Control cabinet door frame and embedded frame type profile screen cabinet door

A cabinet door and door frame technology, which is applied in the direction of wing leaf frame, door leaf, window/door, etc., can solve the problems of large operation noise, single style, cumbersome assembly process, etc., and achieve the effect of low operation noise and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

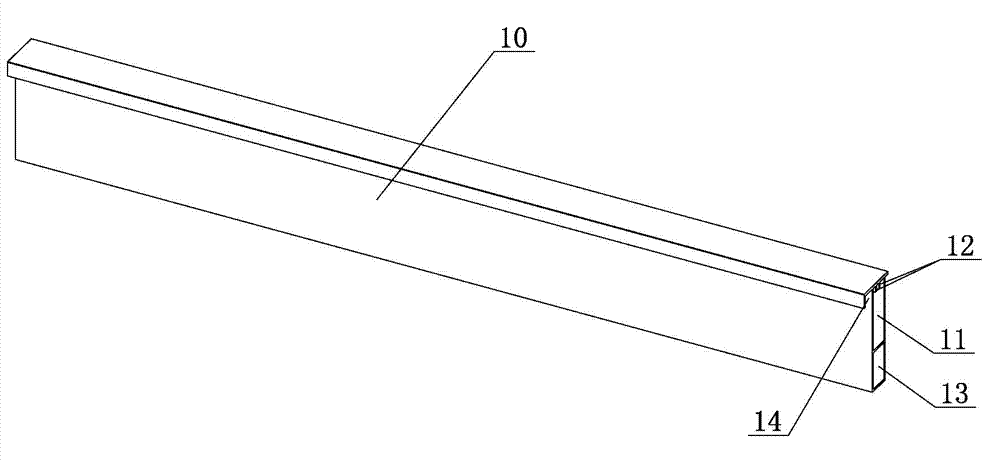

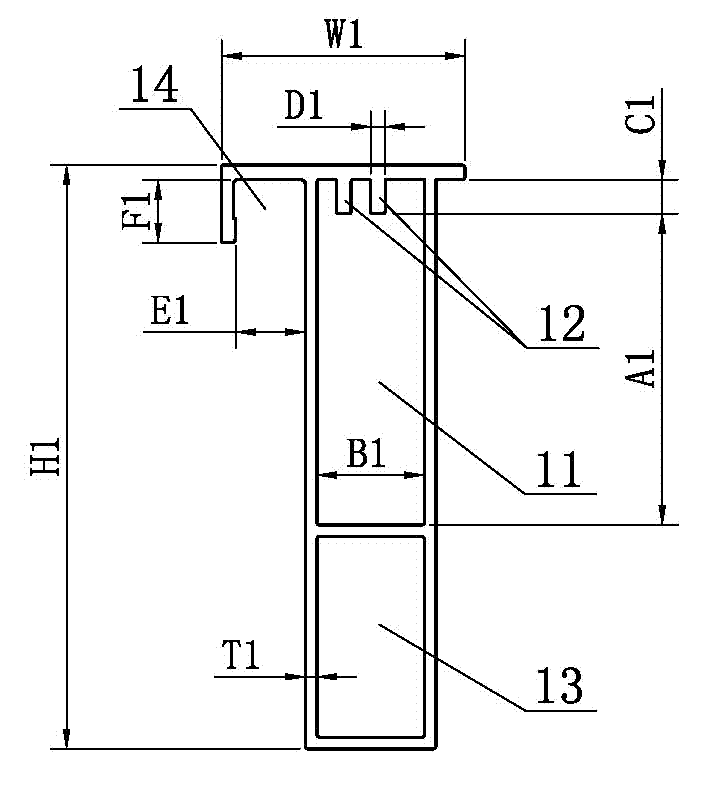

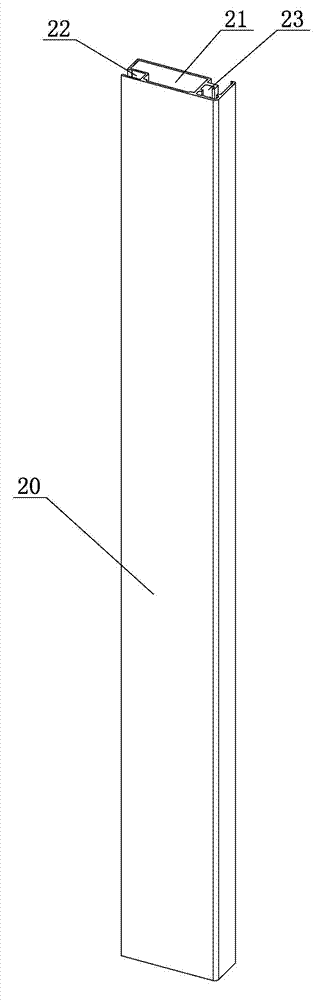

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , a control cabinet door frame profile, including a cabinet door horizontal frame profile 10 for forming an upper door frame and a lower door frame of the cabinet door frame, and a cabinet door vertical frame profile 20 for forming a left door frame and a right door frame of the cabinet door frame;

[0043] The cross-section of the horizontal frame profile of the cabinet door includes a transverse plug-in connection cavity 11, which is a closed rectangular hollow cavity, and is provided on the inner wall of the horizontal plug-in connection cavity towards the outer edge of the cabinet door frame. Rib 12 is arranged, and a structural cavity 13 is also provided on the inboard of the cabinet door horizontal frame section bar towards the cabinet door frame, and a horizontal door panel clamping mouth 14 is provided at the side wall of the cabinet door horizontal frame section bar as the side wall of the cabinet door edge....

Embodiment 2

[0051] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , an inlay frame type profile screen cabinet door, installed on the cabinet body of the control cabinet, including a cabinet door frame and a door panel 30, the cabinet door frame includes an upper door frame 40, a lower door frame 50, a left door frame 60 and a door frame plug-in connection Right door frame 70; described left door frame and right door frame are respectively positioned at the left side and the right side of cabinet door front, and described cabinet door front is the side towards the cabinet body outside after cabinet door is installed on the cabinet body, as Figure 5 shown.

[0052] The upper door frame and the lower door frame are made of the cabinet door horizontal frame profile described in Embodiment 1, and the left door frame and the right door frame are made of the cabinet door vertical frame profile described in Embodiment 1;

[0053] The door frame insert includes a first do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com