, a torque that is produced by an engine is adjusted responsive to a transmission oil temperature and a speed of a torque converter impeller so that temperature of oil in a transmission lube circuit may be maintained at a desired temperature.

Owner:FORD GLOBAL TECH LLC

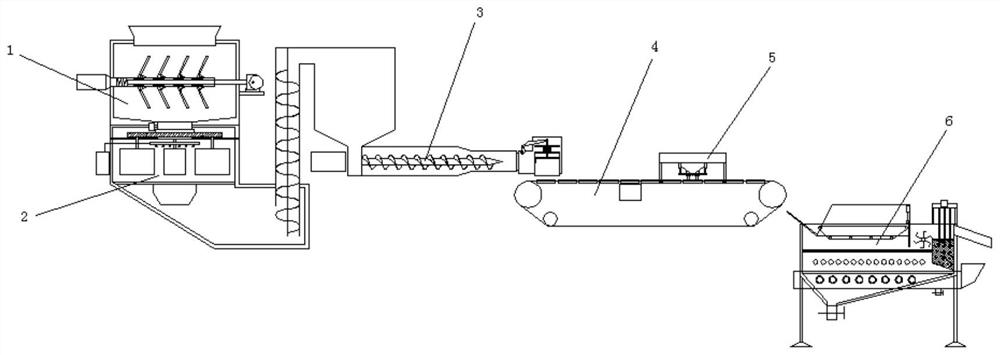

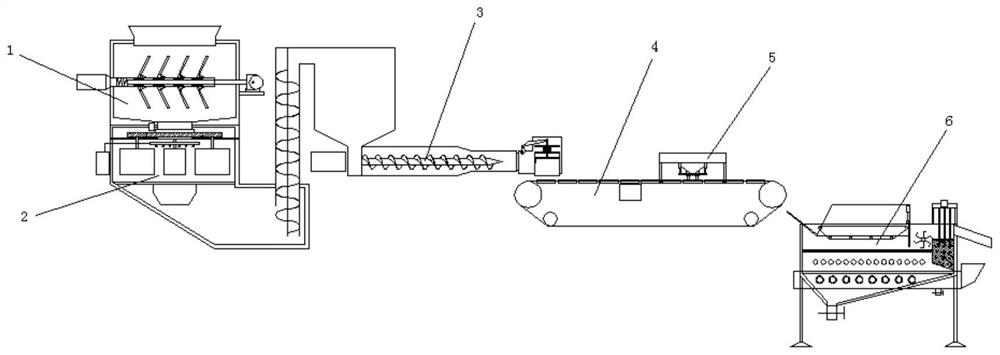

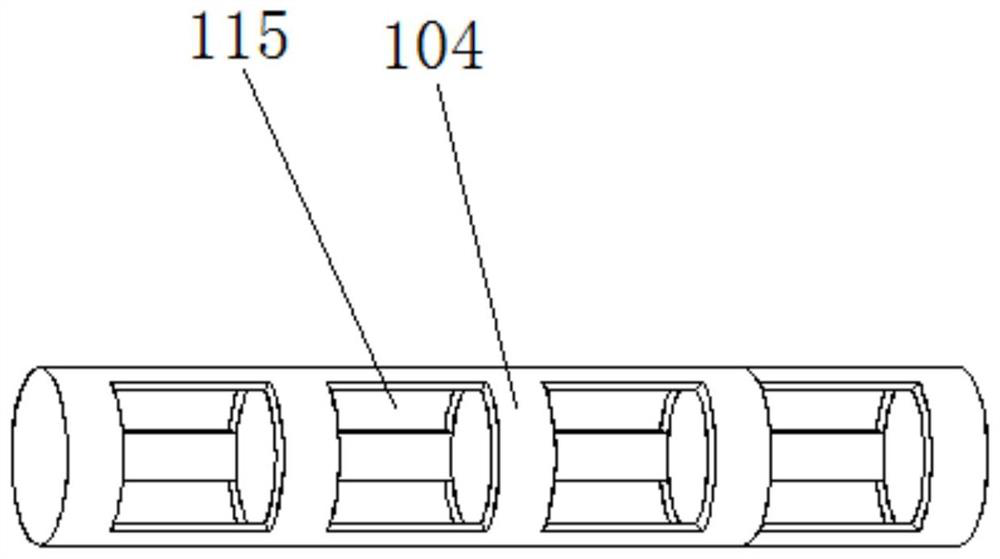

A kind of extruding and other material slitting device of deep-fried dough stick machine

ActiveCN109380458BWell mixedGreat tasteDough shaping and cutting apparatusDough extruding machinesEngineeringMechanical engineering

The invention discloses an extruding and other material slitting device for a deep-fried dough stick machine, which comprises a dough kneading mechanism. The bottom of the kneading dough kneading mechanism is provided with a kneading dough kneading mechanism. warehouse, the bottom of the wake-up noodle warehouse is fixedly equipped with an extruder, the right end of the extruder is provided with a feeding mechanism, the lower part of the feeding mechanism is provided with a conveyor, and the middle part of the conveyor is provided with a composite molding mechanism. The right part of the conveyor is provided with a stretching and disengaging mechanism, and the bottom of the right end of the conveyor is provided with a frying device, which relates to the field of food processing. The invention can automatically add water to the flour and mix it into dough by imitating the manual process of making deep-fried dough sticks. Kneading the dough, waking up the dough, stretching after pressing and forming, and finally frying, greatly reducing the manpower and ensuring the taste of the fried dough sticks, making fried dough sticks efficiently and quickly, suitable for use in breakfast shops.

Owner:张乐

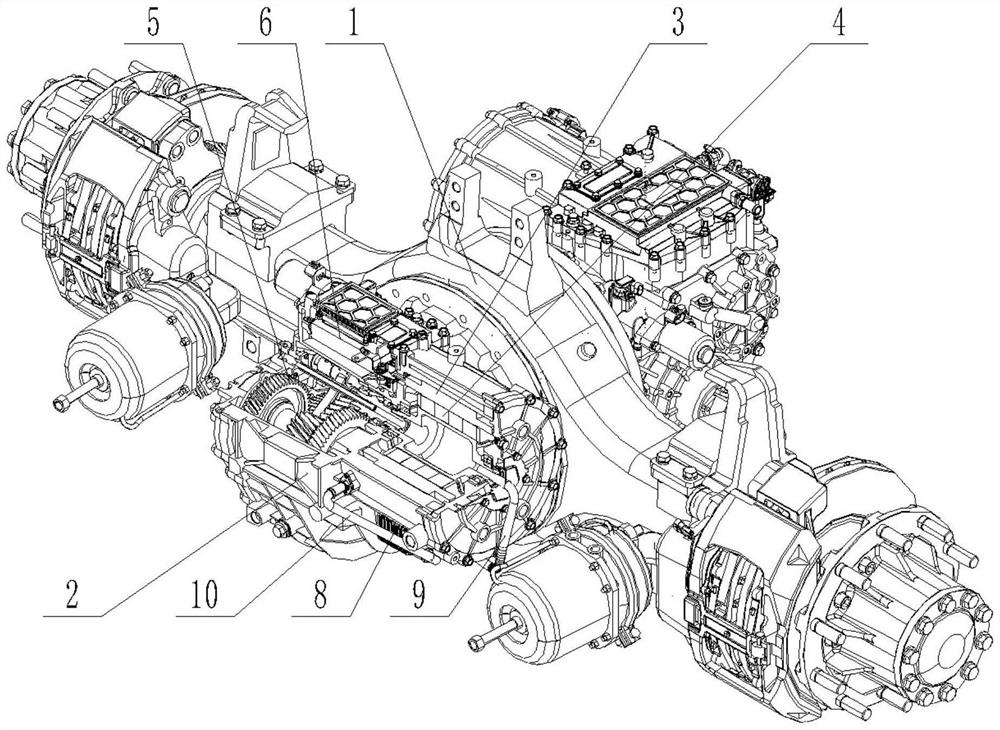

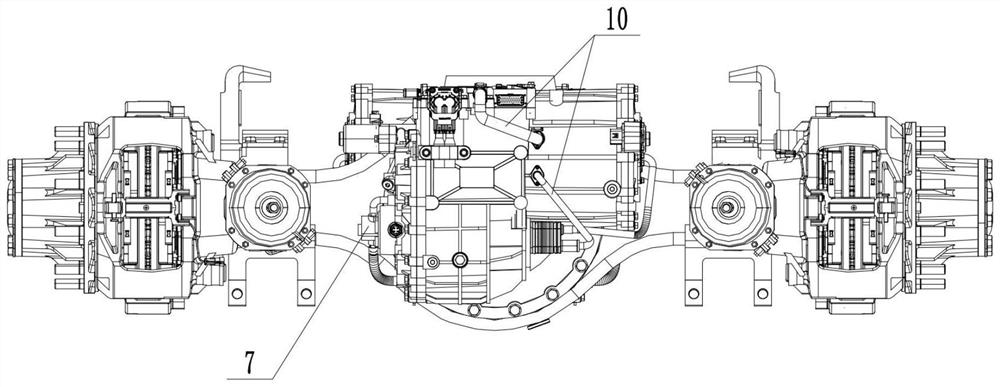

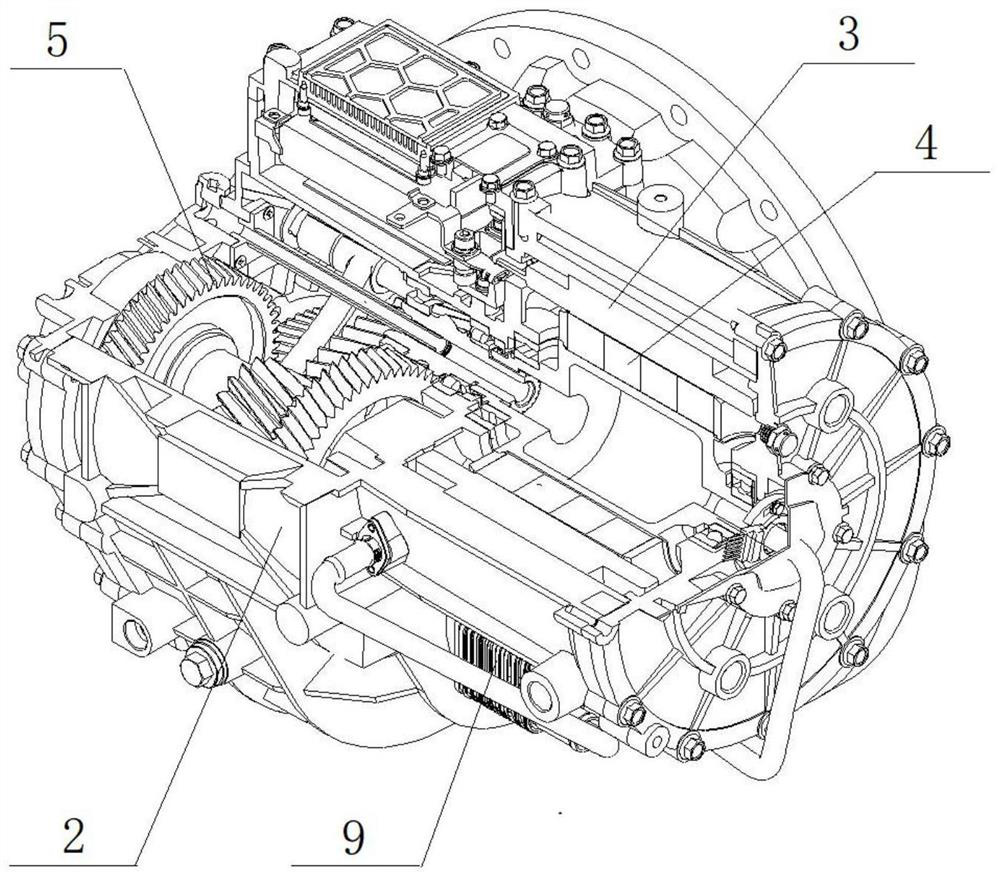

All-in-one integrated commercial vehicle electric drive axle

PendingCN114872493AReduce weightIncrease profitMagnetic circuit rotating partsElectric propulsion mountingGear wheelElectric machine

According to the all-in-one integrated commercial vehicle electric drive axle, two sets of power assemblies are installed on the front side and the rear side of the axle, and each set of power assembly comprises a shell, a heat exchanger, a motor, a gearbox, a motor controller and an electric gear shifting mechanism; cooling water in the external cooling water channel enters the cooling water channel of the motor controller, enters the stator cooling water channel after cooling the motor controller, then enters the cooling water channel of the heat exchanger after cooling the motor stator, and returns to the external cooling water channel after cooling oil passing through the heat exchanger; oil in the gearbox is divided into two ways through the oil pump, one way of oil enters the rotor cooling oil way, the oil enters the heat exchanger after cooling a motor rotor, and the oil is cooled by cooling water in the heat exchanger and then flows back to the gearbox; and the other path of oil liquid reaches all stages of gear shafts of the gearbox through the input shaft of the gearbox and cools gears and bearings under the action of centrifugal force. The integrated design is adopted, the weight of the driving system is reduced, and light weight is achieved.

Owner:NANJING SCAGE AUTOMOBILE TECH CO LTD

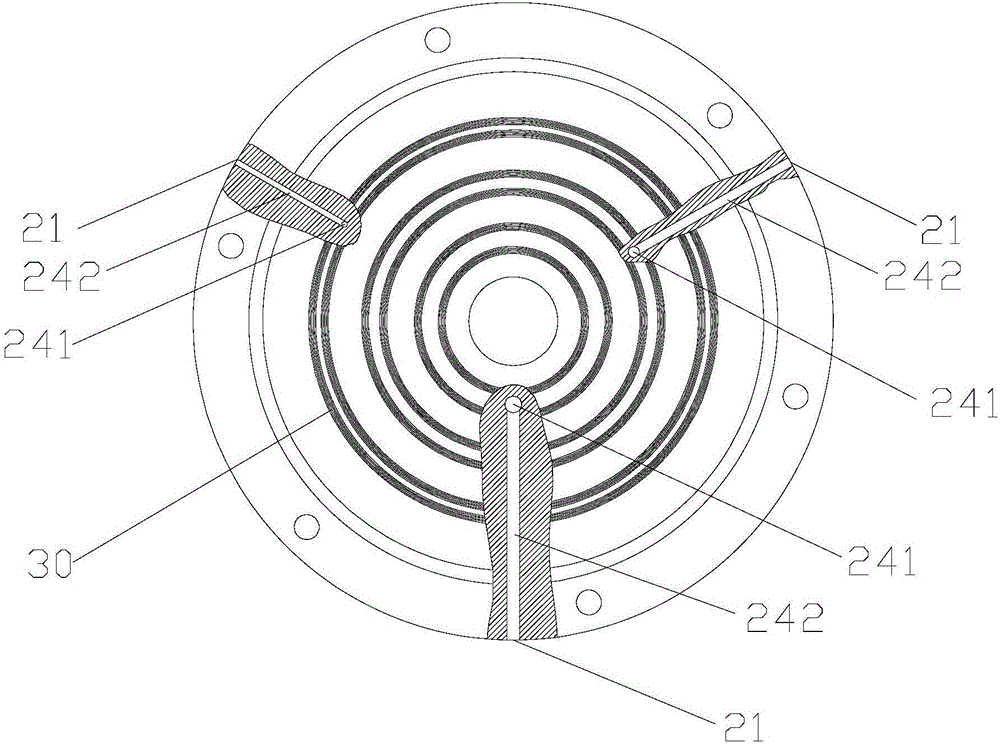

Oil cooling device and air conditioner device with oil cooling device

ActiveCN106438290AControl oil temperatureIncrease cooling areaPositive displacement pump componentsPositive-displacement liquid enginesPulse flowCooling medium

The invention provides an oil cooling device and an air conditioner device with the oil cooling device. The oil cooling device comprises a pulse flow distributing part and a spraying part. The pulse flow distributing part comprises a medium inlet leading a cooling medium in, a medium outlet conveying the cooling medium to the spraying part, and a flow distributing structure controlling the medium inlet and the corresponding medium outlet to be connected or disconnected, and the medium outlet is connected with the spraying part. Through the oil cooling device, the continuous cooling medium flow is converted into the pulse cooling medium flow, accordingly control over the cooling amount is achieved, and the cooling oil temperature is reliably controlled while the lubricating oil is cooled.

Owner:GREE ELECTRIC APPLIANCES INC

Composite forming conveying device for fried dough stick machine

ActiveCN109362820BWell mixedGreat tasteMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringMechanical engineering

The invention discloses a compound forming conveying device of a deep-fried dough stick machine, which comprises a dough kneading mechanism. The bottom of the dough kneading mechanism is provided with a dough kneading mechanism. An extruder is fixedly installed at the bottom of the noodle bin, the right end of the extruder is provided with a feeding mechanism, the lower part of the feeding mechanism is provided with a conveyor, and the middle part of the conveyor is provided with a composite molding mechanism. The right part of the conveyor is provided with a stretching and disengaging mechanism, and the bottom of the right end of the conveyor is provided with a frying device, which relates to the field of food processing. The present invention can imitate the process of manually making deep-fried dough sticks, automatically add water to the flour and mix it into dough, then knead the dough, Wake up the dough and stretch it after pressing and forming, and finally fry it, which greatly reduces the manpower and can ensure the taste of the fried dough sticks. It is efficient and quick to make fried dough sticks, which is suitable for use in breakfast shops.

Owner:张乐

Abelmoschus manihot fine oil

PendingCN105647645AGuaranteed contentQuality assuranceEssential-oils/perfumesMedicinal herbsActive component

The invention relates to a poly-type natural vitamin E oil product, and specifically abelmoschus manihot fine oil. Abelmoschus manihot is a name for a plant traditional Chinese medicine material, which is a nontoxic plant. According to the invention, oil is separated from abelmoschus manihot traditional Chinese medicine material cells; oil temperature in an impurity-removing method is controlled according to a value calculated with an oil boiling point as a base, such that the content and quality of active components in oil are protected to a maximal extent. There are more than four types of molecular formulas of the natural active vitamin E in the oil, and an L-type molecular form reaches approximately 70%. The total content, especially compared based on stability, is greatly higher than that of sea buckthron oil recommended by NASA. The abelmoschus manihot fine oil can be selected as a raw material in the industries of medicine, food, and fragrance and cosmetics.

Owner:王亚伦

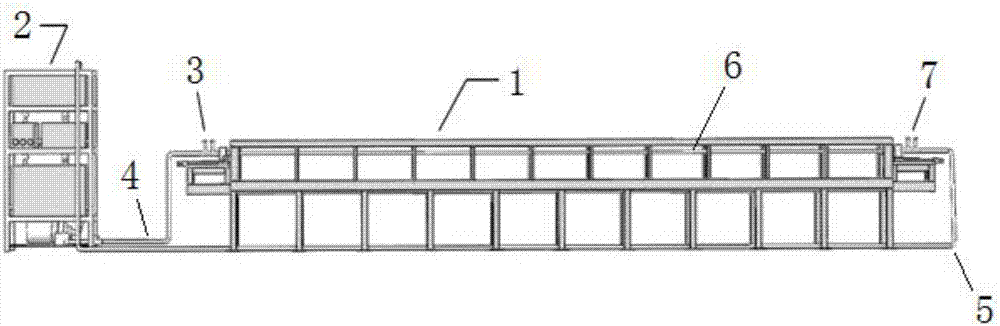

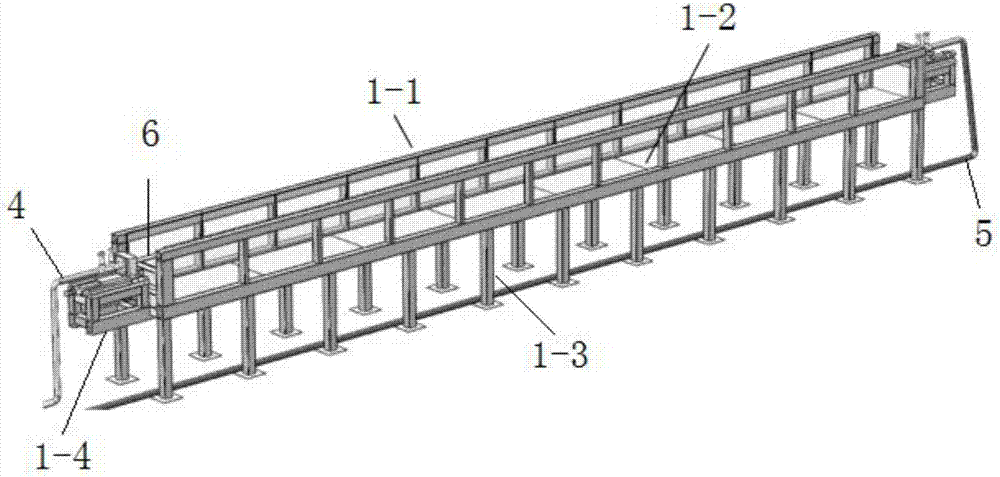

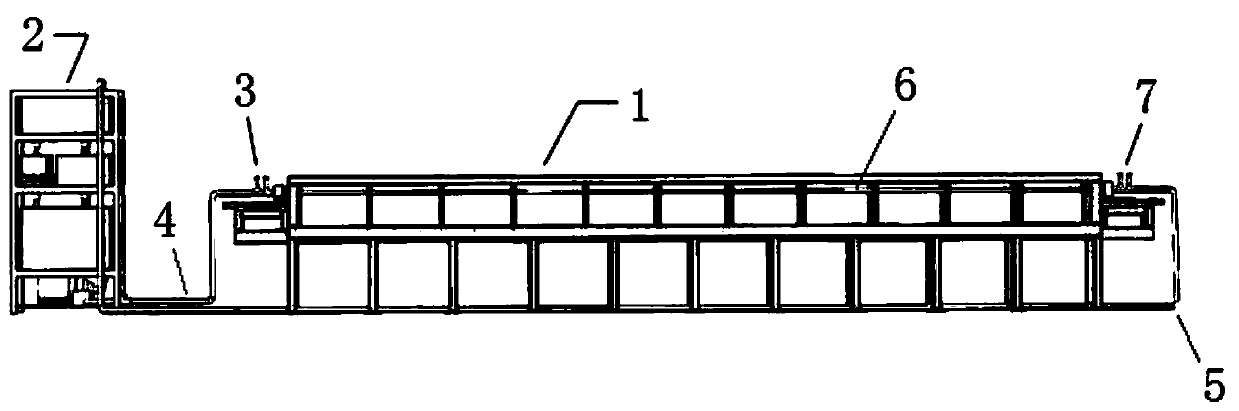

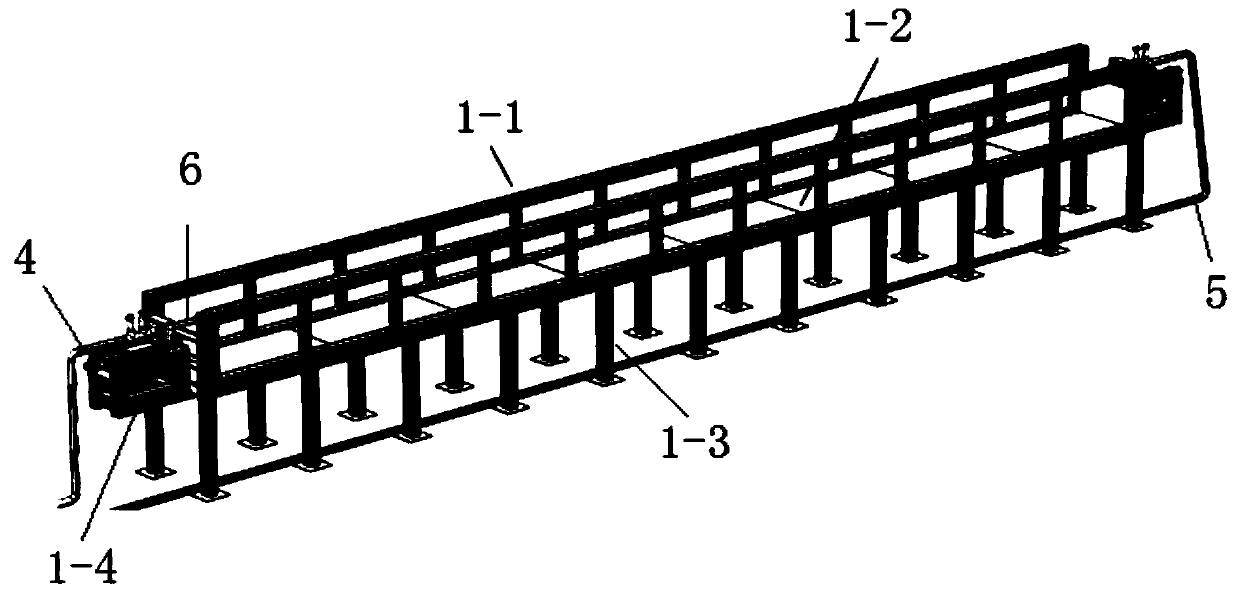

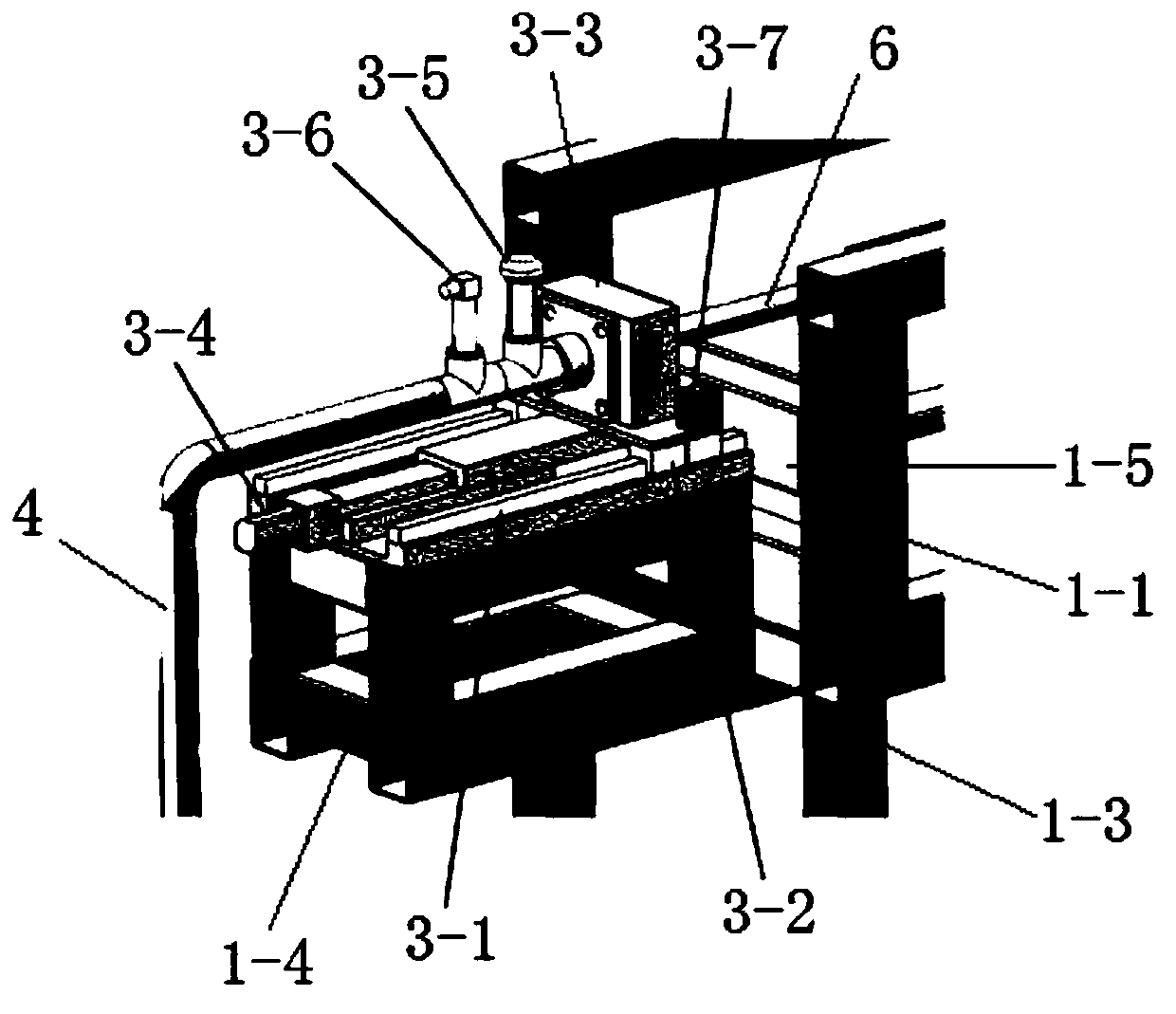

Test device of axial directional displacement of pipeline considering tension action of steel catenary riser

InactiveCN107462432AAdjustable tensionControl oil speedStructural/machines measurementCatenaryGas pipeline

The invention discloses a test device of axial directional displacement of a pipeline considering the tension action of a steel catenary riser. The test device comprises a test groove, oil transportation equipment, an oil outlet pipeline, an oil return pipeline, an outlet collection device, an outlet collection device and a test oil transportation pipe. Innovatively, according to the device, hot oil can be circulated in the pipelines, at the same time, the tensile force is exerted on the pipelines, and the magnitude of the tensile force can be adjusted, so that the situation a submarine pipeline can cause the axial direction displacement under the tension action of the steel catenary riser. Therefore, the influence of different magnitudes of tensile force on the rule of axial movement of the submarine pipeline is researched. Moreover, the speed and temperature of oil entering into the submarine pipeline can be accurately controlled by the device, so that a corresponding temperature variation curve of the submarine pipeline is obtained. Therefore, the influence of different temperature variation conditions on the axial directional displacement of the submarine pipeline.

Owner:TIANJIN UNIV

Methods and system for operating a driveline

PendingUS20210261113A1Propulsive effortSave fuelHybrid vehiclesPlural diverse prime-mover propulsion mountingControl theoryHybrid vehicle

Systems and methods for operating a driveline of a hybrid vehicle are described. In one example, a torque that is produced by an engine is adjusted responsive to a transmission oil temperature and a speed of a torque converter impeller so that temperature of oil in a transmission lube circuit may be maintained at a desired temperature.

Owner:FORD GLOBAL TECH LLC

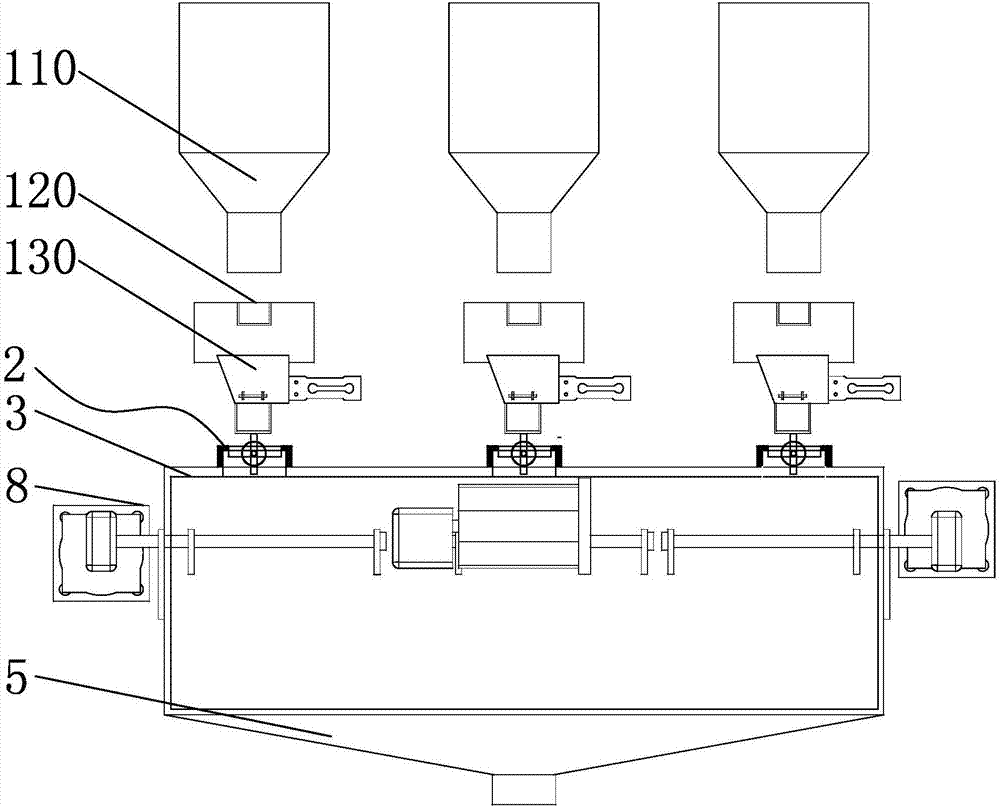

Multi-station automatic deep-frying oven device for food

ActiveCN106993645AControl tasteConsistent tasteBaking ovenOil/fat bakingDeep fryingProcess engineering

The invention relates to a multi-station automatic deep-frying oven device for food. The multi-station automatic deep-frying oven device is characterized by comprising at least three groups of automatic portioning devices, wherein the at least three groups of automatic portioning devices are arranged in parallel; further, one group of transfer conveying devices is arranged blow each group of automatic proportioning devices; oil ovens are arranged below the transfer conveying devices; deep-drying grooves are arranged in the oil ovens; the deep-frying grooves are arranged below the transfer conveying devices; deep-frying material boxes are arranged in the deep-frying grooves; the deep-frying material boxes are connected with driving motors through connecting shafts and right-angle speed reducers; electromagnetic heating devices are arranged below the oil ovens; discharging holes of the oil ovens are provided with one group of material leakage funnels. According to the multi-station automatic deep-frying oven, the heating is carried out through the electromagnetic heating devices; the heating rate and the heating uniformity of an oil temperature are guaranteed; the change of the oil temperature is controlled through infrared temperature sensors; the regulation and control accuracy of the oil temperature are guaranteed.

Owner:哈尔滨兴盛自动化设备制造有限公司

Flour mixing device of a deep-fried dough stick machine

ActiveCN109006896BWell mixedGreat tasteMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsProcess engineeringMechanical engineering

The invention discloses a flour mixing device of a deep-fried dough stick machine, which comprises a dough kneading mechanism, a dough kneading mechanism is arranged at the bottom of the dough kneading mechanism, and a wake-up bin is connected to the right side of the dough kneading mechanism through a hoist. An extruder is fixedly installed at the bottom of the wake-up noodle bin, the right end of the extruder is provided with a feeding mechanism, the lower part of the feeding mechanism is provided with a conveyor, the middle part of the conveyor is provided with a composite molding mechanism, and the conveyor The right part is provided with a stretching and disengaging mechanism, and the bottom of the right end of the conveyor is provided with a frying device, which relates to the field of food processing. The invention can automatically add water to the flour and mix it into dough by imitating the process of artificially making deep-fried dough sticks. The noodles are stretched after being pressed and formed, and finally fried, which greatly reduces manpower and can ensure the taste of fried dough sticks. It is efficient and quick to make fried dough sticks, which is suitable for use in breakfast shops.

Owner:张乐

A test device considering the axial directional displacement of the pipeline under the tension of the steel catenary riser

InactiveCN107462432BAdjustable tensionControl oil speedStructural/machines measurementOcean bottomOil can

The invention discloses a test device of axial directional displacement of a pipeline considering the tension action of a steel catenary riser. The test device comprises a test groove, oil transportation equipment, an oil outlet pipeline, an oil return pipeline, an outlet collection device, an outlet collection device and a test oil transportation pipe. Innovatively, according to the device, hot oil can be circulated in the pipelines, at the same time, the tensile force is exerted on the pipelines, and the magnitude of the tensile force can be adjusted, so that the situation a submarine pipeline can cause the axial direction displacement under the tension action of the steel catenary riser. Therefore, the influence of different magnitudes of tensile force on the rule of axial movement of the submarine pipeline is researched. Moreover, the speed and temperature of oil entering into the submarine pipeline can be accurately controlled by the device, so that a corresponding temperature variation curve of the submarine pipeline is obtained. Therefore, the influence of different temperature variation conditions on the axial directional displacement of the submarine pipeline.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com