Check valve

A check valve and valve seat technology, applied in the directions of safety valves, balance valves, valve devices, etc., can solve problems such as the increase of fuel tank pressure, and achieve the effects of suppressing vibration, simplifying the manufacturing process, and reducing flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

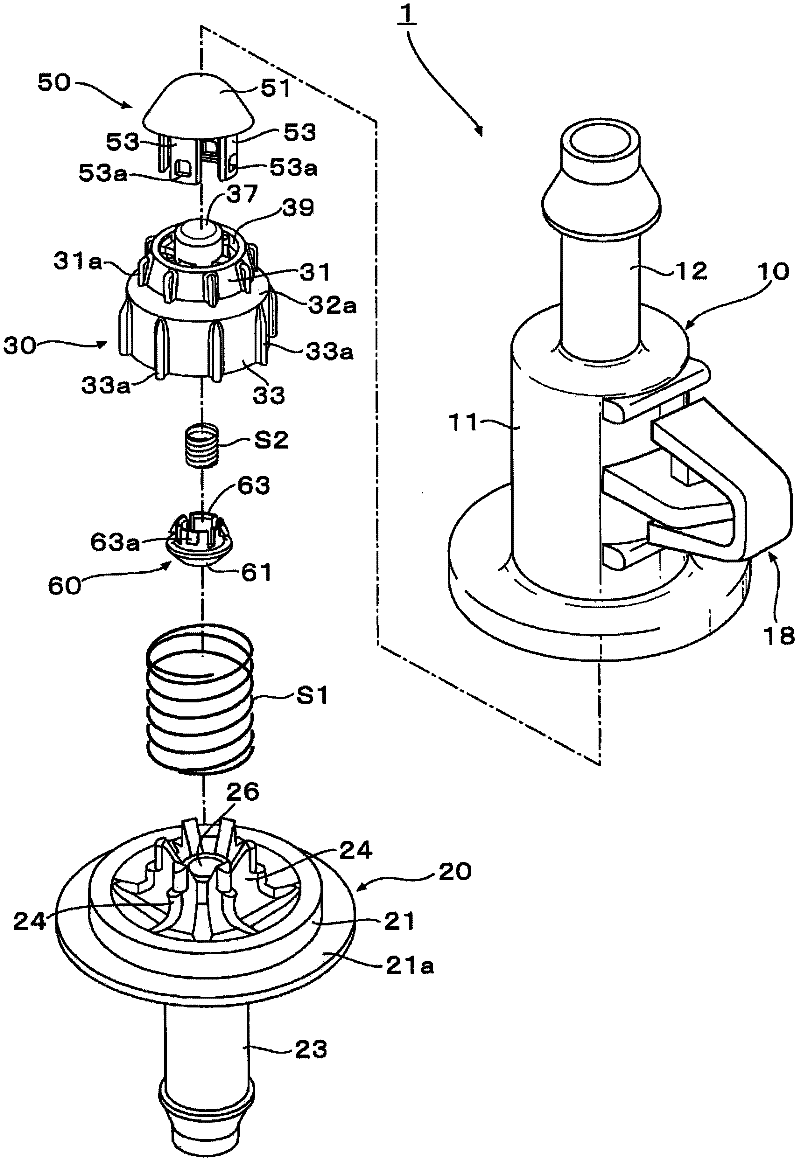

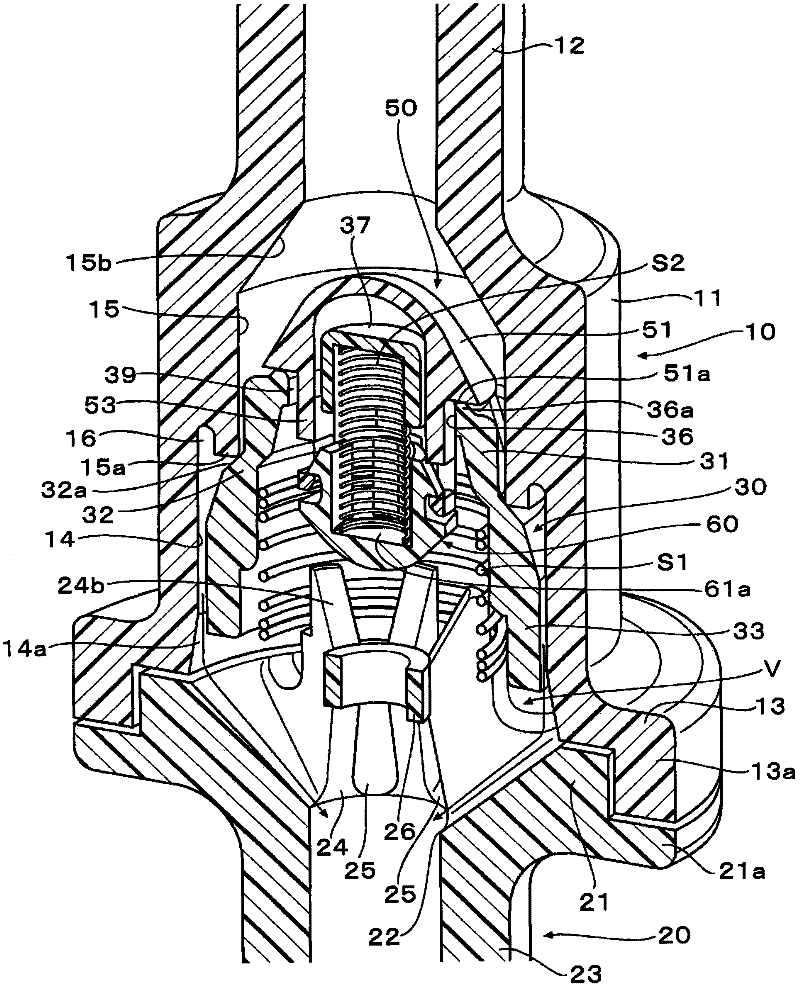

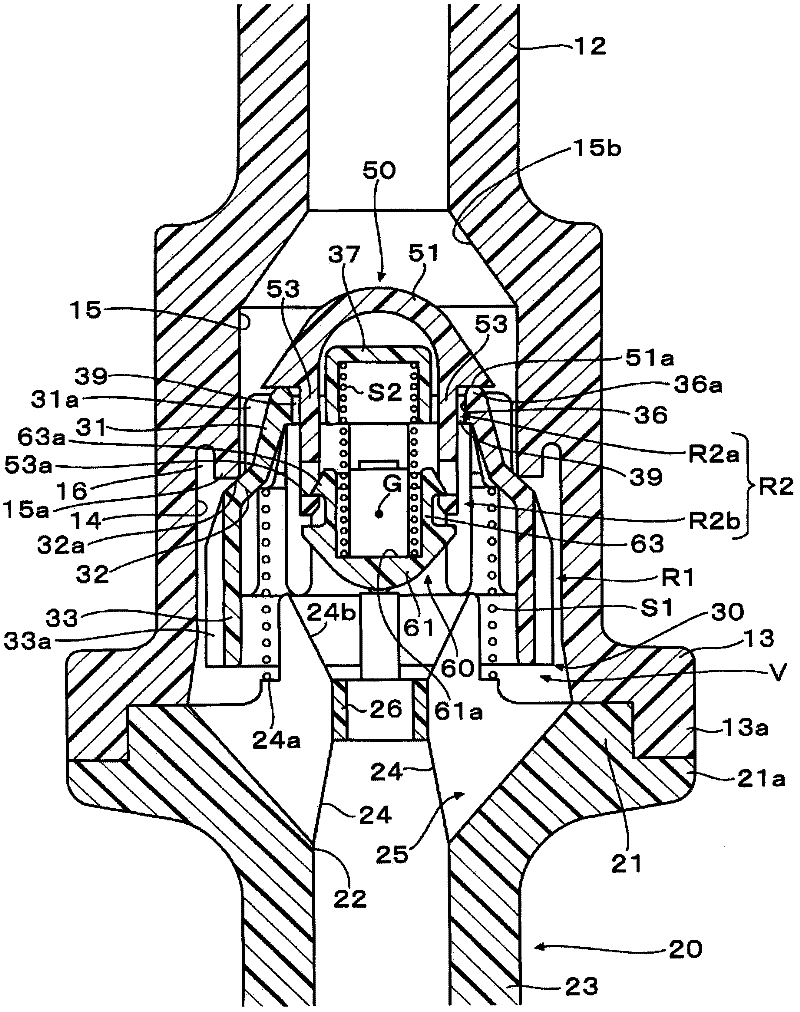

[0069] Next, embodiments of the check valve of the present invention will be described with reference to the accompanying drawings.

[0070] figure 1 , figure 2 Shown is the check valve 1, which prevents the fuel tank from bursting by discharging fuel vapor from the fuel tank when the pressure inside the fuel tank increases to a predetermined value or higher (positive pressure state), and the pressure inside the fuel tank decreases When the pressure reaches a predetermined value or lower than atmospheric pressure (negative pressure state), the check valve 1 prevents the collapse of the fuel tank by introducing external air into the fuel tank. This check valve 1 includes: a main case 10, which is connected to a pipe communicating with the inside of the oil tank, and the main case 10 has a positive pressure valve seat 15a formed therein; a sub case 20, which is fitted to the main case 10 to form a A valve chamber V, and the sub-case 20 communicates with the outside of the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com