Improved grinding ball quenching tank

A technology of quenching tank and tank body, applied in the direction of quenching device, heat treatment equipment, manufacturing tools, etc., can solve the problems of high quenching treatment cost, unstable grinding ball performance, large investment in peripheral equipment, etc., and achieves good quenching effect and saves Equipment, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

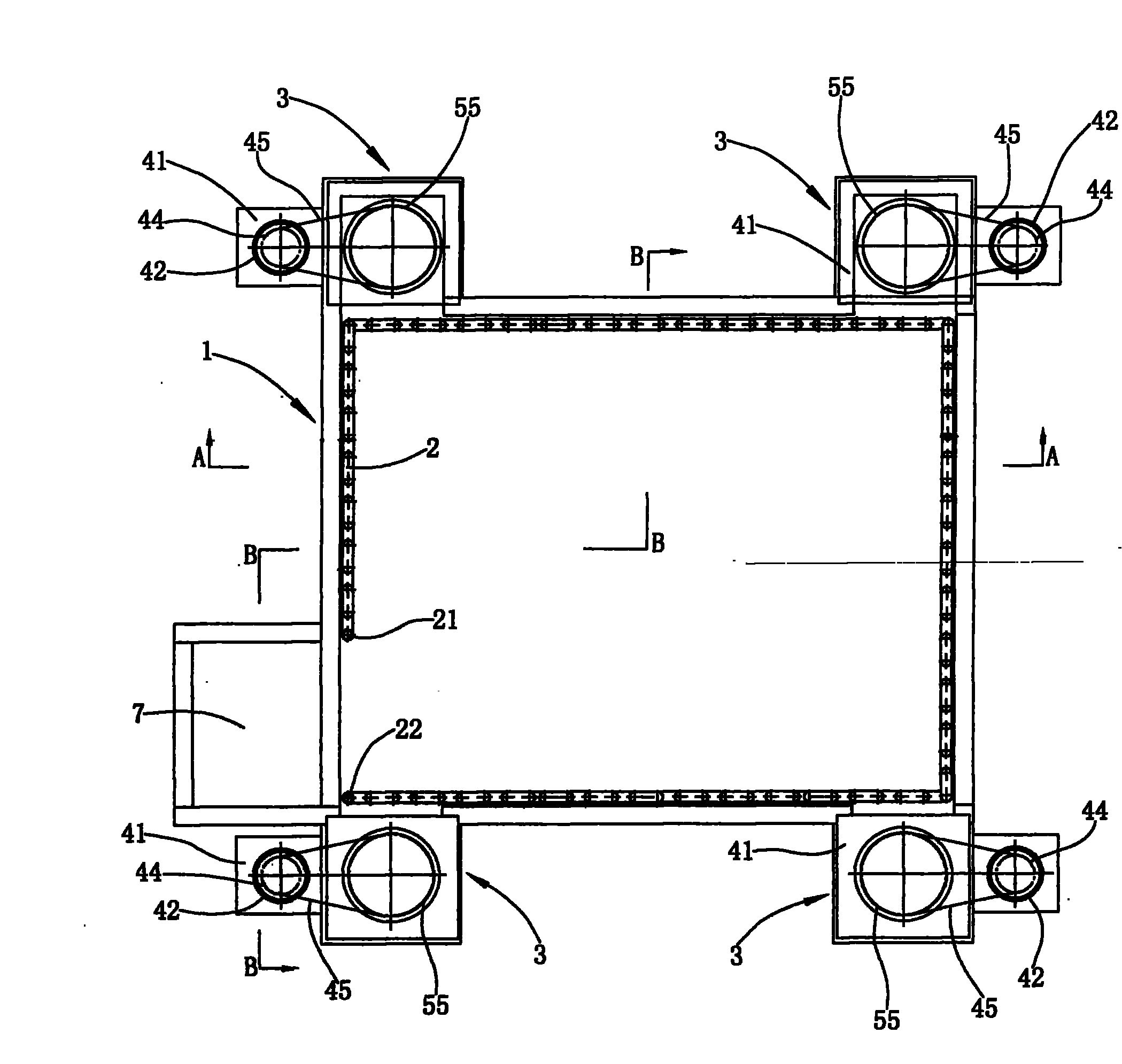

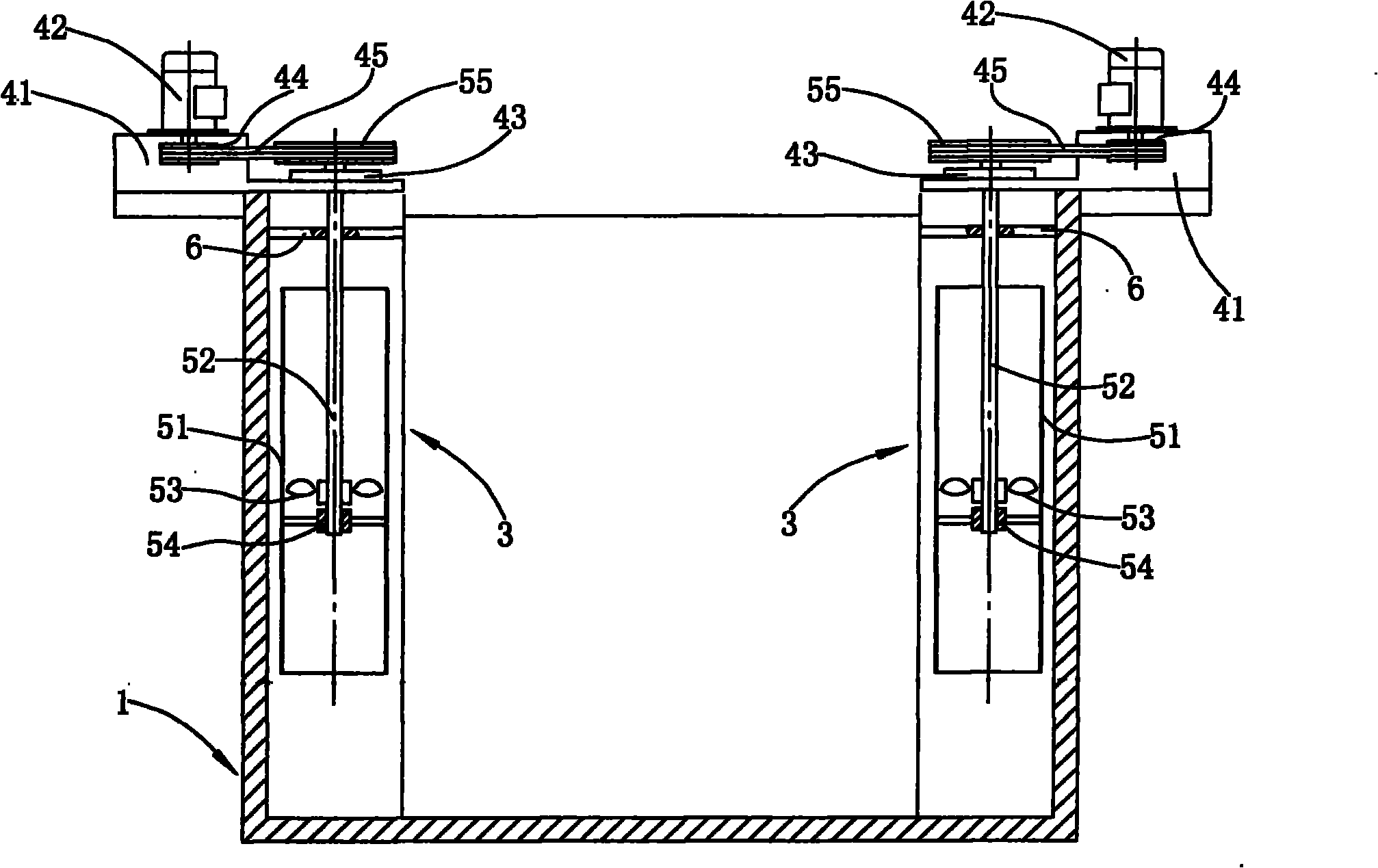

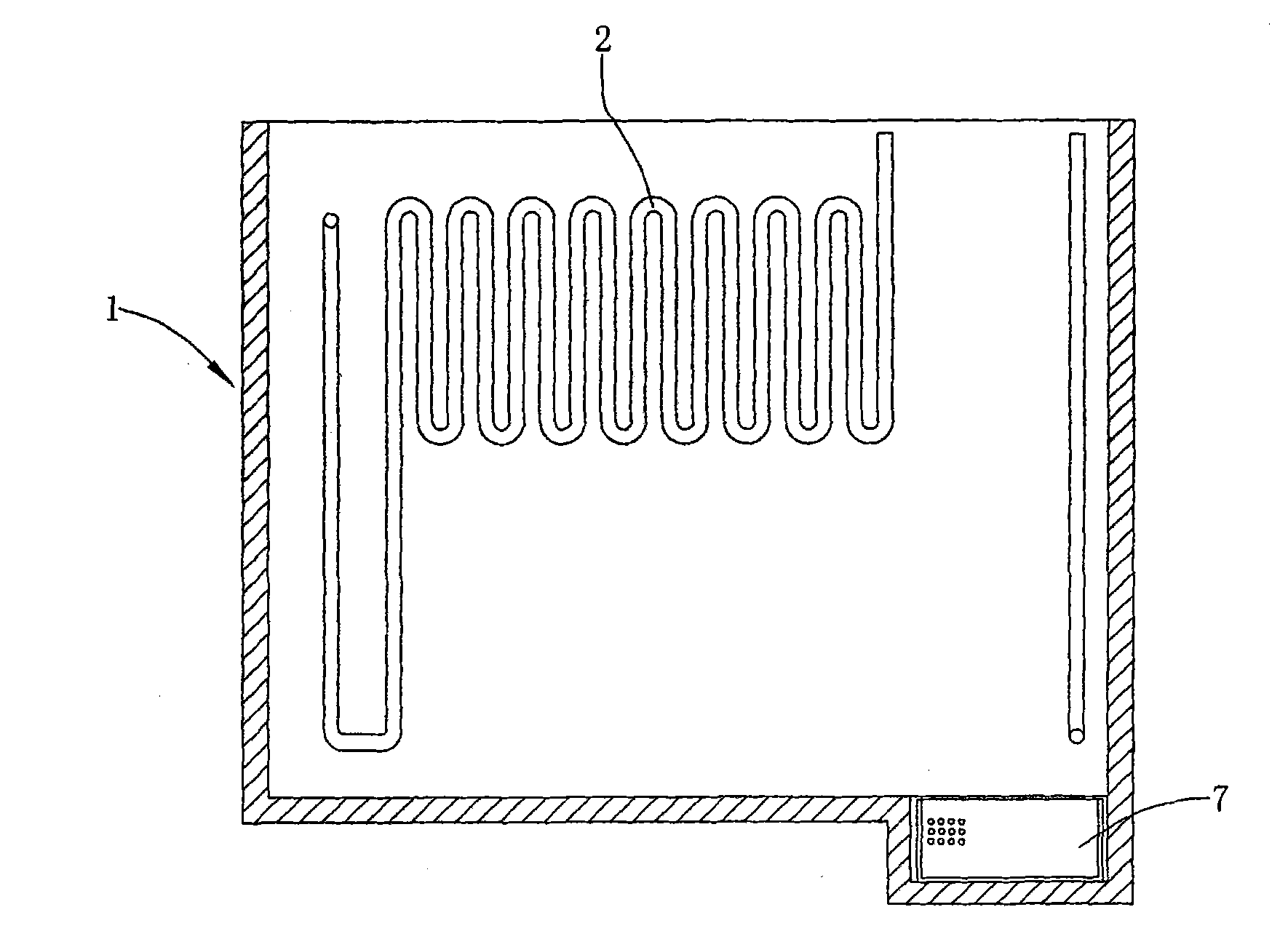

[0025] see Figure 1-Figure 3 : image 3 The protruding parts on the front and rear sides and the corresponding mixers are omitted.

[0026] The quenching tank includes a square tank body 1 with an open upper end. A cooling coil 2 is arranged on the side wall of the tank body 1 .

[0027] Each corner of the tank body 1 has a vertical protruding part 3 that protrudes and communicates with the inner cavity of the tank body 1, and each protruding part 3 is provided with a mixer.

[0028] Each mixer includes an associated power assembly and an agitation assembly.

[0029] The power assembly of each mixer comprises the support 41 that is arranged on the upper end of the corresponding protrusion 3 and stretches out, the vertical motor 42 that is installed on the outside of the support 41, the horizontal support bearing 43 that is arranged on the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com