Hydraulic station novel closed control system

A technology for control systems and hydraulic stations, which is used in fluid pressure actuation system testing, fluid pressure actuation system components, fluid pressure actuation devices, etc., and can solve the impact of oil viscosity drop, damage, seal life and sealing performance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

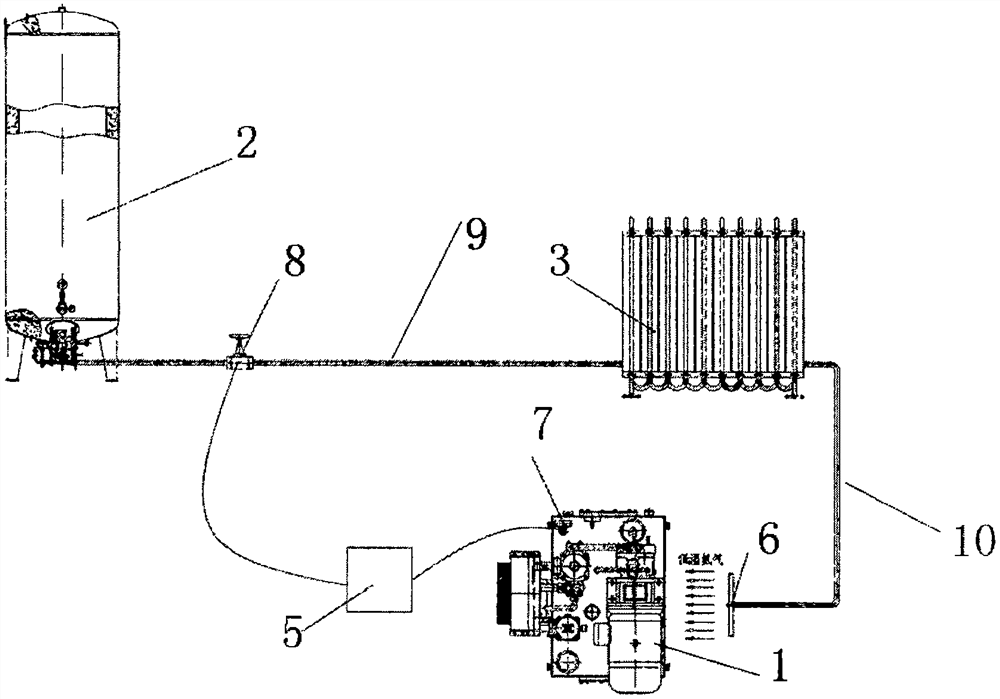

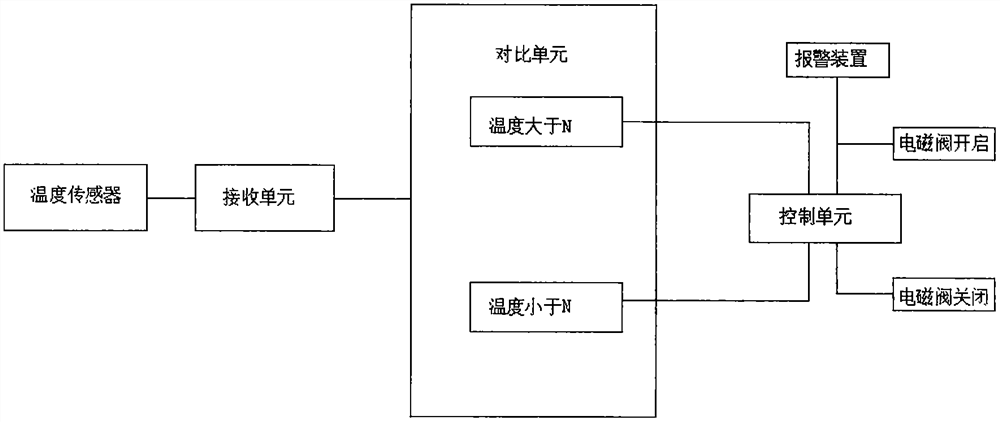

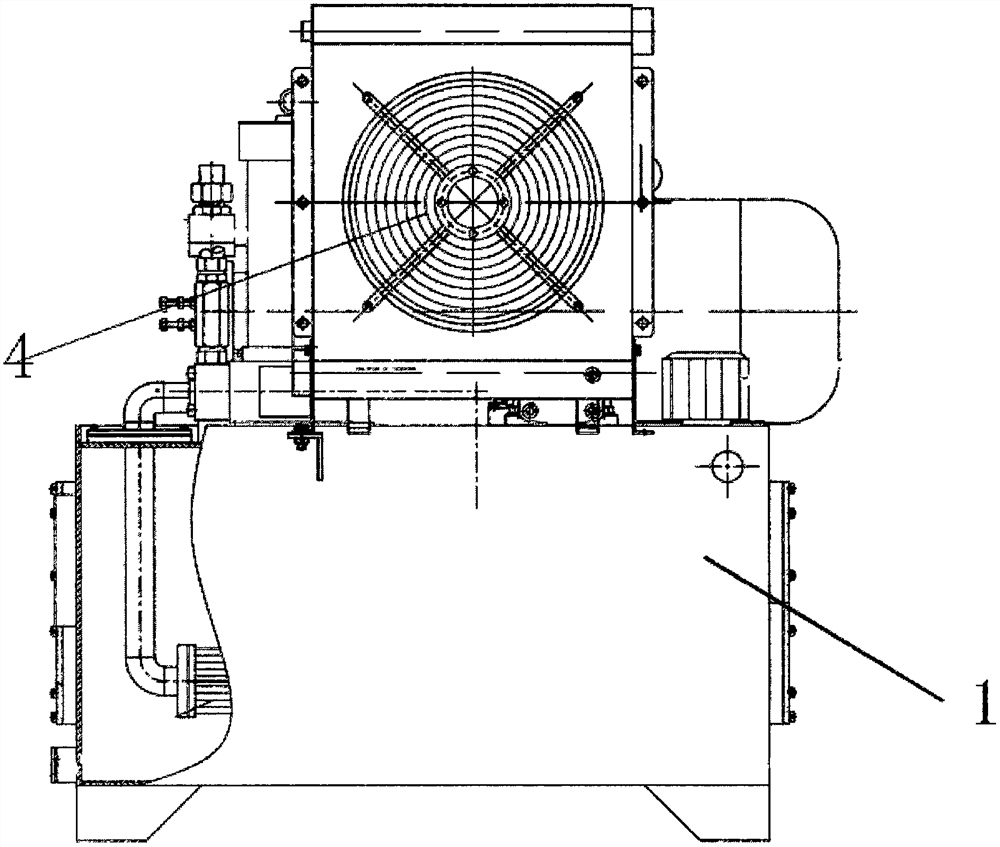

[0022] Please refer to the drawings in the description. In the embodiment of the present invention, a new type of closed control system for a hydraulic station includes a hydraulic station 1, a liquid nitrogen storage tank 2, a vaporizer 3 and a central processing unit 5, wherein the hydraulic station 1 includes a fuel tank , the inside of the fuel tank is provided with an oil suction filter, and the top of the fuel tank is provided with a wind cooler 4; the hydraulic station 1 is provided with a temperature sensor 7, and the temperature sensor 7 is connected to the central processing unit 5 with signals A connecting pipe 9 is provided between the liquid nitrogen storage tank 2 and the vaporizer 3, an output pipe 10 is provided at the output end of the vaporizer 3, and an outlet plate 6 is provided at the end of the gas delivery pipe 10 away from the vaporizer 3, so The outlet of the air outlet disk 6 faces the wind cooler 4.

[0023] Furthermore, the communication pipe 9 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com