V-belt system

A technology of toothed pulleys and pulleys, applied in the directions of V-belts, transmission belts, belts/chains/gears, etc., can solve the problem of not specifying the shape of the synchronous belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

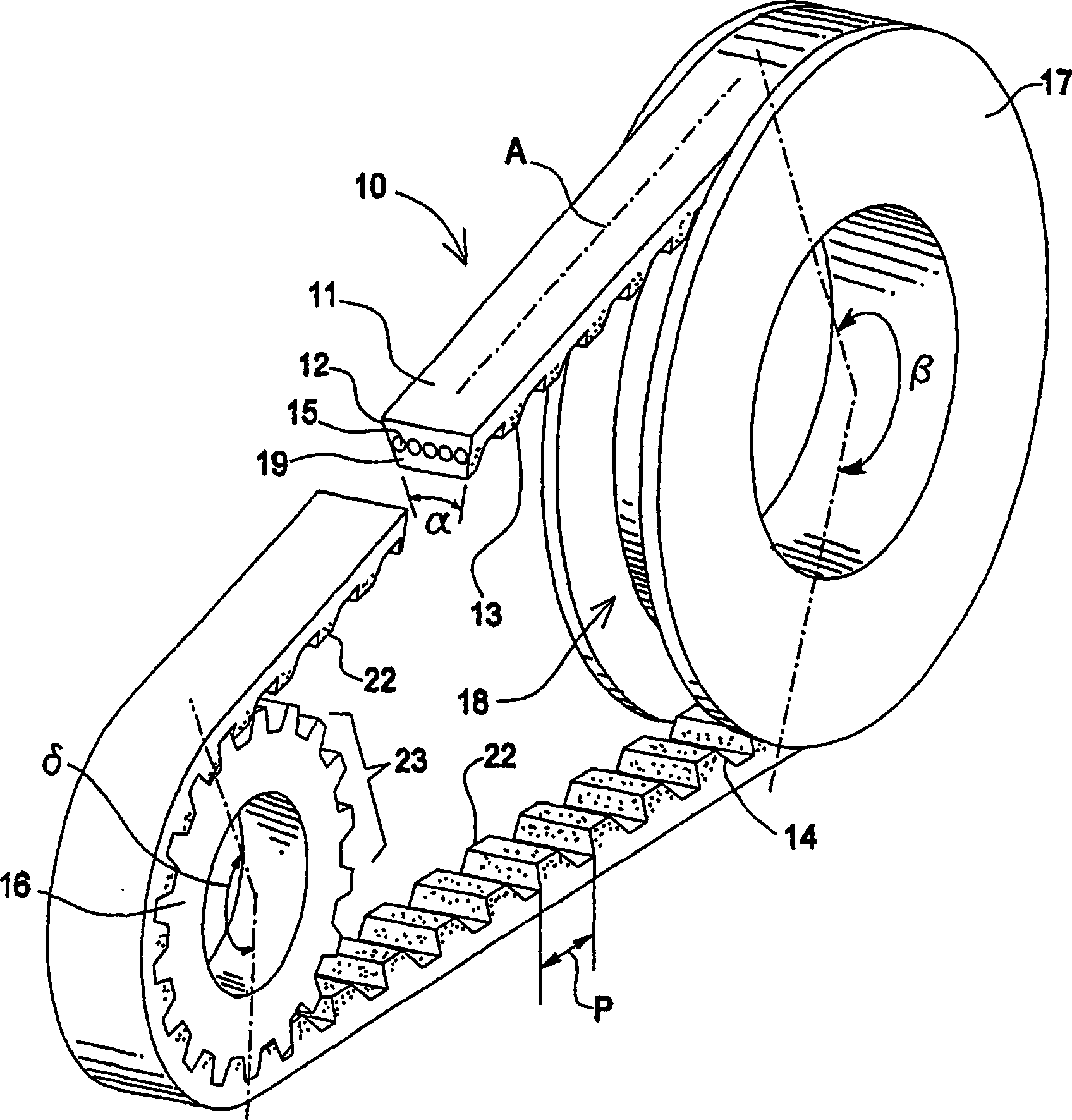

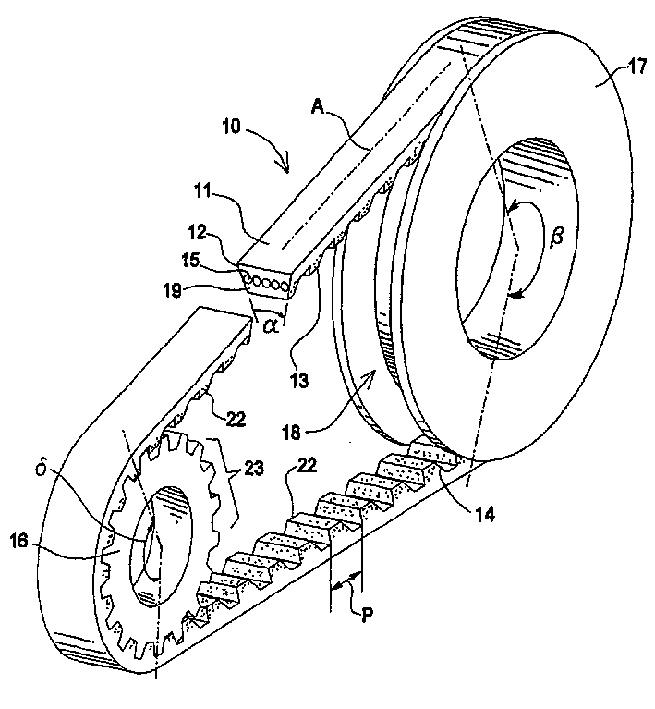

[0020] Referring to the drawings, an endless member or belt 10 is shown connected in series between a timing toothed pulley 16 and a V-belt pulley 17 . The synchronous toothed pulley 16 and the V-belt pulley 17 are connected on the rotating shaft (not shown) as required by the user. Belt 10 includes an upper belt layer 11 and a lower belt layer 19 . Each upper belt layer 11 and lower belt layer 19 comprises any material known in the timing or V-belt art, including but not limited to elastomeric or urethane materials. Belt 10 also includes a stretch belt layer 15 . The tensile tape layer 15 is arranged parallel to the main axis A of the tape. The tensile belt layer comprises any material known in the timing or V-belt art, including but not limited to fiberglass, aramid, nylon, polyester or PBO. The stretch tape layers may be twisted or braided.

[0021] The elastomeric material also incorporates short fibers (not shown) extending from the sides 12 , 13 . The short fibers r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com