Patents

Literature

30results about How to "Uniform oil temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

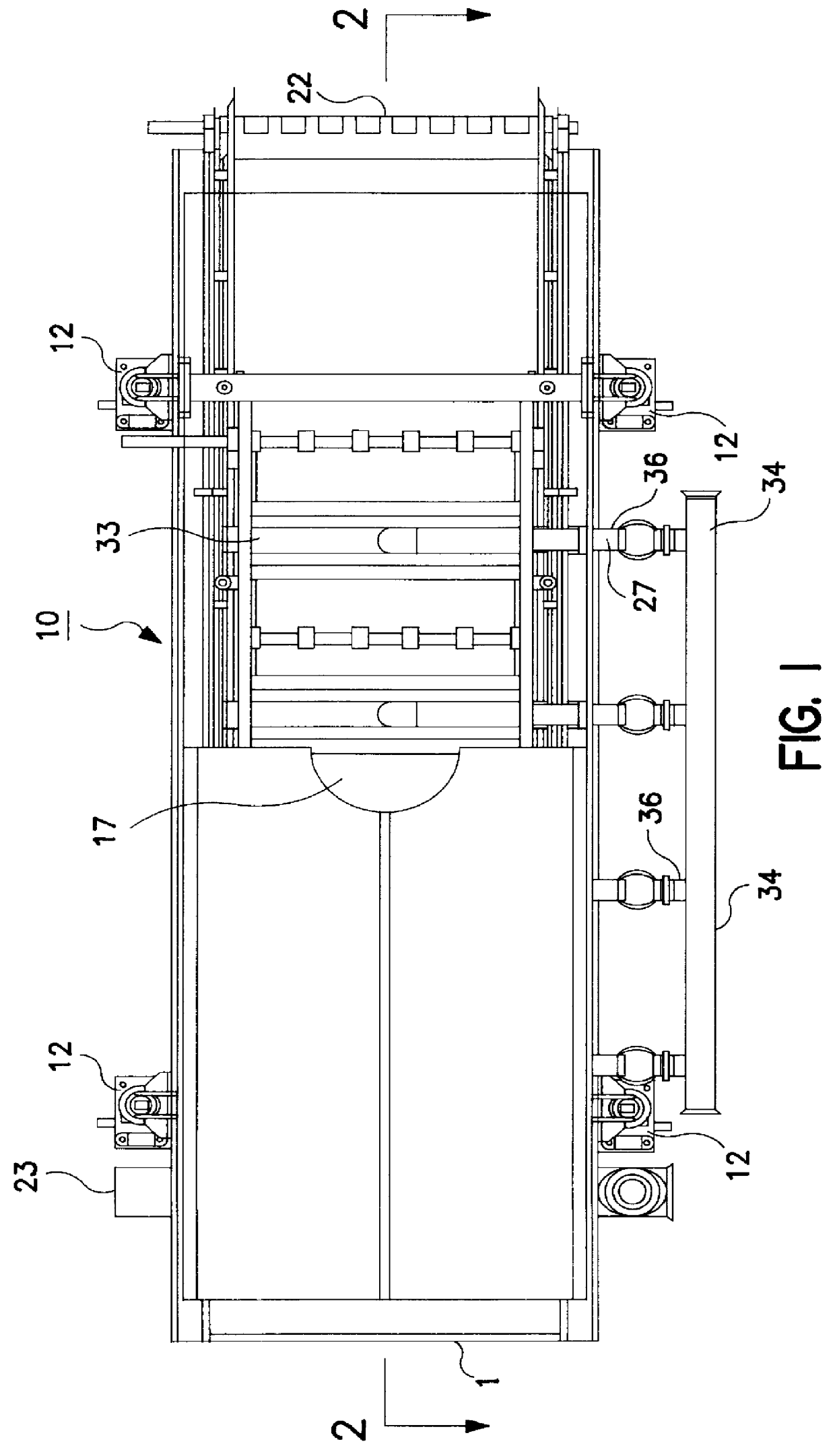

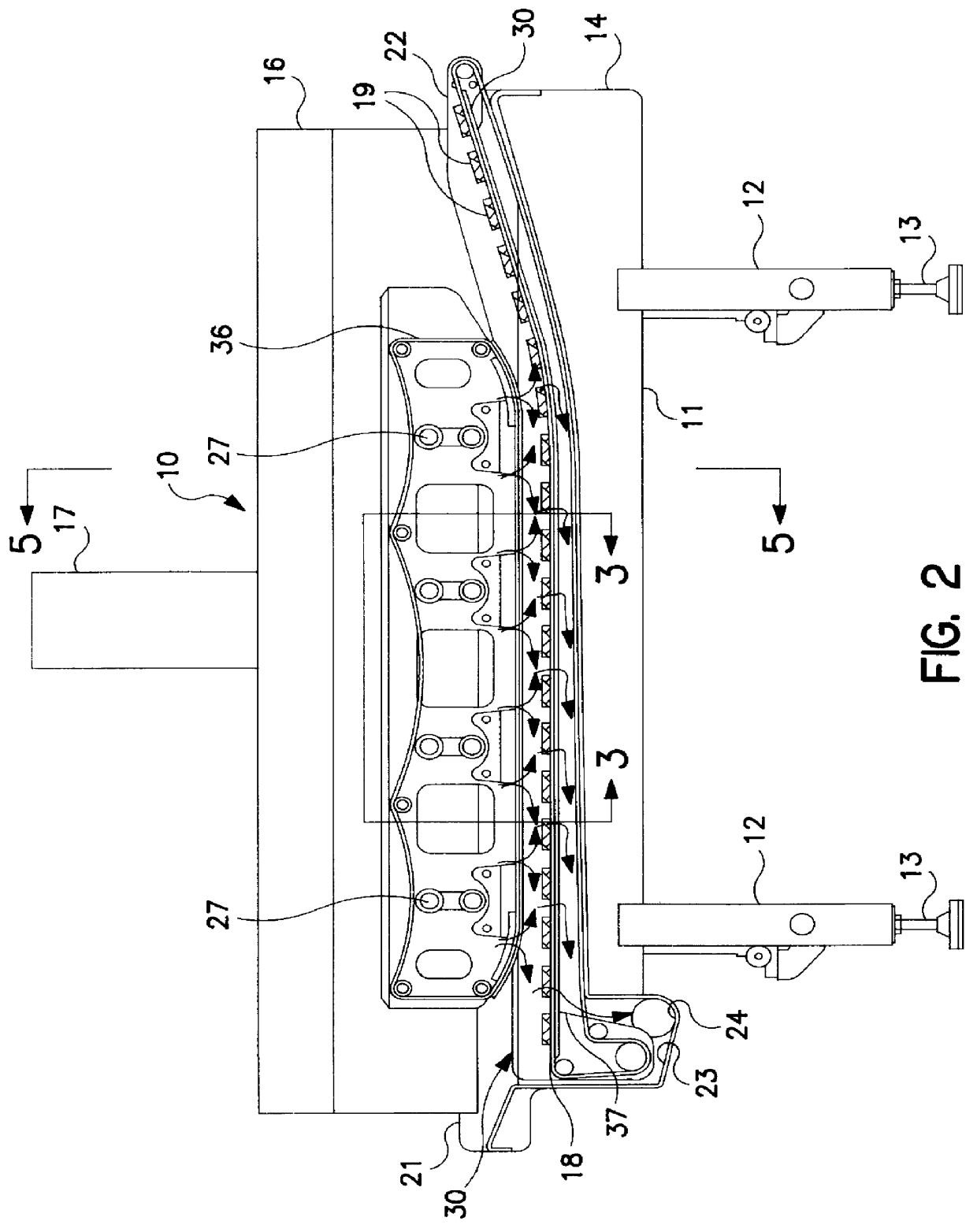

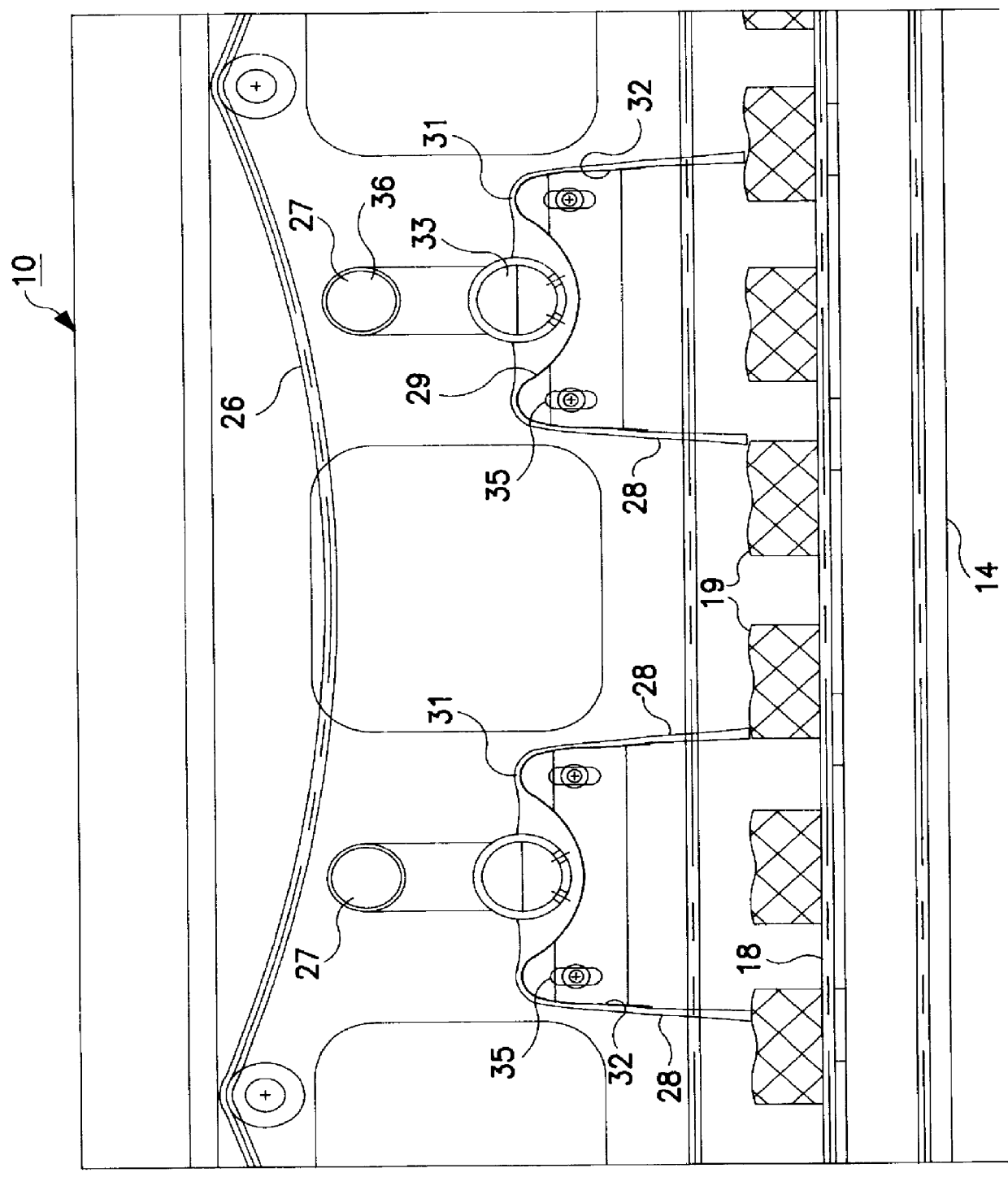

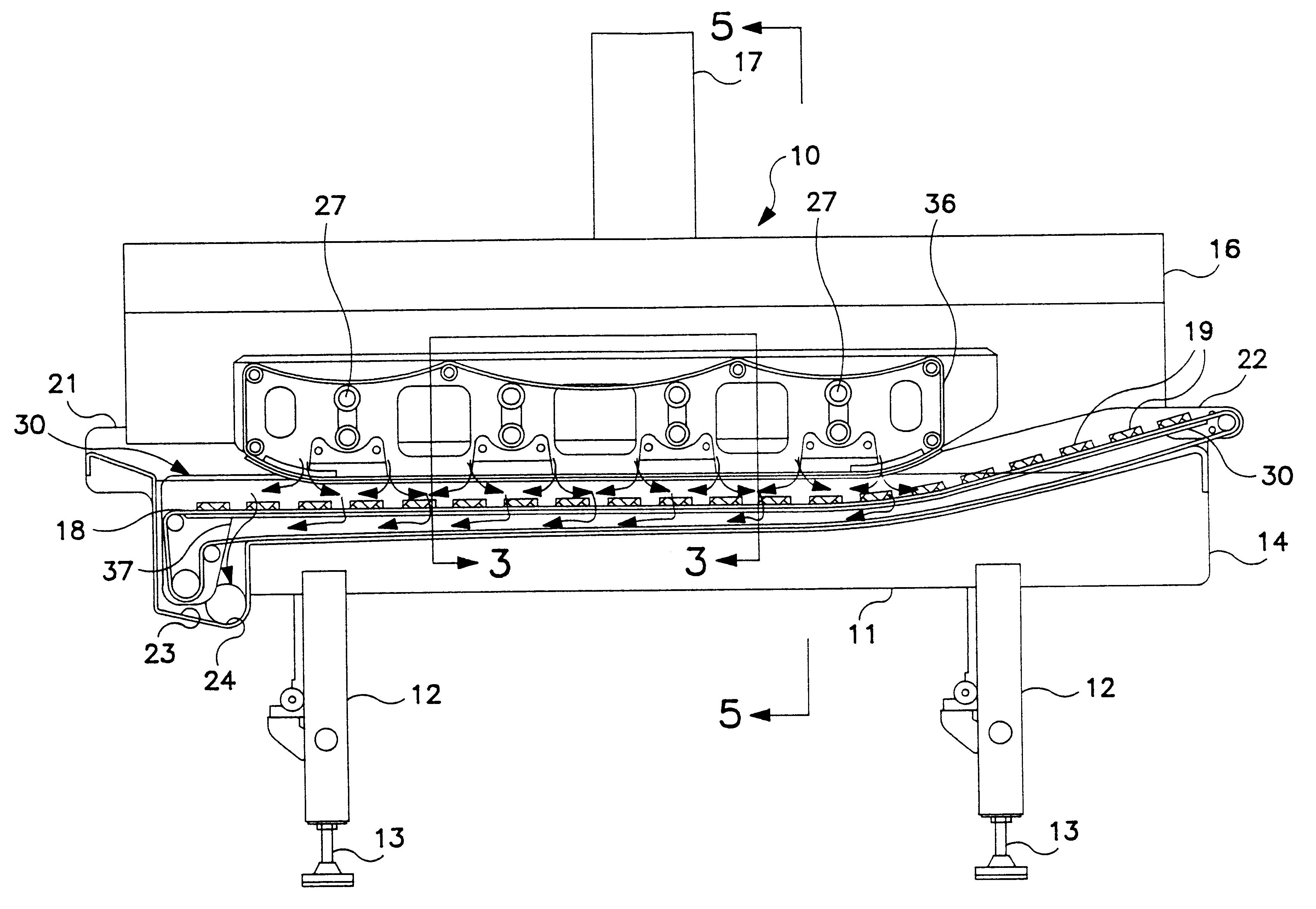

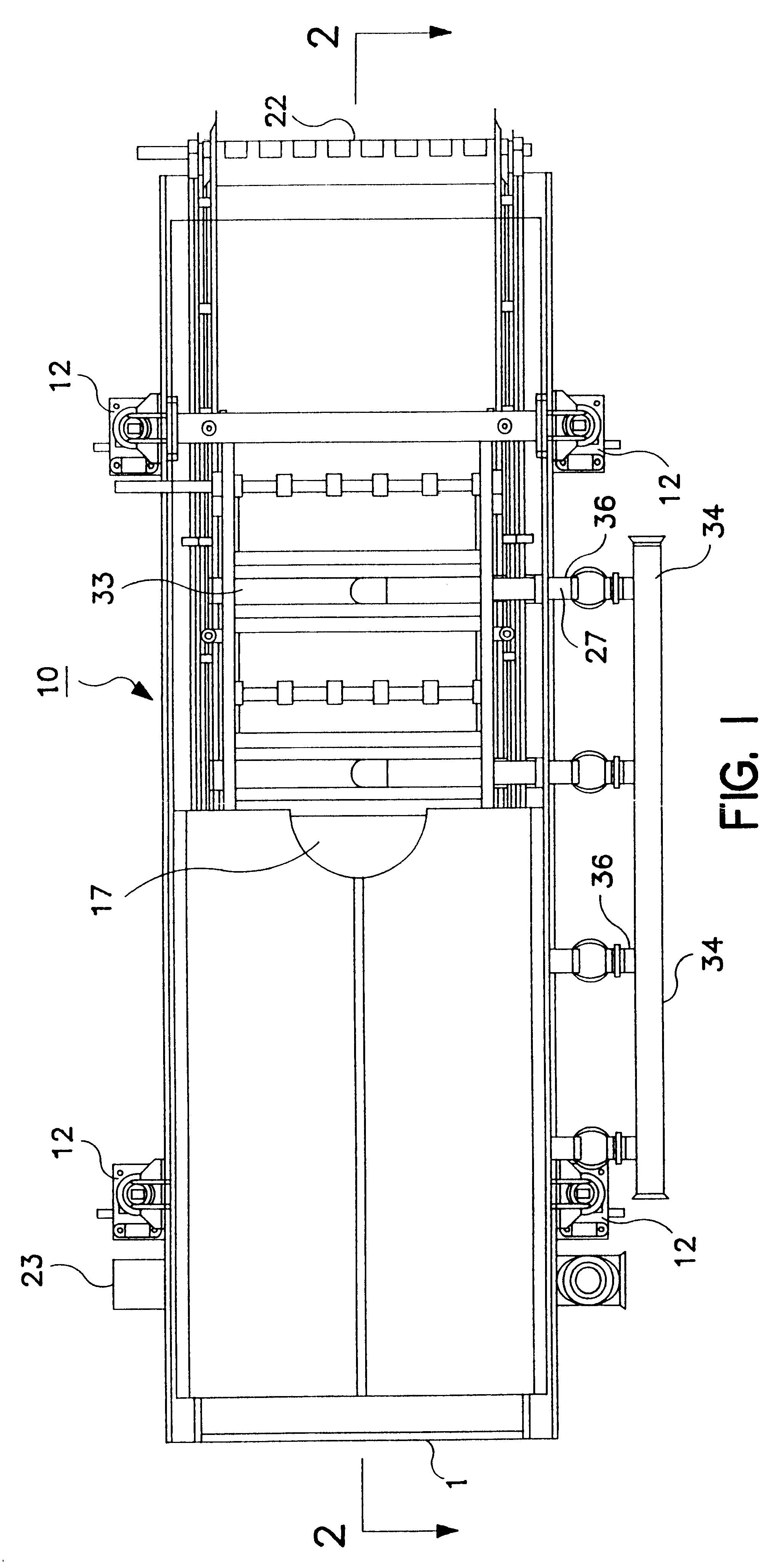

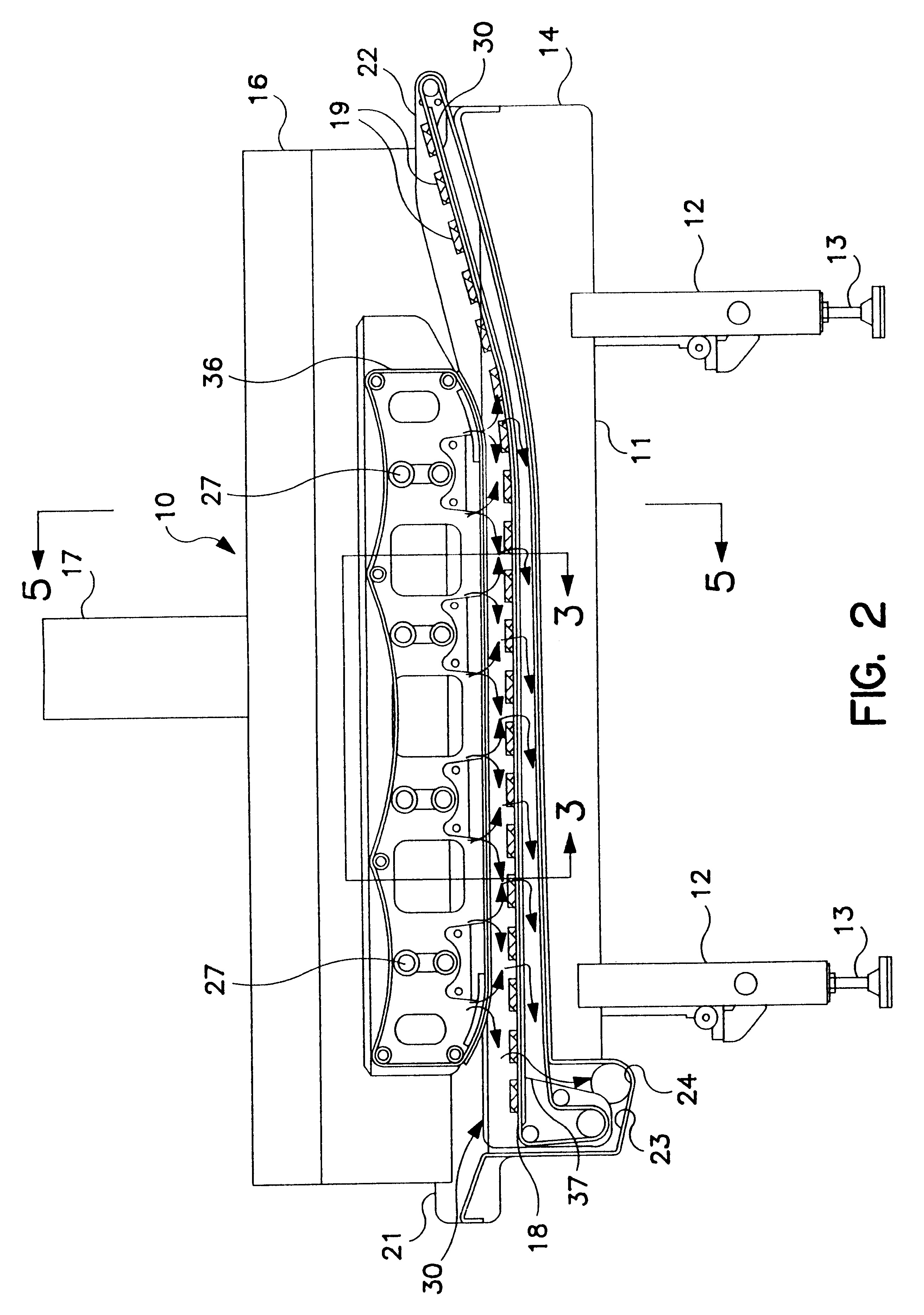

Breaded products fryer

InactiveUS6067899AUniform and accurate vertical flow patternSpeed up the flowFood preservationCooking vesselsCooking oilFood products

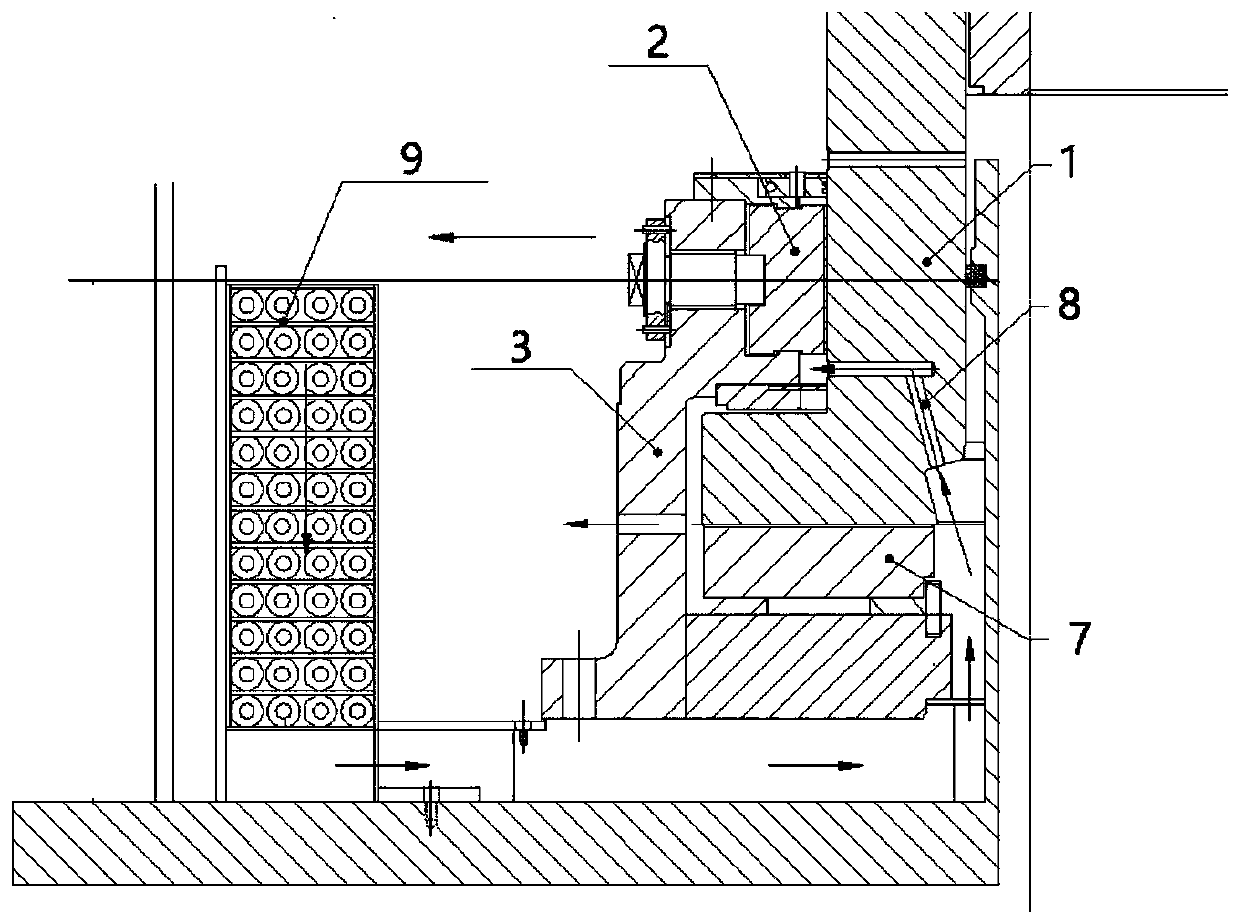

A fryer for food products such as battered and breaded pieces of meat has a main conveyor with forward and return belt paths inside the fryer pan, the belt return dragging the pan bottom sweeping fines to one end for removal. A submerger conveyor prevents products from floating in the cooking oil which enters the fryer from above through oil inlet weirs. A plurality of weirs supply curtains of hot cooking oil in non-turbulent flow onto the food product covering the product as the product is conveyed on the main conveyor. The cooking oil is returned along defined lanes in the pan for reheating outside of the fryer. The food products are removed from the fryer in a cooked condition with the bread coatings intact.

Owner:HEAT & CONTROL

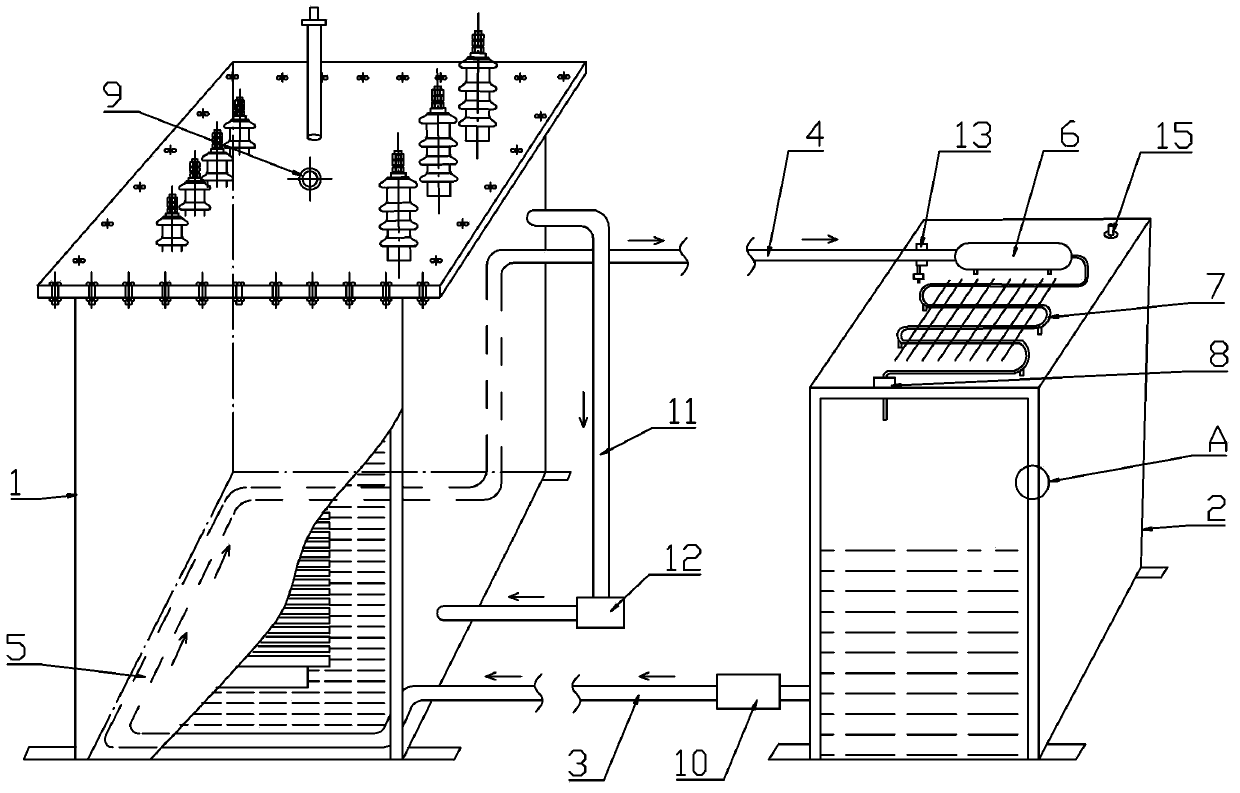

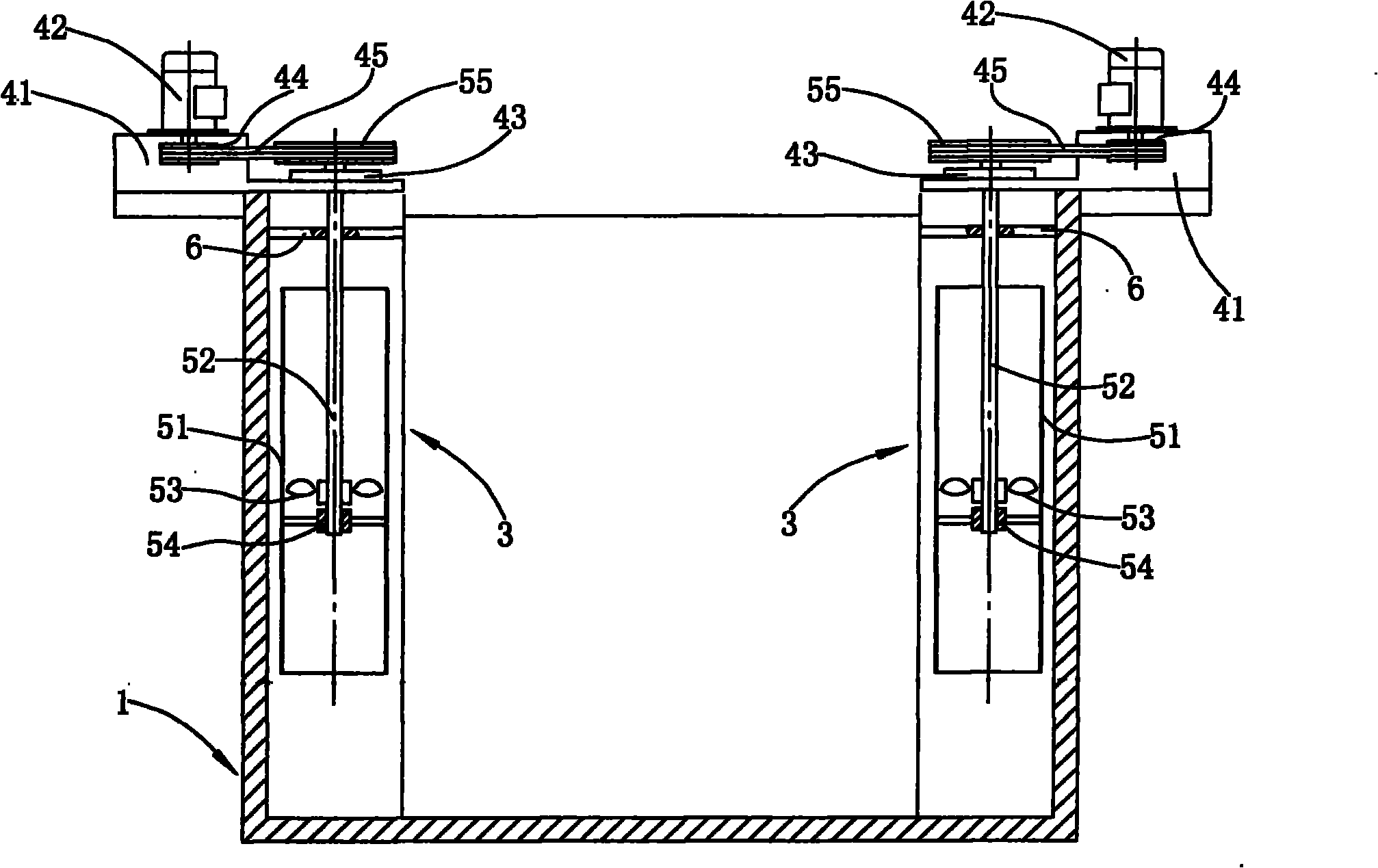

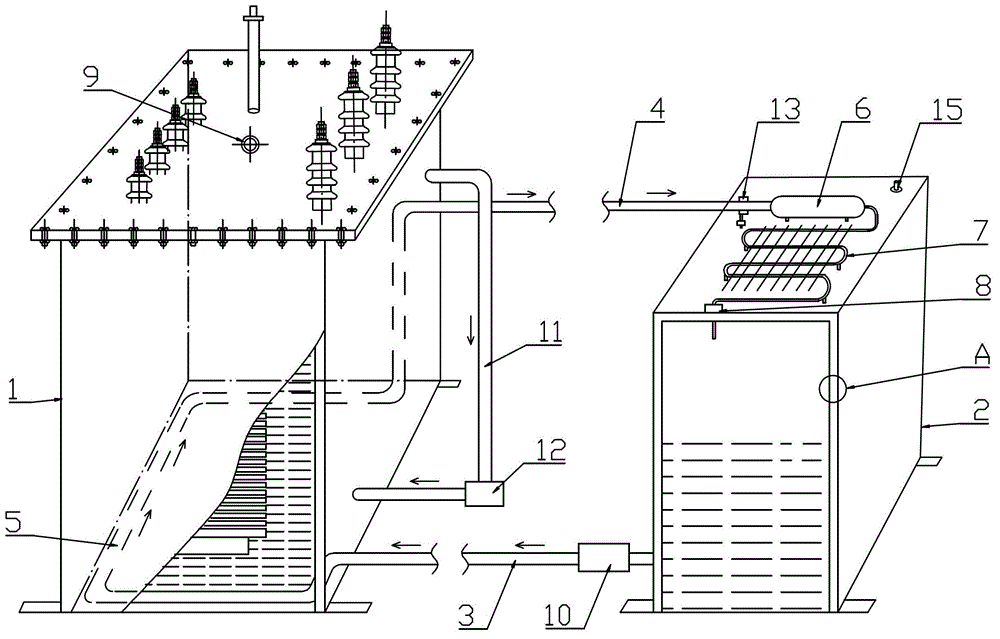

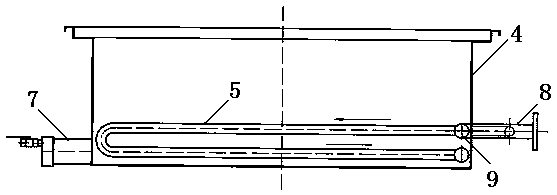

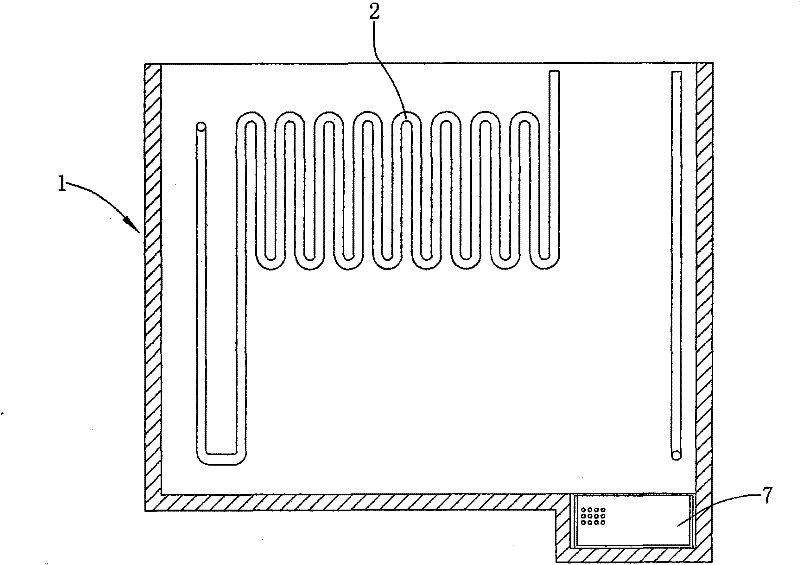

Liquid nitrogen strong cooling transformer and refrigerating method thereof

InactiveCN103390485AImprove heat exchange efficiencyAchieve the purpose of coolingTransformers/inductances coolingTemperature control using electric meansElectricityLiquid state

The invention relates to a liquid nitrogen strong cooling transformer and a refrigerating method thereof. The transformer comprises a transformer oil tank and a liquid nitrogen tank; the liquid nitrogen tank is connected with a liquid nitrogen outlet pipe; the transformer oil tank is connected with a gas nitrogen outlet pipe; an evaporating pipe is coiled in the transformer oil tank; one end of the evaporating pipe is communicated with the liquid nitrogen outlet pipe and the other end of the evaporating pipe is communicated with the gas nitrogen outlet pipe; the gas nitrogen outlet pipe is sequentially provided with a liquid nitrogen compressor, a condenser and a throttling valve; the tail end of the gas nitrogen outlet pipe extends into the liquid nitrogen tank; a temperature sensor is arranged in the transformer oil tank; and the liquid nitrogen outlet pipe is provided with a heat preservation electromagnetic valve electrically connected with the temperature sensor. The liquid nitrogen strong cooling transformer and the refrigerating method thereof have the beneficial effects that 1, heat exchange is carried out between liquid nitrogen and transformer oil, heat exchange efficiency is high and gas nitrogen is retransformed into liquid nitrogen by the liquid nitrogen compressor and the condenser and is recycled; and 2, the transformer oil in upper and lower cavities of the transformer oil tank is repeatedly circulated by a transformer oil circulating pipe and a circulating oil pump so as to enable the oil temperature to be balanced.

Owner:王文中

Cooking by enrobing through controlled curtain spillage

InactiveUS6558724B1Uniform oil temperatureWeight increaseFood preparationDeep fat fryersEngineeringCooking oil

Owner:HEAT & CONTROL

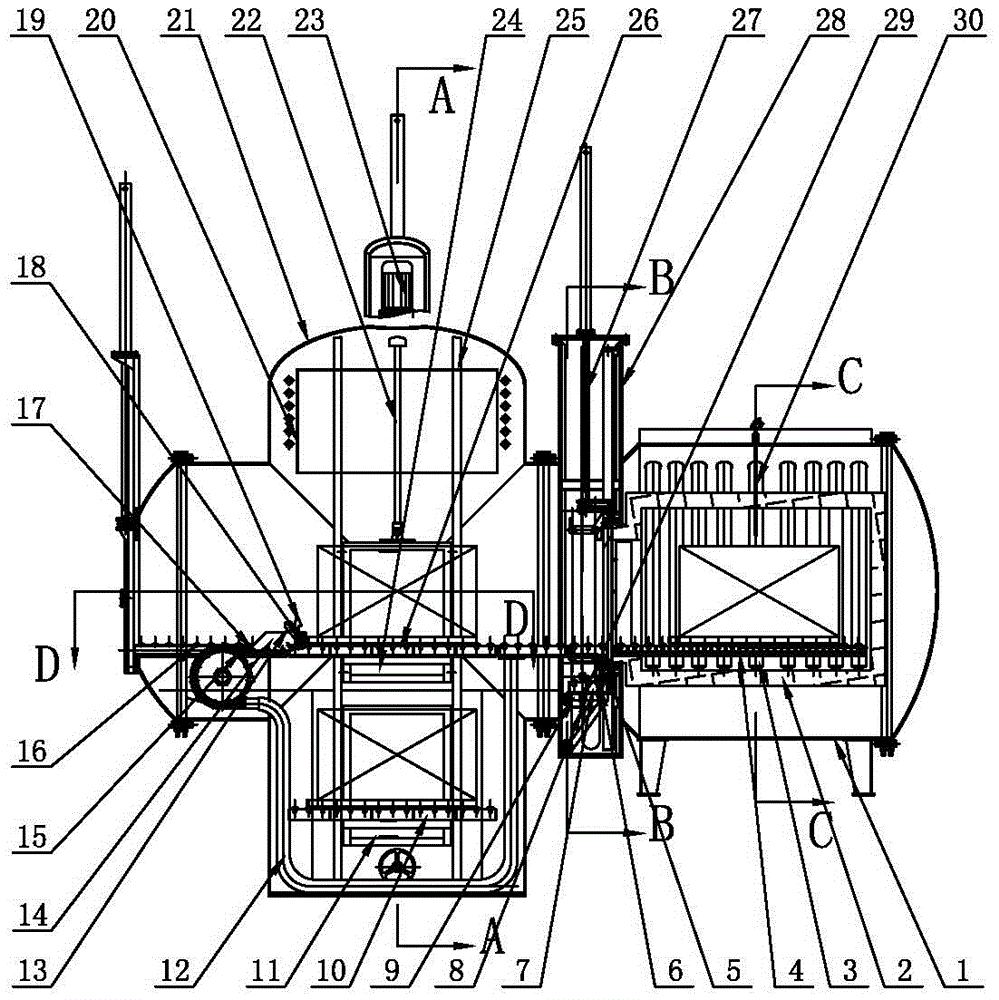

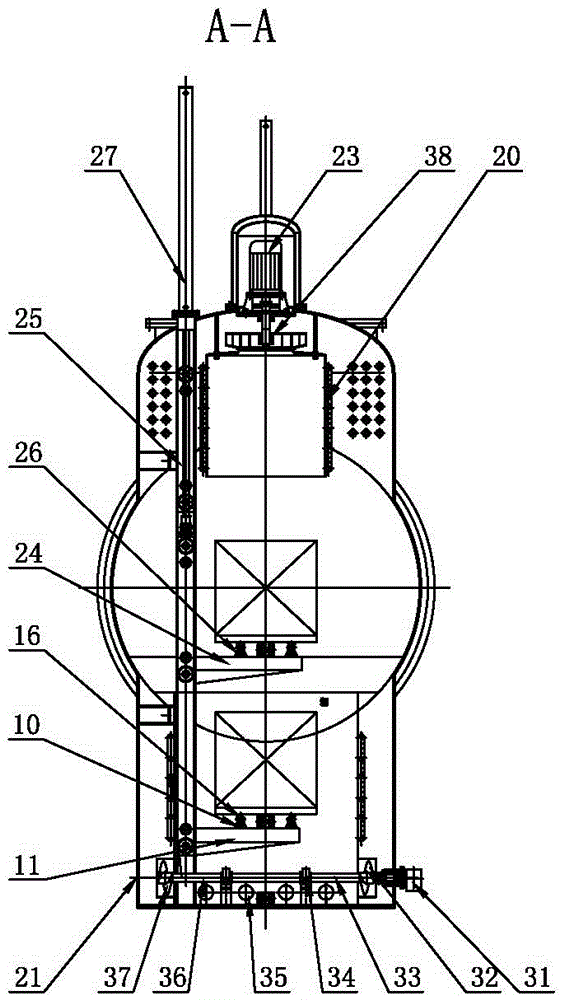

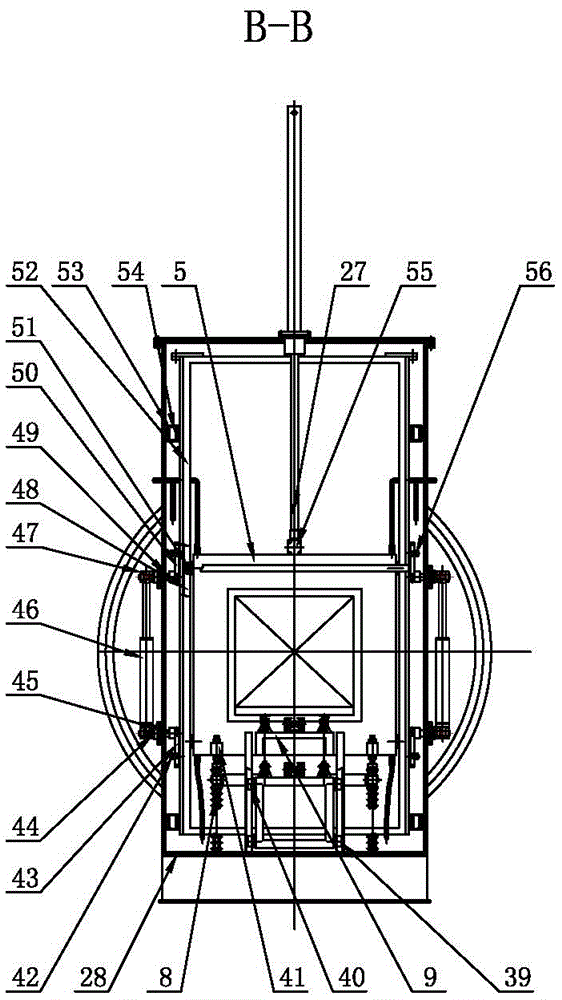

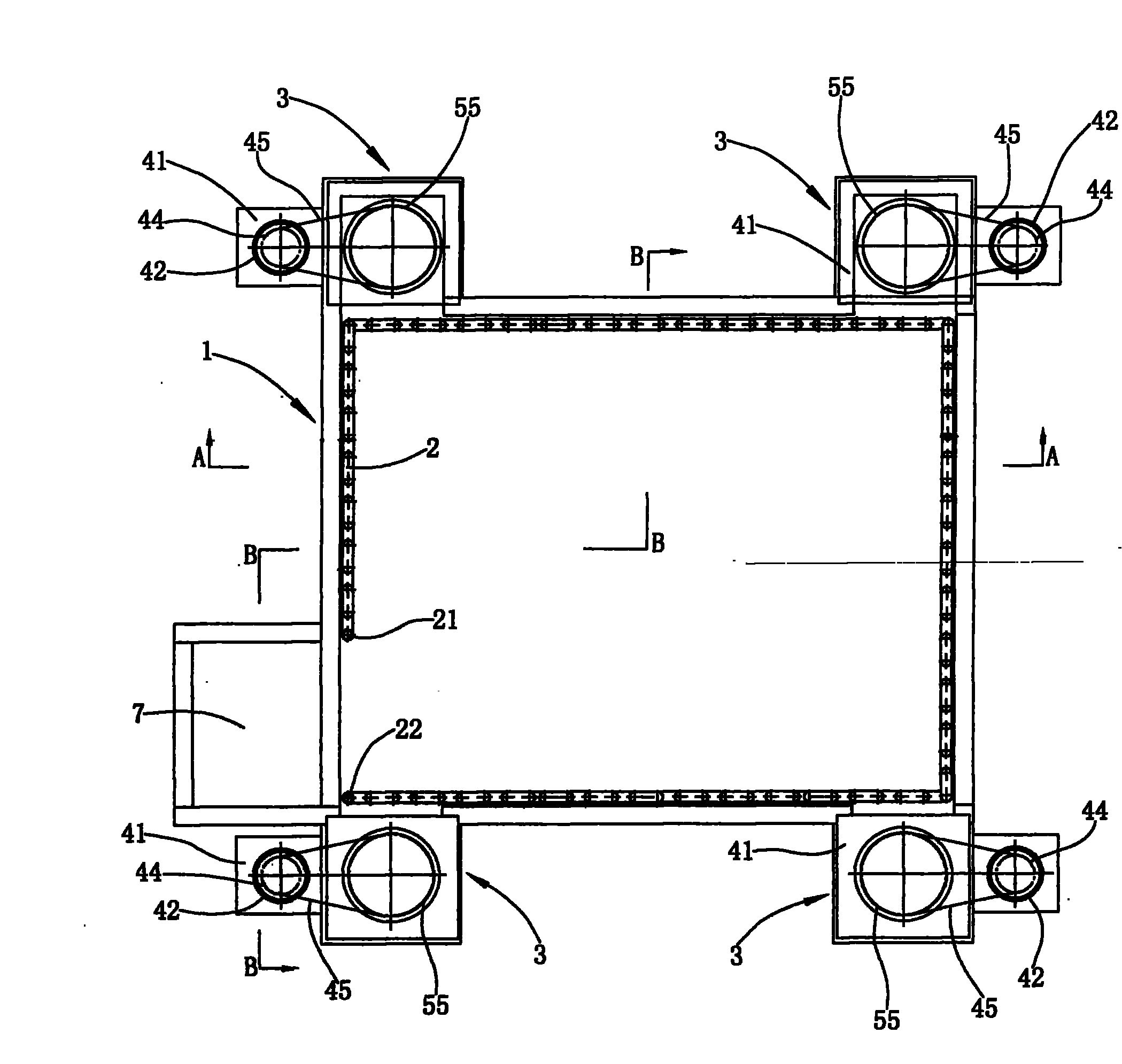

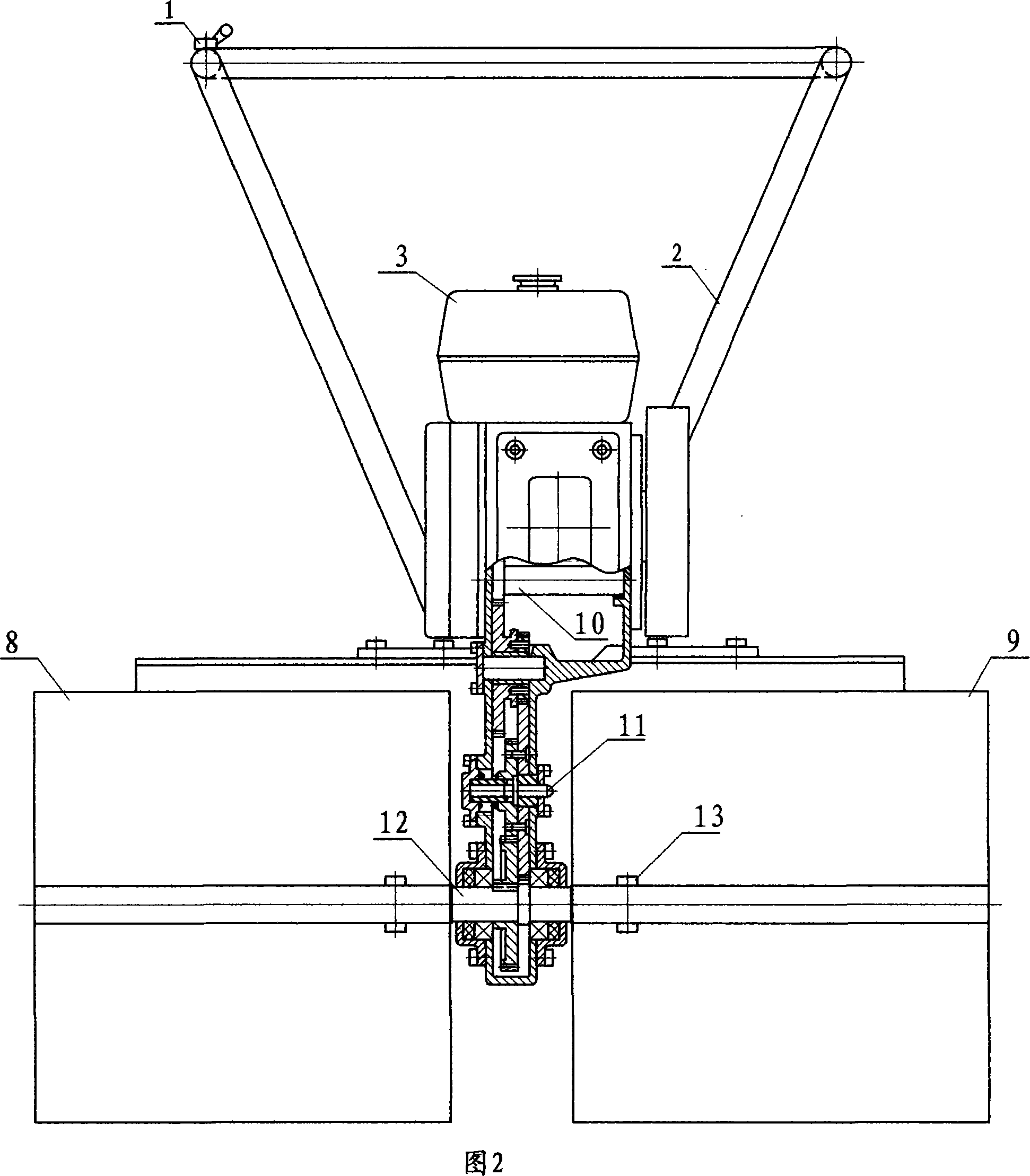

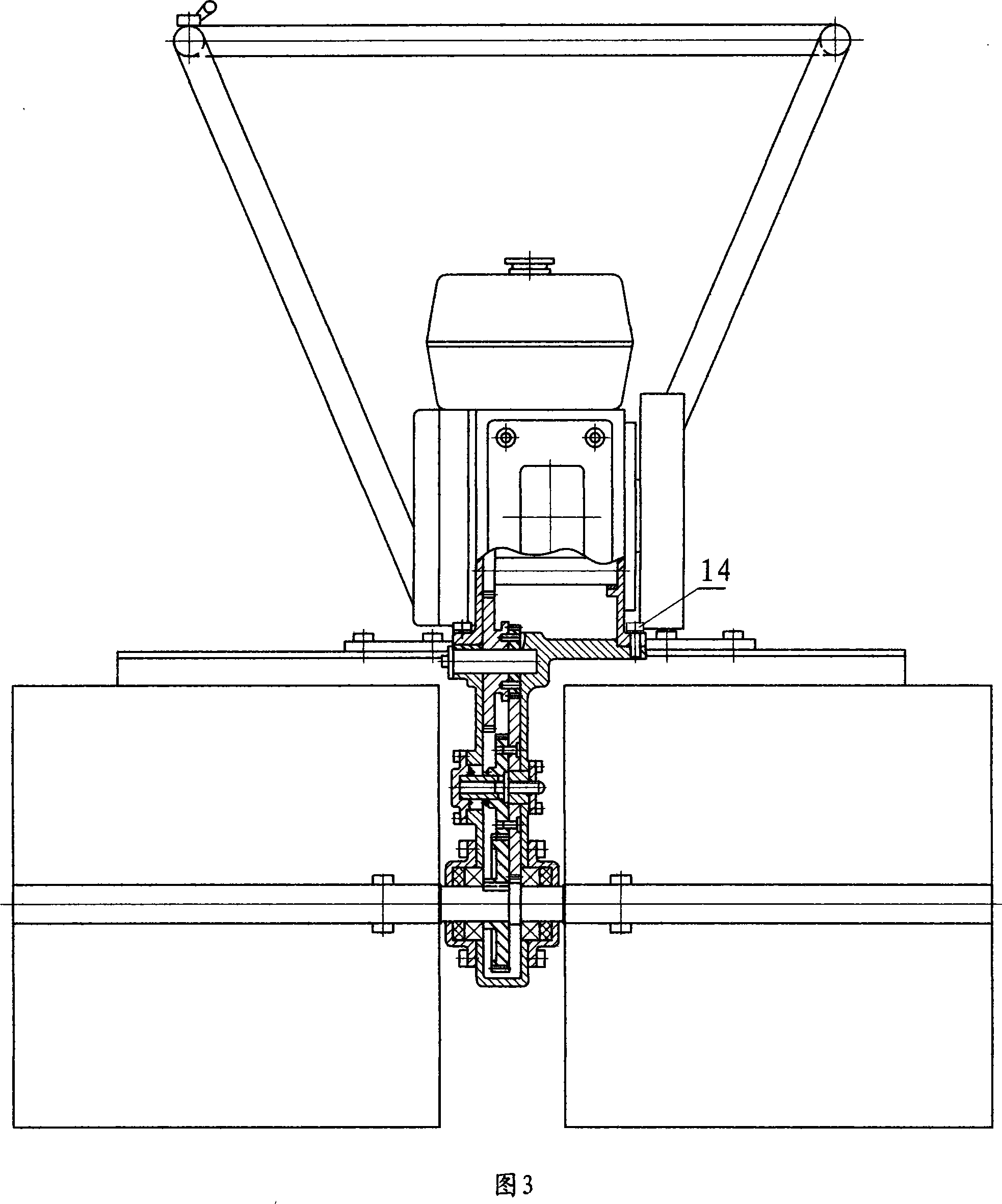

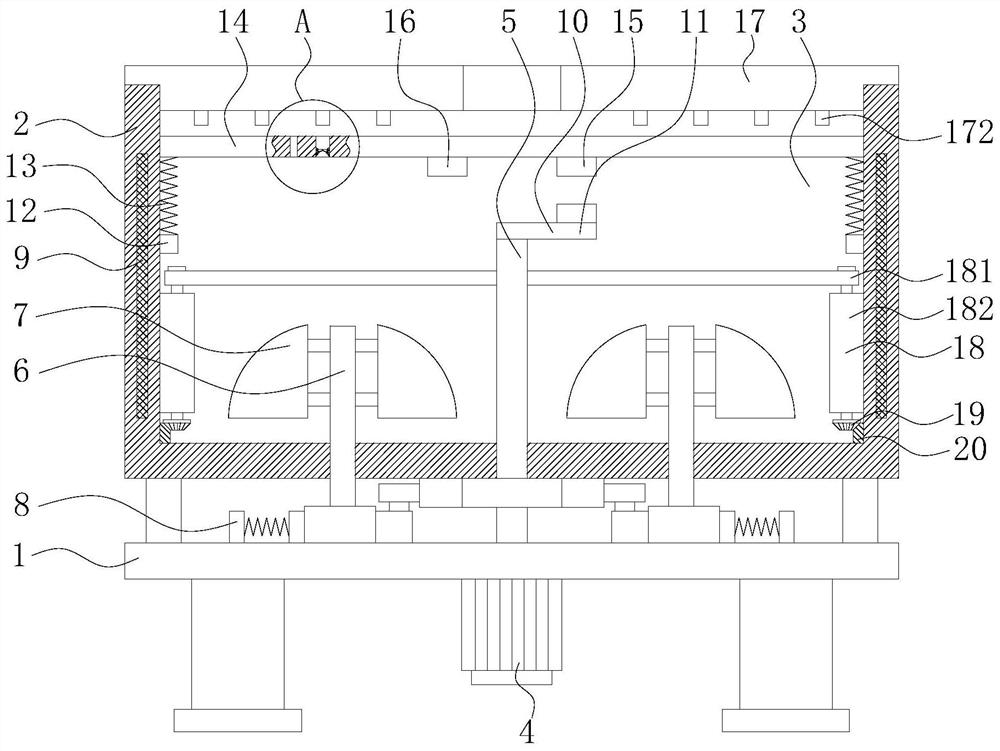

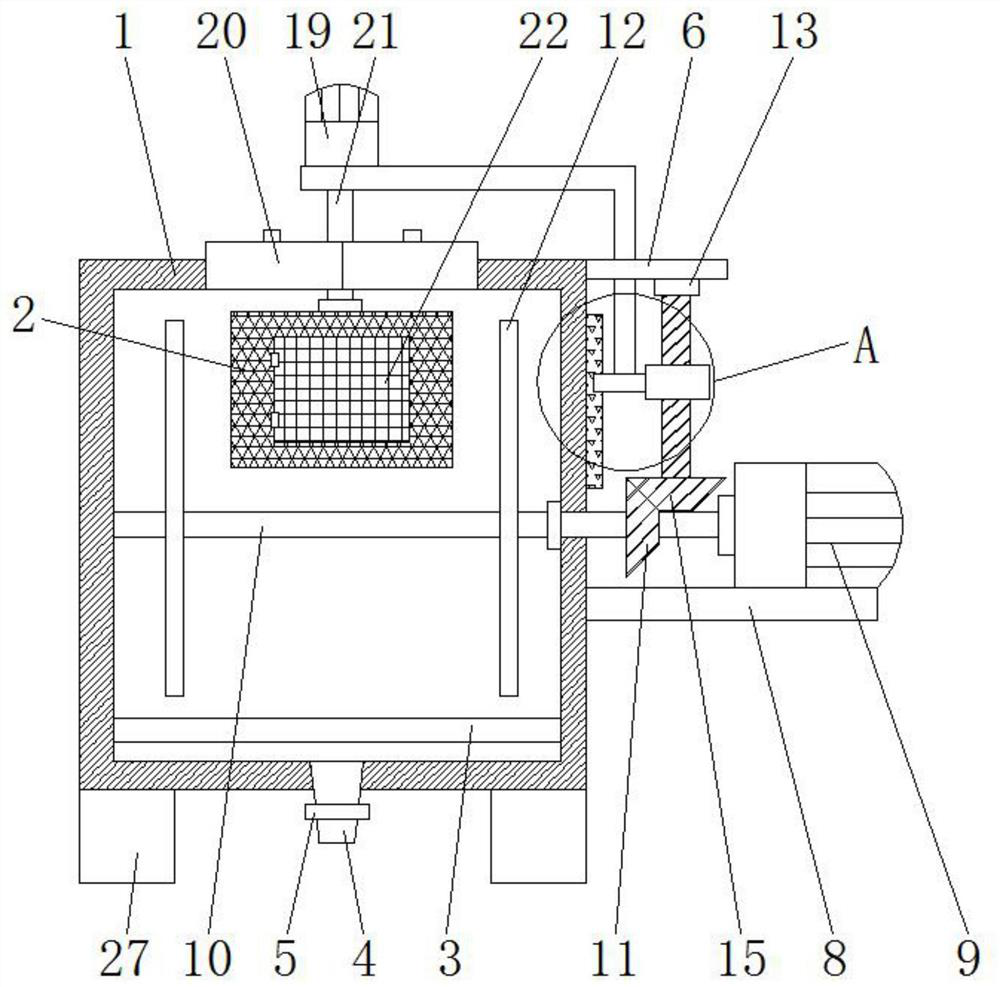

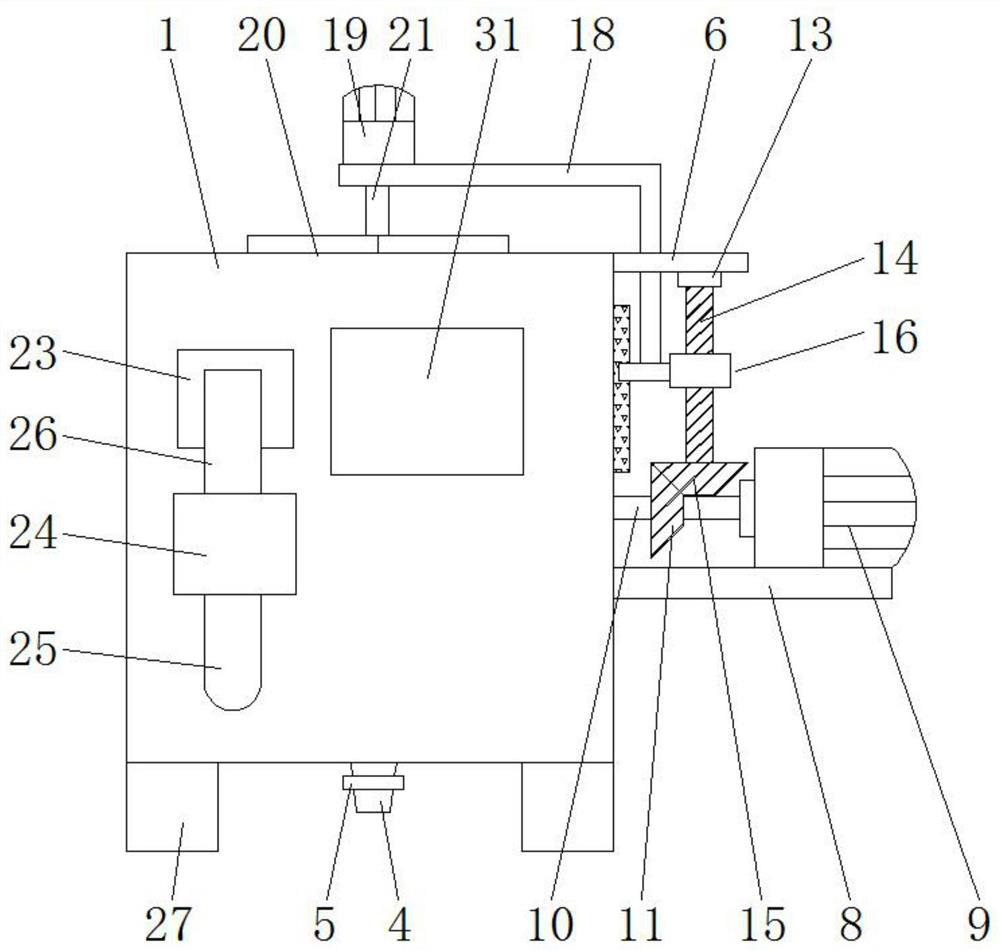

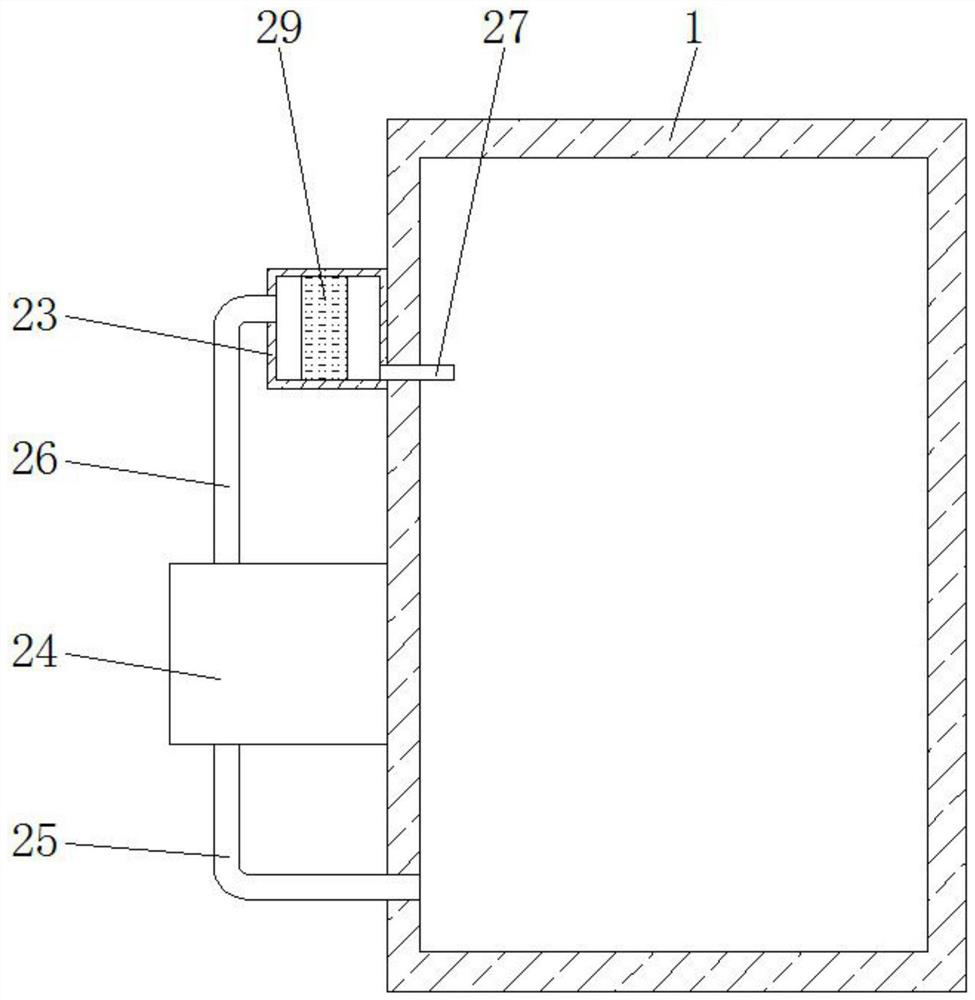

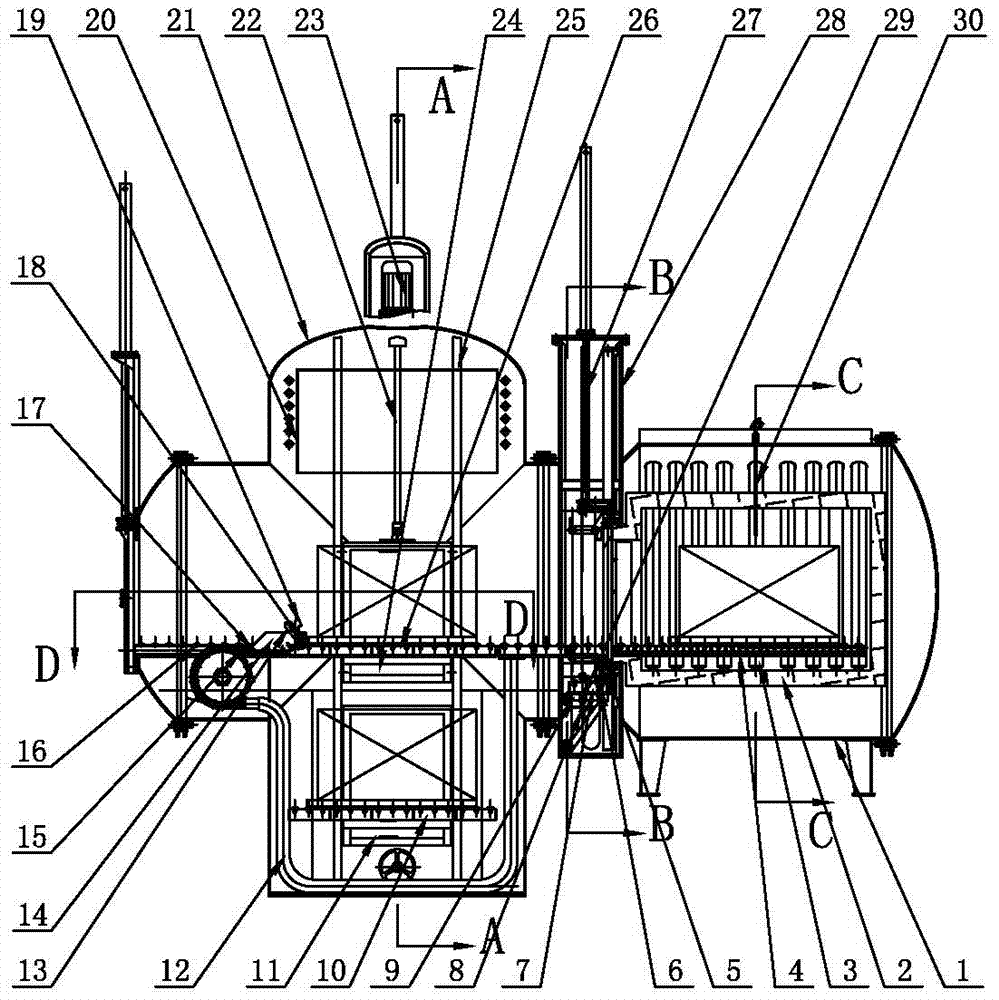

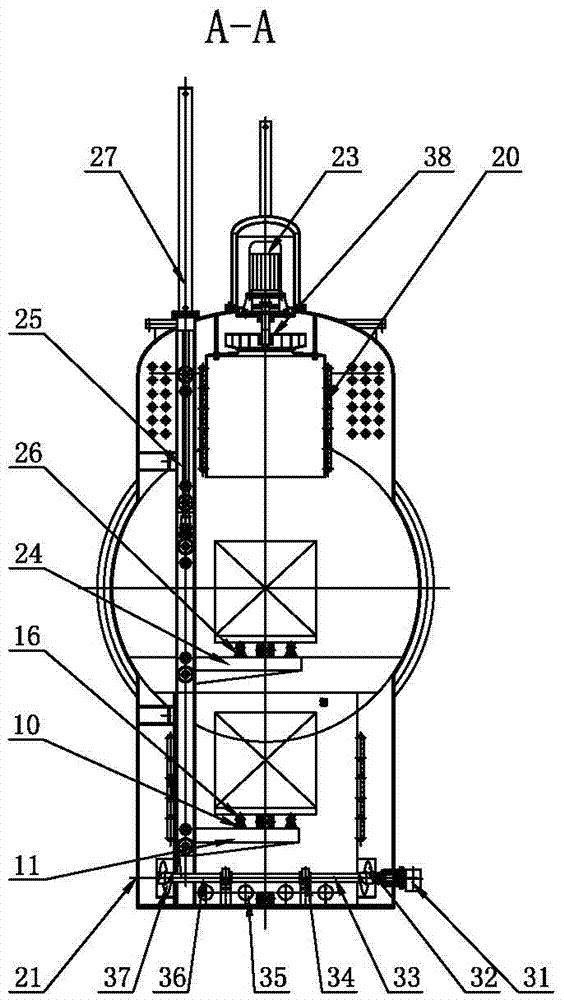

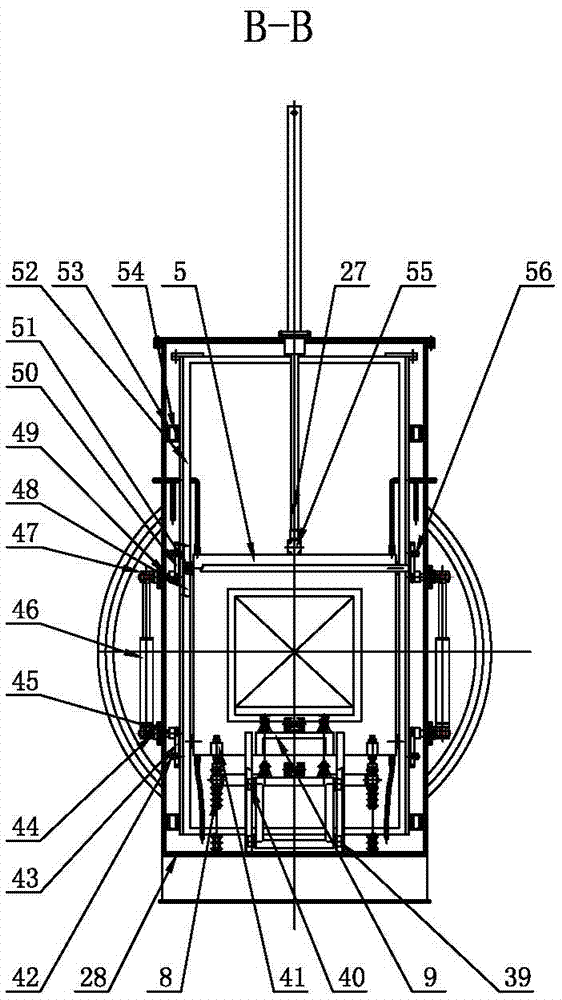

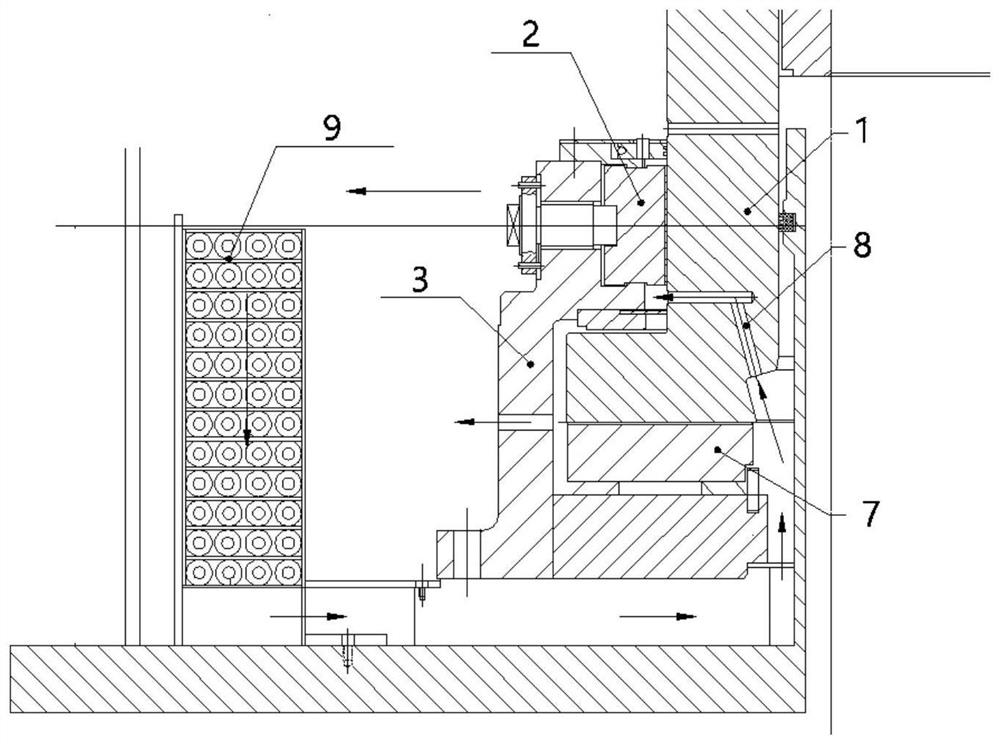

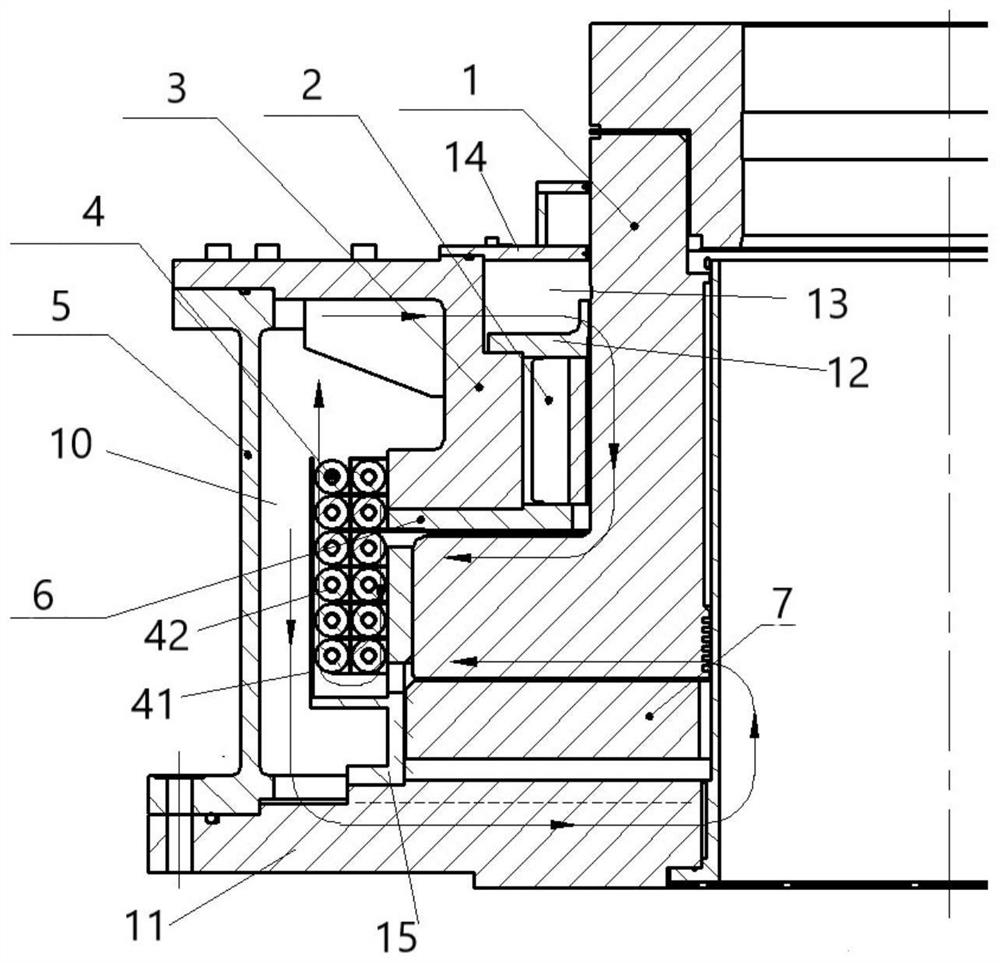

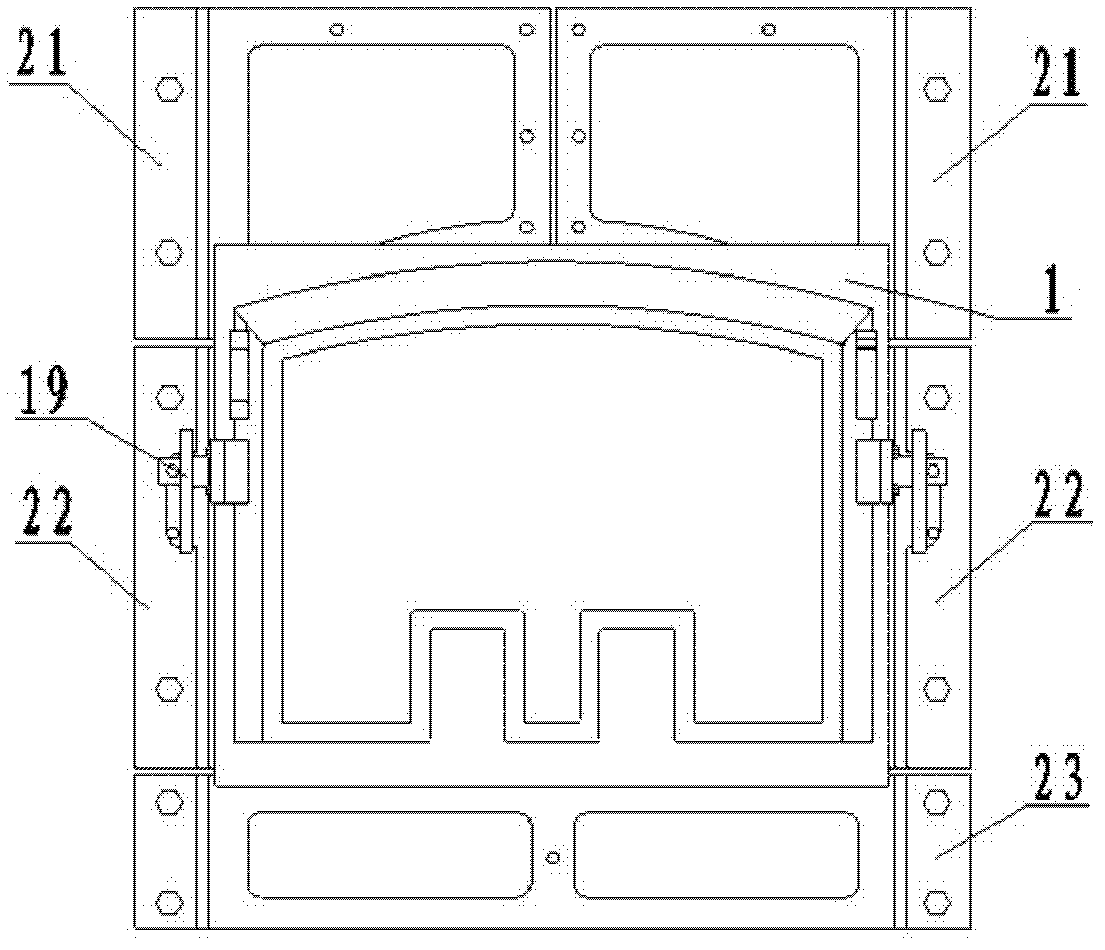

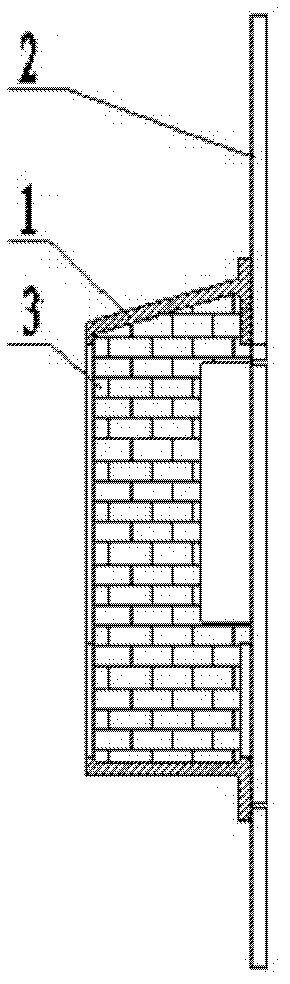

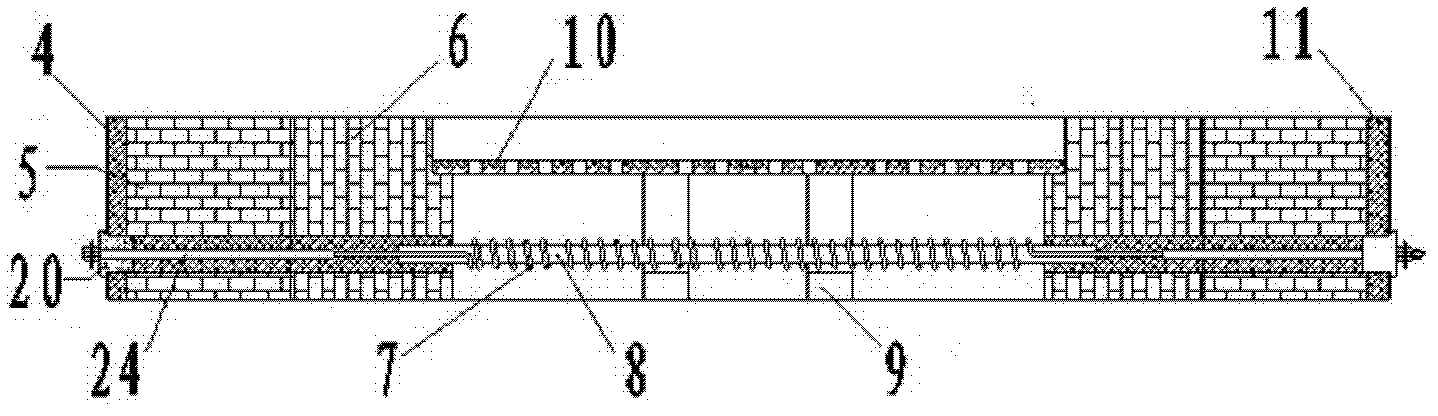

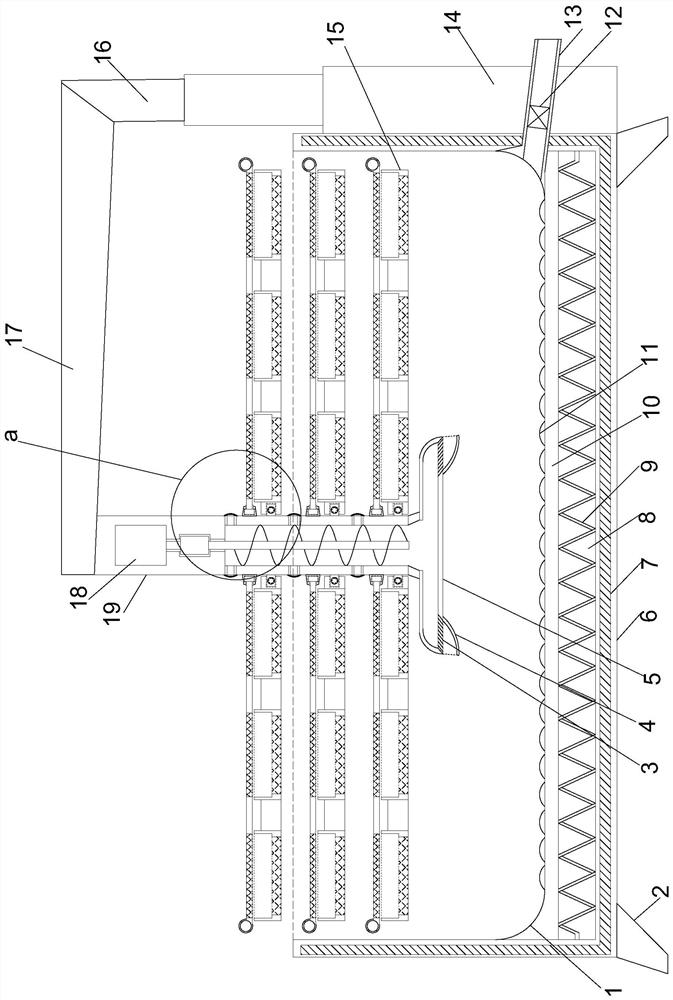

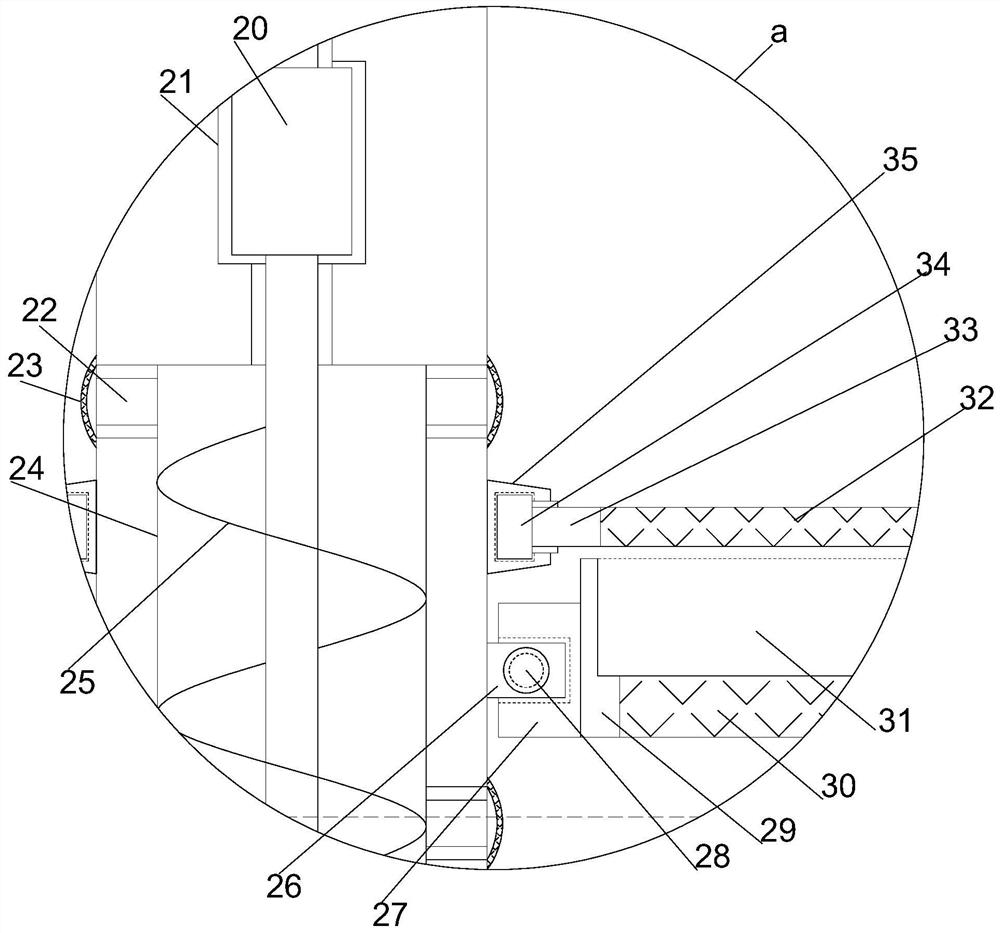

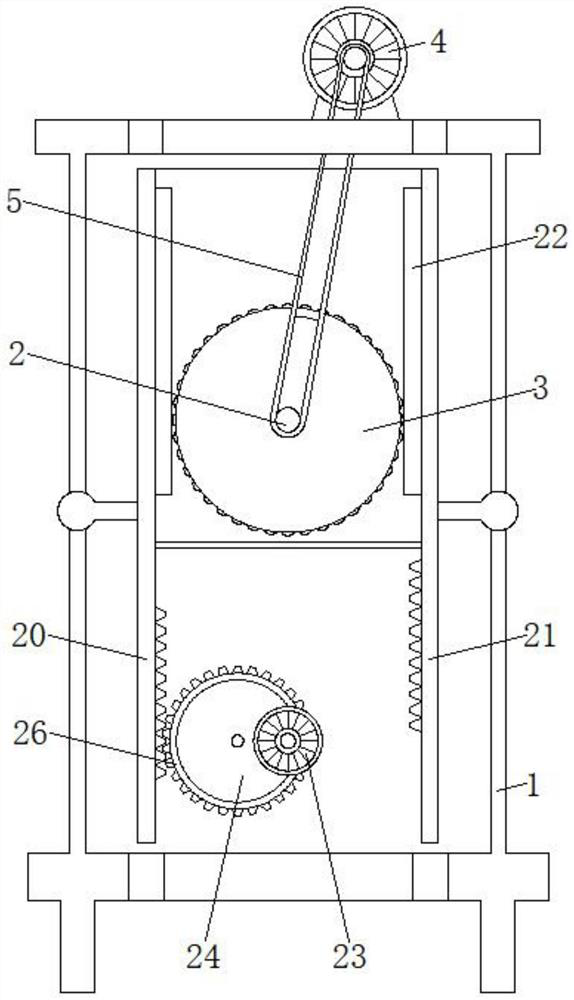

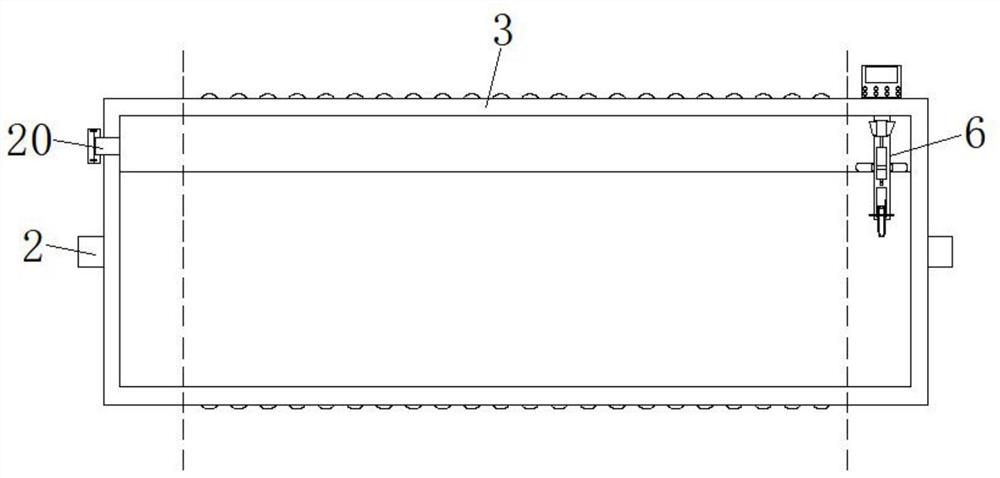

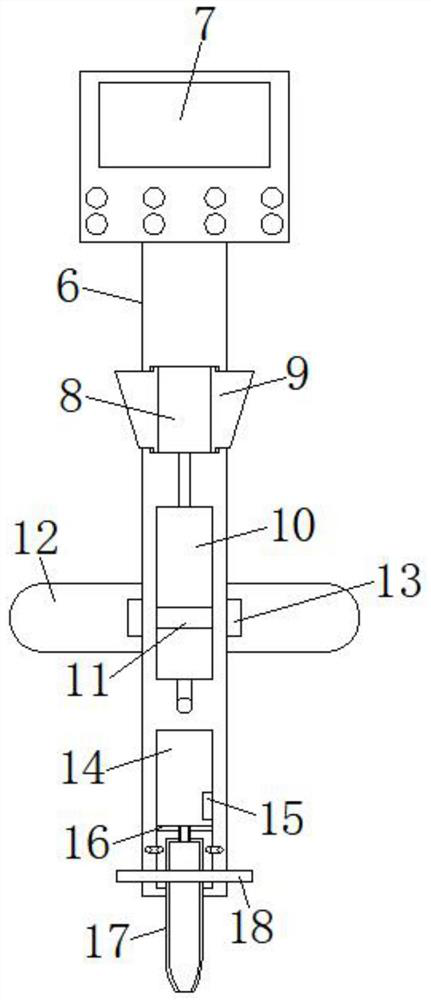

Vacuum multi-purpose furnace

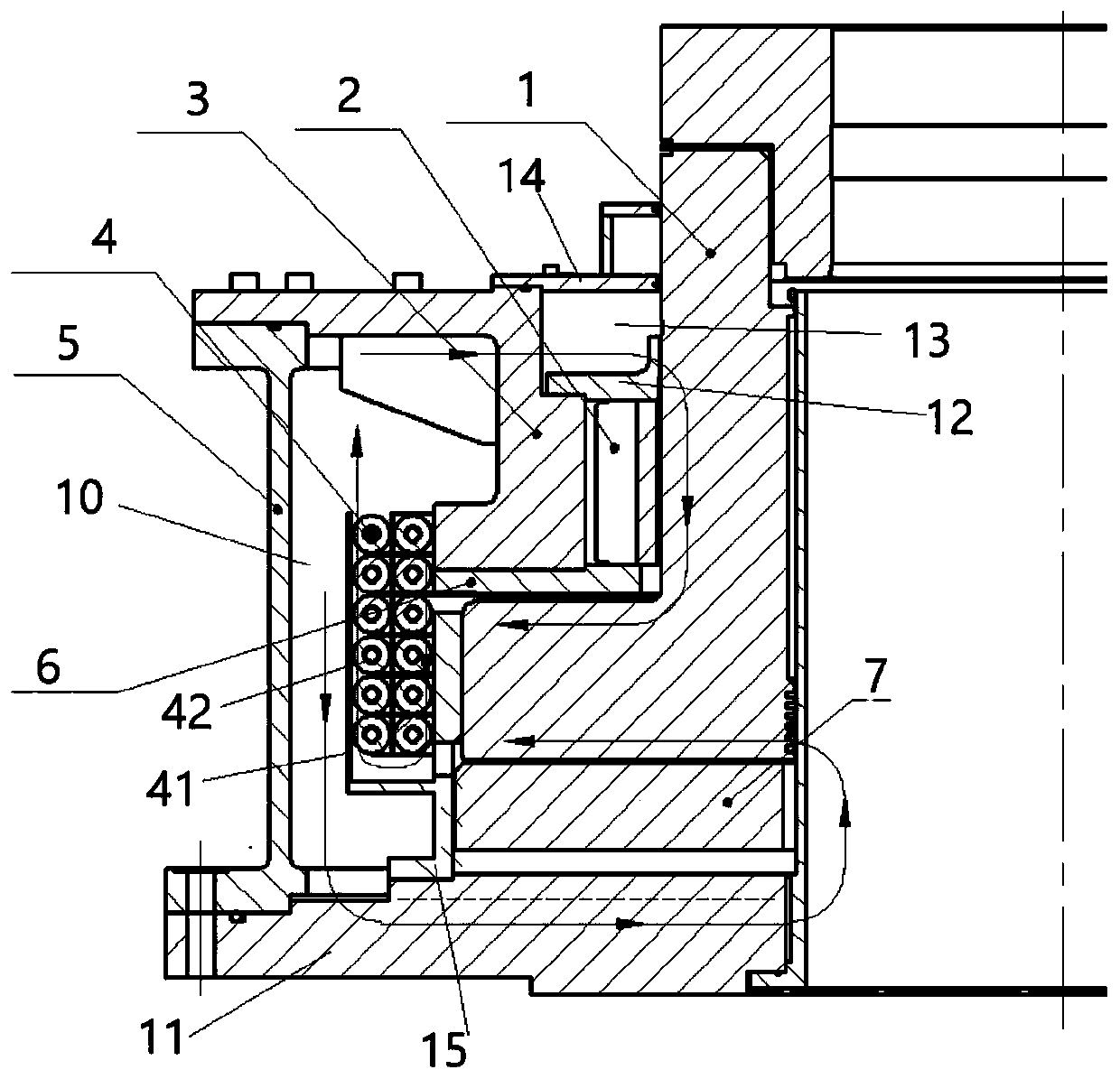

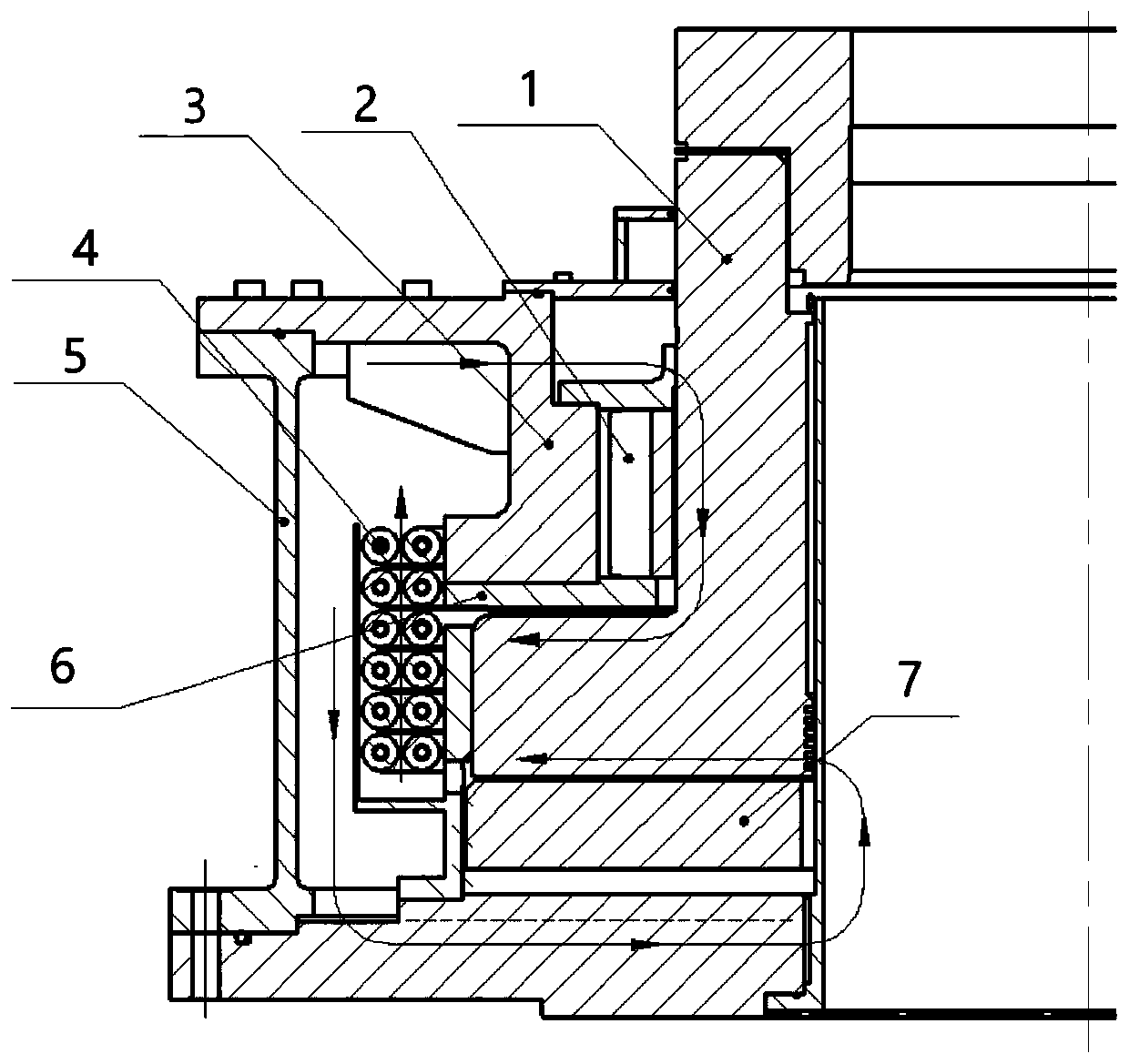

ActiveCN106086342AEasy to pull outUniform oil temperatureSolid state diffusion coatingQuenching devicesPush pullQuenching

The invention provides a vacuum multi-purpose furnace, which belongs to the technical field of heat treatment. The vacuum multi-purpose furnace comprises a quenching furnace shell, an inner furnace shell and a carburizing furnace shell, wherein the quenching furnace shell is connected with the carburizing furnace shell by virtue of the inner furnace shell, an outer furnace door is arranged at an opening of the quenching furnace shell, material inlet and outlet tracks are arranged in the quenching furnace shell and the carburizing furnace shell, a push-pull machine and a lifting platform which are used for feeding and discharging materials are arranged in the quenching furnace shell, the push-pull machine and the lifting platform are crossed, a first motor is arranged on the top of the quenching furnace shell, the first motor is connected with a fan, a lifting inner furnace door, a door frame, a compensation track assembly and a pressing assembly are arranged in the inner furnace shell, the door frame can be pressed on the inner furnace shell by the pressing assembly, the inner furnace door can move along the door frame, the compensation track assembly is lifted along with the inner furnace door, a heater is arranged at the bottom of the quenching furnace shell, an internal furnace is arranged in the carburizing furnace shell, a plurality of electric radiation heating pipes are arranged in the carburizing furnace shell, and vacuum nitrogen charging units are respectively connected to the quenching furnace shell and the carburizing furnace shell. The vacuum multi-purpose furnace has the advantage of high degree of automation, and the efficiency of heat treatment is improved.

Owner:扬州市金盛热处理有限公司

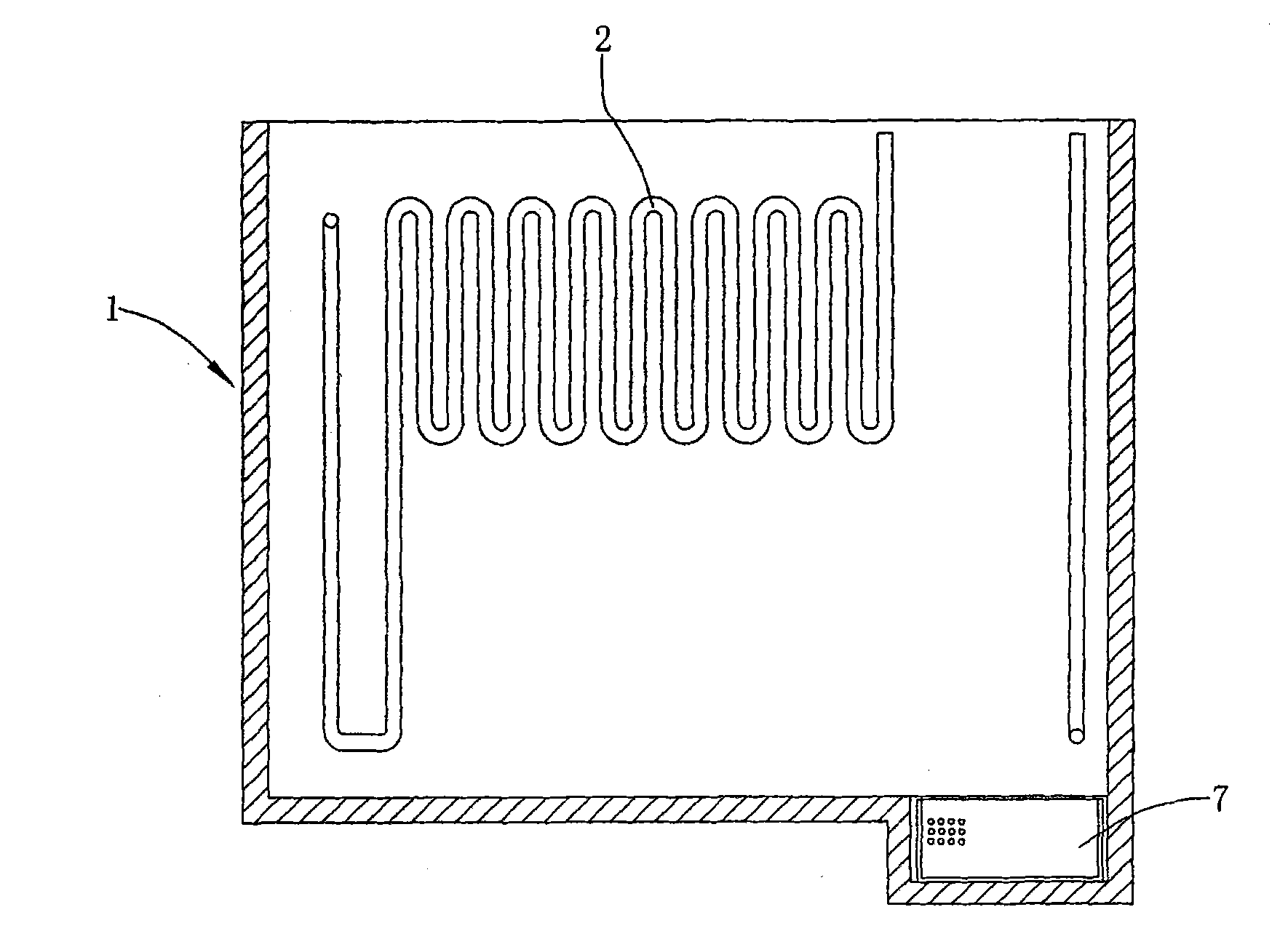

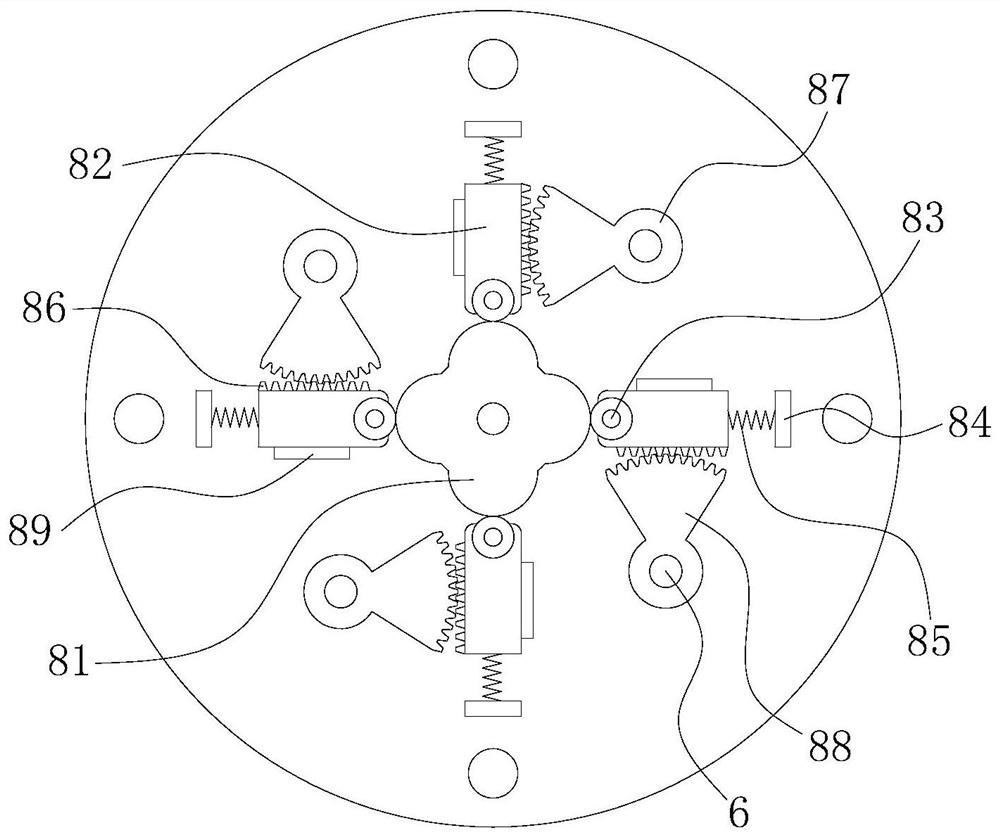

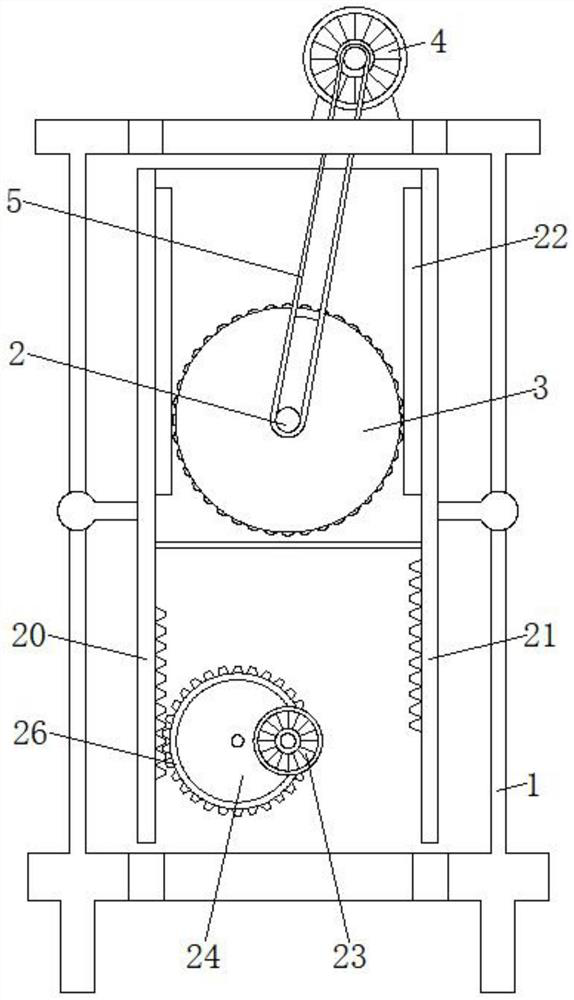

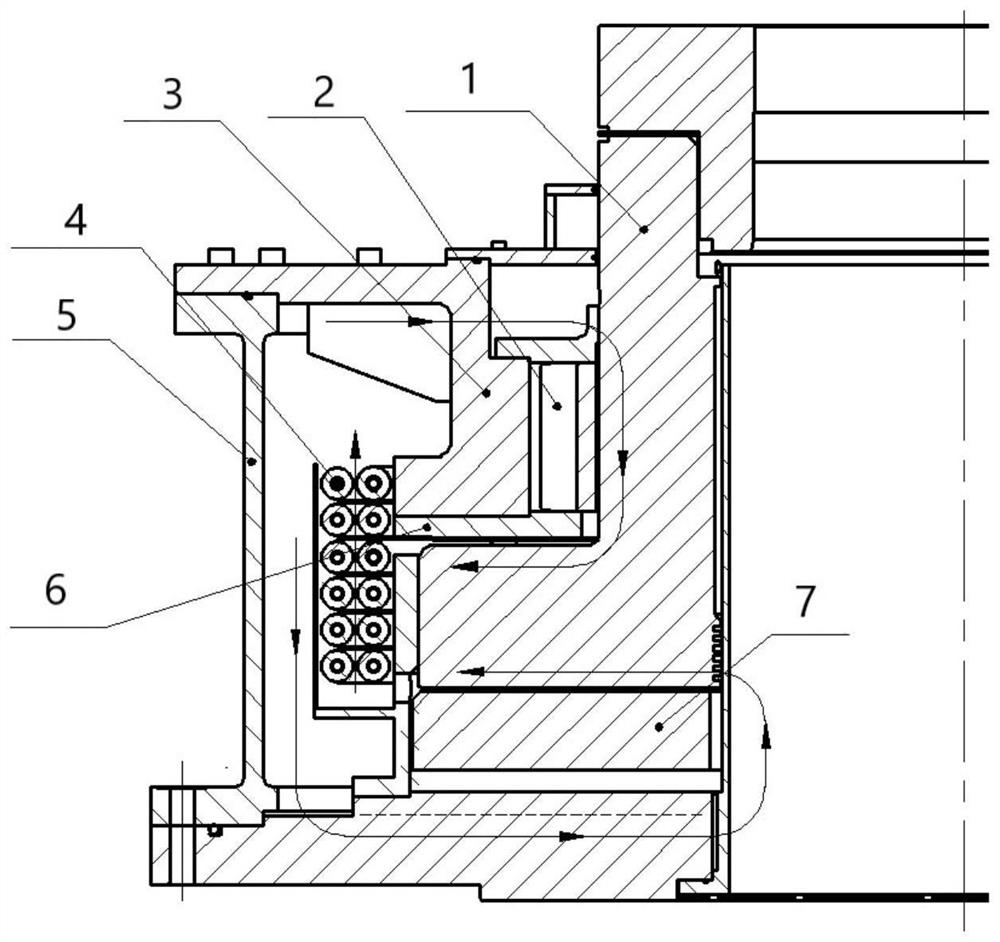

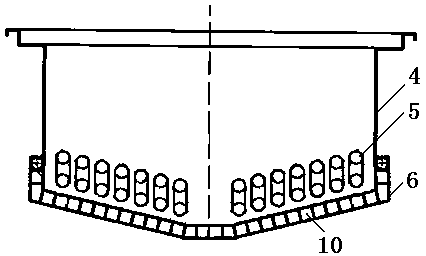

Improved grinding ball quenching tank

ActiveCN102061366AReduce oil temperature gradientReduce temperature gradientQuenching devicesCooling towerCooling effect

The invention relates to an improved grinding ball quenching tank which comprises a tank body of which the upper end is opened, wherein the tank body is provided with at least one stirring machine, and the stirring machine comprises a power assembly and a stirring assembly which are connected; and the stirring assembly extends into the tank body. After the technical scheme is adopted, the stirring machine is started, and by utilizing the stirring and homogenizing effects of the stirring machine, the temperature gradient of quenching oil in the quenching tank is effectively reduced, so that the oil temperature is uniform, the quenching effect is better, and the properties (such as the indexes of hardness, density, and the like) of a grinding ball are greatly improved; and in addition, the cooling effect of the stirring machine effectively reduces the temperature of the quenching oil in the tank body, thus the temperature of the quenching oil cannot be too high so as to ensure that the possibility of burning of the quenching oil while the grinding balls enter the tank body is greatly reduced, equipment such as an external cooling tower, and the like can be omitted, and the investment of external equipment is reduced. In conclusion, when the quenching tank is used in a quenching process of the grinding balls, the quenching tank has the advantages of uniform quenching, good quenching quality, stable properties of the grinding balls and lower quenching treatment cost.

Owner:FIRST DESIGN & RES INST MI CHINA

Novel process for double medium oil-air quenching of alloy wear resistant casting

The invention relates to an alloy abrasion-proof casting double medium oil wind quenching process, characterized as : adopting oil quenching mode in high temperature stage, when product temperature reducing to a certain temperature, adopting slow wind quenching mode, of the quenched product in the invention, quenching rigidity is >=58HRc ,rigidity difference is <=2.5HRc, which fully solve the quenching crack, promote the integral mechanical property.

Owner:安徽省凤形新材料科技有限公司

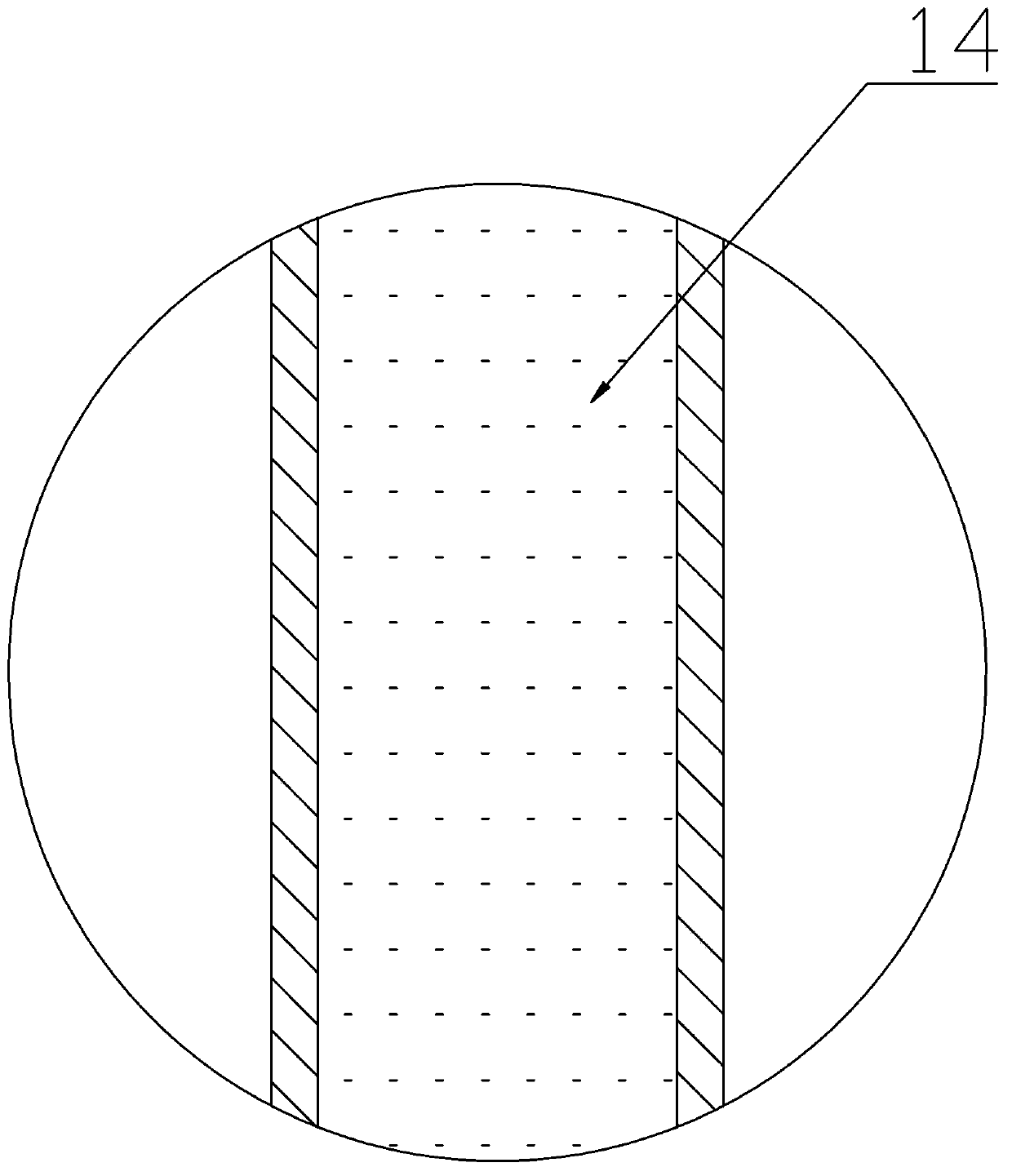

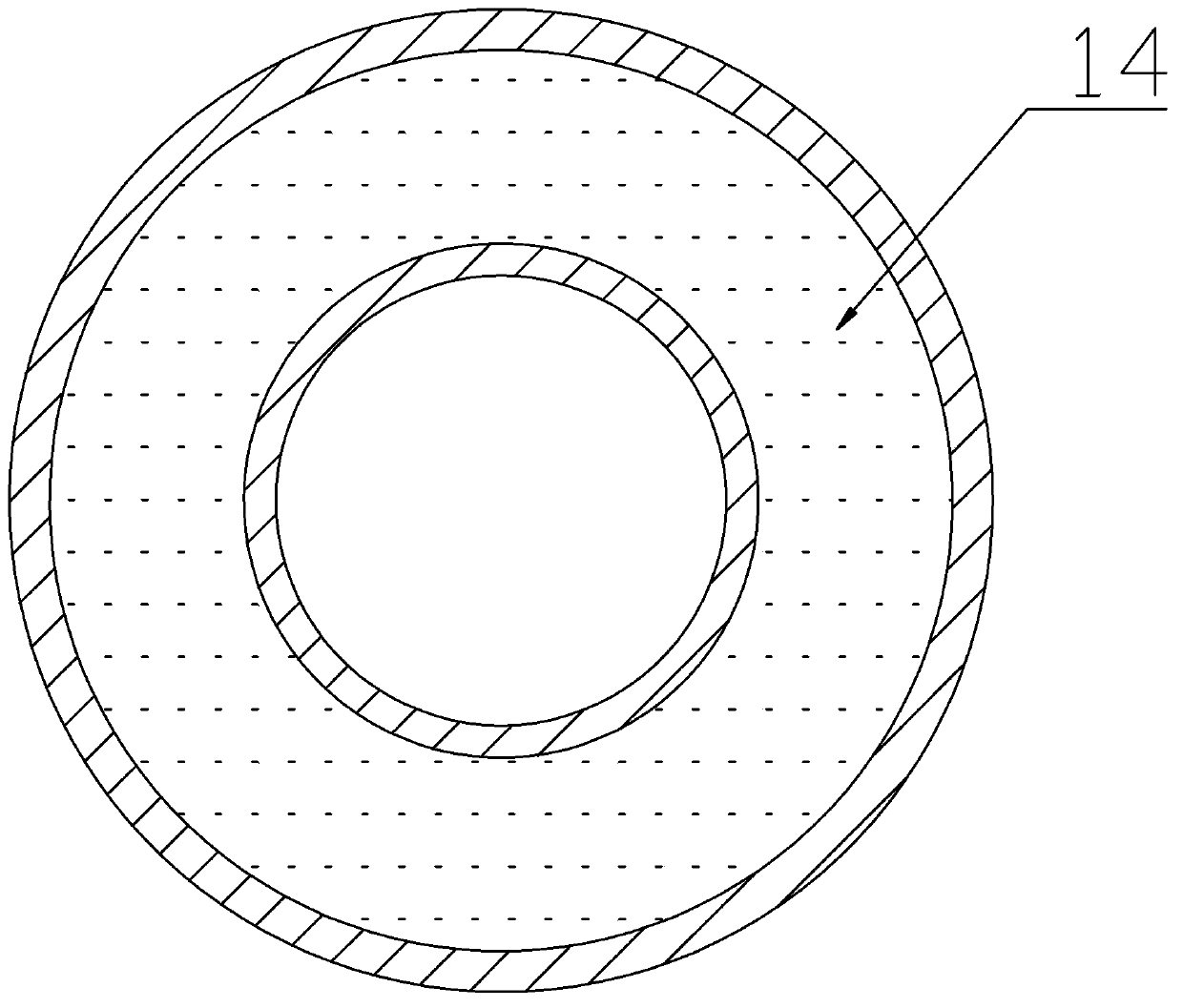

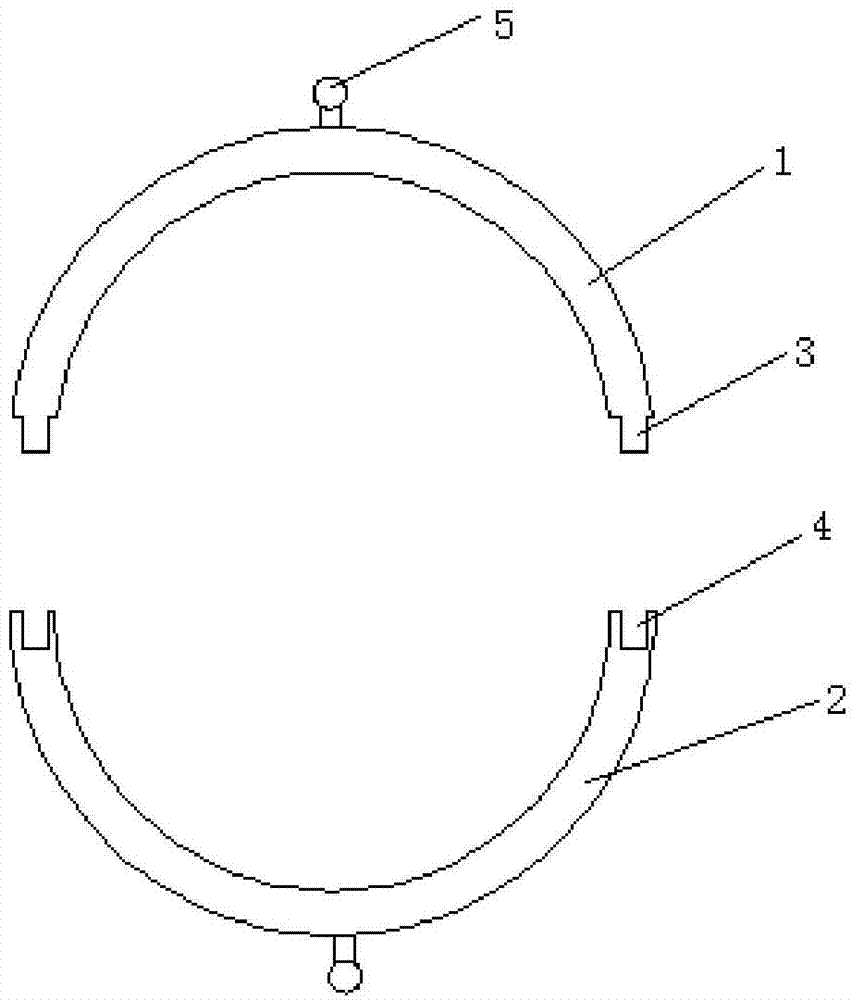

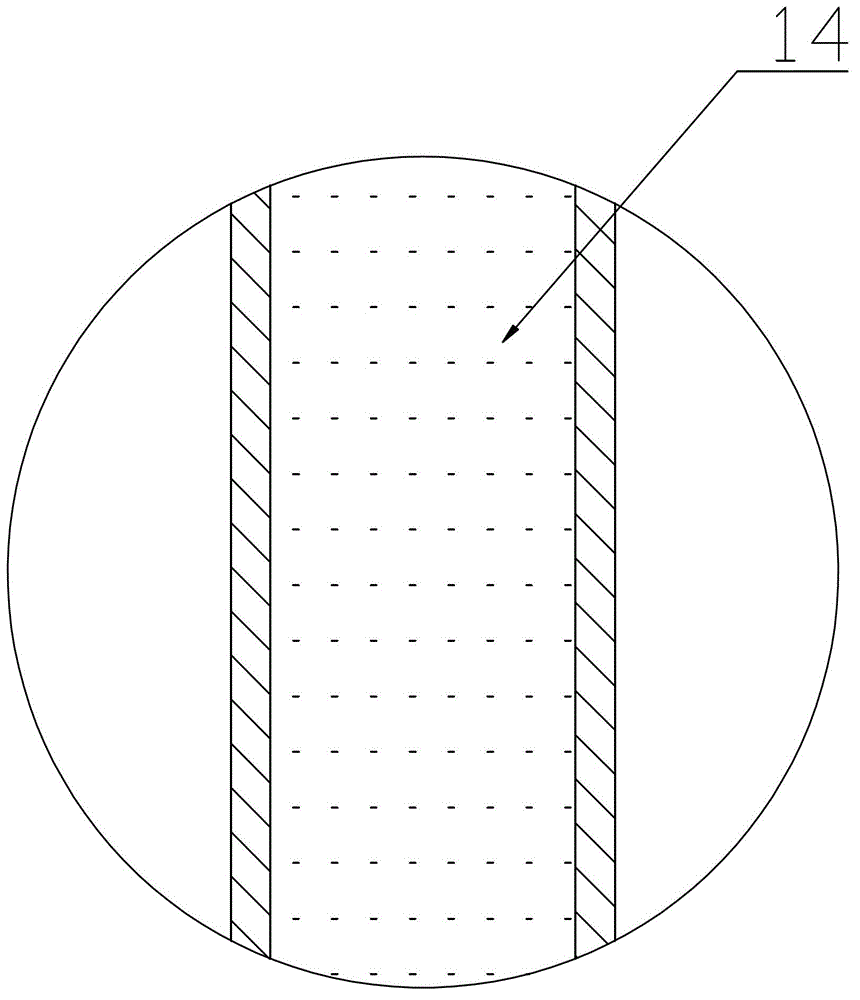

Barrel heater of extruder

The invention provides a barrel heater of an extruder. The barrel heater comprises a barrel, a screw, a heating device and a stirring device. The barrel is in a split top and bottom structure; the screw is disposed in an inner cavity of the barrel and connected with a power device. The heating device comprises a circular cavity, a cavity cover, a heating plate and an insulation layer; the circular cavity sleeves the barrel and filled with heat transfer oil; the outer wall of the circular cavity is provided with the heating plate and the insulation layer. The stirring device comprises a circular bottom plate and a stirring rod; the circular bottom plate is fixedly connected with the cavity cover; the stirring rod penetrates the circular bottom plate and the cavity cover in order through a rotary shaft and is connected with the power device; the power device drives the stirring rod to rotate. The barrel heater has the advantages that the split structure of the barrel allows convenience of disassembly, the addition of the circular cavity filled with the heat transfer oil to the heating device maximizes the heating area, the stirring device allows oil temperature to be evener, plastic can be melted evenly, and product quality is higher.

Owner:天津煊生源高分子科技有限公司

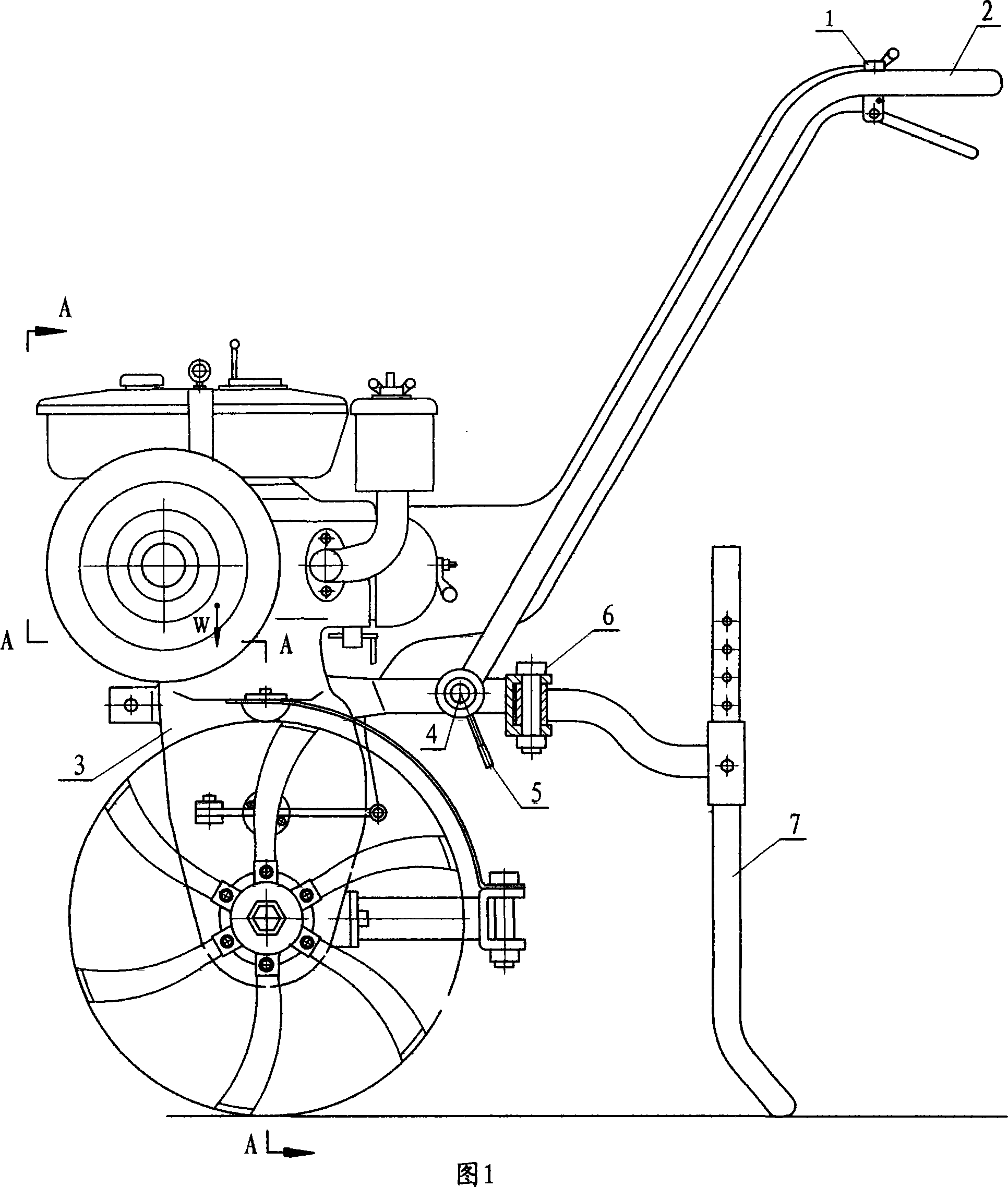

Minisize, light, high-effectiveness and stable tillage of small-sized farm machinery

InactiveCN101080965AStable tillageReduce labor intensityAgricultural machinesTilling equipmentsFarm machineHigh effectiveness

The present invention reveals one small farm machine, which has one speed variable power machine comprising one downwards extending power unit and one speed variator combined together for light weight, small size and high efficiency. The present invention reveals also one walking set, which has the front end connected movably to the farm machine and the pedal in the back end for bearing the operator. The operator has his body weight added to the farm machine, reaching enhanced machine stability and reduced labor strength.

Owner:都灵

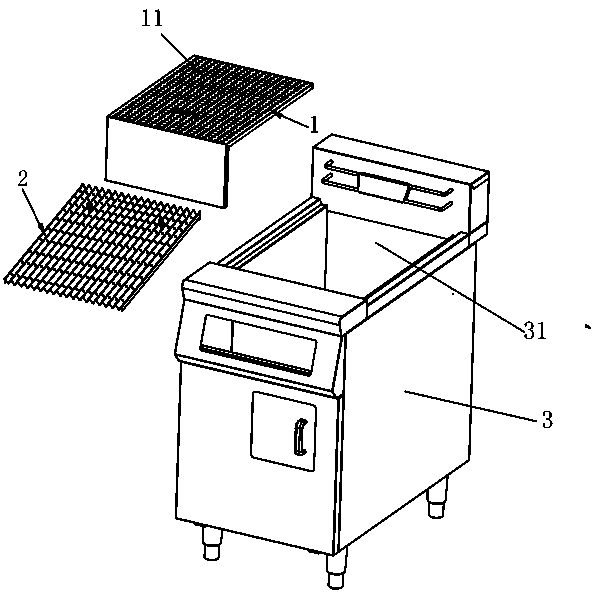

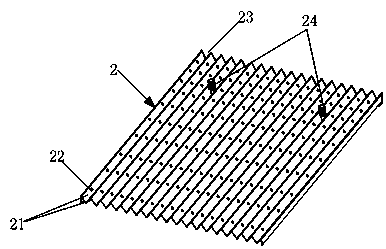

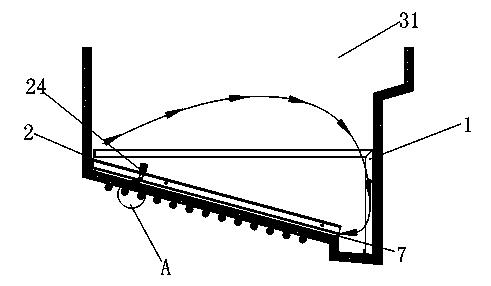

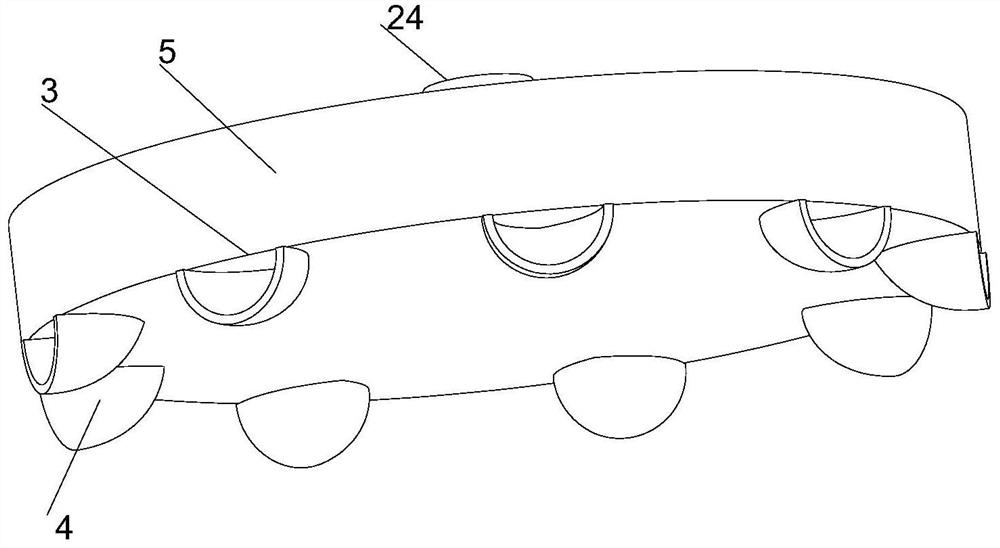

Electromagnetic induction fryer

The invention discloses an electromagnetic induction fryer which comprises a heat convection net, wherein the heat convection net is provided with a plurality of bulges, a groove is formed in a position between the adjacent two bulges, and the heat convection net is in a wave shape. A number of open pores are formed in the side surface of the bulges, and the distance between the open pores gradually reduces from top to bottom. The fryer further comprises a frying basket supporting net and a shell, the frying basket supporting net is installed above the heat convection net, a gap is formed in the top end of the shell, and both the frying basket supporting net and the heat convection net are located in the gap. The fryer is not spontaneously combusted or burnt because of local overheating, the manual stirring control procedure is eliminated, the frying temperature is more uniform, and the service life of the edible oil is prolonged.

Owner:GUANGZHOU HUAYOU FOOD PROCESSING MACHINE

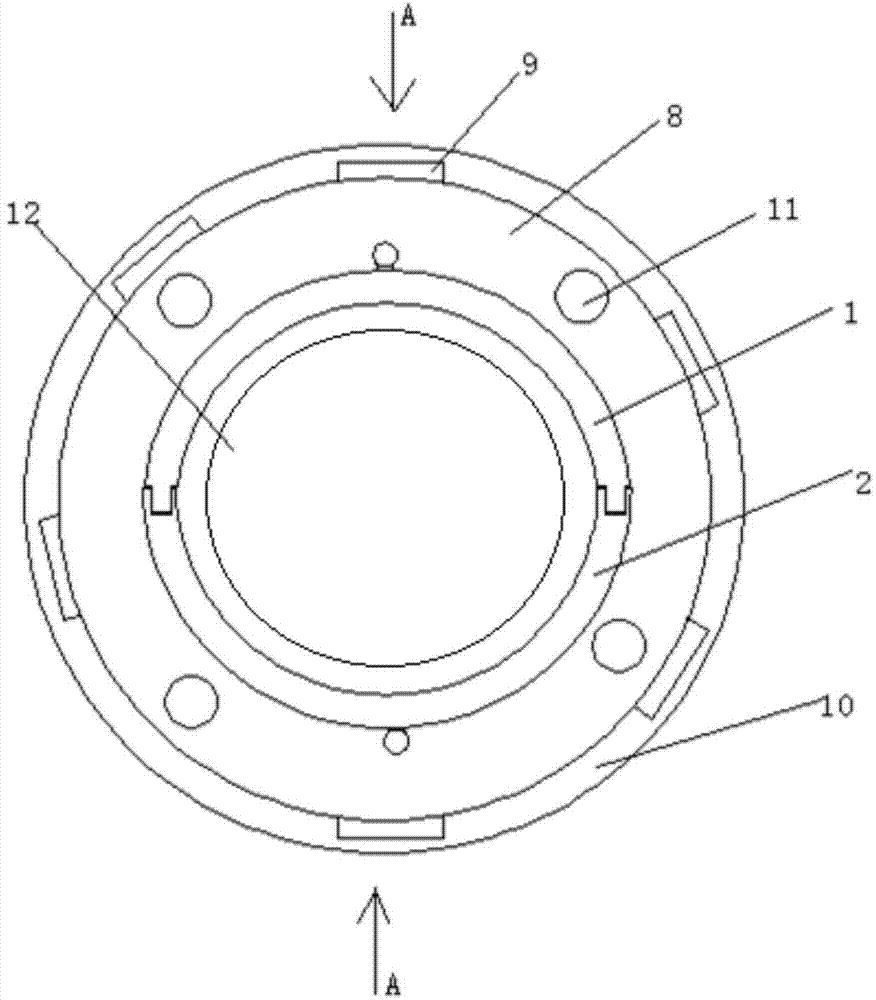

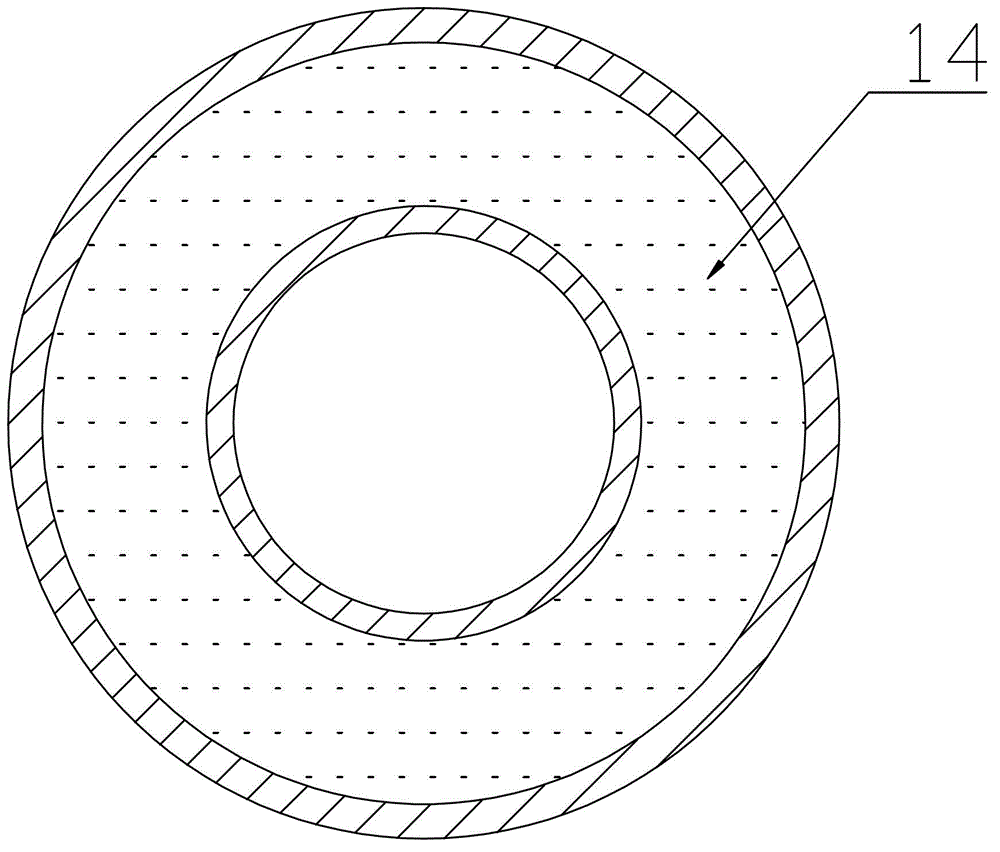

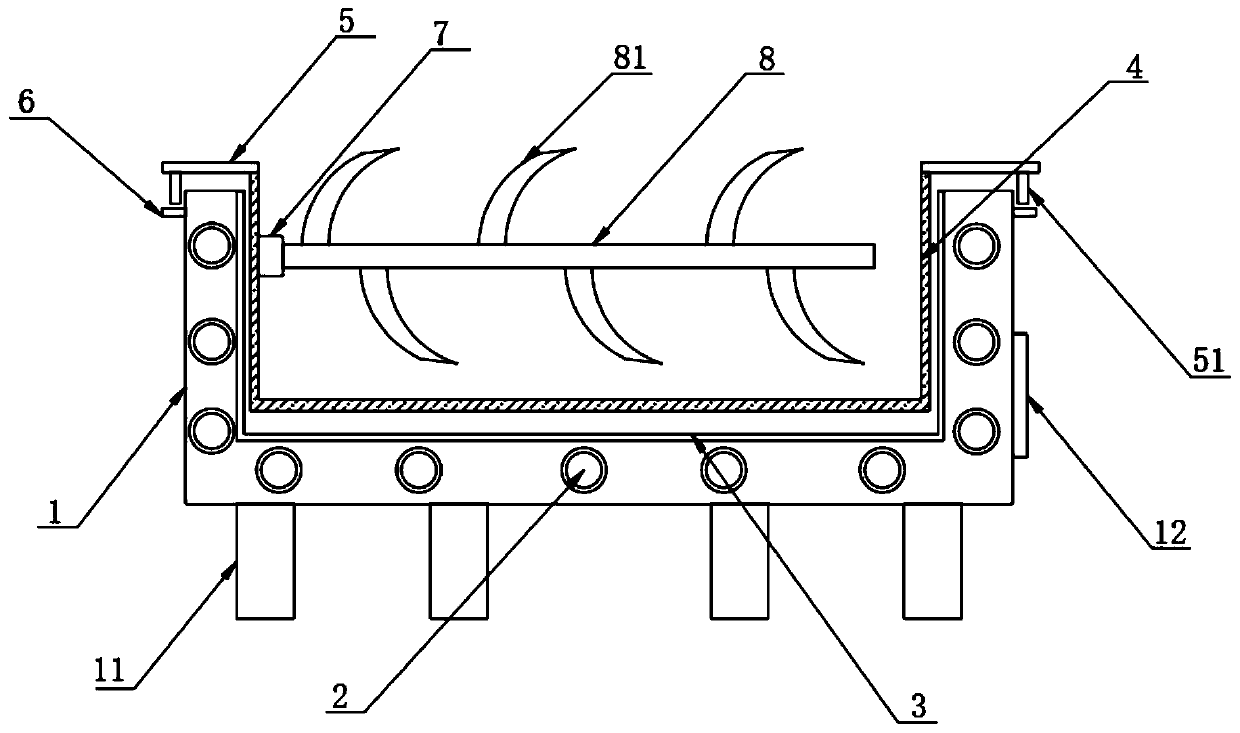

Oil way structure of sliding bearing

ActiveCN111102287AImprove heat transfer efficiencyImprove cooling effectSliding contact bearingsBearing coolingSlider bearingCooling effect

The invention provides an oil way structure of a sliding bearing. The oil way structure comprises a cooling device, and a thrust head, a thrust pad and a pressing plate which sleeve the outer side ofa rotating shaft. The thrust head comprises a big head end and a small head end which are integrally connected. The two end faces of the big head end are connected with the thrust pad and the pressingplate correspondingly. A first gap is formed between the big head end and the thrust pad. A second gap is formed between the big head end and the pressing plate. The cooling device is located in an oil tank which contains lubricating oil. The cooling device comprises an outer partition plate and a plurality of cooling pipes. A space with an inlet and outlet is defined by the outer partition plate. The inlet and outlet communicates with the oil tank. A plurality of cooling pipes are located in the space defined by the outer partition plate. One end of the first gap and one end of the second gap both communicate with the space defined by the outer partition plate. The other end of the first gap and the other end of the second gap both communicate with the oil tank through a channel formed in the bearing. Two planar viscous pumps are formed to provide driving force; and the heat transferring efficiency of a cooler is improved, and the cooling effect of the bearing is improved.

Owner:HUNAN CHONGDE IND TECH

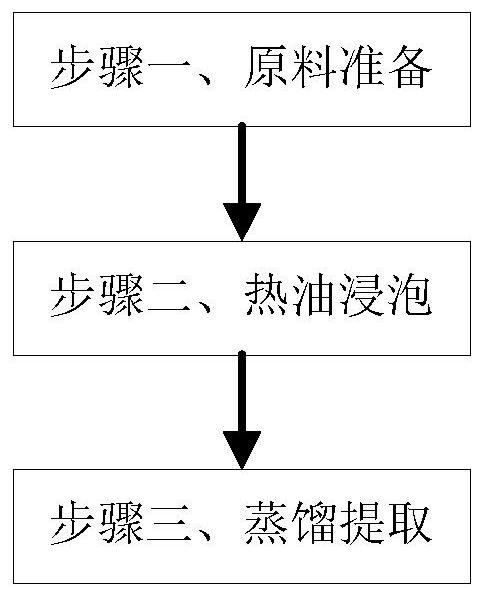

Preparation method of aromatherapy essential oil

InactiveCN112322391AReduce soaking effectImprove soaking effectEssential-oils/perfumesAromatherapyPetal

The invention belongs to the technical field of essential oil preparation, and particularly relates to a preparation method of aromatherapy essential oil, wherein the preparation method comprises thefollowing steps: step 1, raw material preparation: picking off petals in raw material flowers, cleaning the petals cleanly, and drying the moisture on the surface; step 2, hot oil soaking: soaking thedried petals in the step 1 in hot oil, and taking out the petals from the hot oil after soaking; and step 3, distillation and extraction: continuously heating the hot oil soaked with the petals, andcooling and collecting volatilized aroma substances, wherein the step 2 is completed by adopting an aromatherapy essential oil preparation device in a matching manner. When the petals in the hot oil are stirred, bubbles generated in the stirring process are eliminated, the bubbles are prevented from adhering to the surfaces of the petals, and the soaking effect of the hot oil is improved; oil temperature balance of each part in the hot oil is ensured, and the soaking effect of the hot oil is improved.

Owner:合肥蓝胖子生物技术有限公司

Preparation method of cymbopogon citratus flavor composite seasoning hot pepper oil

The invention provides a preparation method of cymbopogon citratus flavor composite seasoning hot pepper oil. The preparation method comprises following steps: 1, oil is delivered into a pot, and is heated to 130 to 150 DEGC with slow-speed stirring, and green Chinese onion, ginger, and garlic are added, and are removed when the green Chinese onion, ginger, and garlic are fried to be gold yellow; 2, hot pepper obtained via treatment is added for boiling at 108 to 115 DEG C until water in the hot pepper is removed; 3, middle-speed stirring is carried out, and a prepared spice mixture is added into the oil of 110 to 130 DEG C for boiling; 4, dried cymbopogon citratus and folium perillae are added for continuous boiling until the oil becomes transparent, and the mixture in the pot is filtered to remove filter residue so as to obtain a seasoning oil crude product; and 5, the seasoning oil crude product is subjected to separation using a segregating unit so as to obtain the cymbopogon citratus flavor composite seasoning hot pepper oil rich in cymbopogon citratus flavor. The preparation method is simple; preparation is convenient; the obtained cymbopogon citratus flavor composite seasoning hot pepper oil is golden red and glossy, is spicy and mellow in taste; cymbopogon citratus flavor is obvious; scorching feeling is not caused; mouthfeel is comfortable; and the fragrance is harmonious and natural.

Owner:HENAN YONGDA MEIJI FOOD CO LTD

Electro-magnetic induction frying device for instant noodles

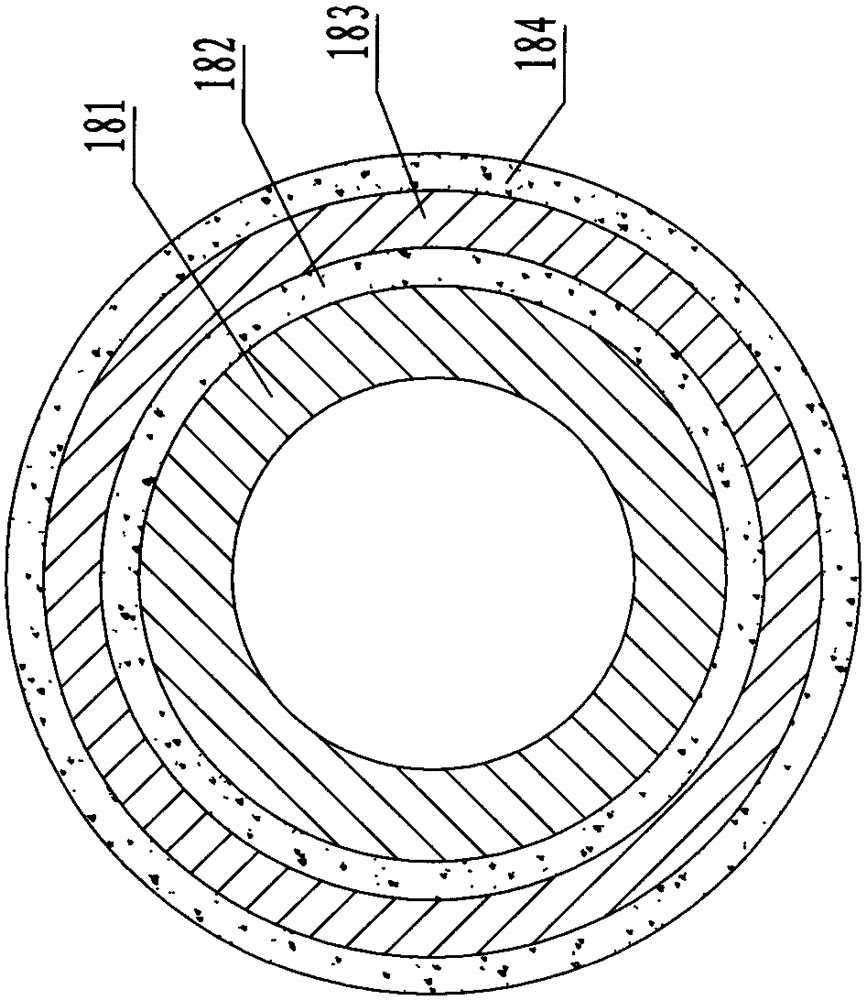

InactiveCN105145692AExtended service lifeInhibit sheddingHigh-frequency/infra-red heating bakingOil/fat bakingThermal insulationInstant noodle

The invention discloses an electro-magnetic induction frying device for instant noodles, comprising a rack and metal frying bath arranged on the rack. The outer side of the metal frying bath is wrapped by macromolecular thermal insulation cotton, the outer side of the macromolecular thermal insulation cotton is uniformly provided with a plurality of high-frequency induction coil fixing plates, and the upper end and the lower end of each high-frequency induction coil fixing plate are fixed on the macromolecular thermal insulation cotton by bolts. A plurality of semicircular grooves are arranged on the inner sides of the high-frequency induction coil fixing plates and the outer side of the macromolecular thermal insulation cotton, respectively. A high-frequency induction coil is wound in each cavity formed by every two corresponding semicircular grooves, and is connected with a high-frequency and high-voltage power supply. An oil outlet tube is arranged at one side of the lower end of the metal frying bath, and a cooling water tank is arranged outside the oil outlet tube. A plurality of cooling fins are uniformly arranged on the oil outlet tube inside the cooling water tank.

Owner:盐城康泽源食品有限公司

Induction Heating Fryer

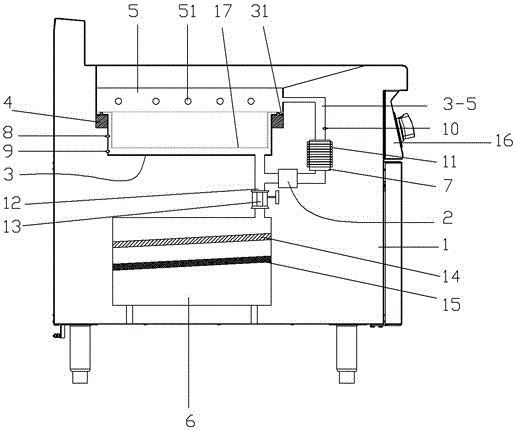

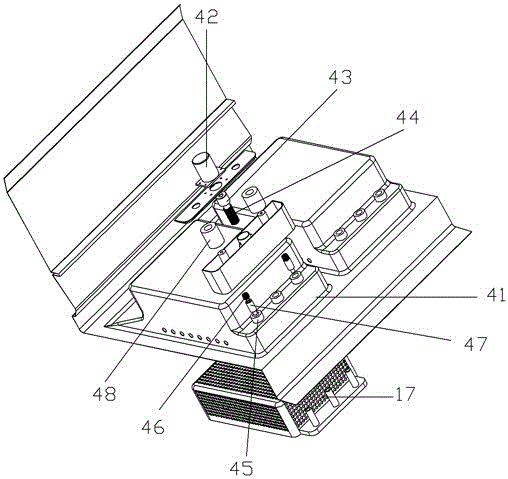

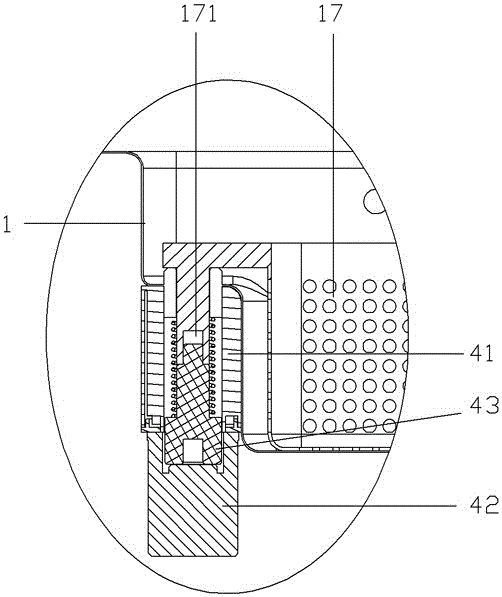

InactiveCN104782697BUniform oil temperatureSmall temperature differenceOil/fat bakingDeep fryingRoom temperature

The invention provides an induction heating deep-frying stove. A deep-frying cylinder is fixed in a cabinet body, deep-frying cylinder ladders are formed on the inner wall of the deep-frying cylinder, a lifting rod inserting socket and vibration magnetic core inserting sockets are formed in a filtering cylinder, a shell body is fixed onto the cabinet body, the upper end of a lifting rod is inserted in the lifting rod inserting socket in a sleeving mode, the lifting rod is sleeved with a lifting reset spring in an inserted mode, the upper end of the lifting rod acts on the filtering cylinder, and the lower end of the lifting rod acts on the lifting rod; vibration sleeves are formed on or fixed onto the shell body, vibration reset springs and vibration magnetic cores are inserted into the vibration sleeves in a sleeving mode, the upper ends of the vibration magnetic cores is inserted into the vibration magnetic core inserting sockets in a sleeving mode, and electromagnetic coils are arranged outside the vibration sleeves and inserted onto the vibration sleeves in a sleeving mode; a deep-frying cylinder liquid-level probe and a deep-frying cylinder temperature probe are installed on the deep-frying cylinder, and a heating room temperature probe is installed on the oil return pipe communicating an oil heating room and an oil outlet pipe. The induction heating deep-frying stove has the advantages that the oil temperature is uniform, the temperature difference is small, and the oil utilization rate can be improved. The induction heating deep-frying stove can control the oil temperature, reduces the oil temperature range and constantly set the oil temperature in a set value.

Owner:GUANGDONG AOUDER TECH STOCK

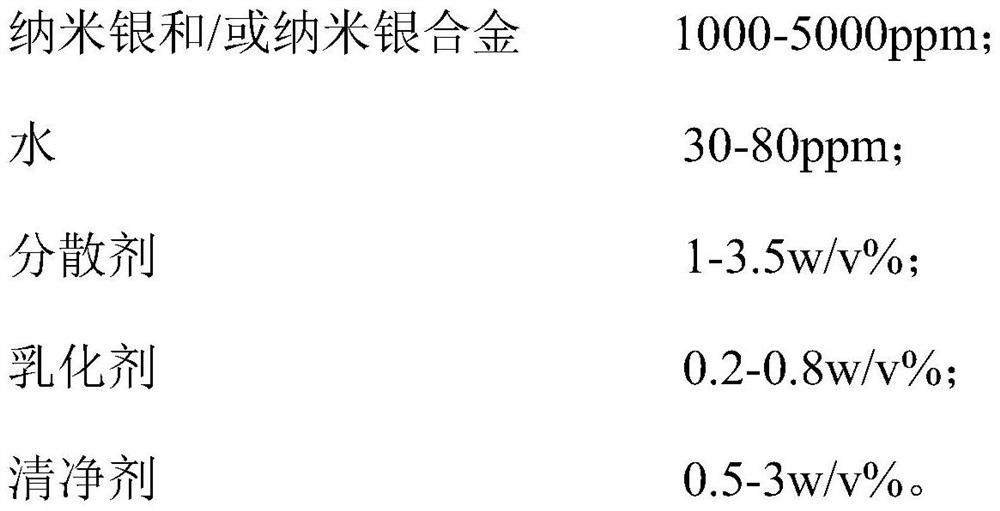

Potato frying equipment for puffed food production

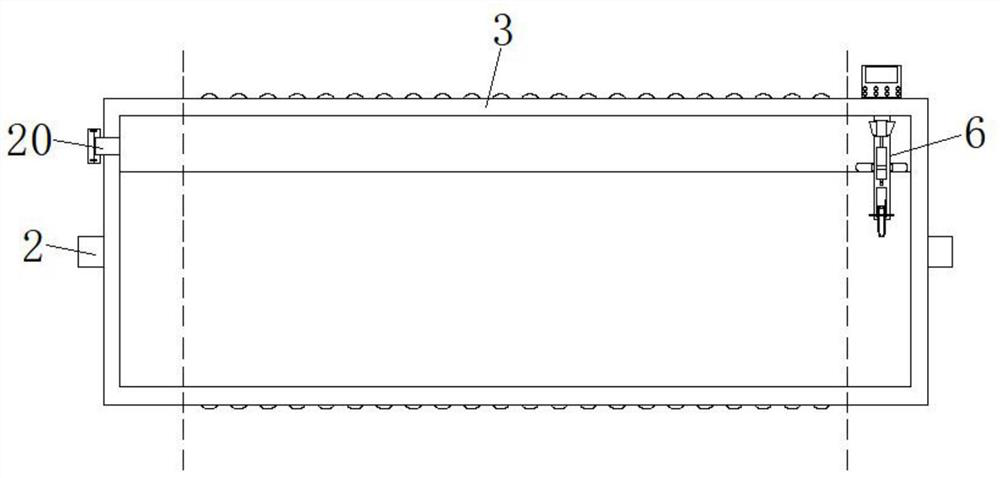

PendingCN113068725AGuarantee the consistency of frying effectUniform oil temperatureBaking ovenOil/fat bakingElectric machineryEngineering

The invention discloses a potato frying equipment for puffed food production, which comprises a frying box and a material box, heating strips are arranged in the frying box, the bottom of the frying box is communicated with an oil discharge pipe, a valve is arranged on the oil discharge pipe, the right end of the frying box is fixedly provided with a top plate, a slide rail and a machine plate in sequence from top to bottom, a first motor is fixedly installed at the top of the machine plate, the output end of the first motor is fixedly connected with a first rotating rod, the outer surface of the first rotating rod is fixedly sleeved with a driving bevel gear, and the end, away from the first motor, of the first rotating rod penetrates through the frying box and is rotationally connected with the interior of the left side of the frying box; the outer surfaces of the left side and the right side, located in the frying box, of the first rotating rod are fixedly sleeved with stirring rods, a bearing seat is fixedly installed on the lower surface of the top plate, a lead screw is rotationally connected into the bearing seat, a driven bevel gear is fixedly installed at the bottom of the lead screw, and the driven bevel gear and the driving bevel gear are meshed with each other. The potato frying equipment disclosed by the invention is compact in structure and can effectively improve the potato frying quality.

Owner:安徽省小岗盼盼食品有限公司

Temperature control type printing equipment for PVC decorative film processing

ActiveCN112810307AImprove printing efficiencyThere will be no printing blind spotsRotary stirring mixersTransportation and packagingTemperature controlElectric machine

The invention discloses temperature control type printing equipment for PVC decorative film processing. The temperature control type printing equipment comprises a printing table, wherein the inner wall of the printing table is rotationally connected with a roll shaft; a hot oil drum is fixedly mounted on the surface of the roll shaft; a rotating motor is fixedly mounted at the top of the printing table; the output end of the rotating motor is in transmission connection with the roll shaft through a conveying belt; and a temperature detection mechanism is fixedly mounted on the hot oil drum. According to the temperature control type printing equipment for PVC decorative film processing, a buoyancy ring can float on an oil surface; when the oil surface in the hot oil drum rises, the buoyancy ring can slide upwards under the buoyancy effect of the buoyancy ring; under the magnetic force effect of an opposite-polarity magnetic block and a sliding position magnetic plate, the sliding position magnetic plate moves upwards in a linkage cavity, and at the moment, gas in an upper cavity enters a sliding groove through a guide pipe, and the pressure intensity in the sliding groove is increased, so that a fitting tool in the sliding groove slides towards the outer side and blocks the side wall of the sliding groove, and the sealing performance of the temperature detection mechanism is better.

Owner:山东沃尔新材料有限公司

A multi-purpose vacuum furnace

ActiveCN106086342BEasy to pull outUniform oil temperatureSolid state diffusion coatingQuenching devicesNitrogenQuenching

The invention provides a vacuum multi-purpose furnace, which belongs to the technical field of heat treatment. The vacuum multi-purpose furnace comprises a quenching furnace shell, an inner furnace shell and a carburizing furnace shell, wherein the quenching furnace shell is connected with the carburizing furnace shell by virtue of the inner furnace shell, an outer furnace door is arranged at an opening of the quenching furnace shell, material inlet and outlet tracks are arranged in the quenching furnace shell and the carburizing furnace shell, a push-pull machine and a lifting platform which are used for feeding and discharging materials are arranged in the quenching furnace shell, the push-pull machine and the lifting platform are crossed, a first motor is arranged on the top of the quenching furnace shell, the first motor is connected with a fan, a lifting inner furnace door, a door frame, a compensation track assembly and a pressing assembly are arranged in the inner furnace shell, the door frame can be pressed on the inner furnace shell by the pressing assembly, the inner furnace door can move along the door frame, the compensation track assembly is lifted along with the inner furnace door, a heater is arranged at the bottom of the quenching furnace shell, an internal furnace is arranged in the carburizing furnace shell, a plurality of electric radiation heating pipes are arranged in the carburizing furnace shell, and vacuum nitrogen charging units are respectively connected to the quenching furnace shell and the carburizing furnace shell. The vacuum multi-purpose furnace has the advantage of high degree of automation, and the efficiency of heat treatment is improved.

Owner:扬州市金盛热处理有限公司

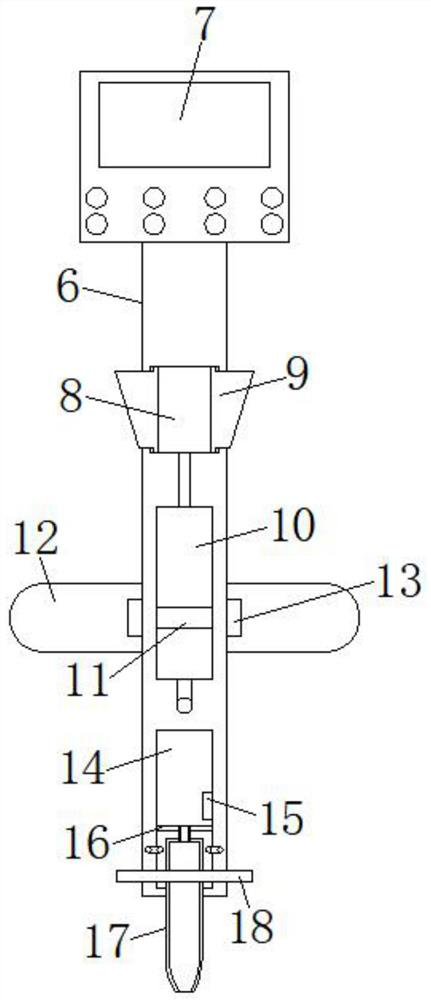

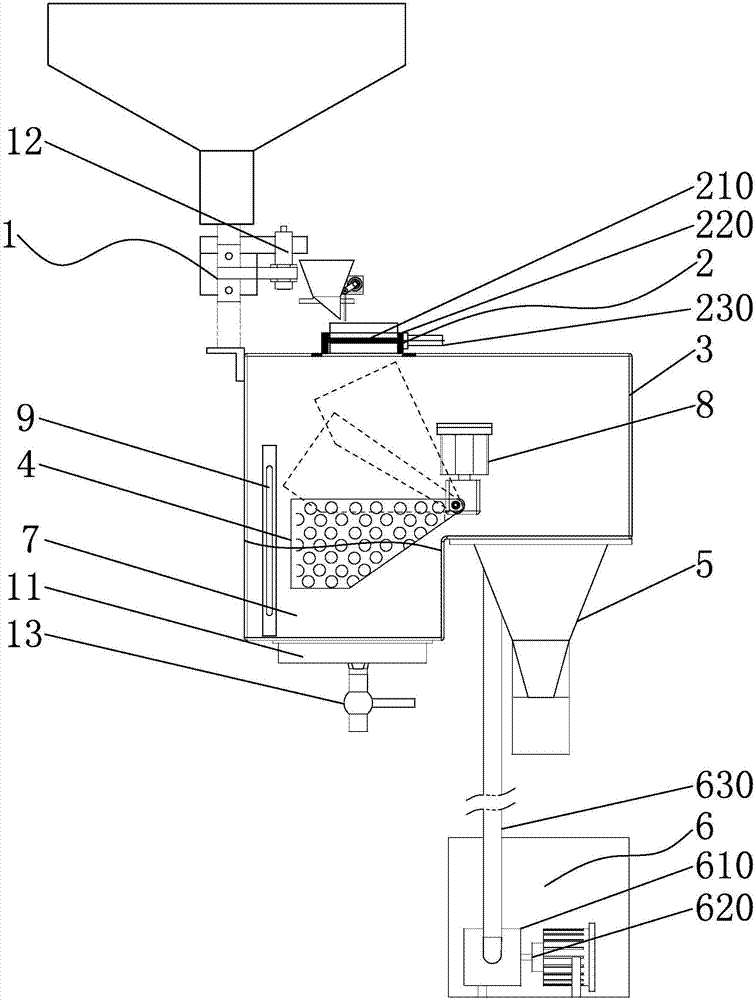

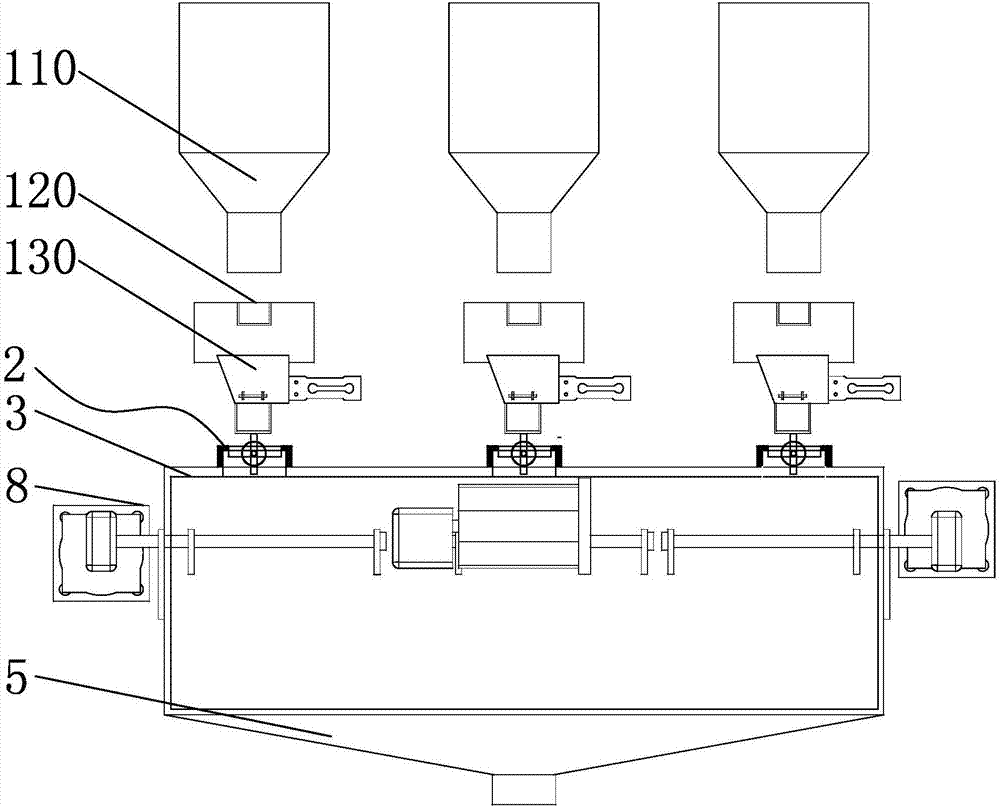

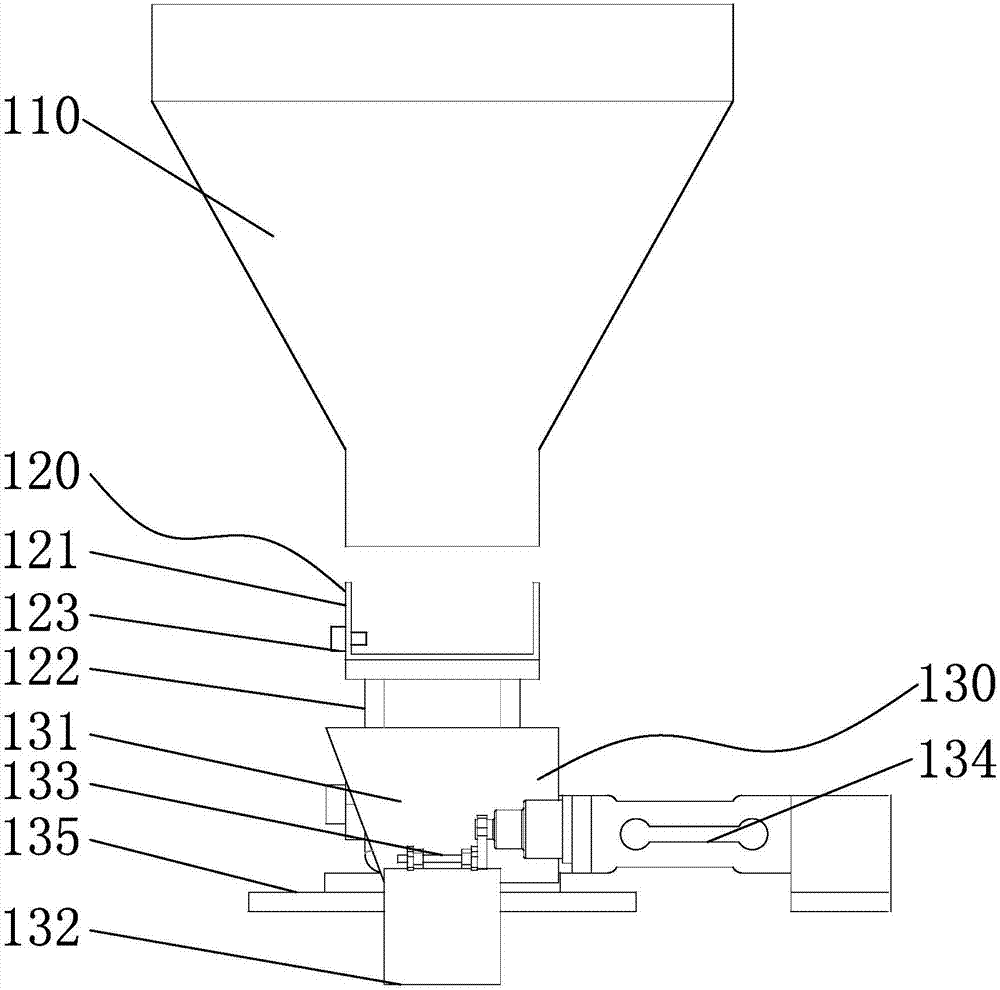

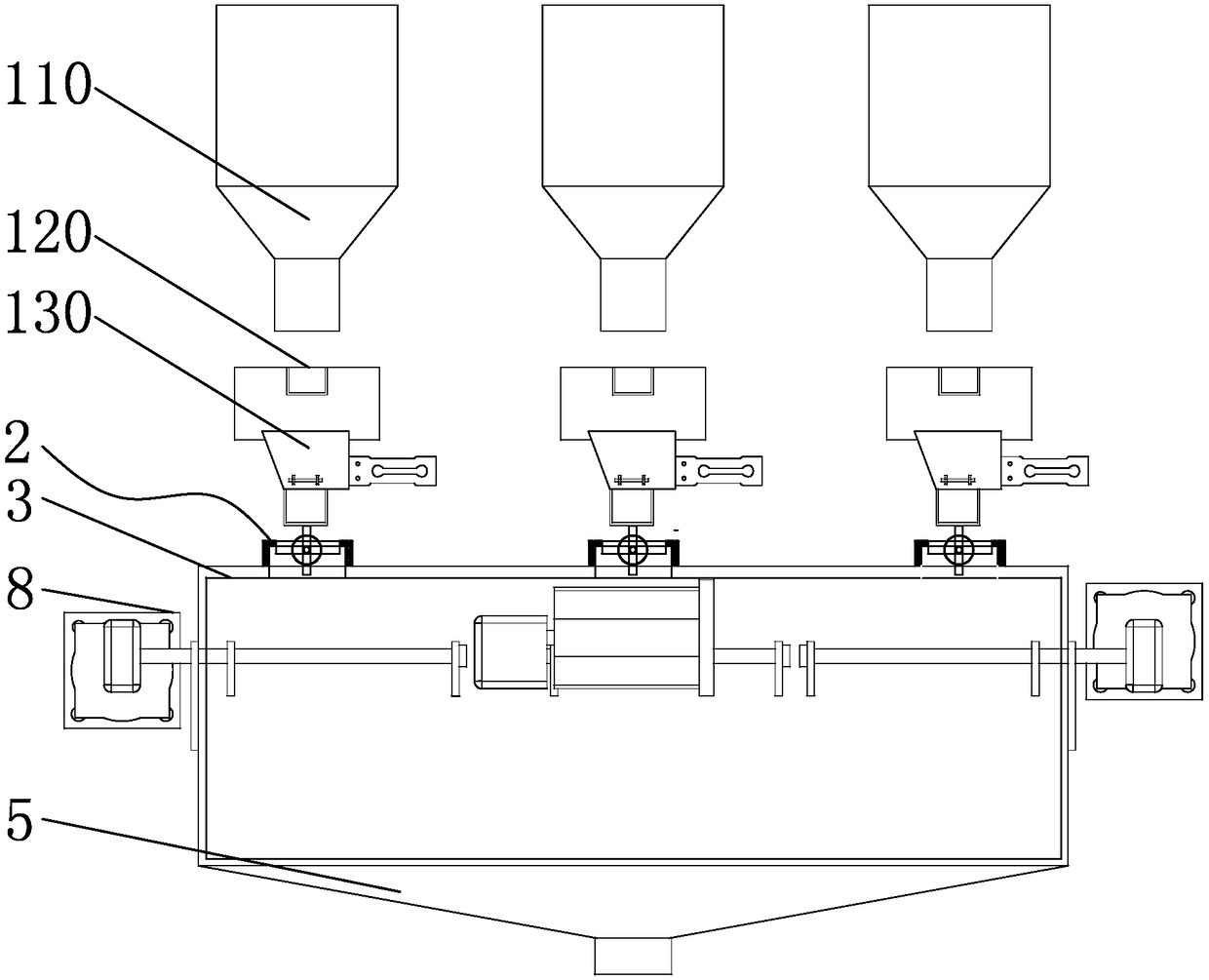

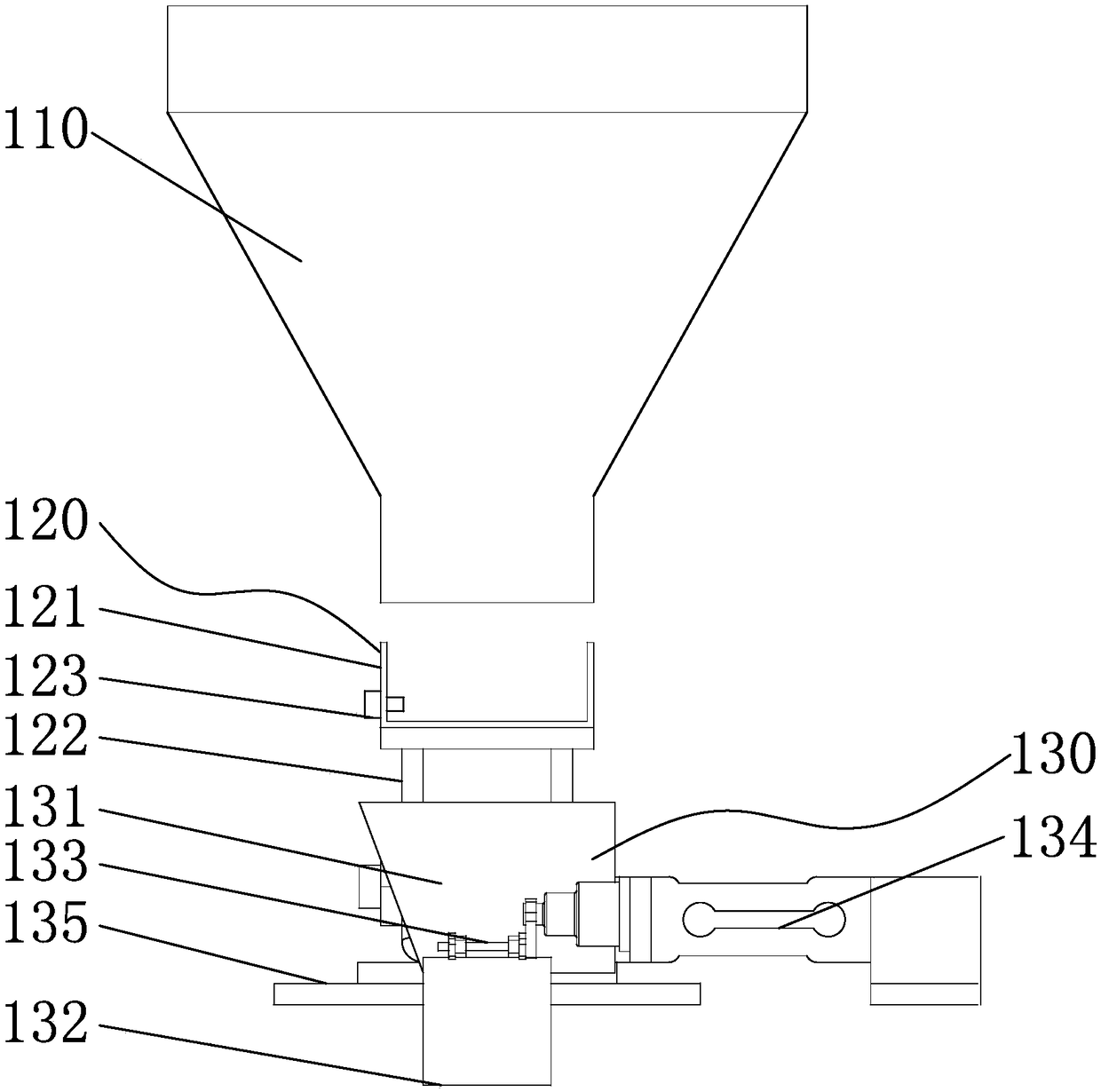

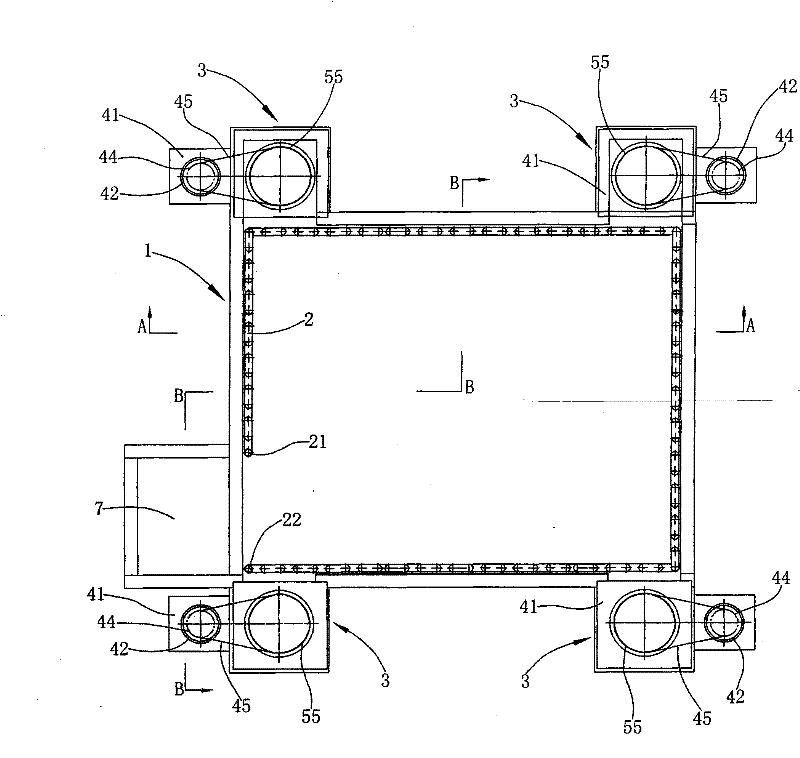

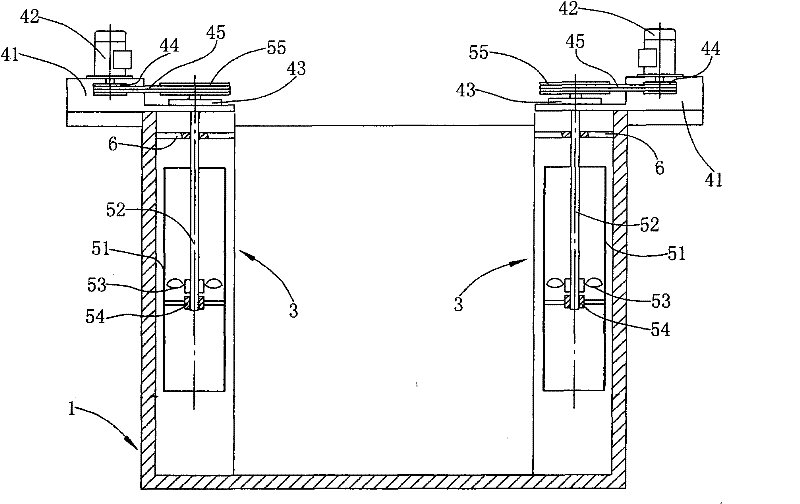

Multi-station automatic deep-frying oven device for food

ActiveCN106993645AControl tasteConsistent tasteBaking ovenOil/fat bakingDeep fryingProcess engineering

The invention relates to a multi-station automatic deep-frying oven device for food. The multi-station automatic deep-frying oven device is characterized by comprising at least three groups of automatic portioning devices, wherein the at least three groups of automatic portioning devices are arranged in parallel; further, one group of transfer conveying devices is arranged blow each group of automatic proportioning devices; oil ovens are arranged below the transfer conveying devices; deep-drying grooves are arranged in the oil ovens; the deep-frying grooves are arranged below the transfer conveying devices; deep-frying material boxes are arranged in the deep-frying grooves; the deep-frying material boxes are connected with driving motors through connecting shafts and right-angle speed reducers; electromagnetic heating devices are arranged below the oil ovens; discharging holes of the oil ovens are provided with one group of material leakage funnels. According to the multi-station automatic deep-frying oven, the heating is carried out through the electromagnetic heating devices; the heating rate and the heating uniformity of an oil temperature are guaranteed; the change of the oil temperature is controlled through infrared temperature sensors; the regulation and control accuracy of the oil temperature are guaranteed.

Owner:哈尔滨兴盛自动化设备制造有限公司

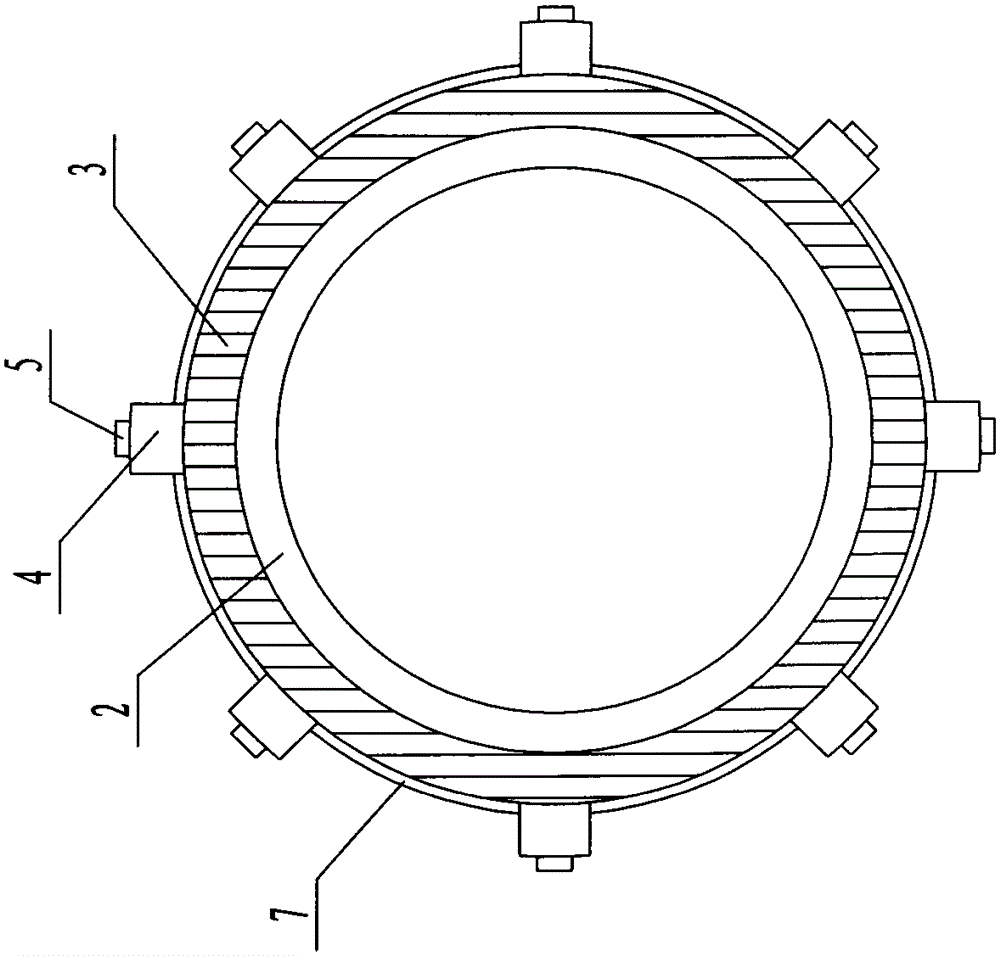

Powder metallurgy oil bearing manufacturing process

InactiveCN114166323AQuality improvementUniform oil temperatureWeighing apparatus for materials with special property/formCooling/ventilation/heating modificationsIron powderGraphite

The invention belongs to the technical field of oil-retaining bearings, and discloses a powder metallurgy oil-retaining bearing manufacturing process. The manufacturing process of the powder metallurgy oil bearing comprises the following steps that S1, aluminum-based powder, iron powder and graphite powder are weighed and mixed, and a mixture is prepared; s2, pressing the mixture into a pressed blank; s3, the pressed blank is sintered, and a sintered blank is obtained; s4, chamfering, sharp edge removing and secondary blank pressing are conducted on the sintered blank, and a semi-finished product is obtained; S5, engine oil is heated, and the semi-finished product is put into the heated engine oil to be soaked; s6, during soaking, the temperatures of the upper layer, the middle layer and the lower layer of the engine oil are detected through a temperature detector; s7, detected data are collected, and when the temperature difference of the upper layer, the middle layer and the lower layer exceeds a preset value, a stirrer is started to stir engine oil, it can be guaranteed that the oil temperature is uniform, and the quality of used raw materials can be controlled.

Owner:ASM ALLOY MATERIALS YIZHENG CO LTD

A liquid nitrogen strong cooling transformer and its refrigeration method

InactiveCN103390485BLow costImprove heat exchange efficiencyTransformers/inductances coolingTemperature control using electric meansElectricityLiquid state

The invention relates to a liquid nitrogen strong cooling transformer and a refrigerating method thereof. The transformer comprises a transformer oil tank and a liquid nitrogen tank; the liquid nitrogen tank is connected with a liquid nitrogen outlet pipe; the transformer oil tank is connected with a gas nitrogen outlet pipe; an evaporating pipe is coiled in the transformer oil tank; one end of the evaporating pipe is communicated with the liquid nitrogen outlet pipe and the other end of the evaporating pipe is communicated with the gas nitrogen outlet pipe; the gas nitrogen outlet pipe is sequentially provided with a liquid nitrogen compressor, a condenser and a throttling valve; the tail end of the gas nitrogen outlet pipe extends into the liquid nitrogen tank; a temperature sensor is arranged in the transformer oil tank; and the liquid nitrogen outlet pipe is provided with a heat preservation electromagnetic valve electrically connected with the temperature sensor. The liquid nitrogen strong cooling transformer and the refrigerating method thereof have the beneficial effects that 1, heat exchange is carried out between liquid nitrogen and transformer oil, heat exchange efficiency is high and gas nitrogen is retransformed into liquid nitrogen by the liquid nitrogen compressor and the condenser and is recycled; and 2, the transformer oil in upper and lower cavities of the transformer oil tank is repeatedly circulated by a transformer oil circulating pipe and a circulating oil pump so as to enable the oil temperature to be balanced.

Owner:王文中

Oil circuit structure of sliding bearing

ActiveCN111102287BImprove heat transfer efficiencyImprove cooling effectSliding contact bearingsBearing coolingSlider bearingCooling effect

The invention provides an oil circuit structure of a sliding bearing, including a cooling device, a thrust head, a thrust shoe and a pressure plate sleeved outside the rotating shaft. There is a first gap between the big end and the thrust pad, and there is a second gap between the big end and the pressure plate. The cooling device is located in the oil tank filled with lubricating oil. The cooling device includes an outer partition and multiple A cooling pipe, the outer partition is surrounded by a space with an inlet and outlet, the inlet and outlet are connected to the oil tank, a plurality of cooling pipes are located in the space surrounded by the outer partition, one end of the first gap and one end of the second gap are connected In the space enclosed by the outer partition, the other end of the first gap and the other end of the second gap communicate with the oil tank through the passage opened on the bearing. The invention forms two planar viscous pumps to provide driving force; the heat transfer efficiency of the cooler is improved, and the cooling effect of the bearing is improved.

Owner:HUNAN CHONGDE IND TECH

Pastry frying device

The invention discloses a pastry frying device, and in particular to the field of pastry processing equipment. The pastry frying device comprises a box body; heating pipes are uniformly arranged in the box body; an oil storage tank is arranged inside the box body; the heating pipes are arranged inside the oil storage tank; a screen tank is arranged in the oil storage tank; connecting plates are respectively arranged on two sides of the top of the screen tank; fixed seats are respectively arranged on the surfaces of two sides of the box body; a motor is arranged on one side of the inner wall ofthe screen tank; and a rotating rod is arranged outside the motor. According to the invention, through arrangement of the screen tank, the connecting plates and the fixing seats, the position of thescreen tank is limited after positioning rods at the bottom of the connecting plates are respectively inserted into the fixing seats. A pastry is placed in the screen tank; meanwhile, oil is added into the oil storage tank for heating and frying; and after frying is finished, the connecting plate is lifted out, then the screen tank and the pastry in the screen tank can be taken out from the oil storage tank, and oil can be quickly drained. Meanwhile, the screen can be replaced to carry out a next batch of frying work, so that oil temperature can be ensured, and whole frying efficiency can be accelerated.

Owner:曾星星

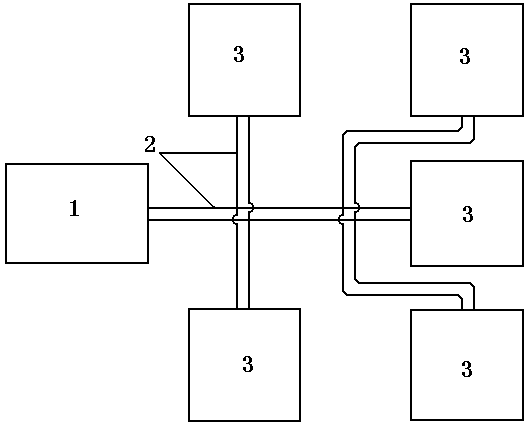

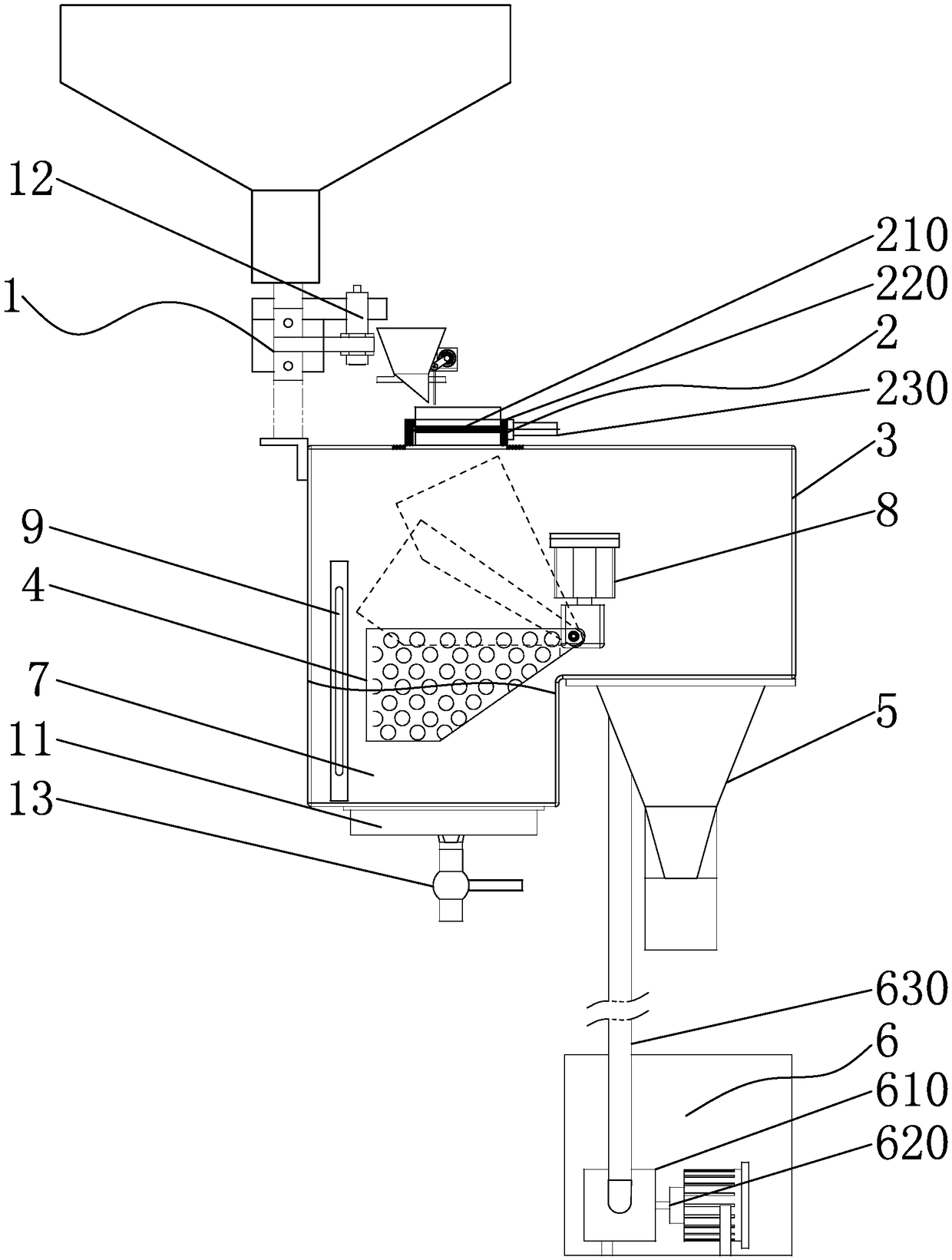

A central heating oil fryer with heat conduction oil connected to multiple boilers

A conduction oil centralized heat supply fryer with multiple fryer bodies communicated is composed of a conduction oil heat source device, circulating pipelines and the fryer bodies. The circulating pipelines are connected between the conduction oil heat source device and the fryer bodies. Each fryer body comprises a fryer main body, inner heat supply coil pipes, an outer heat supply coil pipe and a control assembly, wherein the bottom of the fryer main body is provided with a groove, the portion, at one end of the fryer main body, of the bottom of the groove is provided with an oil drainage valve and a sewage discharge port extending to the outside of the fryer wall, the outer wall of the other end of the fryer main body is provided with a circulating pipeline connecting pipe, the inner heat supply coil pipes are erected on the two sides of the bottom in the fryer main body in a suspended mode, the outer heat supply coil pipe is formed by connecting a plurality of square channels in the outer wall of the bottom of the fryer main body into a communicated coil pipe, heat supply end connectors and backflow end connectors of the inner heat supply coil pipes and the outer heat supply coil pipe are connected to the circulating pipeline connecting pipe in parallel, the control assembly comprises a controller, a temperature sensor and a solenoid valve, the temperature sensor is installed in the fryer main body, the solenoid valve is connected between the heat supply end connectors and the heat supply pipeline connecting pipe, and the temperature sensor and the solenoid valve are connected with the controller through connecting wires.

Owner:泉州恒灼热力机械科技有限公司

Automatic box-type heat treatment equipment

Owner:ANHUI XINNING EQUIP

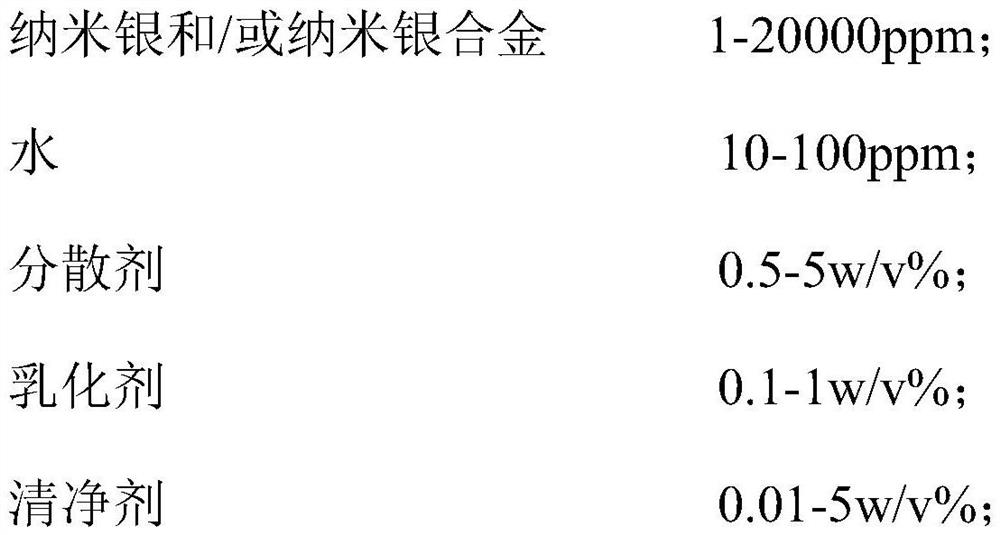

A kind of nano-fuel additive and preparation method thereof

ActiveCN110804470BGuaranteed solution stabilitySmall particle sizeLiquid carbonaceous fuelsOil additiveSilver Nano

Owner:广州市科瑨材料科技有限公司

A multi-station automatic fryer device for food

ActiveCN106993645BAvoid the dangers of manual handlingControl tasteBaking ovenOil/fat bakingDeep fryingProcess engineering

The invention relates to a multi-station automatic deep-frying oven device for food. The multi-station automatic deep-frying oven device is characterized by comprising at least three groups of automatic portioning devices, wherein the at least three groups of automatic portioning devices are arranged in parallel; further, one group of transfer conveying devices is arranged blow each group of automatic proportioning devices; oil ovens are arranged below the transfer conveying devices; deep-drying grooves are arranged in the oil ovens; the deep-frying grooves are arranged below the transfer conveying devices; deep-frying material boxes are arranged in the deep-frying grooves; the deep-frying material boxes are connected with driving motors through connecting shafts and right-angle speed reducers; electromagnetic heating devices are arranged below the oil ovens; discharging holes of the oil ovens are provided with one group of material leakage funnels. According to the multi-station automatic deep-frying oven, the heating is carried out through the electromagnetic heating devices; the heating rate and the heating uniformity of an oil temperature are guaranteed; the change of the oil temperature is controlled through infrared temperature sensors; the regulation and control accuracy of the oil temperature are guaranteed.

Owner:哈尔滨兴盛自动化设备制造有限公司

Improved grinding ball quenching tank

ActiveCN102061366BReduce oil temperature gradientReduce temperature gradientQuenching devicesCooling towerCooling effect

The invention relates to an improved grinding ball quenching tank which comprises a tank body of which the upper end is opened, wherein the tank body is provided with at least one stirring machine, and the stirring machine comprises a power assembly and a stirring assembly which are connected; and the stirring assembly extends into the tank body. After the technical scheme is adopted, the stirring machine is started, and by utilizing the stirring and homogenizing effects of the stirring machine, the temperature gradient of quenching oil in the quenching tank is effectively reduced, so that the oil temperature is uniform, the quenching effect is better, and the properties (such as the indexes of hardness, density, and the like) of a grinding ball are greatly improved; and in addition, the cooling effect of the stirring machine effectively reduces the temperature of the quenching oil in the tank body, thus the temperature of the quenching oil cannot be too high so as to ensure that the possibility of burning of the quenching oil while the grinding balls enter the tank body is greatly reduced, equipment such as an external cooling tower, and the like can be omitted, and the investment of external equipment is reduced. In conclusion, when the quenching tank is used in a quenching process of the grinding balls, the quenching tank has the advantages of uniform quenching, good quenching quality, stable properties of the grinding balls and lower quenching treatment cost.

Owner:FIRST DESIGN & RES INST MI CHINA

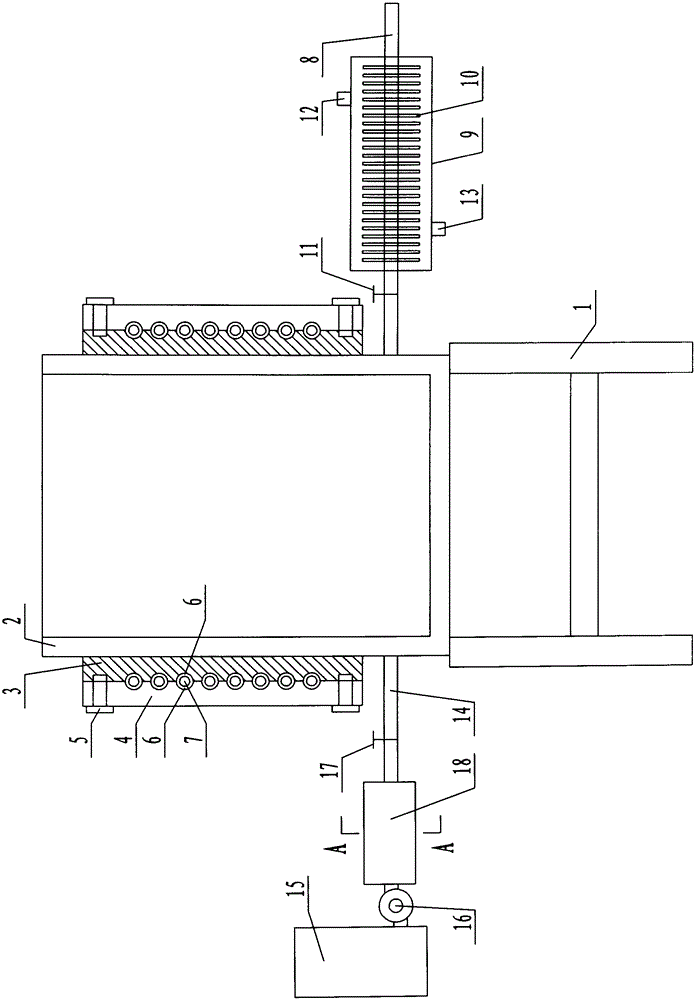

Combined type instant noodle oil-noodle separating device

InactiveCN111789136AIncrease productivityImprove product qualityOil/fat bakingStationary filtering element filtersFoot supportsProcess engineering

The invention relates to the field of food processing equipment, and particularly relates to a combined type instant noodle oil-noodle separating device. The combined type instant noodle oil-noodle separating device comprises a supporting mounting barrel which is vertically arranged, wherein supporting foot pads are arranged at four corners of the lower end of the supporting mounting barrel; a supporting mounting plate is vertically arranged at the right end of the supporting mounting barrel; an electric control lifting column is vertically arranged at the upper end of the supporting mountingplate; a lifting mounting column is vertically arranged above the supporting mounting barrel; the upper end of the lifting mounting column and the upper end of the electric control lifting column arehorizontally connected with a synchronous lifting plate; and a heat-insulating layer is embedded into the barrel wall of the supporting mounting barrel. Through a combined type quick mounting structure, maintenance performance of the device is remarkably improved; through matching of a rotary structure for blocking materials in a staggered mode, multi-layer noodle cakes are fried at the same time;and through an active flow guide structure, oil temperature inside is uniform, so that frying progress of the multi-layer noodle cakes is guaranteed to be synchronous, and synchronous lifting is realized, and therefore, instant noodle production efficiency and quality of the device are remarkably improved.

Owner:魏蔚

Novel process for double medium oil-air quenching of alloy wear resistant casting

The invention relates to an alloy abrasion-proof casting double medium oil wind quenching process, characterized as : adopting oil quenching mode in high temperature stage, when product temperature reducing to a certain temperature, adopting slow wind quenching mode, of the quenched product in the invention, quenching rigidity is >=58HRc ,rigidity difference is <=2.5HRc, which fully solve the quenching crack, promote the integral mechanical property.

Owner:安徽省凤形新材料科技有限公司

A temperature-controlled printing equipment for pvc decorative film processing

ActiveCN112810307BImprove printing efficiencyThere will be no printing blind spotsRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention discloses a temperature-controlled printing equipment for PVC decorative film processing, comprising a printing table, a roller shaft is rotatably connected to the inner wall of the printing table, and a hot oil roller is fixedly installed on the surface of the roller shaft. A rotary motor is fixedly installed on the top of the rotary motor, and the output end of the rotary motor is connected with the roller shaft through a conveyor belt, and a temperature detection mechanism is fixedly installed on the hot oil roller. In this temperature-controlled printing equipment for PVC decorative film processing, the buoyancy ring will float on the oil surface. When the oil level in the hot oil roller rises, the buoyancy ring will slide up under the action of its buoyancy. Under the action of the magnetic force between the block and the sliding magnetic plate, the sliding magnetic plate moves up in the linkage cavity. At this time, the gas in the upper cavity enters the sliding groove through the conduit, so that the pressure in the sliding groove increases, thereby making the sliding groove inside the sliding groove. The fitting tool slides to the outside and blocks the side wall of the sliding groove, so that the sealing performance of the temperature detection mechanism is better.

Owner:山东沃尔新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com