Proceeding for flushing of pipes at hydraulic systems and a plant for the flushing

A technology of hydraulic system and equipment, applied in the field of pipeline flushing process, can solve the problems of high cost and difficult system, and achieve the effect of compact design, low operation noise and lower operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

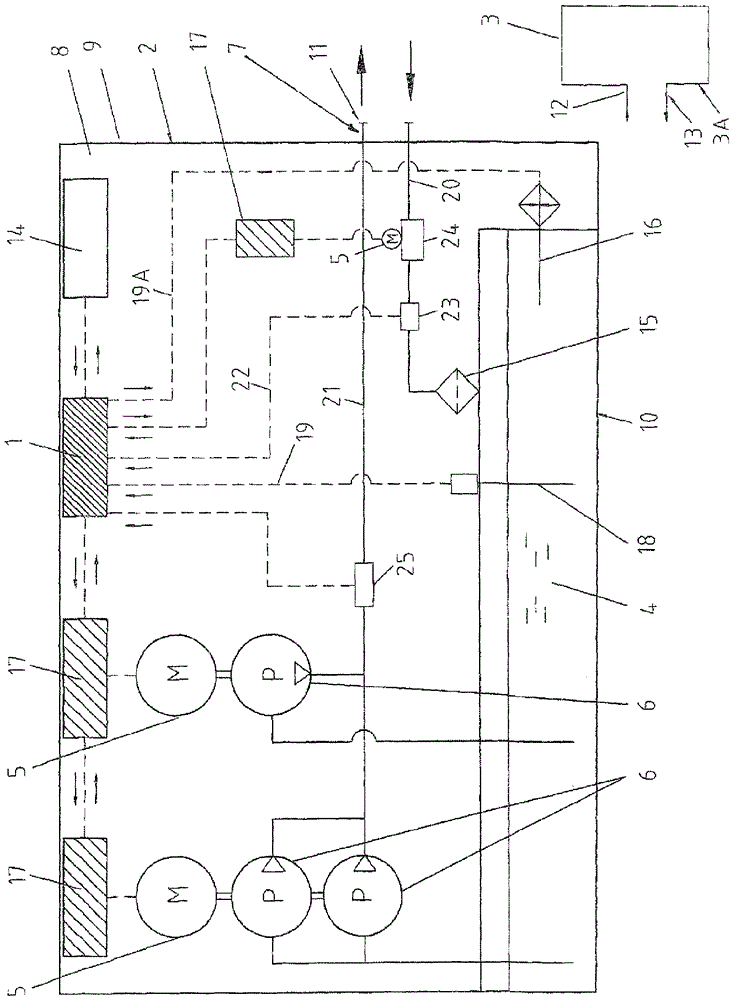

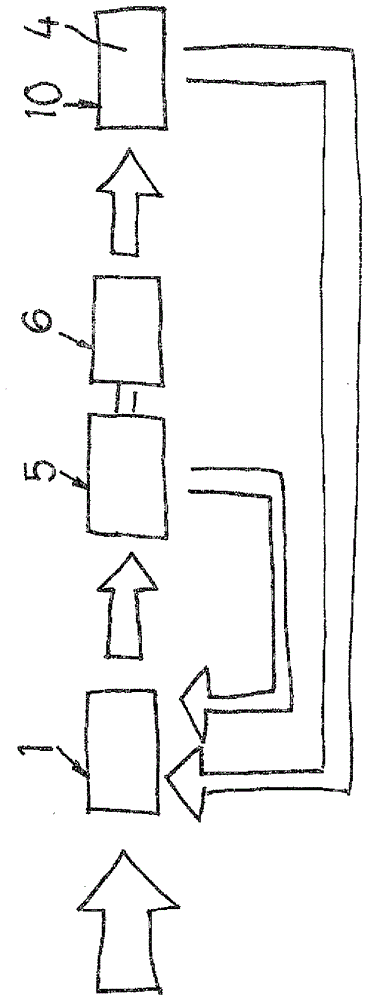

[0050]A process for achieving the so-called flushing of the interior of the pipes of a hydraulic system 3 by supplying a fluid 4 through said hydraulic system 3 as a flow of at least Re 2300 (Renault) according to this The process of the invention is realized in such a way that an automatic cleaning of the hydraulic lines is provided by means of oil 4 or another suitable fluid which is utilized in a so-called closed loop system. Through the pipe size selected in the user interface 14 and by means of the control unit 1, which regulates the motor 5, the pump 6, and the desired degree of purification included in the device 2 utilized, the motor 6 or Feedback of rotational speed of multiple motors 6, turbulent oil flow, and oil temperature.

[0051] The invention according to "closed loop" comprises the steps indicated below.

[0052] I. The operator selects the pipe size in the user interface 14 .

[0053] II. The control unit 1 regulates the motor 5 and the pump 6 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com