Multi-station automatic deep-frying oven device for food

A multi-station, fryer technology, used in food ovens, food science, oil/fat baking, etc., can solve the problems of lag in advanced components, low economic benefits, and no advancement, and achieve oil temperature balance , to avoid insufficient oil, the effect of consistent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

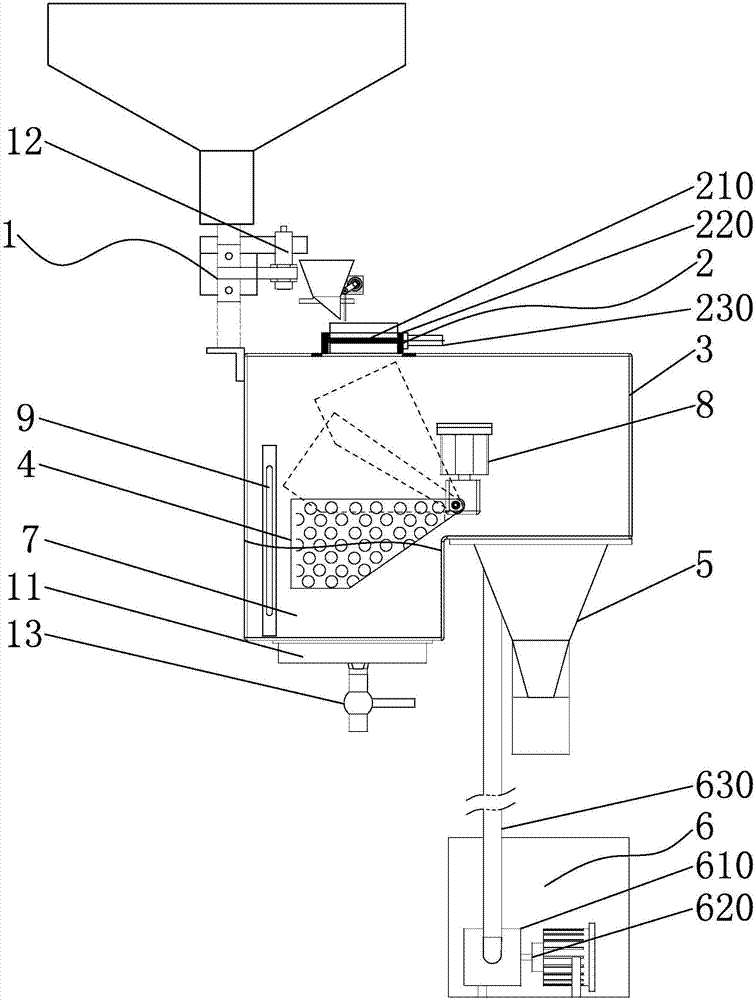

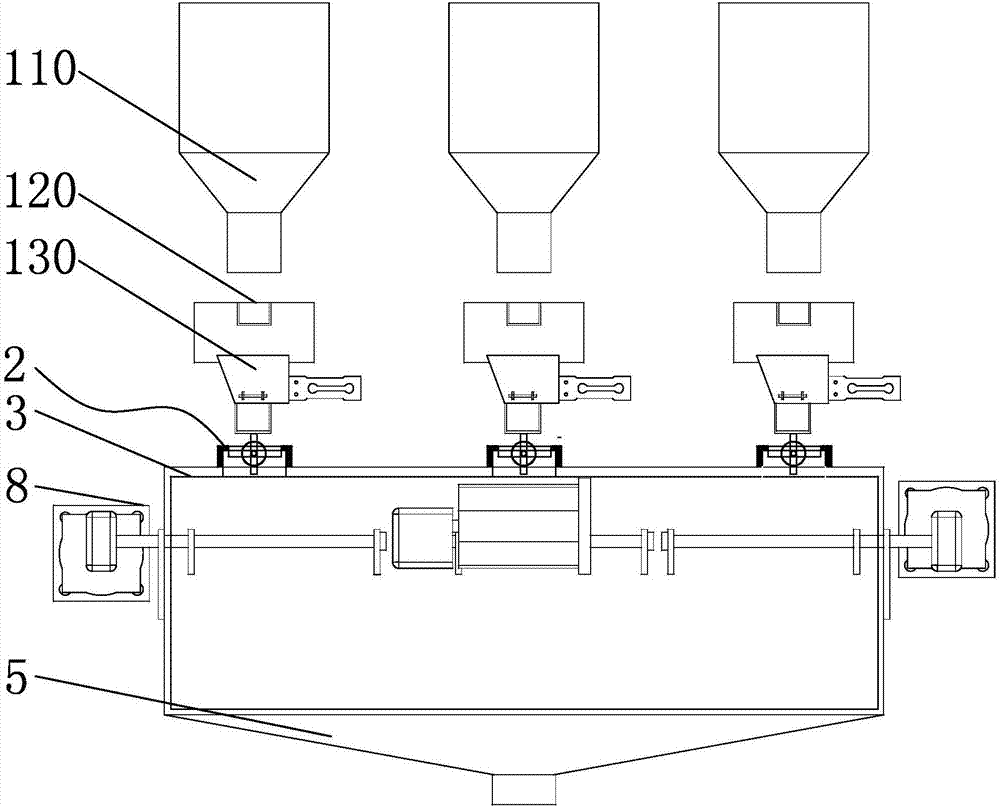

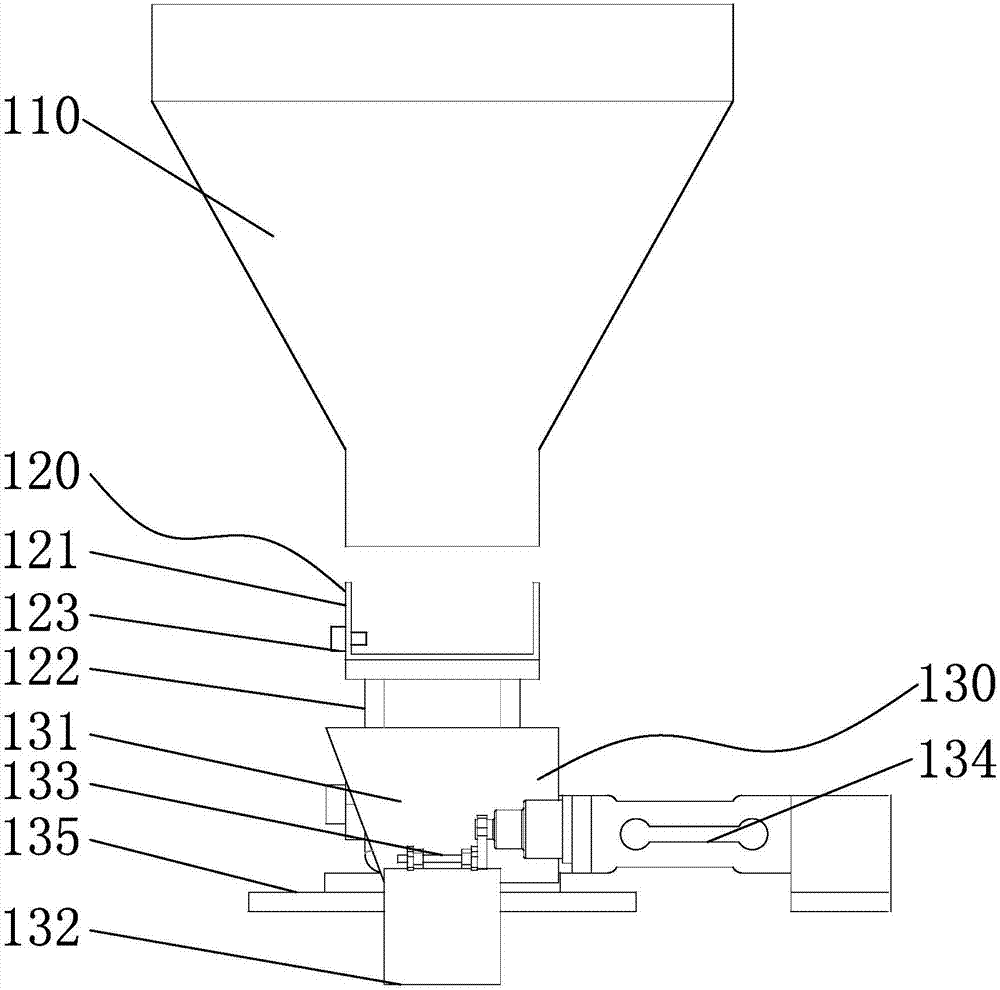

Image

Examples

Embodiment 2

[0045] Such as Image 6 As shown, the difference from Example 1 is that it is a multi-station automatic fryer device for food. The vibrating groove in this example is set on a circle, and the fried food is vibrated from the circumferential direction, and finally vibrates out from the discharge port. .

Embodiment 3

[0047] Such as Figure 7 As shown; in this embodiment: the transfer transmission device includes a transfer frame 14, and the transfer frame 14 is equipped with a group of transfer pull plates 15 through a rotating shaft, and one end of the transfer pull plate 15 is fixedly connected with a group of electric push rods 16; In this embodiment; after the fried food is portioned in the automatic portioning device, it falls to the transfer pull plate and is driven by the electric push rod to complete the tilting, and the fried food is poured into the fried material in the frying tank box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com