Forming furnace for multiple specifications of pipes

A multi-specification, forming furnace technology, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of high cost of forming furnaces and high production costs, save operation steps and parts costs, reduce heat transfer, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

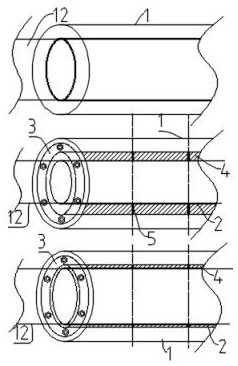

Embodiment 1

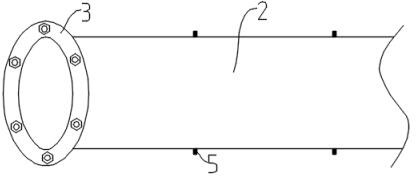

[0031] The multi-standard pipe 12 forming furnace includes a furnace cylinder 1 and a sleeve 2 whose outer diameter is smaller than the inner diameter of the furnace cylinder 1. The end of the sleeve 2 is connected to the furnace cylinder 1 by bolts through a flange 3. It should be understood that the furnace cylinder 1 The thickness of the ring-shaped end face is relatively large and screw holes are provided for connecting the flange 3. In this scheme, the flange 3 is provided with a port that is installed on the inlet of the furnace tube 1, and the sleeve 2 and the furnace tube 1 is filled with a heat-conducting material 4, and the heat-conducting material 4 in this solution is heat-conducting silicone grease or heat-conducting adhesive or heat-conducting paste.

[0032] In this scheme, the inner diameter of the furnace cylinder 1 is 200 mm, and the sleeve 2 has various specifications, and the outer diameter of the sleeve 2 suitable for the furnace cylinder 1 is 150 mm, 175 m...

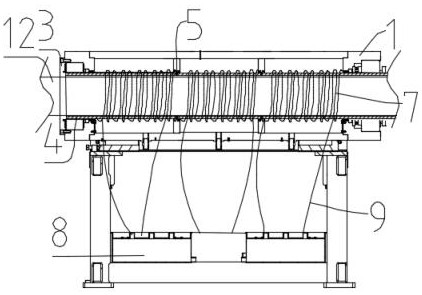

Embodiment 2

[0036] In this embodiment, on the basis of Embodiment 1, the way of heating and raising the temperature of the heating chamber 6 is improved. In this solution, the furnace cylinder 1 includes an inner cylinder 13 and an outer cylinder 14. The outer wall of the inner cylinder 13 is provided with a circumferential oil groove 10. The oil grooves 10 are arranged in sections according to the number of heating chambers 6. The oil grooves 10 start from one end of each heating chamber 6. Extending axially along the inner cylinder 13 to the other end, the outer cylinder 14 is sheathed in the outer wall of the inner cylinder 13 for clearance fit and forms a closed oil circuit with the oil tank 10. Both ends of the oil circuit are connected to the oil pipe 9 to form a circuit, and the oil pipe 9 is connected to the oil temperature machine 11 . It should be understood that, in order to ensure the arrangement of the oil inlet pipe 9 and the oil outlet pipe 9 of the oil passage, the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com