Asphalt tank container heating system

A heating system and container technology, which is applied in the direction of tank trucks, packaging, transportation and packaging, etc., can solve the problems of low heating efficiency, uneven temperature field distribution, and asphalt coking in asphalt tanks, and solve the problem of asphalt aging and easy Automatic control, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

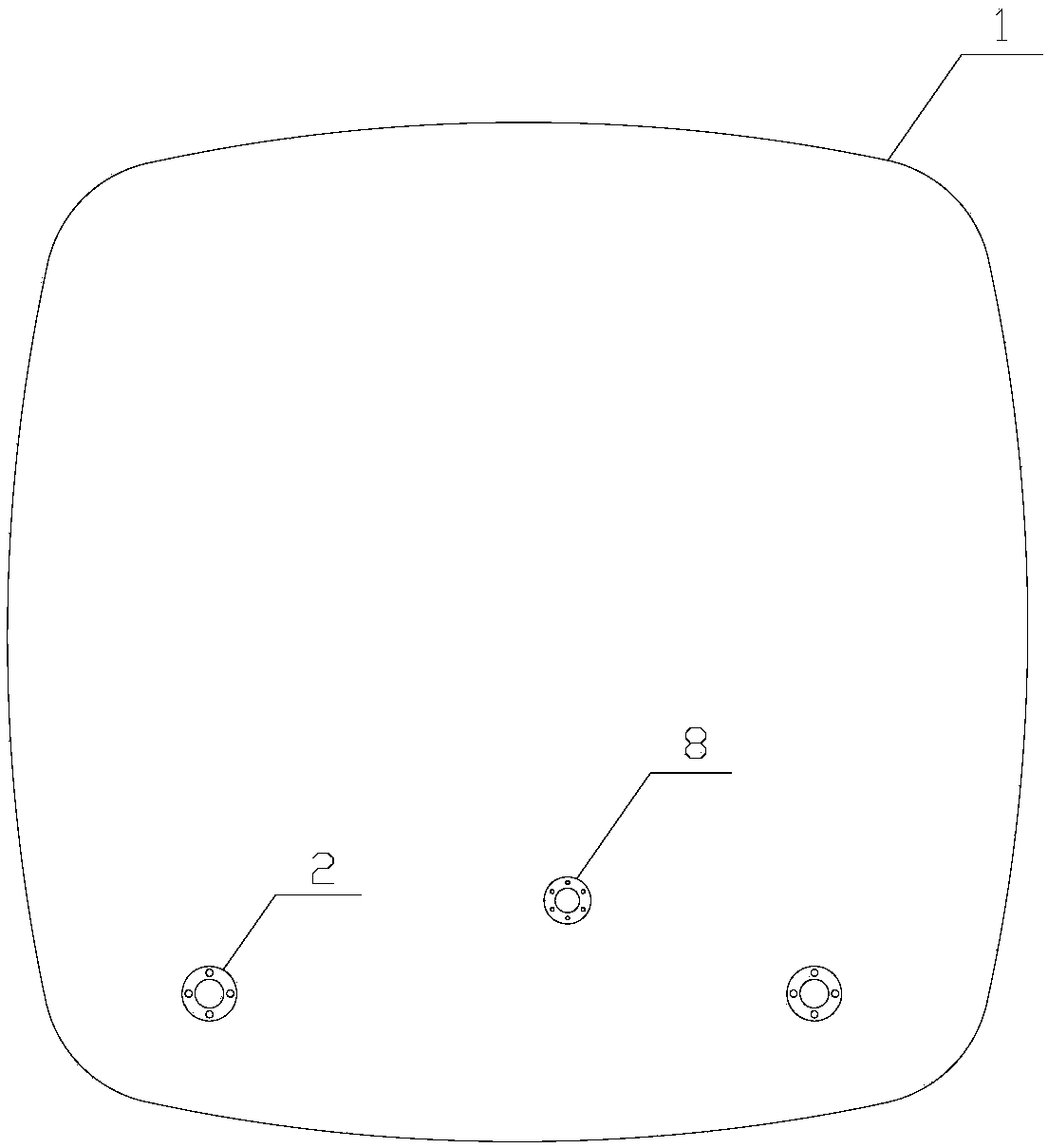

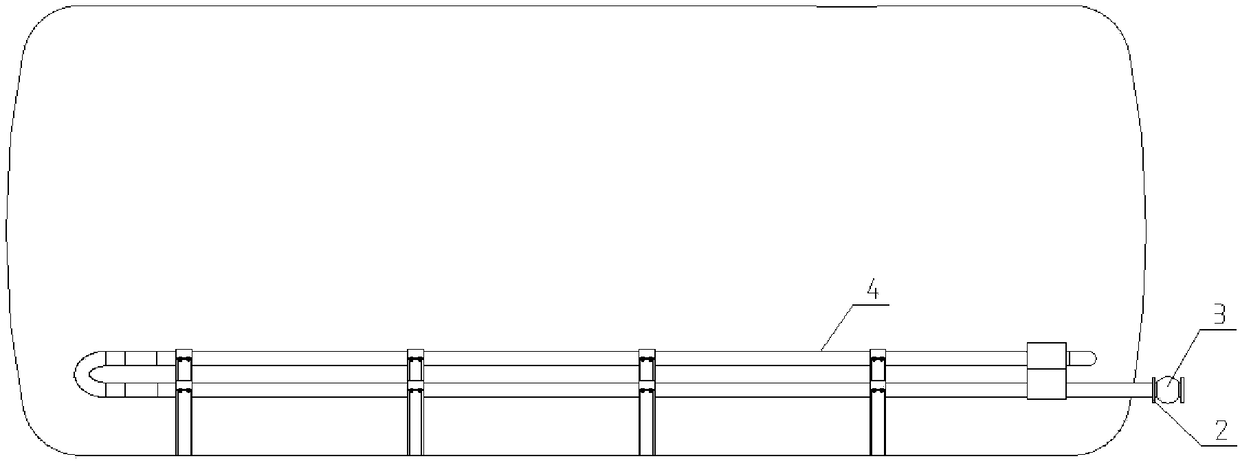

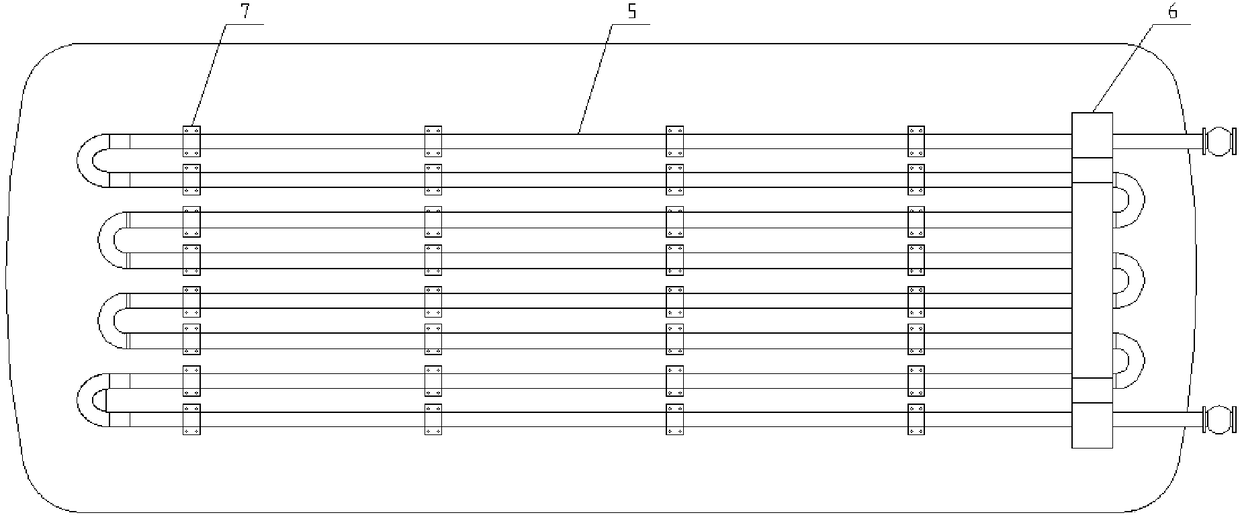

[0023] Such as Figure 1 to Figure 4 An asphalt tank container heating system shown includes a tank body 1, a heat transfer oil inner pipe assembly 4, a heat transfer oil inlet and outlet valve 3, and a heat transfer oil furnace assembly 9; the heat transfer oil inner pipe assembly 4 includes an inner pipe 5 , row pipe end support platform 6, a plurality of row pipe supports 7; One end of the tank body 1, the pipe end support platform 6 fixedly supports the inlet and outlet of the inner row pipe 5, and the inlet and outlet of the inner row pipe 5 protrude outside the tank body 1, and a connecting flange 2 is provided, and the connecting flange 2 and the Heat transfer oil inlet and outlet valve 3 connection;

[0024] The heat transfer oil furnace assembly 9 includes a heat transfer oil outlet 10, a heat transfer oil inlet 16, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com