Oil cooling device and air conditioner device with oil cooling device

A technology of cooling oil and being cooled, applied in mechanical equipment, liquid variable capacity machinery, variable capacity pump components, etc., can solve the problems of uneven oil temperature distribution, large fluctuations in the control process, mixing of refrigerants, etc., to improve cooling area, improve the cooling effect, prevent the effect of low cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

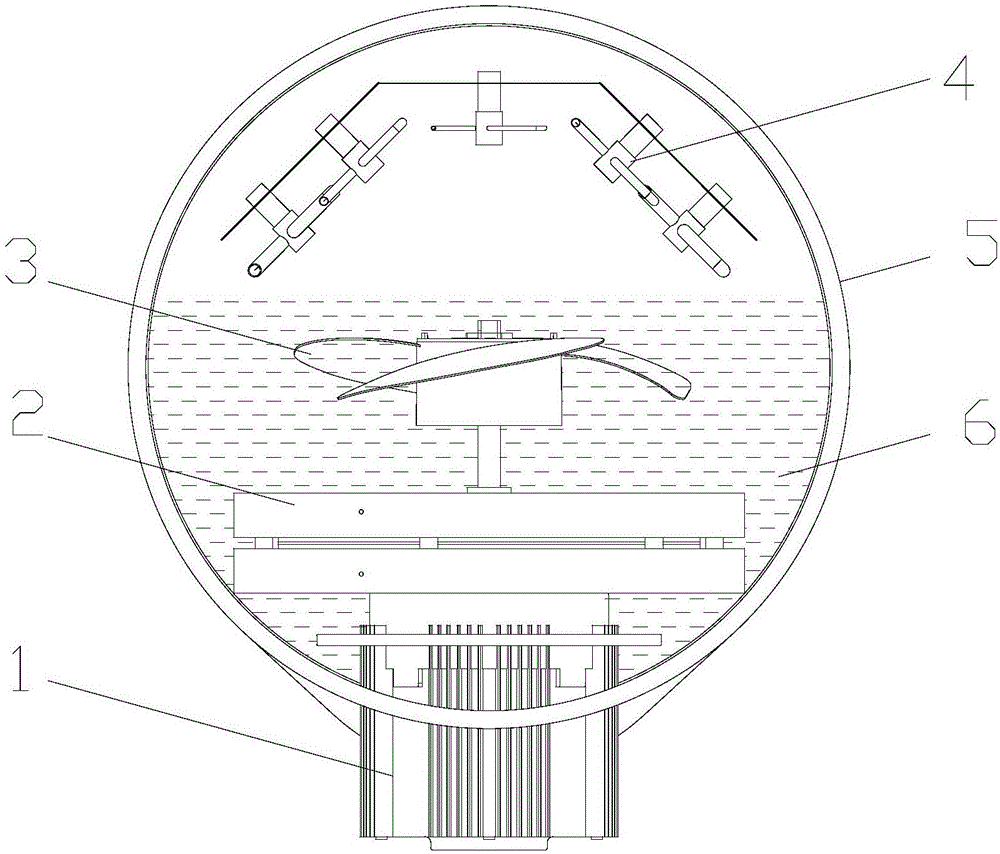

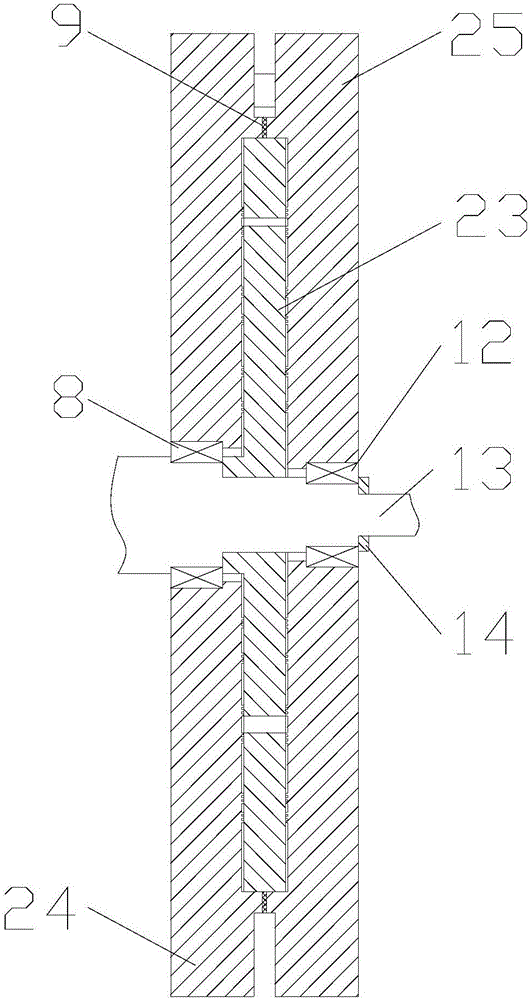

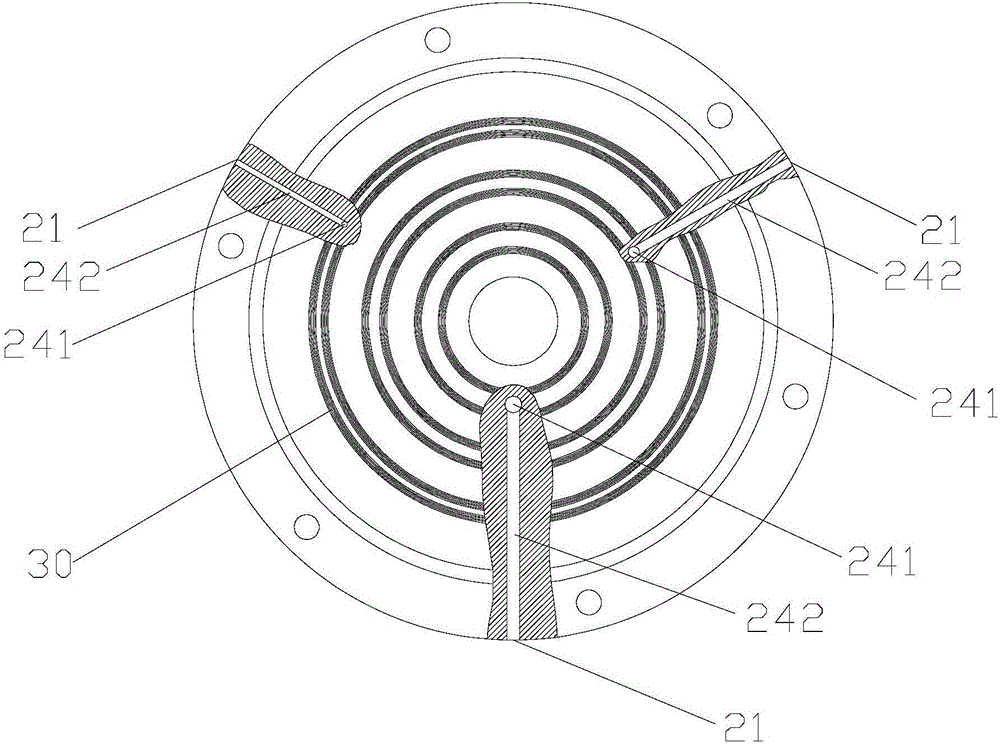

[0032] Such as figure 1 As shown, according to the embodiment of the present invention, the cooling oil device includes a pulse distribution part 2 and a spray part 4, and the pulse distribution part 2 includes a medium inlet 21 for introducing a cooling medium, a medium outlet 22 for delivering a cooling medium to the spray part 4 and The flow distribution structure 23 that controls the communication between the medium inlet 21 and the corresponding medium outlet 22 or blocks, and the medium outlet 22 is connected with the spray part 4 .

[0033] The cooling oil device sends the cooling medium to the spraying part 4 through the pulse distribution part 2, and sprays the cooling medium to the lubricating oil to be cooled through the spraying part 4 to realize the temperature control of the lubricating oil. The distribution structure 23 of the pulse distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com