High-strength plastic chain

A high-strength plastic and chain technology, applied in the field of plastic products, can solve problems such as insufficient strength, high operating noise, and heavy weight, and achieve the effect of increased strength, high strength, and low operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

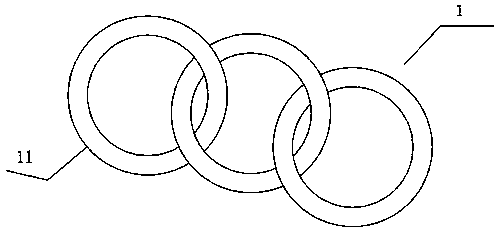

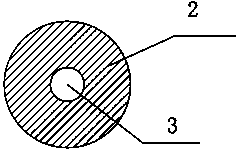

[0017] A high-strength plastic chain, the chain 1 is connected in series by several circular chain links 11, and the circular chain links 11 include an annular metal wire 3 located at the axis center of the circular chain link 11 and wrapped in The plastic layer 2 on the periphery of the circular wire 3; the diameter of the circular chain link is 4cm; the circular metal wire is steel wire, iron wire or copper wire; the circular chain link is a closed ring; the circular chain link The radius of the cross-section of 11 is 2 mm, and the radius of the cross-section of the metal wire is 0.5 mm.

Embodiment 2

[0019] This embodiment is basically the same as Embodiment 1: the only difference is that the diameter of the circular chain link is 5 cm.

[0020] The invention further improves the strength of the plastic chain by arranging the metal wire at the center of the plastic layer and adjusting the diameter of the metal wire and the section diameter of the plastic chain. Tests have proved that the radius of the cross-section of the circular chain link is 2 mm, and the radius of the cross-section of the metal wire is 0.5 mm. This technical feature can achieve the best strength under the same conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com