Inlet air filter device of gas turbine

An inlet air and gas turbine technology, which is applied to the air inlet of the turbine/propulsion unit, combustion air/combustion-air treatment, dispersed particle filtration, etc. Removing salt, reducing the service life of filter cartridges, etc., to reduce operational risks, prolong effective service life, and reduce equipment wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

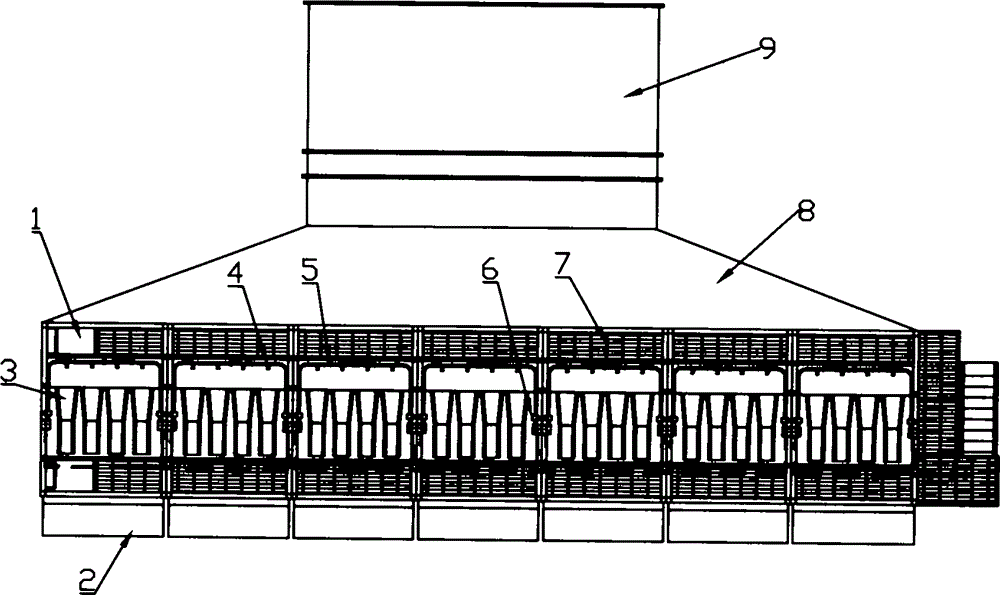

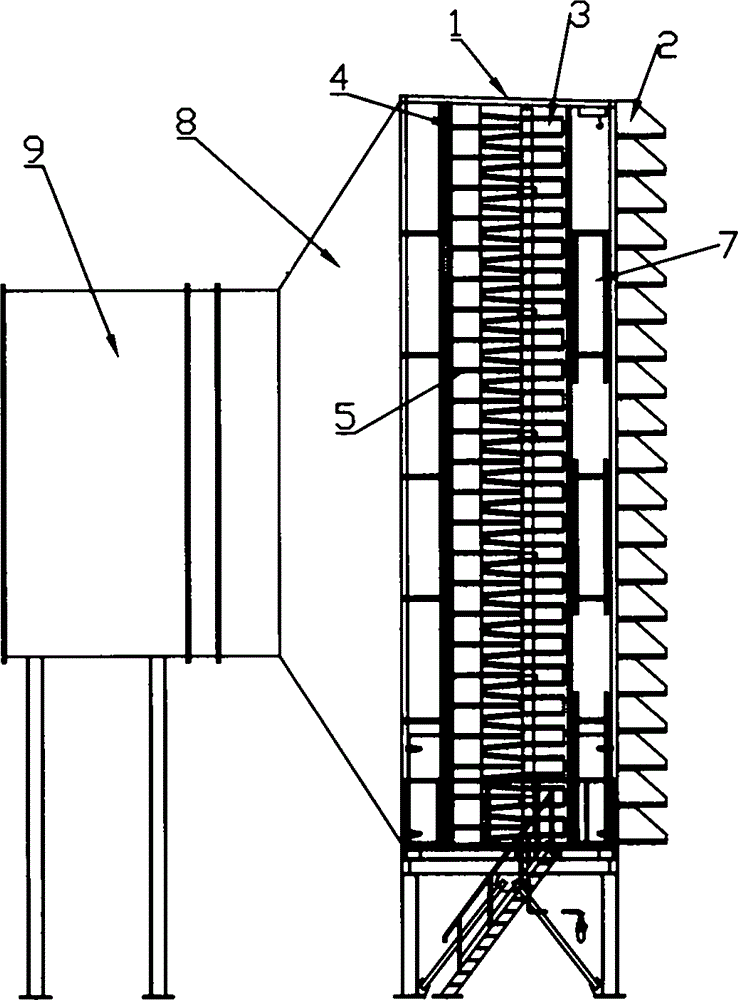

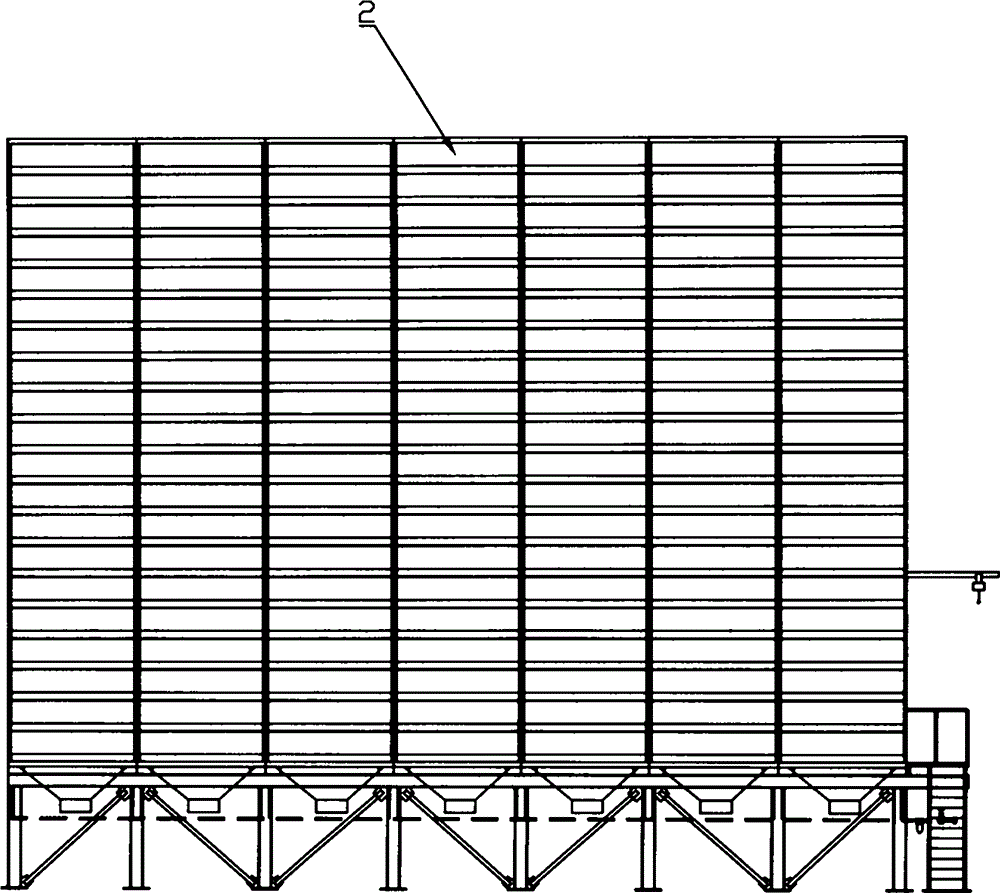

[0027] As shown in the figure, the gas turbine inlet air filter device according to the present invention includes: a filter 1, a rainproof cap 2, a high-precision filter element 3, a blowback nozzle 4, a compressed air pipe 5, a solenoid valve 6, an inspection platform 7, Air duct 8, muffler 9; rainproof cap 2 is installed at the entrance of filter 1, and high-precision filter element 3 is installed inside filter 1. The element 3 has a double-layer structure, the first layer is an E-class filter layer 10, and the second layer is a moisture-proof filter layer 11, so that single-stage filtration can meet the standard of E12 in EN1822-2009, that is, for the most penetrable particle diameter When it is 0.4μm, the filtration efficiency is >99.95%, which is 5 times higher than that of similar products and increases the output power of power generation by up to 6%; it will not cause output power loss due to compressor pollution, reduce the pressure loss of downstream equipment, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com