Full-electric controlled container lifting machine with centralized drive axle

A centralized and hoisting machine technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of oil resource consumption, noise, not in line with the development trend of energy saving and emission reduction green economy, etc., to reduce environmental pollution, reduce The effect of operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

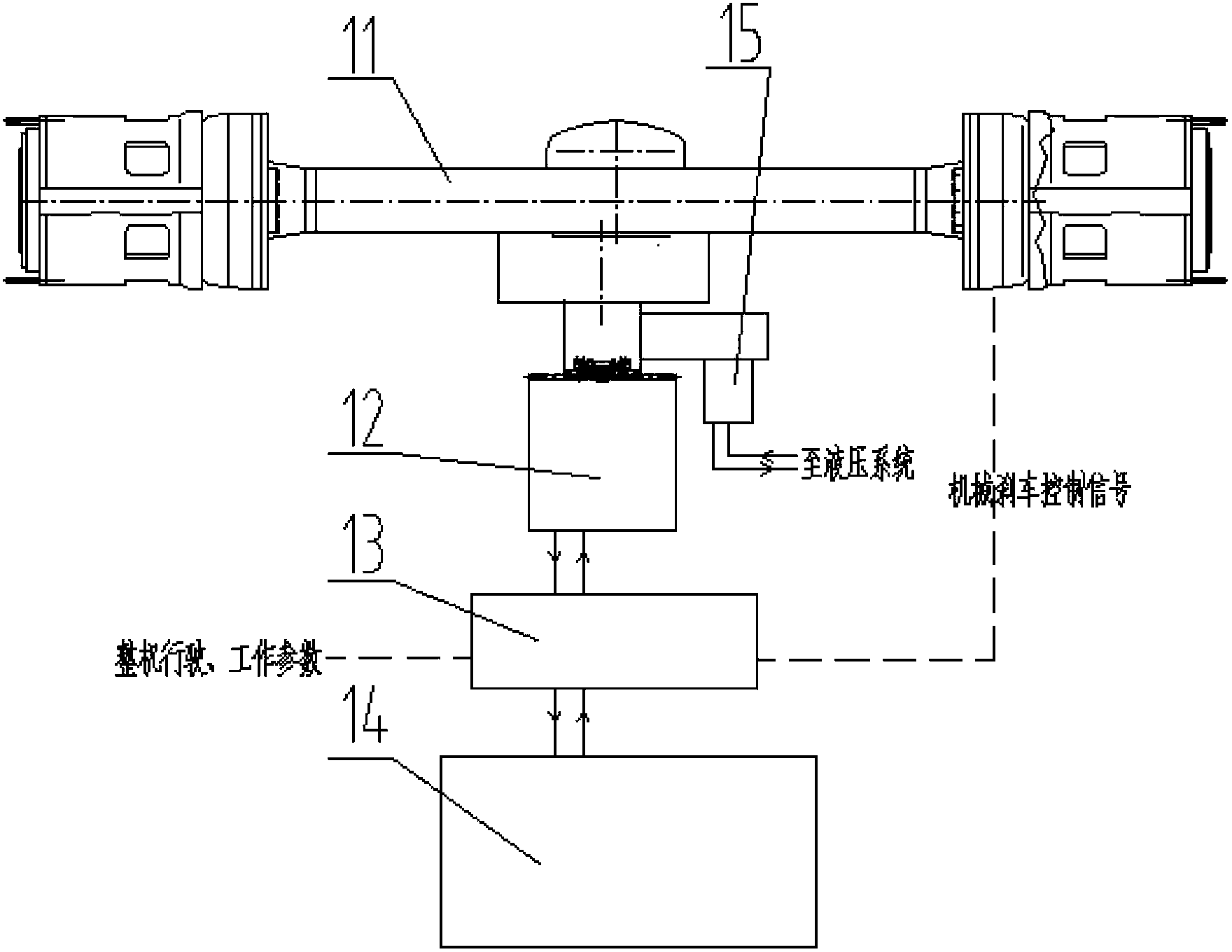

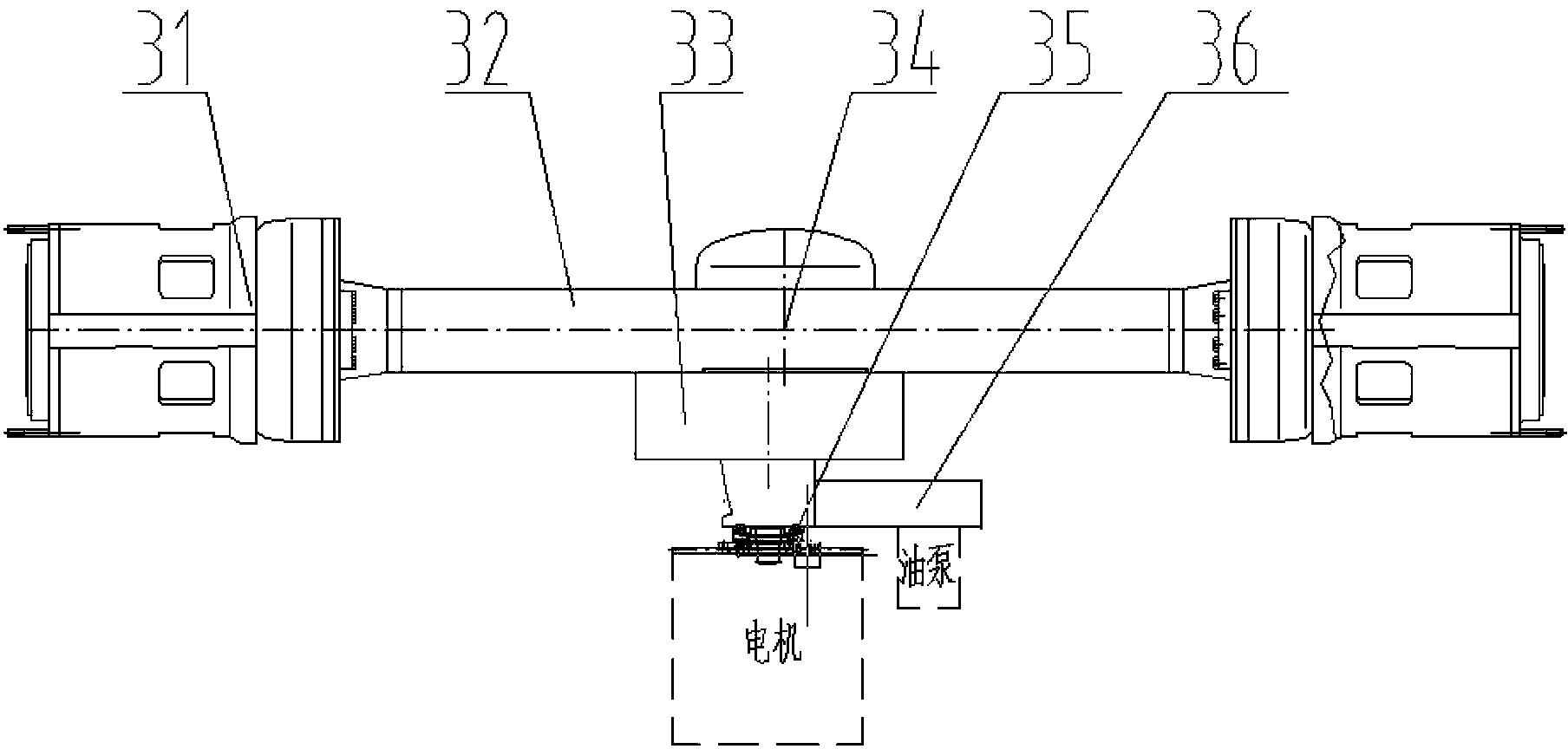

[0044] refer to figure 1 , The all-electric container lifter of this embodiment includes: a centralized drive axle 11 , a motor 12 , a controller 13 , a battery 14 , and an oil pump-motor 15 .

[0045] Wherein, the battery 14 provides power for the entire container lifter, and the battery 14 in this embodiment is preferably a modular battery. The electric power from the storage battery 14 passes through the controller 13 to drive the motor 12, and the motor 12 further drives the centralized drive axle 11 to perform the driving function of the whole machine. As a preferred embodiment, the motor 12 is a motor with a power generation function.

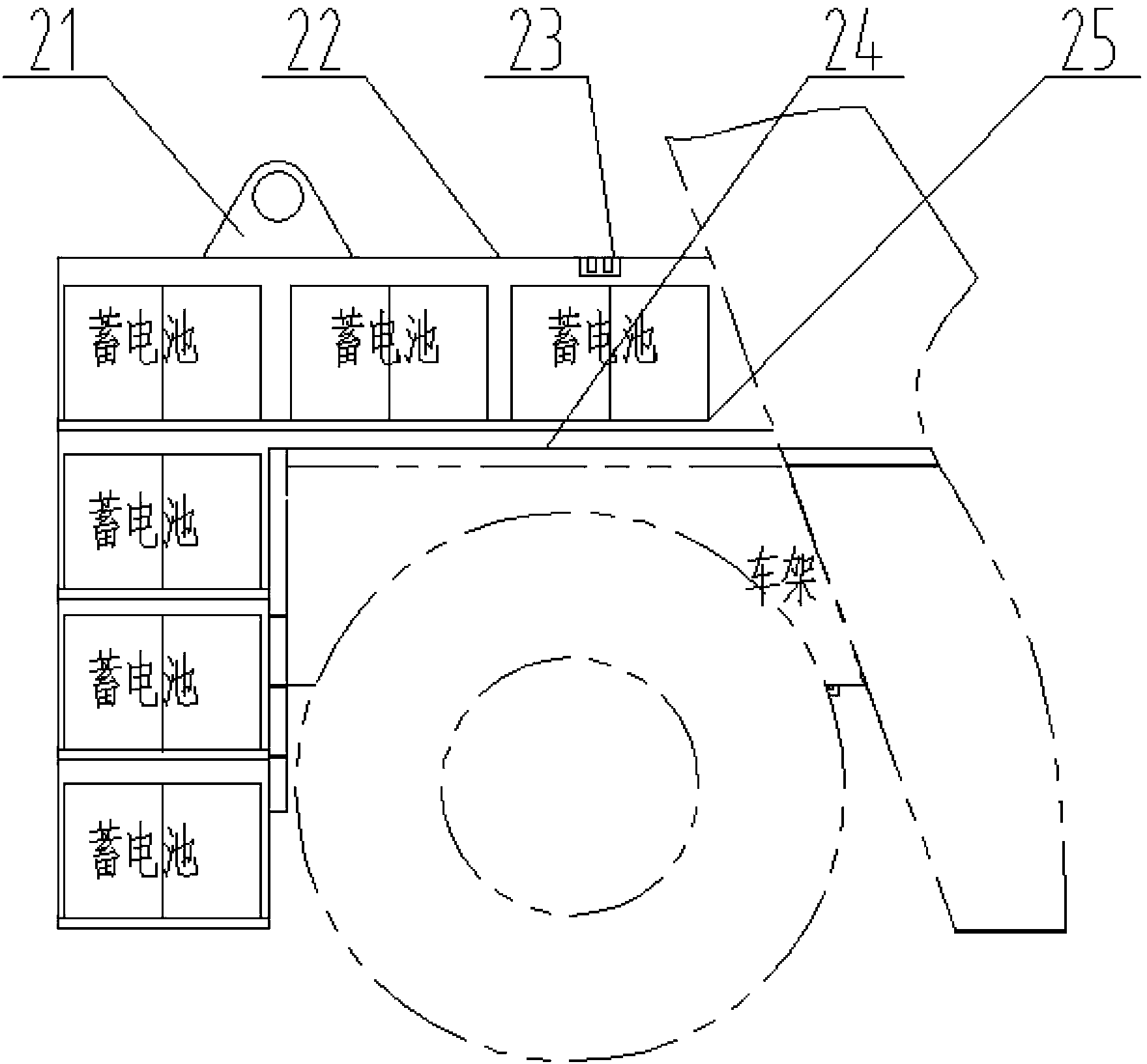

[0046] Furthermore, the power is provided by the battery 14, which can be placed behind the car body and can also serve as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com