Patents

Literature

253results about How to "Lower oil temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

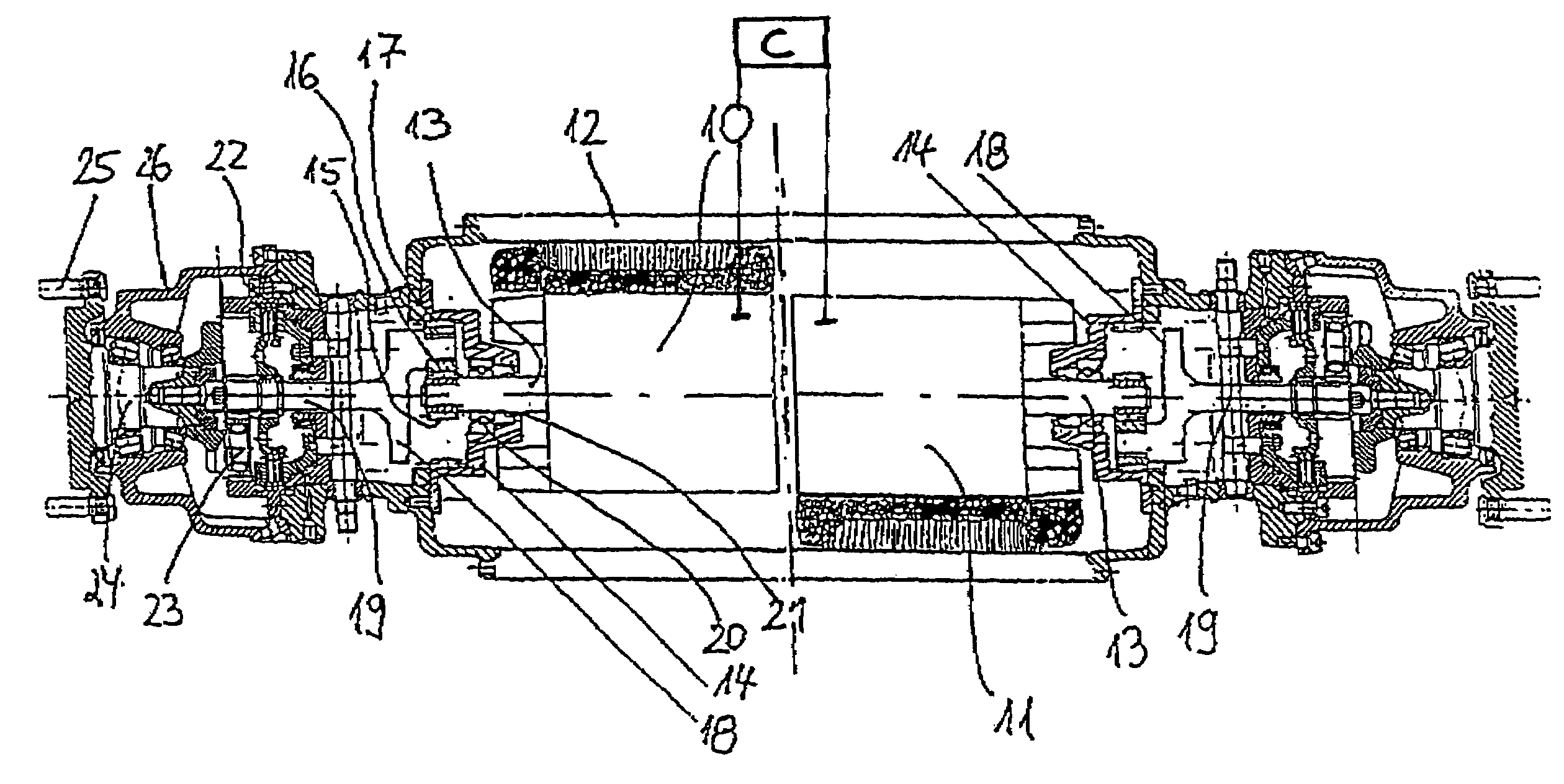

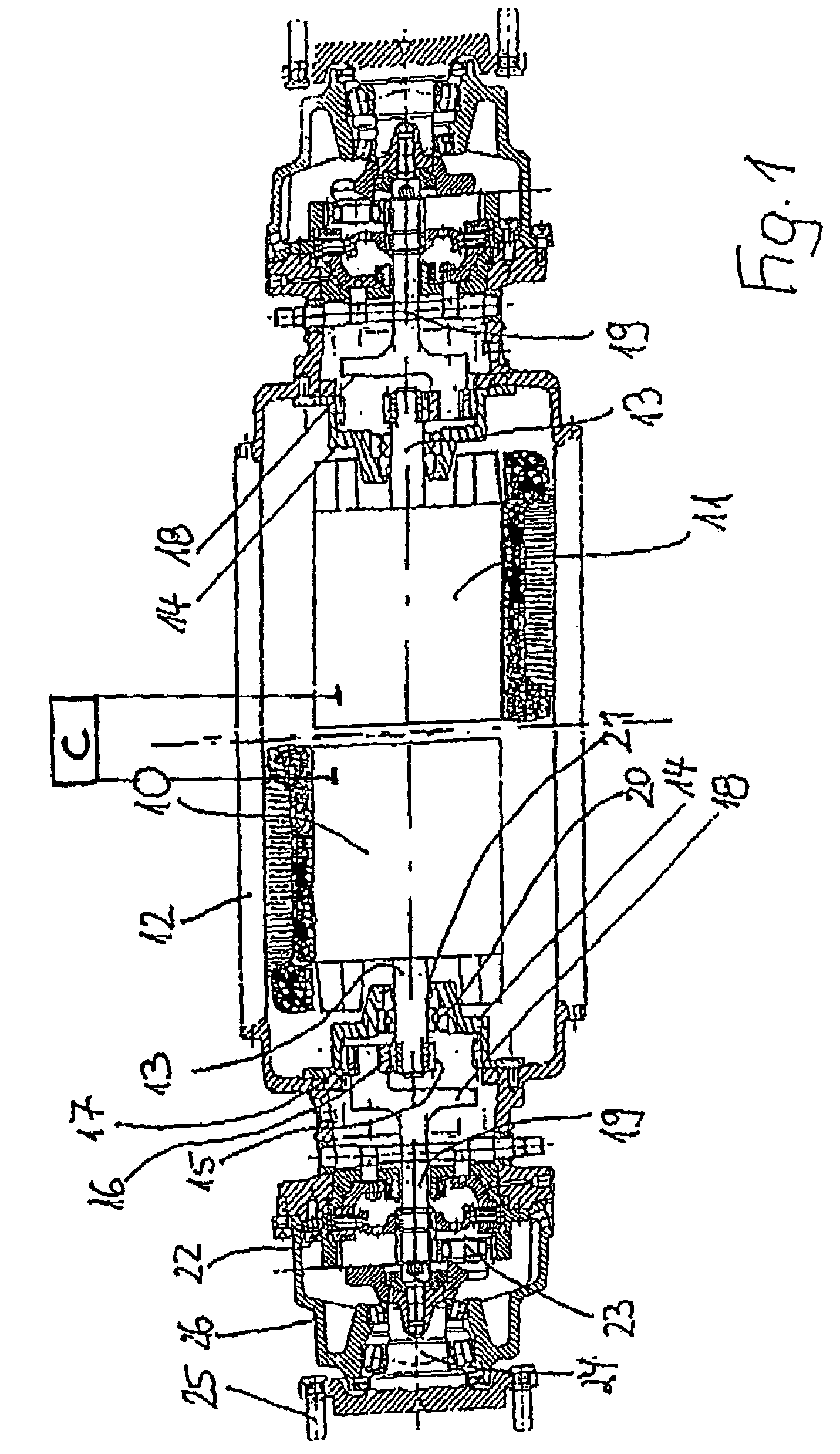

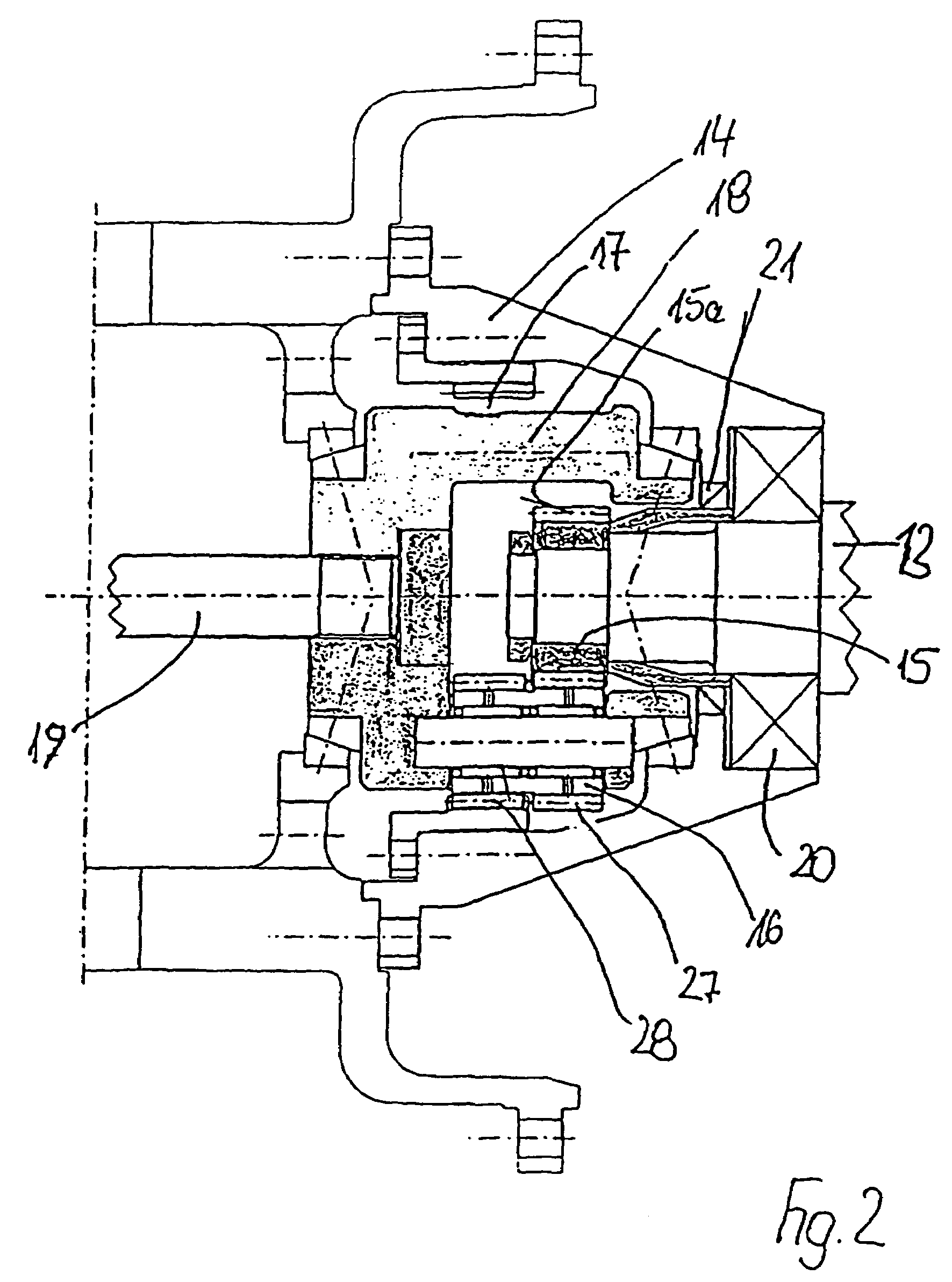

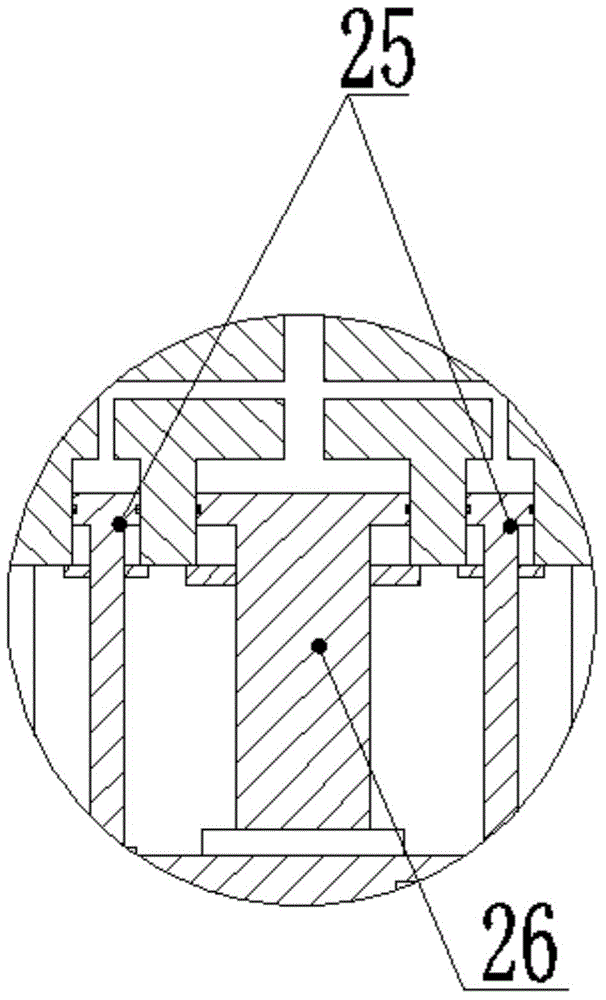

Directly driven driving axle having two drive motors

ActiveUS7112155B2Large degree of freedomGreat output torqueSpeed controllerElectric devicesWork functionDrive motor

The invention relates to a driving axle for electric motor-driven vehicles provided with at least one electric motor mounted on the axle and drive shafts driven by the motor shaft thereof with a planetary gear step inserted therebetween, connected to the output shafts bearing the wheels resting on the drive axle with a braking device and another planetary gear inserted therebetween. The invention is characterised in that two controlled asynchronous motors (10, 11) are disposed on the axle, said motors working separately and being controlled by a common control in the working functions thereof. The motor shafts (13) of both asynchronous motors (10, 11) are connected respectively by the planetary gear step (15, 16, 17) to the drive shaft (19) driving the downstream output shaft (24).

Owner:HARLAN GLOBAL MFG

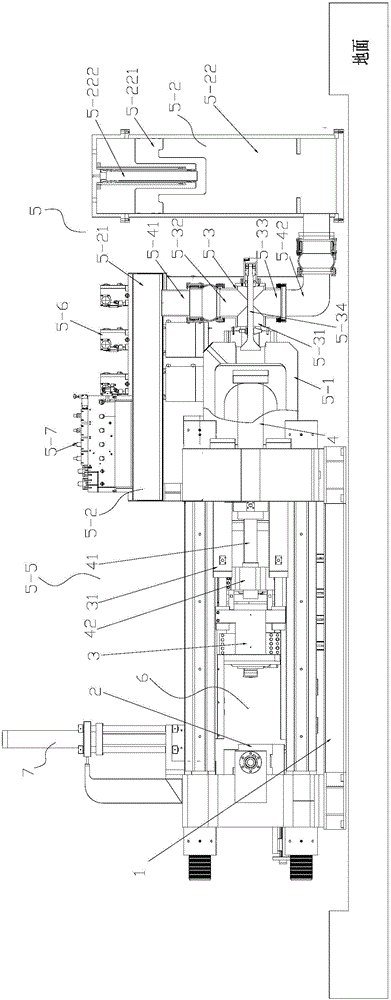

Plunger pump type hydraulic injection moulding machine system driven by servo motor and control method thereof

The invention discloses a plunger pump type hydraulic injection moulding machine system driven by a servo motor. The system comprises an oil tank, a servo pump, a mould height motor, a mould clamping cylinder, an ejector cylinder, a movable ejection cylinder, a glue-ejecting cylinder, a glue-smelting motor and an electronic ruler measurement sensor and also comprises a computer controller, a pressure and speed comprehensive control module, a servo driver, the servo motor and a pressure sensor. The invention also discloses a control method of the plunger pump type hydraulic injection moulding machine system driven by the servo motor. In the control method, the pressure sensor and the torque control of the servo motor are adopted, the multilevel control of pressure and flow can be realized;real-time closed-loop control is adopted to control the pressure and flow during injection moulding; and in the control process, the instructions on the pressure and flow are compared with feedbacks in real time and some parameters such as the speed, pressure and current at each moment are controlled accurately, thus effectively realizing technical motions such as the mould open / closing, ejection, glue ejection and glue smelting of the injection molding machine and the closed-loop follow control of the oil cylinder. The method of the invention has the advantages of high precision, high speed and efficiency, energy-saving, environmental friend, low noise and the like.

Owner:SOUTH CHINA UNIV OF TECH

Modified gear oil

A modified gear oil can be used for extreme worm oil, open industrial gear oil and closed industrial gear oil in traffic transportation, machinery, metallurgical, chemical industries. In the mineral lube-oil or synthetic lube-oil, modified nano-carbon with average grain size 2-6nm is added as extreme anti-scuff agent and oily agent, quality fraction is 2X10-5-1X10-2, nano-diamond occupies 10-99%, wear rate is decreased by 46.7%, mechanical efficiency improves by 2.84%, polishing scratch depth is decreased from 4.94 mu m to 0.07 mu m.

Owner:TIANJIN CHANYU SUPERHARD SCI TECH CO LTD

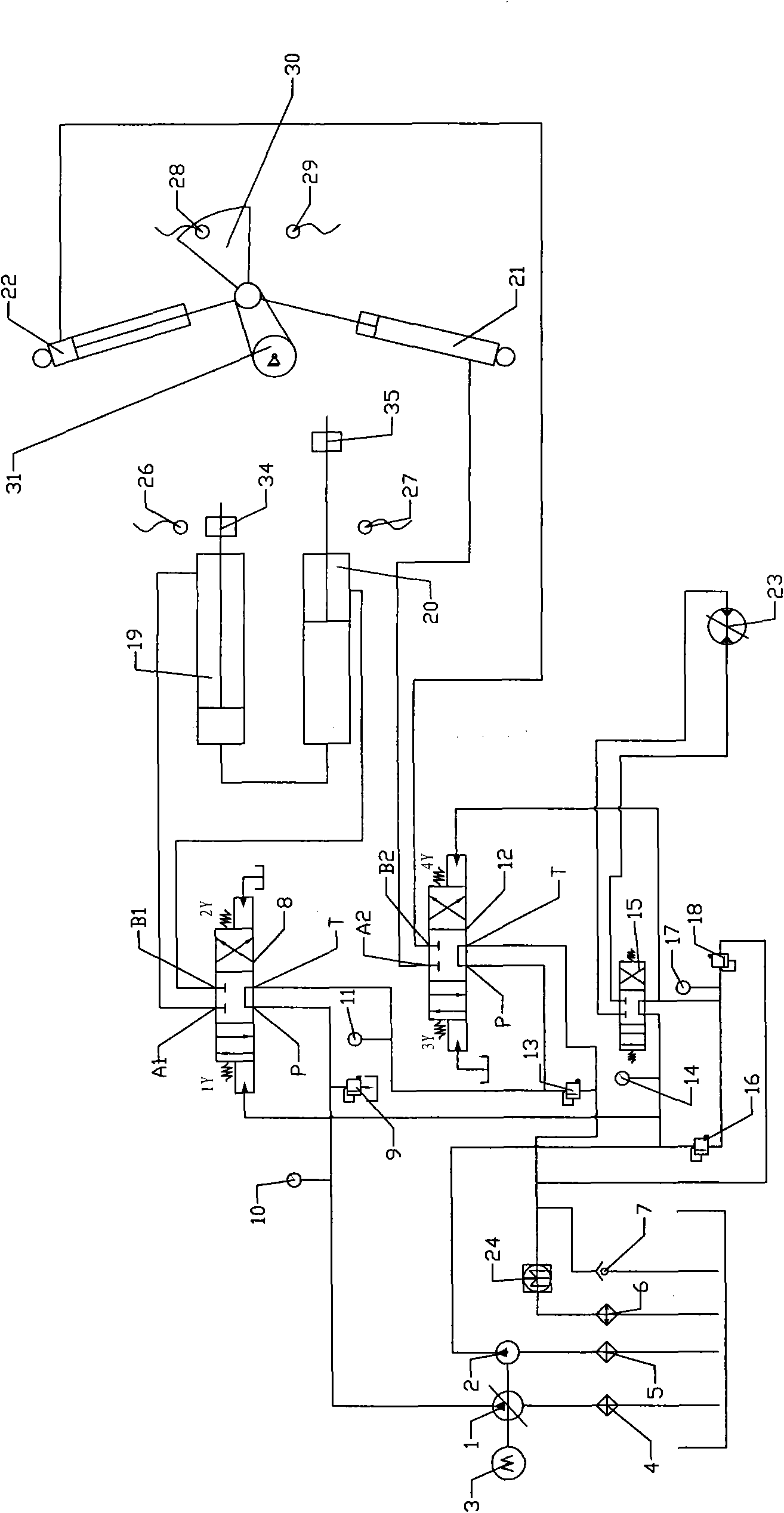

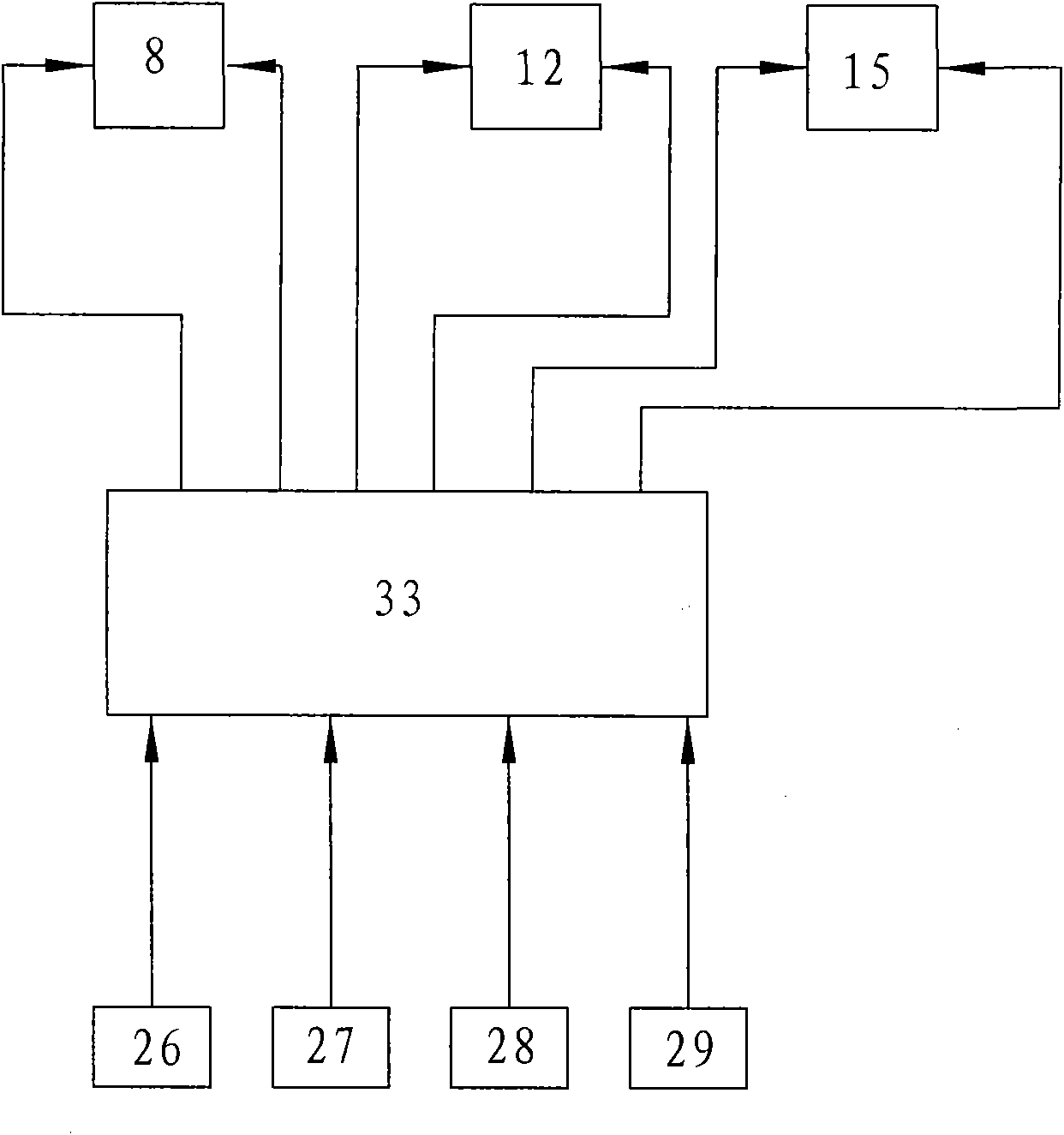

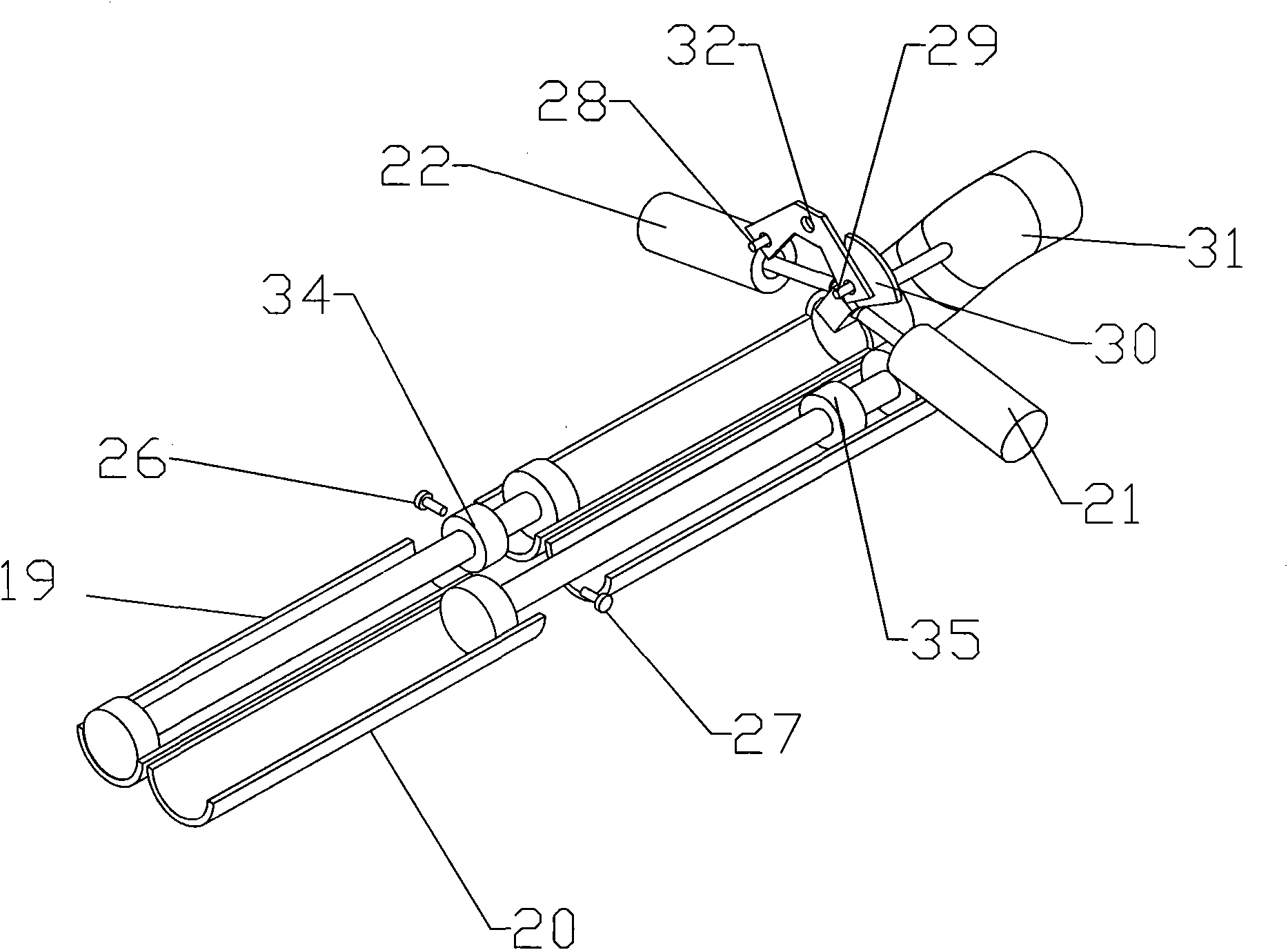

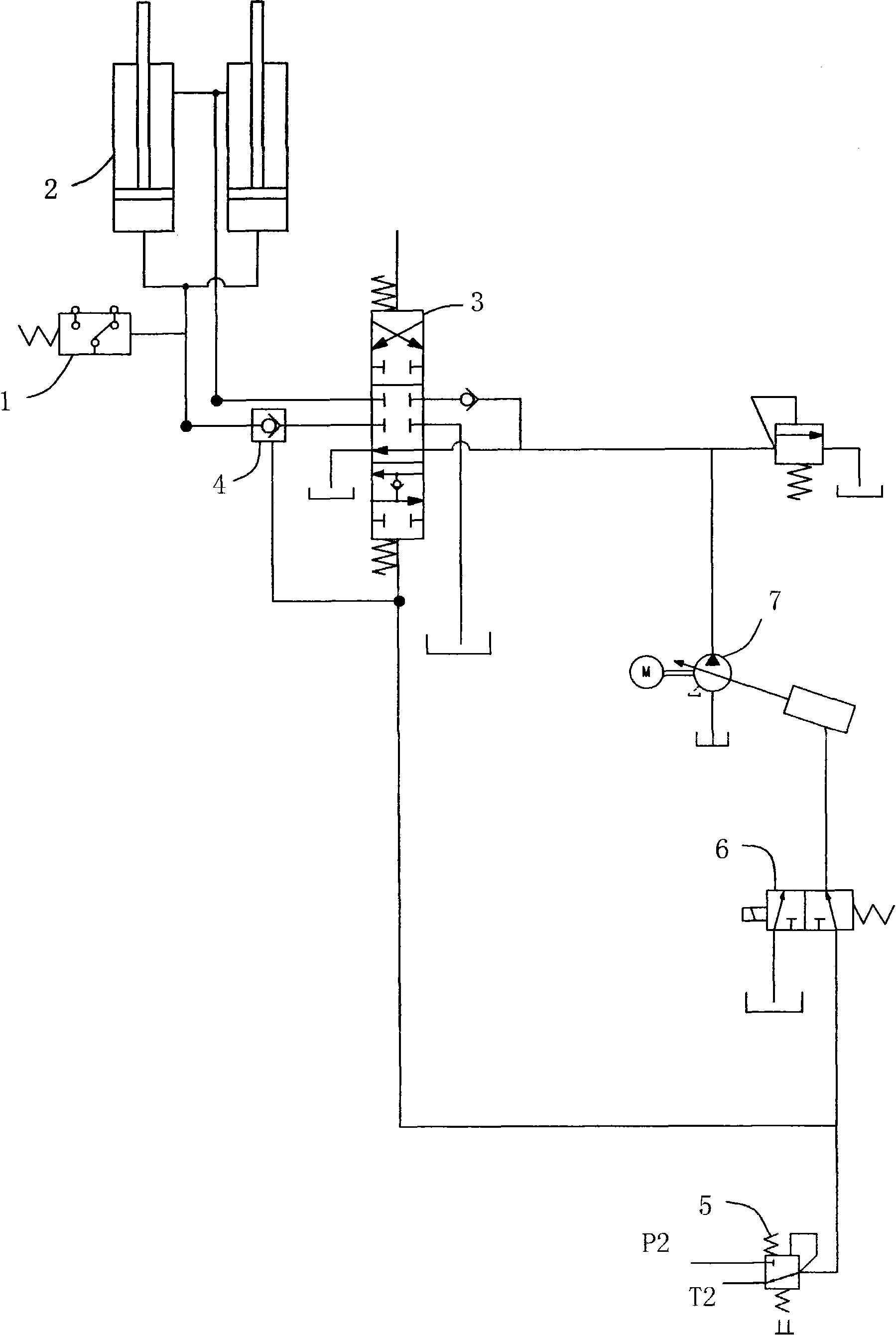

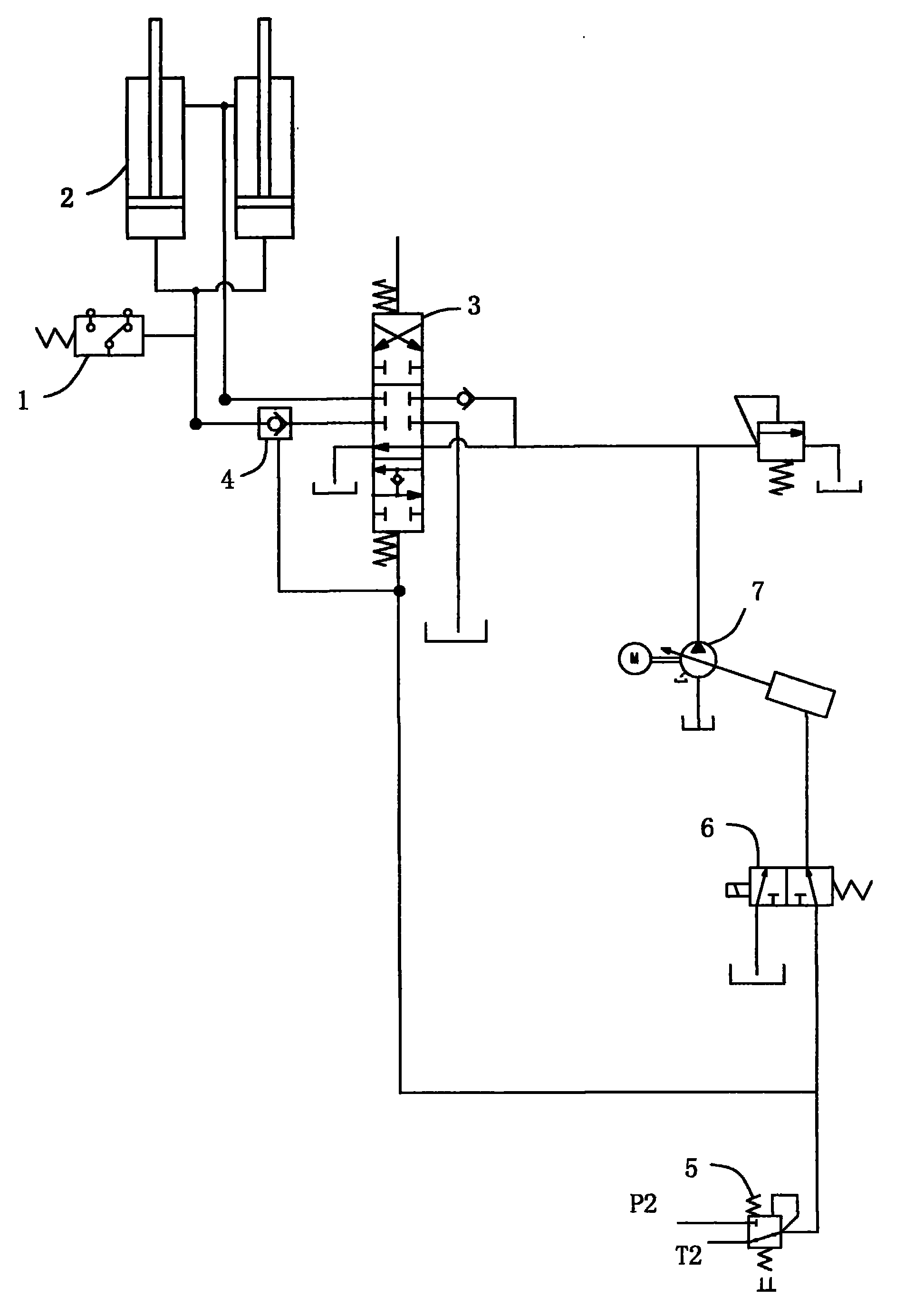

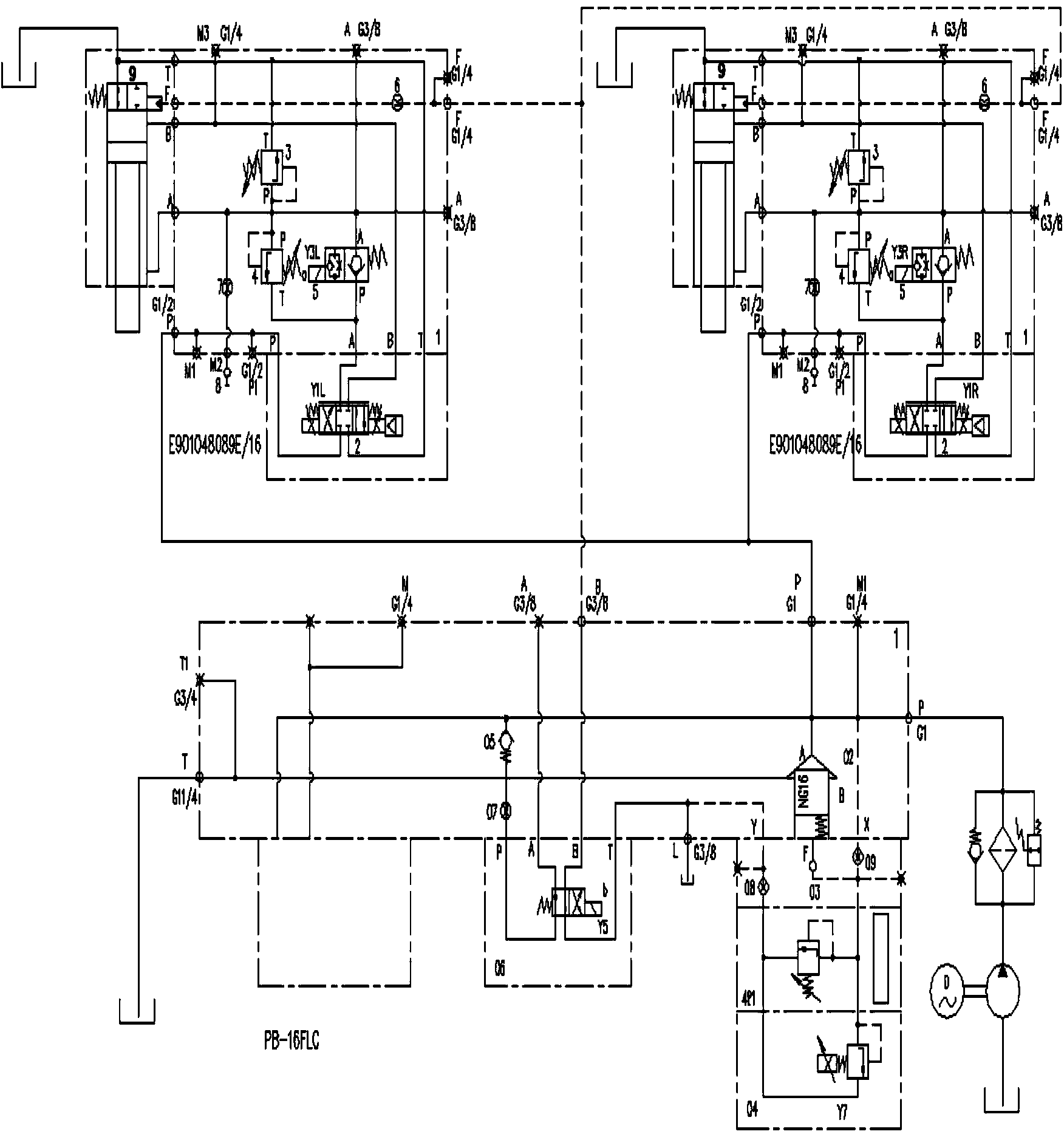

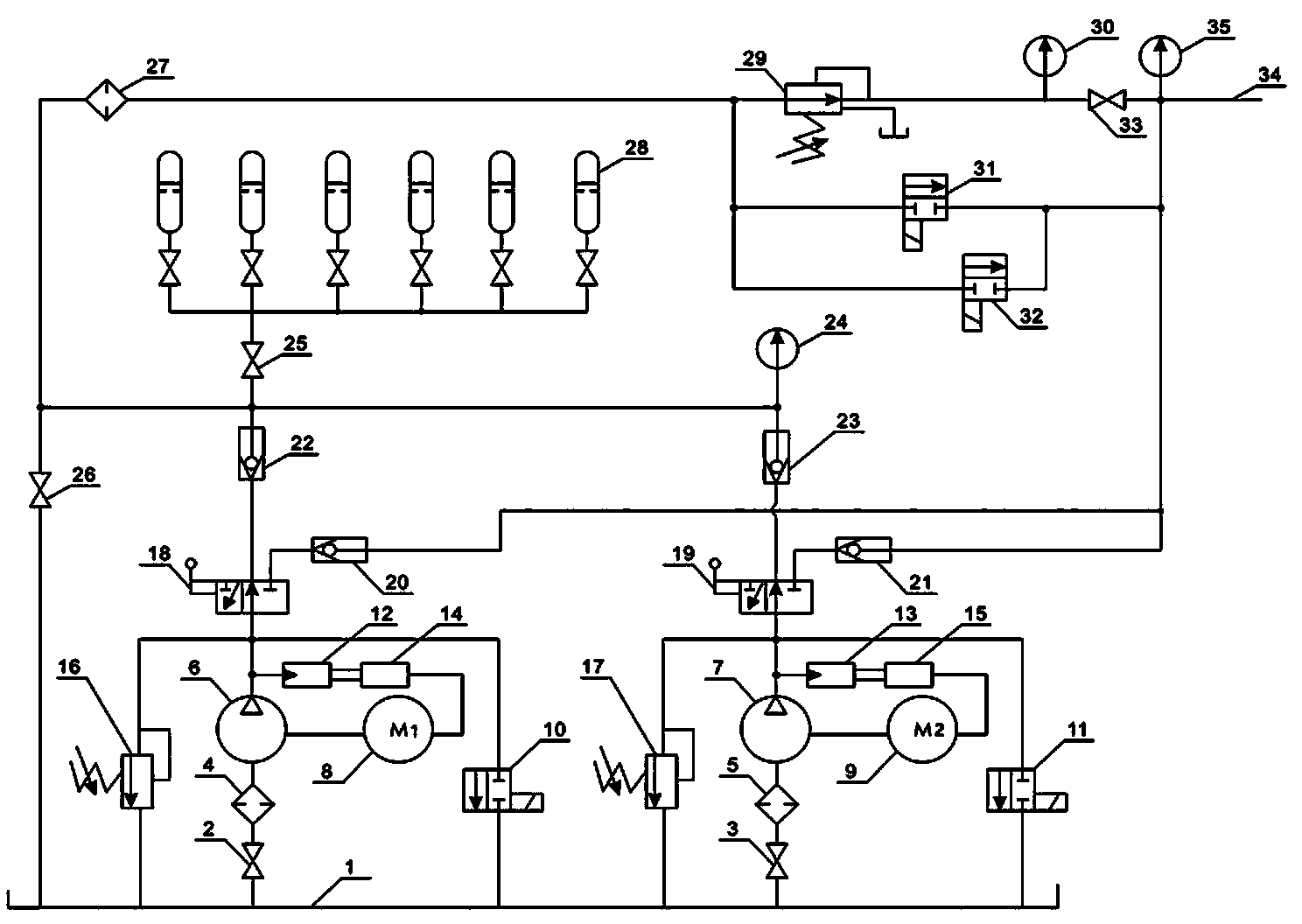

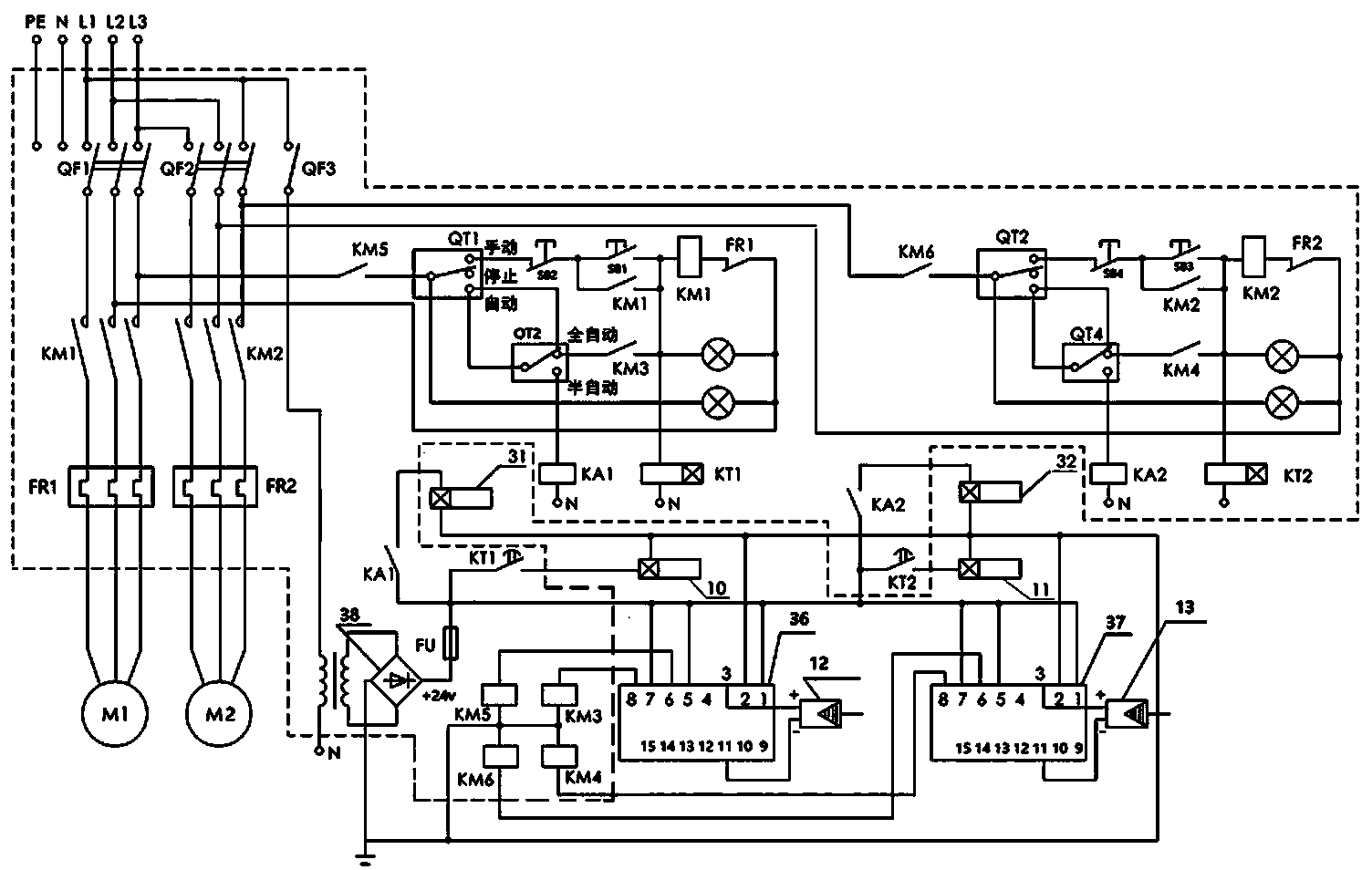

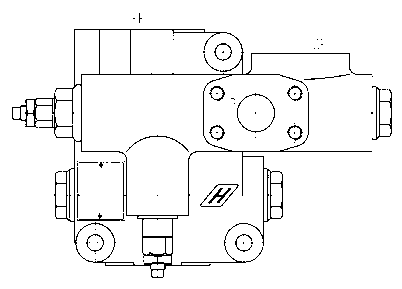

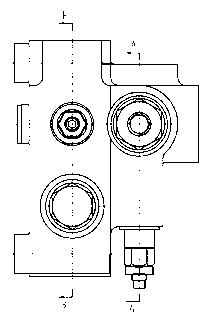

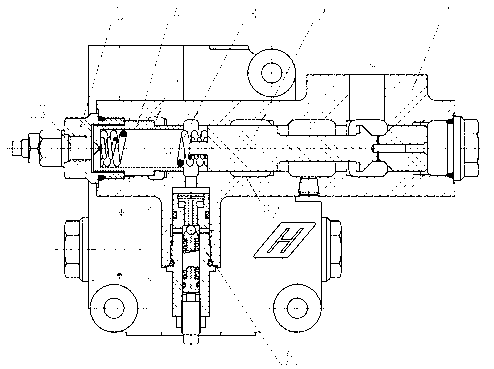

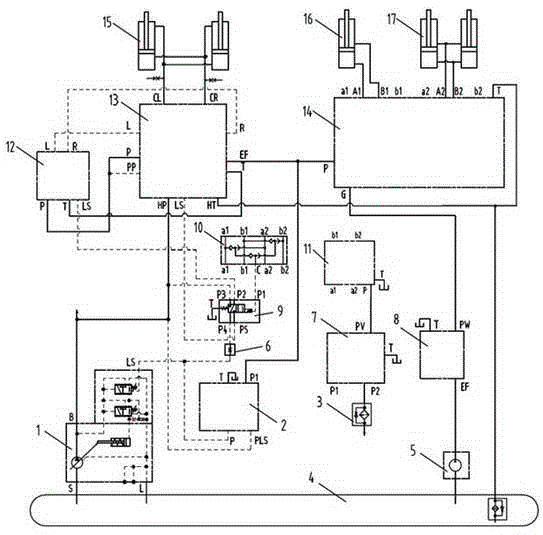

Electro-hydraulic control system for concrete or coal slime conveying device and method for controlling system

InactiveCN101865189ALower oil temperatureLow manufacturing and maintenance costsFluid-pressure actuator componentsLow noiseControl system

The invention discloses an electro-hydraulic control system for a concrete or coal slime conveying device and a method for controlling the system. The electro-hydraulic control system comprises a programmable logic controller PLC, a swinging S tube, a sensor, a pumping oil cylinder, a hydraulic pump, an overflow valve, three M-shaped three-position four-way electro-hydraulic directional control valves, an oil tank, an oil stirring path, a pumping oil path and a swinging oil path, wherein a T port of a first M-shaped three-position four-way electro-hydraulic directional control valve is connected with a P port of a second M-shaped three-position four-way electro-hydraulic directional control valve; the baffles of the pumping oil cylinder and the swinging oil cylinder act on the sensor, so that a signal is emitted from the sensor and received by the PLC; the PLC sequentially acts on the two electro-hydraulic directional control valves according to a program set therein; and the two electro-hydraulic directional control valves control the on-off of oil paths flowing to the pumping oil cylinder and the swinging oil cylinder. The electro-hydraulic control system has the advantages of low oil temperature, low noise, long service life, low manufacturing and maintenance cost, low energy consumption and high reliability.

Owner:秦月明

Excavator swing arm descending hydraulic control loop

ActiveCN101775822AReduce power consumptionLower oil temperatureSoil-shifting machines/dredgersHydraulic pumpFuel tank

The invention discloses an excavator swing arm descending hydraulic control loop. The key points of design are as follows: an electromagnetic directional valve is arranged between a servo variable mechanism of a emission variable hydraulic pump and an oil outlet of a swing arm descending manual pilot valve; a hydraulic controlled electric contact pressure switch is arranged on the connecting pipeline between a rodless cavity of a swing arm cylinder and a swing arm two-way hydraulic controlled directional valve, and the electric contact pressure switch is electrically connected with the electromagnetic directional valve; the spool of the swing arm two-way hydraulic controlled directional valve is provided with a compensation channel, and the compensation channel is internally provided with a one-way valve. When the swing arm descends, under actions of the swing arm and the load gravity thereof, hydraulic oil supposed to flow back to an oil tank enters into a rod cavity quickly via the compensation channel, while the emission variable hydraulic pump maintains in the lowest emission state, thus reducing power consumption, lowering system oil temperature and saving energy. And when the swing arm descends too quickly or the bucket nearly touches with the ground, the air suction phenomenon is avoided from occurring, and the swing arm cylinder is under reliable control all the time.

Owner:QINGDAO LOVOL EXCAVATOR

Engine lubricant passage

InactiveCN101907005AReduce volumeCompact structureMachines/enginesPressure lubricationCylinder headCrankcase

The invention relates to an engine lubricant passage. An oil inlet of a first cavity of an oil pump is communicated with an oil outlet of an once oil filter, an oil outlet of the first cavity of the oil pump is communicated with an oil inlet of an external oil tank, a first oil outlet of the external oil tank is communicated with an oil inlet of a second cavity of the oil pump, a second oil outlet of the external oil tank is communicated with an external oil inlet of a cylinder head, an oil outlet of the second cavity of the oil pump is communicated with an oil inlet of an oil filter, a crankcase cover oil passage communicated with an oil outlet of the oil filter is divided into two passages, one passage is communicated with an oil inlet passage of a crank roller pin, the other passage is connected with an oil inlet of an external three-way oil pipe, a first oil outlet of the external three-way oil pipe is communicated with oil holes of a main shaft and a secondary shaft, and a second oil outlet of the external three-way oil pipe is communicated with a camshaft oil channel. The invention not only achieves the purpose of lubricating an engine, but also can obviously reduce the cylinder temperature and the oil temperature of the engine, improves engine operating conditions and increases engine power.

Owner:力帆科技(集团)股份有限公司

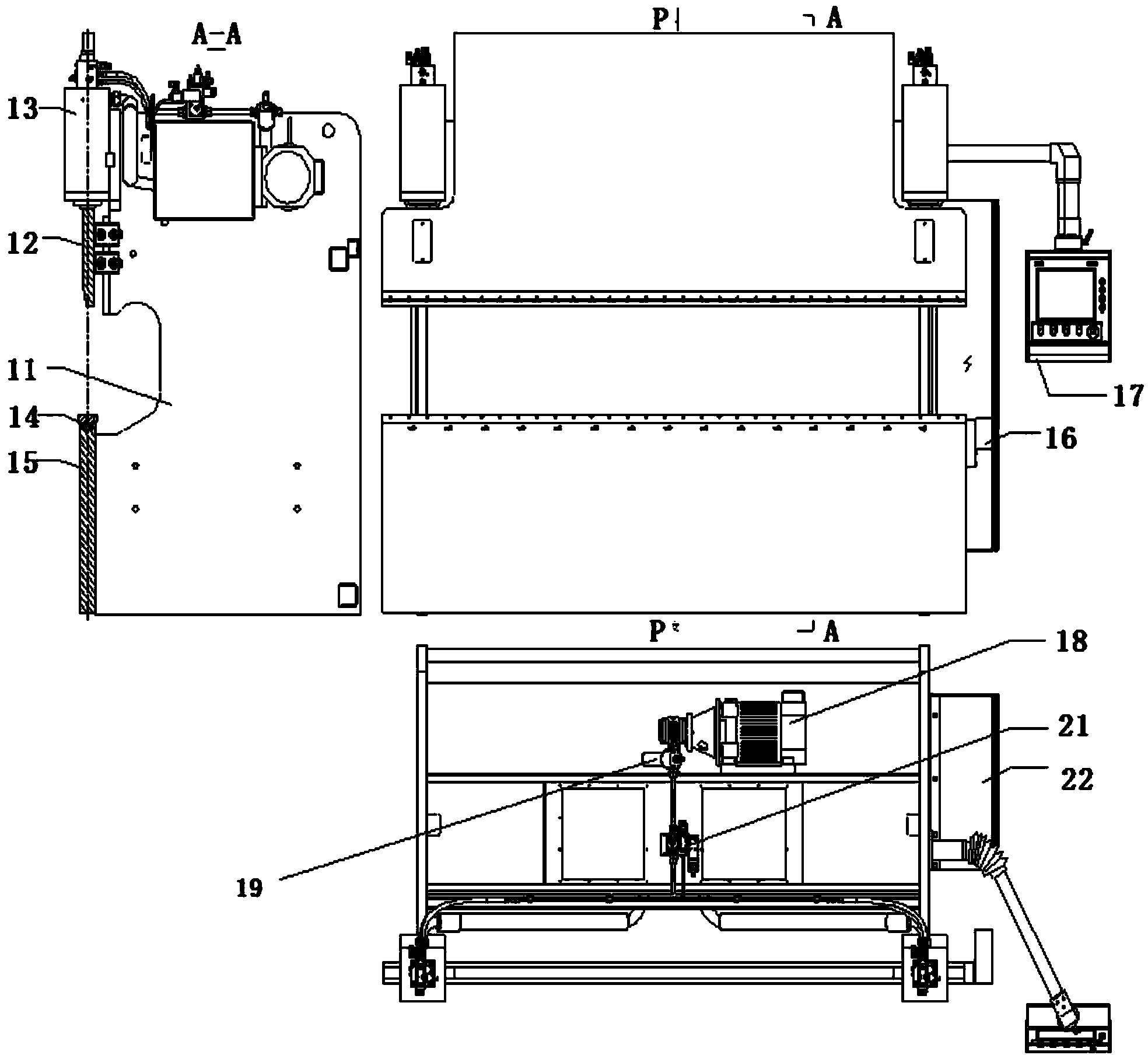

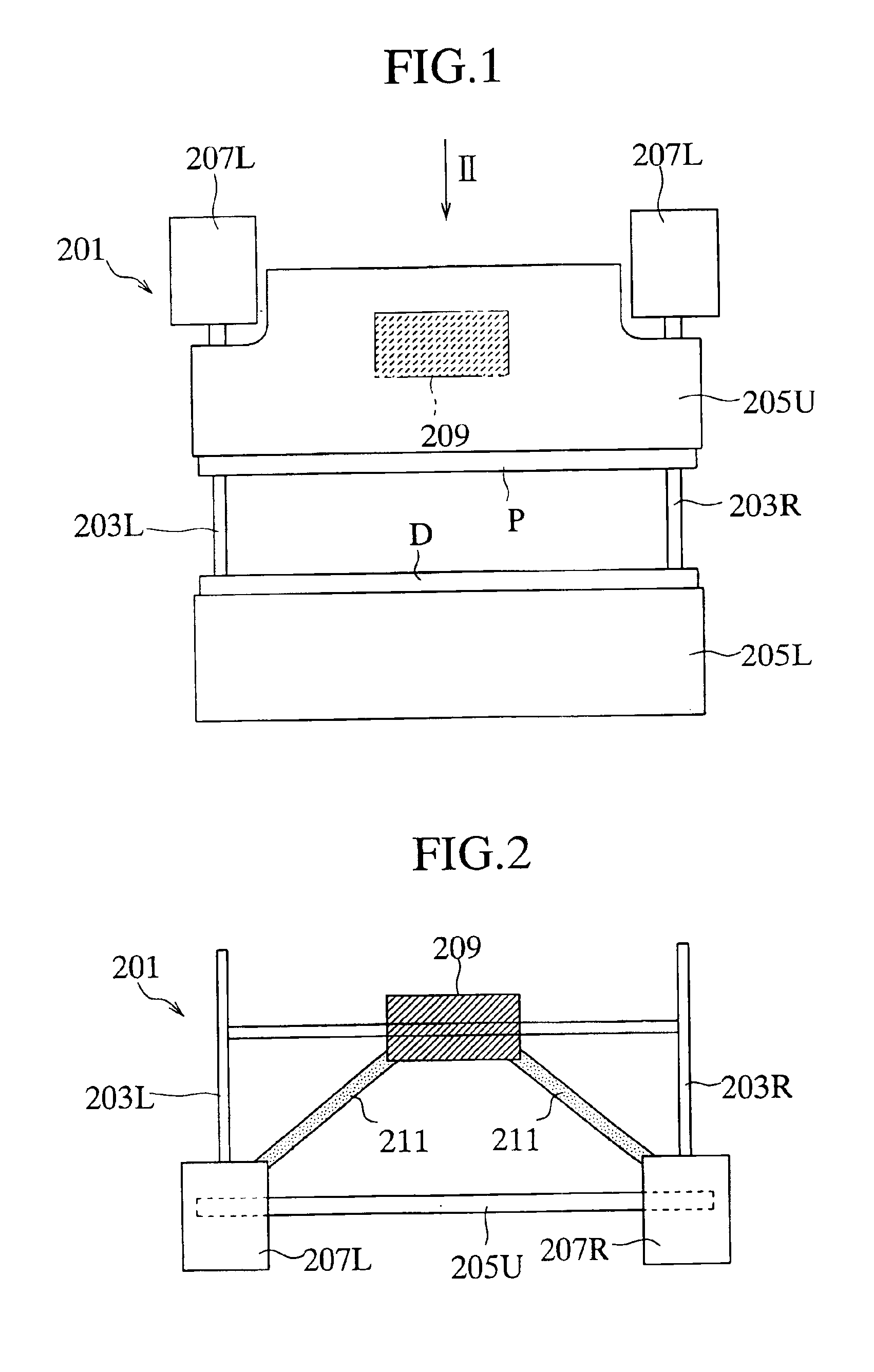

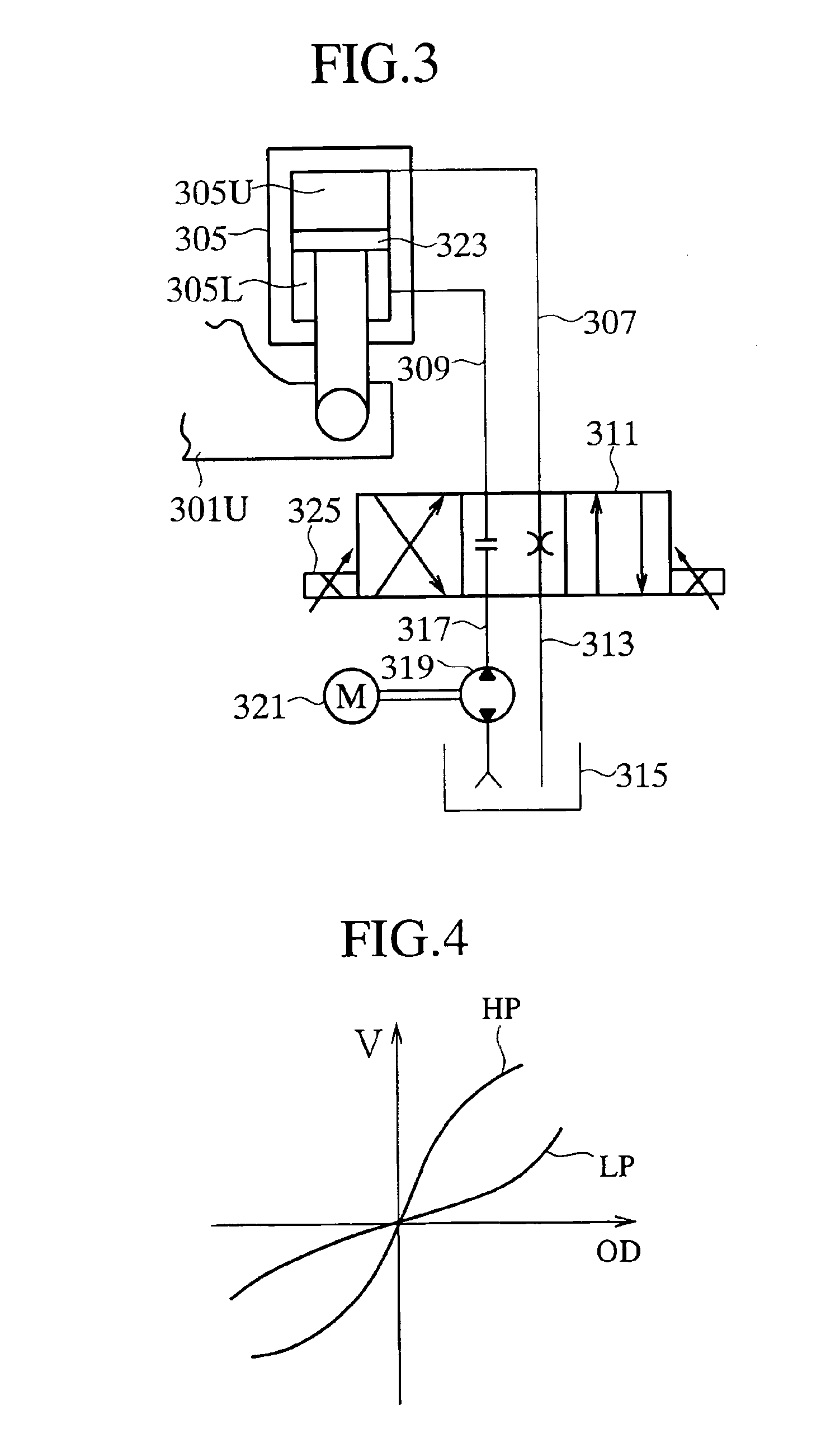

Full-closed loop electro-hydraulic servo plate bending machine

The invention relates to a full-closed loop electro-hydraulic servo plate bending machine which comprises a frame, master cylinders, a vertical plate, a mechanical deflection compensating workbench, a slide block and a numerical control system, wherein the master cylinders are located on the two sides above the frame; the vertical plate is located on the lower part of the frame; the mechanical deflection compensating workbench is located on a lateral side of the upper part of the vertical plate; the slide block is located above the vertical plate; the numerical control system is located on the frame; the full-closed loop electro-hydraulic servo plate bending machine is characterized by further comprising a hydraulic system and a servo motor which are connected with the numerical control system, and an oil pump which is connected with the servo motor; the hydraulic system is connected with the oil pump and the cylinder; a cylinder piston rod of the cylinder is connected with the slide block; a pressure value is closed-loop fed back to a servo driver by a machine tool; the system pressure is controlled by adjusting the rotating speed of the oil pump motor by the servo driver, so that the full-closed loop control is realized. The pressure of the hydraulic system is accurately closed-loop controlled by a servo system provided by the invention, so that the stability of the hydraulic pressure is ensured, the flow of the whole hydraulic system is subjected to accurate closed-loop control, and the overflow quantity is reduced.

Owner:SHANGHAI ACL CNC MACHINE TOOL

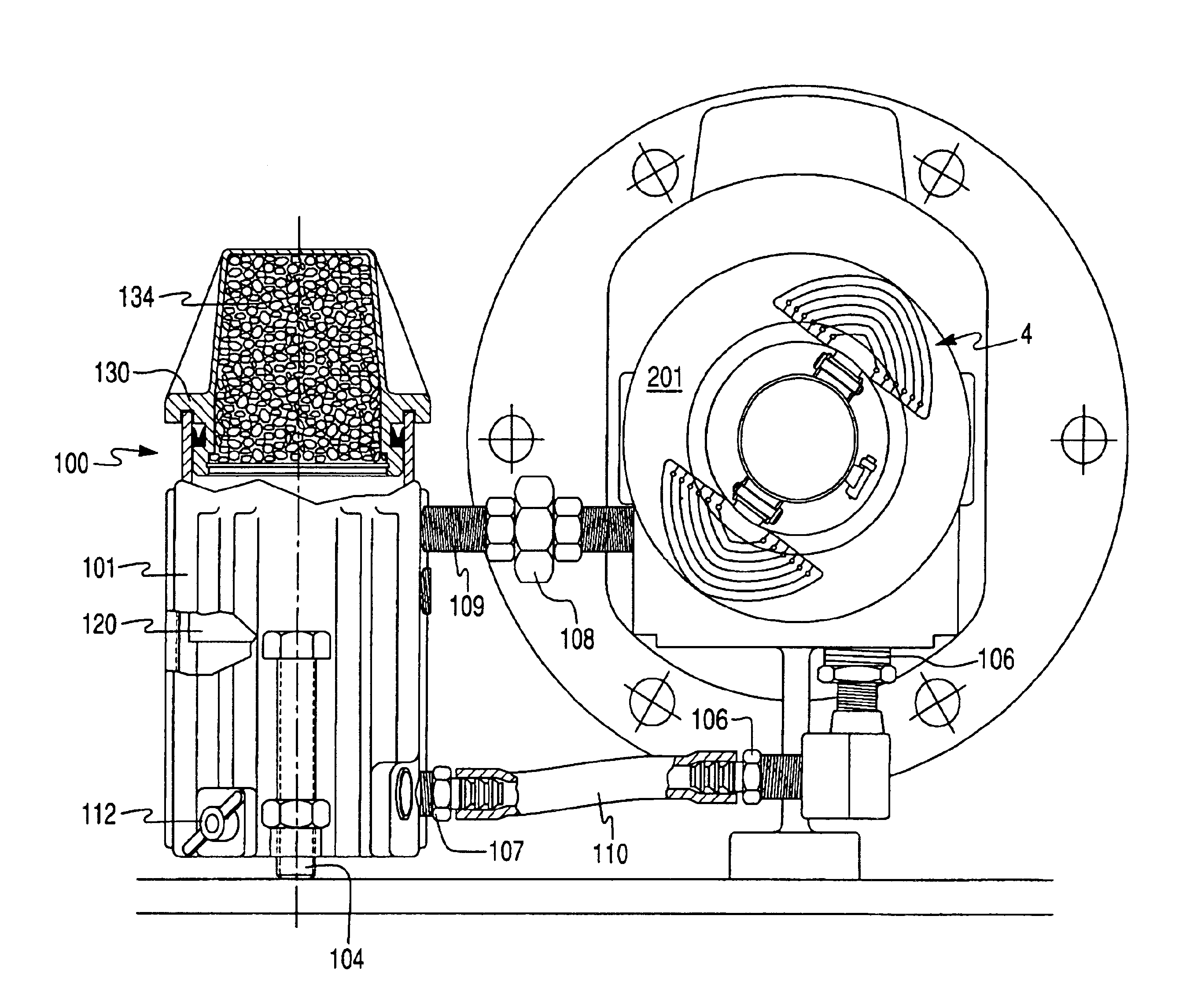

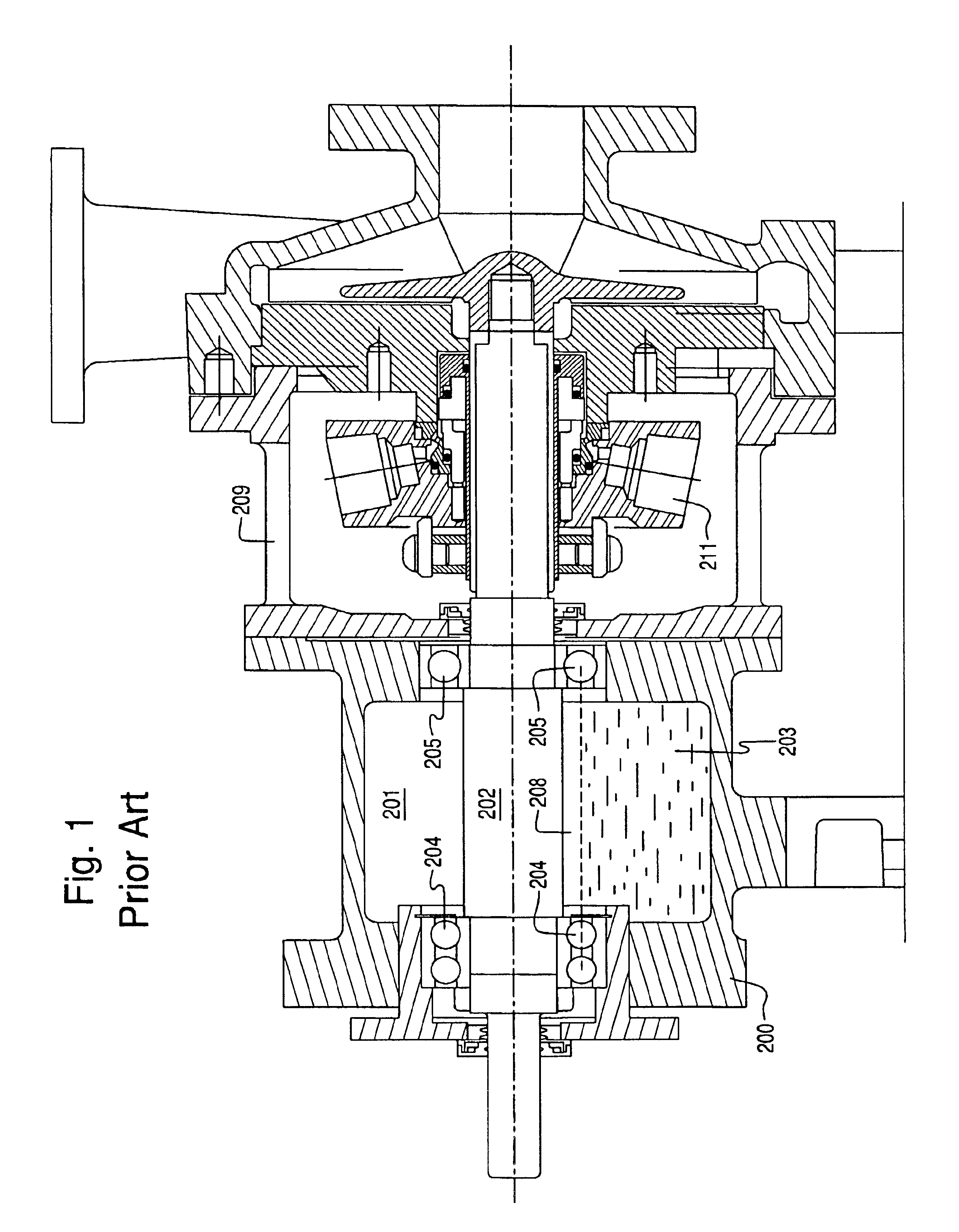

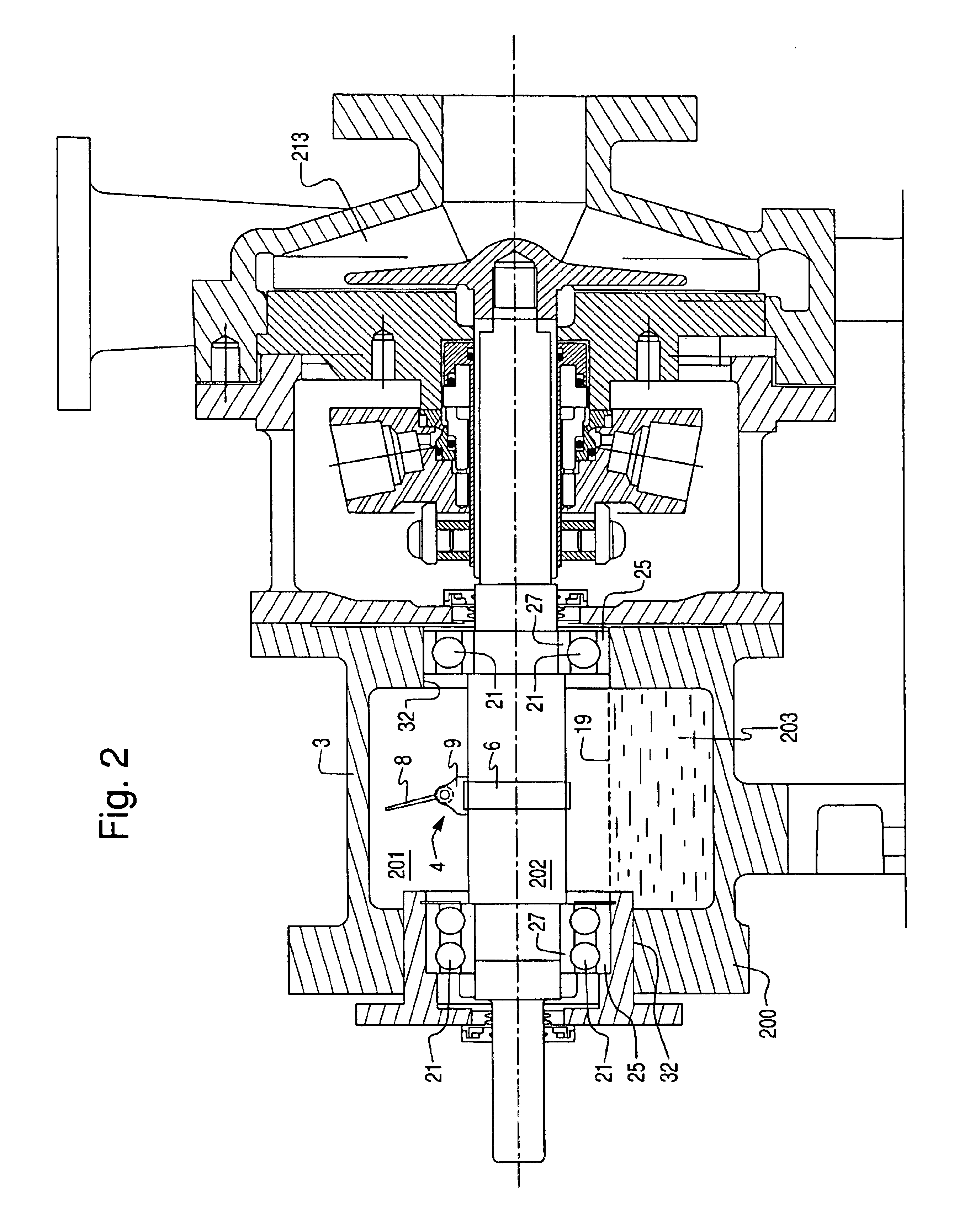

Pump lubrication system including an external reservoir

InactiveUS6913438B2Extended service lifeLower oil temperatureLubricant conduit arrangementsEngine cooling apparatusEngineeringLubrication

A circulating lubrication system for a centrifugal pump, or other rotating equipment utilizing an oil sump, is disclosed. The lubrication system includes an external reservoir located distant from the main lubrication chamber, so that lubricating fluid from the main misting chamber is forced out of the main chamber, cooled and cleaned (i.e. filtered) in the external reservoir, and thereafter fed back into the main lubricating chamber. In such a manner, the lubrication system maintains substantially clean, cool, and moisture free lubricating fluid in the main misting chamber and reduces the required downtime of the device. Thus, the life span of the device is lengthened while at the same time production is increased.

Owner:ENVIRONAMICS +1

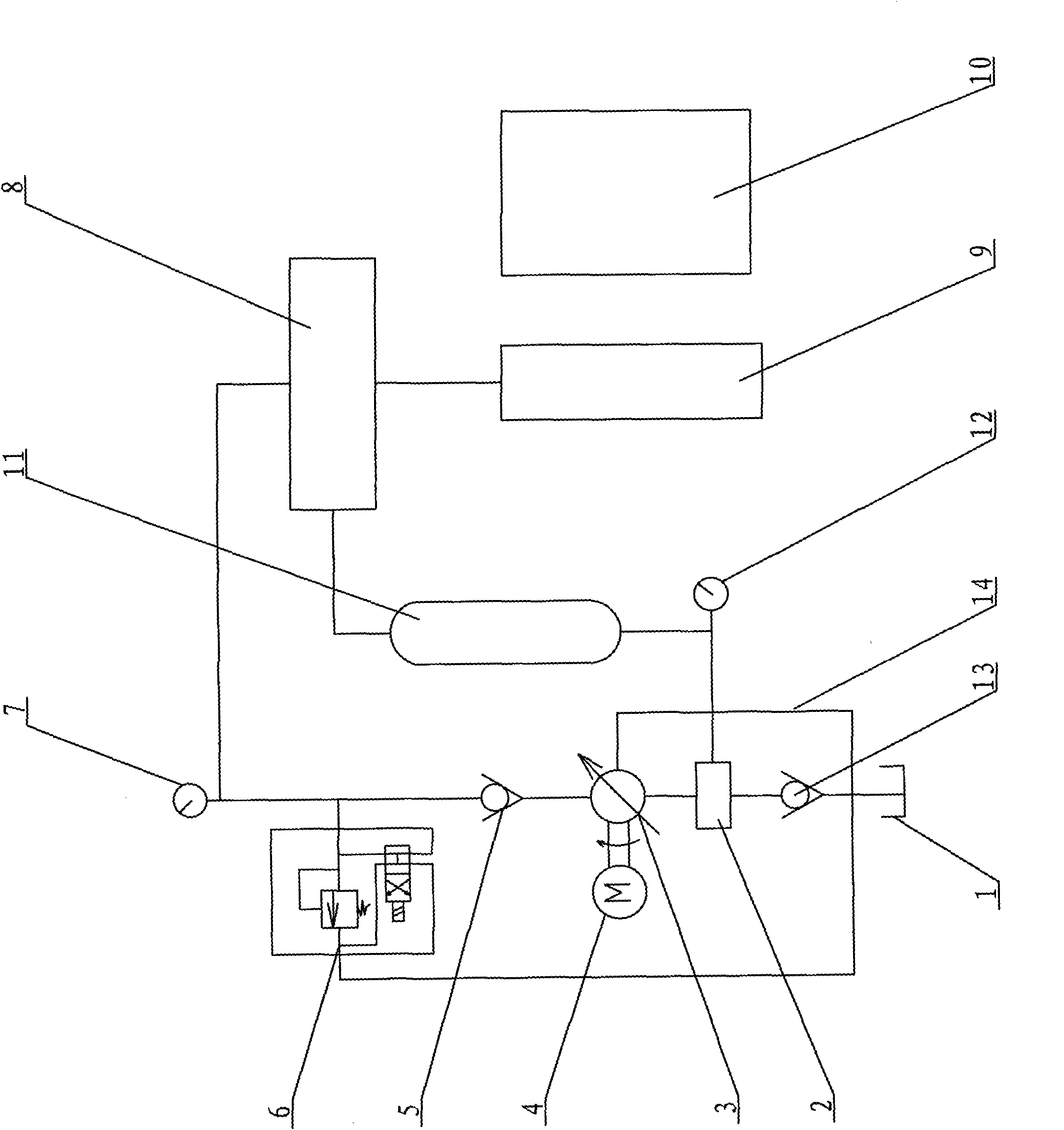

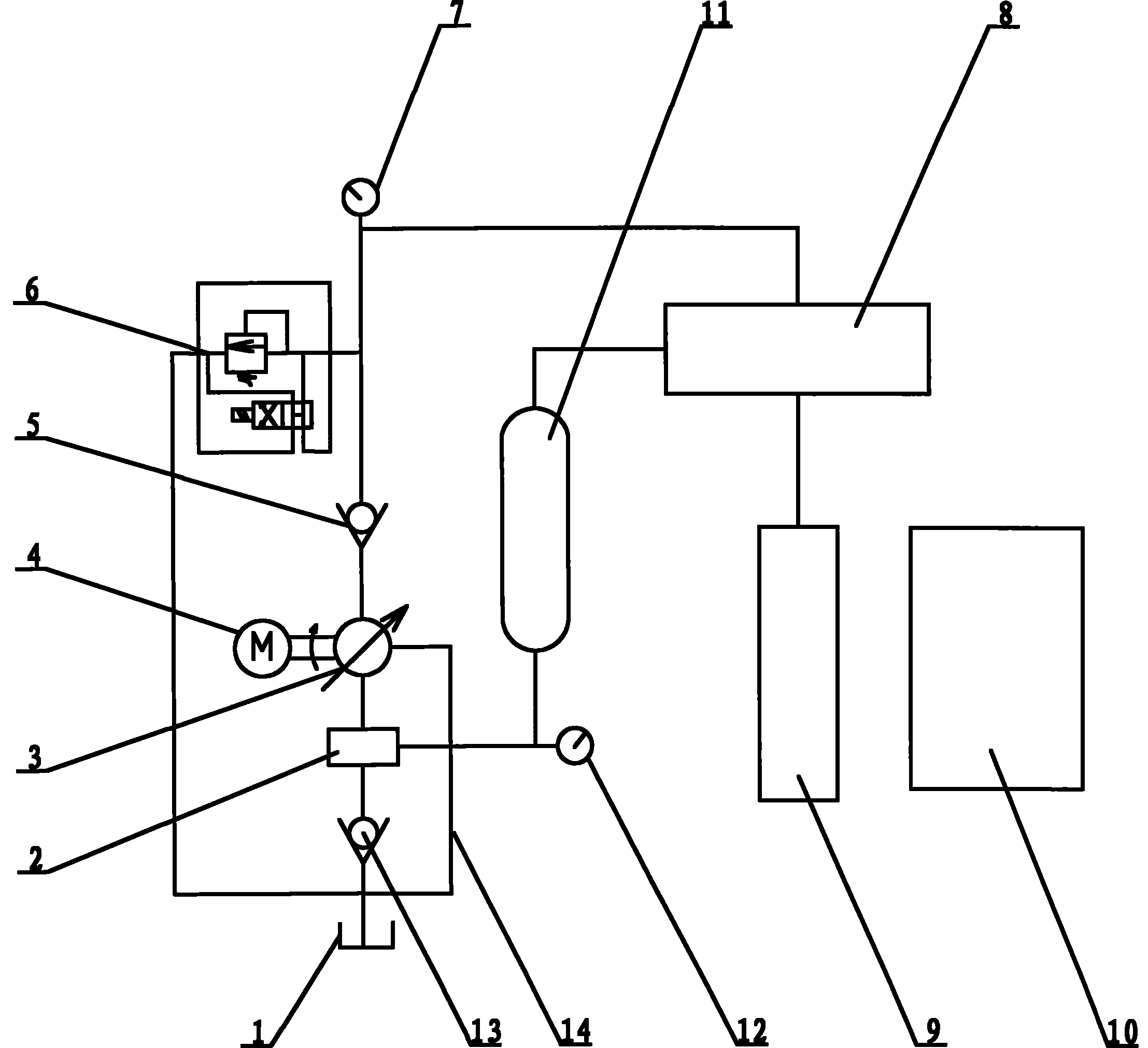

Efficient and energy-saving device for hydraulic station

InactiveCN102003421ALower oil temperatureExtended service lifeMechanical apparatusElectricityFuel tank

The invention relates to an efficient and energy-saving device for a hydraulic station. The device comprises a control cabinet, a hydrocylinder, a hydraulic control valve, an oil pump with a motor, a pressure gauge with an electric contact, an electromagnetic relief valve, an accumulator, a check valve and an intelligent control valve, wherein the intelligent control valve is arranged between theinlet of the oil pump and a hydraulic oil tank and connected with the hydraulic control valve through the accumulator; an oil return tubule which is communicated with the hydraulic oil tank is arranged on the oil pump; the check valve and the pressure gauge with the electric contact are arranged between the oil pump and the hydraulic control valve in turn; a pipeline between the check valve and the pressure gauge with the electric contact is communicated with the oil tank through the electromagnetic relief valve; and the intelligent control valve, the pressure gauge with the electric contact and the electromagnetic relief valve are all connected with the control cabinet. The device has the advantages that: the structure is simple; cooling equipment does not need to be added; the using cost is low; the control cabinet is matched with the intelligent control valve, so that the hydrocylinder is automatically boosted, and high-speed oil return is avoided and the oil pump can run in an unpowered mode continuously; the whole energy consumption is low; and the equipment runs safely, has a long service life and is environmental-friendly.

Owner:泰兴市同济工程机械厂

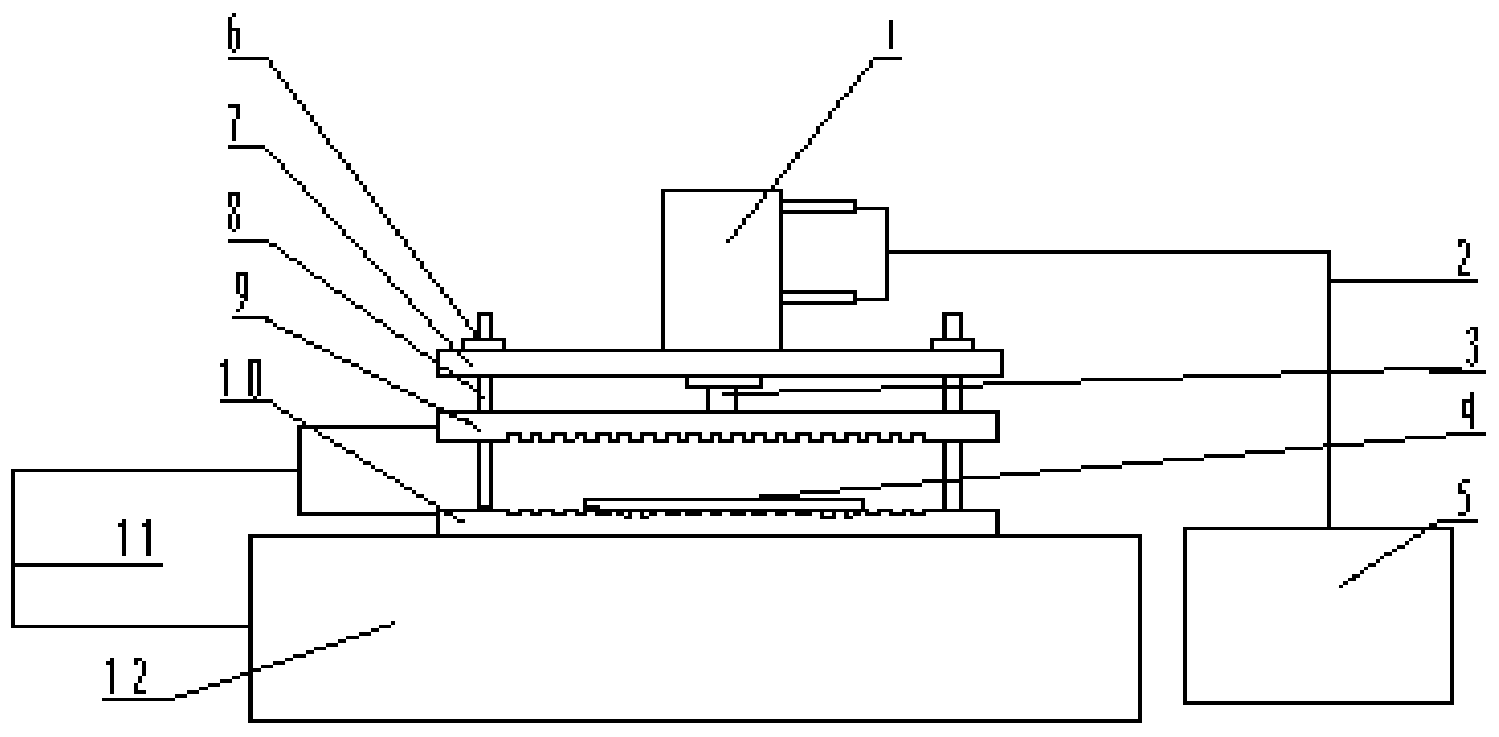

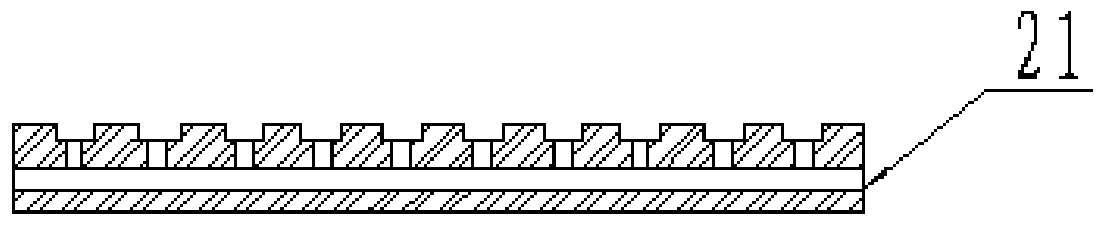

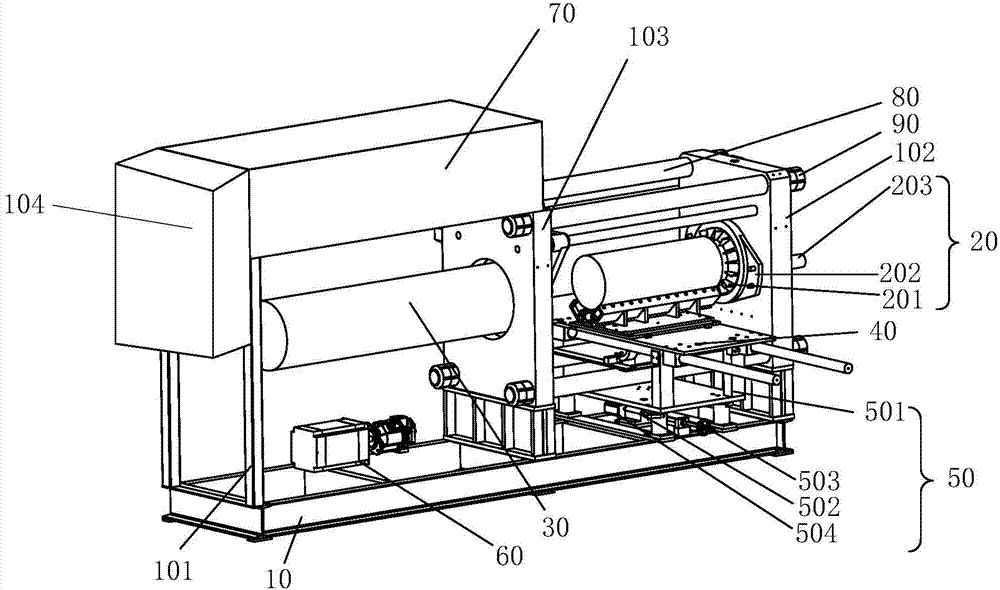

Saw blade matrix pressure quenching device and quenching process thereof

ActiveCN103320599ACool evenlyEliminate deformationFurnace typesHeat treatment furnacesMovable typeFuel tank

The invention relates to the field of manufacturing of diamond saw blade matrixes and in particular relates to a saw blade matrix pressure quenching device and a quenching process thereof. The device comprises a hydraulic oil cylinder, a hydraulic control loop system, a hydraulic oil cylinder and upper pressing plate connecting device, a saw blade matrix, a hydraulic oil tank, an upper fixing rack, a guide post, an upper pressing plate, a lower pressing plate, a quenching oil control loop system and a quenching oil tank, wherein the upper pressing plate is in a vertical movable type and can move up and down under driving of the hydraulic oil cylinder; during quenching, the saw blade matrix is arranged on the lower pressing plate, the upper pressing plate is pressed downwards and presses the matrix in the up-down manner by means of a correction pressure block, the spread oil cooling is performed, and the press tempering is performed after the cooling. When the saw blade matrix is subjected to quenching treatment, so that the hardness can be guaranteed, the deformation of the saw blade matrix can be controlled, the production cost is controlled, the production efficiency is improved, and the saw blade matrix pressure quenching device is suitable for quenching various sheets of the saw blade matrix and suitable for large-scale automatic production.

Owner:BOSUN TOOLS CO LTD

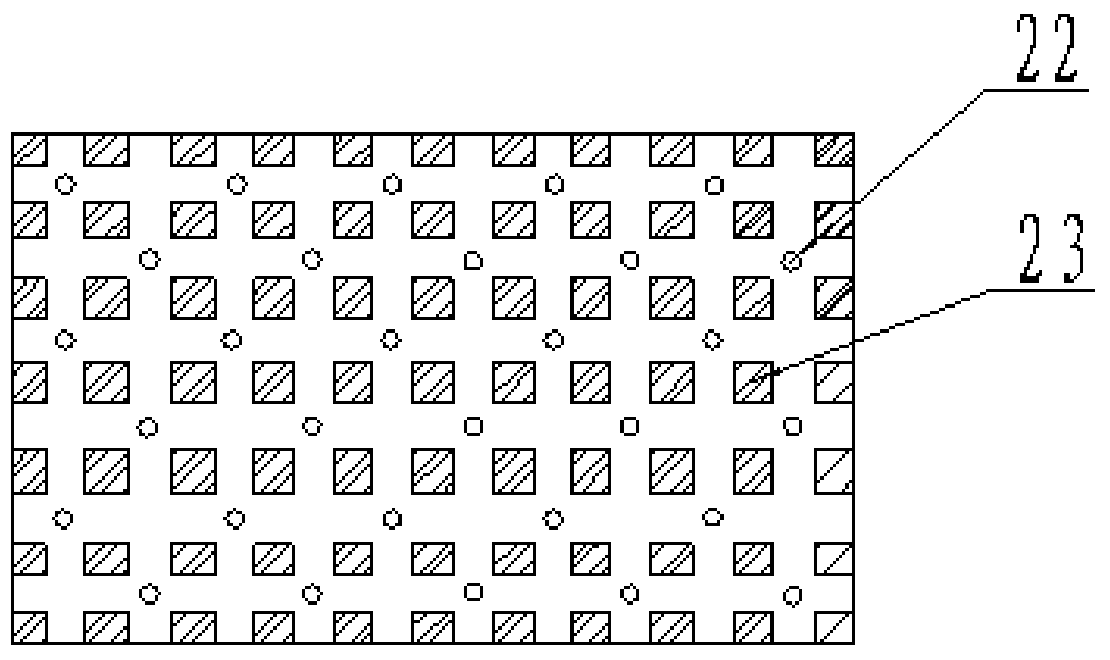

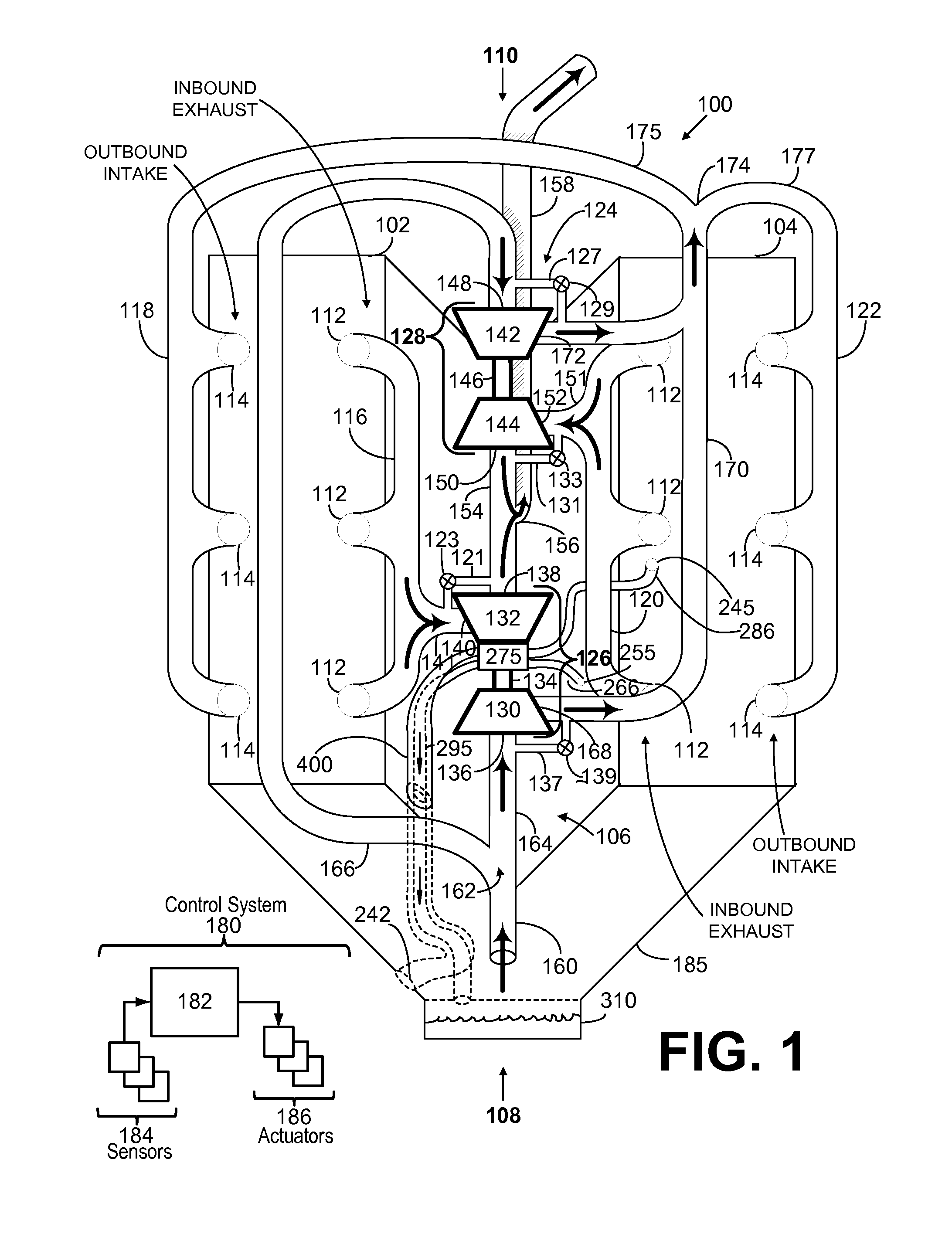

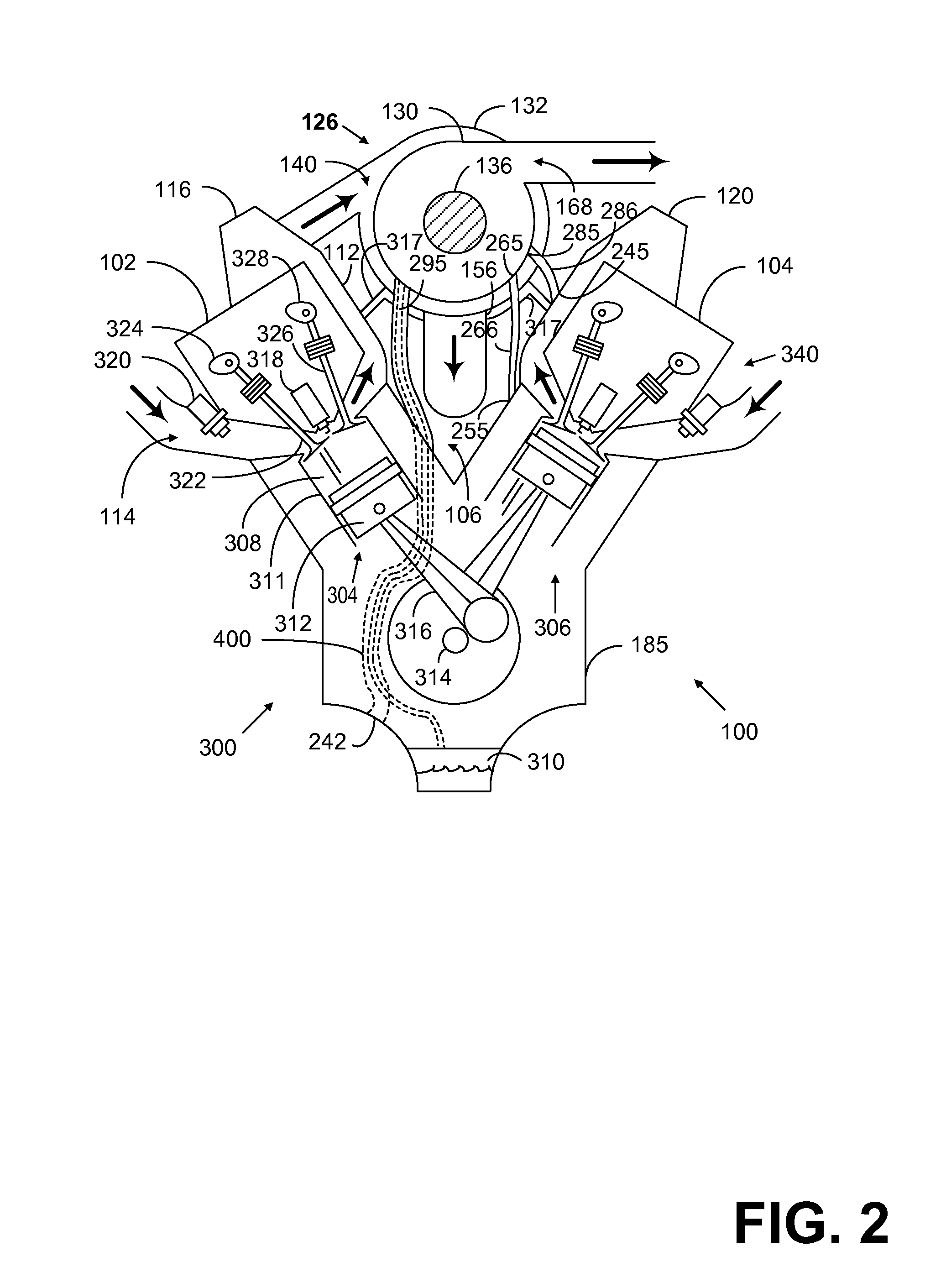

Coolant jacket for a turbocharger oil drain

ActiveUS20140157773A1Increase engine torque/power output densityIncrease air flowCombustion enginesEngine cooling apparatusCoolantDrive shaft

A system including a turbocharger, comprising a turbocharger bearing housing supporting a turbocharger drive shaft; an oil drain including an inlet in fluidic communication with the turbocharger bearing housing and an outlet in fluidic communication with an oil sump; and a coolant jacket enveloping the oil drain. The coolant jacket envelopes the oil drain and is positioned to provide coolant to the turbocharger bearing housing and draw heat from the oil draining through the oil drain to prevent coking of hot oil within the oil drain.

Owner:FORD GLOBAL TECH LLC

Multifunctional hydraulic power station

ActiveCN104389827ALower skill requirementsRelieve stressServomotorsEnergy industryAutomatic controlPower station

The invention relates to a multifunctional hydraulic power station, which mainly consists of two pump groups, an electric cabinet, a hand-operated direction valve, a check valve, an overflow valve, an energy accumulator, a manual pressure-reduction pressure-regulation overflow valve, a normally-closed solenoid valve, a normally-opened solenoid valve, a stop valve, a high-pressure oil output end and an automatic control device. On the basis that the hydraulic power station has an original function, the defects and the deficiencies of an original hydraulic power station are overcome, and functions, such as free regulation of oil pressure, optimal torque control, energy saving and accumulation, multifunctional changeover, no-load time delay startup and automatic control, which are provided for a load, are increased. The multifunctional hydraulic power station is simple in operating, saves electric energy by more than 50%, can provide hydraulic power for various petroleum drilling tools, is also suitable for other industries to provide hydraulic power for hydraulic tools by taking high-pressure hydraulic oil as mediums, and can achieve the effects of energy saving, energy accumulation and controllable torque.

Owner:范清云 +1

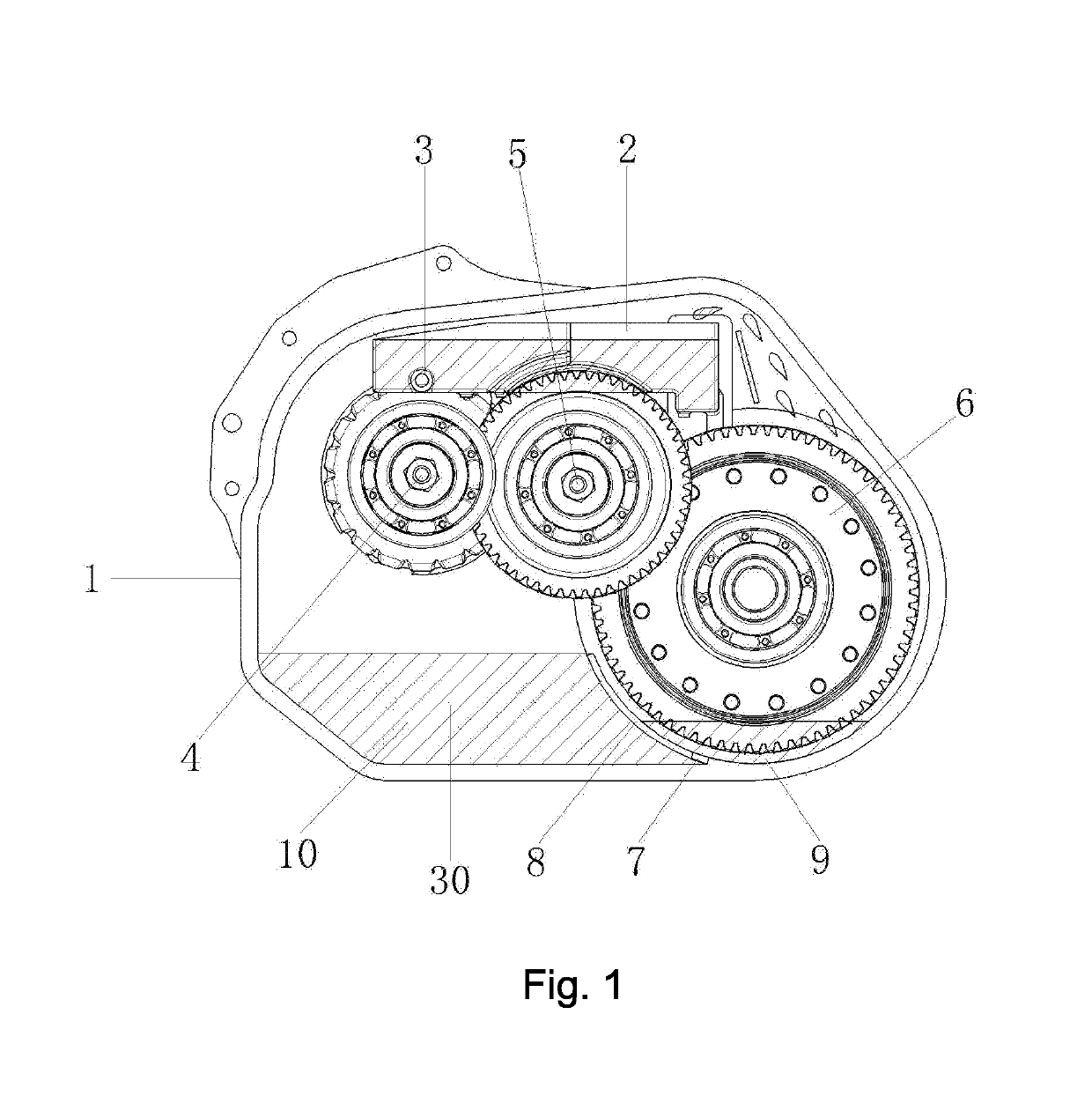

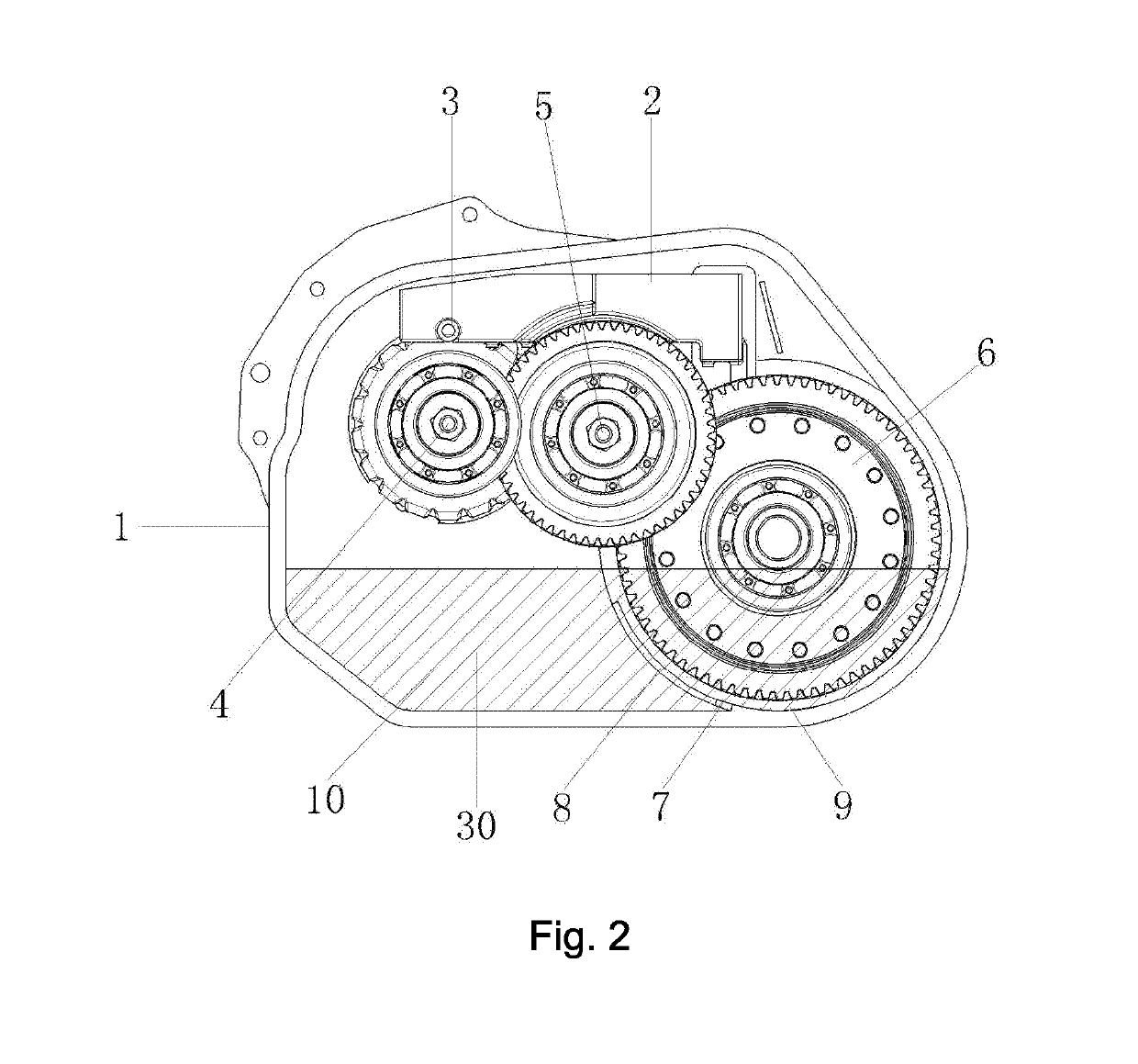

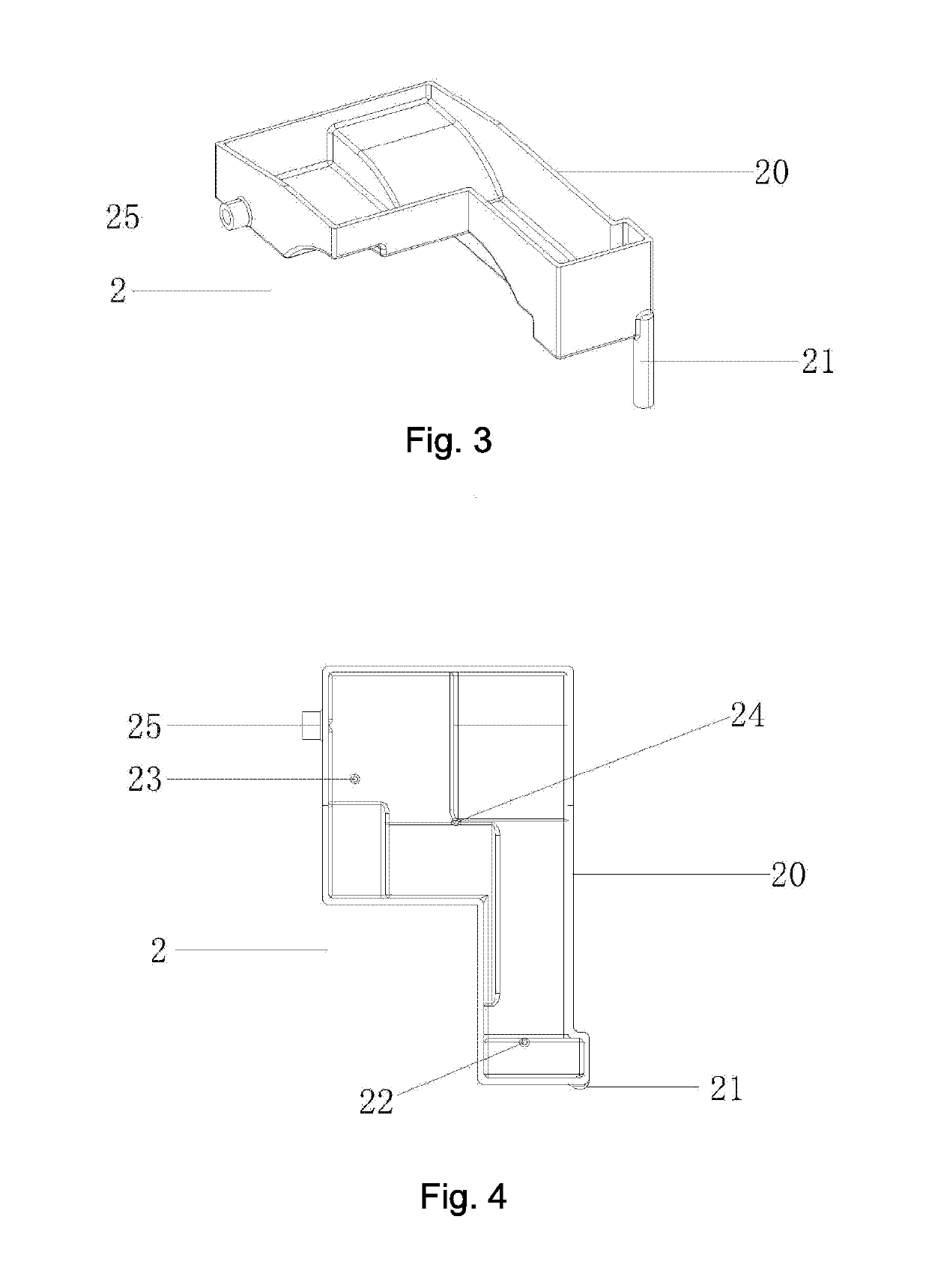

Pure electric vehicle transmission with novel lubrication structure

ActiveUS20190145509A1Good flexibilityAvoids unnecessary agitationGear lubrication/coolingTransmission elementsCouplingGear wheel

A pure electric vehicle transmission includes a transmission box, a top side of the transmission box is provided with a temporary oil storage case, a bottom side thereof is stored with lubricating oil, the temporary oil storage case is provided with a plurality of lubricating oil holes, a gear-connected transmission input shaft and an intermediate coupling are located at a lower side of the oil storage case and arranged above a lubricating oil surface, an intermediate coupling gear is connected with a differential gear, a lower side of the differential gear is immersed in the lubricating oil, the lubricating oil at the bottom side of the transmission box is splashed in the temporary oil storage case via the rotation of the differential gear, the lubricating oil lubricates various parts of the transmission through the lubricating oil holes, and then returns to the bottom side of the transmission box to form circulation.

Owner:ZHEJIANG XIN PRECISION MACHINERY CO LTD

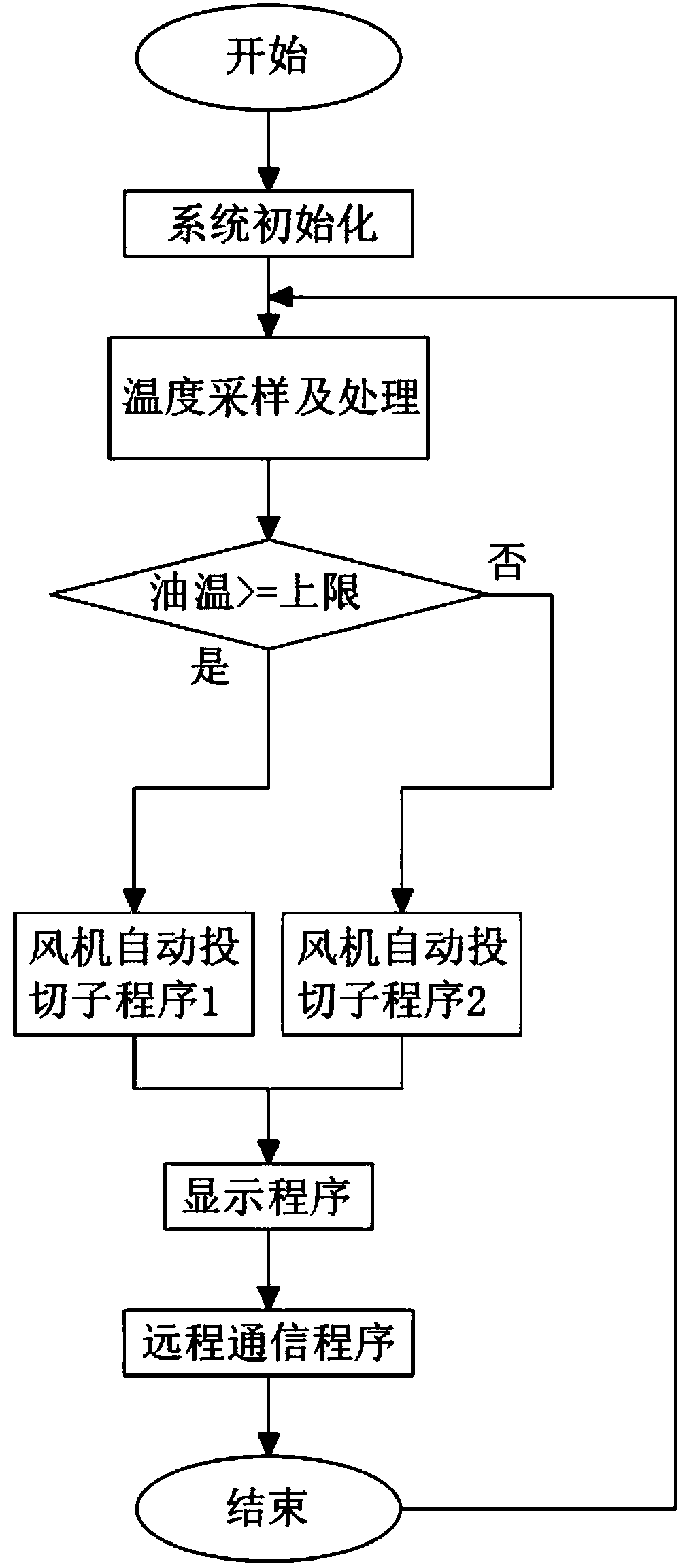

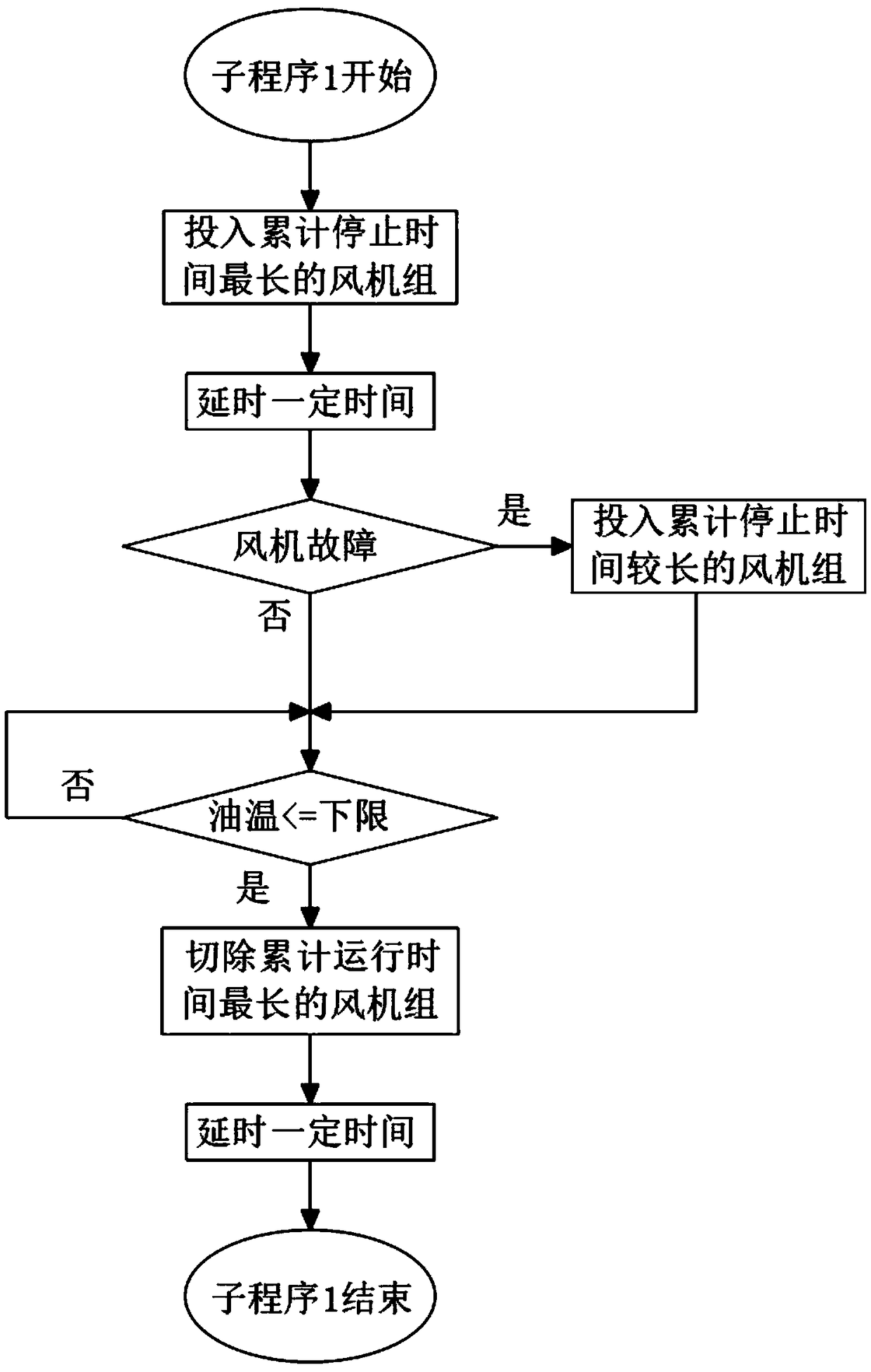

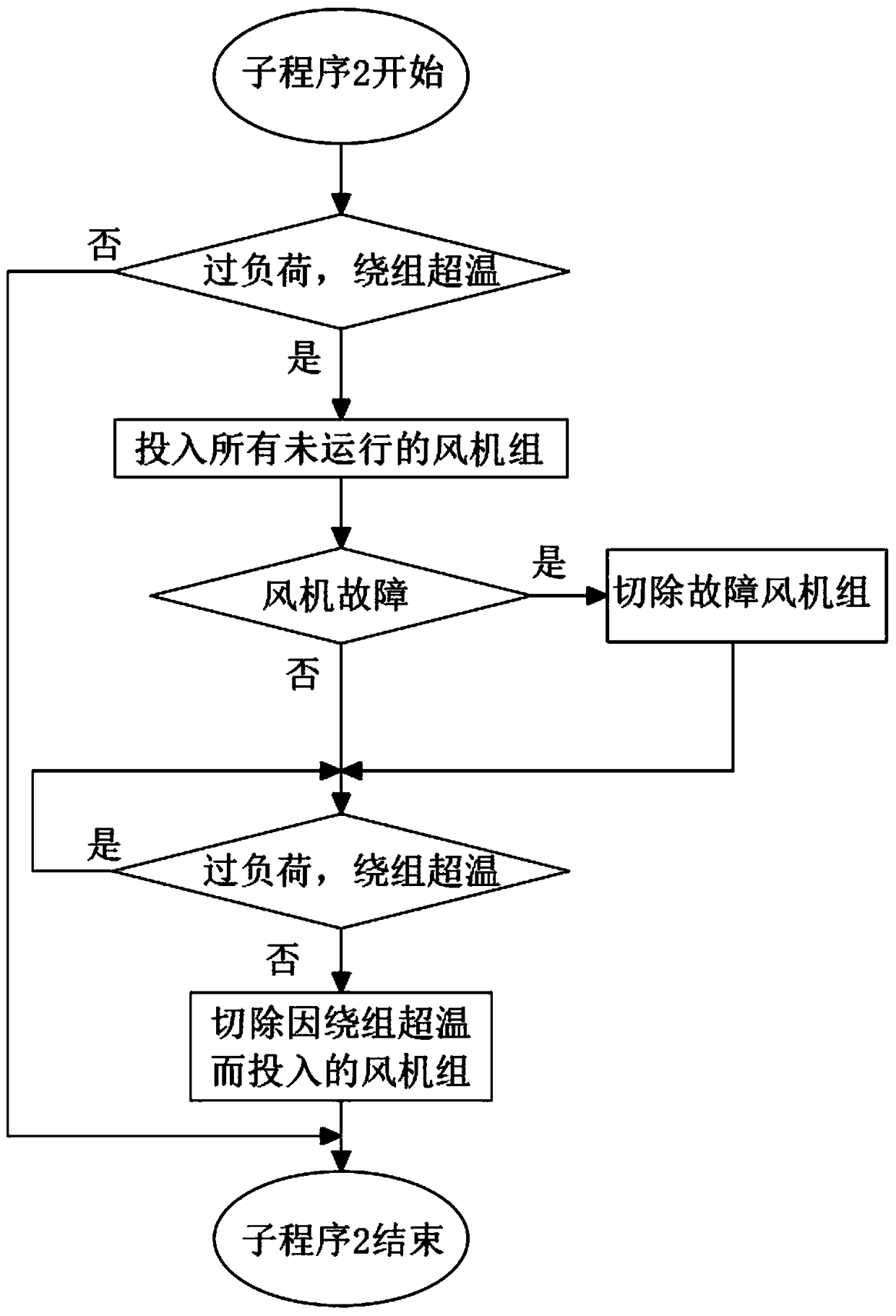

An intelligent control method for strong oil air cooling of transformer

InactiveCN109166705AOperation Status MonitoringRealize real-time controlTransformers/inductances coolingCircuit arrangementsOil temperatureIntelligent control

The invention discloses an intelligent control method for strong oil air cooling of a transformer, which comprises the following steps: step a: the program starts, initializes, and then turns into a main program for circulating operation; B, sample and processing that upper oil temperature of the transform; C, judge that sampling temperature in the step b; Step d: if the oil temperature judged instep c is greater than the upper limit temperature, the fan automatically switches on and off subroutine 1; If the oil temperature judged in the step c is less than the upper limit temperature, the fan automatically switches on and off the subroutine 2; E, sending that temperature signal and the running program to a liquid crystal screen for display; (f) send that upper oil temperature of the current transformer and the operation condition of the fan to the upper compute through a remote communication program; Step g: End the current program and return to step b. The invention has the advantages that the problems that the prior art is not conducive to energy saving and effective utilization of equipment, and the air cooling device is frequently switched on and off are solved.

Owner:国网黑龙江省电力有限公司超高压公司 +1

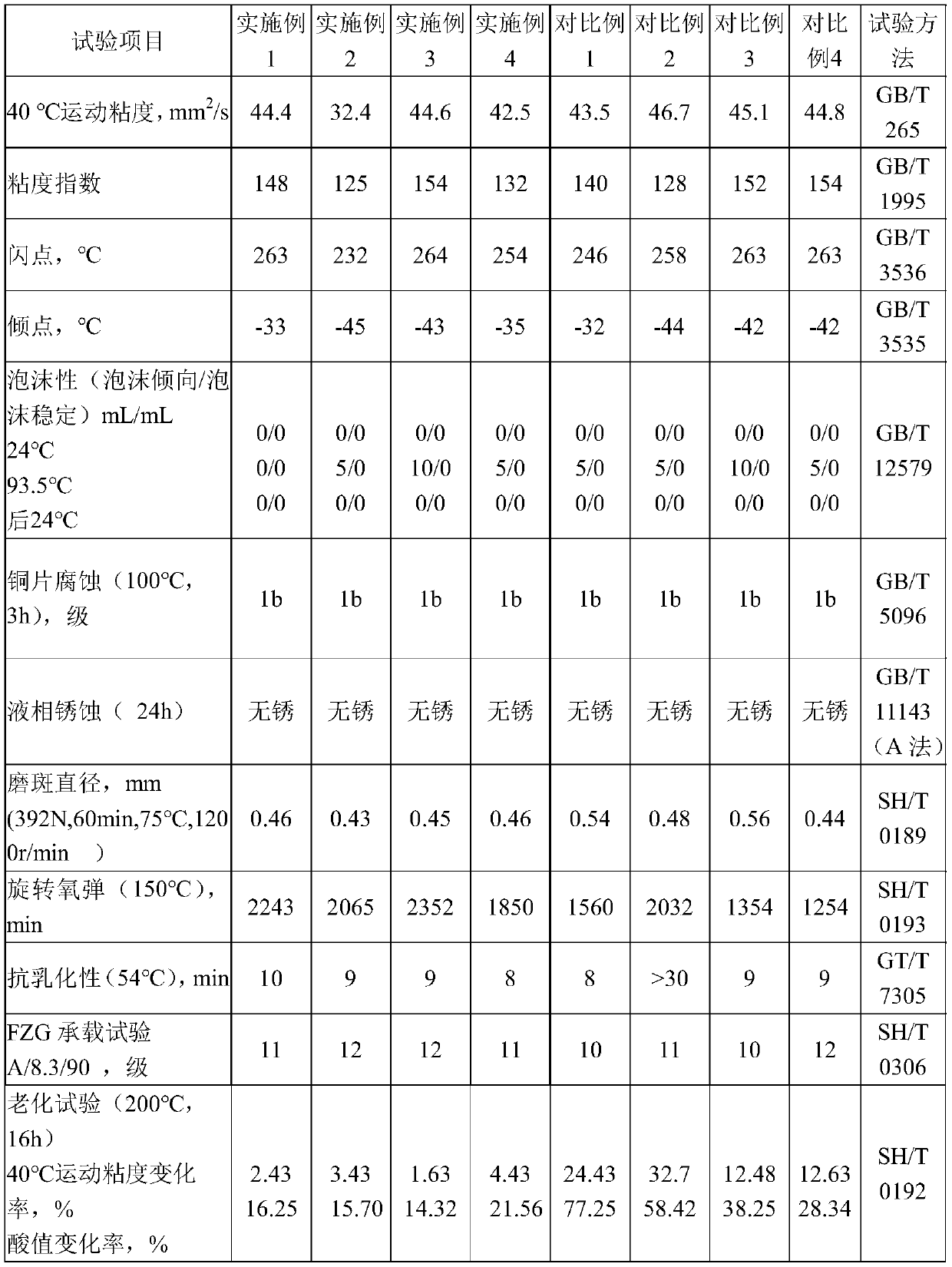

Long-life air compressor oil composition

InactiveCN111234906AInhibition of viscosity growthGood extreme pressure and anti-wear propertiesLubricant compositionProcess engineeringBase oil

The invention discloses a long-life air compressor oil composition. The long-life air compressor oil composition comprises the following components in percentage by weight: 0.6-1.5% of an ashless composite additive, 0.3%-1.0% of an antioxidant, 0.1%-0.5% of an extreme pressure anti-wear agent, and 0.002% to 0.005% of an anti-foaming agent, with the balance being base oil, wherein the base oil comprises a mixture of III-type hydrogenated base oil and alkyl naphthalene base oil or polyether base oil. The air compressor oil provided by the invention has excellent high-temperature detergency and oxidation resistance, and can effectively avoid the generation of oil sludge and carbon deposit; excellent wear resistance and hydrolytic stability are achieved, and excellent wear resistance protection is provided for the air compressor; the excellent heat conduction efficiency can help to reduce the temperature and oil temperature of the compressor; and the oil change period is long and can reach6000 hours or above. In addition, compared with known long-life air compressor oil, the air compressor oil has the advantages of being low in cost, simple in preparation method, easy to popularize and apply on a large scale and the like.

Owner:LONGPAN LUBRICATION NEW MATERIAL TIANJIN CO LTD +1

Energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder

ActiveCN104624691AShort work scheduleReduce no-load travelPump assembliesPressesProduction rateMaster cylinder

The invention relates to an energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder which comprises a base, a mould, an ingot containing barrel, an auxiliary cylinder, a shearing device and an oil supply system, wherein the mould, the ingot containing barrel and the auxiliary cylinder are sequentially arranged on the base; the oil supply system comprises a main cylinder and an oil storage tank; the main cylinder is provided with a plunger; the extruder is a short-stroke extruder; the ingot containing barrel of the extruder is arranged on the top position of an extrusion rod, and the ingot containing barrel forms a feed space with the mould during displacement; the oil storage tank includes a closed oil return tank and a closed pressurizing oil cylinder; the oil return tank is connected with the main cylinder through a reflux oil way connected into the main cylinder, and the oil return tank is connected with the pressurizing oil cylinder through an oil supply pipeline; the pressurizing oil cylinder is provided with a piston which acts on the pressurizing oil supply pipeline to supply oil to the main cylinder, and oil inside the pressurizing oil cylinder is extruded into the main cylinder or oil inside the main cylinder is refluxed into the pressurizing oil cylinder through a circulating oil way through the reciprocating motion of the piston; and the oil supply system is controlled by a plurality of servo motor oil pump sets. The energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder disclosed by the invention can be used for effectively enhancing the production rate, reducing the manufacturing cost of an integral machine, saving the material and reducing the oil consumption.

Owner:FOSHAN NANHAI MINGSHENG MACHINE MFR

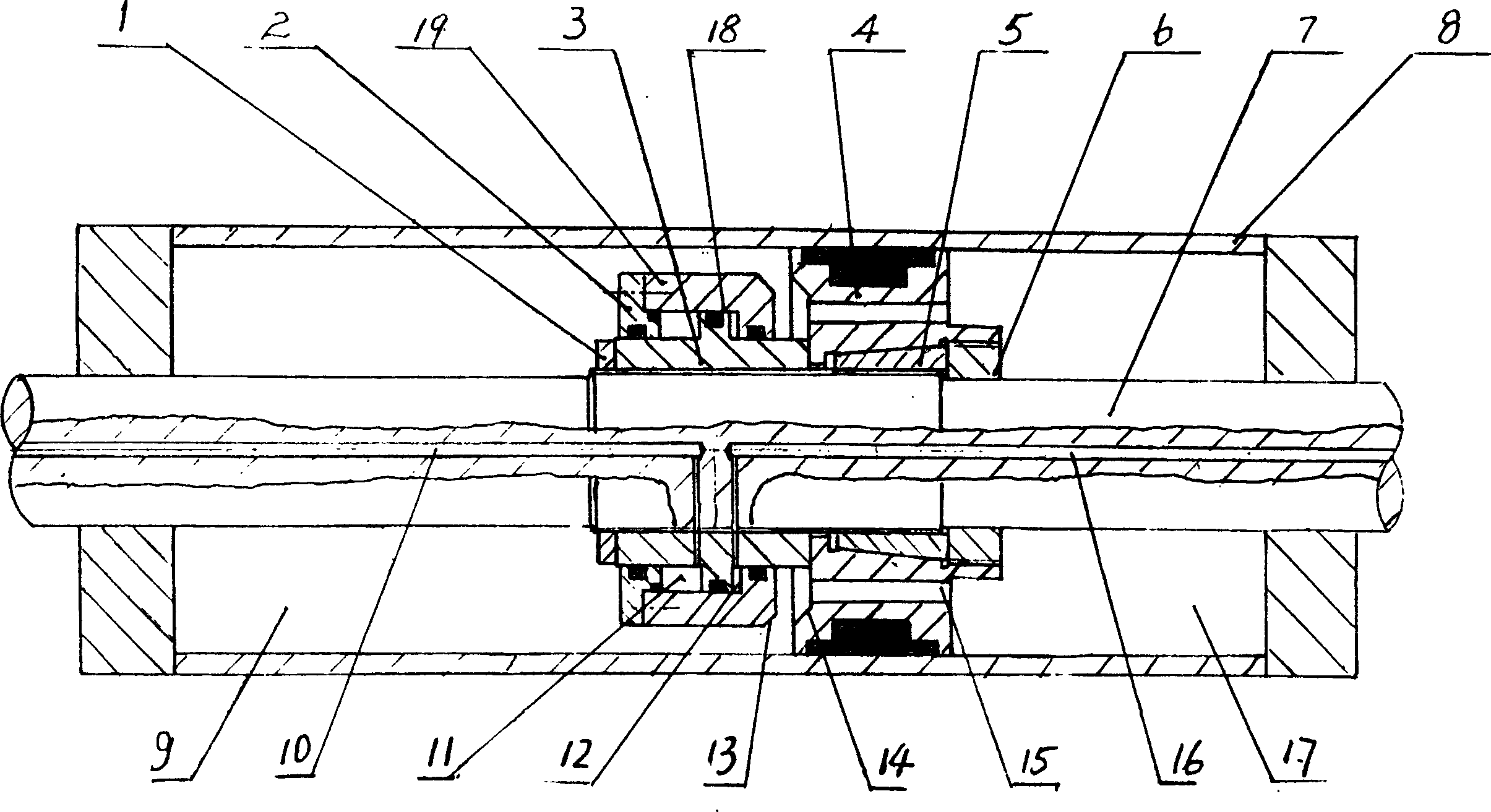

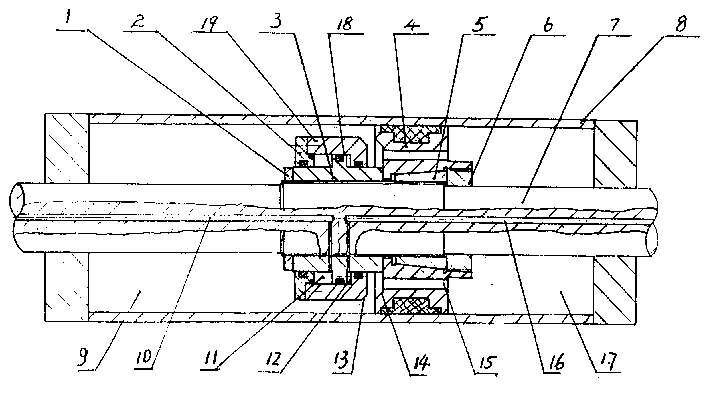

Internal circulation oil cylinder having built in logic valve

InactiveCN1514140AMove quicklyLower oil temperatureServomotor componentsEngineeringInjection molding machine

An internal circulation hydro-cylinder is composed of piston, hydro-cylinder, piston rod and logic valve. The piston has axial channel for two oil cavities isolated by piston rod in hydro-cylinder of guide channel, the logic valve is set on one side of the piston and closely fixed on the piston rod to make high-pressure oil go into oil control chamber of the logic valve separately through channels set on the piston rod so valve bush is pushed to move the block or open of axial channel of the piston rod as oil in two oil cavities flows forward and back ward within internal circulation. It is not necessary to set external channel for oil circulation.

Owner:广东泓利机器有限公司

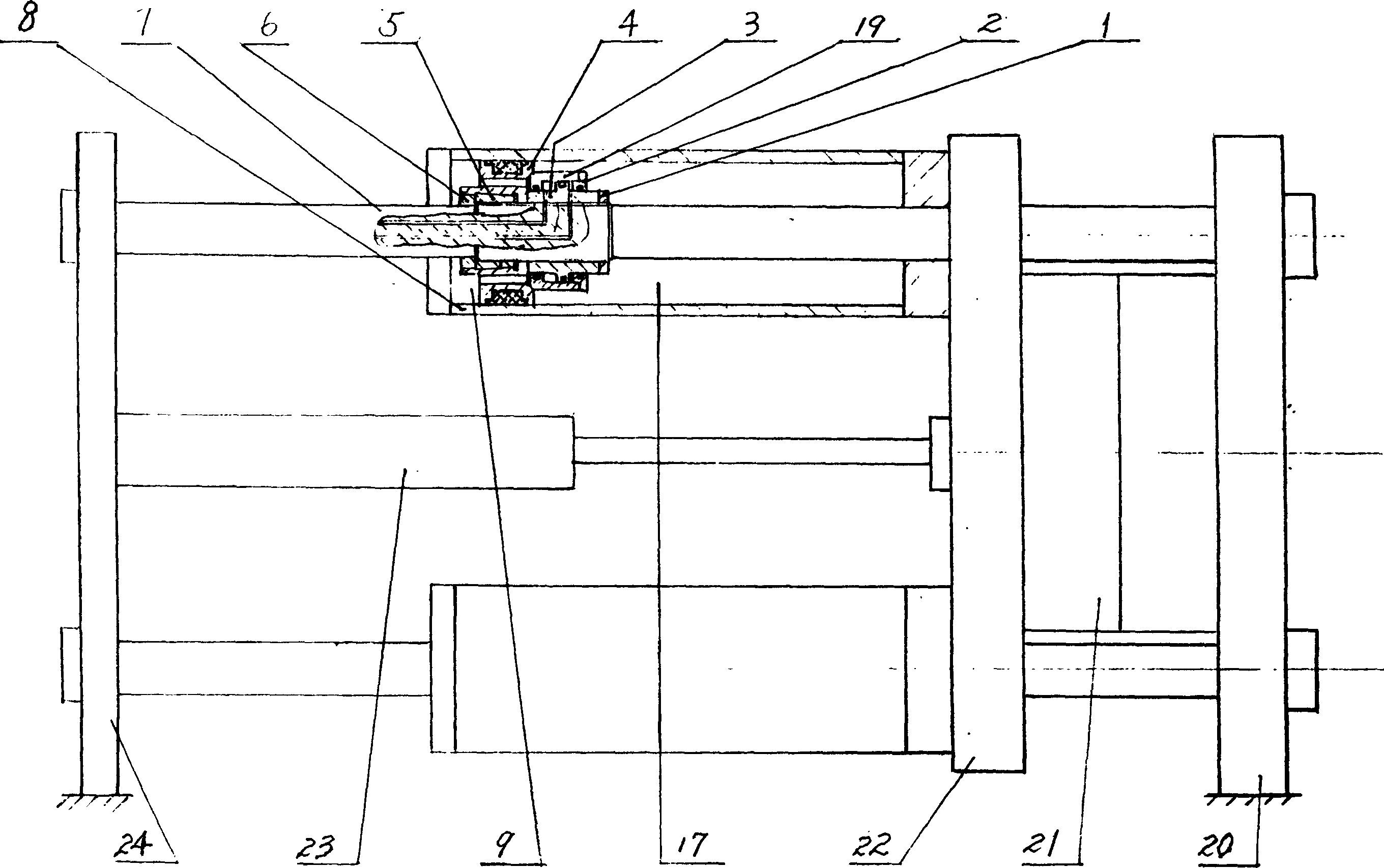

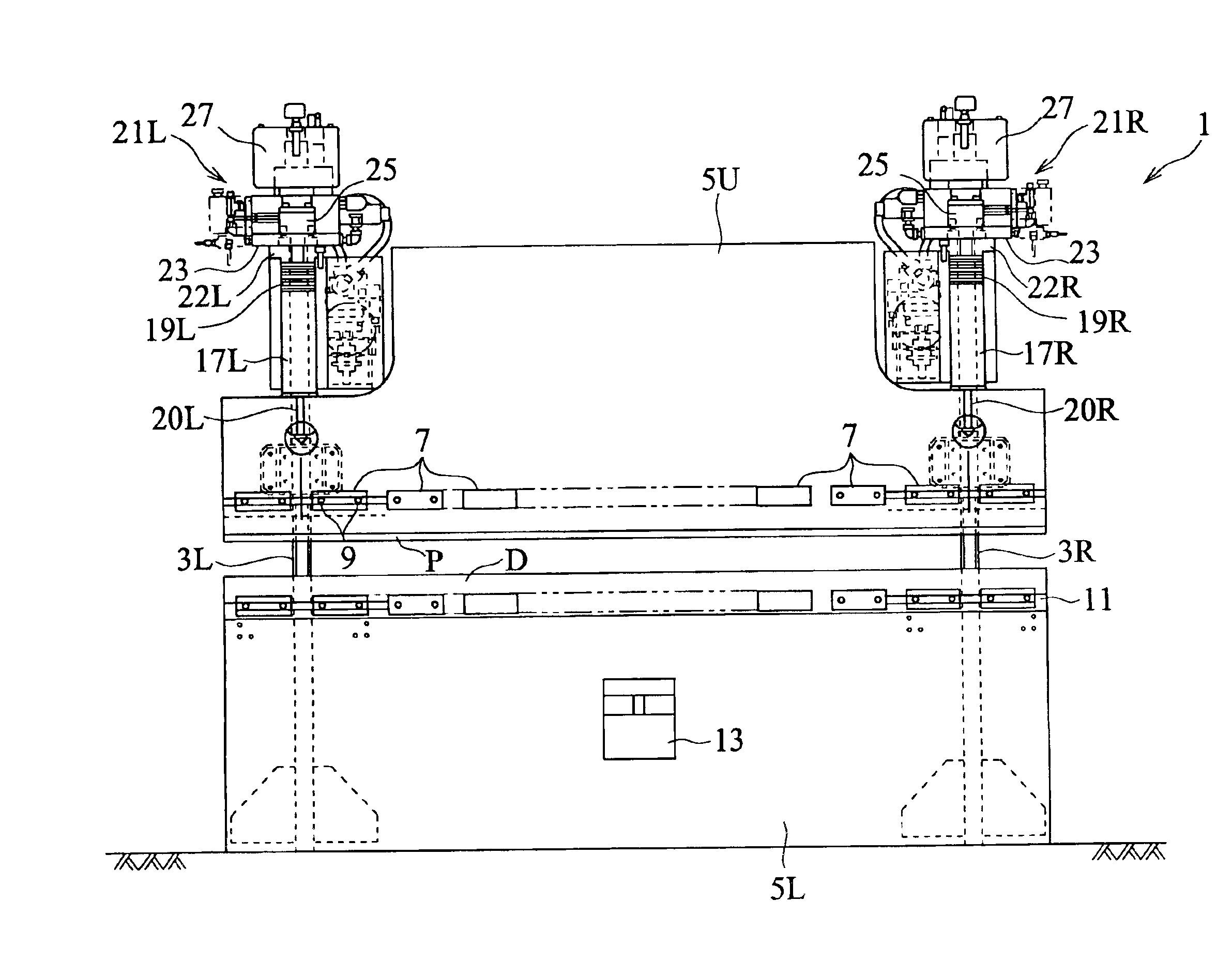

Press brake and ram movement method for press brake

Owner:AMADA CO LTD

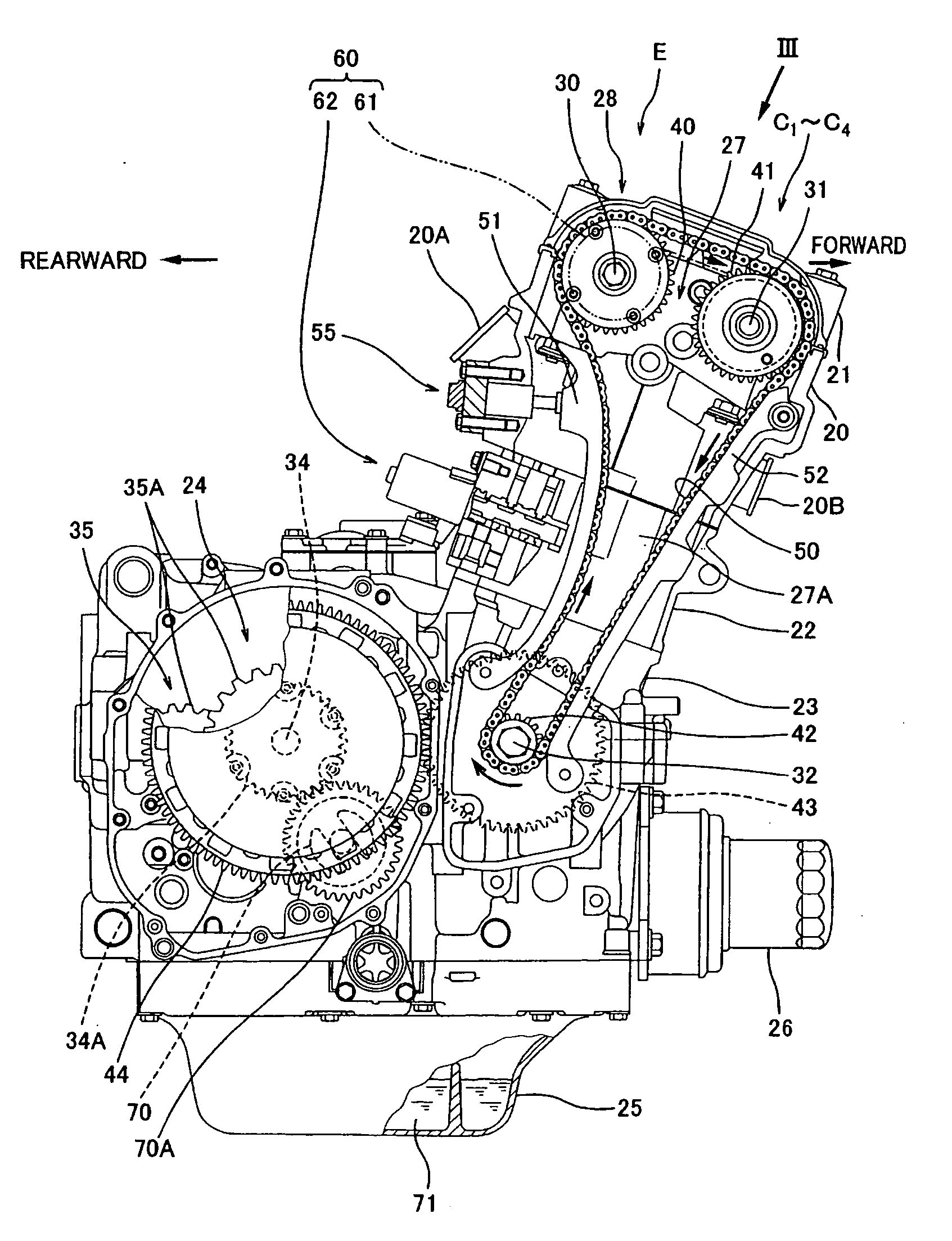

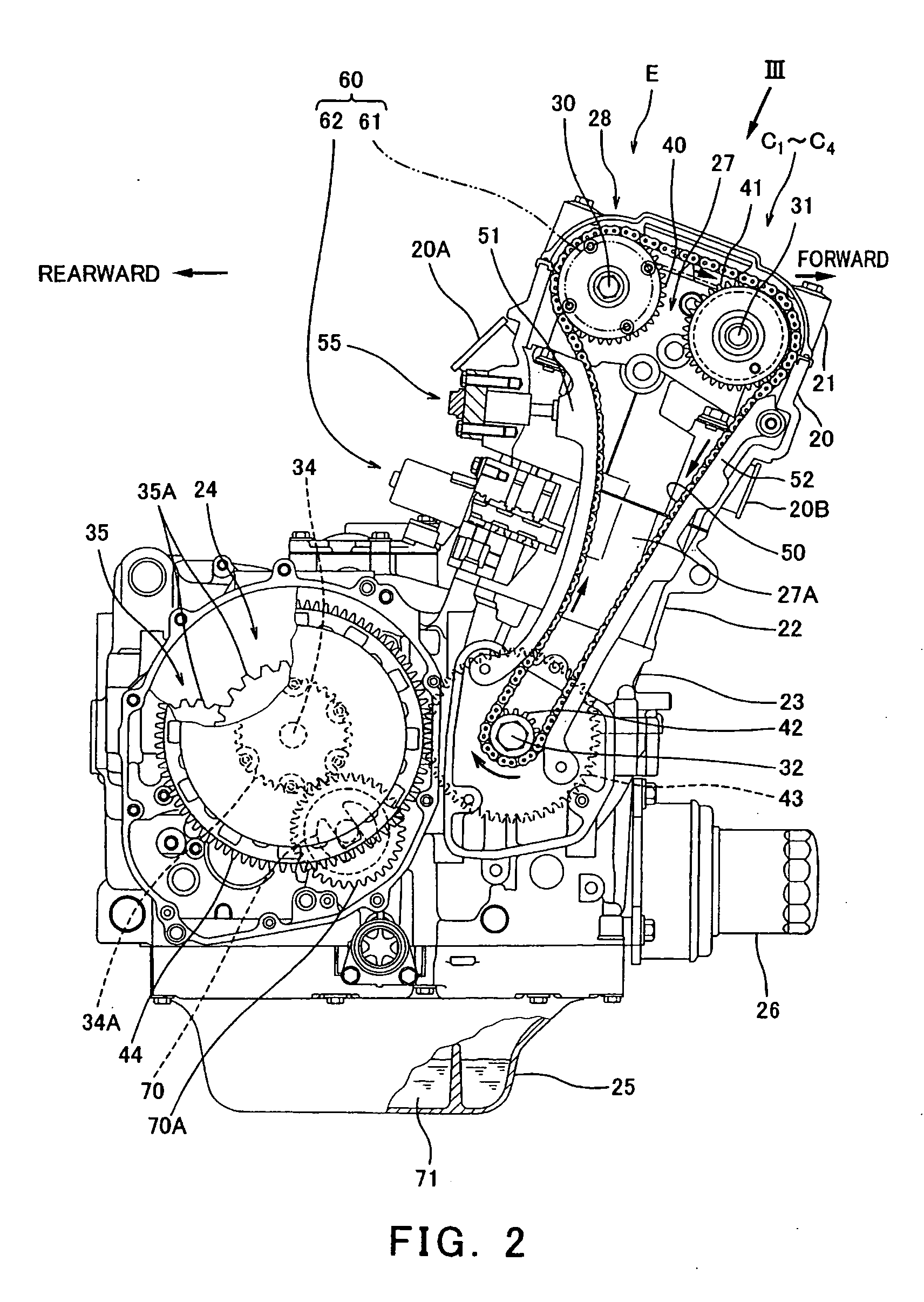

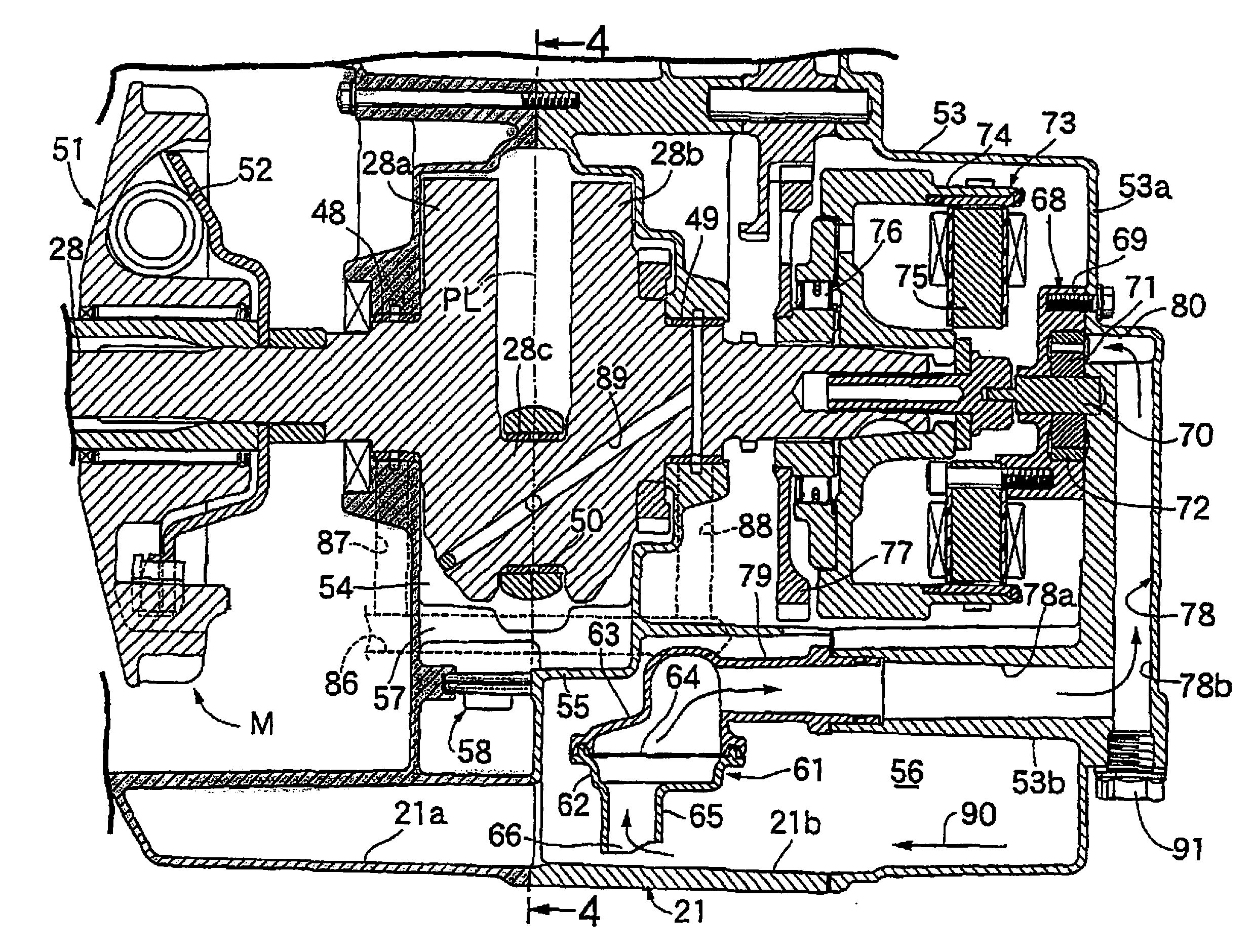

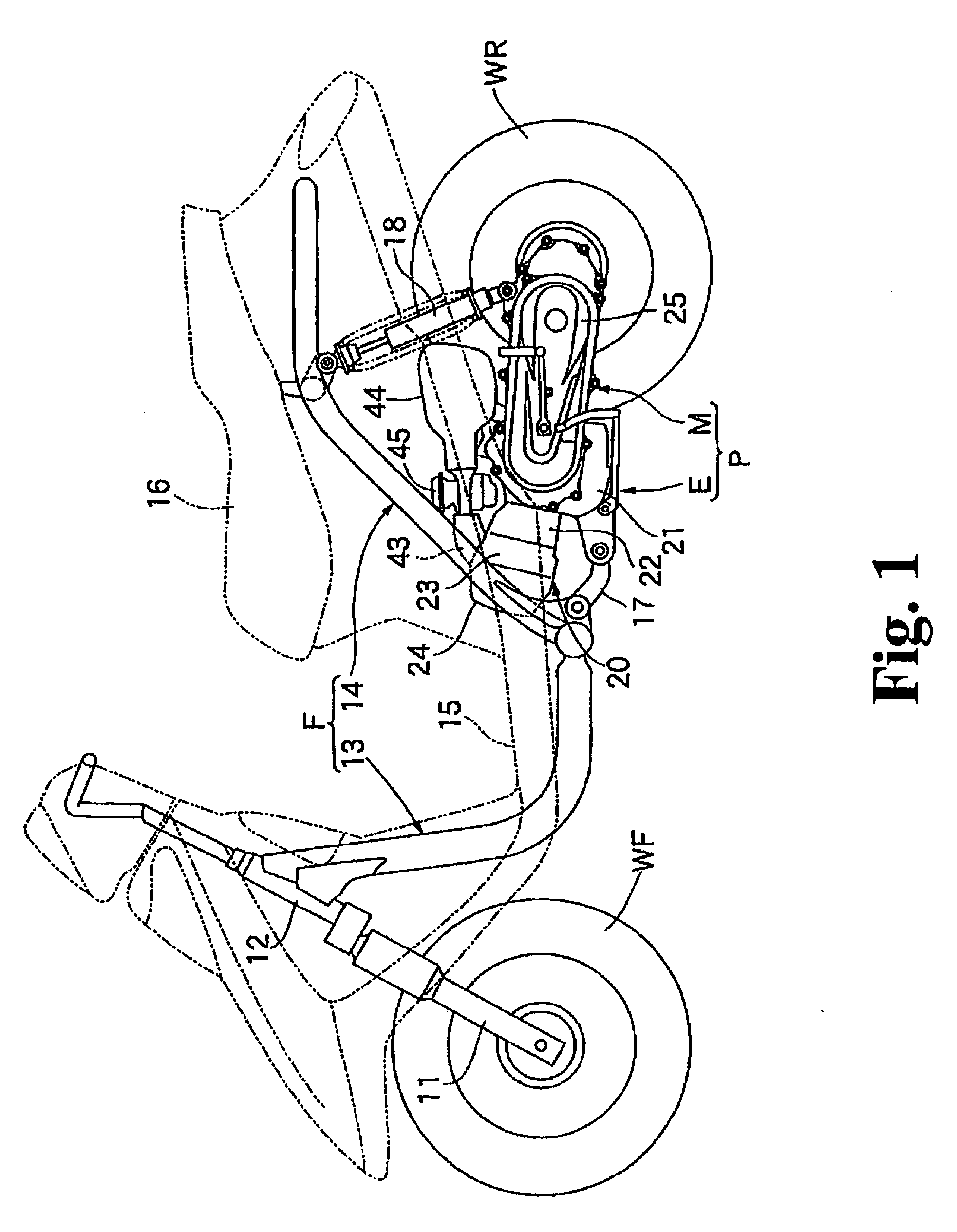

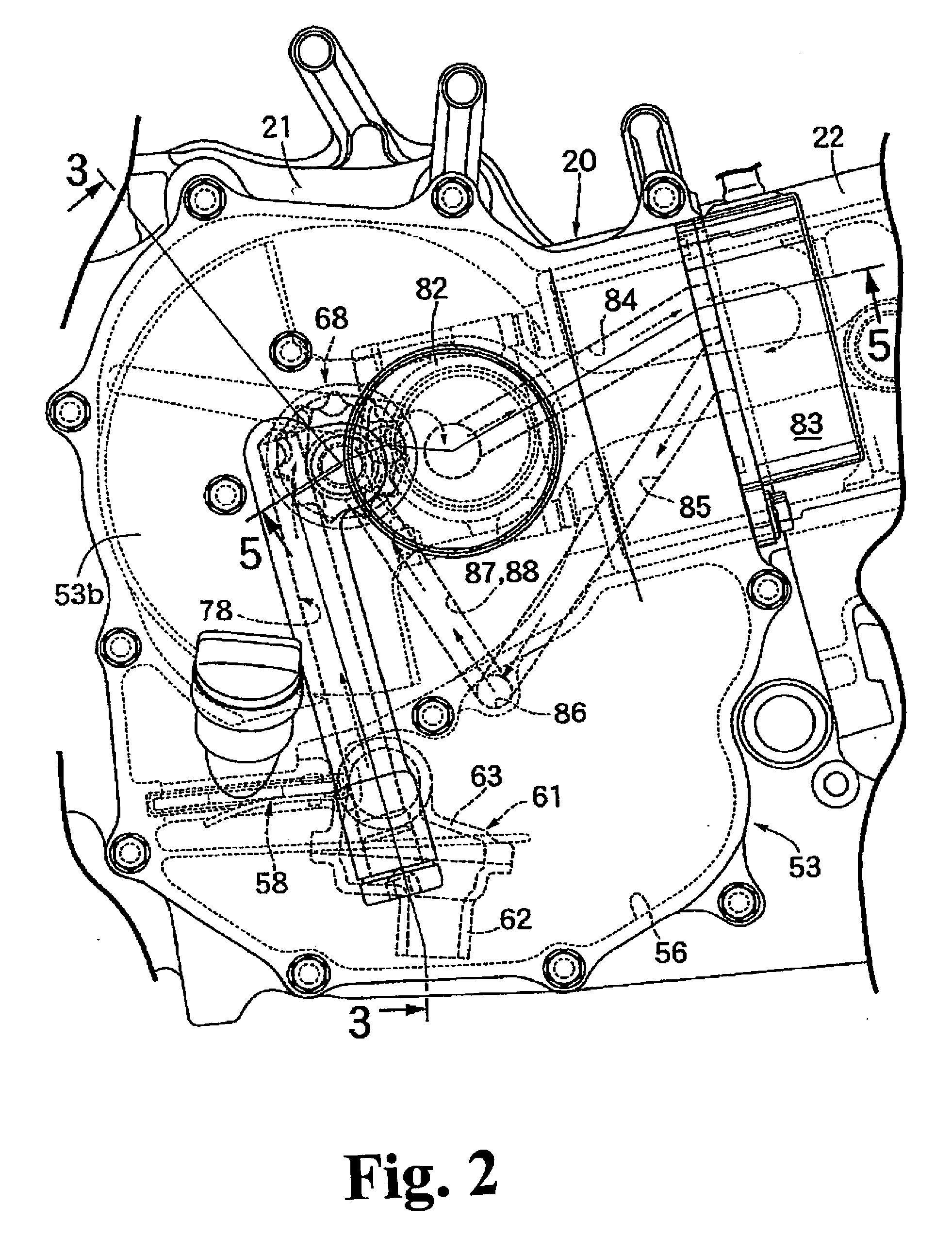

Engine

ActiveUS20070157900A1Reduce total pressure lossLower oil temperatureLubrication of auxillariesValve drivesPetroleum engineering

An engine including an oil passage through which oil output from an oil pump flows, an oil cooler mounted to the oil passage, and a branched oil passage for a hydraulically-powered device of the engine that is configured to branch in a location of the oil passage extending from the oil pump to the oil cooler to deliver the oil to the hydraulically-powered device.

Owner:KAWASAKI MOTORS LTD

Coolant jacket for a turbocharger oil drain

A system including a turbocharger, comprising a turbocharger bearing housing supporting a turbocharger drive shaft; an oil drain including an inlet in fluidic communication with the turbocharger bearing housing and an outlet in fluidic communication with an oil sump; and a coolant jacket enveloping the oil drain. The coolant jacket envelopes the oil drain and is positioned to provide coolant to the turbocharger bearing housing and draw heat from the oil draining through the oil drain to prevent coking of hot oil within the oil drain.

Owner:FORD GLOBAL TECH LLC

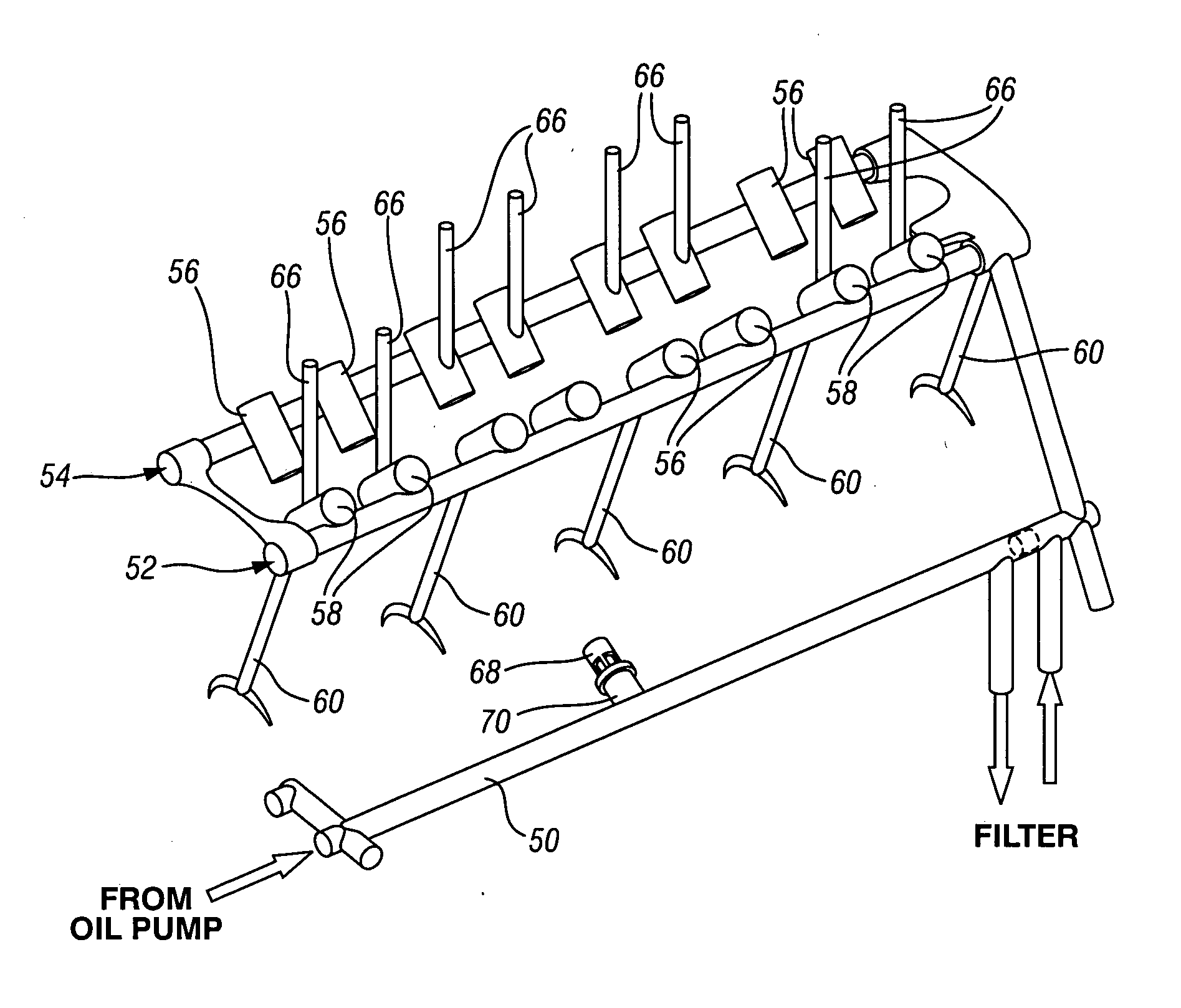

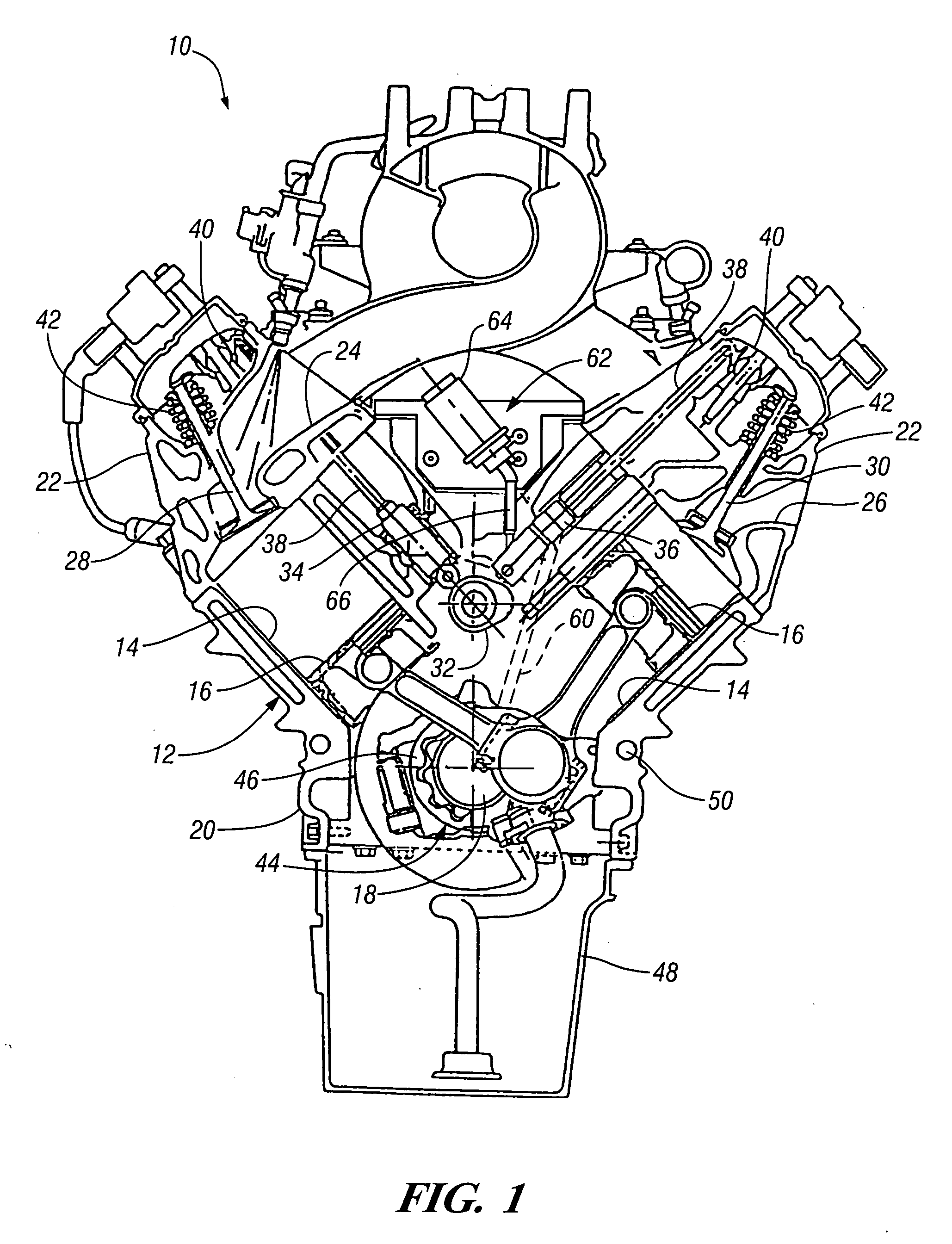

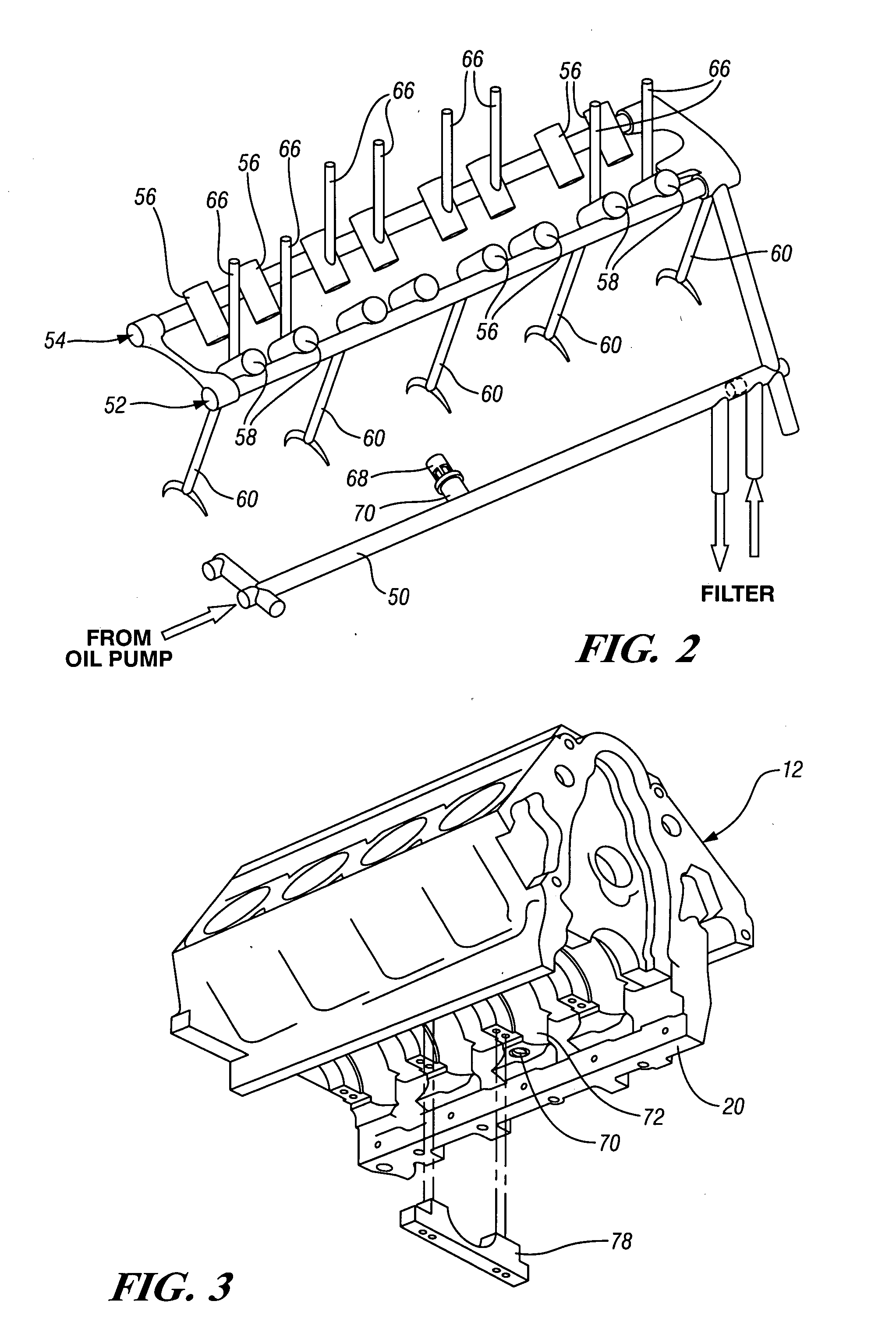

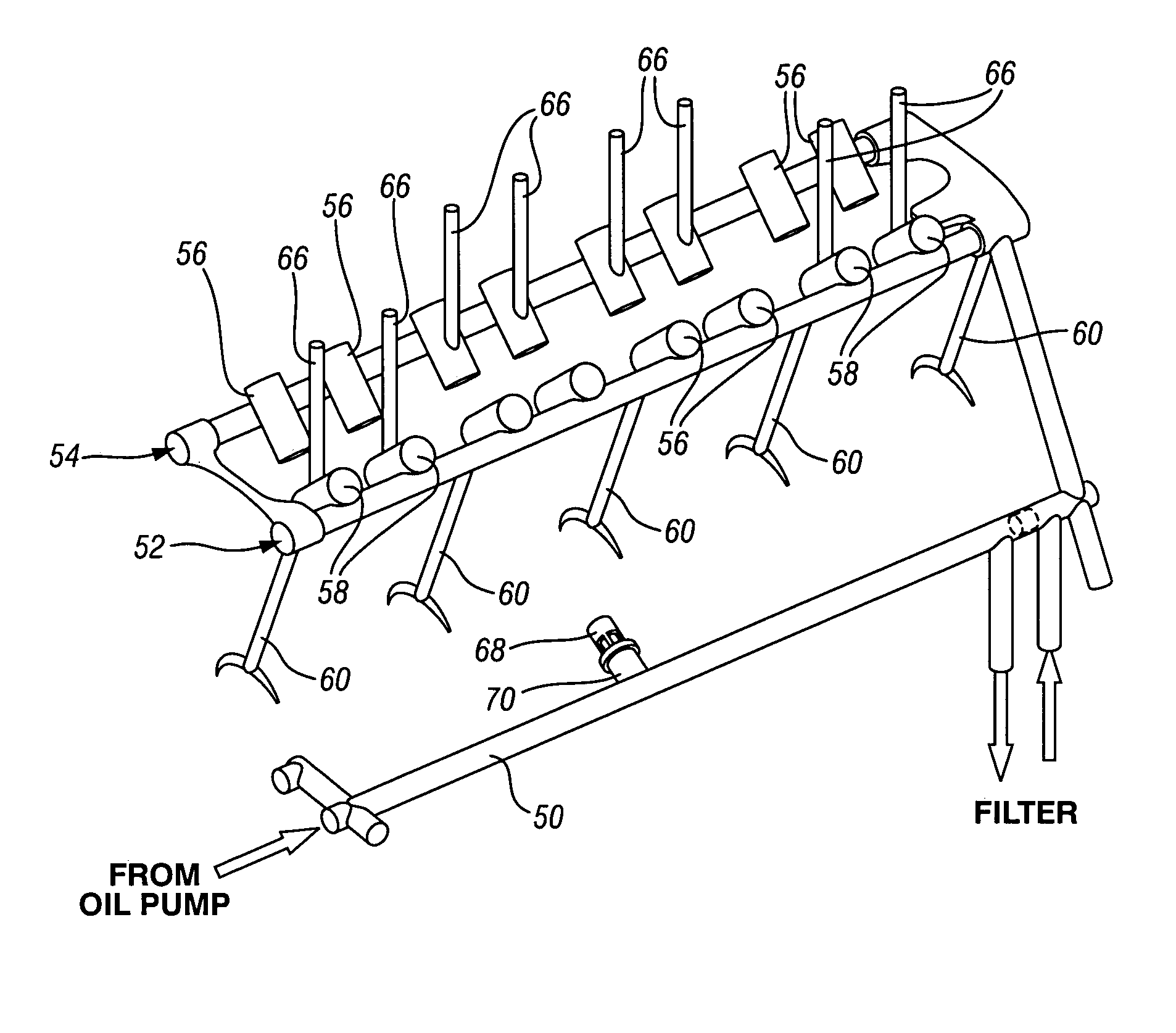

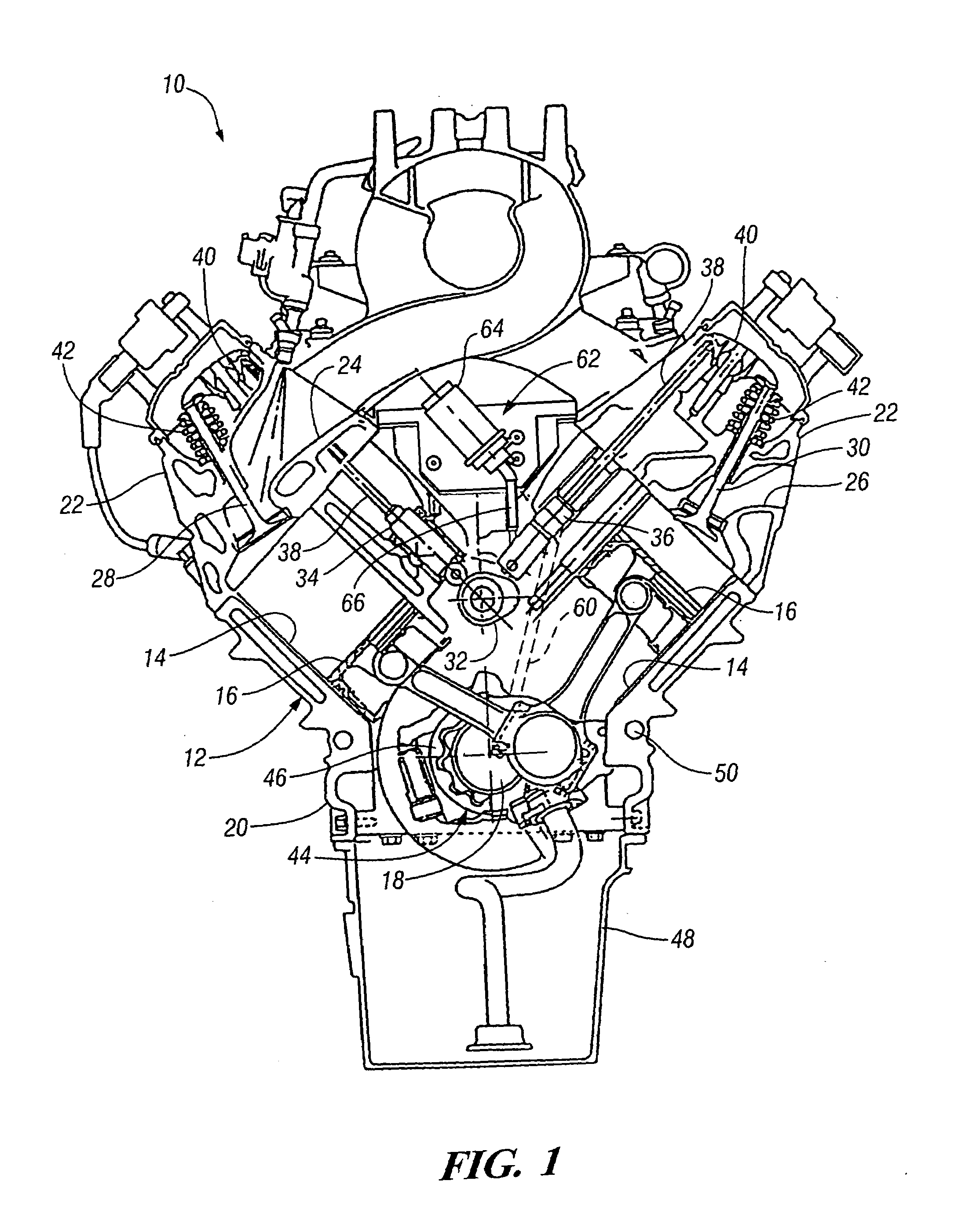

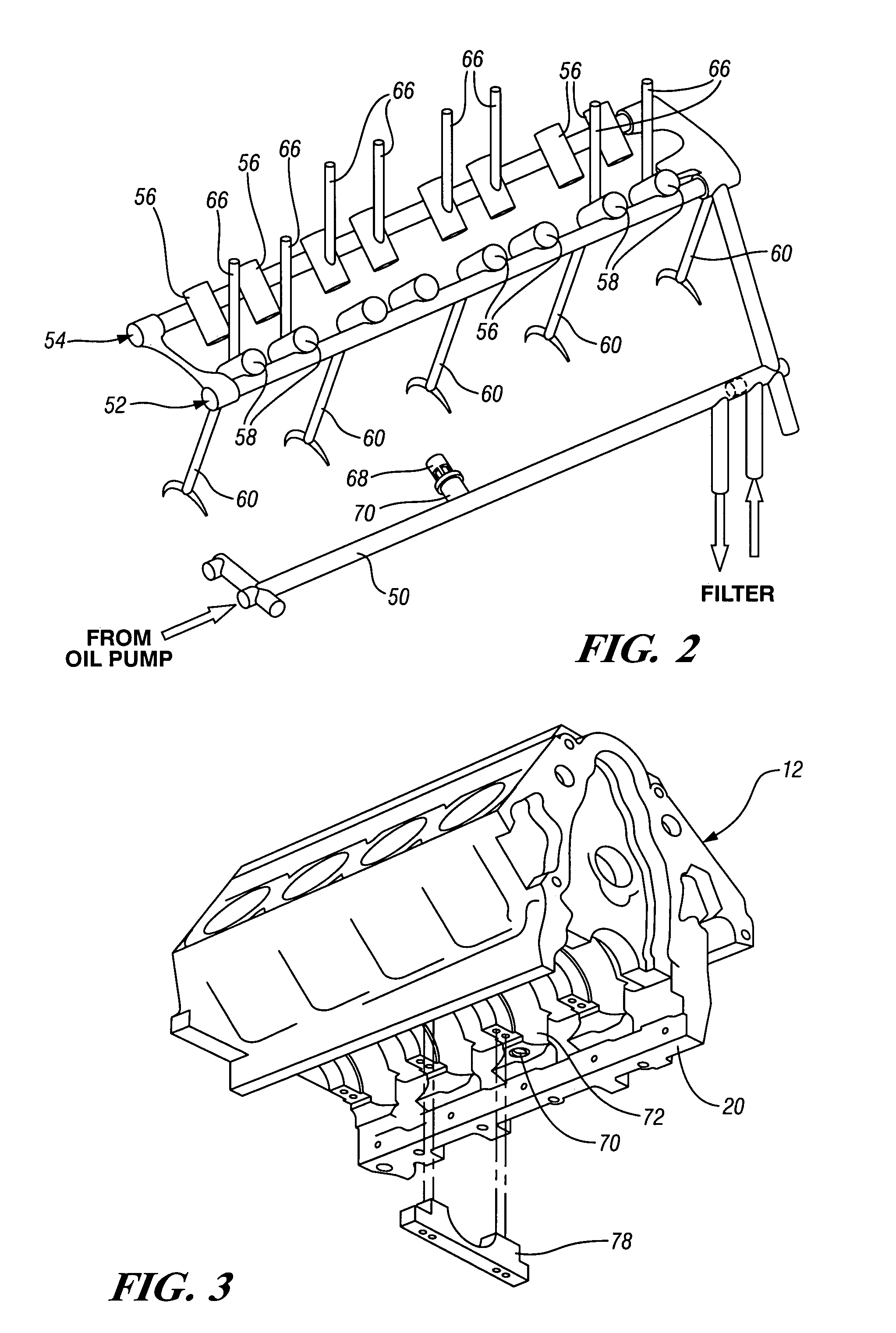

Oil pressure control system and method for engines with hydraulic cylinder deactivation

InactiveUS20050045142A1High engine operating speedOperating oil temperatureValve arrangementsOutput powerHydraulic cylinderSystems design

An oil lubrication and control system, for an engine having cylinder deactivation switching lifters operated at the pressure of the full oil system, is provided with an auxiliary pressure relief valve which opens to control maximum oil pressure in the system whenever the engine speed and temperature conditions lie beyond the ability of the oil pump pressure control unit to maintain the maximum pressure limit. Addition of the auxiliary pressure relief valve allows extended operation of the switching lifters, which are limited by their construction to operation below a prescribed pressure limit. In a preferred embodiment, the auxiliary pressure relief valve is mounted in the engine crankcase in a bore connected directly with the main oil gallery to provide mounting and actuation of the auxiliary pressure relief valve with a minimum of modifications to the engine oil system design.

Owner:GM GLOBAL TECH OPERATIONS LLC

Oil pressure control system and method for engines with hydraulic cylinder deactivation

InactiveUS7082918B2High engine operating speedLower oil temperatureValve arrangementsLubrication of auxillariesHydraulic cylinderSystems design

An oil lubrication and control system, for an engine having cylinder deactivation switching lifters operated at the pressure of the full oil system, is provided with an auxiliary pressure relief valve which opens to control maximum oil pressure in the system whenever the engine speed and temperature conditions lie beyond the ability of the oil pump pressure control unit to maintain the maximum pressure limit. Addition of the auxiliary pressure relief valve allows extended operation of the switching lifters, which are limited by their construction to operation below a prescribed pressure limit. In a preferred embodiment, the auxiliary pressure relief valve is mounted in the engine crankcase in a bore connected directly with the main oil gallery to provide mounting and actuation of the auxiliary pressure relief valve with a minimum of modifications to the engine oil system design.

Owner:GM GLOBAL TECH OPERATIONS LLC

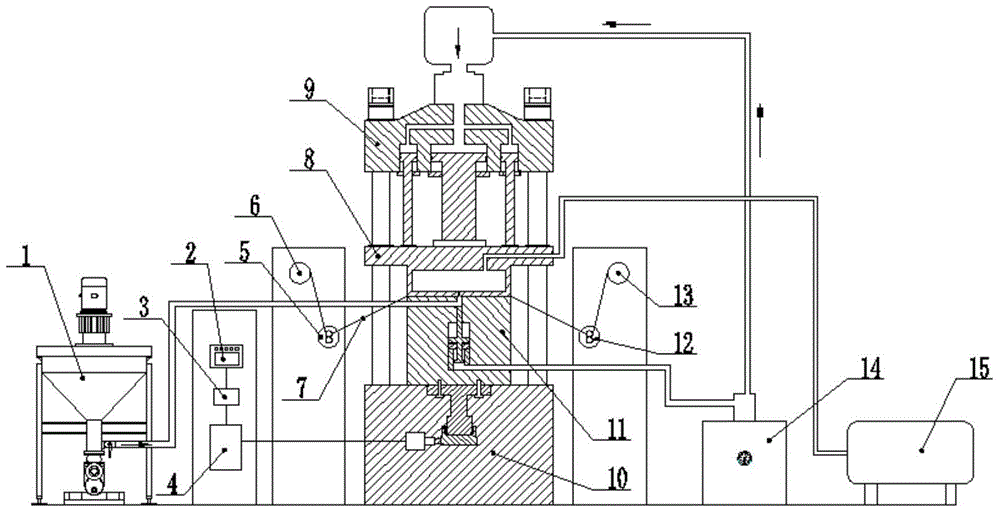

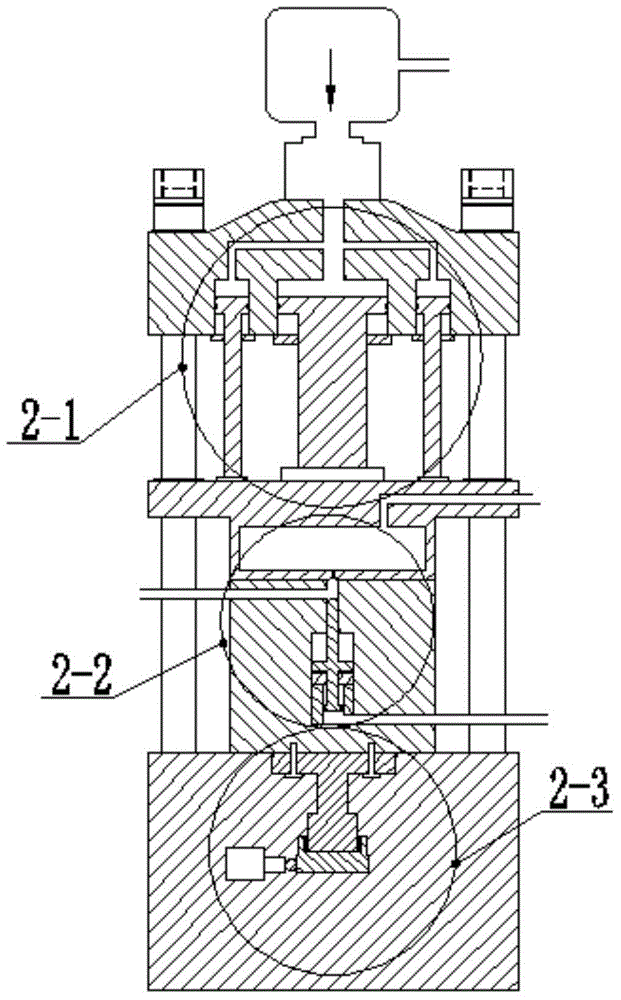

Downward-pushing magnetic material wet forming hydraulic machine and use method thereof

The invention discloses a downward-pushing magnetic material wet molding hydraulic machine and a use method thereof and belongs to the magnetic material wet forming field. The downward-pushing magnetic material wet molding hydraulic machine comprises a downward-pushing pressing structure. The downward-pushing magnetic material wet molding hydraulic machine further comprises a mechanical limiting structure, a packing structure, a blank fetching system, a double-oil cylinder balance system and a mould surface cleaning system; the downward-pushing pressing structure comprises an upper mould seat, a pushing rod, a large-bore oil cylinder, a fixing mould frame and a lower mould hydraulic cylinder, wherein the upper mould seat is driven by the large-bore oil cylinder, the pushing rod is located in the fixing mould frame, and the fixing mould frame is connected with the lower mould hydraulic cylinder, the large-bore oil cylinder and the lower mould hydraulic cylinder are both communicated with a hydraulic station; the mechanical limiting structure includes a horizontal mechanical limiting structure and a longitudinal mechanical limiting structure; the horizontal mechanical limiting structure comprises the pushing rod and the fixing mould frame; a fixing mould cavity is arranged in the fixing mould frame; the pushing rod is located in the fixing mould cavity in the fixing mould frame; and the longitudinal mechanical limiting structure includes a servo motor A and a transmission mechanism. With the downward-pushing magnetic material wet molding hydraulic machine and the use method thereof adopted, product formation error is small, and the pollution source of slurry to hydraulic oil can be eliminated.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Energy-saving type prior unloading valve

The invention discloses an energy-saving type prior unloading valve which belongs to the technical field of hydraulic steering systems of engineering machinery. The energy-saving type prior unloading valve comprises a valve body, a prior valve core, a sliding valve, an unloading valve core and an LS control plug screw, wherein an oil channel CF, an oil channel P, an oil channel P2, an oil channel P1 and a return oil channel T1 are formed in a valve hole of the prior valve core; and the oil channel P2, a return oil channel T, an oil channel LS and an unloading safety valve guide return oil channel T2 are formed in a valve hole of the unloading valve core. A load sensing complete hydraulic steering hydraulic system is formed by the energy-saving type prior unloading valve together with a load sensing steering gear and a steering pump, the sliding valve is additionally arranged, and the movement of the sliding valve is controlled through the pressure of the steering gear LS, so that the divided and combined flow high / low pressure control is realized, and the steering prior is ensured; and when a loader is not steered, steering pump hydraulic oil is subjected to prior valve flow combination or load oil returning under the lower pressure, so that the pressure loss of the steering pump combination or the load oil returning in the working condition that the loader is not steered is reduced, the unnecessary energy loss of the system is reduced to the maximum extent, the oil temperature is lowered, and the energy saving effect is effectively achieved.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

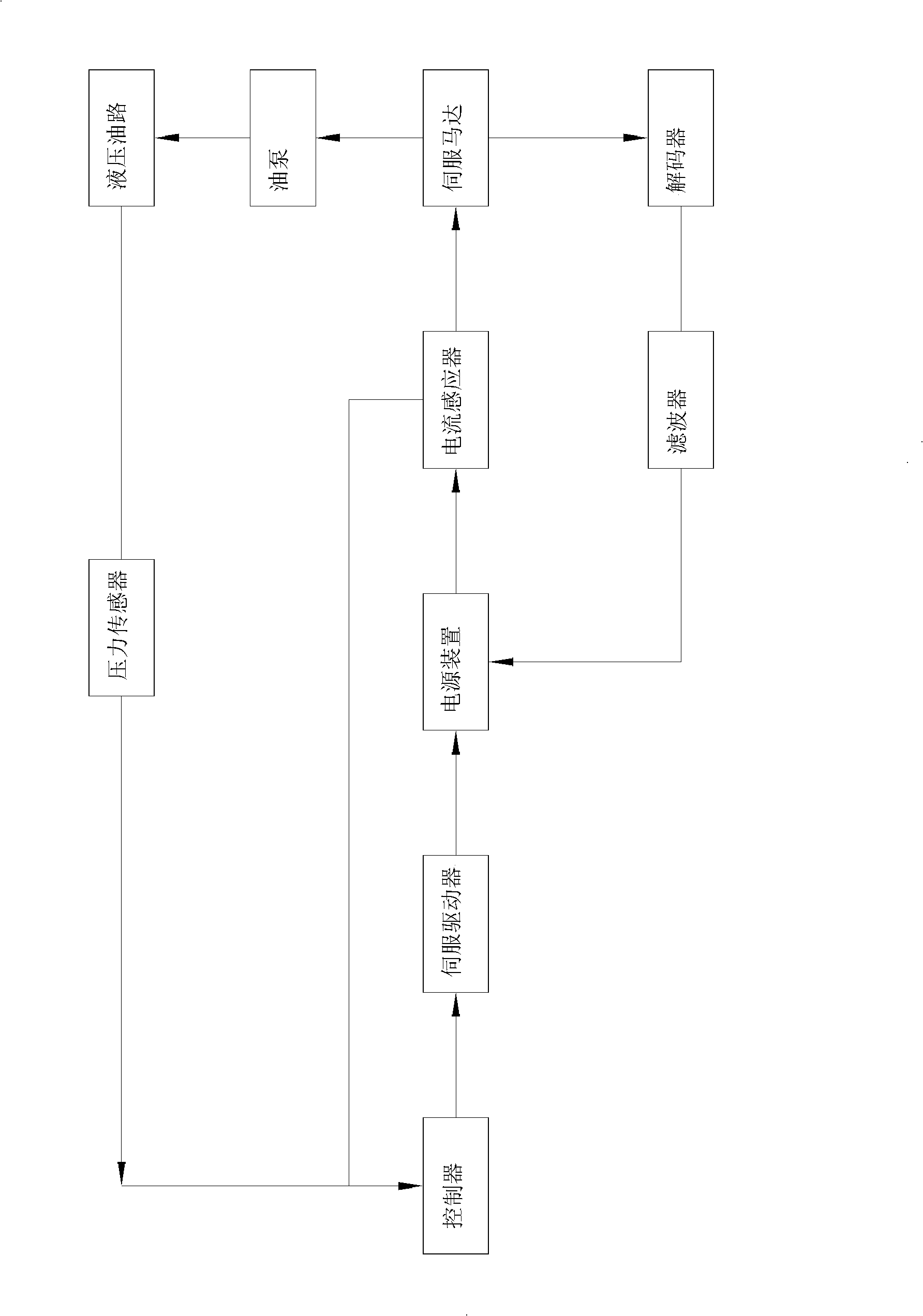

Oil electric compound energy-saving type closed-loop control system and control method thereof

InactiveCN101408211AExtended service lifeExtend the life cycleServomotorsFluid-pressure actuator componentsLoop controlClosed loop

The invention relates to a hydraulic control system and a control method thereof, in particular to a hydraulic closed-loop energy-saving control system and a control method thereof. The system consists of a controller, a servo drive, a servo motor, a drive power device, a hydraulic circuit, a forward control circuit and a feedback circuit; the forward control circuit is connected with the controller, the servo drive, the drive power device and the servo motor in sequence; the power output end of the servo motor is connected with an oil pump; the working signal of the servo motor is fed back to the power device by the feedback circuit; a pressure sensor is arranged in the hydraulic circuit; and the signal circuit of the pressure sensor is connected with the controller. The invention has the advantages that the energy-saving effect is markedly improved, the stability of the speed is enhanced, the oil temperature is lowered, and the using cycle of a sealing part is extended, thereby prolonging the service life of the whole machine, and the like.

Owner:NINGBO TECHMATION

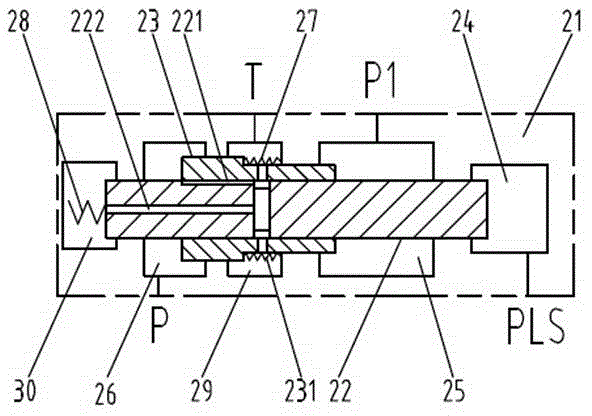

Power control valve and loader quantitative-variable hydraulic system

ActiveCN104153419ALimit maximum powerReduce power ratioSoil-shifting machines/dredgersPump controlEngineeringControl valves

The invention relates to a loader quantitative-variable hydraulic system and aims to overcome the defect that the input power of a variable pump in the existing quantitative-variable hydraulic system accounts for a large amount. The invention further discloses a power control valve. A first cavity in a valve body is communicated with a port PLS and acts on the right end of a main valve element. A valve element spring is disposed at the left end of the main valve element. A valve sleeve sleeves the main valve element. A second cavity is communicated with a port P1 and acts on the right end of the valve sleeve. A third cavity is communicated with a port P and acts on the left end of the valve sleeve. A valve sleeve spring provides leftward elastic force for the valve sleeve. An oil drainage passage communicated with the third cavity and a port T are formed in the main valve element and the valve sleeve. When the main valve element moves leftwards relative to the valve sleeve, the oil drainage passage is communicated. When the main valve element moves leftwards relative to the main valve element, the oil drainage passage is reduced or closed. The power control valve has the advantages that the valve sleeve and the main valve element form a follow-up mechanism, the input power of the variable pump of the loader quantitative-variable hydraulic system can be controlled by the power control valve, and the input power is prevented from accounting for a large amount.

Owner:GUANGXI LIUGONG MASCH CO LTD

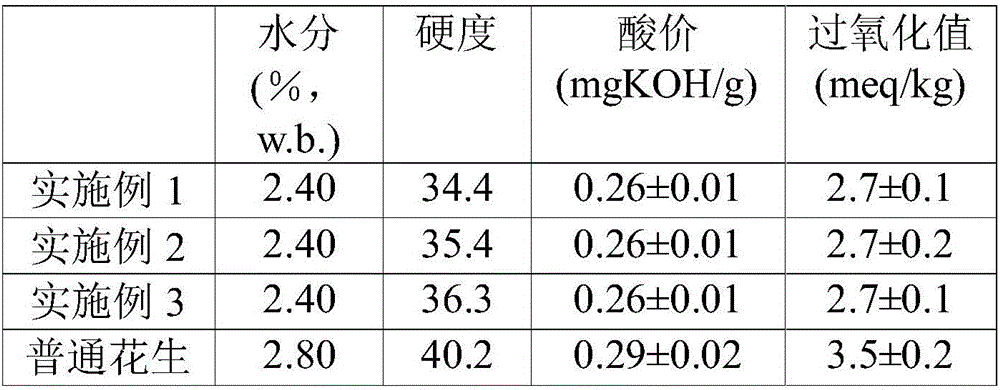

Processing technology of spicy peanuts

InactiveCN106107841AReduce churnInhibition of growth and reproductionFood scienceResidual oilThermal water

The invention discloses a processing technology of spicy peanuts, which is characterized by particularly comprising the following steps: (1) soaking in hot water; (2) peeling; (3) picking of half-finished products; (4) preserving for flavoring; (5) airing; (6) frying; (7) oil draining; (8) seasoning; and (9) cooling and sorting. The processing technology of the spicy peanuts, disclosed by the invention, is simple in process and convenient to operate; the loss of nutrient substances is low; the frying process is carried out at relatively low temperature; the prepared peanuts have relatively long shelf life; the obtained finished products of the spicy peanuts have bright chromaticity, attractive color and unique taste, are spicy and crisp, have delicious taste and relatively high nutritional values, and are suitable for people of all ages; bright appearance of the products is ensured; the special frying process improves the brittleness of the products; a part of additional oil is supplemented to the peanuts after oil draining by the residual oil of seasonings; unique taste of the products is ensured; the surface dryness is moderate; and the seasoning process is slow, and the seasonings penetrate uniformly, so that the flavoring uniformity of the finished products of the peanuts is ensured.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

Energy-saving automatic alloy bar thermal peeling machine

The invention discloses an energy-saving automatic alloy bar thermal peeling machine which comprises a base, a front beam, a rear beam, a peeling mechanism arranged between the front beam and the rear beam, an extruder corresponding to the position of the peeling mechanism and a feeding mechanism installed under the peeling mechanism. The front beam and the rear beam are installed on the base and parallelly arranged, the extruder adopts an oil cylinder, the oil cylinder is driven by a drive device to complete an extruding action, and the drive device adopts a servo motor pump set or a variable-frequency motor pump set and a program control system. The drive device adopts the servo motor pump set or the variable-frequency motor pump set, and the cyclic actions of the oil cylinders can be adjusted according to a production period of the energy-saving automatic alloy bar thermal peeling machine. Compared with peeling machines in the prior art, the energy-saving automatic alloy bar thermal peeling machine saves energy by higher than 60%.

Owner:TAICANG BEST MECHANICAL EQUIP

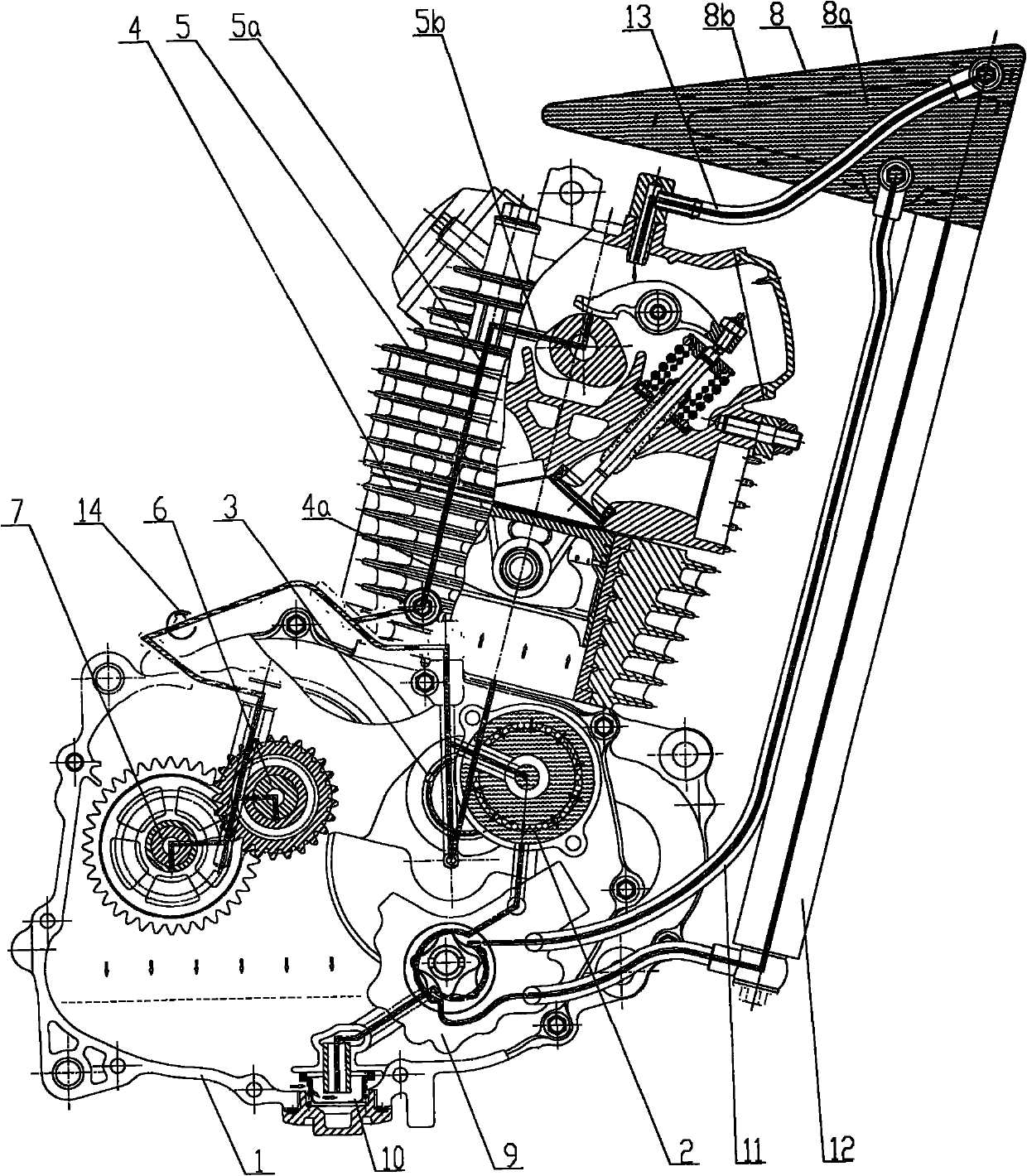

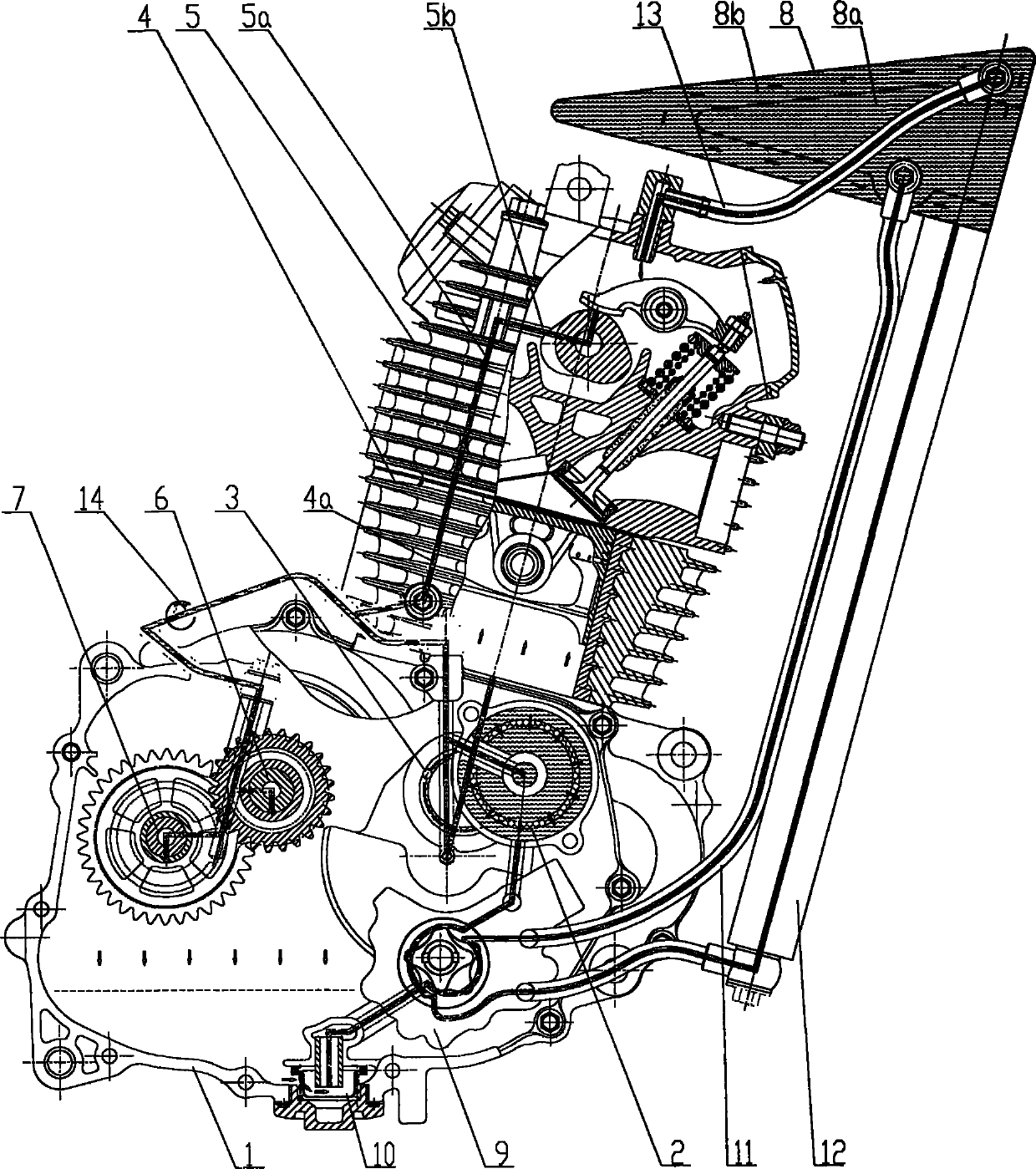

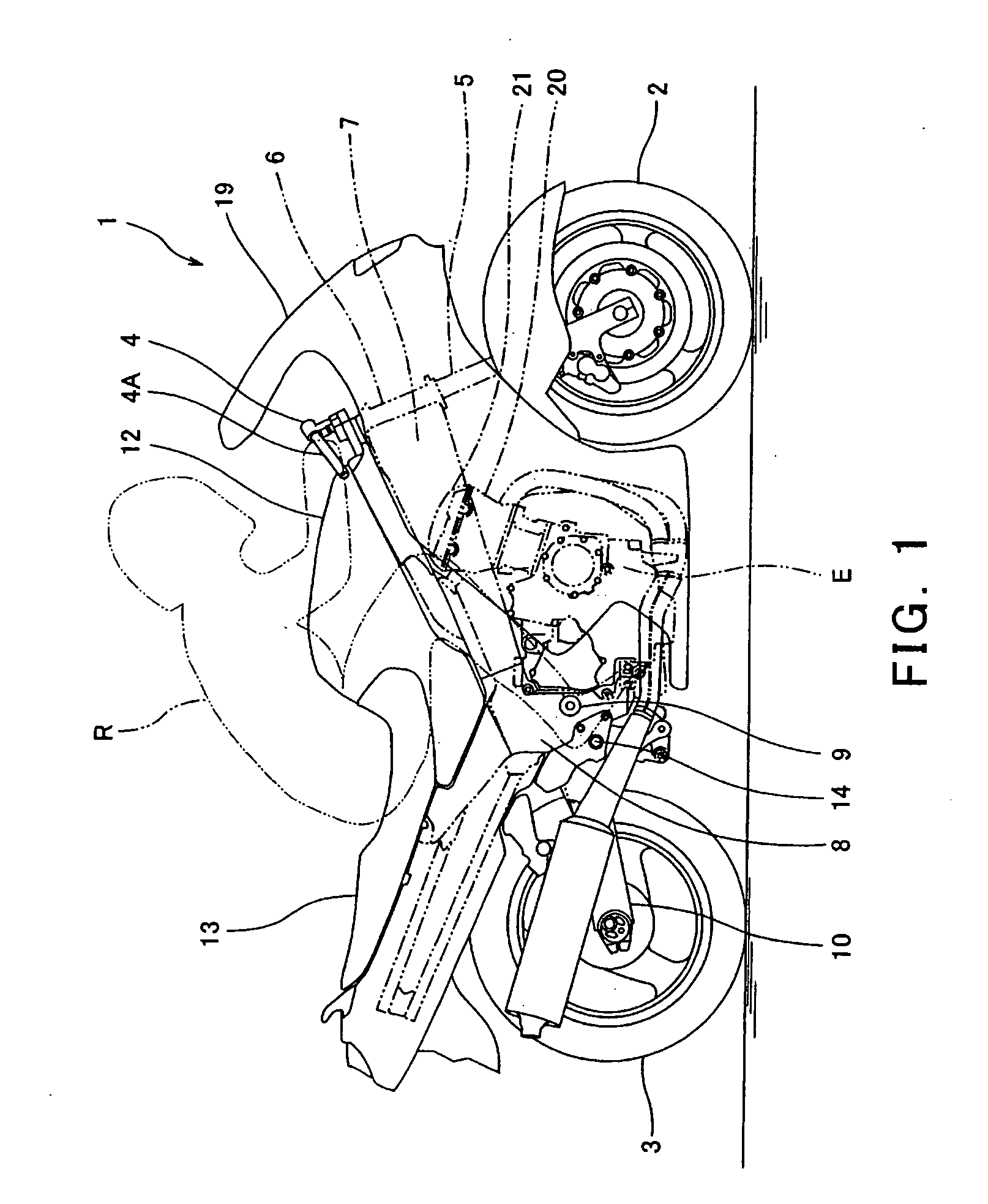

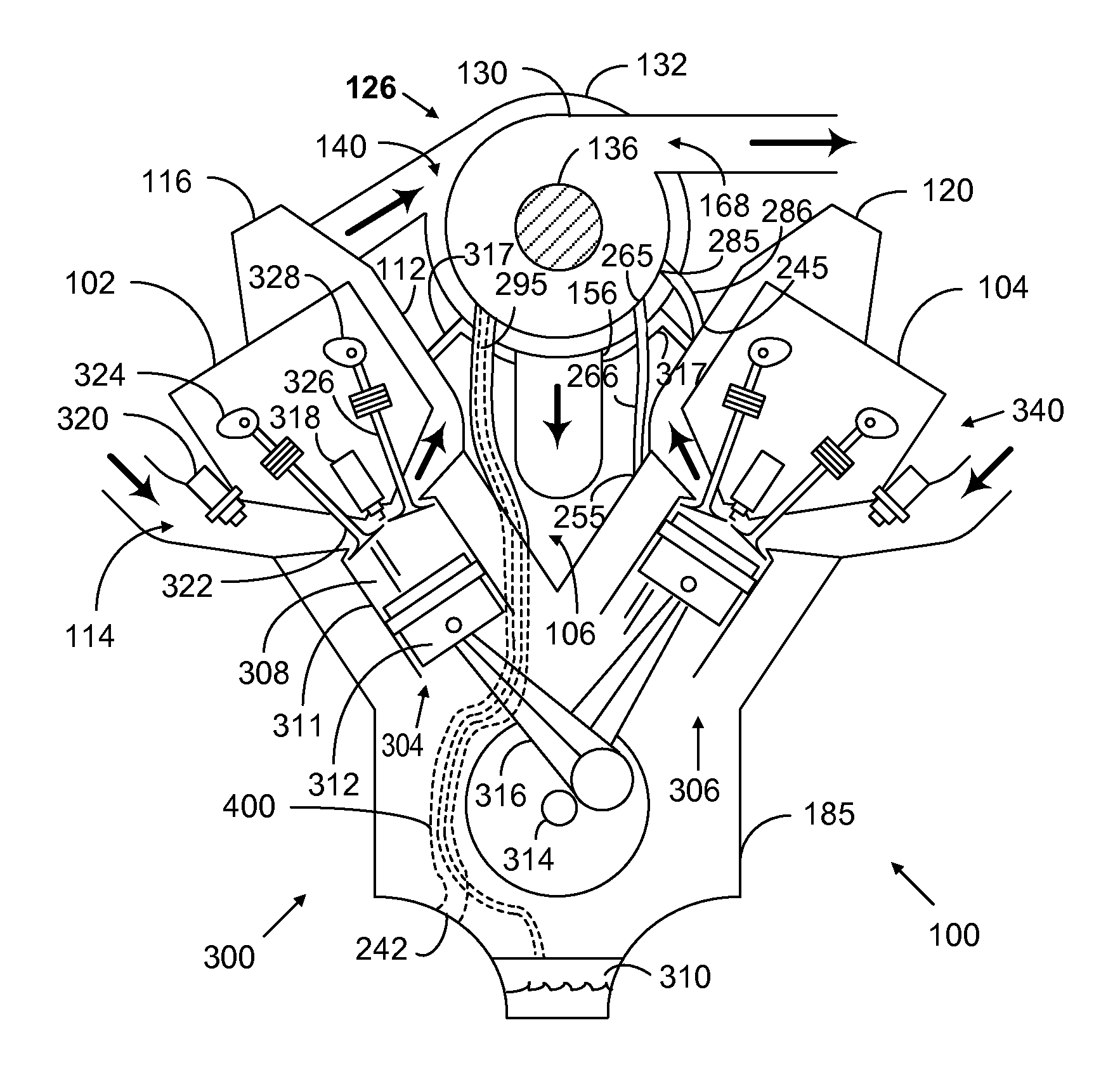

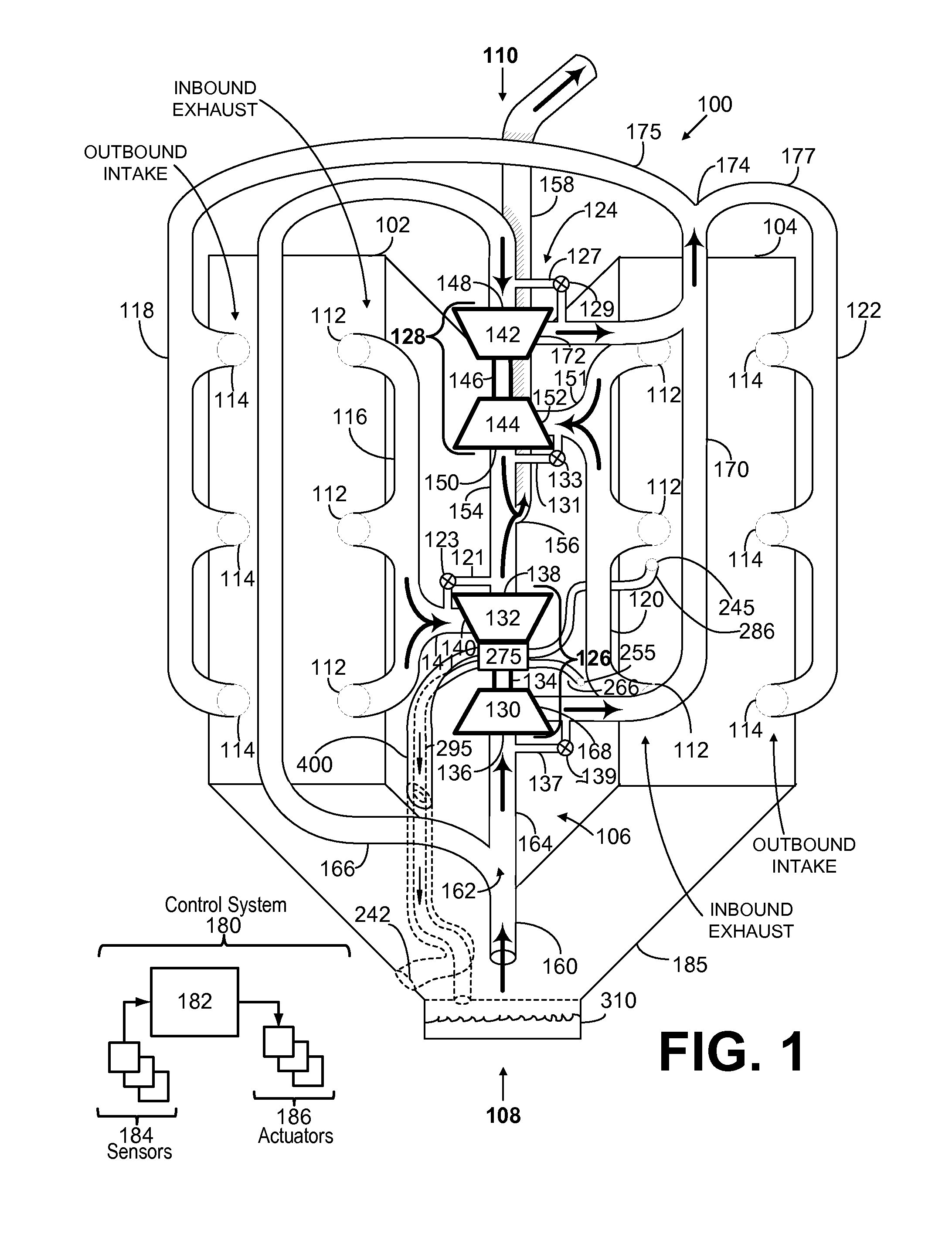

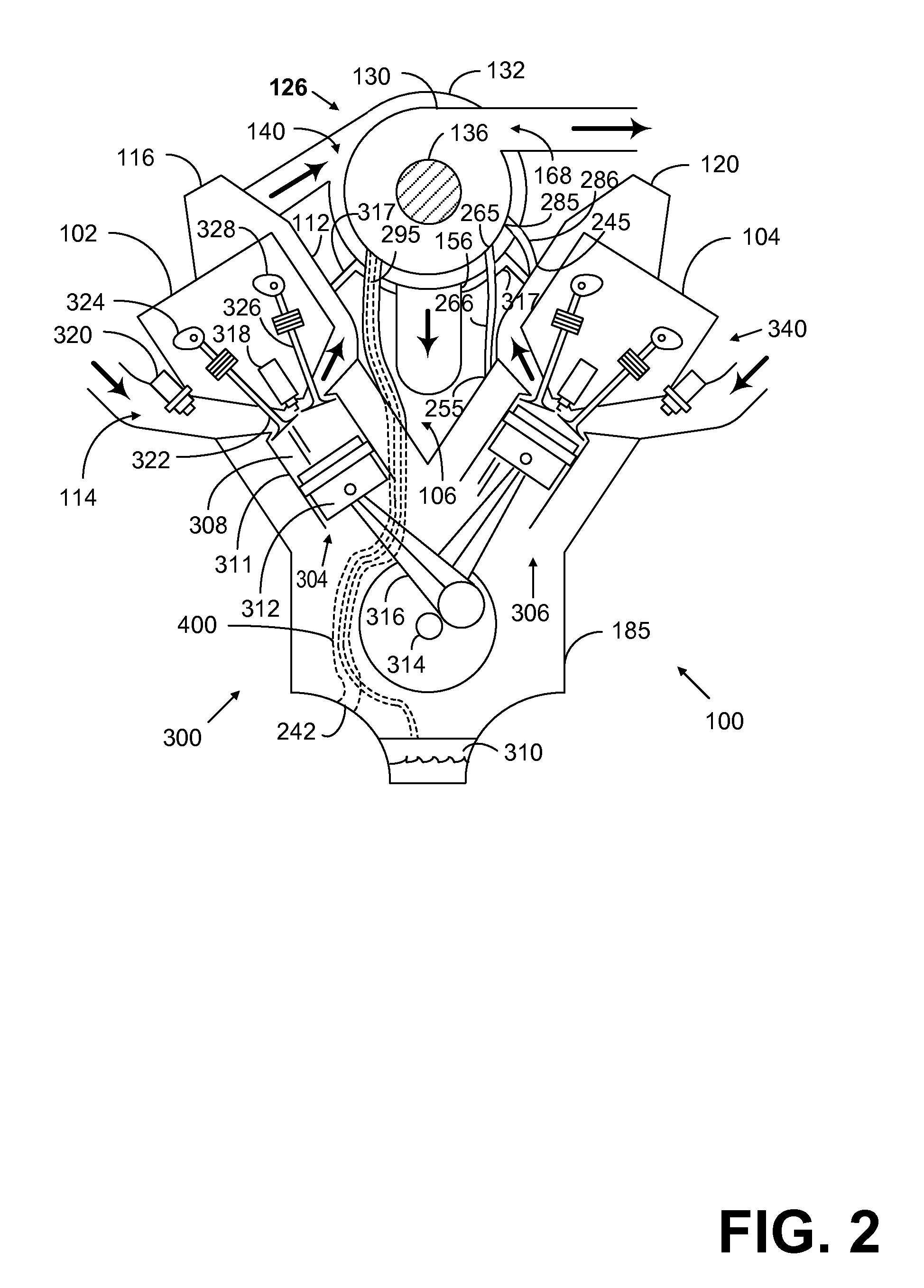

Lubricating device for engine

InactiveUS20070079789A1Increase oil temperatureReduce overall man-hoursLubrication of auxillariesLubricant conduit arrangementsFree rotationEngineering

An lubrication device for an engine includes: a crank case which freely rotatably supports a crank shaft and also which stores oil at its lower part; an oil strainer which is so arranged as to be fixed in the crank case; and an oil pump which suctions the oil at the lower part in the crank case via the oil strainer. In the lubricating device, the machining efficiency can be improved by reducing the time of machining to a crank case to thereby decentralize machining processes, and also the oil temperature can be reduced. A crank case cover covering part of a crank case and coupled with the crank case is provided with an oil suction passage which leads to an oil pump, and an oil strainer communicates with the oil suction passage via a connecting pipe which is a member different from the crank case

Owner:HONDA MOTOR CO LTD

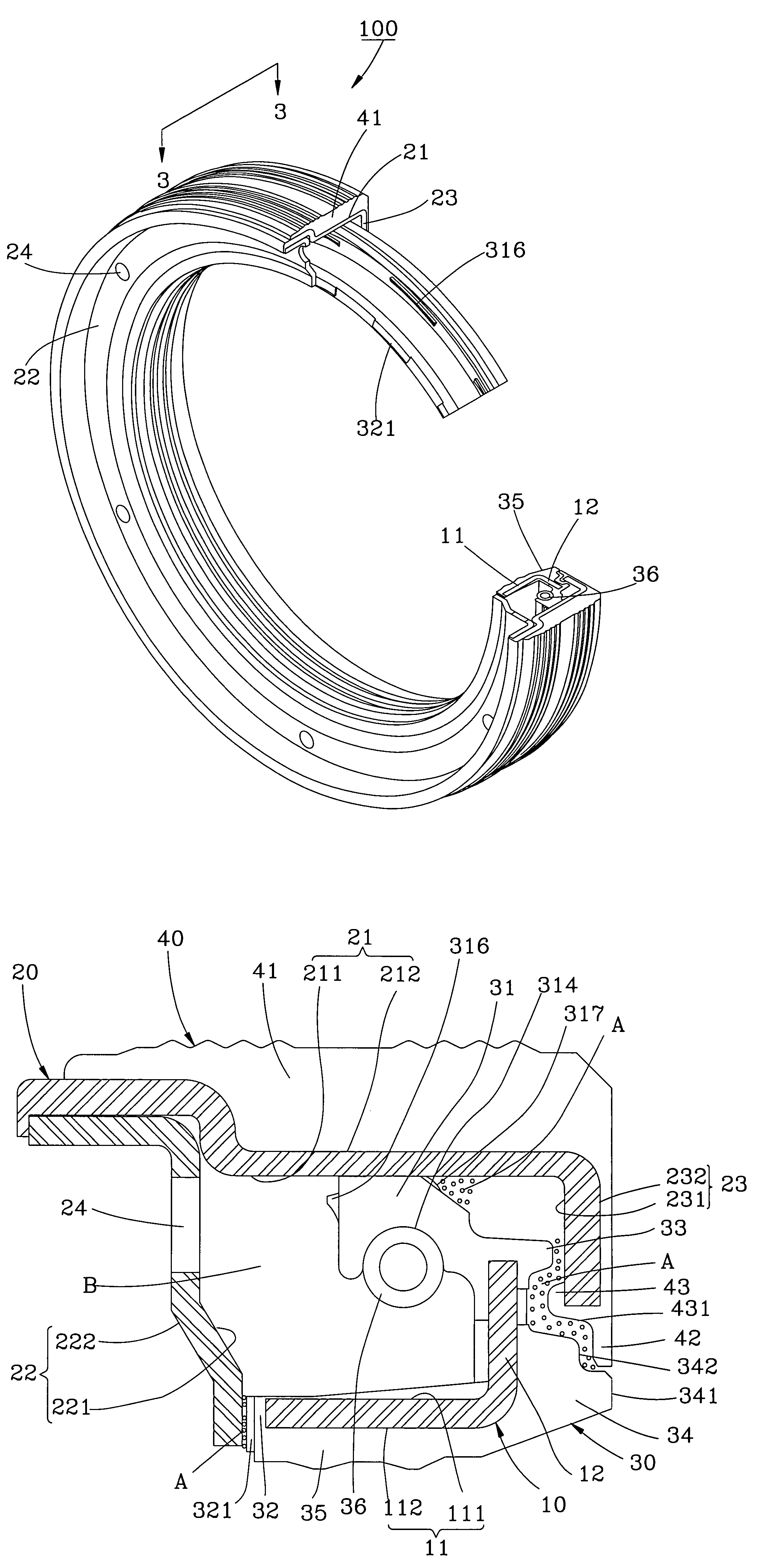

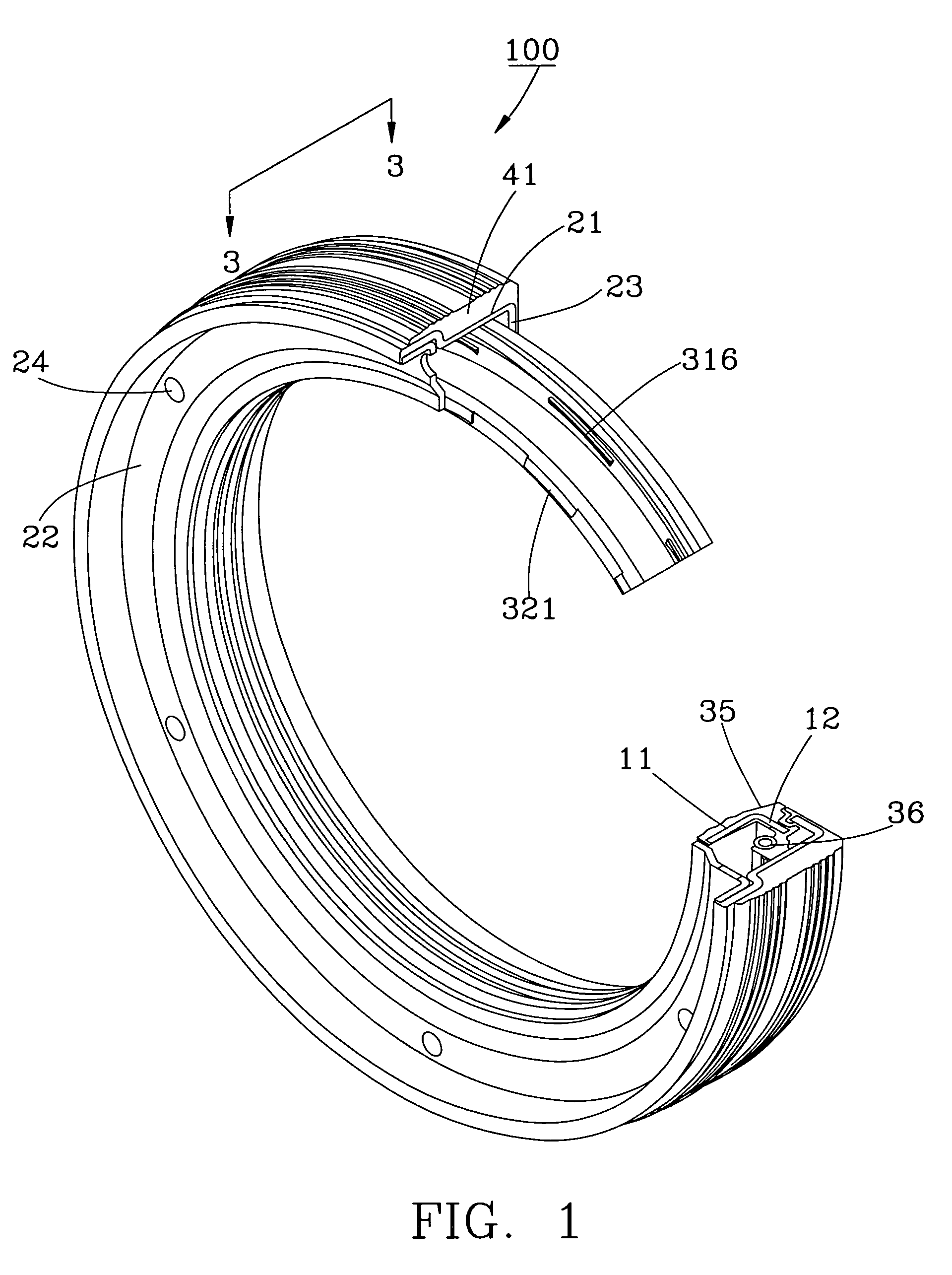

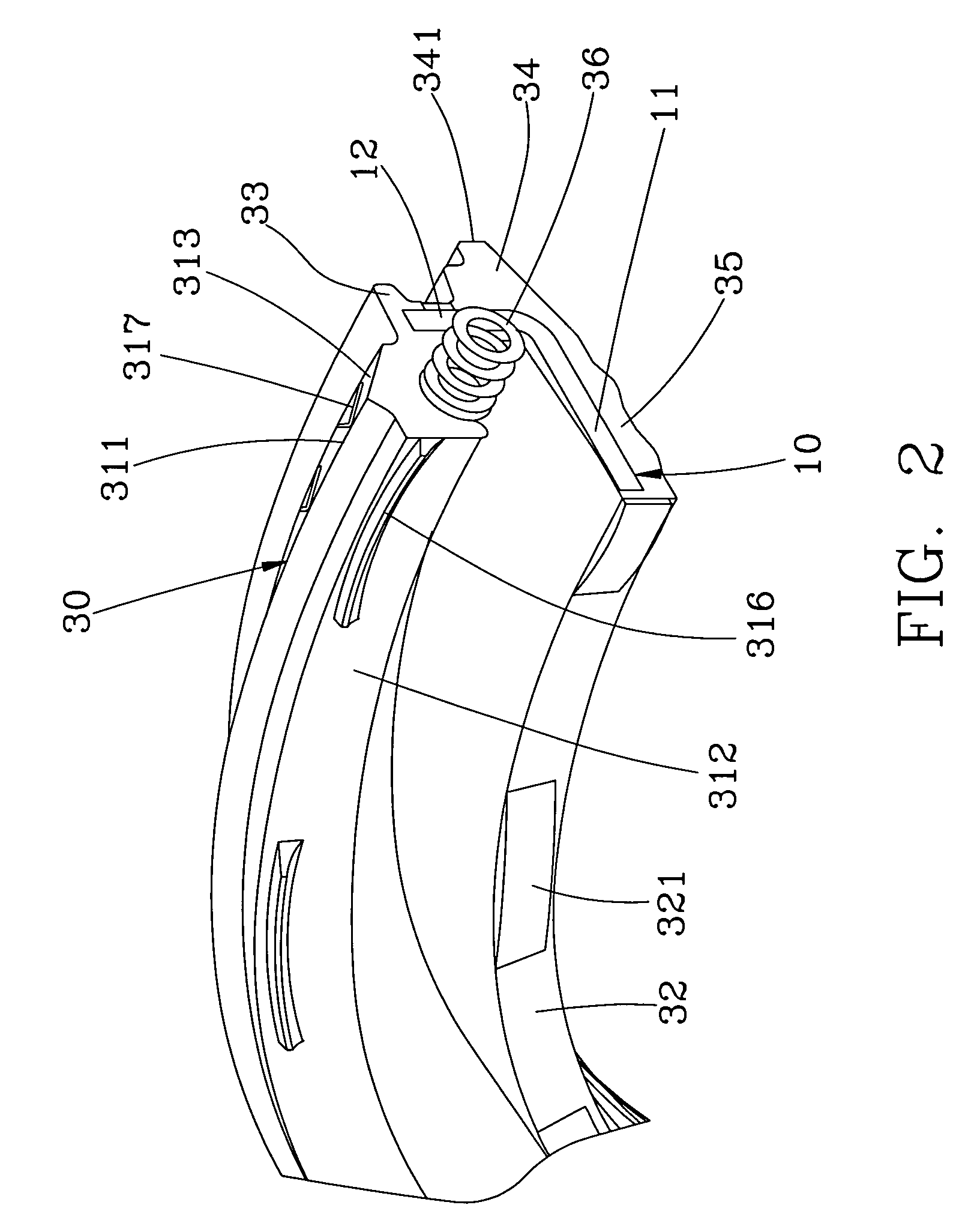

Sealing device

A sealing device includes an inner race, an outer race capped on and rotatable relatively to the inner race, a rubber oil seal mounted between the inner race and the outer race, a lubricating oil received between the inner race and the outer race, radiation holes formed in the outer race, and a spoiler provided between the inner race and the outer race for causing convection of the lubricating oil to lower the temperature of the lubricating oil upon rotation of the outer race relatively to the inner race.

Owner:NAK SEALING TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com