Patents

Literature

87results about How to "Reduce operating noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

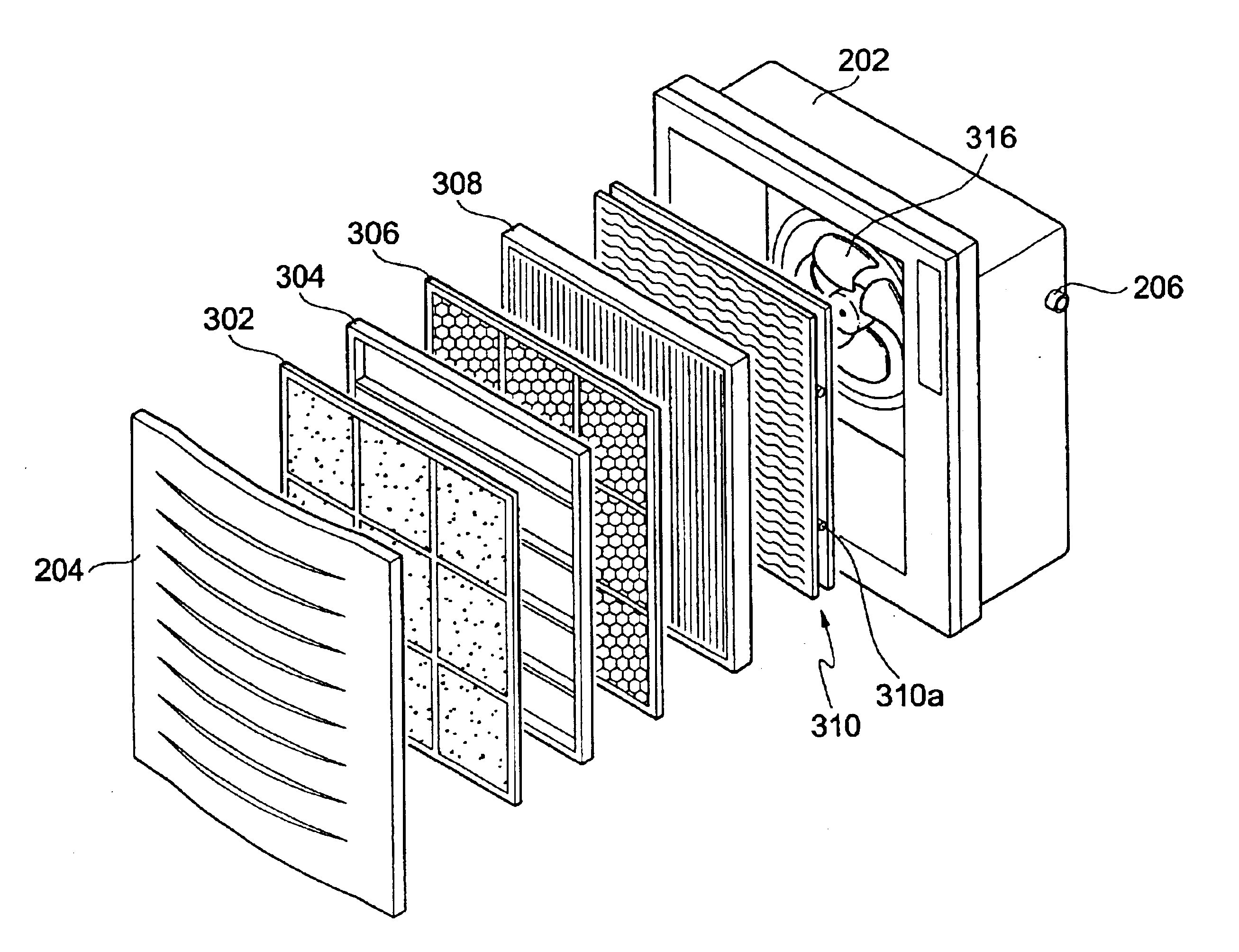

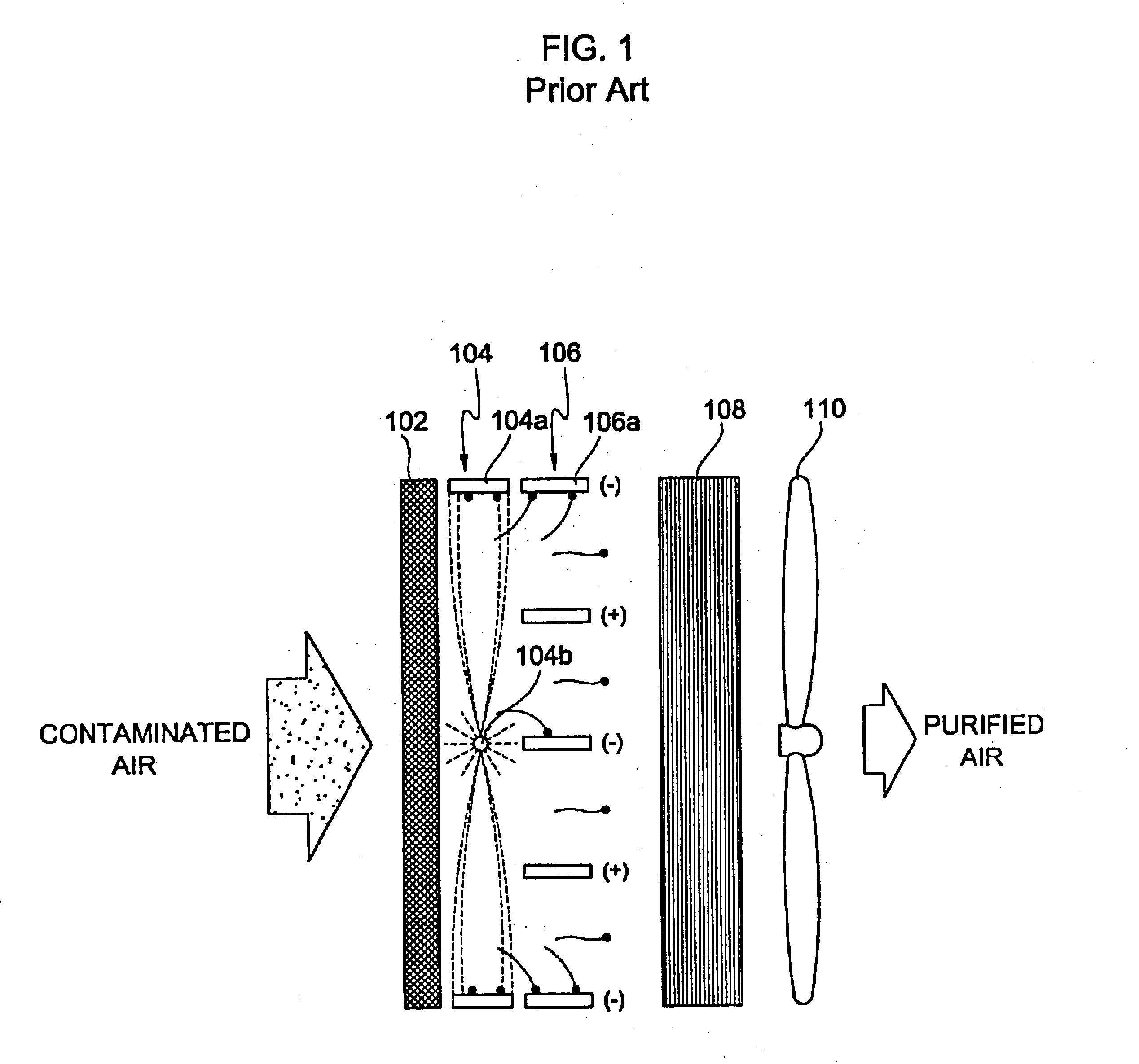

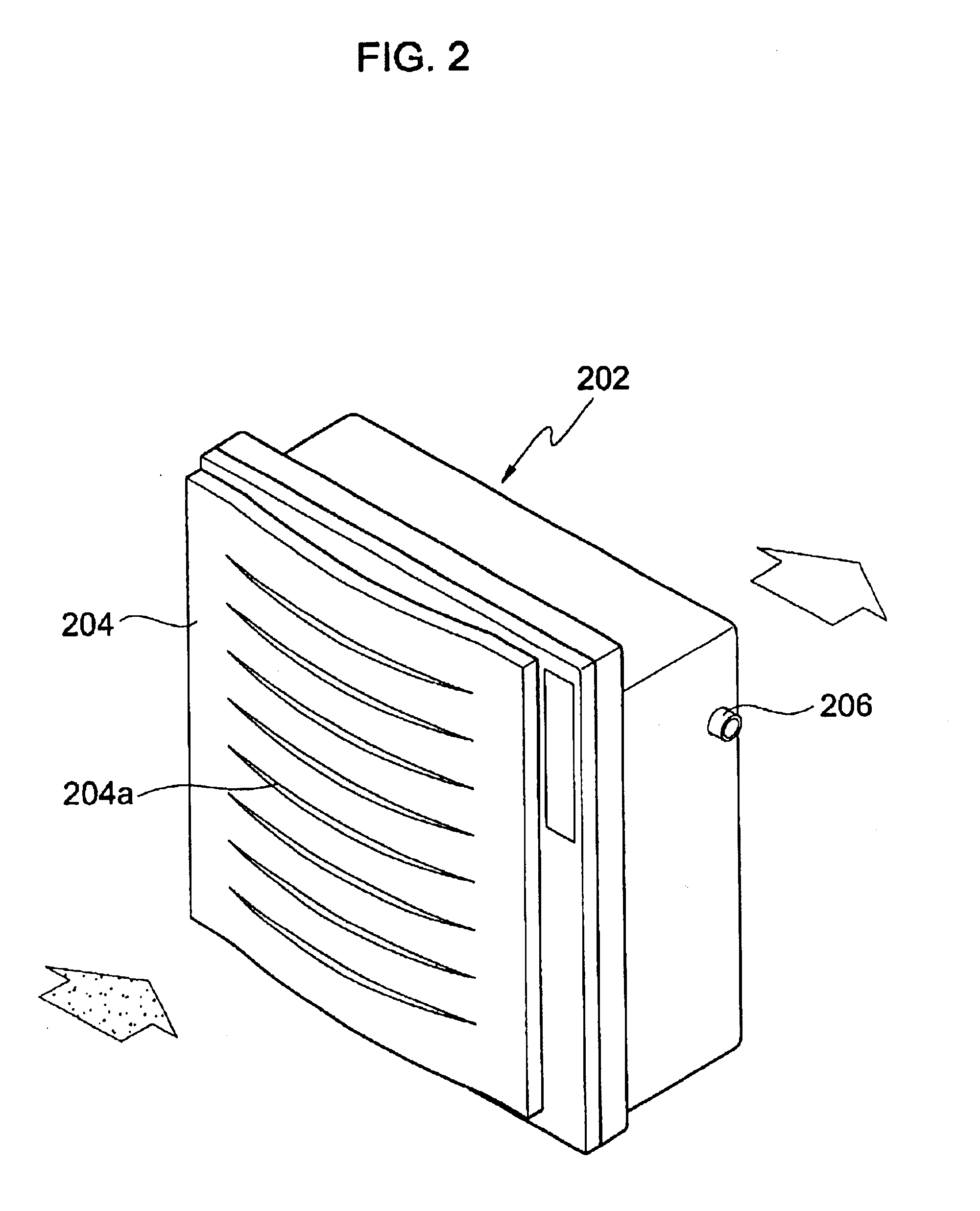

Air purifier

InactiveUS6913637B2Minimizing air pressure lossReduce operating noiseCombination devicesMechanical apparatusPollutantEngineering

An air purifier includes a main body defining an air passage therein to allow sucked air to pass therethrough prior to being discharged, and a first filter installed in the main body to be switched between a closed state and an open state. The first filter removes contaminants from the sucked air in the closed state, and allows the sucked air to pass through the air passage in the open state. The air purifier may include a main body to suck and discharge air, with a bypass passage formed in the main body so that the bypass passage is opened or closed by a door, and a first filter installed in the main body. The sucked air passes through the first filter prior to being discharged when the door is closed, and passes through the bypass passage prior to being discharged when the door is opened.

Owner:SAMSUNG ELECTRONICS CO LTD

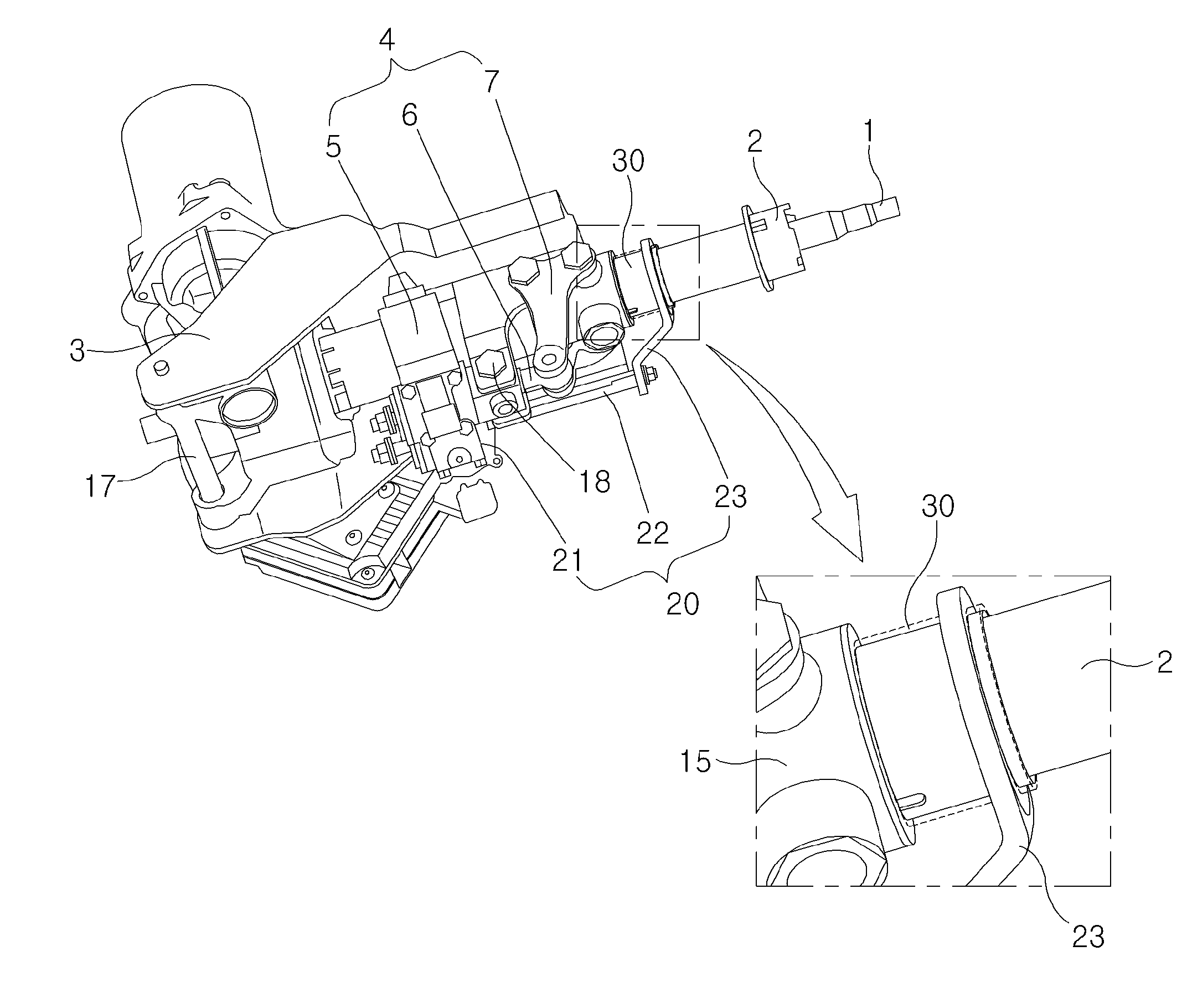

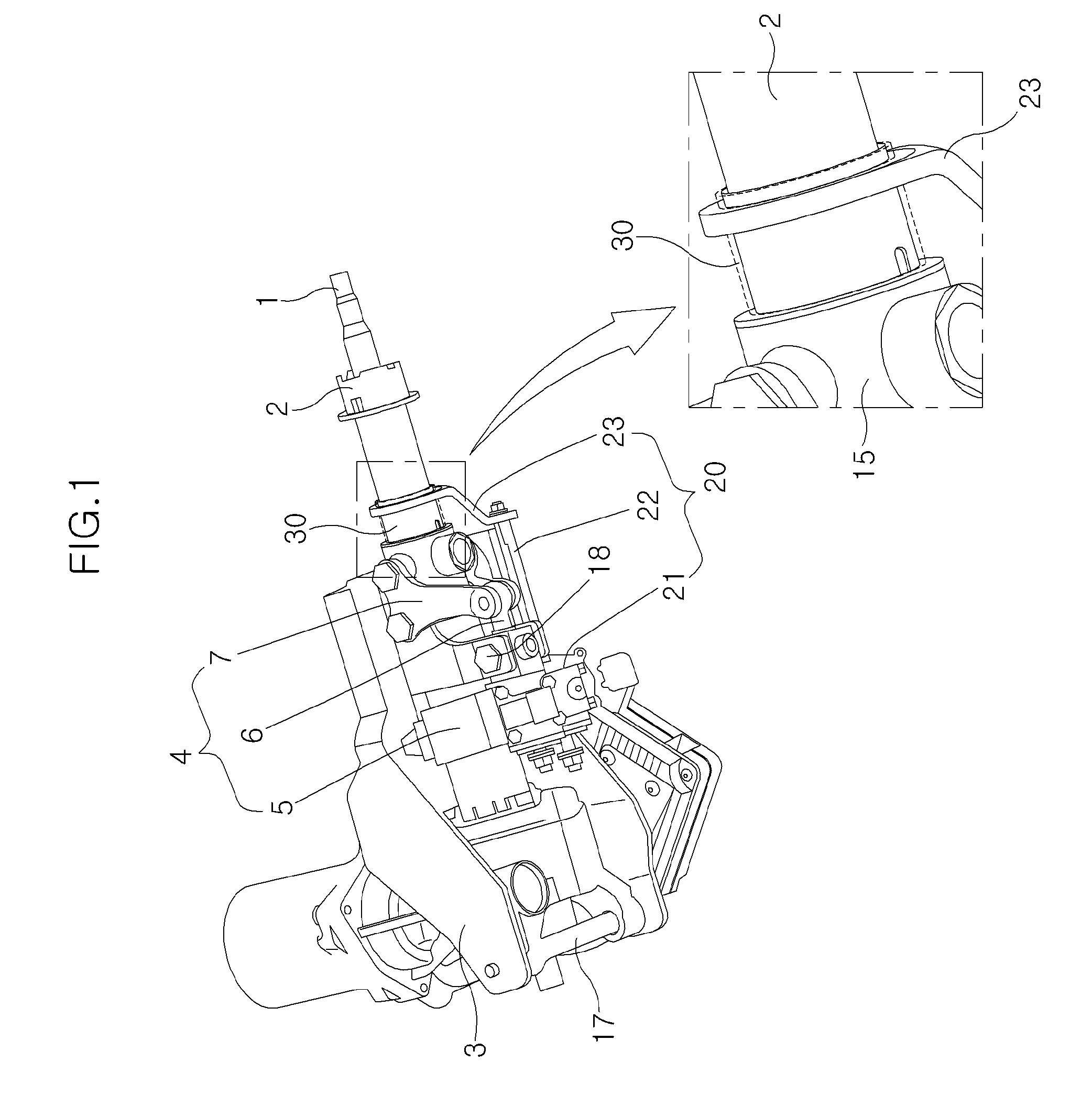

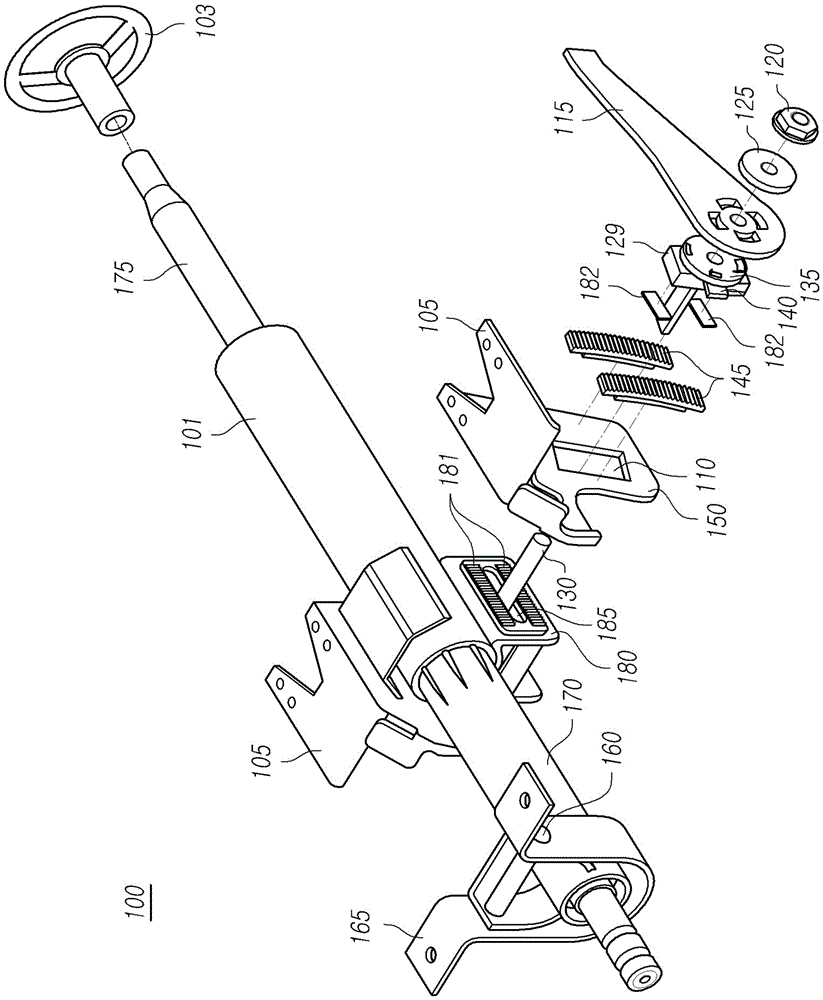

Lower type motor driven column apparatus

ActiveUS20110162904A1Easy to useSave fuelElectrical steeringSteering columnsSteering wheelMotor drive

A lower type motor-driven column apparatus includes a tilt unit having a column tube and a tilt link forming a plurality of hinge fixed points in order to tilt up / down a steering wheel by vertical motion generated with rotation due to straight motion of a tilt rod through a tilt motor, a telescopic unit implementing telescopic movement pushing or pulling the column tube by means of straight motion of a tele-rod through a tele-motor, and a shock-absorbing member absorbing and attenuating a shock stroke of the column tube, ahead of the tilt unit and the telescopic unit, in which the operation mechanism of the tilt unit and the operation mechanism of the telescopic unit are individually implemented, such that the MDPS can be easily used for middle-sized and large-sized vehicles which are difficult to use the upper type and it is possible to save fuel of the middle-sized and large-sized vehicles.

Owner:HYUNDAI MOTOR CO LTD +2

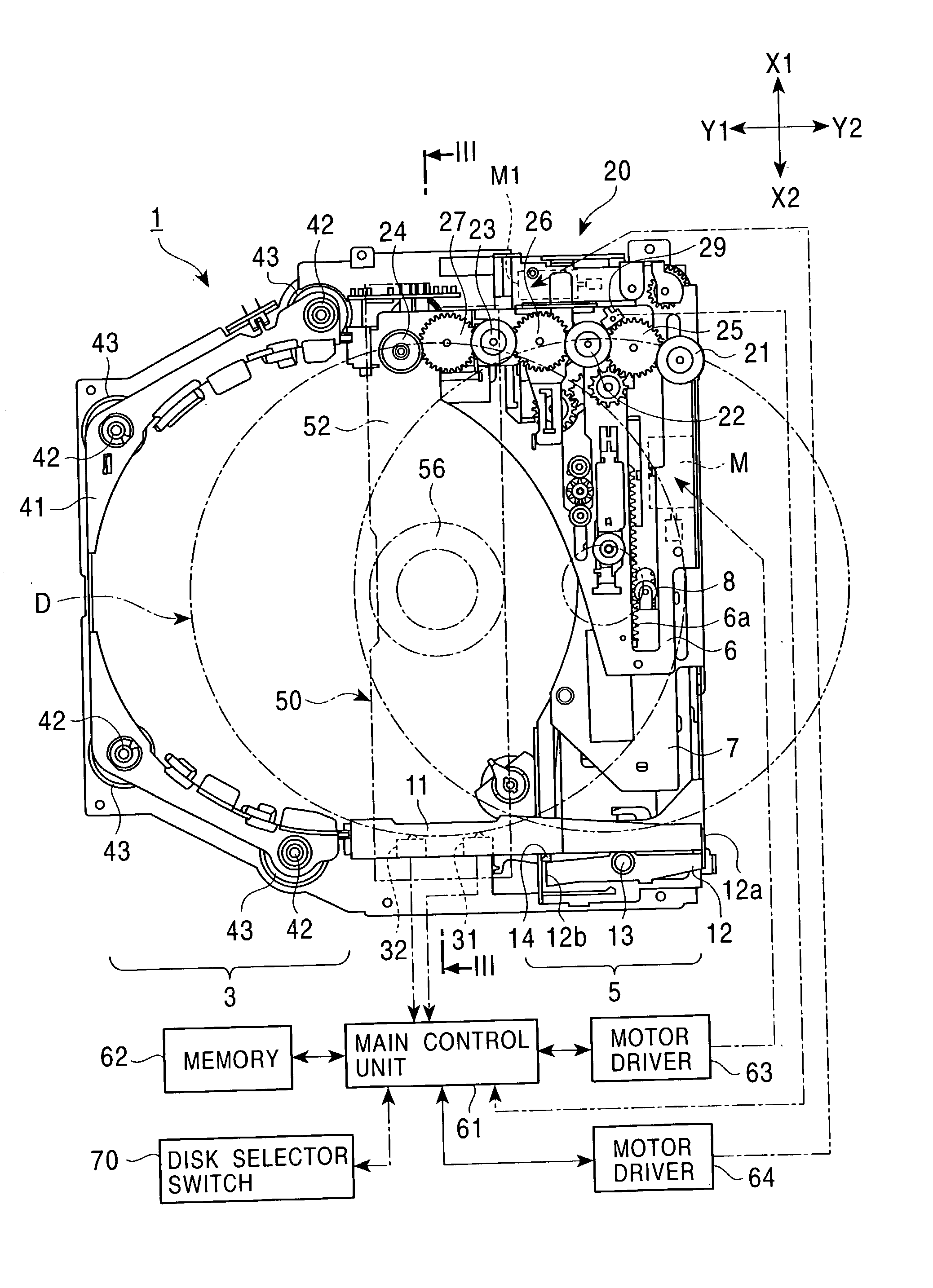

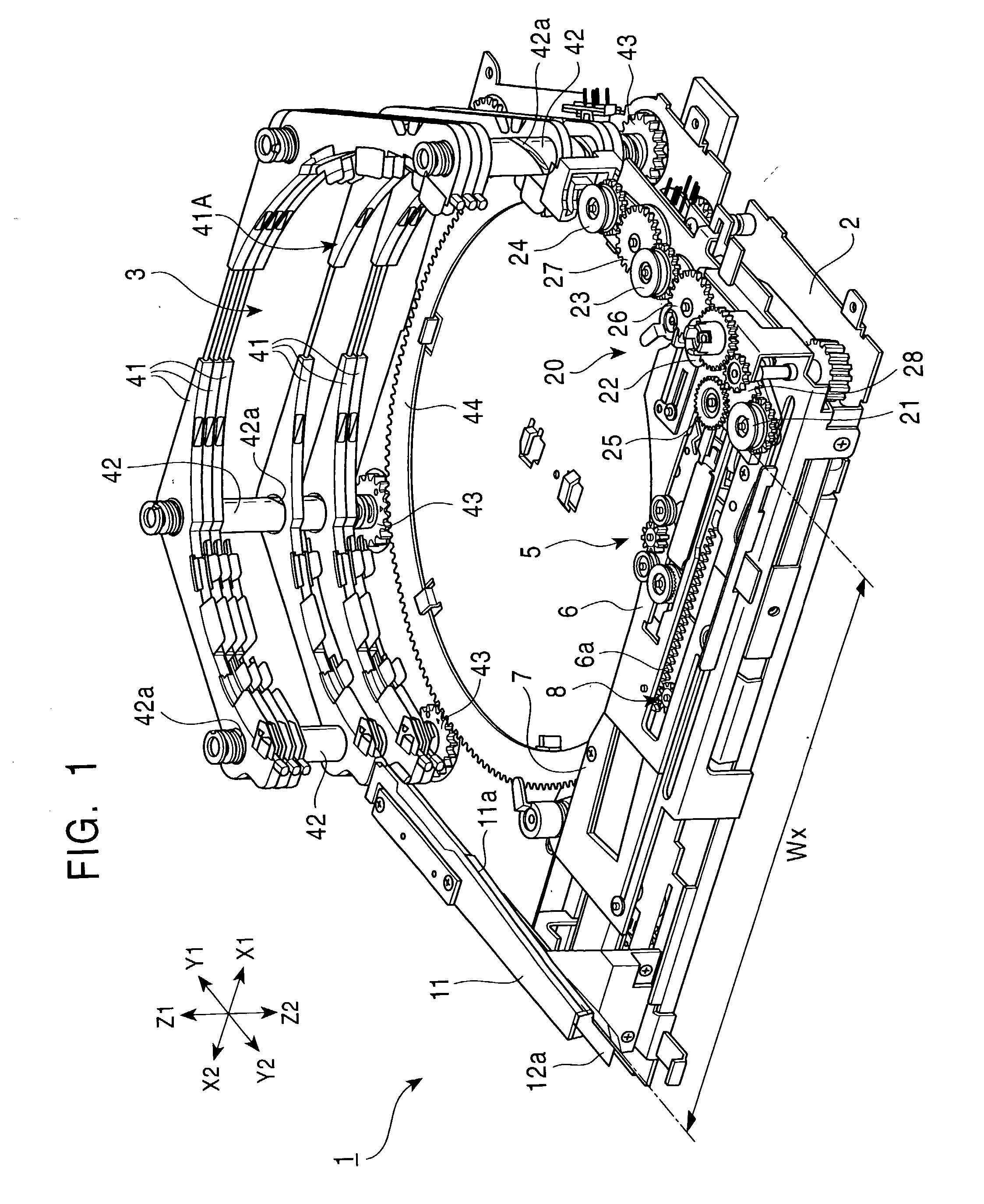

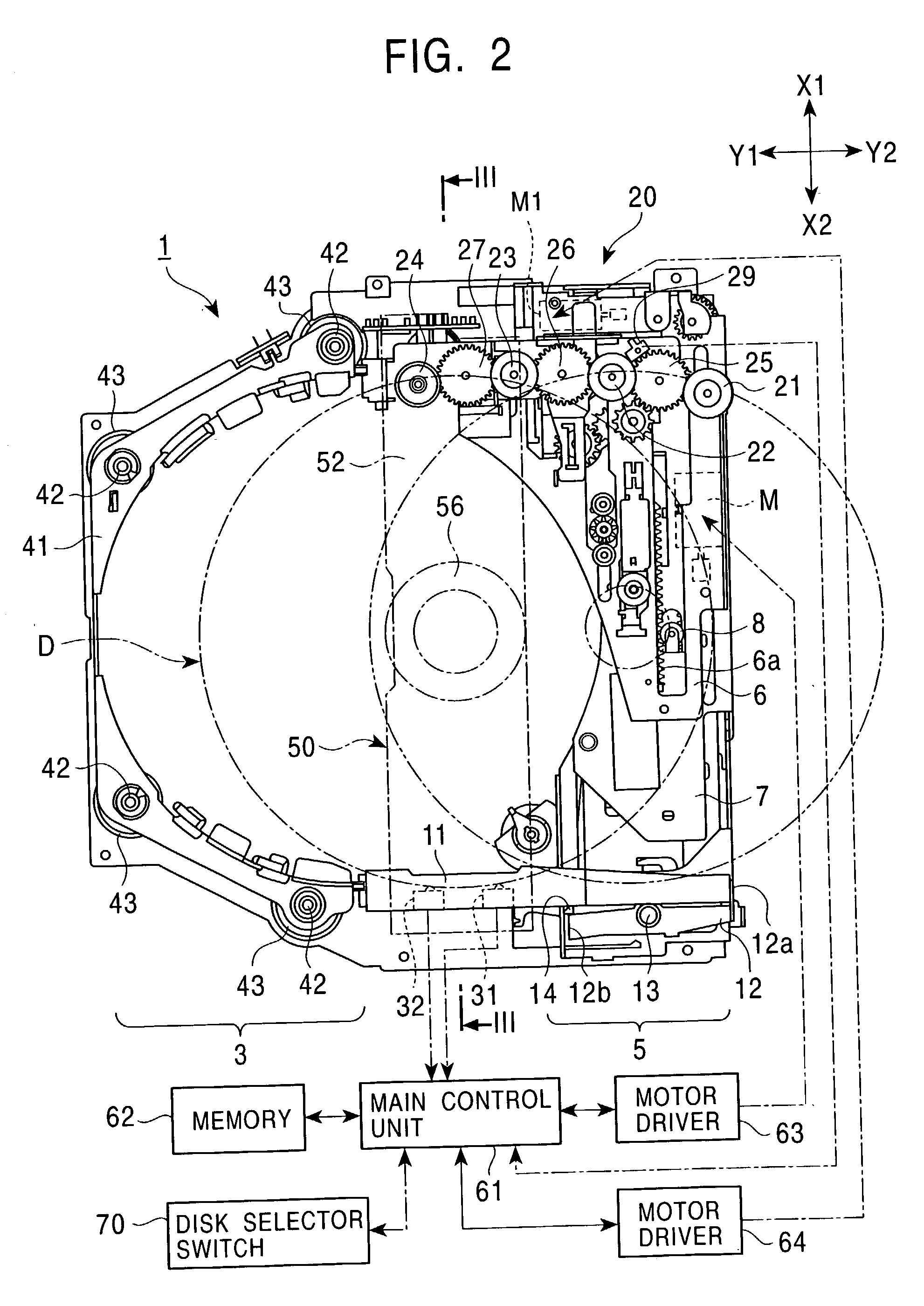

Disc device

InactiveUS20030112716A1Evenly loadedReduce operating noiseRecord information storageRecord carrier contruction detailsLow speedMechanical engineering

A disc device comprising a transfer unit operable to provide a transferring force to a disc inserted from the outside to transfer the disc into a storage area in the device, a sensor unit for detecting the position of the inserted disc, and a control unit for controlling a operational speed of the transfer unit. The control unit controls the operational speed of the transfer unit in the disc loading direction at a low-speed until the disc inserted from the outside reaches the transfer unit. The control unit then adjusts the operational speed of the transfer unit in the disc loading direction from a low-speed to a high-speed when the sensor unit detects that the disc is inserted into the position in which a transferring force from the transfer unit is given to the disc, or after a predetermined period of time has elapsed. Accordingly, the disc device reduces operation noise and resistance when the disc is inserted.

Owner:ALPINE ELECTRONICS INC

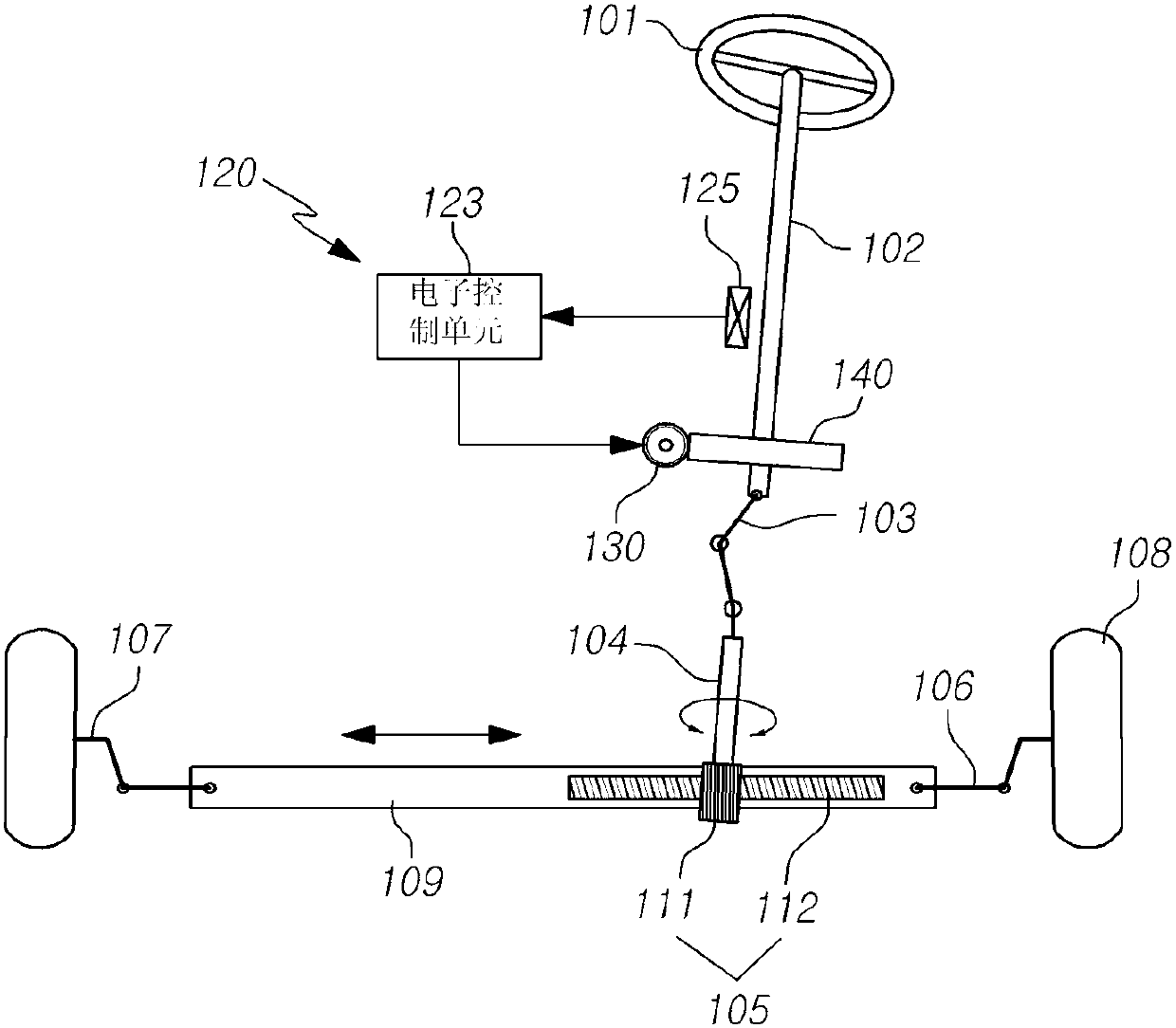

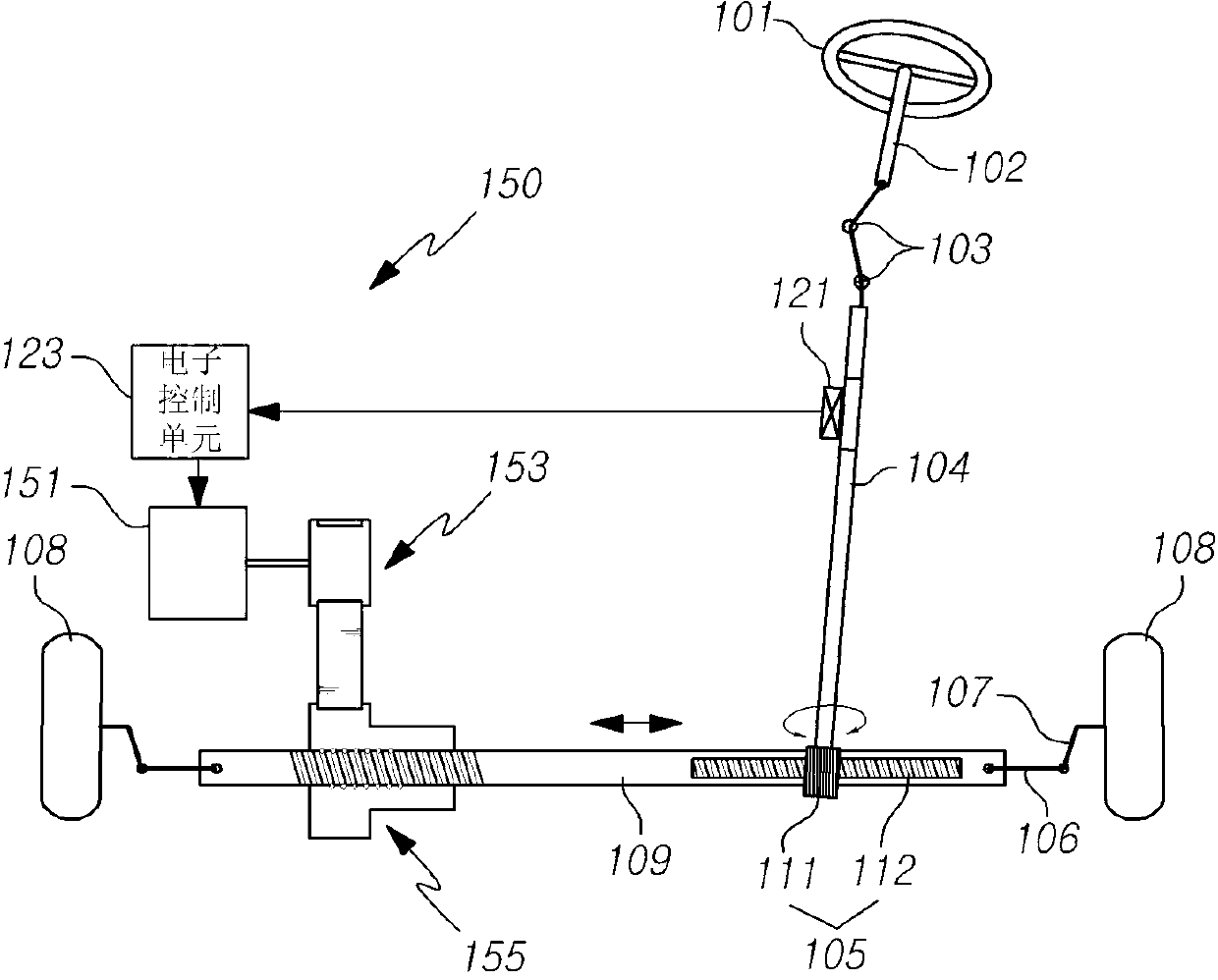

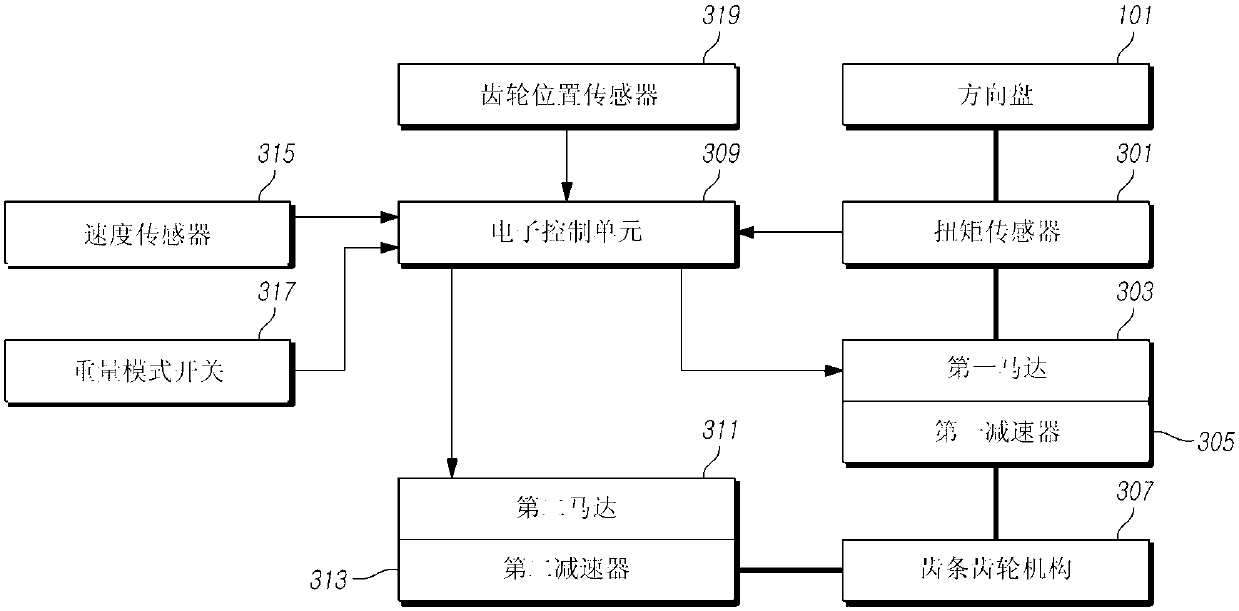

Electric power steering apparatus for vehicle

ActiveCN103303361AIncreased durabilityReduce loadSteering linkagesAutomatic steering controlElectric power steeringControl signal

An electric power steering apparatus for a vehicle, includes: a first auxiliary steering unit for assisting with steering power while rotating a steering shaft in a forward or reverse direction with a driving power of a first motor; a second auxiliary steering unit for assisting with steering power while sliding a rack bar in one or an opposite direction with a driving power of a second motor; a torque sensor for detecting a rotary torque of the steering shaft; a speed sensor for detecting a speed of the vehicle; and an electronic control unit for transmitting a target current value control signal to the first motor and the second motor respectively in response to input signals input from the torque sensor and the speed sensor, respectively.

Owner:HL MANDO CORP

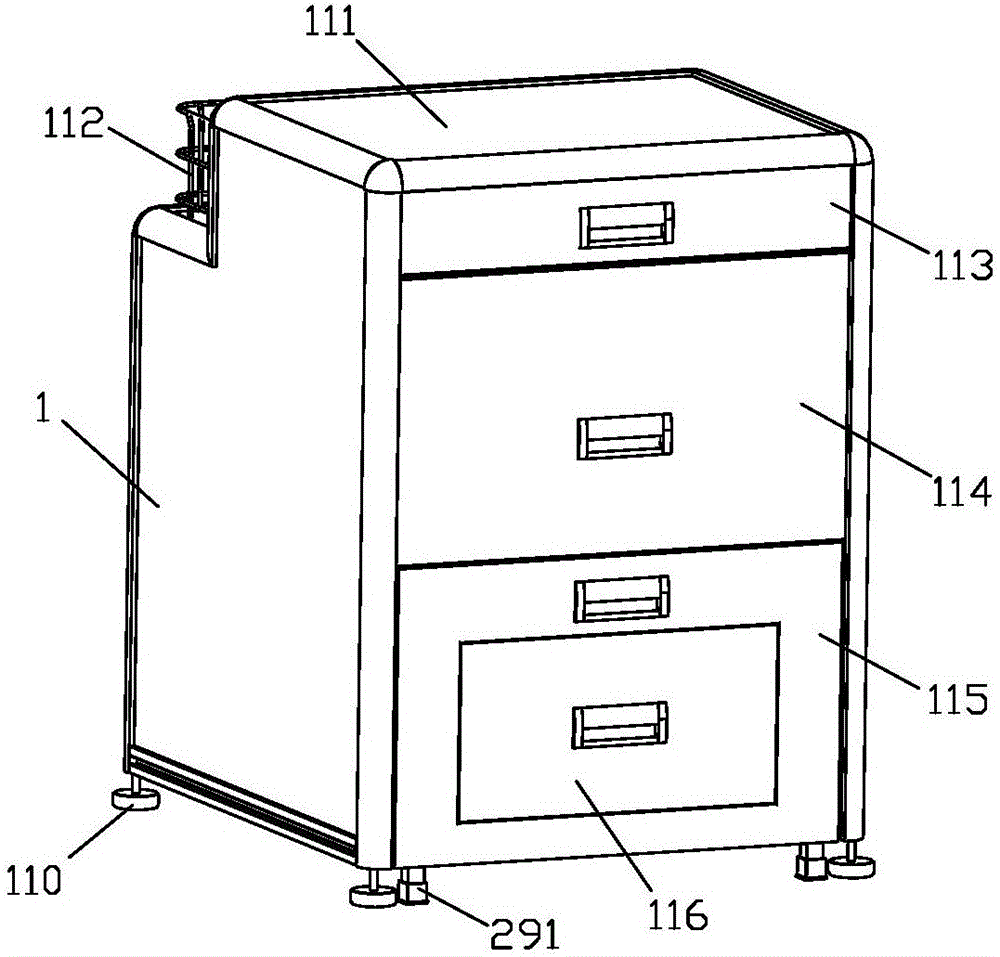

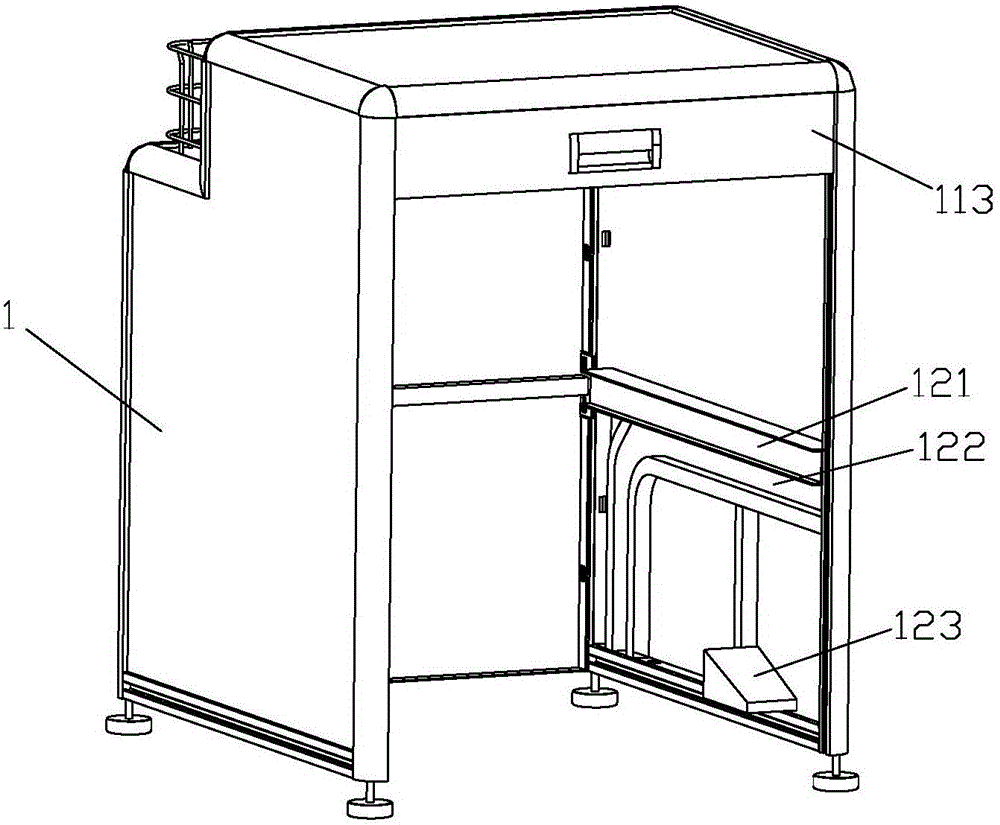

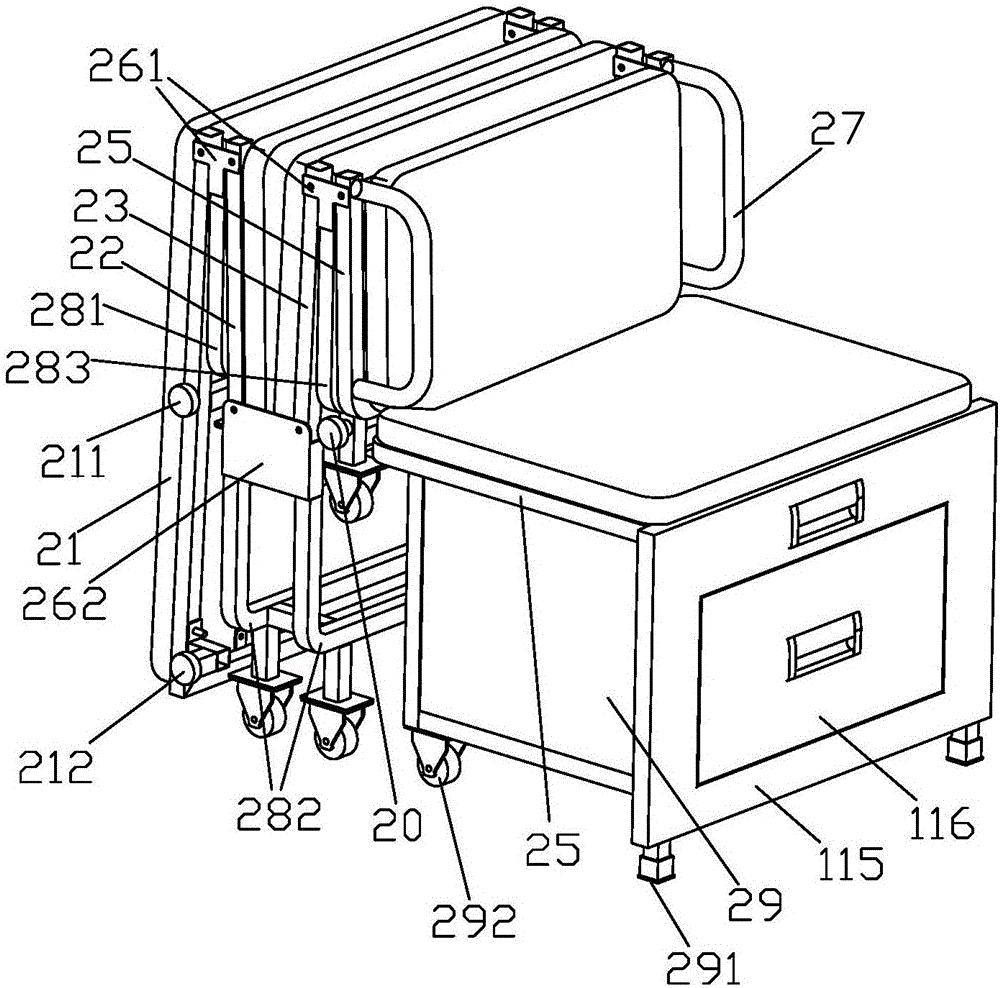

Multi-functional cabinet

The invention discloses a multi-functional cabinet. The multi-functional cabinet comprises a cabinet body and a folding bed which can be accommodated in the cabinet. The folding bed comprises a tail board, a first pinboard, a second pinboard, a third pinboard and a head board, wherein the tail board, the first pinboard, the second pinboard, the third pinboard and the head board are hinged in sequence. A tail part bed leg is arranged on the hinged portion between the tail board and the first pinboard, a middle part bed leg is arranged on the hinged portion between first pinboard and the second pinboard, and a head part bed leg is arranged on the hinged portion between the second pinboard and the third pinboard. A sliding structure is arranged between the cabinet body and the folding bed for facilitating pulling out of the folding bed from the cabinet or pushing the folding bed into the cabinet, and a folding-aiding structure is also arranged between the cabinet body and the folding bed for facilitating the folding operation of the folding bed. The arrangement of the sliding structure and the folding-aiding structure between the cabinet body and the folding bed enhances the convenience of the use of the folding bed, the multi-functional cabinet has a storage function, seats or beds can also be assembled as required, and the multi-functional cabinet thus has preferably marketing and application prospects.

Owner:湖南德一智能智造科技有限公司

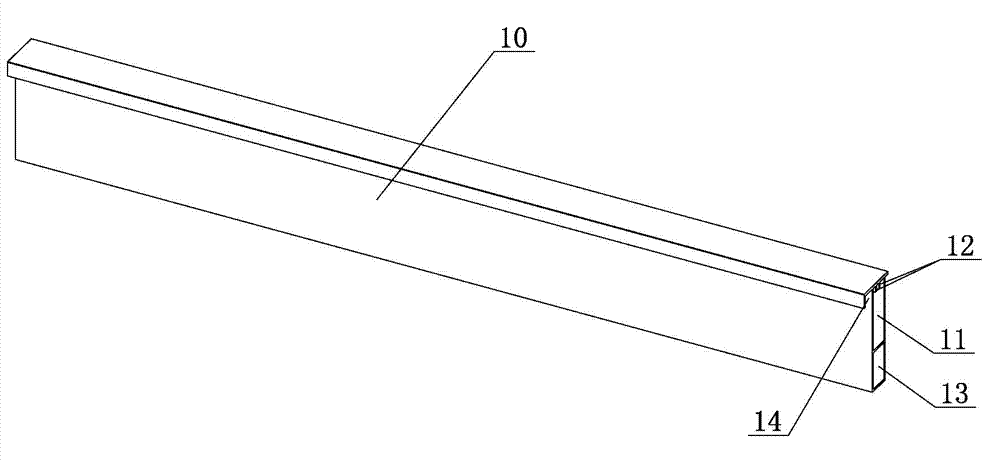

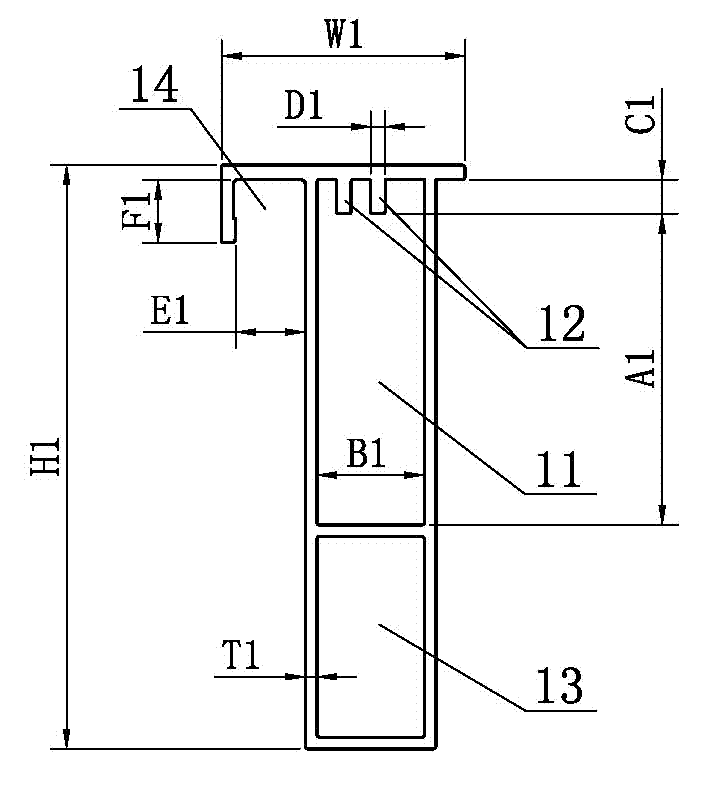

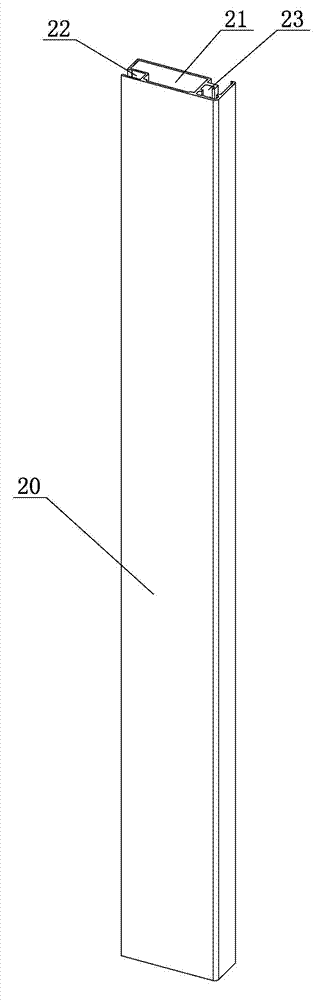

Control cabinet door frame and embedded frame type profile screen cabinet door

ActiveCN103573107APrevent rustReduce operating noiseCasings/cabinets/drawers detailsWing framesEmbedded systemBatch production

The invention relates to a control cabinet door frame and an embedded frame type profile screen cabinet door. The control cabinet door frame profile comprises a horizontal cabinet door frame profile and a vertical cabinet door frame profile, and is provided with piece connecting cavities, a strengthening rib, door sheet clamping mouths and a door spindle cavity. The embedded frame type profile screen cabinet door comprises a cabinet door frame and a glass door sheet, wherein the cabinet door frame is formed by the control cabinet door frame profiles which are connected through door frame plug-in components; and a retractable door spindle is arranged on the door frame. The control cabinet door frame and the embedded frame type profile screen cabinet door have the benefits that the control cabinet door is produced by the aluminum alloy door frame and the glass door sheet, so that rust is not generated, the operation noise is small, and the operating condition of equipment in the control cabinet can be observed without opening the cabinet door; the cabinet door is mounted on the control cabinet in an embedded mode, the door spindle is not exposed, and the appearance is attractive; and the cabinet door is produced by the profiles as well as universal door frame plug-in components and the door spindle, and accordingly, the cabinet door is convenient to produce and assemble and suitable for industrialized batch production.

Owner:XINLITONGCHUANG TIANJIN ELECTRONICS EQUIP LLC

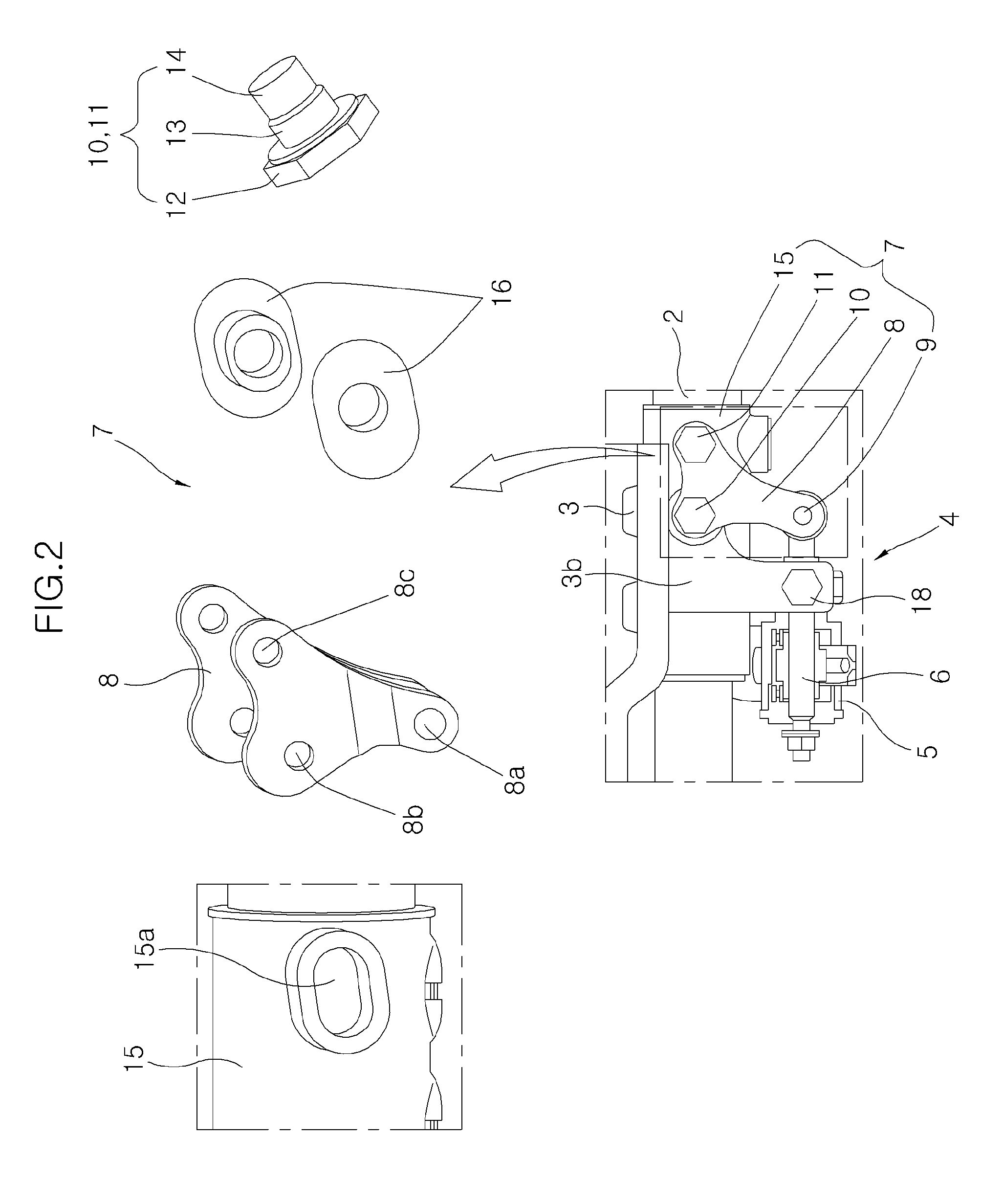

Structure of mounting bracket

InactiveUS20170167559A1Reduce operating noiseImproving vehicle dynamic controlJet propulsion mountingInternal combustion mountingVehicle dynamicsMechanical engineering

A structure of a mounting bracket that connects a vehicle body and a transmission is provided. The structure includes an outer pipe having an insulator disposed therein and the insulator includes a plurality of stoppers having curved portions and a protrusion formed at an inner top portion of an aperture of the insulator and directed downwards. An inner pipe is coupled in the aperture of the insulator and a core is press-fitted into the inner pipe. The inner pipe and the core abut each other by the protrusion. Accordingly, vehicle dynamics control and quasi-static motion performance are improved, and operational noise, vibration, and noise attributable to vibration are reduced. Since the outer pipe and the inner pipe are made of plastic, the weight of the structure is decreased. Further, a decrease in the gap between stoppers is achieved without a swaging process.

Owner:HYUNDAI MOTOR CO LTD

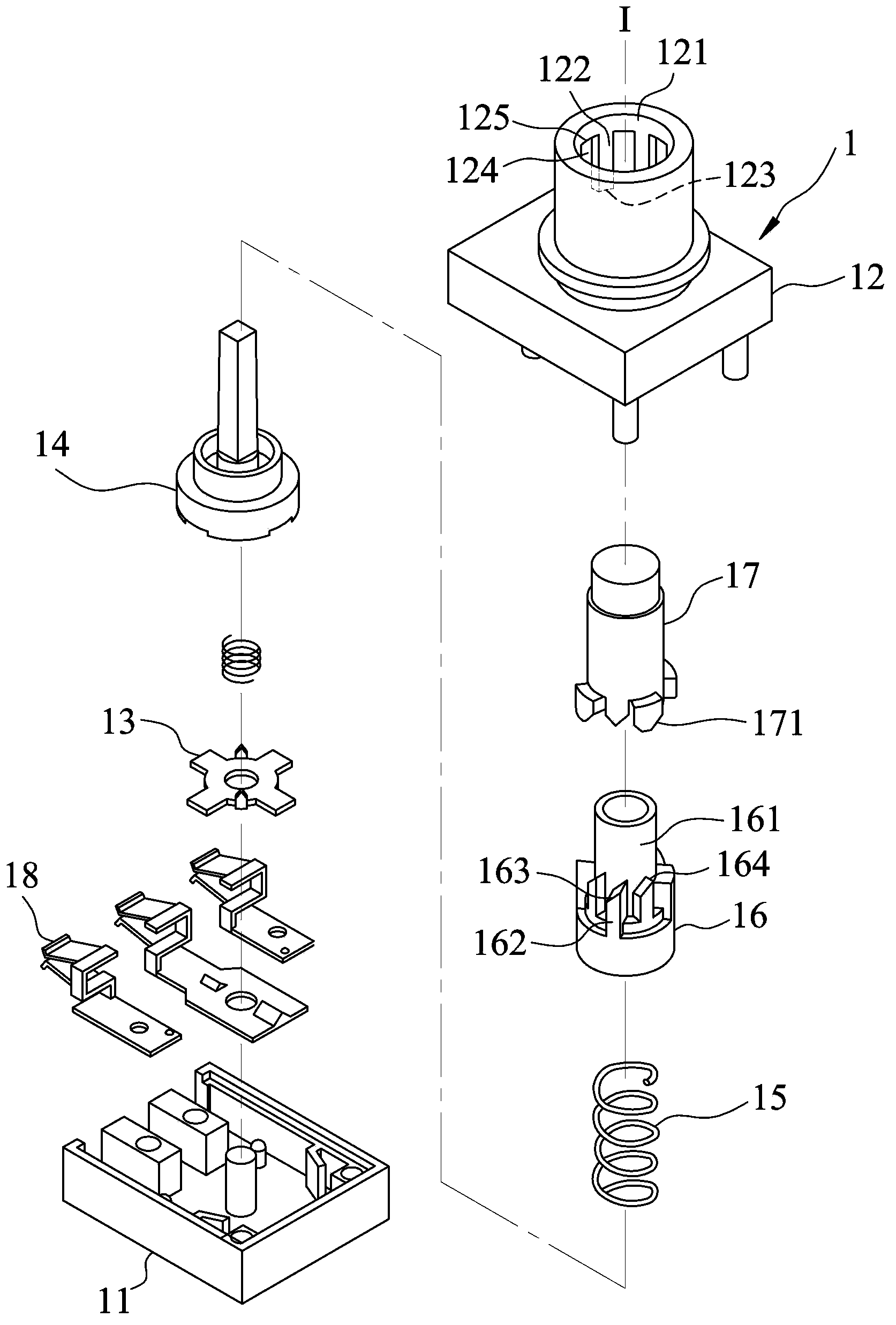

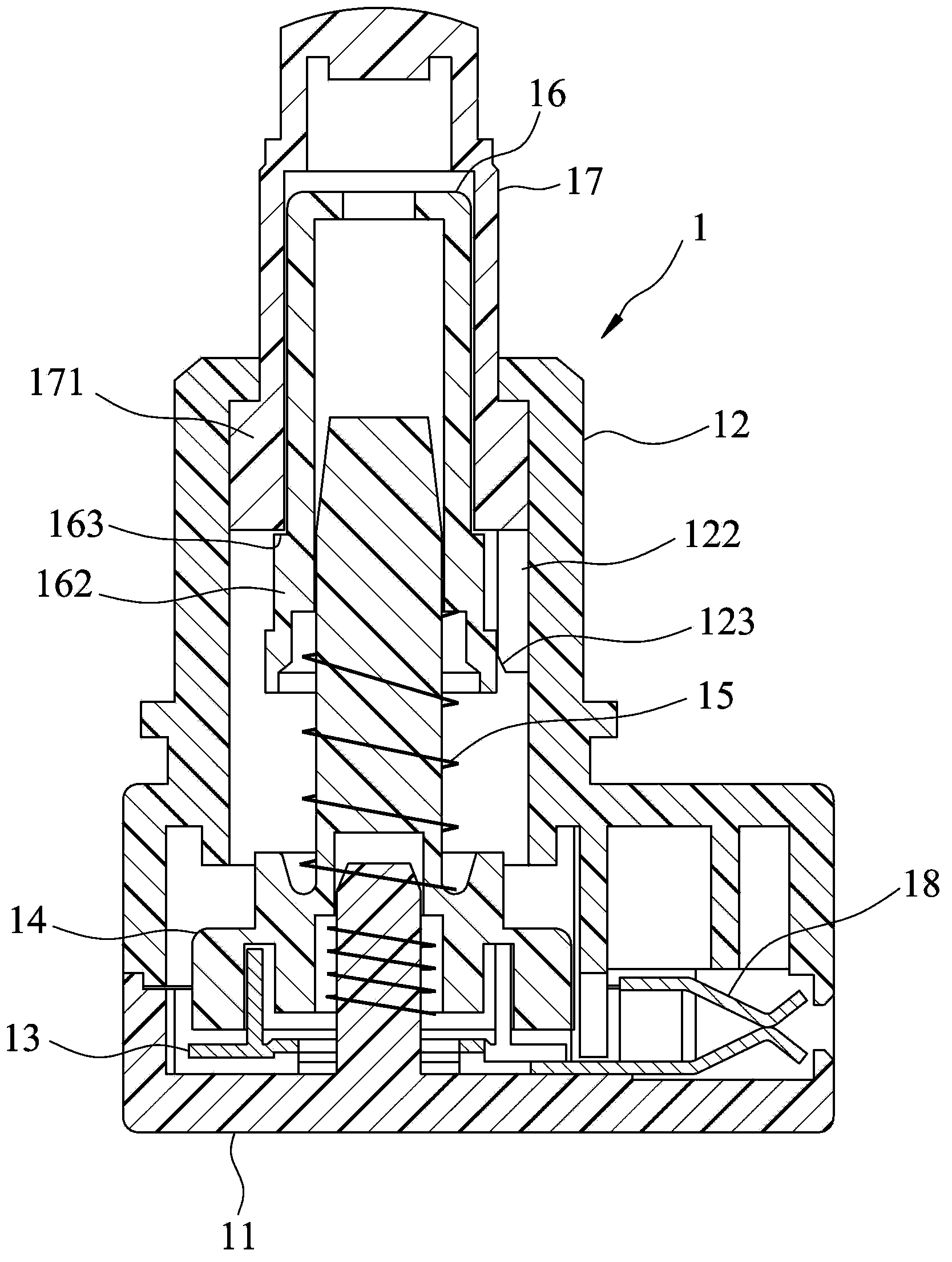

Pushbutton switch

InactiveCN104134563AReduce contact friction areaSimple structureContact operating partsLower limitEngineering

Owner:EXCEL CELL ELECTRONICS

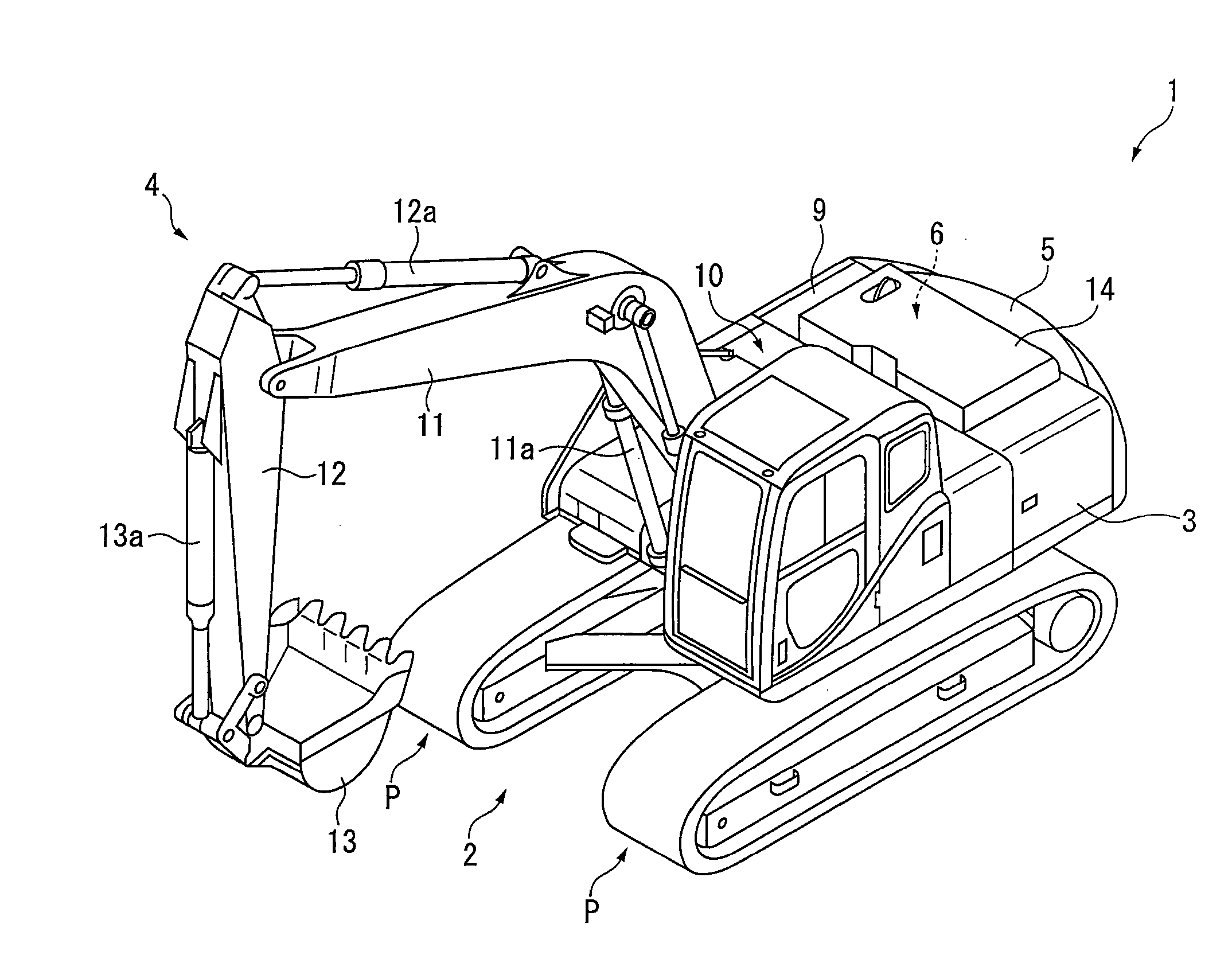

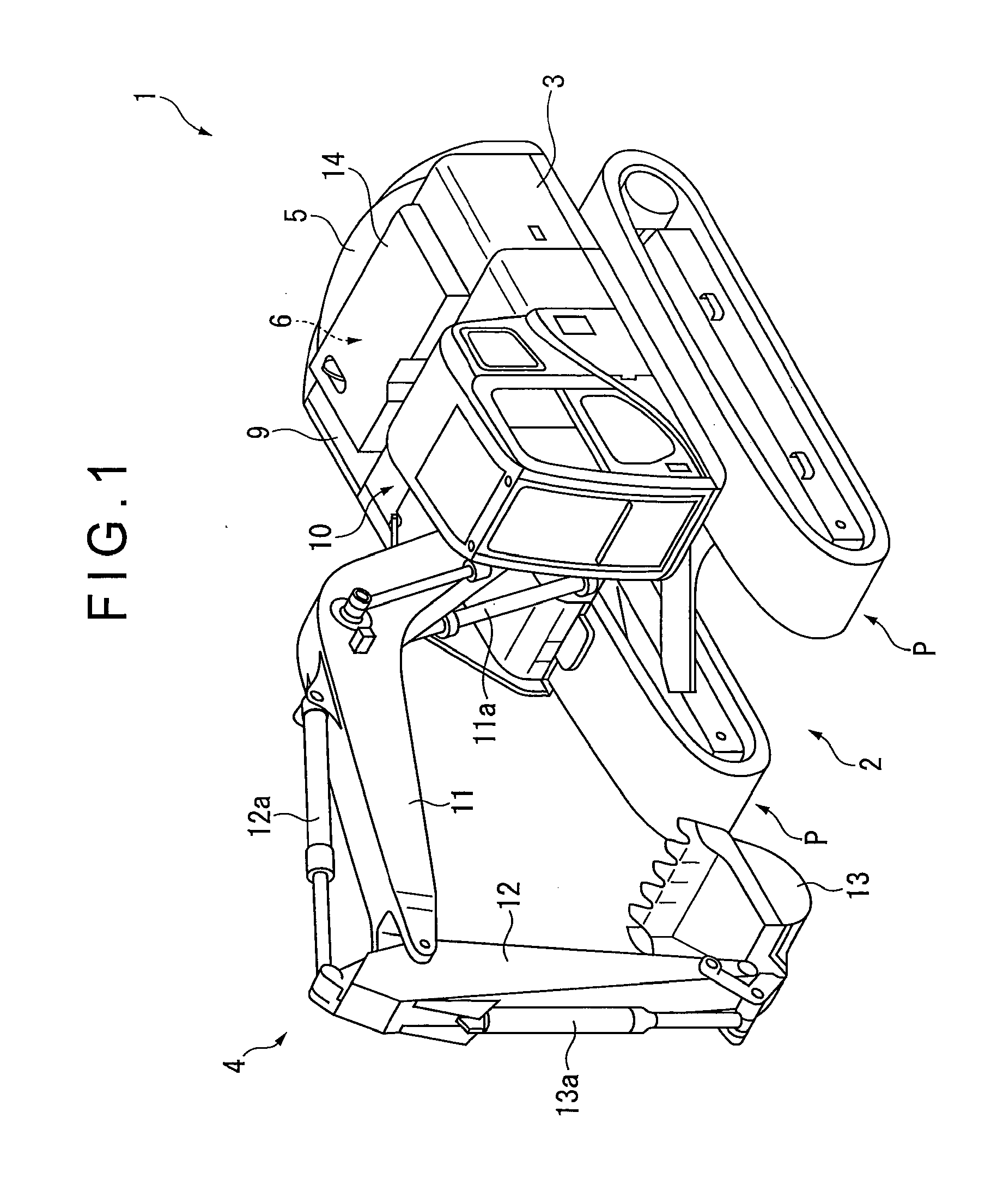

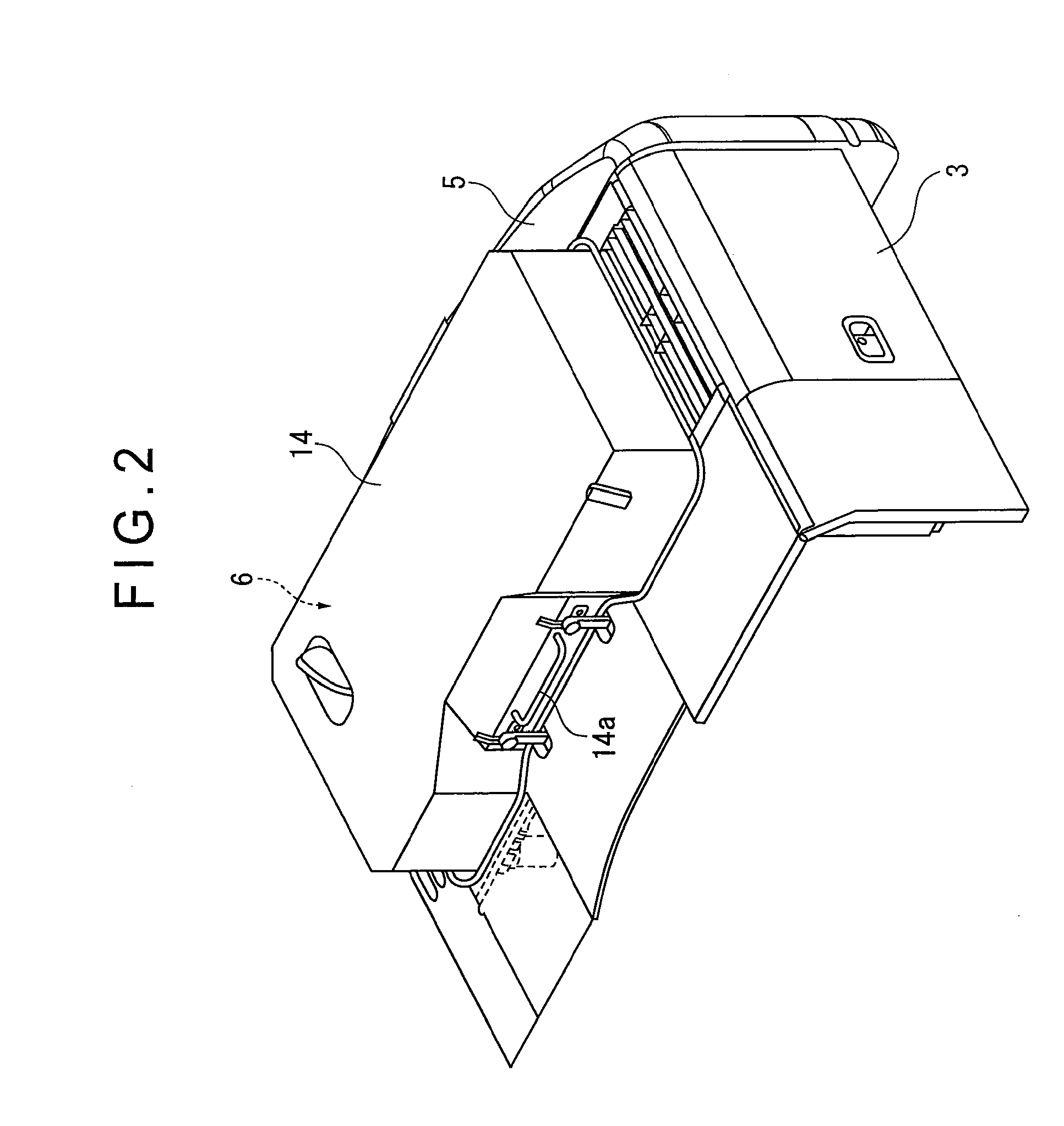

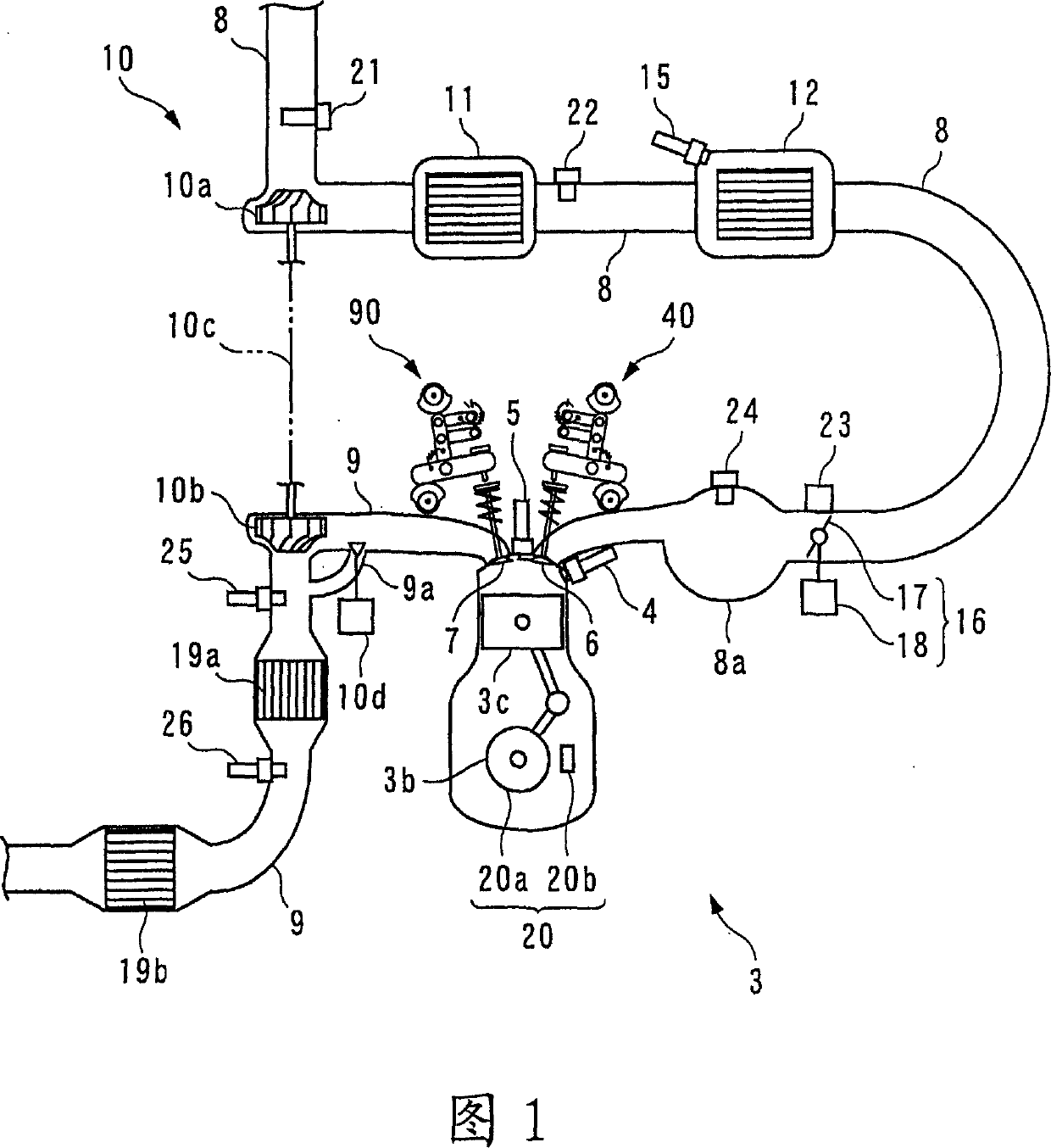

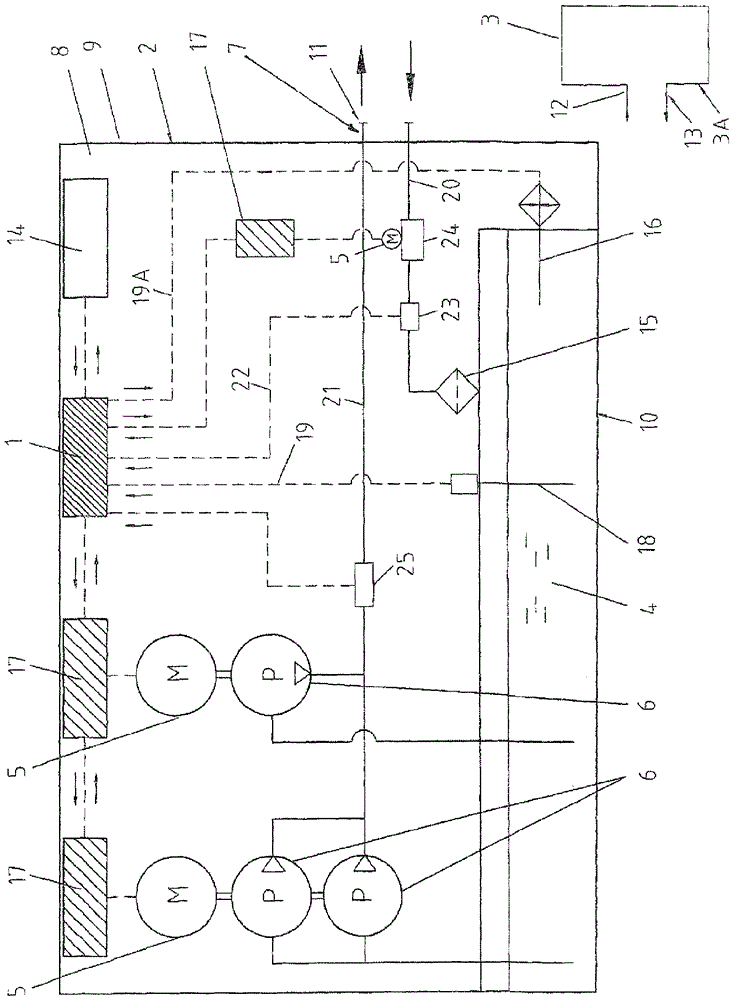

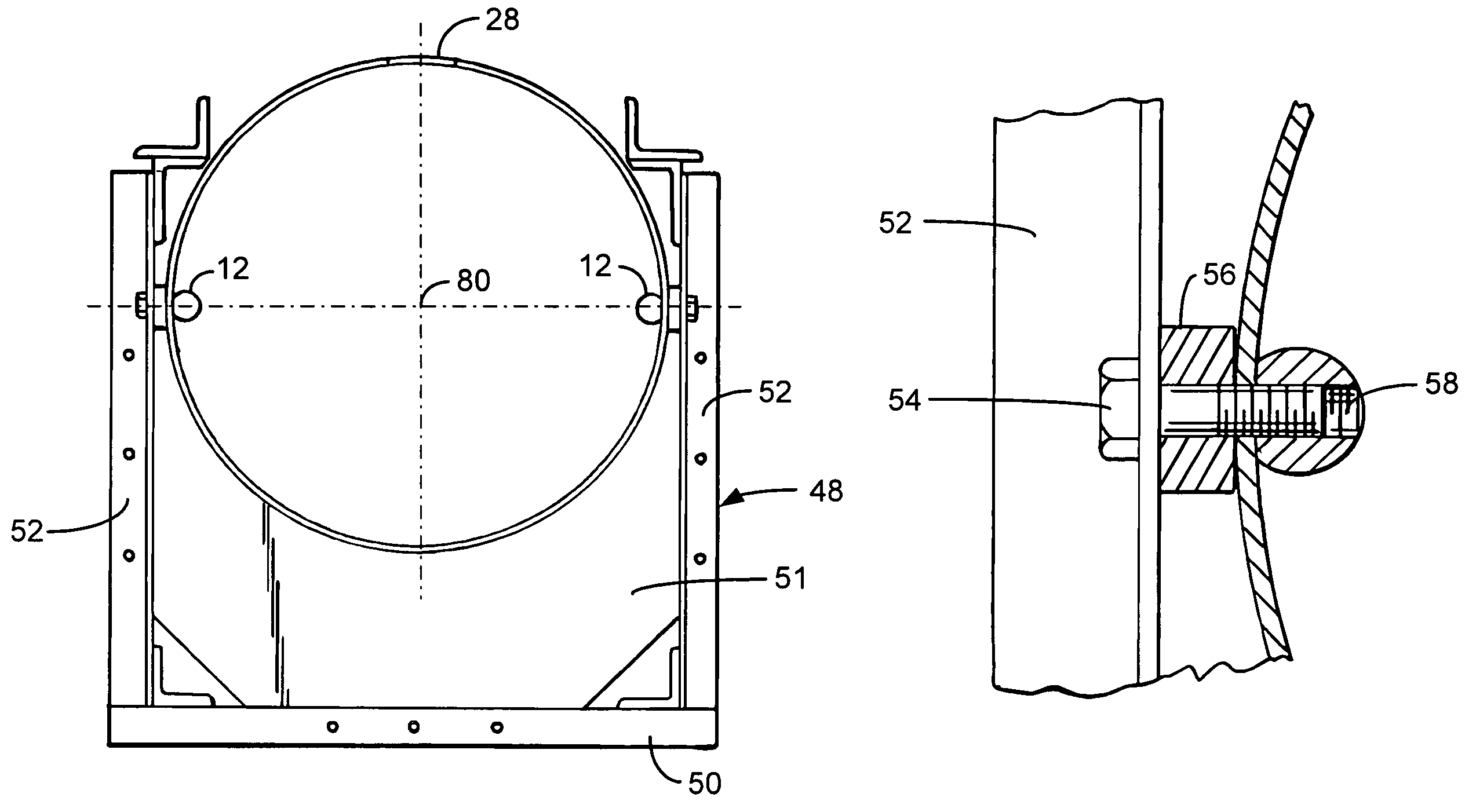

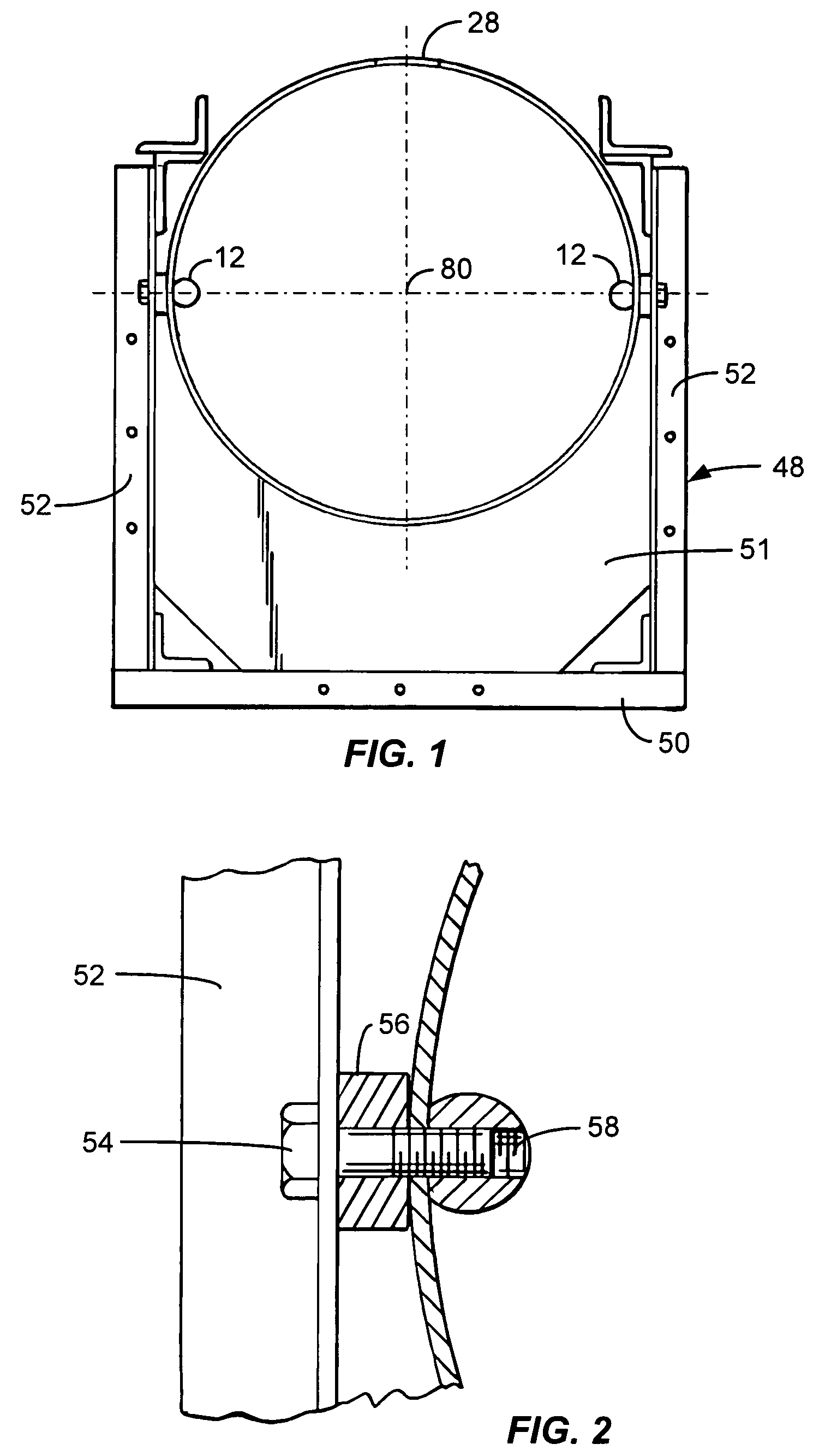

Cooling device and construction machine or working machine equipped with the same

ActiveUS20100200194A1Highly quiet operationReduce operating noisePump componentsAir coolingEngineering

Owner:KOMATSU LTD

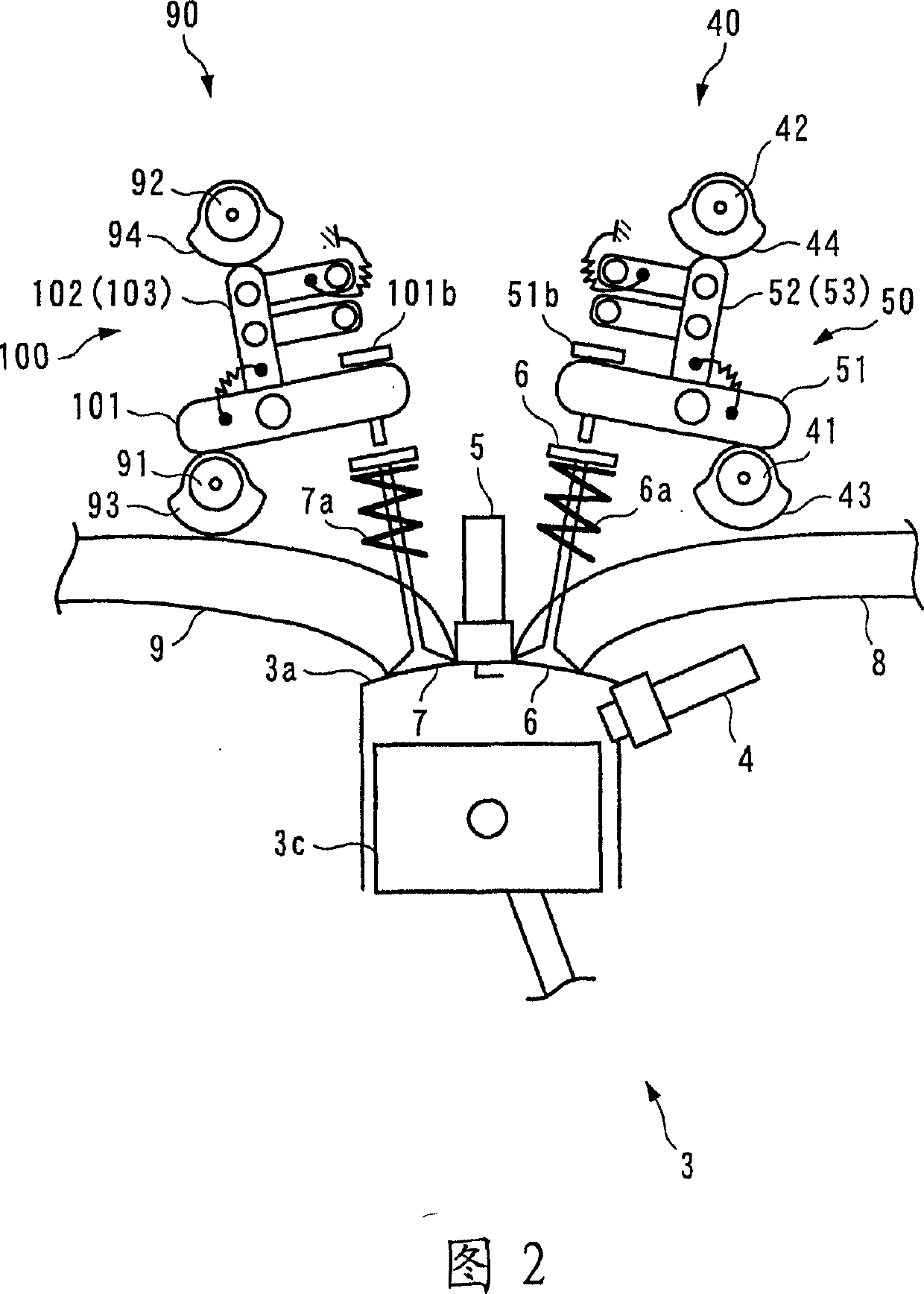

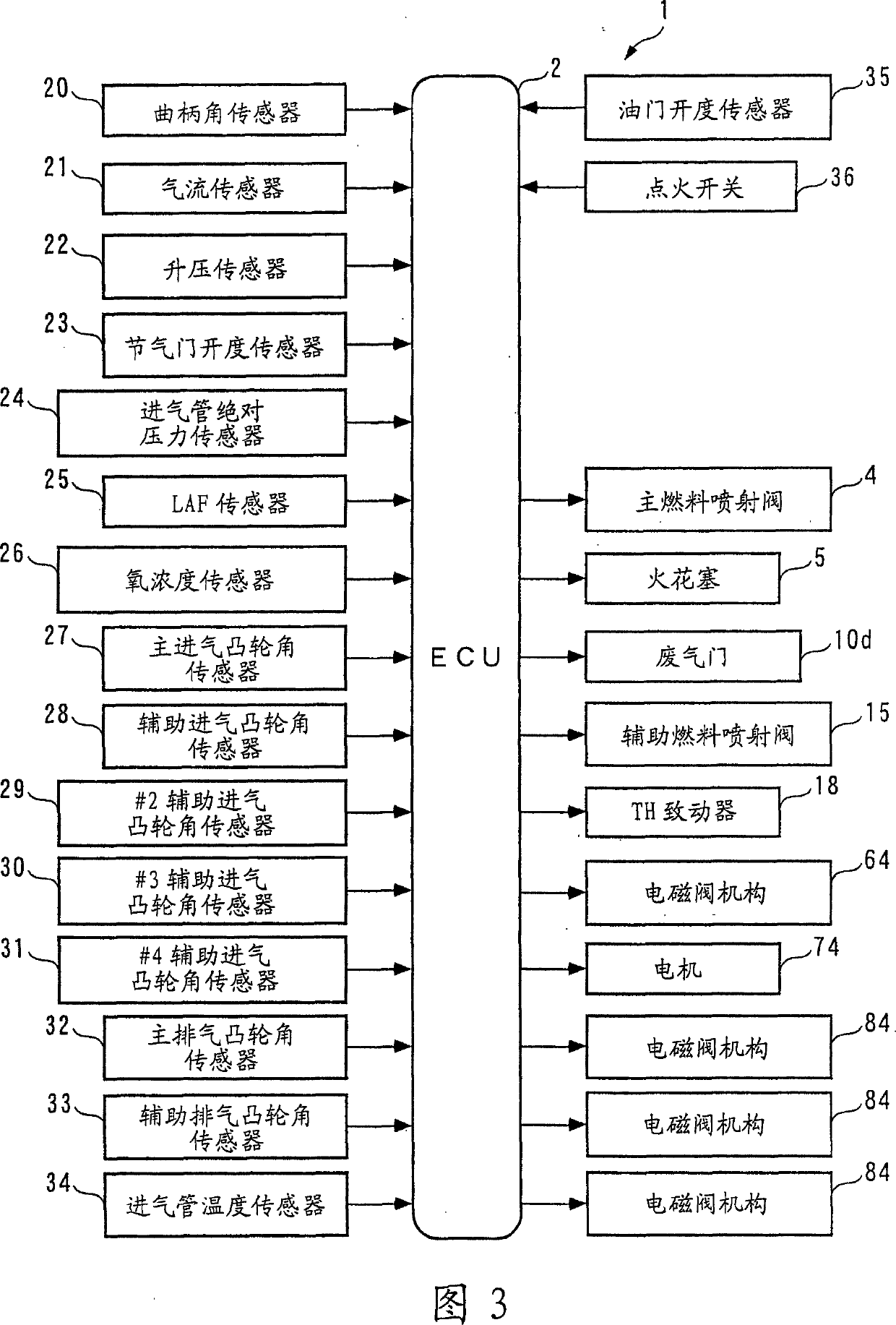

Intake air volume controller of internal combustion engine

InactiveCN1816688AReduce operating noiseReduce energy consumptionElectrical controlInternal combustion piston enginesAir volumeCam

An intake air amount control system for an internal combustion engine, which controls respective amounts of intake air drawn into four cylinders #1 to #4, independently of each other, by variable inter-intake cam phase mechanisms 80, identifies intake air amount variation coefficients ¦#i, based on a model [equation (43)] defining a relationship between an estimated value Gth_est of a TH passing intake air amount and a plurality of simulation values Gcyl_OS#i, such that the estimated value Gth_est becomes equal to the TH passing intake air amount, calculates a target inter-intake cam phase ¸ssi#i_cmd, on a cylinder-by-cylinder basis, according to the identified intake air amount variation coefficients ¦#i (step 81), and calculates control input DUTY_ssi#2 to #4 to the variable inter-intake cam phase mechanisms 80 according to the target inter-intake cam phases ¸ssi#i_cmd (step 75).

Owner:HONDA MOTOR CO LTD

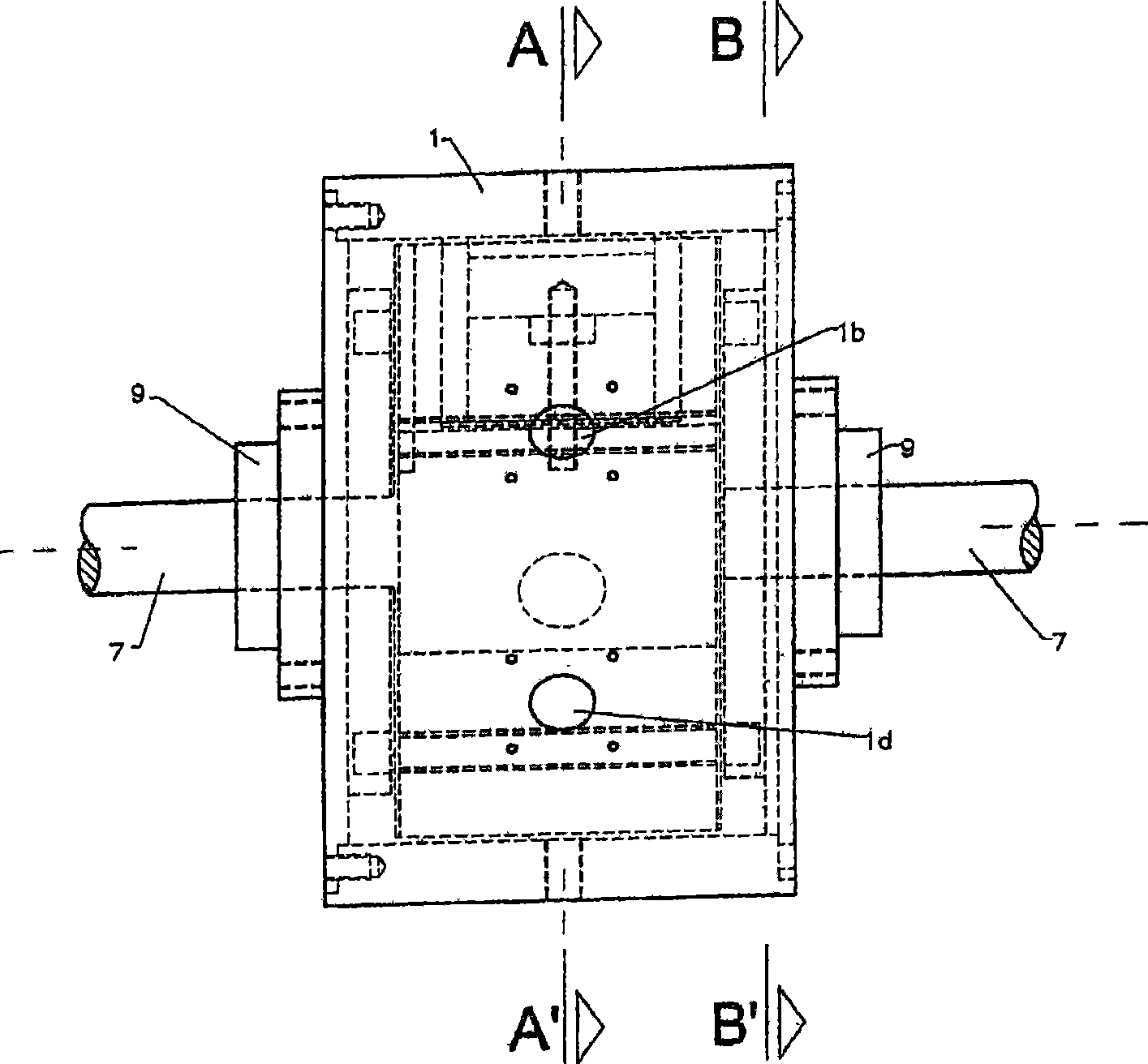

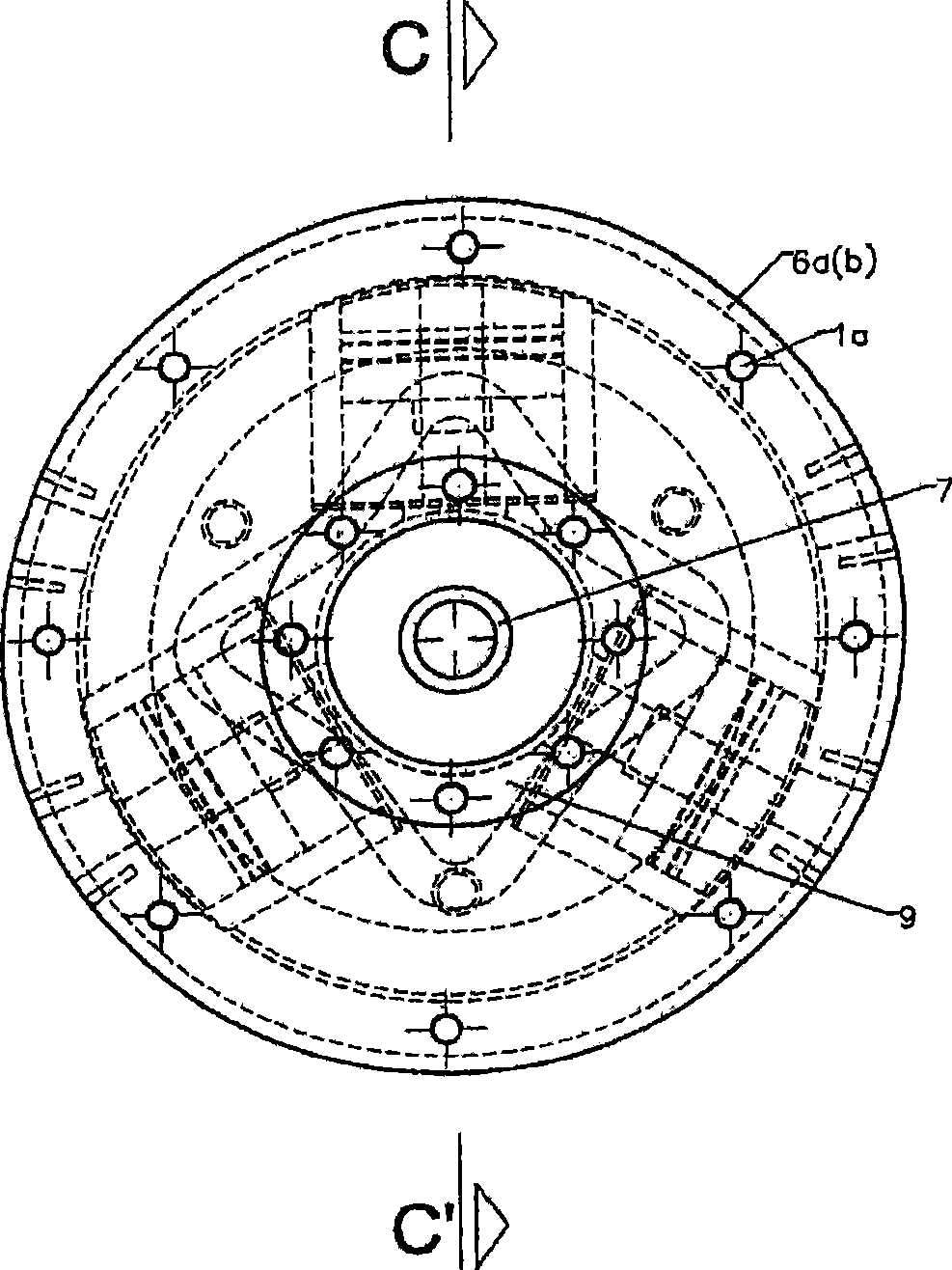

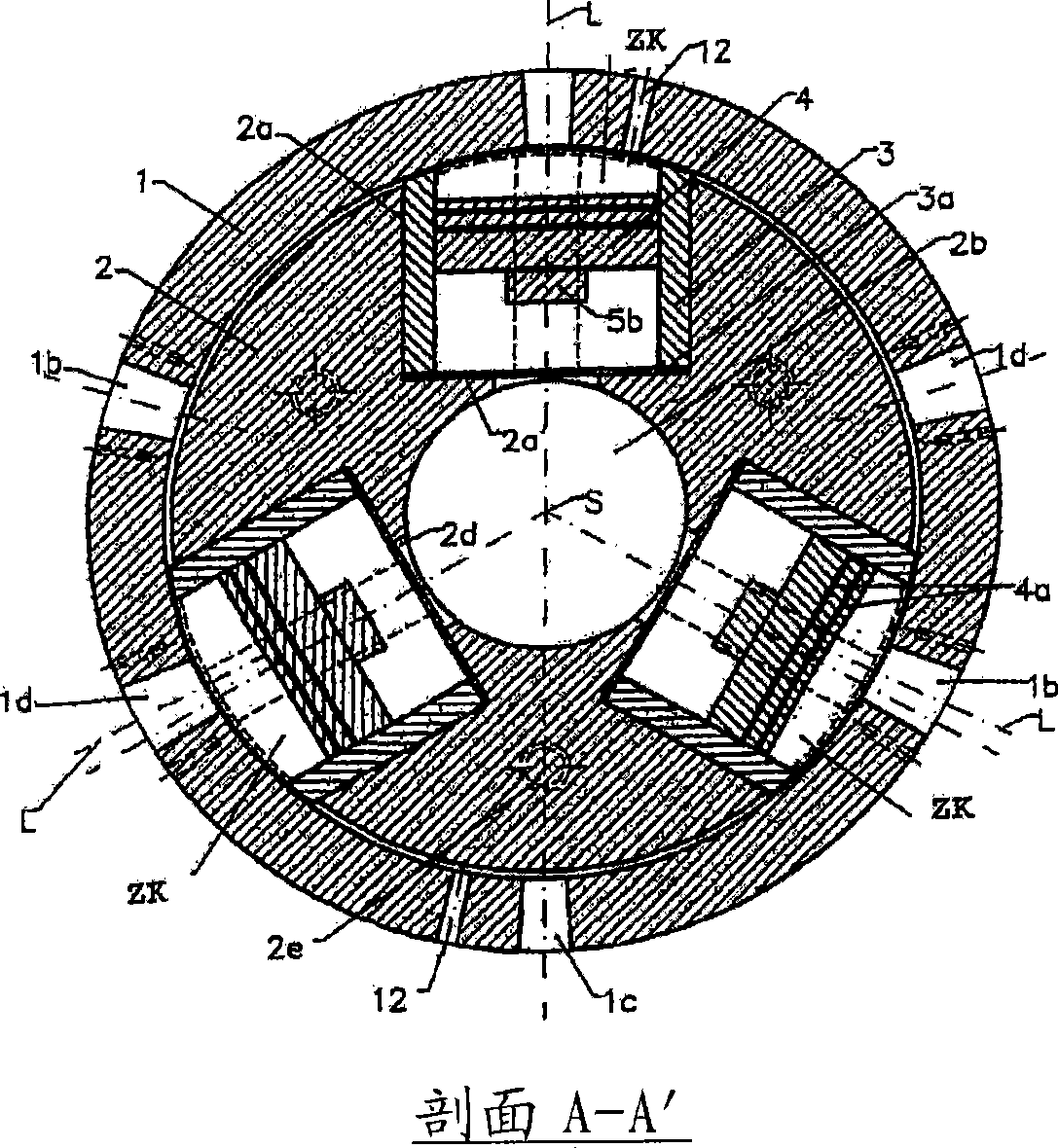

Engine with rotary piston

InactiveCN101371006ASmall structureSave materialInternal combustion piston enginesEngines with rotating cylindersEngineeringMechanical engineering

Disclosed is a rotary piston engine comprising a rotor which is rotatably mounted in a housing and in which several pistons can be moved in a radial direction between an outer and an inner dead center. Each piston is provided with a piston rod which sits on a transversal shaft that is fastened to a sliding piece at each end, said sliding piece being movable within radial grooves in the rotor, on both sides of the piston. The external side of the sliding pieces which faces away from the piston is fitted with a pin that is accommodated in a star-shaped continuous guiding groove which is fixed to the housing. The guiding groove extends around an axis of rotation of the rotor and causes the pistons to move in a radial direction between the inner and outer dead centers.

Owner:DEZMOTEC

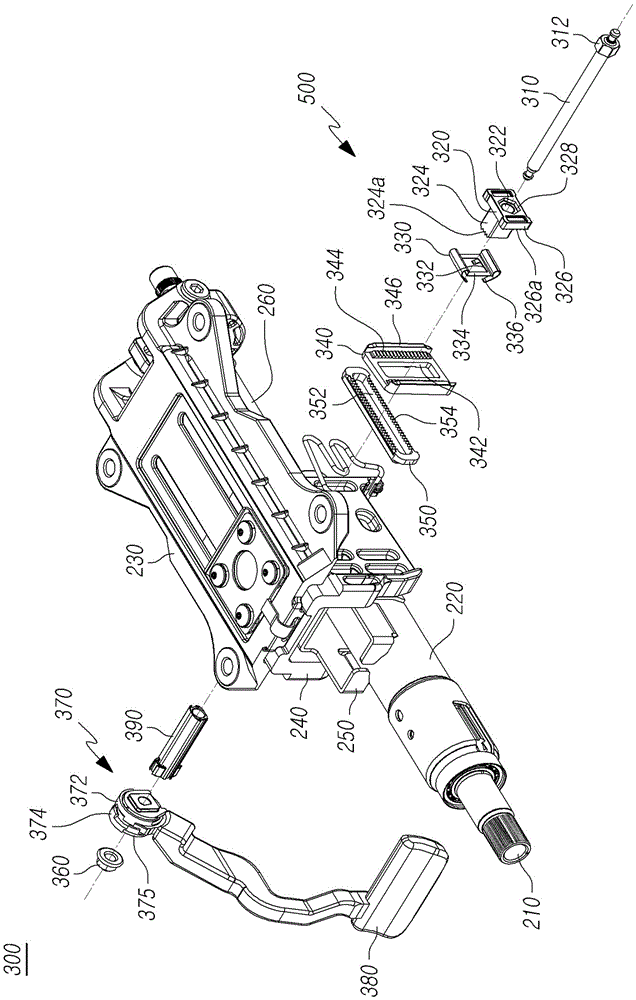

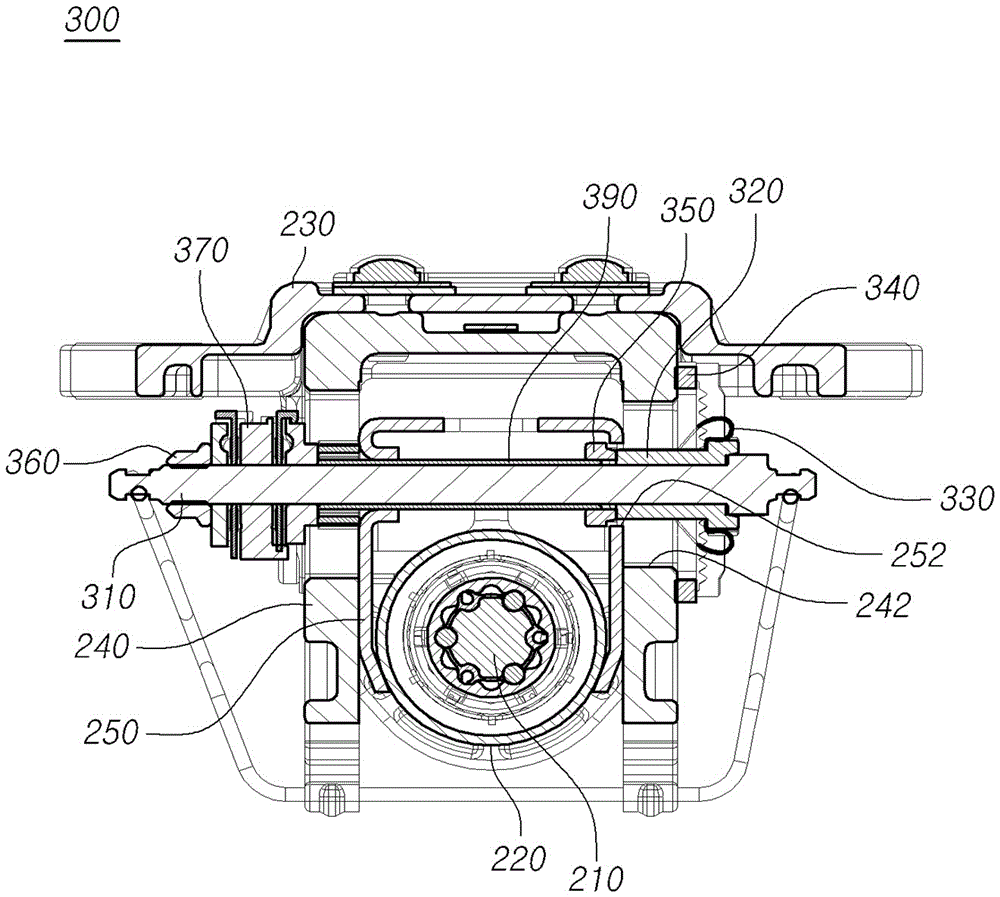

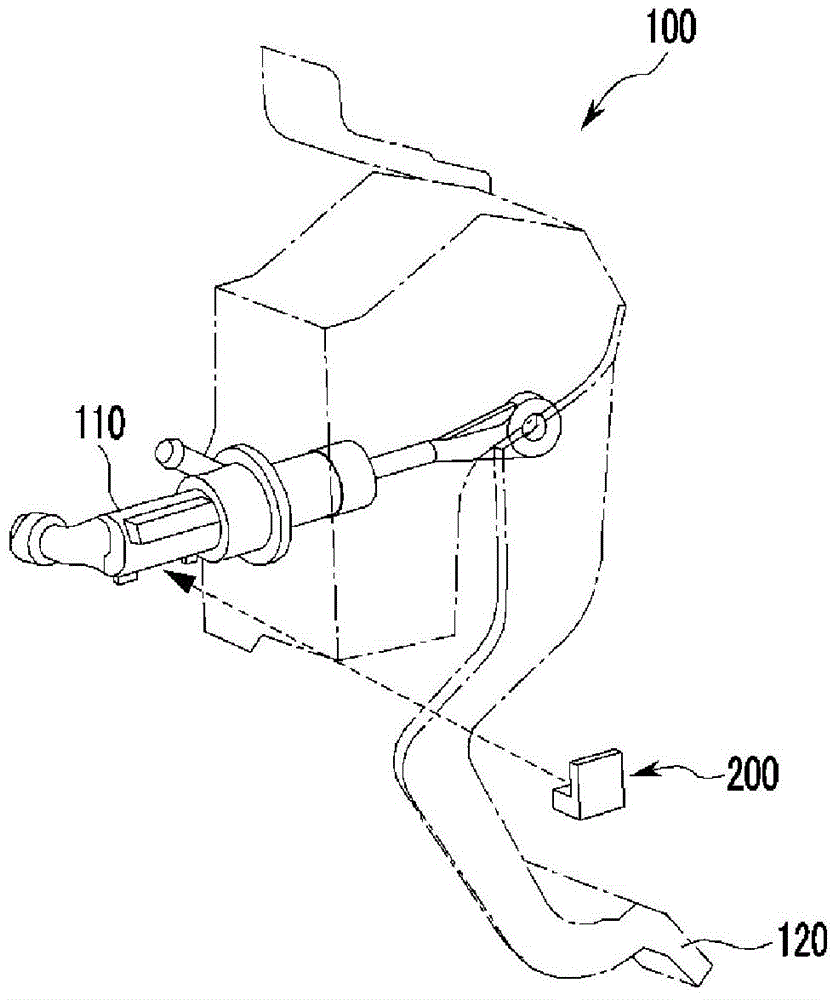

Steering column for vehicle

ActiveCN105711636AImprove the sense of operationReduce operating noiseSteering columnsSteering columnEngineering

The present invention relates to a steering column for a vehicle. The steering column of a vehicle includes: an adjusting bolt that passes through tilting guide holes having slot shapes and are formed on opposite sides of a plate bracket, and telescoping guide holes having slot shapes and are formed on opposite sides of a distance bracket; and an impact absorbing member having a hollow pipe shape into which the adjusting bolt is inserted therein, and having tilting impact absorbing parts, which protrude on an outer peripheral surface thereof that are supported by opposite lengthwise ends of the tilting guide hole, and telescoping impact absorbing parts, which protrude on the outer peripheral surface thereof that are supported by opposite lengthwise ends of the telescoping guide hole. The steering column for a vehicle can allow an impact absorbing member no absorb an impact that is generated when an adjusting bolt collides with a tilting guide hole or a telescoping guide hole during a tilting or telescoping operation, thereby improving the operational feeling and reducing operational noise.

Owner:HL MANDO CORP

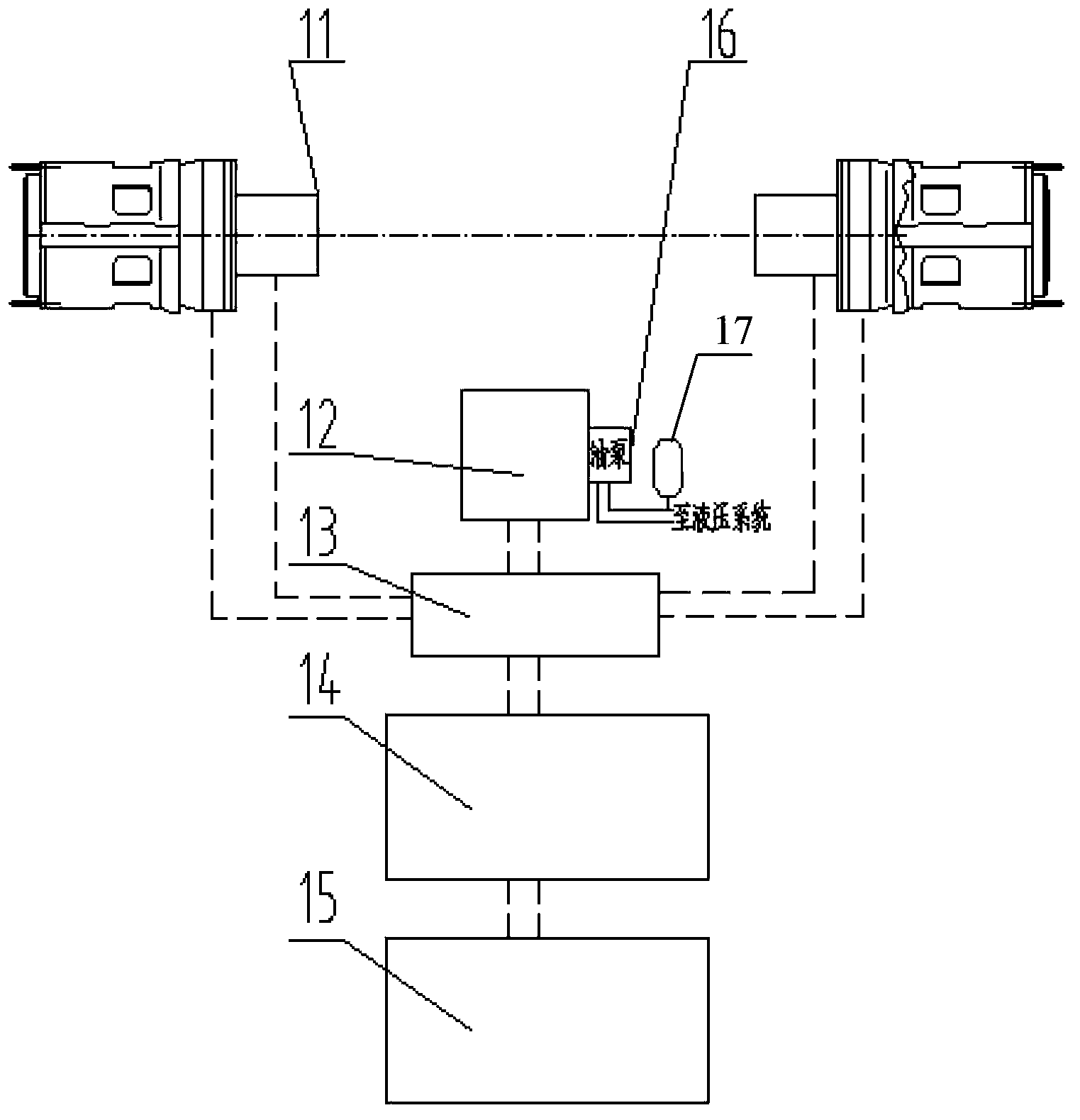

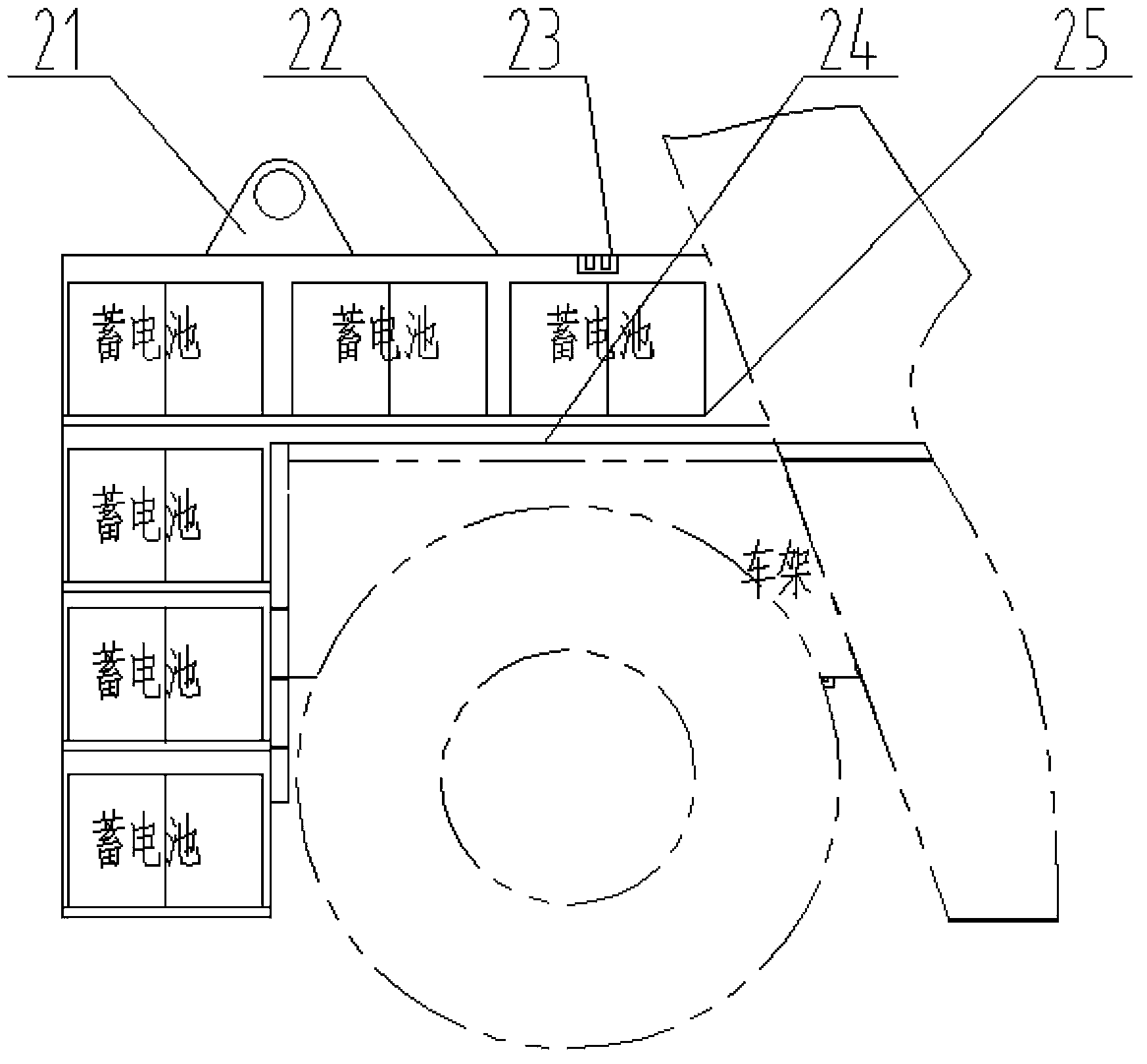

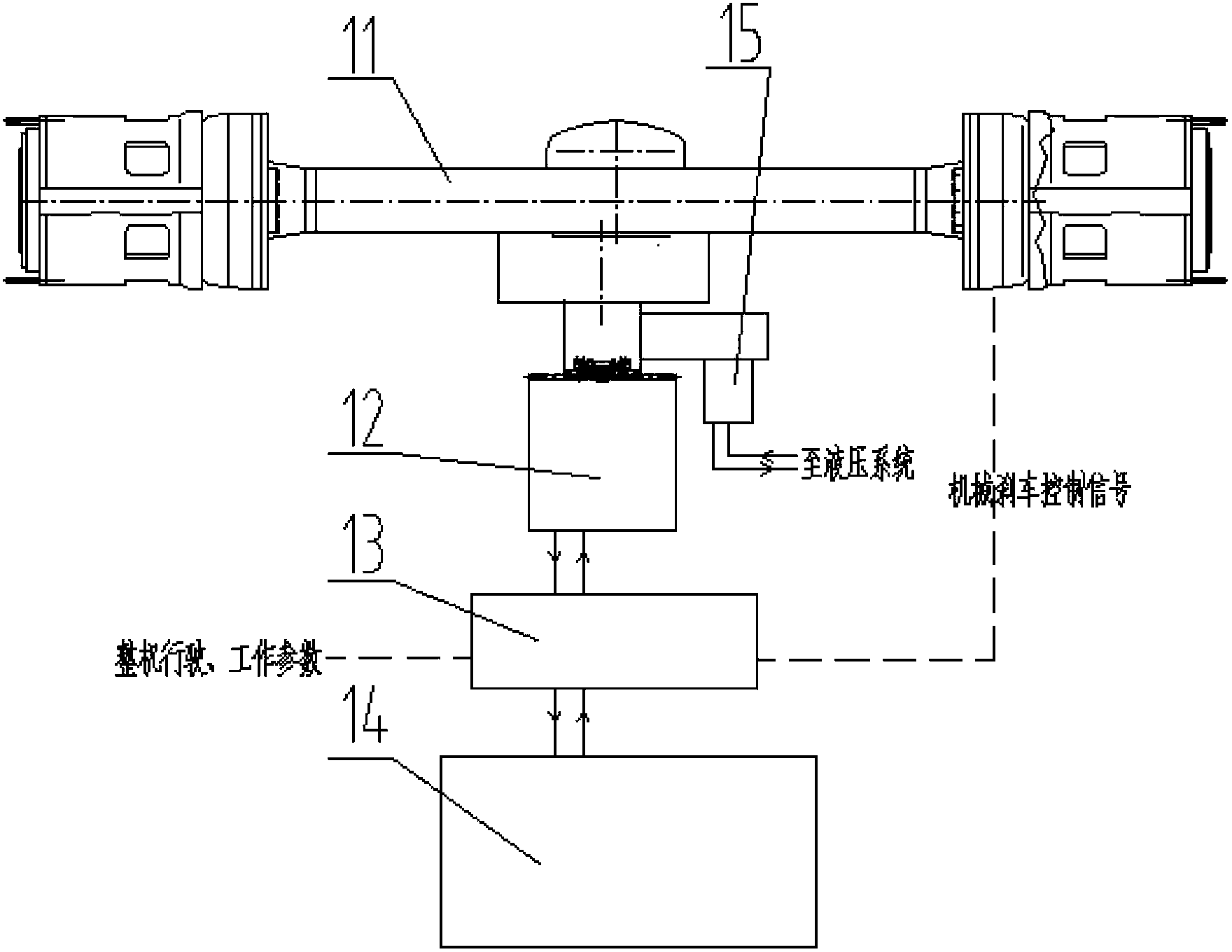

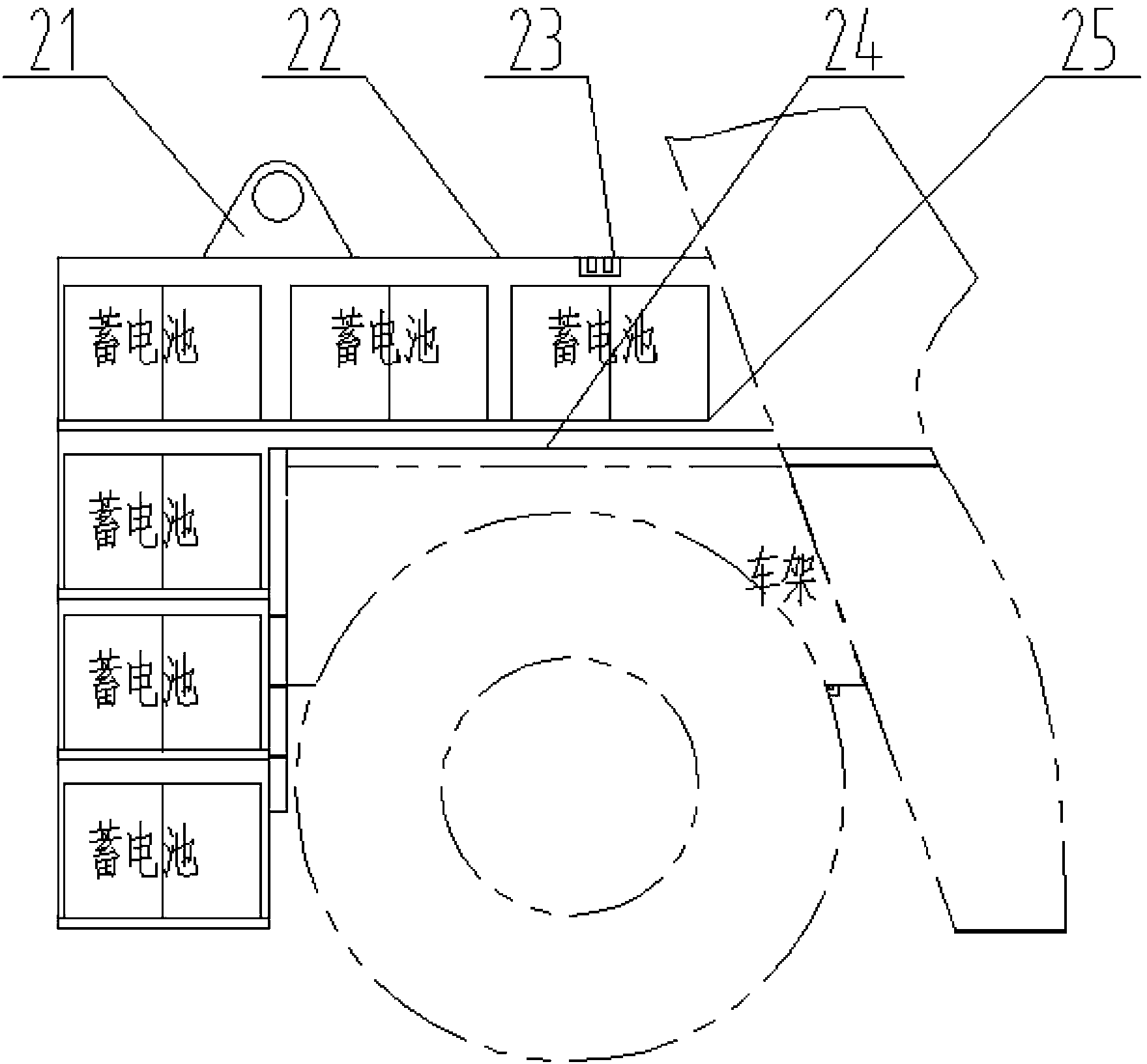

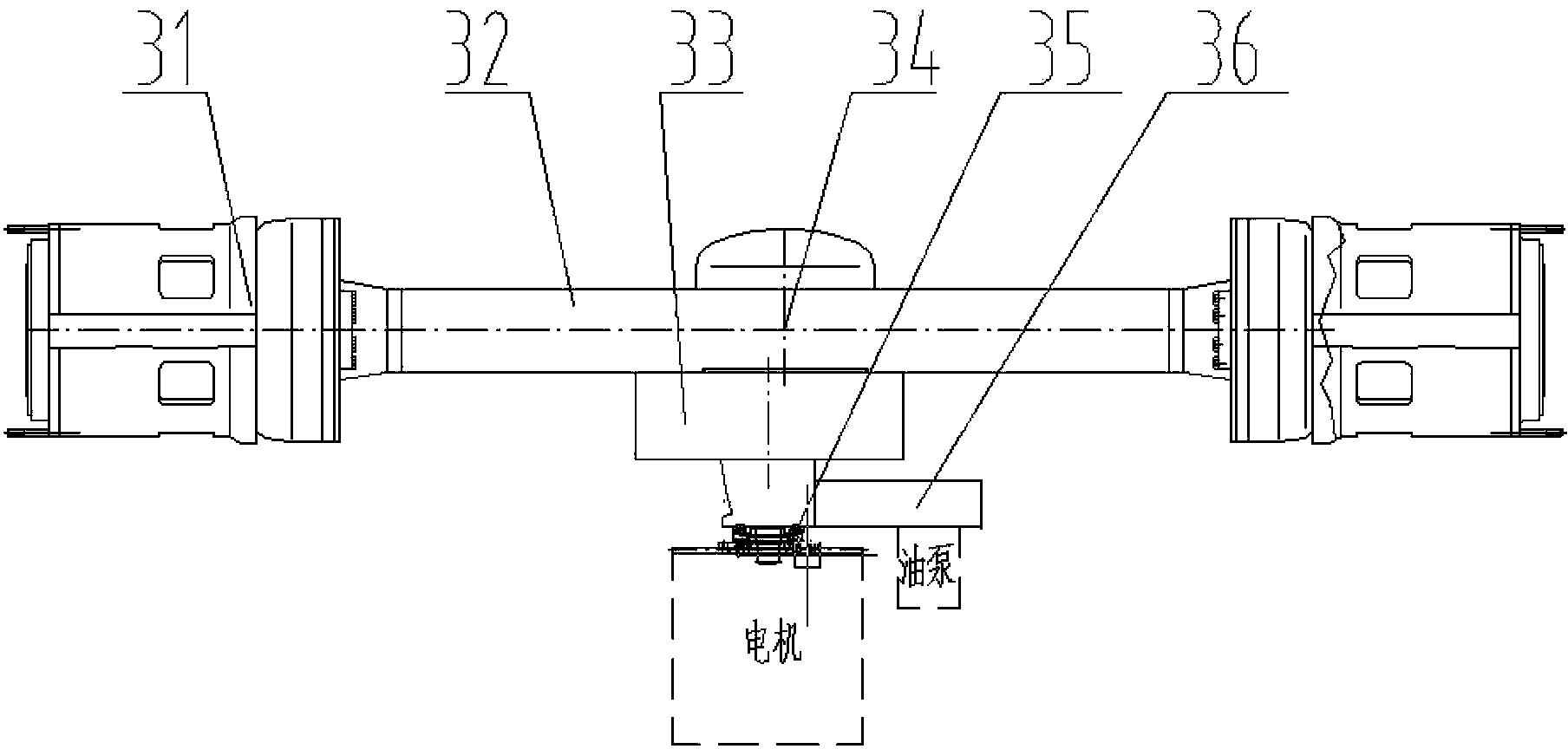

Wheel driven hybrid power container lifting machine

InactiveCN103350954AReduce pollutionReduce operating noiseLoad-engaging elementsElectric powerGenerating unit

The invention provide a wheel driven hybrid power container lifting machine, which comprises a generator set, a storage battery, a controller, and wheel driving devices, wherein the storage battery is charged by the generator set; the controller is connected with the storage battery; the electric power from the generator set or the storage battery passes through the controller and drives the wheel driving devices, so as to realize the running function of the complete machine. The lifting machine adopts the storage battery and the generator set to provide electric power for driving the running of each part, so as to be able to reduce the environmental pollution furthest and lower the operation noise.

Owner:SHANGHAI PORT MACHINERY HEAVY IND +1

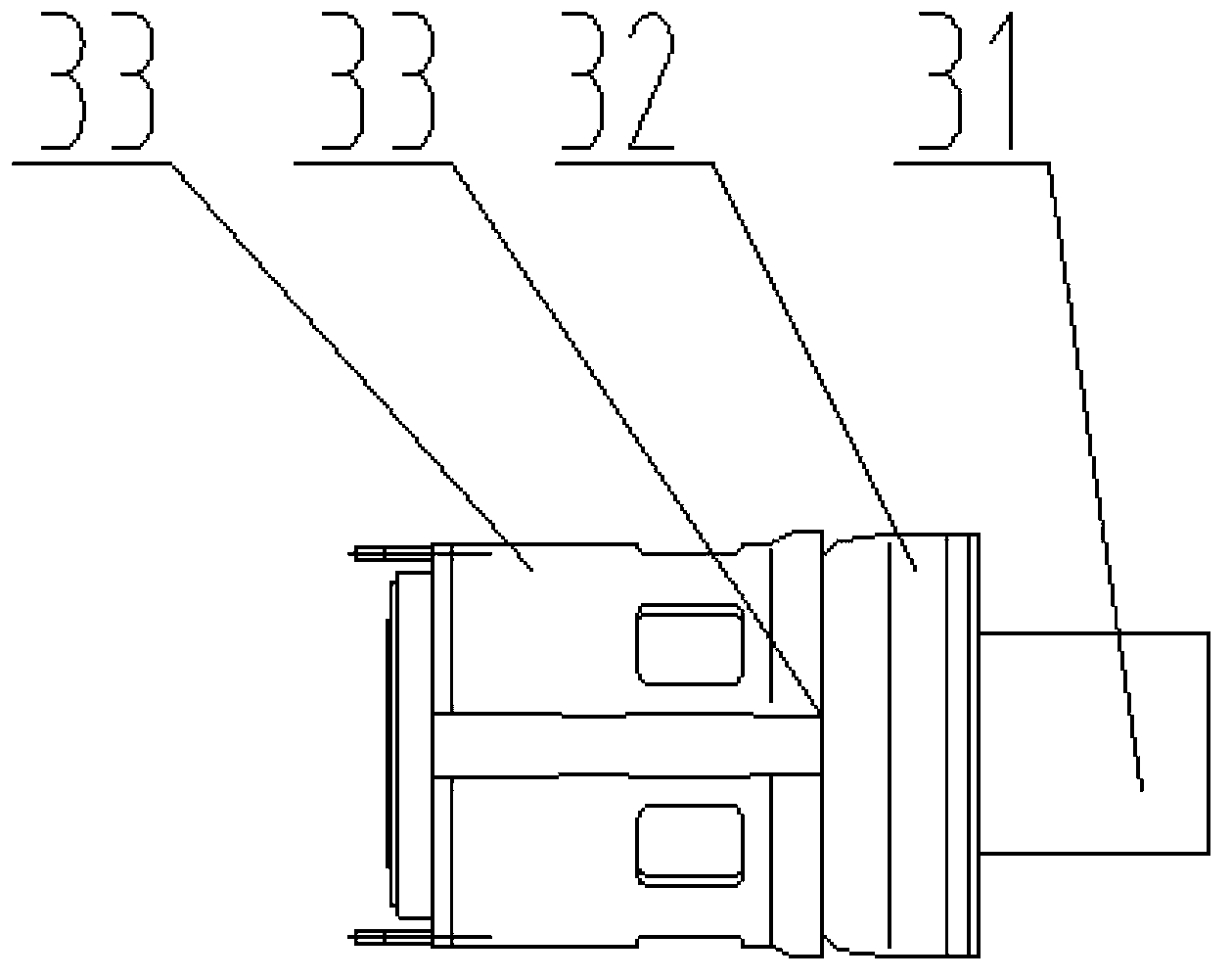

Full-electric controlled container lifting machine with centralized drive axle

ActiveCN103359619AReduce pollutionReduce operating noiseLoad-engaging elementsMotor driveElectric machinery

The invention provides a full-electric controlled container lifting machine with a centralized drive axle. The full-electric controlled container lifting machine comprises a storage battery, a controller connected with the storage battery, a motor driven by the electric power from the storage battery through the controller, and the centralized drive axle driven by the motor to execute the driving function of the whole machine. According to the full-electric controlled container lifting machine, the storage battery and the motor are adopted to provide power for the operation of the container lifting machine. Environmental pollution can be minimized to the maximum, and operation noise is reduced.

Owner:SHANGHAI PORT MACHINERY HEAVY IND +1

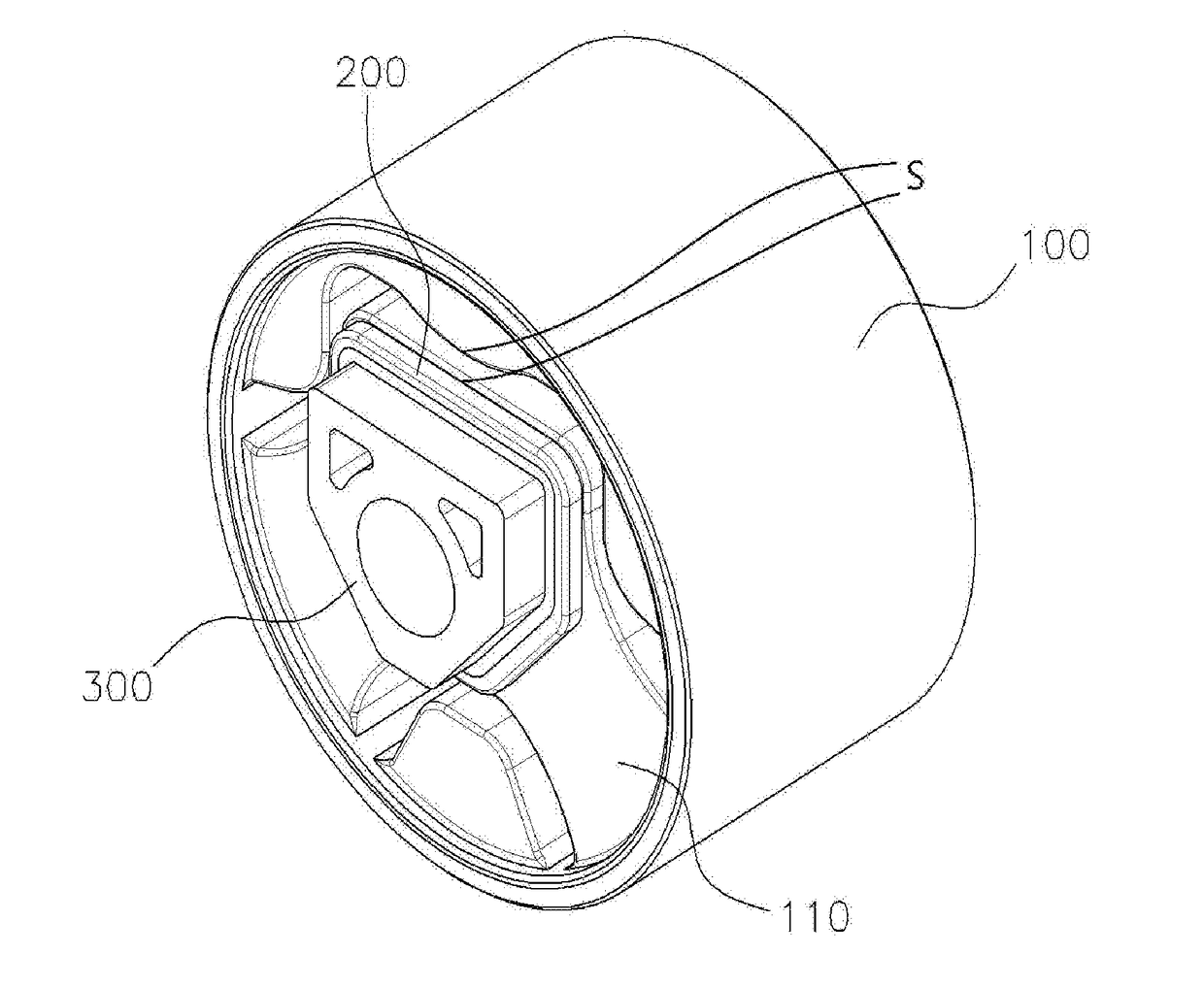

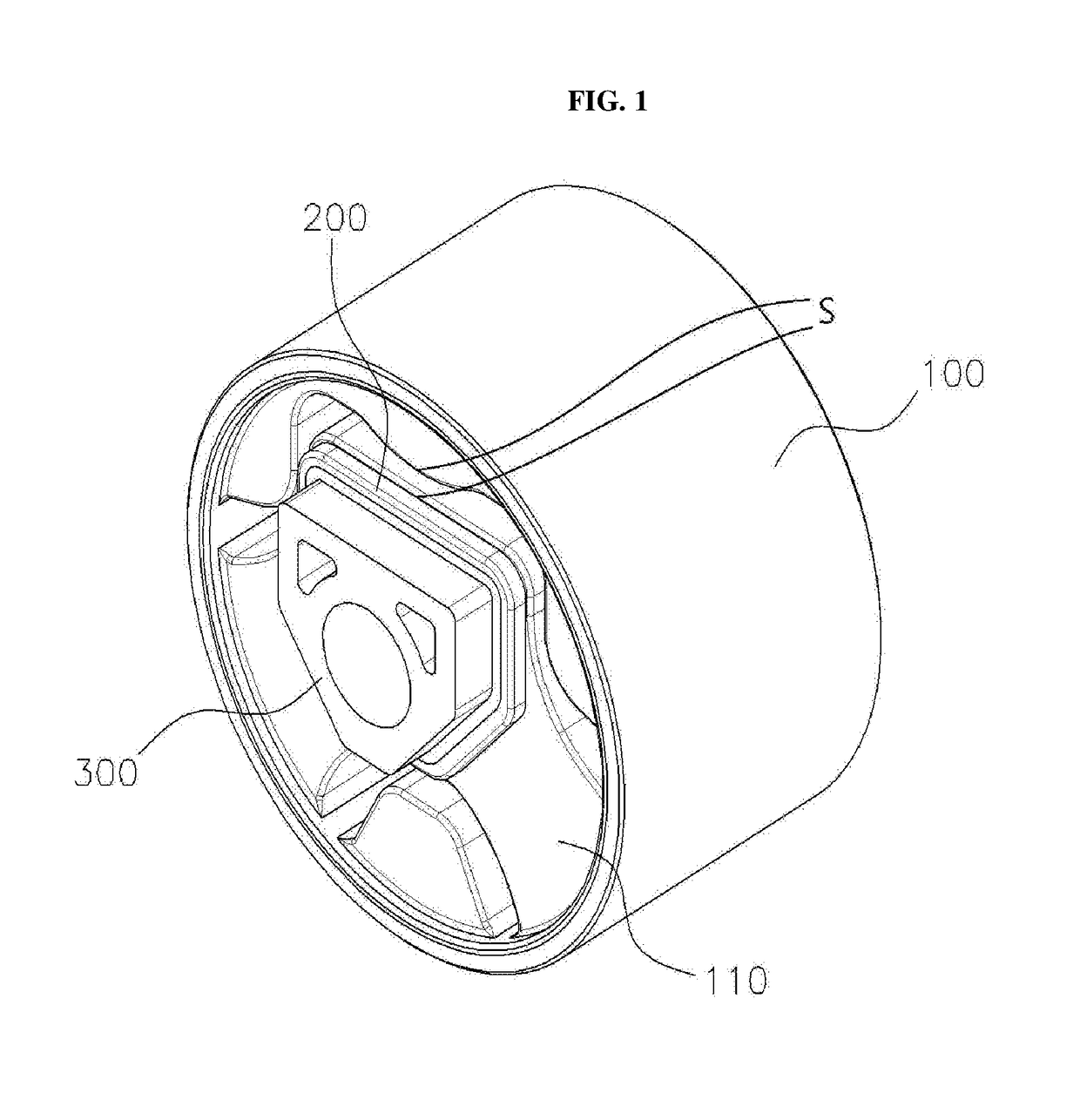

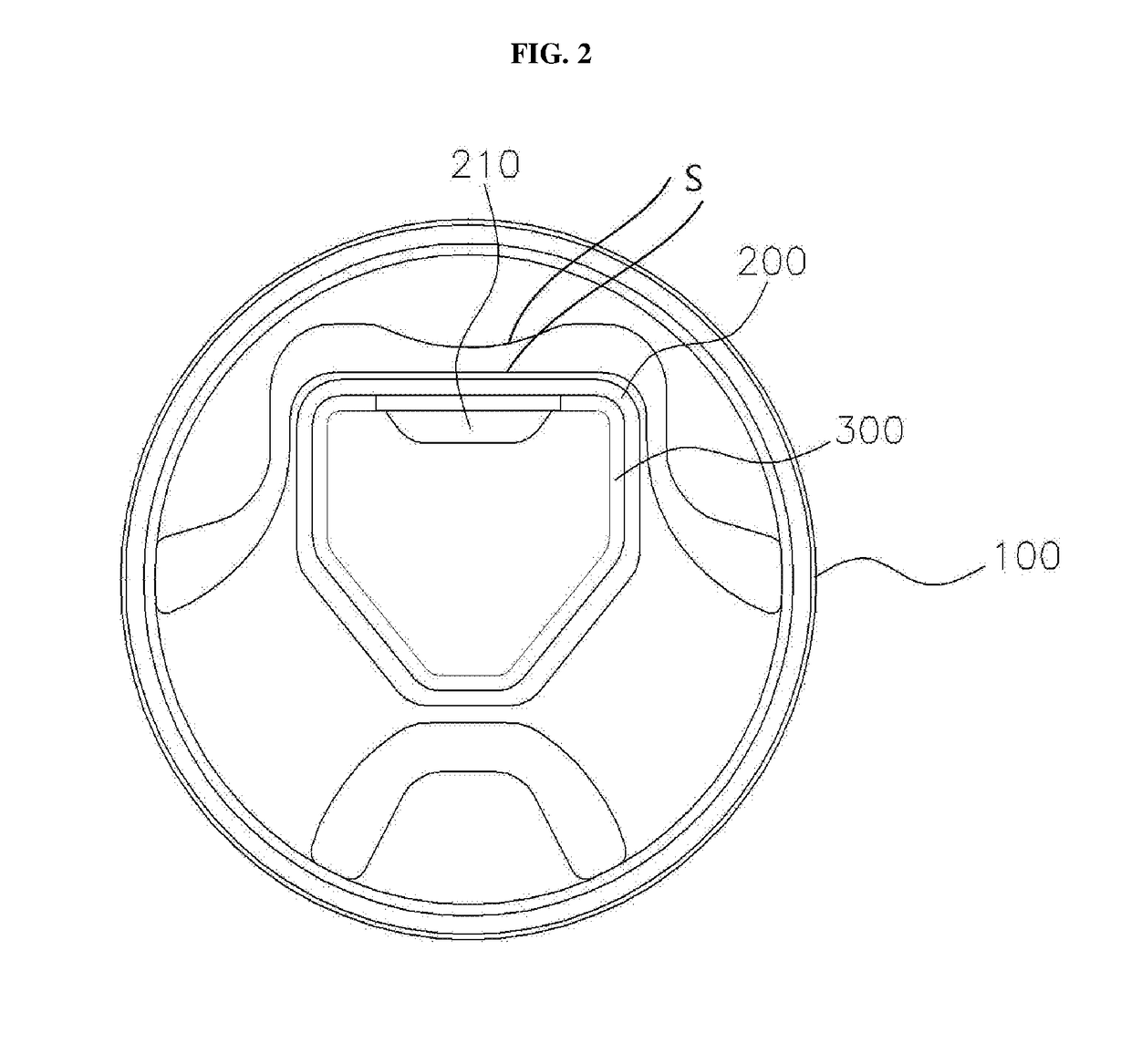

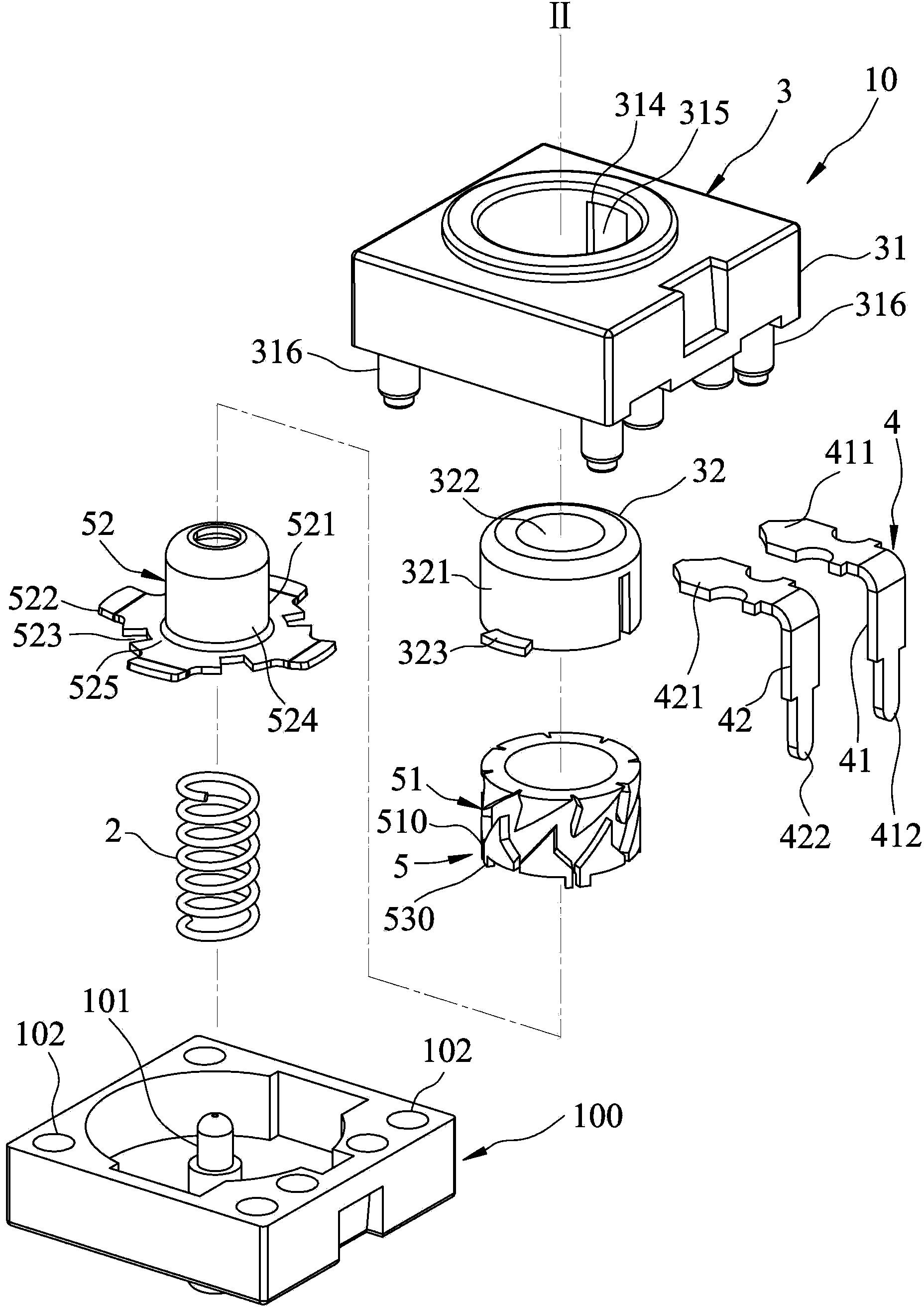

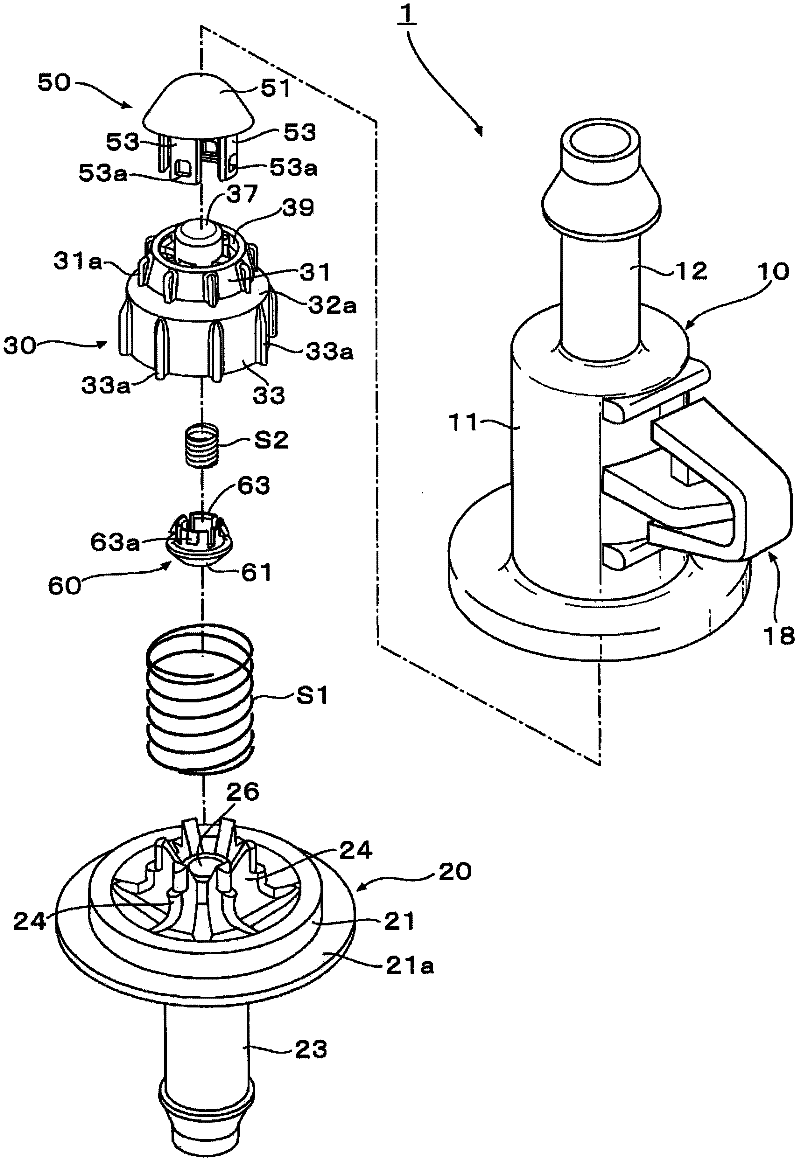

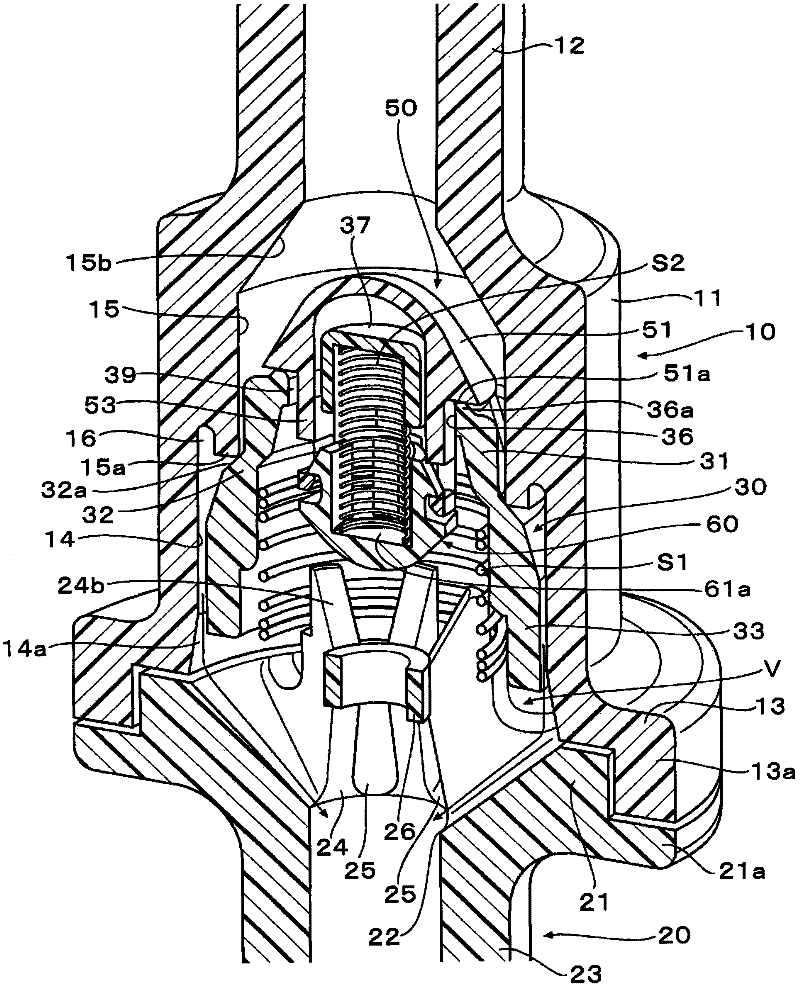

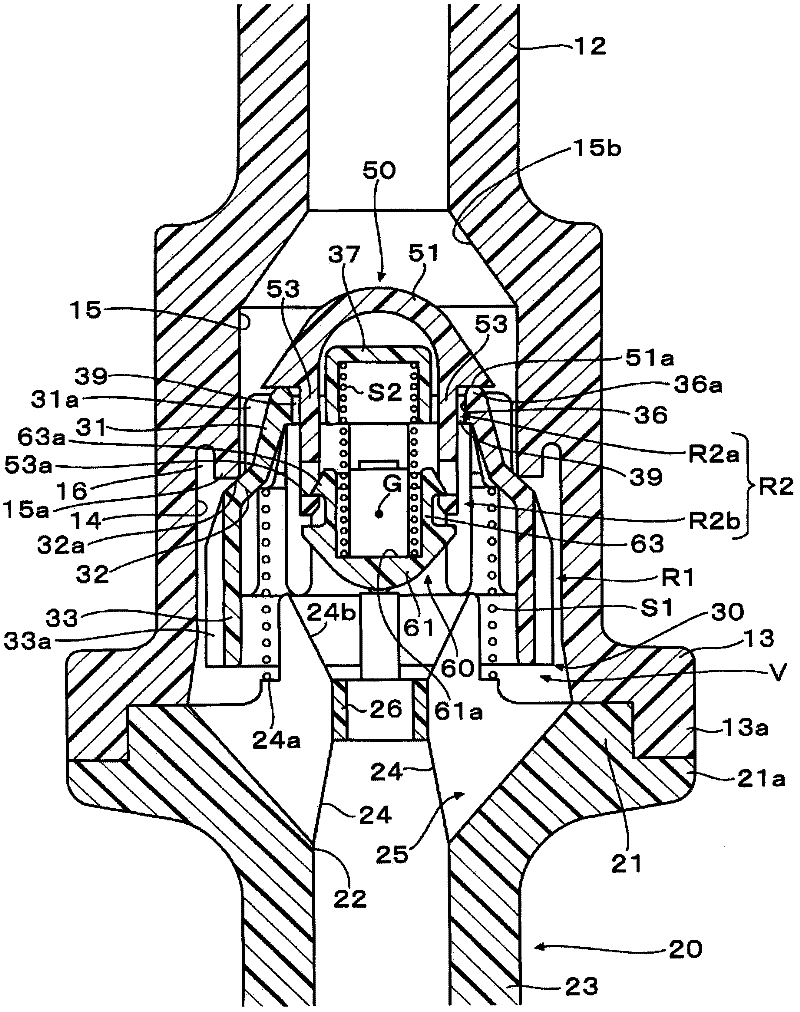

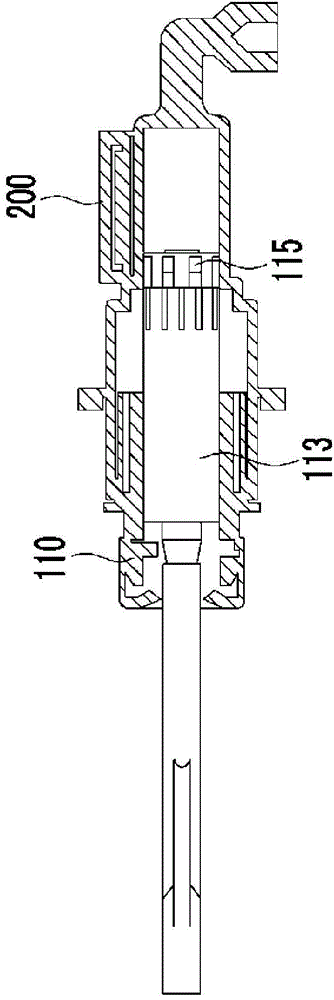

Check valve

ActiveCN102227329AReduce vibrationShake suppressionLarge containersEqualizing valvesPositive pressureEngineering

A check valve is capable of reducing the operation noise produced when a positive pressure valve and a negative pressure valve are slid and facilitates the assembling of the positive pressure valve and the negative pressure valve. The check valve (1) comprises a casing body (10), a sub casing (20), the positive pressure valve (30), and the negative pressure valve (50). The positive pressure valve (30) comprises a through hole (39) and a negative pressure valve seat (36a), and the negative pressure valve (50) comprises a leg section (53). A cap (60) is disposed in the positive pressure valve (30). A positive pressure spring (S1) is disposed between the positive pressure valve (30) and the sub-casing (20), and a negative pressure valve (S2) is disposed between the positive pressure valve (30) and the cap (60). A positive pressure flow passage (R1) allowing fuel vapor to flow out is formed between the outer periphery of the positive pressure valve and the inner periphery of the casing body. The positive pressure flow passage is disposed further on the outer side than the positive pressure spring (S1). A negative pressure flow passage (R2) allowing the outside air to flow in is formed between the inner periphery of the positive pressure valve and the outer peripheries of the leg section and the cap and between the through hole and the leg section. The negative pressure flow passage is disposed further on the outer side than the negative pressure spring (S2).

Owner:PIOLAX CO LTD

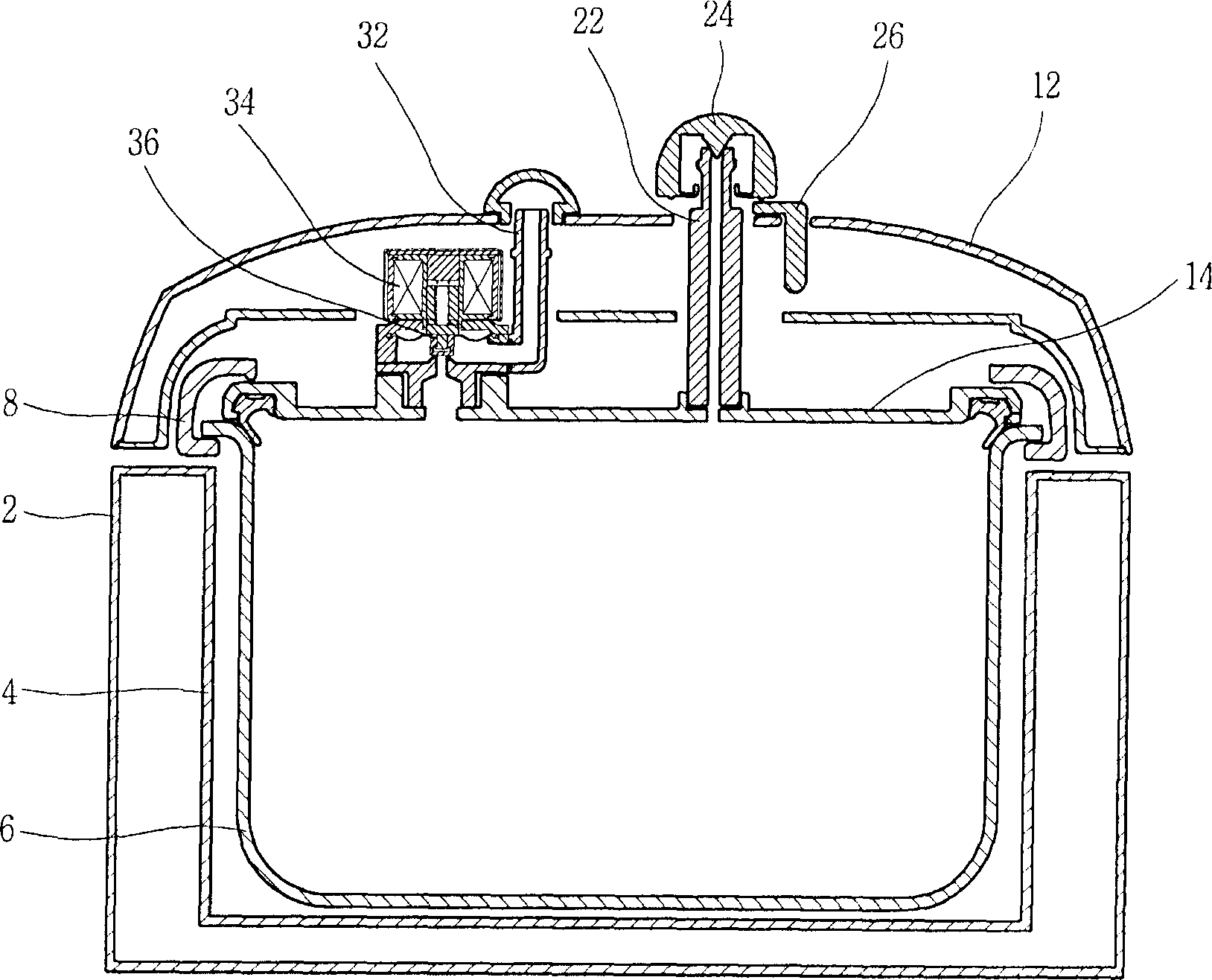

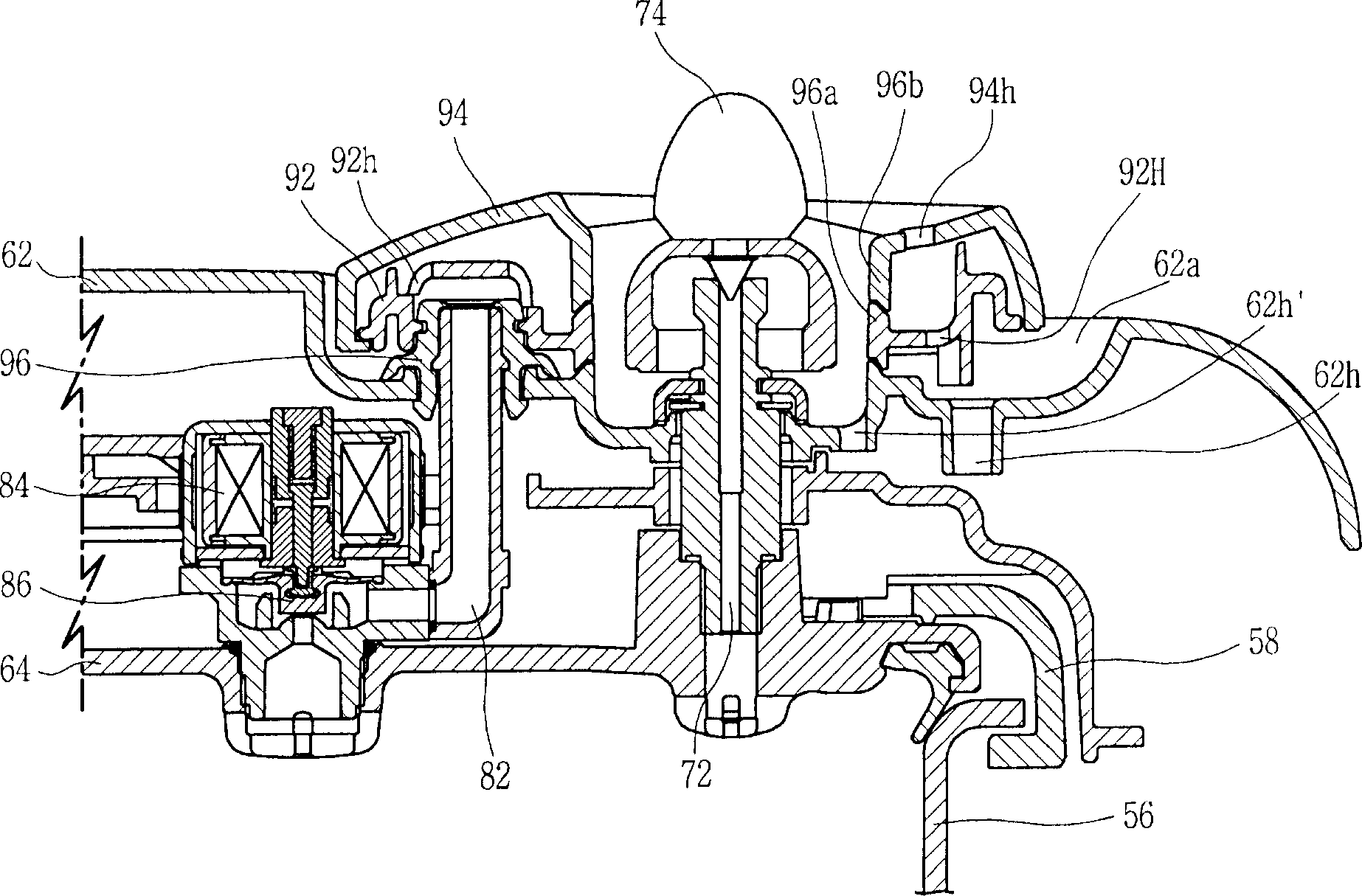

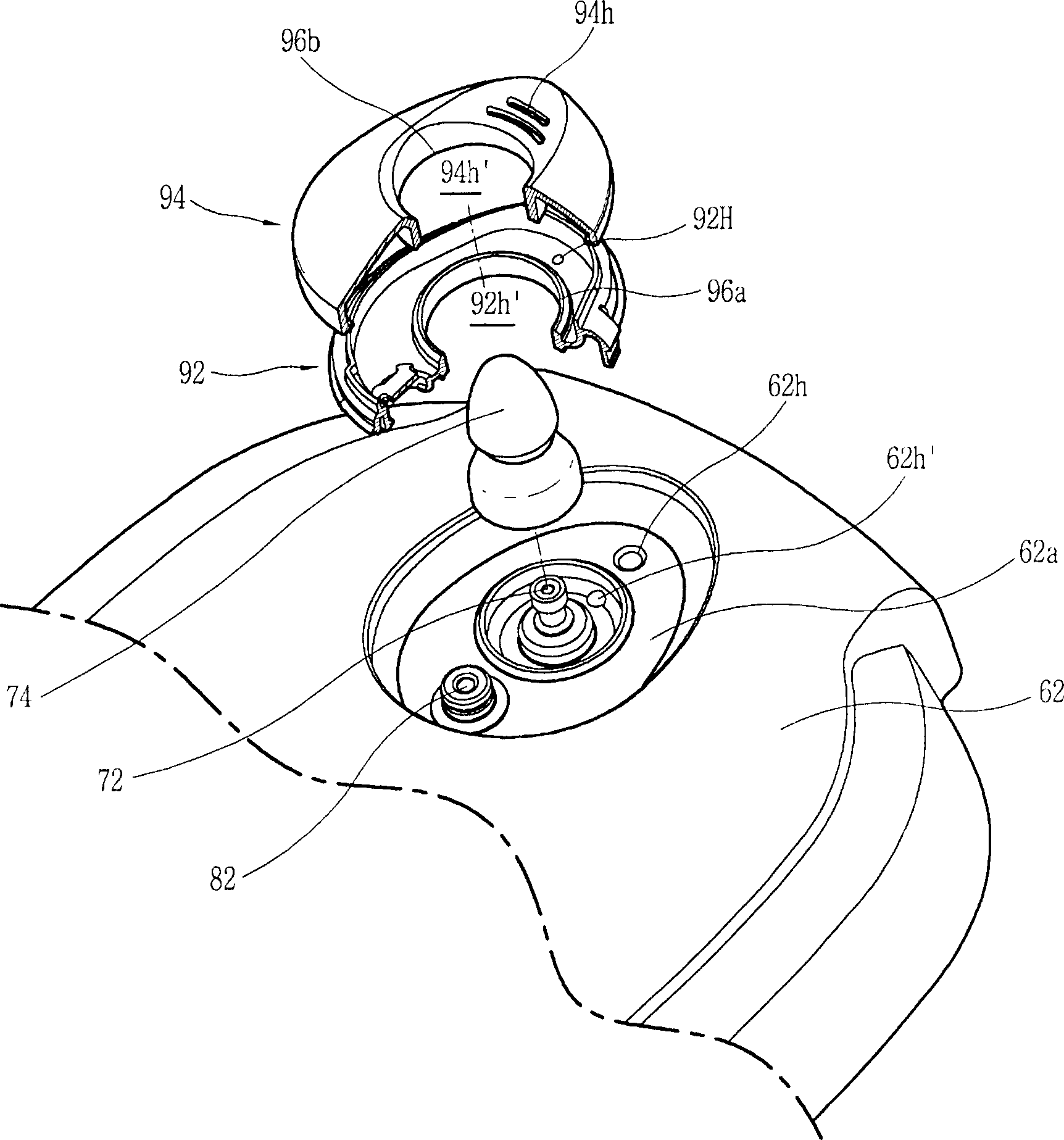

Steam discharging device for electric pressure cooker

PROBLEM TO BE SOLVED: To provide a steam discharging device for an electric pressure rice cooker which is hygienic, has safety, and can improve productivity and reduce periodical motion noise without separately adding constituting parts to discharge residual pressure and a production process. SOLUTION: This steam discharging device for an electric pressure rice cooker is constituted so as to discharge steam by inner pressure of an inner pot 56 for rice cooking. Covers 92, 94 to form prescribed closed steam flow spaces in which steam can flow are set at the end part of an automatic steam discharging passage 82 as well as a steam storage part to store steam while communicating with the steam flow spaces. After the steam discharged along the automatic steam discharging passage is caused to flow and stored in the steam storage part, the steam can be discharged at a stroke at a time a user desires. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:CUCKOO ELECTRONICS CO LTD

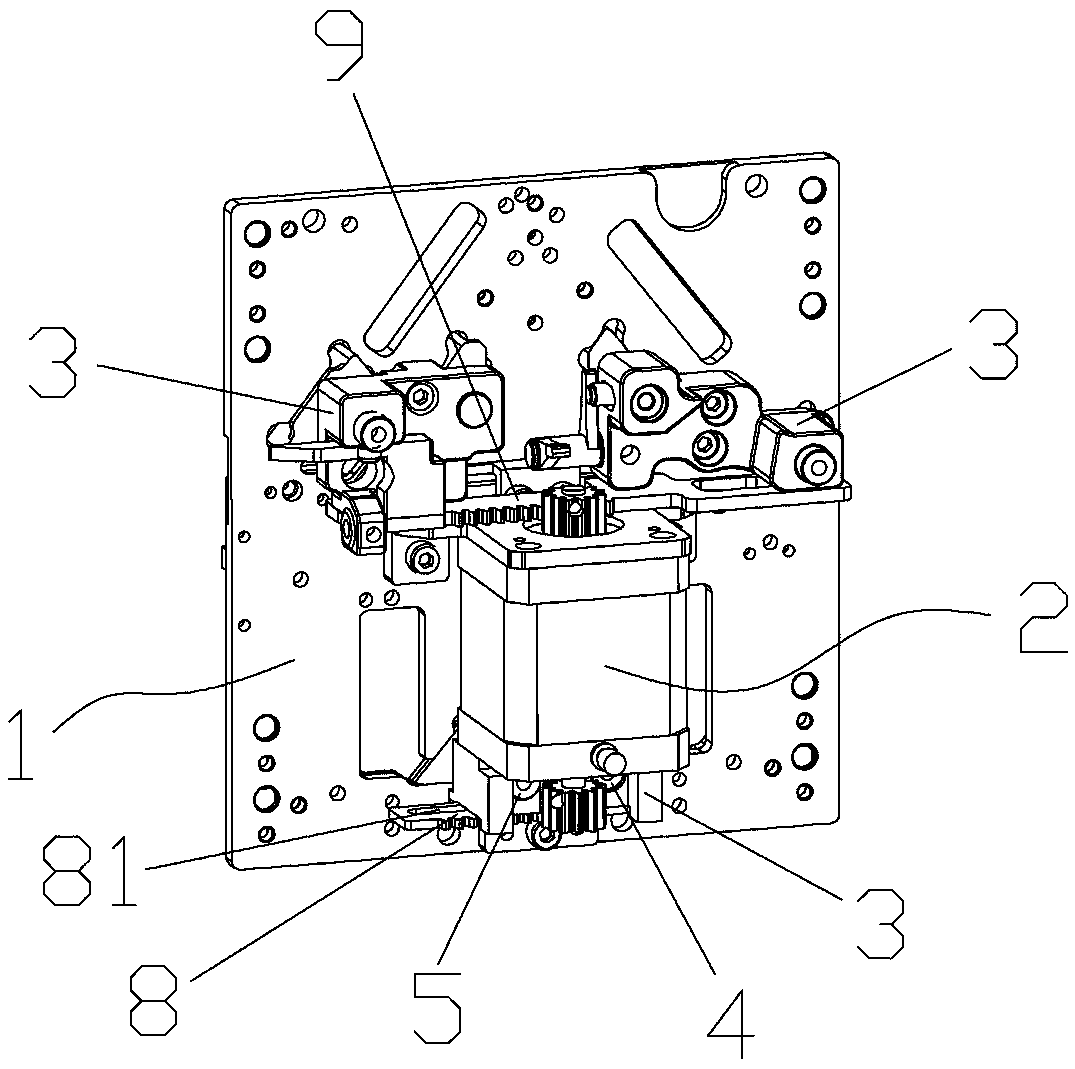

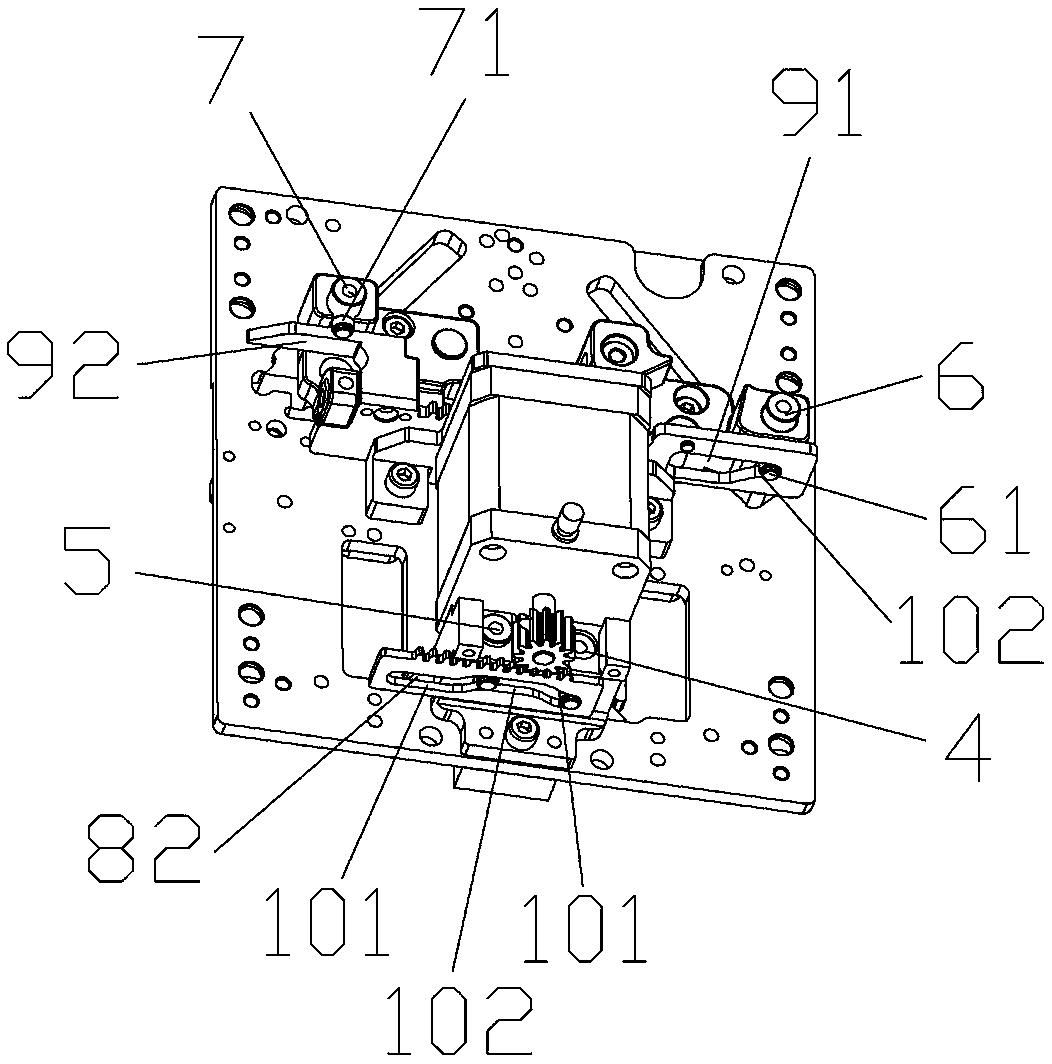

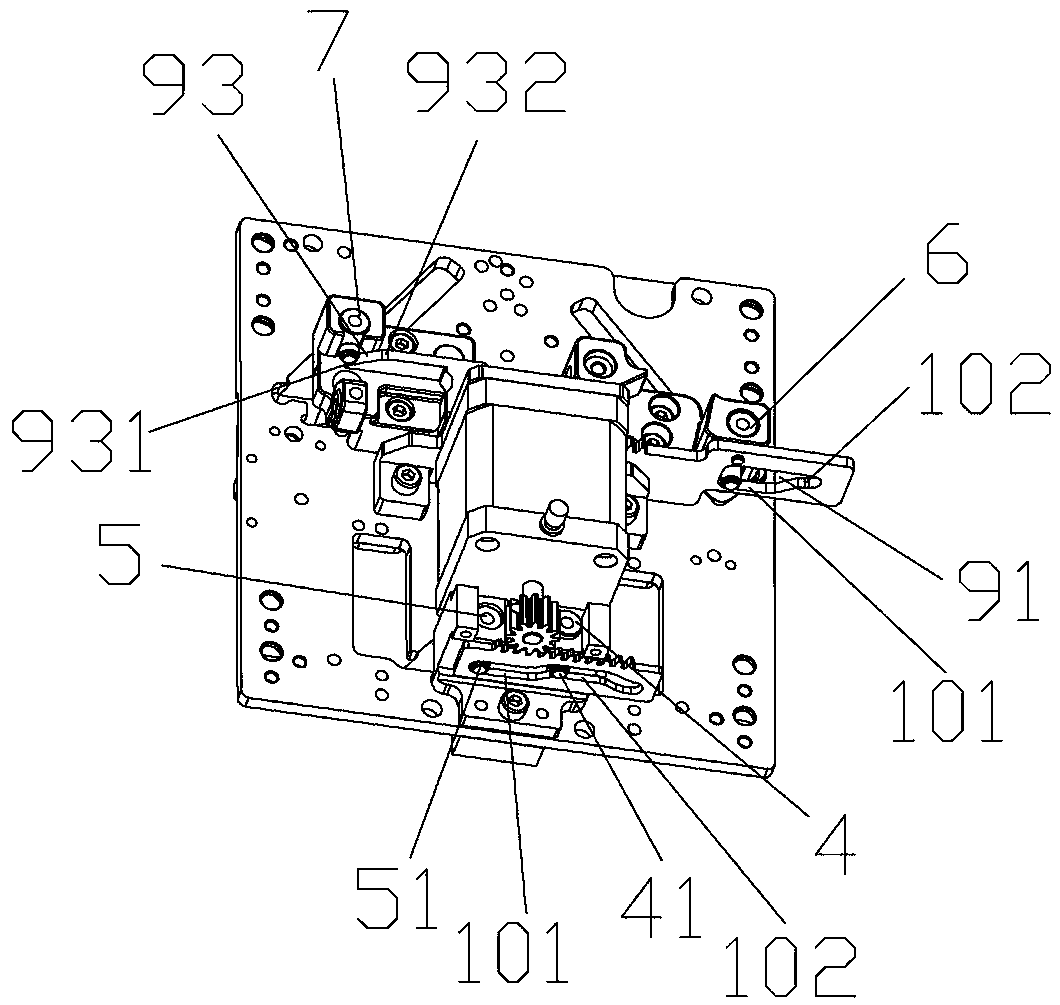

Linkage control mechanism for machine head triangle

PendingCN110485044ARealize synchronous controlEasy to controlWeft knittingEconomic benefitsEngineering

The invention mainly relates to a linkage control mechanism for a machine head triangle. The linkage control mechanism comprises a fixing plate, wherein a double-output-shaft motor and a plurality oftriangular seats are arranged on the fixing plate; a first needle selection triangle, a second needle selection triangle, a needle clearing triangle and a rubber band triangle are movably arranged onthe corresponding triangular seats; the double-output-shaft motor is capable of controlling the first needle selection triangle, the second needle selection triangle, the needle clearing triangle andthe rubber band triangle to move; a first control rack is installed at one end of the double-output-shaft motor in a driving mode; a first control rail is arranged in the first control rack and used for controlling the first needle selection triangle and the second needle selection triangle to move; a second control rack is installed at the other end of the double-output-shaft motor in a driving mode; a second control rail is arranged at one end of the second control rack and used for controlling the needle clearing triangle to move; the other end of the second control rack is connected with acontrol rod, and the control rod is used for controlling the rubber band triangle to move. The mechanism is ingenious in structural design, convenient to operate, stable and flexible to control, longin service life and low in operation noise, and economic benefits of enterprises are greatly improved.

Owner:ZHEJIANG RUIFENG INTELLIGENT TECH CO LTD

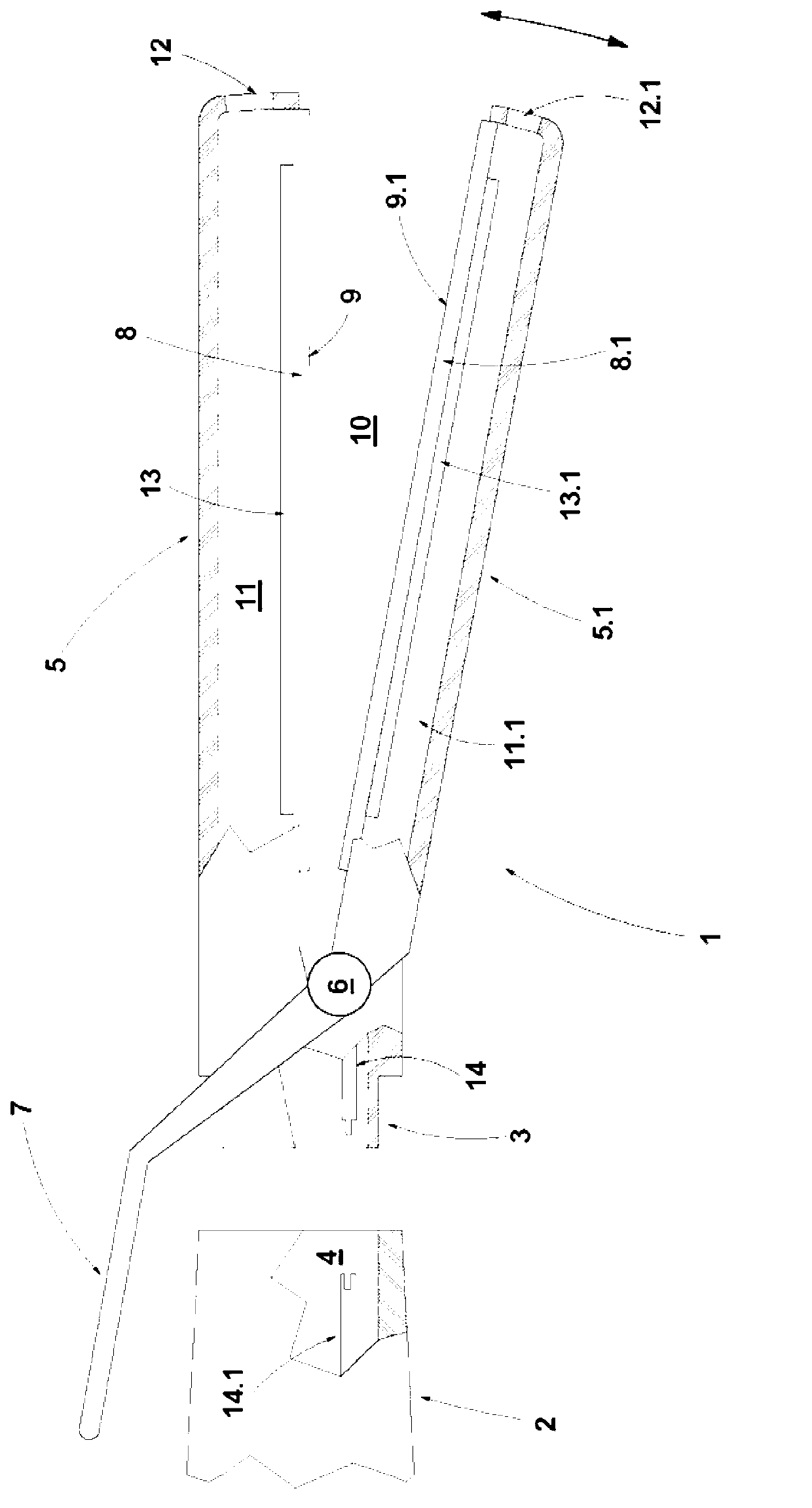

Hair care or styling apparatus and method for operating such a device

InactiveCN103099418ARapid responseHighly constant temperatureCurling-ironsCurling-tongsHeat conductingEngineering

A hair care or hair styling device 1 comprises two arms 5, 5.1 arranged articulated to one another and movable relative to one another in the manner of tongs 5, 5.1, with the top sides of each of said arms, which face one another, each having a complementary styling surface 9, 9.1 for forming a hair styling space 10 between the styling surfaces 9, 9.1. By virtue of the articulated arrangement of the arms 5, 5.1 the hair styling space 10 can be opened and closed. Each of the arms 5, 5.1 is equipped with a flow passage 11, 11.1 for conducting a flow of hot air, wherein the component 8, 8.1 that forms the styling surface 9, 9.1 of each arm 5, 5.1 is arranged such that a flow of hot air conducted through the flow passage 11, 11.1 of said arm 5, 5.1 flows along the back side of the component 8, 8.1 that forms the styling surface 9, 9.1 for the purpose of heating said styling surface 9, 9.1. In a heat-conducting arrangement, at least one self-regulating heating element having a positive temperature coefficient-a PTC heating element 13, 13.1-is connected as an additional heating device to the component 8, 8.1 that forms the styling surface 9, 9.1 of at least one arm 5, 5.1, for the purpose of supplying heat to the styling surfaces 9, 9.1.

Owner:WIK FAR EAST

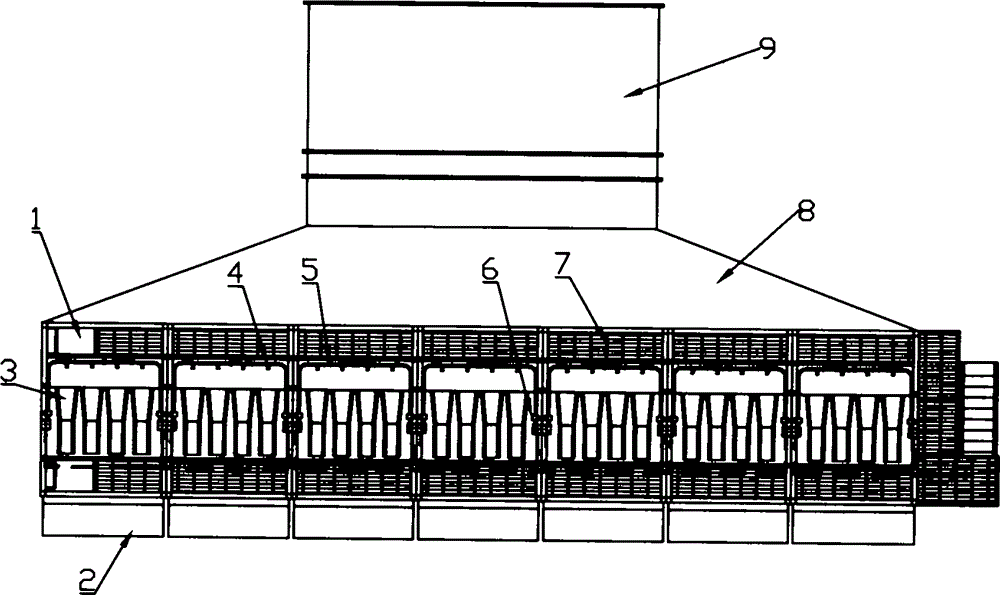

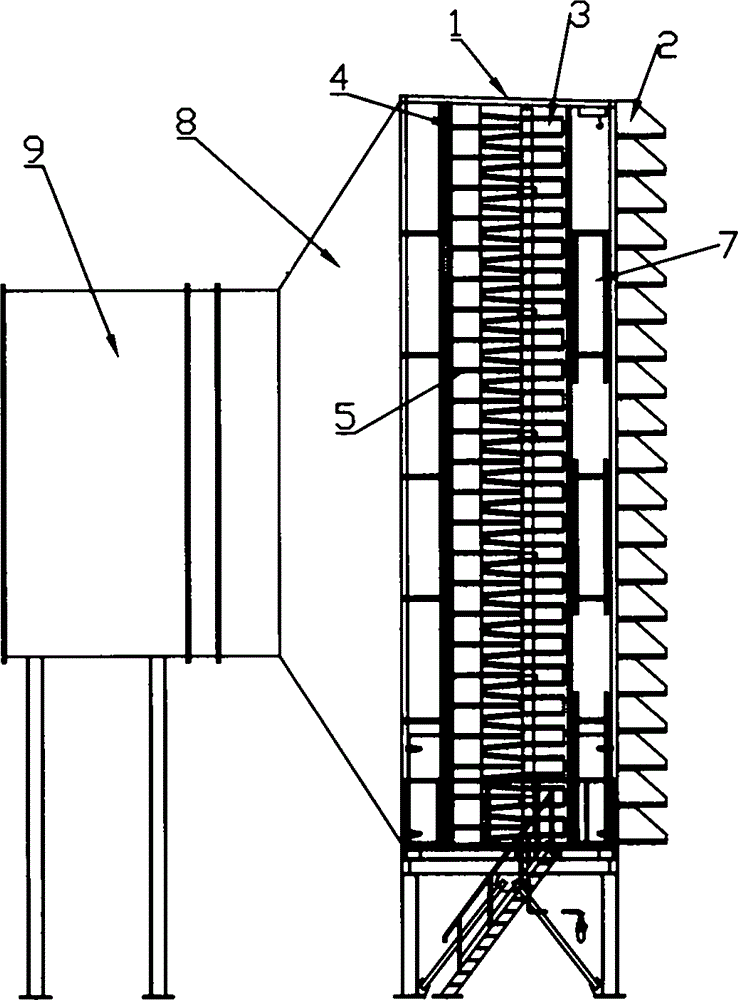

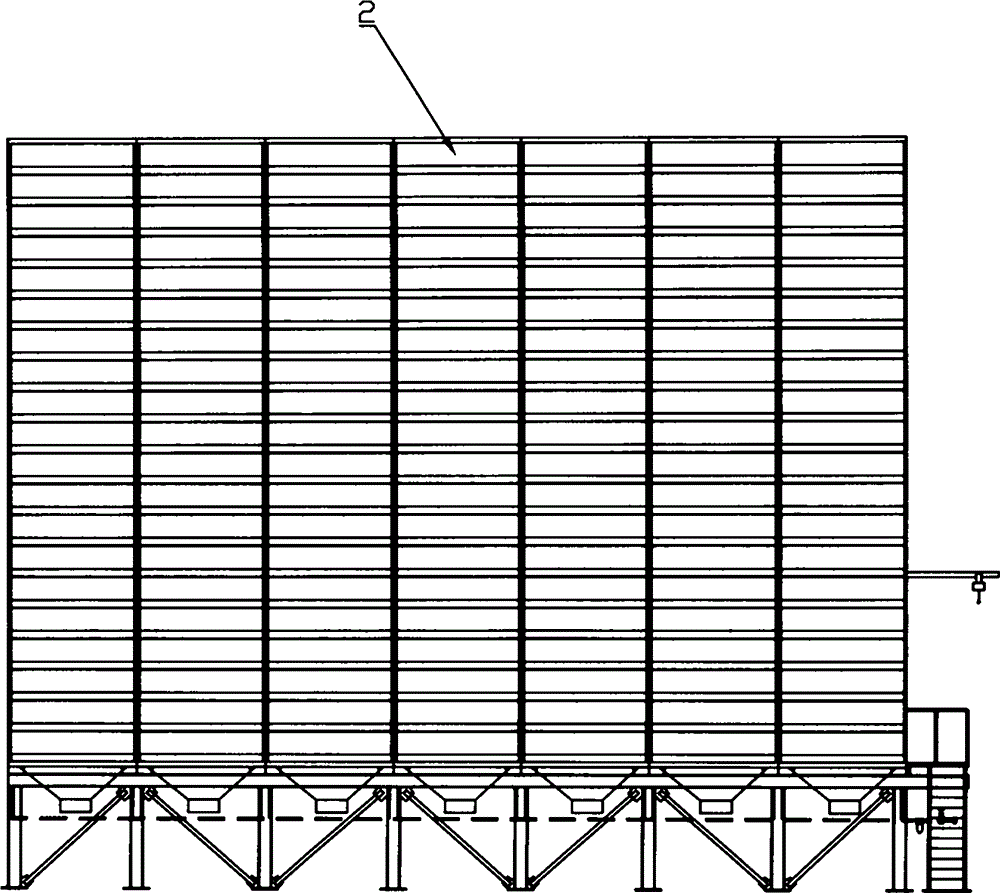

Inlet air filter device of gas turbine

InactiveCN104061075ASmall pressure lossReduce consumptionDispersed particle filtrationTurbine/propulsion air intakesAir filtrationAir filter

The invention relates to an inlet air filter device of a gas turbine. The inlet air filter device comprises a filter, an anti-rain hood, a high-precision filter element, a back-blowing nozzle, a compressed air pipe, an electromagnetic valve, inspection and repair platforms, an air channel and a silencer, wherein the anti-rain hood is arranged at the inlet of the filter; the high-precision filter element is arranged in the filter; the back-blowing nozzle is arranged in the filter outlet direction of the high-precision filter element and is connected with the compressed air pipe; the electromagnetic valve is arranged on the compressed air pipe; the inspection and repair platforms are arranged at two sides of the high-precision filter element in the filter; the outlet of the filter is connected with the silencer through the air channel; the high-precision filter element is in a double-layer structure, the first layer is an E class filtering layer and the second layer is an anti-moisture filtering layer. The inlet air filter device of the gas turbine has the advantages of efficient filtering, long service life and low operation risk, and has a good promotional value.

Owner:JIANGSU DONGZE ENVIRONMENTAL PROTECTION TECH

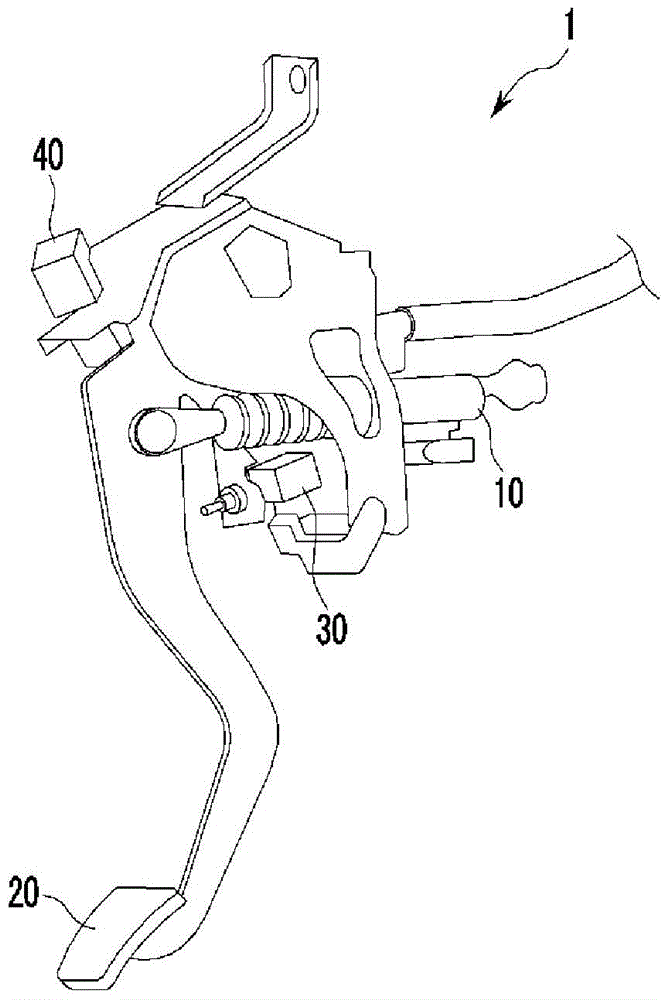

Clutch operating system

ActiveCN104653658AReduce the numberSave assembly timeFluid actuated clutchesAutomatic initiationsReciprocating motionMaster cylinder

Disclosed are a clutch operating system and a driving method of a clutch operating system. The system may include a clutch master cylinder connected to a clutch pedal and generating hydraulic pressure by operation of the clutch pedal, a piston provided in the clutch master cylinder and reciprocally moving according to the operation of the clutch pedal, and an integrated sensor detecting a stroke of the piston, selectively supplying power to a starting motor according to the stroke of the piston, and providing the stroke of the piston to an ECU (electronic control unit) to control a transmission and an EPB (electronic parking brake).

Owner:HYUNDAI MOTOR CO LTD

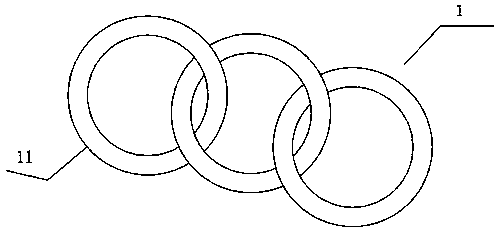

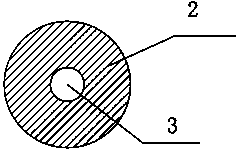

High-strength plastic chain

The invention discloses a high-strength plastic chain. The high-strength plastic chain is characterized in that a chain body (1) is formed by connecting a plurality of circular chain links (11) in series, and each circular chain link (11) comprises an annular metal wire (3) located in the center of the circular chain link (11) and a plastic layer (2) for wrapping the periphery of the annular metal wire (3); the diameter of the circular chain links (11) ranges from 3 cm to 8 cm; the annular metal wires (3) are steel wires, iron wires or copper wires; the circular chain links (11) are in closed ring shape; the radius of the cross sections of the circular chain links (11) is 2 mm, and the radius of the cross sections of the metal wires (3) is 0.5 mm. The high-strength plastic chain is low in operation noise, high in intensity and capable of bearing large tensile force.

Owner:WUXI HUIYUAN MECHANICAL TECH

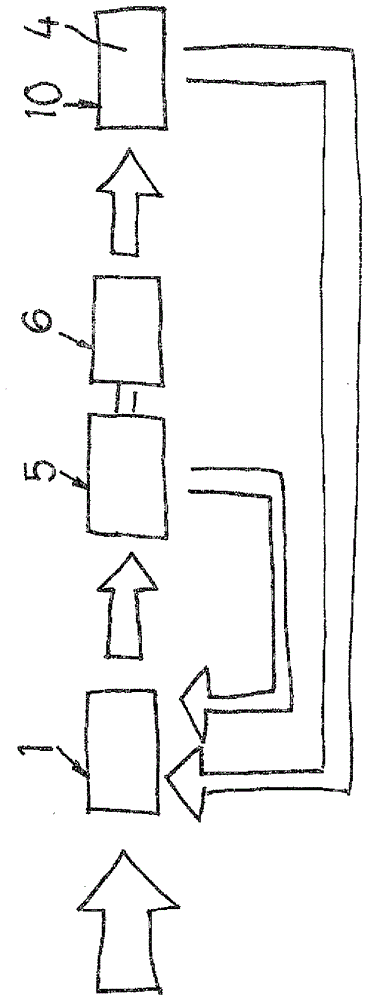

Proceeding for flushing of pipes at hydraulic systems and a plant for the flushing

ActiveCN106573278AEasy to moveIncrease powerHollow article cleaningServometer circuitsMotor speedClosed loop

The invention concerns a proceeding for the pipe flushing of a hydraulic system (3) internally by throughput of said hydraulic system (3) with fluid (4) in a flow of at least Re 2300 Reynolds. According to the invention, motor (5), pump (6) included in utilized plant (2) and the desired purification degree are regulated by a control unit (1) by the feedback of motor speed, oil flow, oil temperature, and contamination degree via particle counter (23). In that connection, there is provided automatic purification of the oil (4) or of another fluid, which is utilized in a so-called closed loop system with corrections automatically made by the control unit (1) after predetermined desired final result of the purification degree before approved result report can be delivered. The invention also concerns a plant (2) for accomplishing a said proceeding.

Owner:麦基嘉瑞典股份公司

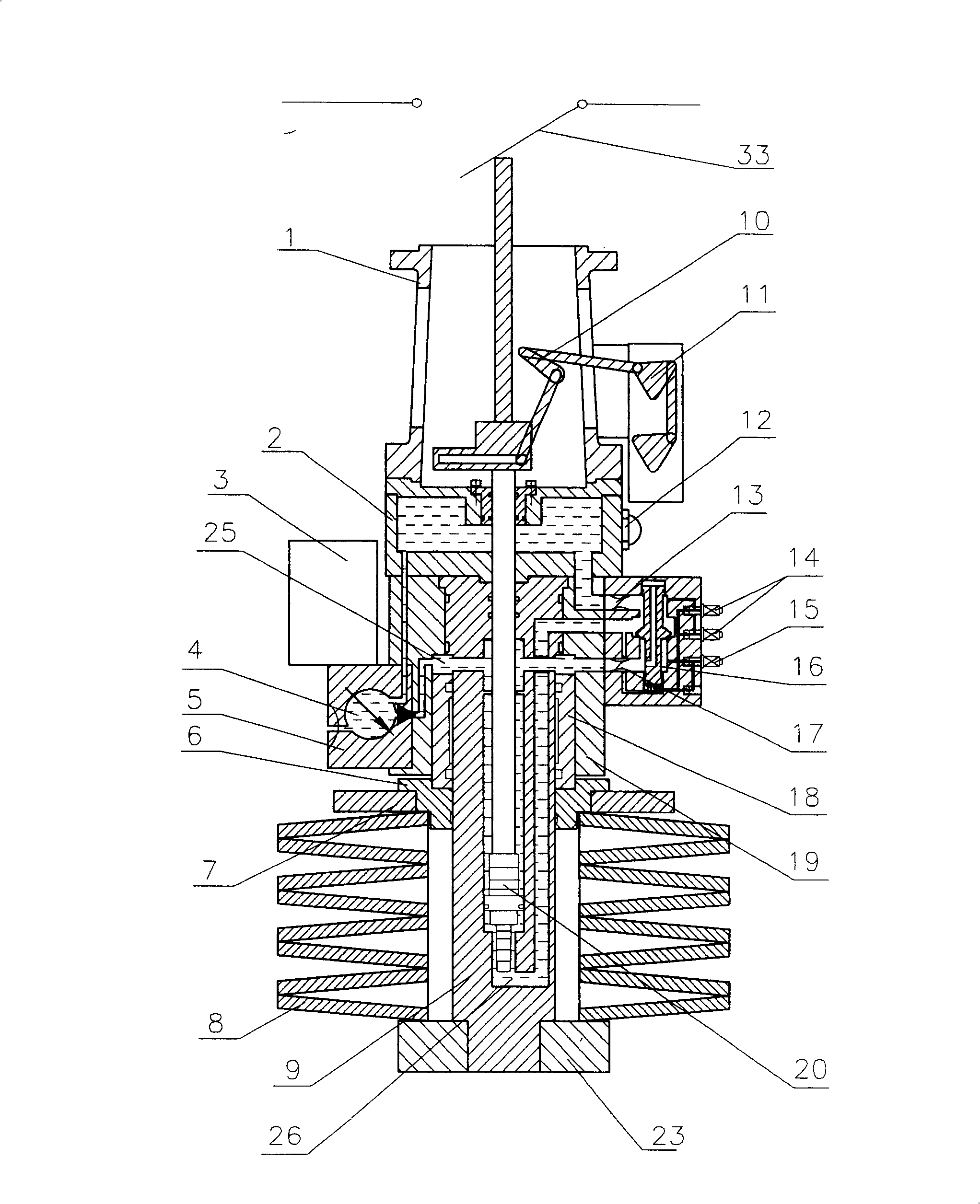

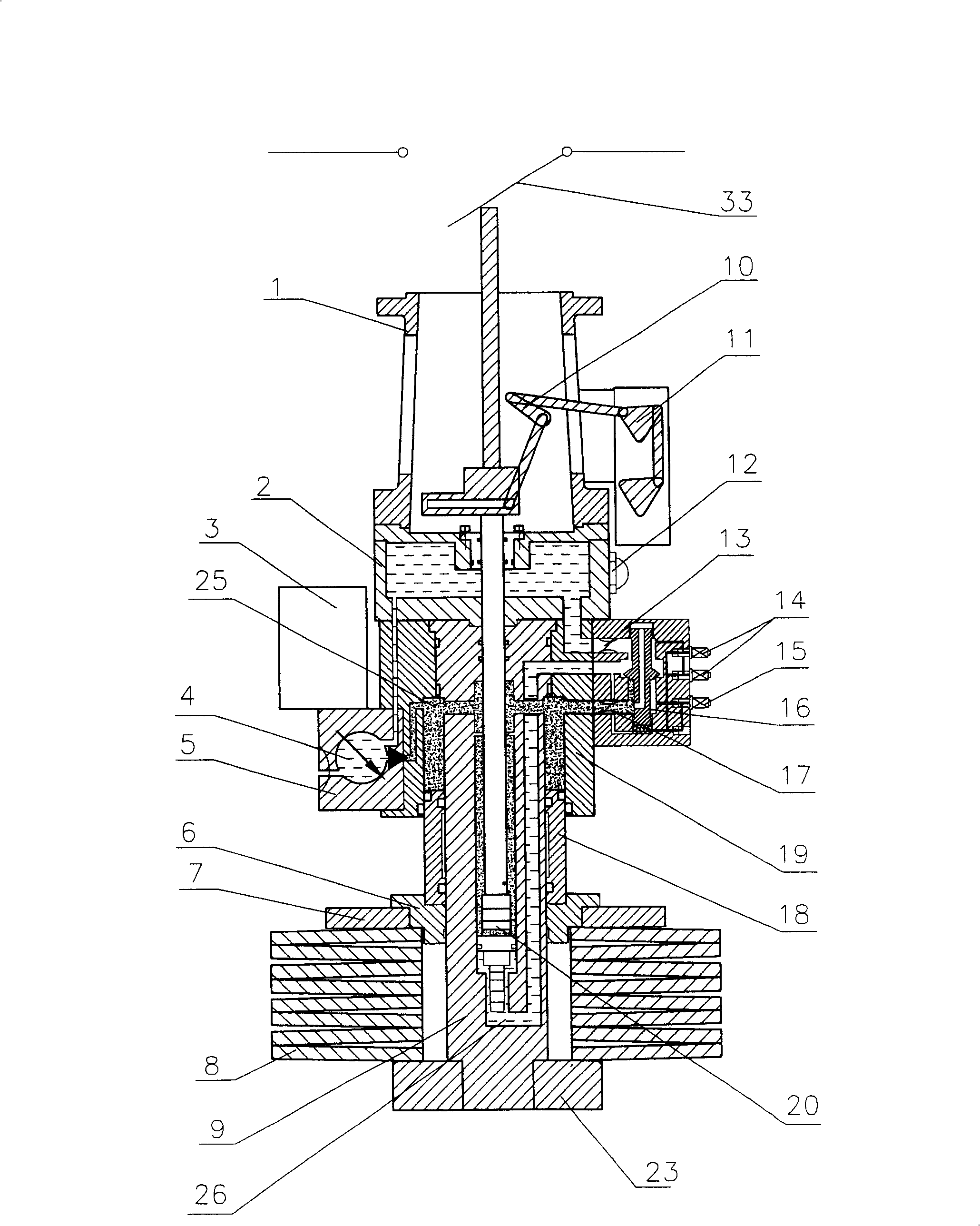

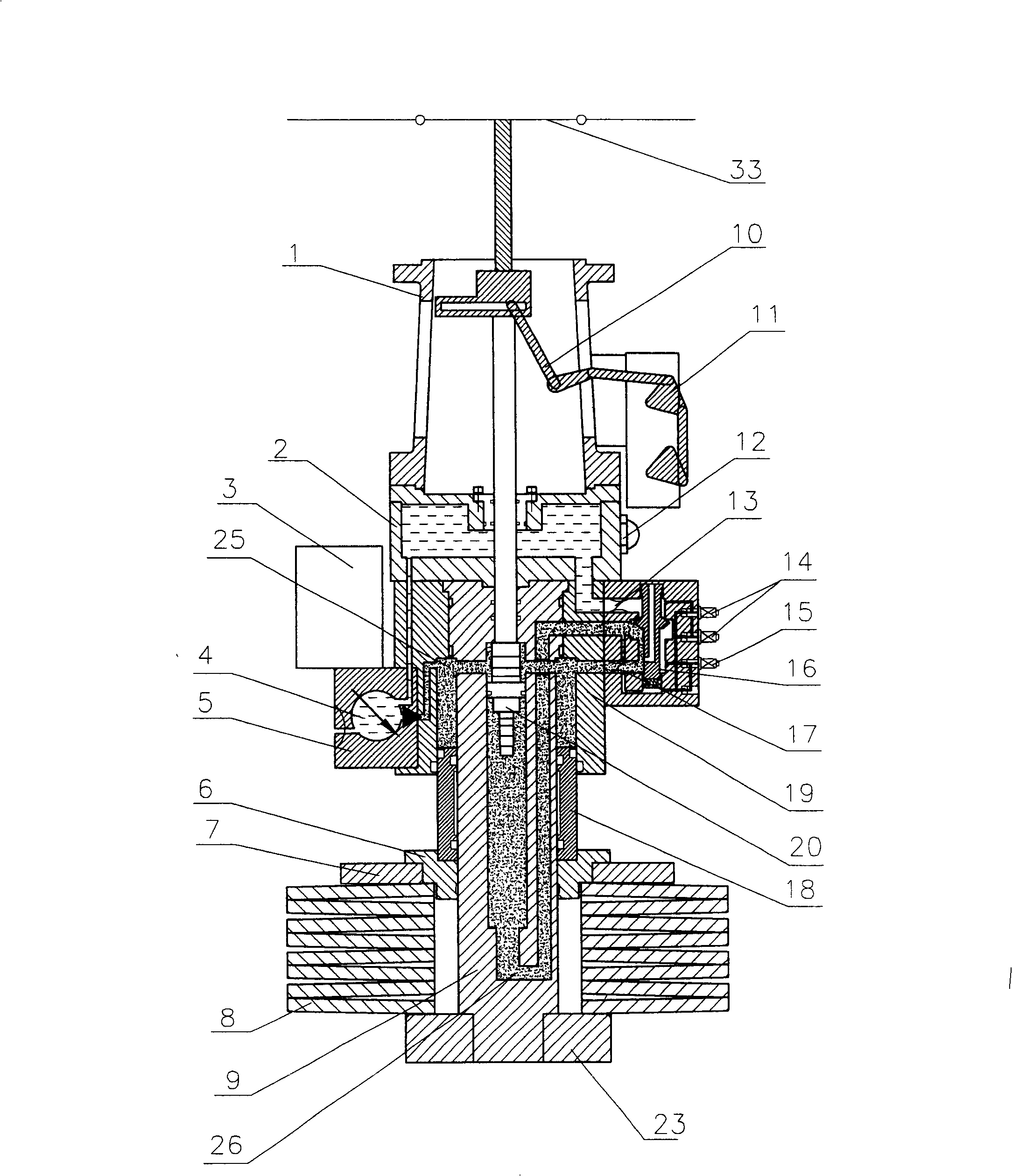

Spring hydraulic operating mechanism for high voltage circuit breaker

ActiveCN100437869CEven by forcePrevent leakageHigh-tension/heavy-dress switchesAir-break switchesFuel tankEngineering

This invention relates to a spring hydraulic operating unit used in a high voltage breaker including an oil tank, disk reed set, a working cylinder, an energy stored piston and a cylinder, in which, the working cylinder is set in the hole of the cylinder to be spaced by a circular truncated cone end face with the diameter of phia, an oil tank is fixed above the cylinder, the energy-stored piston is installed between the working cylinder and the cylinder to form a bush-like energy stored mode of the piston and the working cylinder, a press board is set under the energy stored piston on the working cylinder, the phim end face of the board is contacted with the end surface of the piston, the phin face is contacted with the disk reed set, a round plate is set outside of the phin cylinder of the press board, a plate is jacketed on the other end of the working cylinder, the disk reed set is sleeved between the press board and the plate and all sides of the cylinder is set with a reversing valve, an oil pump, a safety pressure releasing valve and a travel switch.

Owner:沈阳广驰工大高压电气有限公司

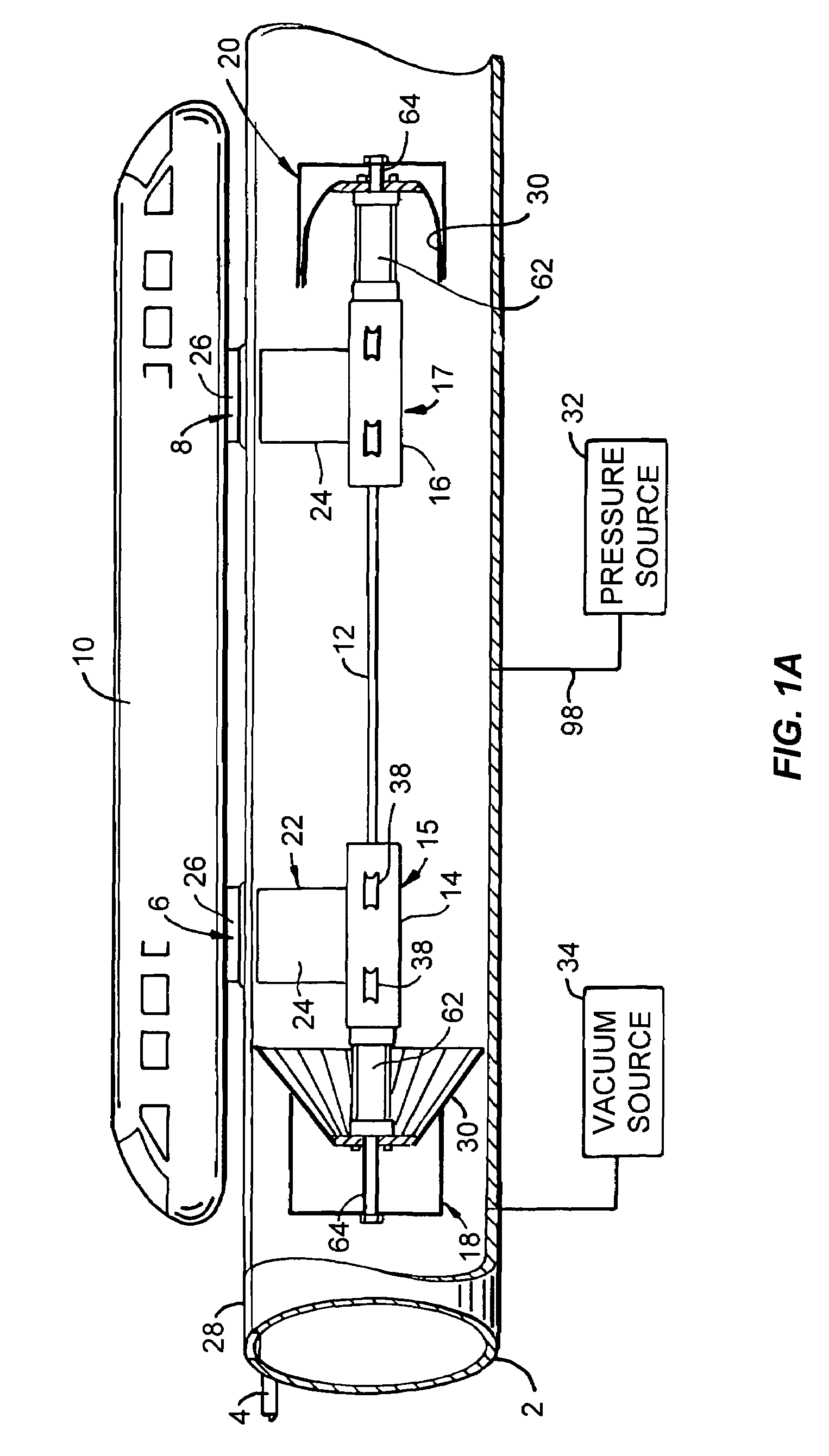

Elevated rail transportation system

ActiveUS7225743B2Eliminates differential speedReduce wearRailway tunnelsRailway componentsAbove groundTransit system

A system for propelling a vehicle along an elevated, pneumatic power tube carried by exterior support structure above ground. First and second angles define tracks for the vehicle and extend parallel to the power tube. Undercarriages secured to the vehicle including vehicle support and guidance wheels which are rotatable about axes inclined relative to legs of the angle tracks have a periphery that engages the legs of the angle tracks so that the weight of the vehicle is supported by the tracks and the support structure only. A pneumatic propulsion unit is movably disposed inside the power tube and is guided along rails on the inside of the power tube. A magnetic coupler having first and second cooperating magnetic elements is attached to the vehicle and the propulsion unit in operative alignment with each other. A portion of the power tube located between the magnetic elements is constructed of a non-magnetic and non-conductive material and extends over the length of the power tube. The propulsion unit has a thrust carriage with a thrust valve that forms a collapsible, frusto-conically shaped wall formed by a multiplicity of overlapping, angularly inclined blades that are concentrically disposed in the power tube. An actuator is coupled to the blades for selectively increasing an angle of the blades until free ends thereof contact an interior surface of the power tube, to thereby prevent the flow of air through the tube past the wall, and for retracting the blades so that the free ends thereof are spaced apart from the interior surface of the power tube, the valve generating a force acting in the longitudinal direction of the power tube when the free ends of the valve blades engage the interior surface.

Owner:FLIGHT RAIL CORP

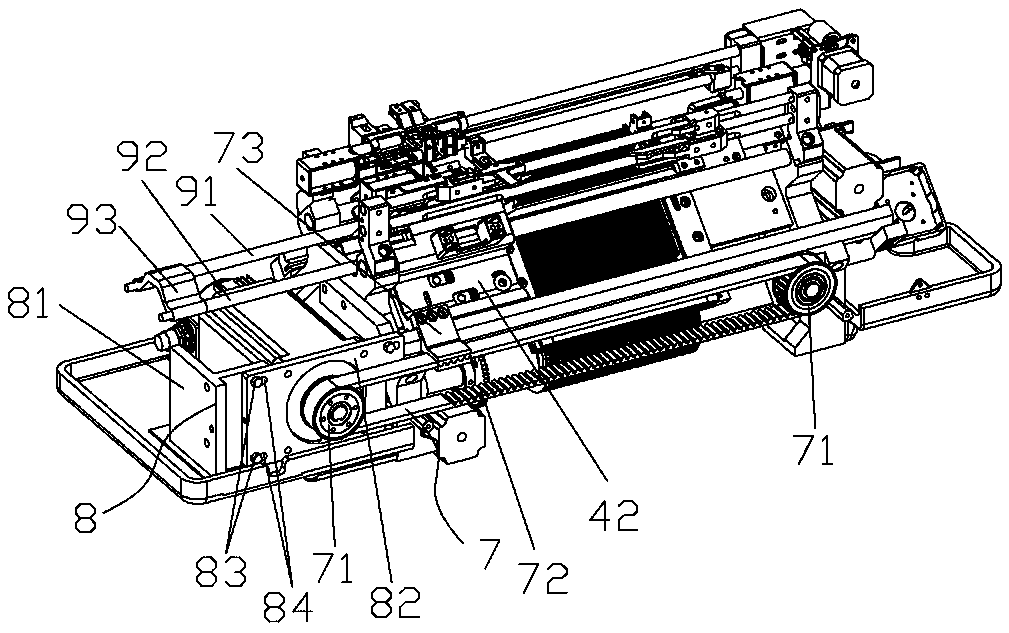

Integrated conveyor motor

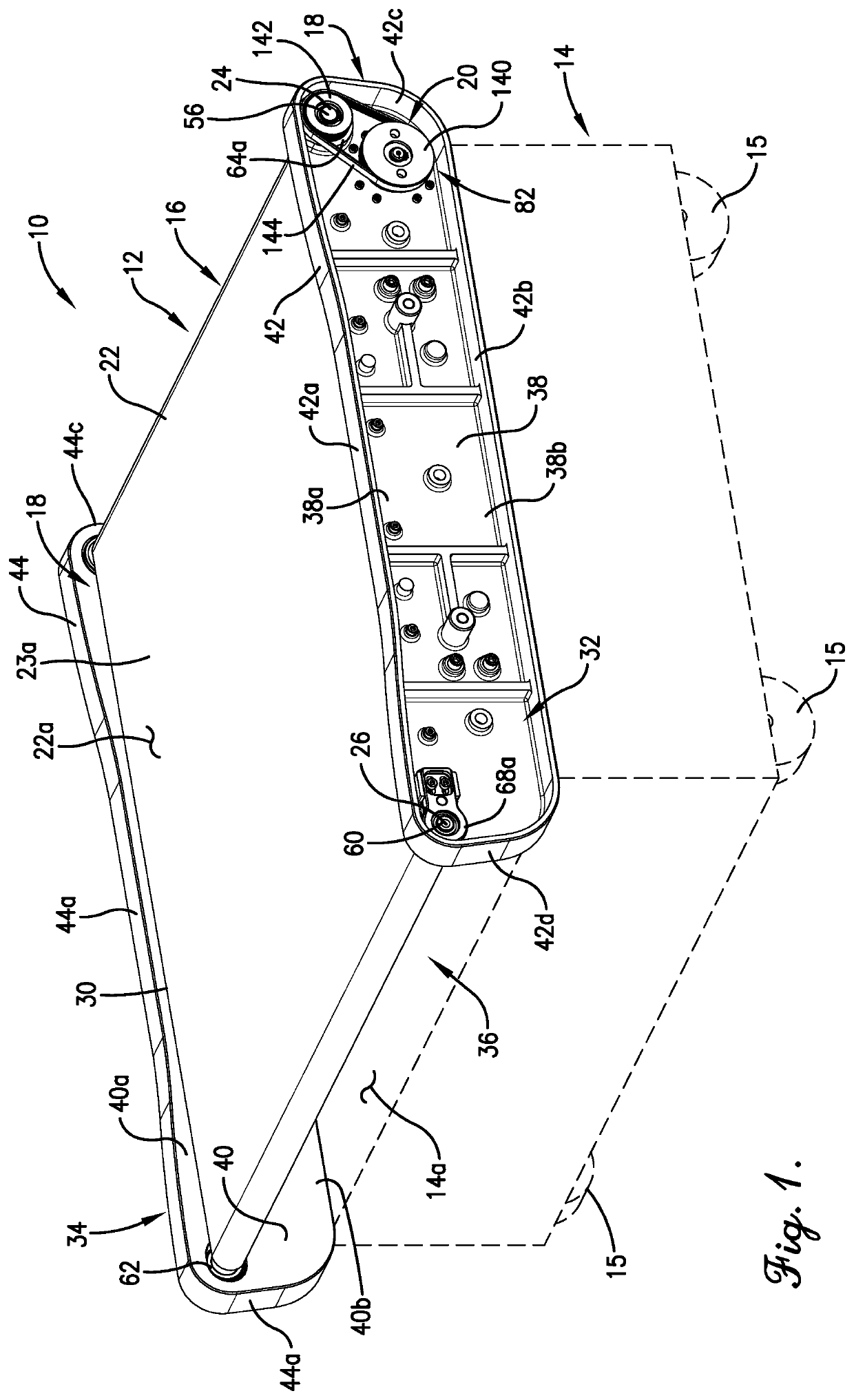

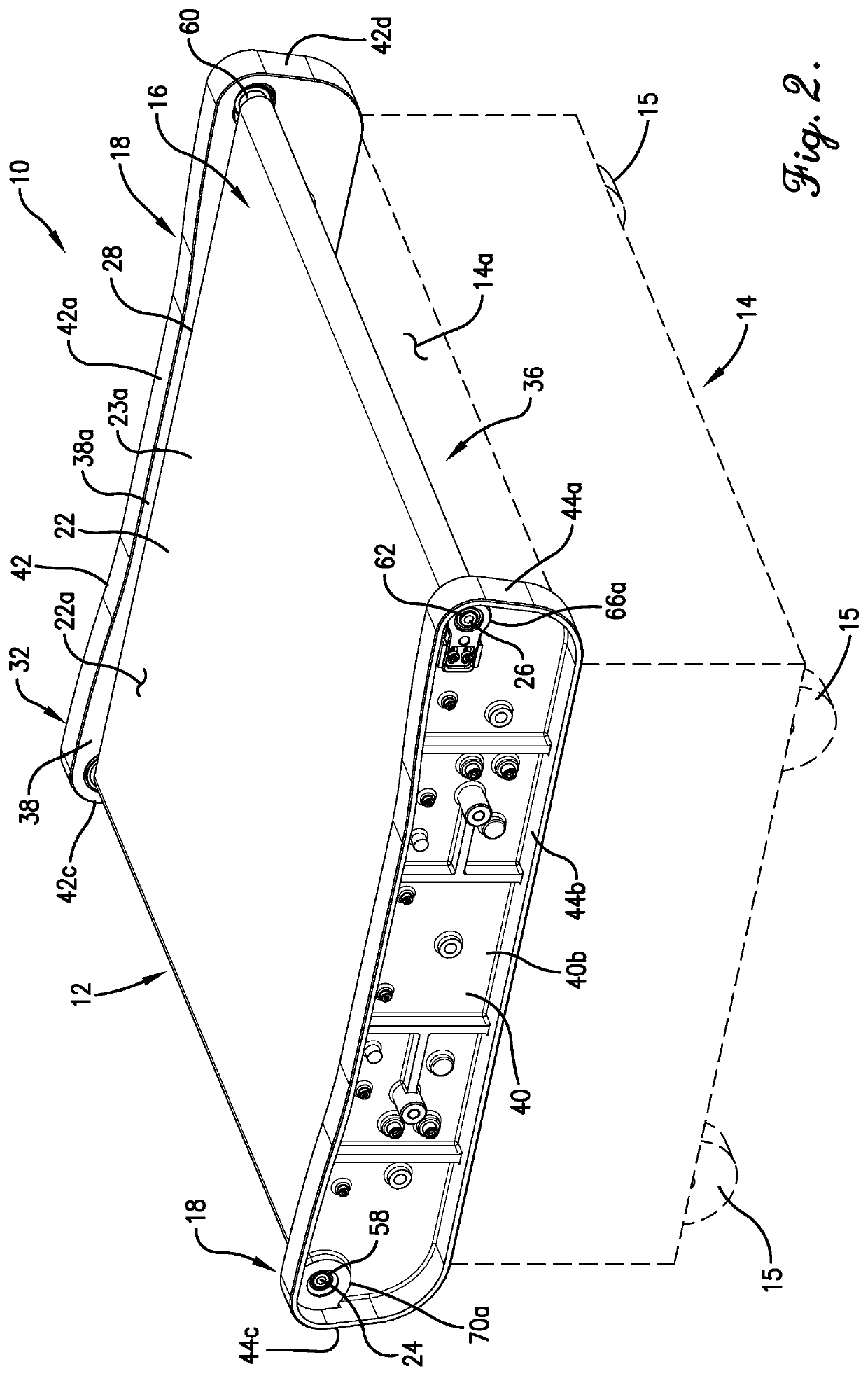

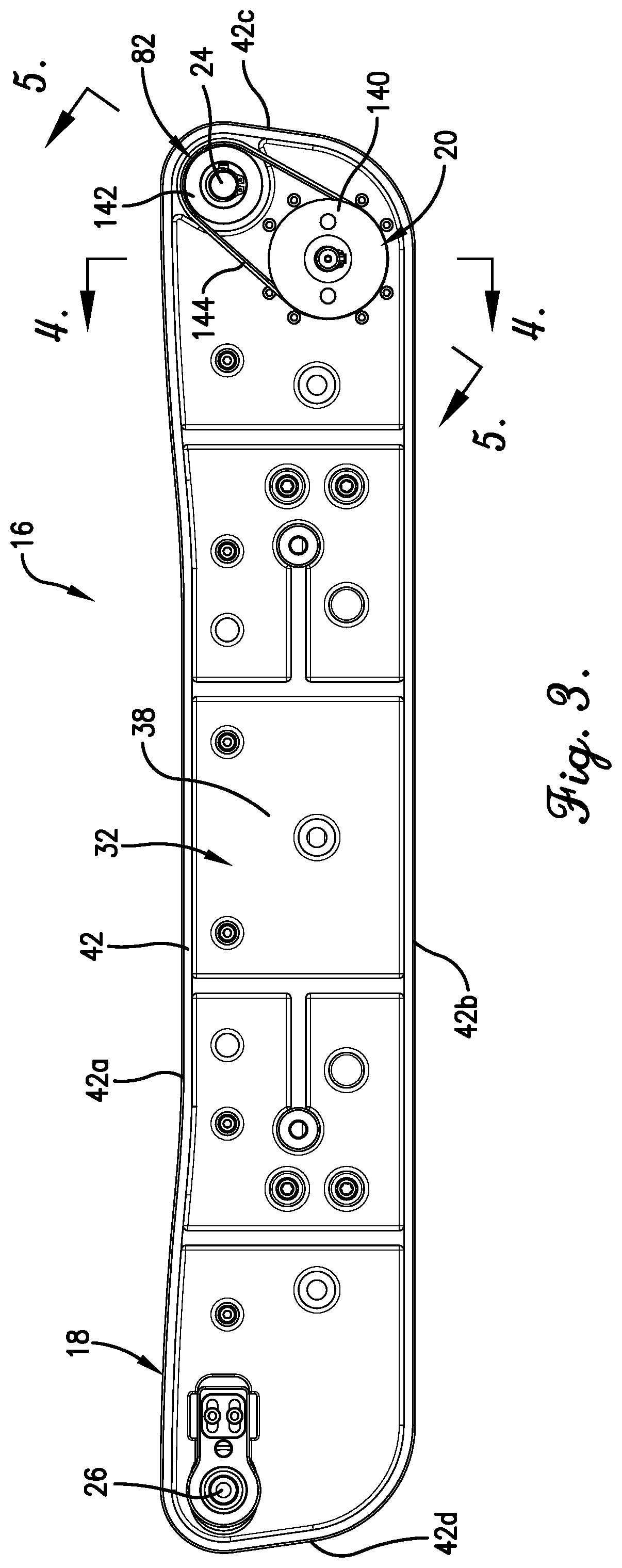

PendingUS20210130101A1Easy to adjustEfficient and secure adjustment and setting and maintenanceConveyorsRolling contact bearingsTransmission beltControl engineering

A conveyor assembly includes a conveyor module including first and second roller bodies and a conveyor belt; a chassis; and a tensioning system. The tensioning system is operable to adjust the tension of the conveyor belt and includes a tensioning device selectively shiftably mounted to the chassis such that shifting of the tensioning system in the fore-aft direction along the chassis results in corresponding fore-aft shifting of the first roller body relative to the second roller body, thereby facilitating adjustment of the tension of the conveyor belt. The chassis includes a pair of side rails and a slider bed. A stiffening assembly includes a bracket spaced vertically below the slider bed such that a vertical gap is formed between the slider bed and the bracket. The stiffening assembly further includes an insert disposed on the bracket and extending upward across at least a portion of the gap.

Owner:NIDEC MOTOR CORP

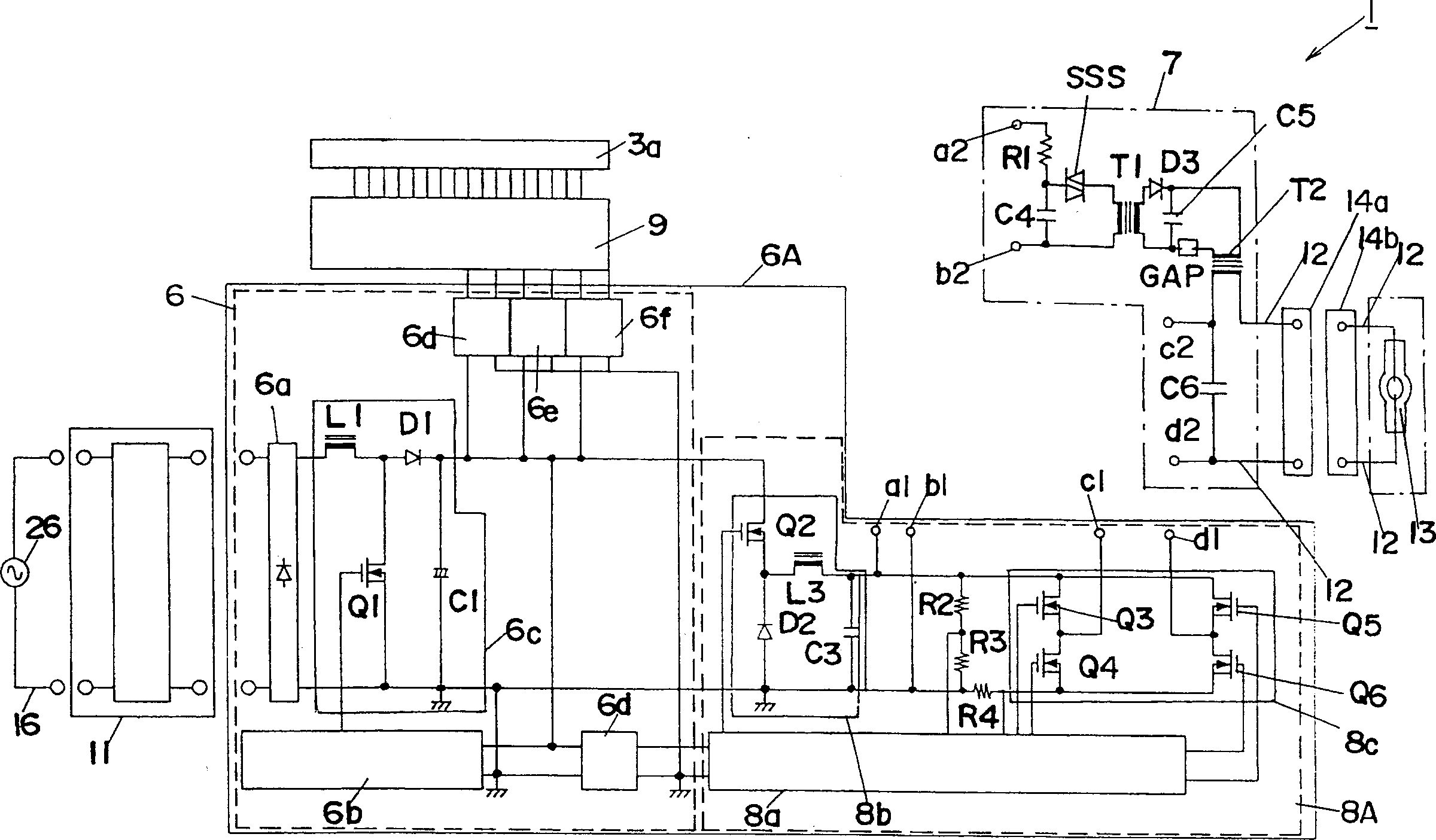

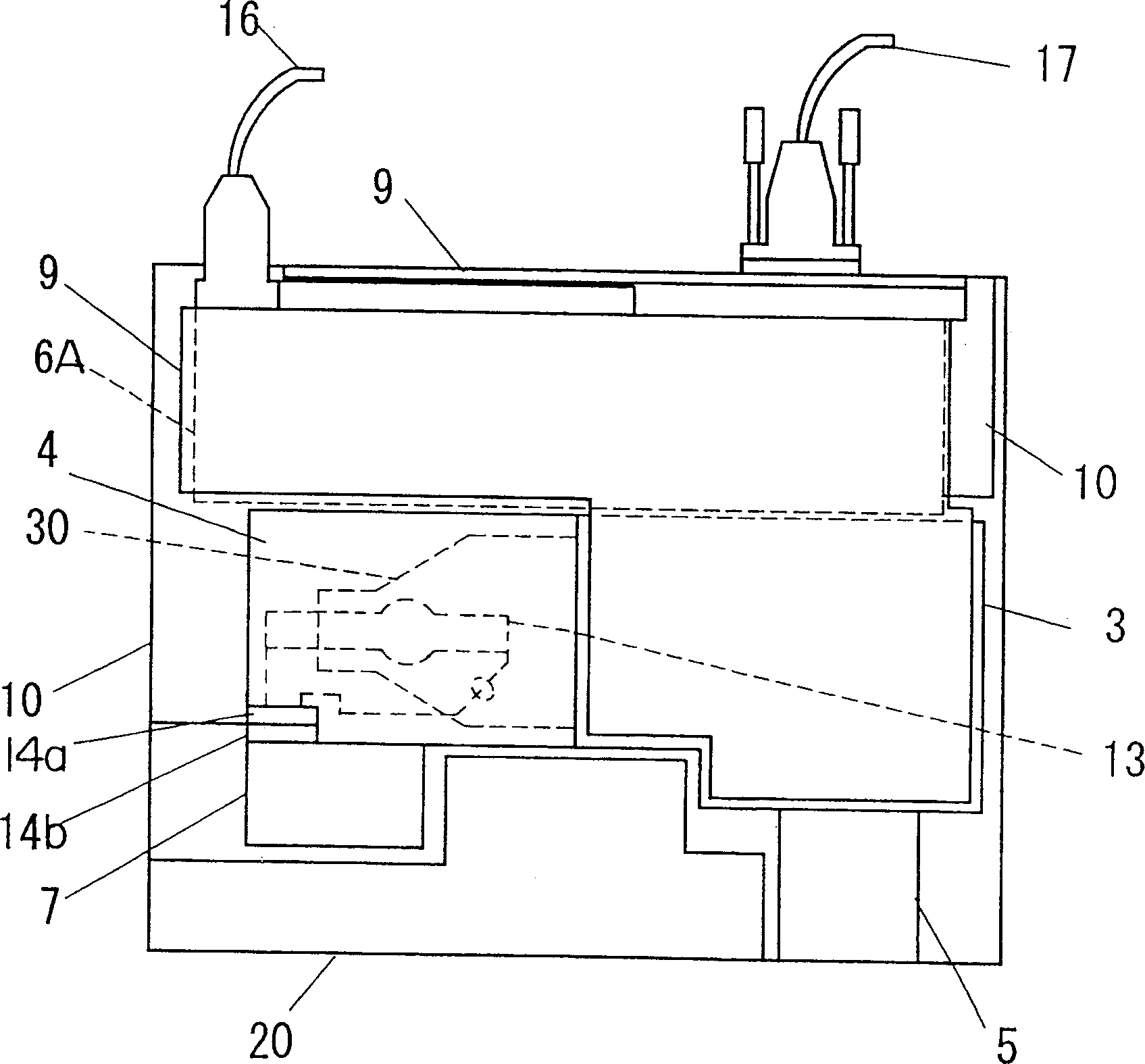

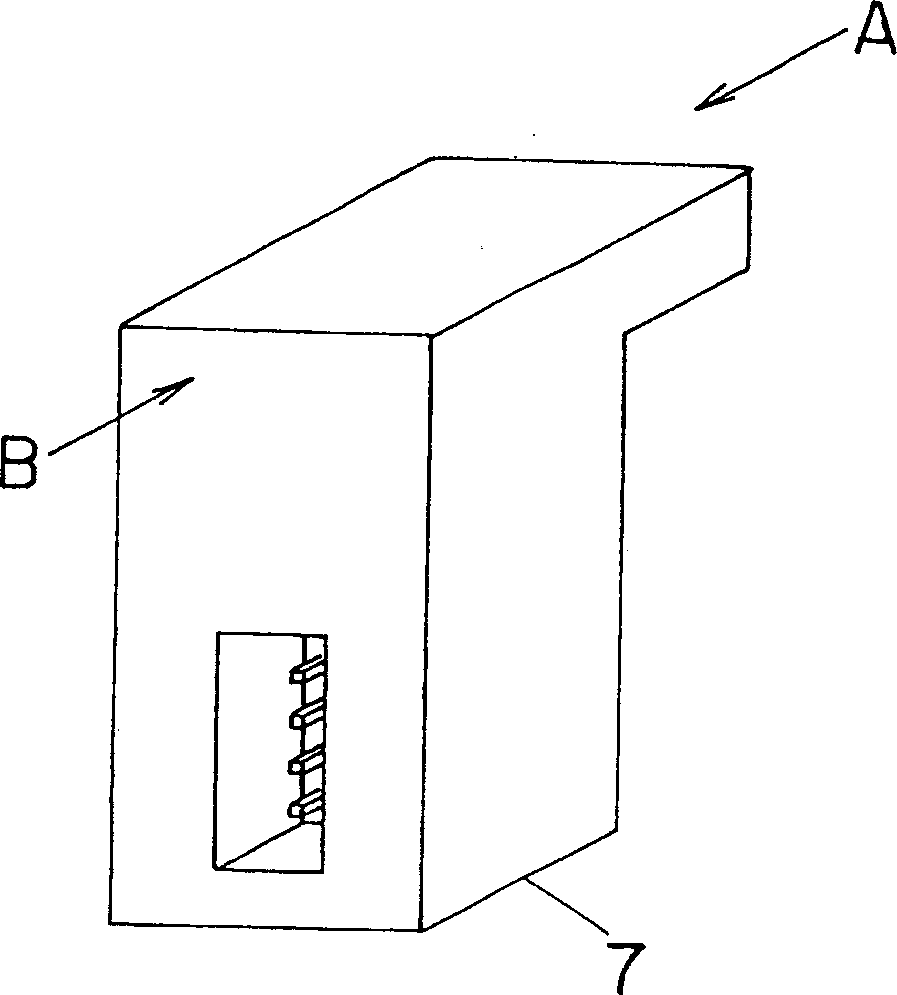

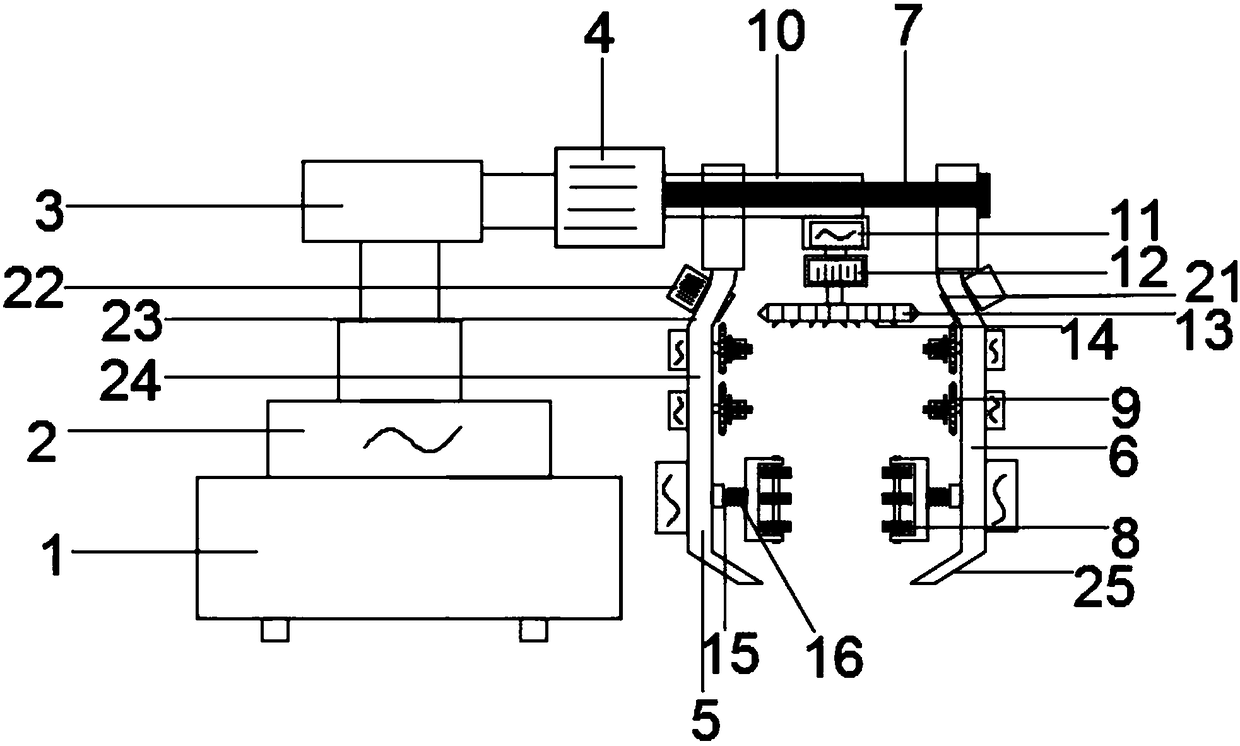

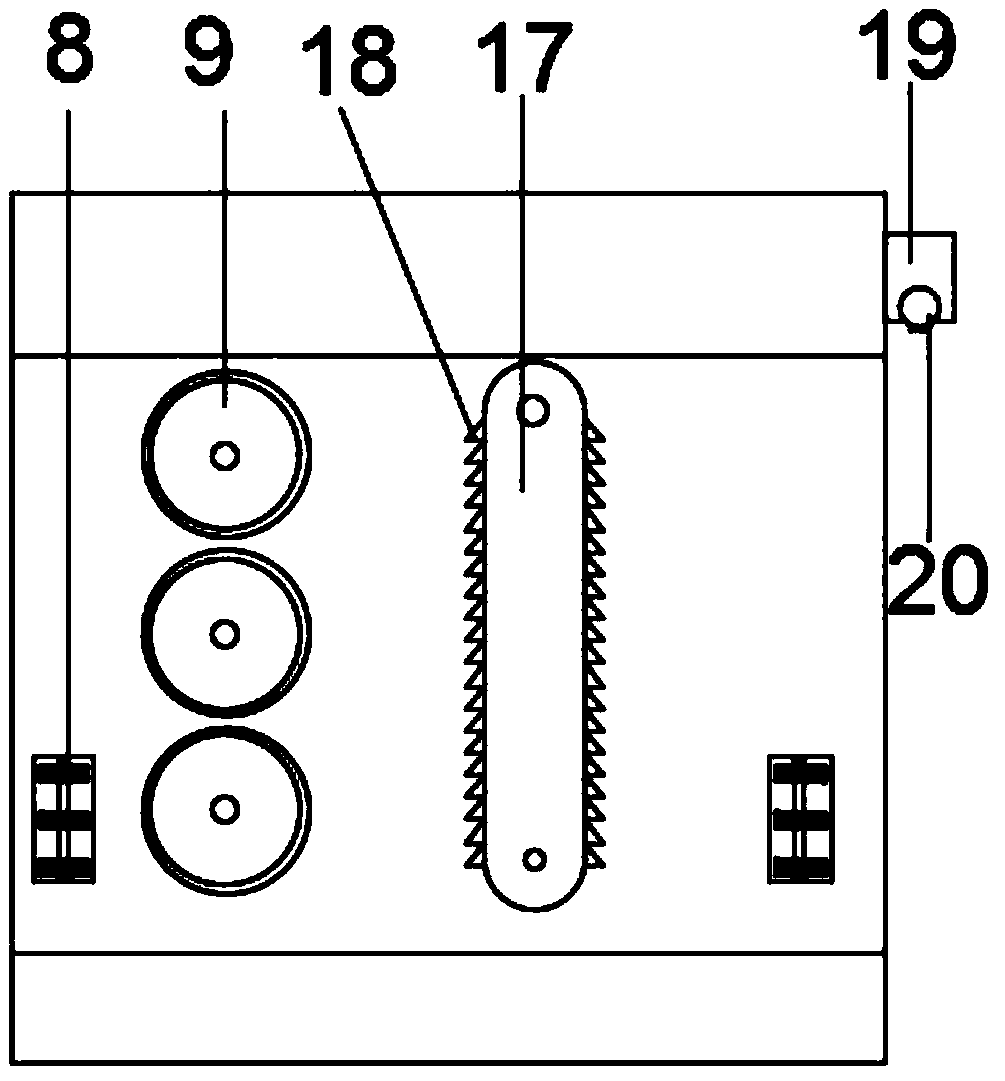

Image display apparatus

InactiveCN1439115ASuppress failureAvoid damageElectrical apparatusElectric circuit arrangementsElectricityGas-discharge lamp

A cabinet accommodates therein a discharge lamp 13, an ignitor module 7 applying a high voltage to the discharge lamp 13 for igniting the same, a lighting device 8A which is connected to the ignitor module and applies a discharging voltage to the discharge lamp so as to keep the discharge lamp turned on, a signal processing unit 9 providing an image signal in accordance with an input signal, an image display which, in response to the image signal from the signal processing unit, produces an image to be projected by use of a light of the discharge lamp 13, and a power supply supplying electric power to the above parts. At least a high voltage generating unit of the ignitor module 7 is arranged to be separated from the lighting device 8A and is disposed away from the signal processing unit 9 and close to the discharge lamp 13 for restraining malfunction of the signal processing unit.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

Road separation zone pruning machine

ActiveCN108142134AAvoid spreadingPromote formationHedge trimming apparatusCuttersDrive shaftPulp and paper industry

The invention relates to the technical field of environmental sanitation mechanical equipment, in particular to a road separation zone pruning machine which comprises a carrying vehicle and pruning mechanisms. The pruning mechanisms are arranged on the inner side of a left barrier and the inner side of a right barrier; a descending air cylinder is further connected with the lower side of a shaft sleeve of a traverse air cylinder; a cutting motor is connected with a telescopic rod end of the descending air cylinder, a cutting disc is connected with a driving shaft end of the cutting motor, andcutting teeth are arranged at the bottom of the cutting disc; two groups of side moving pulleys are positioned at two ends of the inner side of each barrier; vertical cutting knife groups are adjacentto the side moving pulleys at the front ends of the barriers; conveying caterpillars are vertically arranged on the barriers and are positioned at the rears of the cutting knife groups. The road separation zone pruning machine has the advantages that the road separation zone pruning machine is provided with the left barrier and the right barrier, accordingly, noise transmission can be prevented to a great extent, and equipment operation noise can be lowered; the top surfaces and the side surfaces of shrub branches can be simultaneously cut, and branches generated in cutting procedures can beguided into separation zones and can be conveniently decayed to form organic fertilizers.

Owner:重庆汇盛园林景观设计工程有限公司

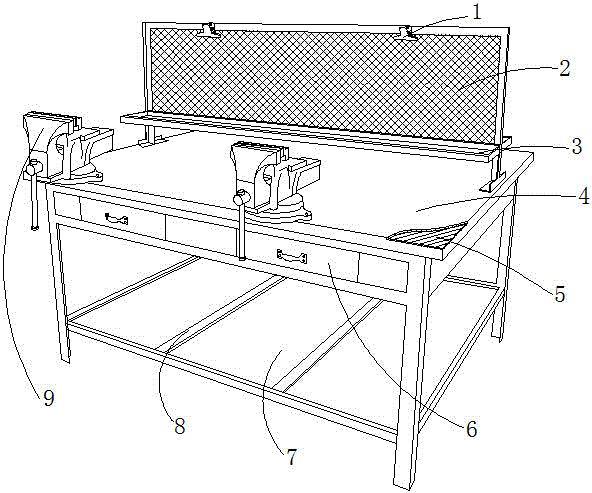

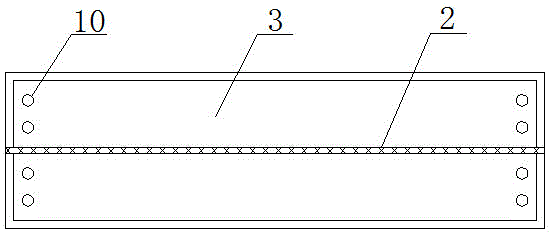

Fitter practical training operating console with vibration and noise reduction function

InactiveCN105632319AInnovative designSimple and beautiful shapeEducational modelsSolid woodEngineering

A fitter practical training operating console with a vibration and noise reduction function comprises a working bench, bench vices arranged on the working bench, a protective net arranged at the middle of the working bench, and drawers arranged at the lower parts of the working bench, wherein a sound absorption material is laid in the working bench, the protective net is arranged at the middle of the working bench in a suspension way, the upper ends of the front and back sides of the protective net are symmetrically provided with drawing clips, the bottom ends of the front and back sides of the protective net are provided with measuring tool ledges, the bottoms of the measuring tool ledges are provided with chip leakage holes, and an object support plate is arranged under the draws in a suspension way. According to the fitter practical training operating console, a solid wood board is laid in a cold-roll steel plate for adsorbing vibration generated during an operation process, thereby effectively reducing operation noise; the measuring tool ledges and the object support plate are designed for storing tools, measuring tools, workpieces and scraps by categories, thereby prolonging the service lives of the tools and the measuring tools; therefore, the fitter practical training operating console is especially suitable for a practical teaching occasion with many operators.

Owner:苗洪敏

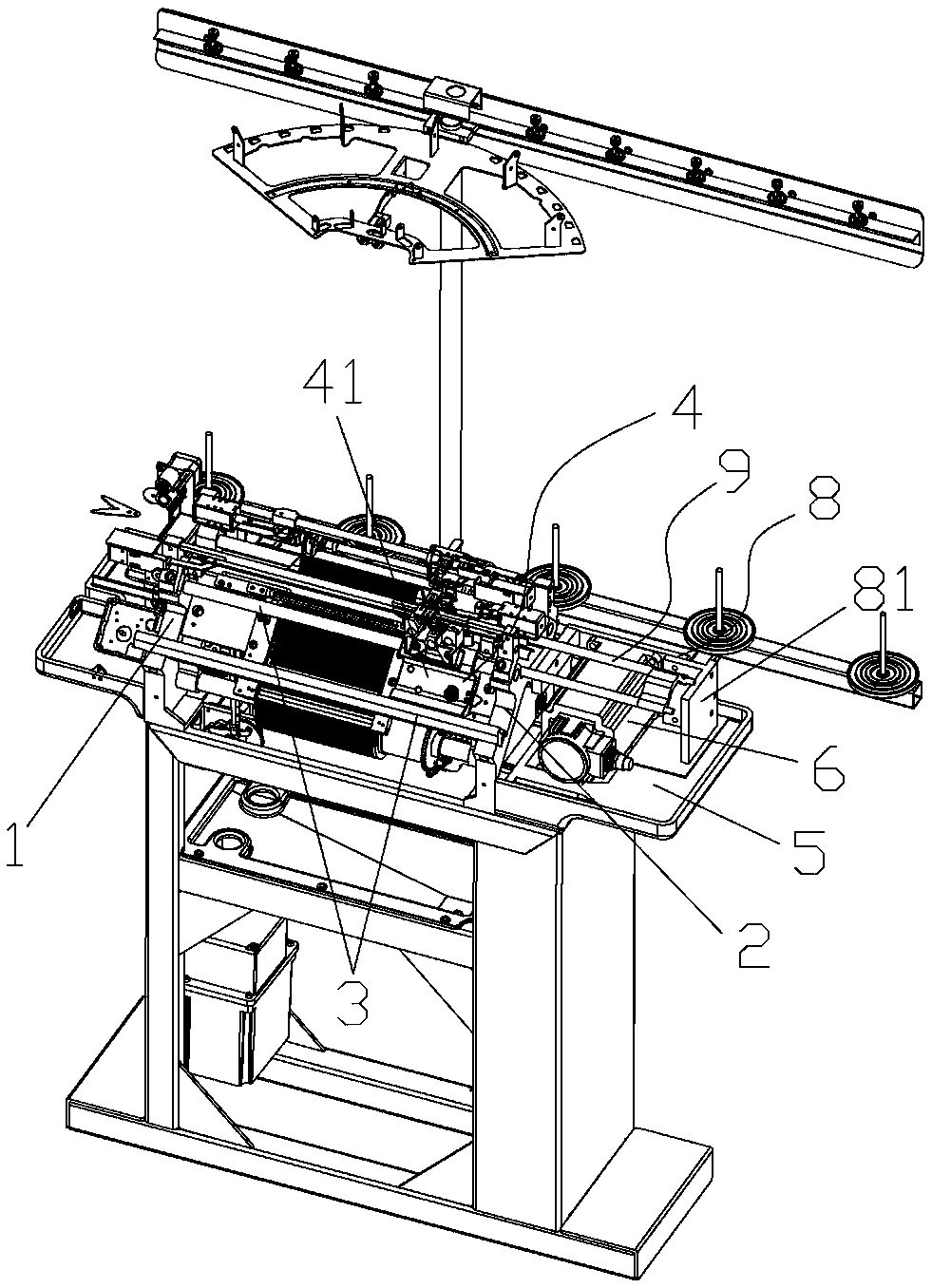

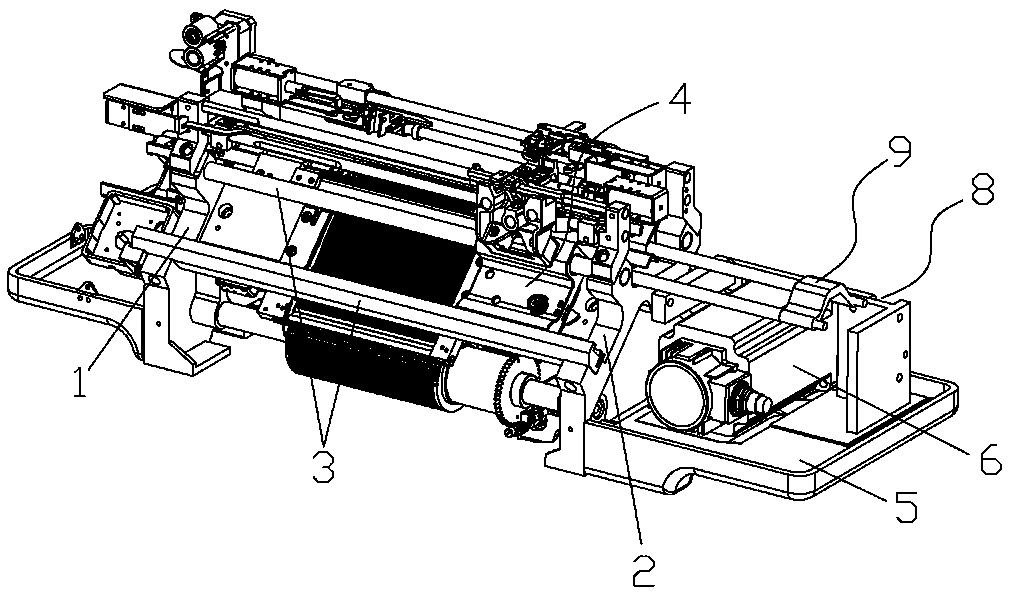

Main drive mechanism used for flat knitting machine

PendingCN108221158ASimple designSmooth transmissionFlat-bed knitting machinesReciprocating motionEngineering

The invention mainly relates to a main drive mechanism used for a flat knitting machine, comprising a left base and a right base, wherein a slide rail component is arranged between the left base and the right base, a headpiece part is arranged in matched on the slide rail component and comprises a front headpiece component and a rear headpiece component, a motor seat is arranged at the right sideof the right base, a main driving device is arranged on the motor seat, synchronous belt drive devices arranged in parallel are arranged at the rear sides of the left base and the right base, the maindriving device independently drive the rear headpiece component to move in a reciprocating way by the synchronous belt drive device, a fixing adjusting device is arranged on the main driving device and is used for fixing the main driving device on the motor seat, the tension of the synchronous belt drive device on the main driving device can be adjusted by the fixing adjusting device, and the front headpiece component is connected with the rear headpiece component by a connecting device, so as to realize synchronous reciprocating movement of the front and rear headpiece components. The designof the main drive mechanism is simple in structure, steady in driving, long in service life, low in operation noise and increased in economic benefit.

Owner:ZHEJIANG RUIFENG INTELLIGENT TECH CO LTD

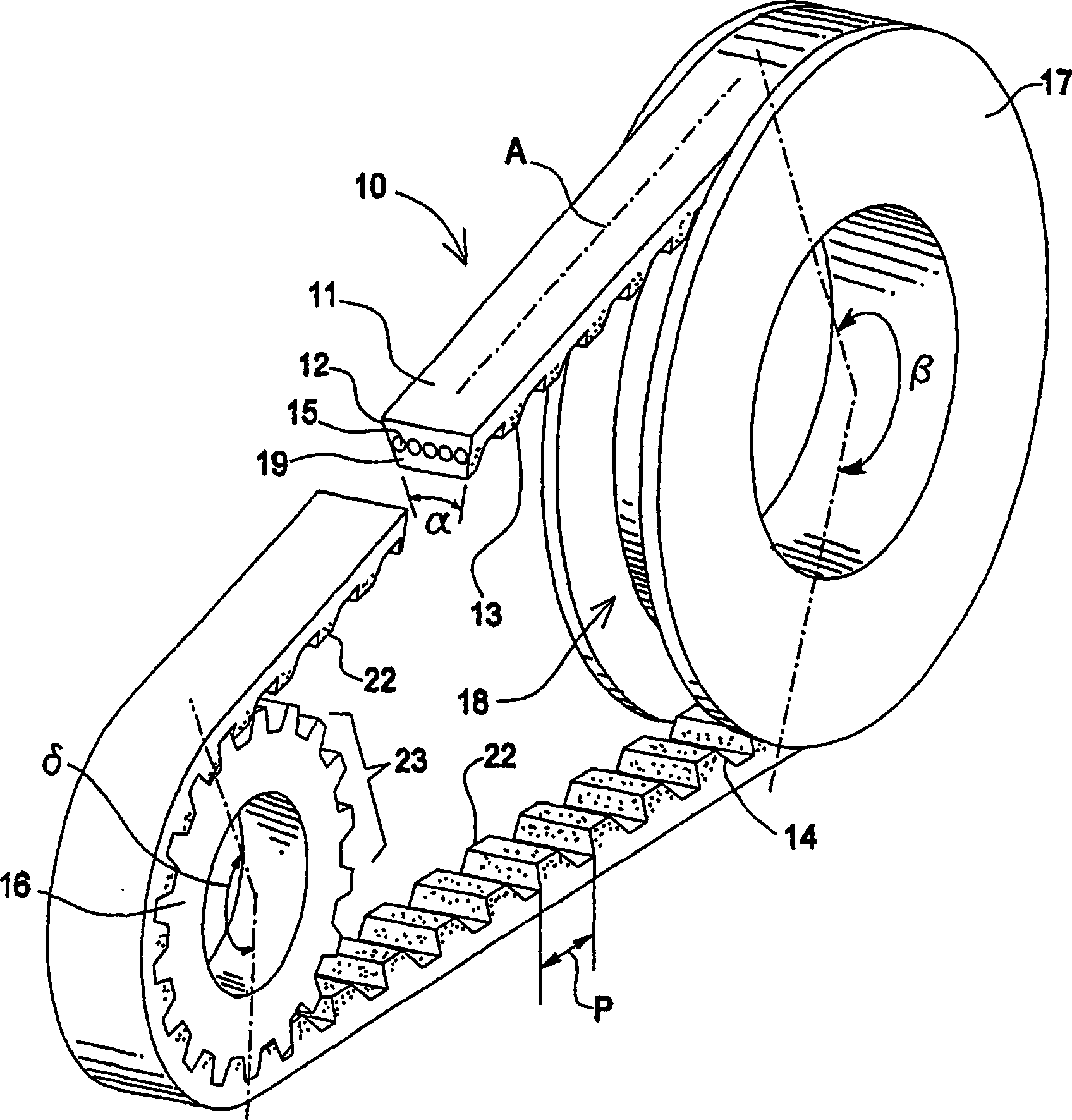

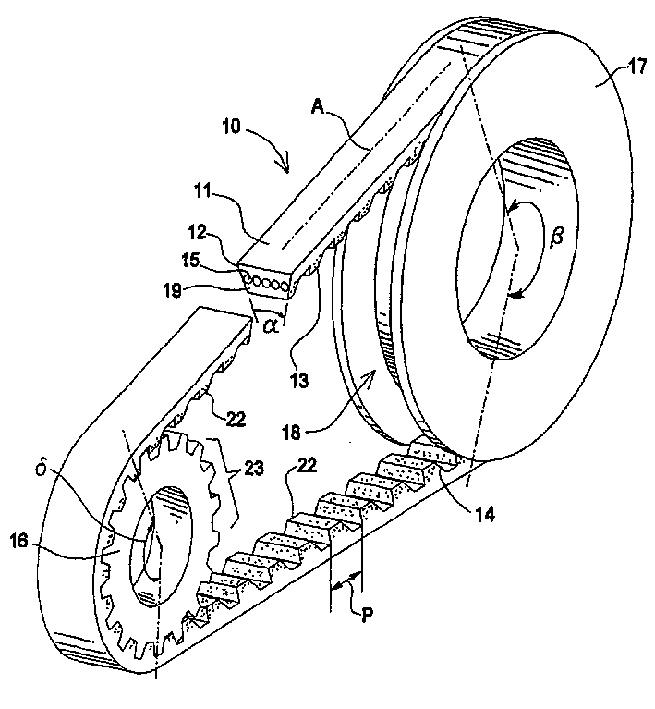

V-belt system

The invention comprises a synchronous v-belt. The belt (10) has a pulley engaging surface (13) having a toothed or cogged profile for engaging a synchronous pulley (16). The pulley engaging surface (13) further comprises a cover layer to increase belt life and reduce noise. The belt (10) also has opposing sides cut, ground or molded to describe an included angle (a) for engaging a v-belt or single groove pulley (17). The belt (10) is preferably used in conjunction with one synchronous pulley (16) and one v-belt pulley (17). The belt meshes with the teeth (23) of the synchronous pulley (16) and simultaneously runs in the groove (18) of the v-belt pulley (17). On start up, the v-belt (10) may slip slightly in the v-grouve pulley (17), thereby reducing the initial start up shock to the system. Therefore, the limit for power transmission in now the size and angle ( beta ) of wrap of the larger v-belt pulley (17). In addition, the synchronous drive pulley (16) provides a positive mechanical belt drive interface which, in conjunction with the larger v-blet pulley (17), allows up to 30% more torque to be transmitted by the inventive belt while reducing operating noise, depending upon the system design parameters.

Owner:THE GATES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com